User Manual

Quincy 390 / Col tri MCH 36

Electric

Nitrox System

REV: 03.19

www.nuvair.com

Q-390/MCH 36Electric Nitrox System

If you have any questions on this equipment please contact technical support at:

Nuvair

1600 Beacon Place

Oxnard, CA 93033

Phone: +1 805 815 4044

Fax: +1 805 486 0900

Email: info@nuvair.com

Hours: Monday through Friday

8:00 AM to 5:00 PM PST USA

If you lose this manual, you can download the latest version at www.nuvair.com.

This user manual contains important safety information and should always be available to

those personnel operating this equipment. Read, understand and reta in all instructions

before operating this equipment to prevent injury or equipment damage.

Every effort was made to ensure the accuracy of the information contained within. Nuvair, however,

retains the right to modify its contents without notice. If you have problems or questions after reading

the manual, stop and call Nuvair at +1 805 815 4044 for information.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

2

Q-390/MCH 36Electric Nitrox System

Table of Contents

Introduction

1.0 Introduction ..................................................................................................................................... 4

2.0 Safety Warnings and Warning Graphics Defined............................................................................. 5

3.0 Safety and Operation Precautions ................................................................................................... 7

4.0 Legal Precautions ............................................................................................................................ 8

5.0 Theory of Operation .......................... ....... ...... ................................................................................. 9

6.0 Low Pressure Air Compressor Technical Data …………………………………………………………. 10

7.0 High Pressure Compressor Technical Data ………………………………………..…………..…........ 11

8.0 System Components ………………………………………...........……………………………………..... 12

9.0 Nitrox System Specifications ............................................................................................................ 13

10.0 Nitrox System Component Identification……………...…………........................................................ 14

11.0 System Drawing/Schematic …………………………………………….…………………………………. 17

12.0 System Flow Chart ……………………………………………………………………………………….… 18

Setup, Operation, and Maintenance

13.0 Installing the Nitrox System ……………........................................................................................... 19

13.1 Precautions ......................................................................................................................... 19

13.2 Attaching Nitrogen Discharge Hose (Optional) ................................................................... 19

13.3 Electrical Power Connection .............................................................................................. 20

13.4 Check Compressor Lubricant Levels …………………………………………………………… 21

13.5 Control Panel Identification……………………………………………………………………….21

14.0 Pre-Operation Instructions ............................................................................................................... 22

14.1 Oxygen Analyzer Calibration............................................................................................... 22

15.0 Producing nitrox ............................................................................................................................... 24

15.1 Flow to Membrane and Setting Proper Pressure................................................................ 24

15.2 Final Adjustments Before Pumping Nitrox ......................................................................... 24

15.3 Pumping Nitrox ................................................................................................................... 26

15.4 Pumping Air ......................................................................................................................... 28

15.5 Shutting Down ..................................................................................................................... 28

16.0 Nitrox Operational Notes .................................................................................................................. 29

16.1 Correlation of Feed Air Pressure to Oxygen Content .......................................................... 29

16.2 Hot Fills ............................................................................................................................... 29

17.0 Maintenance ...................... ......... ....... ...... ....... .................................................................................. 30

17.1 Daily Maintenance ............................................................................................................... 30

17.2 Routine Maintenance .......................................................................................................... 31

17.3 Compressor lubricant .......................................................................................................... 32

17.4 LP Feed Air Filtration and Bowls........................................................................................ 34

17.5 LP Filtration Inspection …………………………………………………………………………. 34

17.6 Changing LP Filtration Elements ……………………………………………………………… 35

17.7 HP Compressor Filtration .............……………………………............................................. 36

18.0 Spare Parts List …………................................................................................................................. 37

19.0 Service Record Log ......................................................................................................................... 38

20.0 Appendix .......................................................................................................................................... 39

20.1 Supply and Breathing Air Specific ati ons .............................................................................. 39

20.2 Filter Element Life Factors .................................................................................................. 39

Material Safety Data Sheets ............................................................................................................ 40

Owner’s Warranty Responsibilities ……… ……… ………………....................................................... 43

Warranty ………………………………………………… ………… ……………………………………….. 42

Additional Record of Changes ……………………………………………………………………………. 43

Separate Manuals Included:

Nuvair Pro O

Coltri MCH-36 High Pressure Compressor Manual

TM

Oxygen Analyzer Operation Manual

2

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

3

Q-390/MCH 36Electric Nitrox System

1.0 Introduction

Nuvair has taken extreme care in providing you with the information you will need to operate this

system. However, it is up to you to carefully read this manual and make the appropriate decisions

about system safety.

This manual will assist you in the proper set-up, operation and maintenance of the Nuvair nitrox

system. Be sure to read the entire manual.

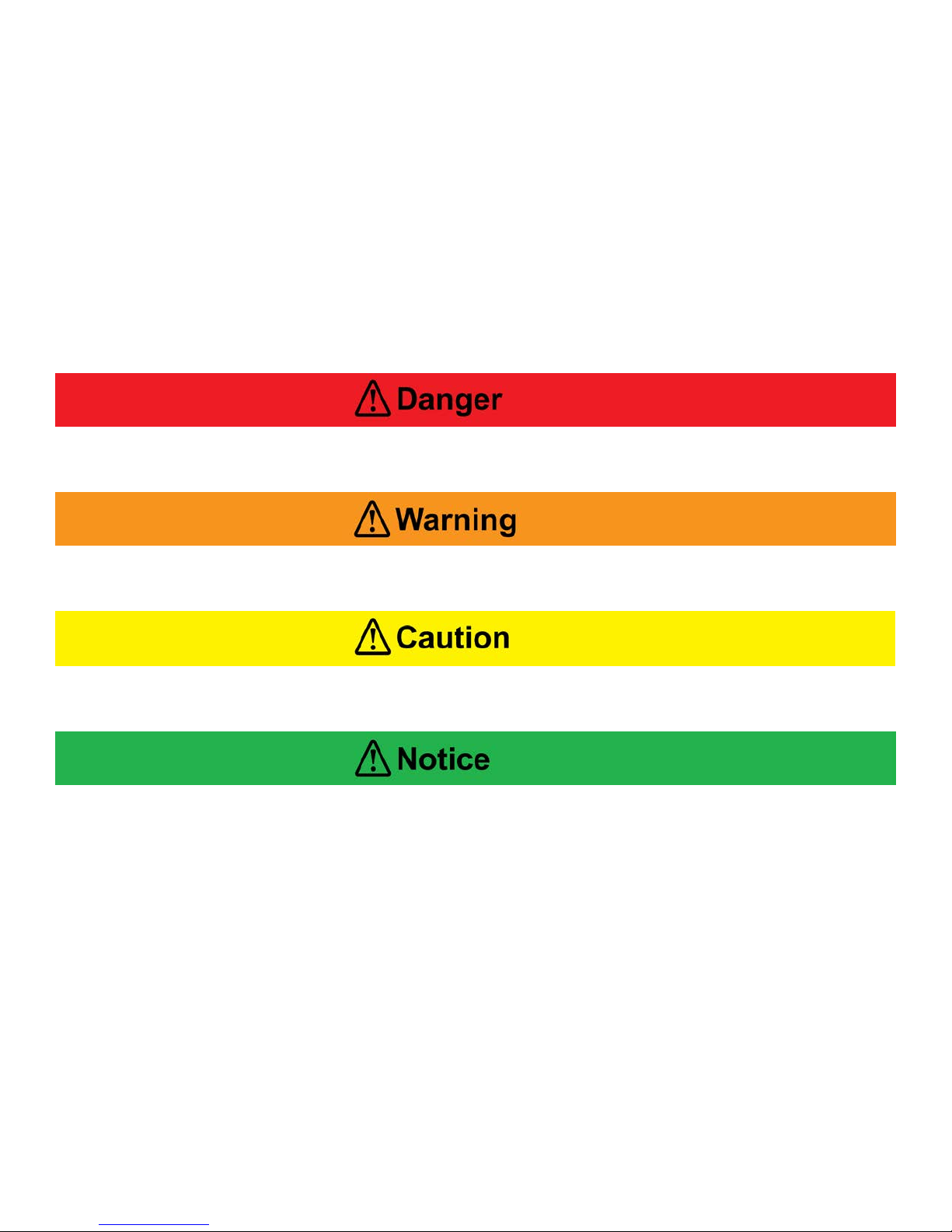

Throughout this manual we will use certain words and symbols to call your attention to conditions,

practices, and / or techniques that may directly affect your safety. Pay particular attention to

information introduced by the following signal words:

Indicates an imminently hazardous situation, which if not avoided, will result in serious

personal injury or death.

Indicates a potentially hazardous situation, which if not avoided, could result in serious

personal injury or death.

Indicates a potentially hazardous situation, which if not avoided, may result in minor or

moderate injury. It may also be used to alert against unsafe practices.

Notifies people of installation, operation or maintenance information which is important but

not hazard-related.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

4

Q-390/MCH 36Electric Nitrox System

2.0 Safety Warnings

This equipment is used to provide breathing gas for the purpose of underwater life support.

Read this manual in its entirety. Failure to heed the warnings and cautions contained in this

document may result in severe injury or death.

The equipment you will be using to manufacture nitrox (oxygen rich air) will expose you to

both low and high-pressure gas. Gas, even under moderate pressures, can cause extreme

bodily harm. Never allow any gas stream to be directed at any part of your body.

Any pressurized hose can cause extreme harm if it comes loose or separates from its restraint

(or termination) while under pressure and strikes any part of your body. Us e appropriate care

in making and handling all gas connections.

Pure nitrogen is a colorless, odorless, tasteless gas that will not support life.

Breathing gas mixtures containing more than 84% nitrogen at surface pressures

will lead to unconsciousness and may cause death.

The nitrogen discharge from the membrane system must be vented to the

exterior of any closed building, boat, or similar enclosed s pace. Breathing gas

mixtures containing more than 84% nitrogen at surface pressure will lead to

unconsciousness and may cause death.

Do not use any form of mineral oil or synthetic l ubricant not rated for nitrox in

any compressor in this system. Use only the recommended nitrox c ompressor

lubricant. Never mix the nitrox compressor lubricant with other lubricants.

Remove all existing lubricant and replace with the proper nitrox compressor lubricant prior to

installing the membrane system. The use of improper lubricants can lead to fire or explosions,

which may cause serious personal injury or death.

Do not use this system to produce nitrox mixtures containing more than 40%

oxygen. Pumping nitrox mixtures with higher concentrations of oxygen may

lead to fires or explosions, which can cause serious personal injury or death.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

5

Q-390/MCH 36Electric Nitrox System

The use of enriched air nitrox does not eliminate the risk of decompression sickness (DCS) in

diving. Decompression sickness can lead to permanent disability or death.

Do not pump nitrox mixtures at pressures above the HP compressor

manufacturer’s rating, and never above 3600 psi (250 bar). The system is not

rated for pressures above 3600 psi (250 bar). Higher pressures may lead to

explosions which may cause serious personal injury or death.

Ambient room temperature should never exceed 104o F (40o C) during operation of the nitrox

system. Operation at higher temperatures may lead to system damage and malfunction. A

damaged membrane will not produce the correct nitrox mixture which can lead to severe

personal injury if the gas is used for diving purposes without proper analysis.

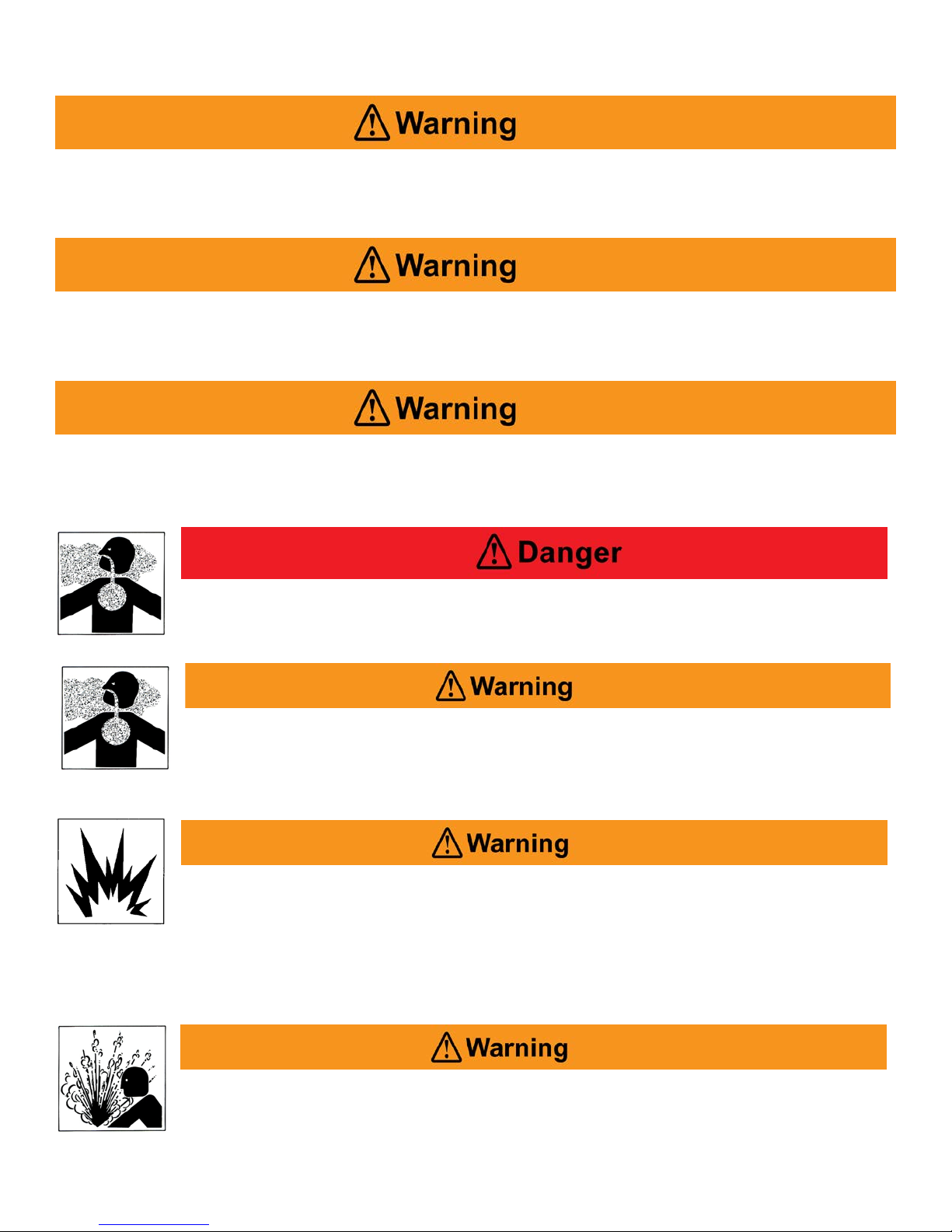

Warnings Graphics Defined:

Moving belts Electrocution Fire Eye protection Gas inhalation

Skin damage Explosion Explosion Electrocution Machinery

Abbreviations commonly used in this manual:

PSI Pounds Per Square Inch CFM Cubic Feet per Minute

HP High Pressure RPM . Rotations per Minute

LP Low Pressure PPM Parts Per Million

O2 Oxygen L/min Liters Per Minute

CO Carbon Monoxide O2% Oxygen Percentage of Gas

CO2 Carbon Dioxide B.P. Back Pressure

N Nitrogen

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

6

3.0 Safety And Operation Precautions

Because a compressor is a piece of machinery with moving and rotating parts, the same precautions

should be observed as with any piece of machinery of this type where carelessness in operations or

maintenance is hazard ous to personnel. In additi on to the many obvious saf ety precautions, those list ed

below must also be observed:

1) Read all instructions completely before operating any compressor or nitrox system.

2) For installation, follow all local electrical and safety codes, as well as the National Electrical Code

(NEC) and the Occupational Safety and Health Administr ation (OSHA) standards.

3) Electric motors must be securely and adequat ely grounded. This ca n be accomplished by wiring with a

grounded, metal-clad raceway system to the compressor starter; by using a separate ground wire

connected to the bare m etal of the motor frame; or other suitable means.

4) Protect all power cables from coming in contact with sharp objects. Do not kink power cables and

never allow the cables to c ome in contact with oil, grease, hot surfaces, or chemi c als.

5) Make certain that power source conforms to the requirements of your equipment.

6) Pull main electrical disconnect switch and disconnect any separate control lines, if used, before

attempting to work or perform maintenance. “Tag Out” and

7) Do not attempt to remove any parts without first relieving the enti r e system of pressure.

8) Do not attempt to service any part while system is in an operational mode.

9) Do not operate the system at pressures in excess of its rating.

10) Do not operate compressor at speeds in excess of its rating.

11) Periodicall y check all safety devices for proper operation. Do not change pressure setting or restrict

operation in any way.

12) Be sure no tools, rags or loose parts are left on the nitrox system.

13) Do not use flammable solvents for cleaning the air inlet filters or elements and other parts.

14) Exercise cleanliness during maintenance and when making repairs. Keep dirt away from parts by

covering parts and exposed openings with clean cloth or K raft paper.

15) Do not operate the compressor without guards, shields, and screens in place.

16) Do not install a shut-off valve in the compressor discharge line, unless a pressure relief valve, of

proper design and size, is ins talled in the line bet ween the compressor unit and shut-off valve.

17) Do not operate this compressor in an y location where there is a possibility of toxic levels of carbon

monoxide (CO), carbon dioxide (CO

the compressor intake.

18) Be careful when touching the exterior of a rec ently run electric, gasoline, or diesel motor - it m ay be

hot enough to be painful or cause inj ury. With modern mot ors this condition is normal if operated at

rated load - modern motors ar e bui lt to operate at higher temperatures.

19) Inspect unit daily to observe and correct any un s afe operating conditions found.

20) Do not “play around” with compressed air, or direct air stream at body, because this can cause

injuries.

21) Compressed air f rom this machine absolutely m ust not be used for food processing or brea thing air

without adequate downstream filters, purifier s and c ontrols and periodic air quality testing.

22) Always use an air pr essure-regulating devic e at the point of use, and do not use air pressure greater

than marked maximum pressure.

23) Check hoses for weak or worn conditions before each use a nd make certain that all connec tions are

secure.

The user of any compressor or nitrox system manufactured by Nuvair is hereby warned that failure to

follow the preceding Safety and Operation Precautions can result in injuries or equipment damage.

However, Nuvair does not st ate as fact or does not mean to imply that the preced ing list of Safety and

Operation Precautions is all -inclusive, and f urther that t he observance of this list will prevent all inj uries or

equipment damage.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Q-390/MCH 36Electric Nitrox System

“Lock Out” all power sources.

), nitrogen (N), or any flammable or toxic fumes being sucked into

2

Page

7

Q-390/MCH 36Electric Nitrox System

4.0 Legal Precautions

It is highly recommended that a nitrox fill log be maintained when filling scuba cylinders to document

the following information. This log must be of permanent binding style with no loose pages.

• Fill date and time of day

• Tank serial number

• Supplier’s check of oxygen content O2% plus signature and dat e

• User’s check of oxygen content O2% plus signature and date

• Fill pressure

• MOD (maximum operating depth) in user’s handwriting

• Nitrox certifying agency and card number

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

8

Q-390/MCH 36Electric Nitrox System

5.0 Theory of Operation

The Nuvair high pressure nitrox system is a turnkey package that produces oxygen-rich air (nitrox)

and then compresses it with a High Pressure (HP) compressor to fill scuba tanks or storage cylinders.

The package is designed to be fully automatic. Although it is described as the “nitrox compressor”, it

can also be used to pump air.

This nitrox system allows for efficient and cost effective nitrox production using electric power, without

the hazards or expense of blending with stored high-pressure oxygen (O2). Instead, the system uses

a semi-permeable membrane to produce nitrox from air. A portion of the nitrogen in air is separated

out, leaving an oxygen rich nitrox mixture.

This system uses a Quincy LP compressor, air aftercooler, and filtration to provide the membrane

system with a source of clean, pressurized feed air for separation. The air is filtered to CGA Grade D

or better air quality prior to entering the membrane system so it will not damage or plug the

membrane fibers. Specifications for Grade D air are provided in the appendix.

The Package’s membrane system is rated for a maximum feed air pressure of 300 psi (21 bar) and

has been configured to work well with the 175 P.S.I (12 bar) maximum pressure delivered by the LP

compressor. A back-pressure regulator is used to adjust the amount of air the Quincy compressor

produces to meet the appropriate levels for various O2% nitrox production. The air is then heated to a

temperature that provides stability over a wide range of ambient conditions, is optimal for membrane

permeation, and prevents moisture condensation.

The heated air enters the membrane, which is made up of thousands of miniature hollow fibers. The

walls of these fibers are semi-permeable and designed for different gases to move through them (or

permeate) at different speeds. The resulting gas mixture is known as the “permeate.” As air flows

through the hollow fibers, both oxygen and nitrogen permeate through the fiber walls. The oxygen

permeates faster than the nitrogen, which produces permeate with oxygen content greater than air.

The gas that reaches the end of the hollow fibers without permeating is almost entirely nitrogen and is

discharged. The flow rate of this discharge is set by the factory via a fixed orifice, which controls the

permeate.

The permeate is a concentrated mixture that is diluted with air prior to entering the HP compressor. It

exits the membrane at ambient to slightly negative pressure and travels into the mixing tube, where it

mixes homogeneously with filtered outside air. The amount of dilution, and thus final O2%, is

obtained by adjusting the amount of air produced by the compressor and supplied to the membrane,

with the back pressure regulator. As air flow to the membrane is increased, permeate flow increases

and a higher O2% nitrox is produced. As air flow to the membrane is decreased, permeate flow

decreases, compressor intake air increases, and a lower O2% nitrox is produced.

This relationship between permeate flow and intake air flow exists because the total of these two flow

rates will always equal the intake flow rate demanded by the HP compressor. The resulting nitrox

mixture is analyzed for O2% before entering the HP compressor for approximate content and again

when pumping nitrox for precise content. The HP compressor pumps the nitrox to a maximum

pressure of 3600 psi (250 bar) to fill scuba tanks or storage cylinders.

A unique feature of Nuvair nitrox systems is that the feed air pressure that correlates to a specific

nitrox O2% is repeatable. For example, if your HP compressor pumps 36% O2 when the feed air

pressure is at 125 psi (9 bar), then adjusting the back pressure regulator to 125 psi (9 bar) during the

next use will produce the same mixture.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

9

Q-390/MCH 36Electric Nitrox System

6.0 Low Pressure Compressor Technical Data

See separate manual for Quincy QR-390 LP compressor

Capacity and Power Consumption:

• Normal working pressure: 125-175 psi

• Capacity at normal working pressure: 69 (C.F.M.) cubic feet per minute (1950 l/min)

• Shaft power at normal working pressure: 20 horse power (15 kW)

• Maximum working pressure: 175 psi (12 bar)

• Transmission: belt drive

Cooling:

• Allowed ambient temperature: 32-104° F (0-40° C)

Motor and Electrical Values:

• Motor: F class TEFC, 20 horse power (15 kW) three phase

• Speed of rotation: 3450 RPM @ 60Hz or 2850 RPM @ 50Hz

• Compressor current: 440 V 50 or 60 Hz three phase – 27 Amps

• Control voltage: 230 V

General Technical Data:

• Oil capacity: 9 Quarts – 16 Ounces (9 liters)

• Maximum oil content in air: 3 mg/m3

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

10

Q-390/MCH 36Electric Nitrox System

7.0 High Pressure Compressor Technical Data

See separate manual for Coltri MCH 36 HP compressor

Capacity and Power Consumption:

• Normal working pressure : 3600 psi (250 bar)

• Free air delivery flow: 22 CFM (623 l/min)

• Charging rate: 26.4 SCFM (750 l/min)

• Compressor spe ed o f rotation: 1115 RPM

• Maximum working pressure air: 6000 psi (425 bar), nitrox 3600 psi (250 bar)

• Transmission: belt drive

Cooling:

• Allowed ambient temperature: 32-104° F (0-40° C)

• Air cooled Interstage & aftercooler

Motor and Electrical Values:

• Motor: F class TEFC, 20 horse power (15 kW) three phase

• Speed of rotation: 3450 RPM @ 60 Hz or 2850 RPM @ 50Hz

• Compressor current: 440V 50 or 60 Hz three phase – 27 Amps

• Control voltage: 230 V

General Technical Data:

• Number of stages: 4

• Number of cylinders: 4

• Lubrication: pressure & splash lubricated

• Oil capacity: 4.25 qt. (5 liters)

• HP filtration rating: CGA Grade E, 60,000 cu. ft. at 68o F (20o C)

(see page 39 for filtration fac tor char t)

• Condensate drains: automatic & manual interstage & final

• Fill Pressure Stop: automatic & manual

• Low oil level auto shutdown

• Interstage pressure gauges

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

11

Q-390/MCH 36Electric Nitrox System

8.0 System Components

• Low pressure compressor, including:

♦ Soft start motor starter

♦ Hour meter

♦ External lubricant dip stick, fill, and drain

♦ Nuvair 455 food grade compressor lubricant (see MSDS starting on page 40)

♦ Large air aftercooler

• Back-pressure regulator that controls LP compressor feed air supply

♦ Supply air pressure regulated between 90-175 psi (6-12 bar) depending on nitrox O2%

• Low pressure feed air filtration, Grade D breathing air , incl uding four stages:

♦ Coalescing & particle removal to 1 micron, auto drain, liquid level indicator

♦ Water & oil vapor removal to 0.01 micron, auto drain, liquid level & service life indicators

♦ Oil vapor removal to 0.003 PPM

• Heater including:

♦ Thermostat control

♦ Digital temperature gauge

♦ Pressure switch

♦ 200 psi (14 bar) ASME over pressure relief

• Semi-permeable membrane

• Mixing tube & air intake filter

• Nuvair Pro O2 Remote permeate oxygen analyzer

• Nitrogen discharge

• Nuvair Pro 4 Warn O2, CO, CO2 analyzers and H2O Moisture Monitor, High Temp warning

including:

♦ High Pressure/Low Pressure regulator

♦ Flow Meter, 1 - 10 L/Min

• High pressure compressor, including

♦ Soft start motor starter

♦ Hour meter

♦ Automatic condensate drains

♦ Automatic fill pressure stop

♦ External lubricant sight gauge, fill, and drain

♦ Compressor lubricant see page see MSDS page 40

• High pressure filtration, Grade E breathing air (see page 39 for filtration f actor ch ar t)

• Air/nitrox quality analysis kit

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

12

Q-390/MCH 36Electric Nitrox System

LP

Physical

Full Load Amps

Membrane Input

HP

9.0 Nitrox System Specifications

Delivery @ 175 psi (12 bar)

Horse Power –

Compressor

Electric

Height

Width

Length

Specifications

Weight

440V / E3 / 50 or 60 Hz

69 C.F.M. free air (1950 L/min)

20 horse power

(15 kW)

90 in (229 cm)

63 in (160 cm)

96 in (244 cm)

3800 lb (1724 kg)

54 Amps

System

Operating Pressure Range

90 -175 psi (6-12 bar)

Maximum Input Pressure

Feed Air Volume Range

LP Feed Air Quality

Optimum Temperature

Nitrox O

Charging Rate

Horse Power –

Compressor

NUVAIR

Q-390/MCH36 Nitrox system User Manual

%Range

2

Electric

Page

300 psi (21 bar)

13 - 60 SCFM (354 -1700 L/min)

Grade D

o

110 +/- 5

F (43 +/- 3o C)

24 - 40%

26.4 SCFM (750 L/min)

20 horse power

(15 kW)

13

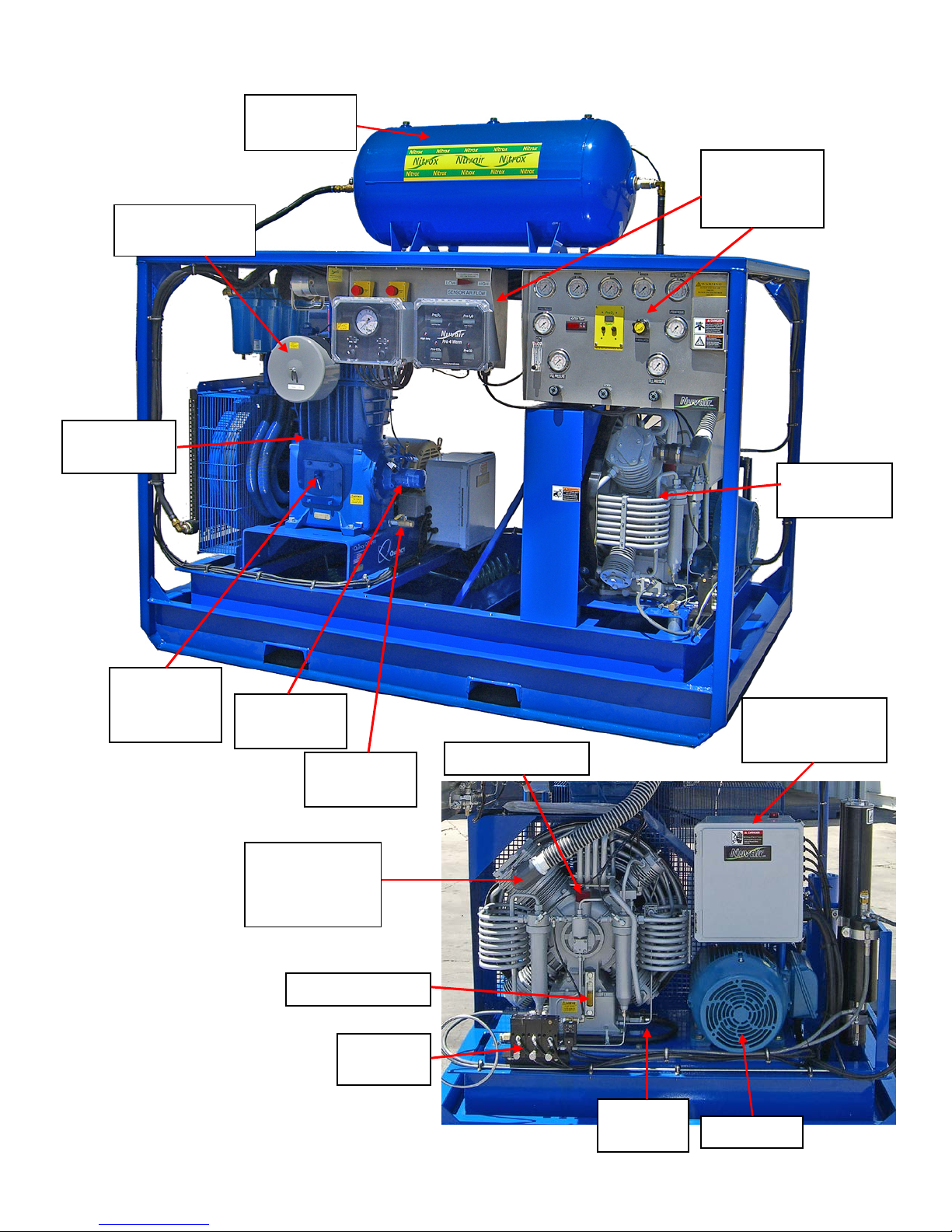

10.0 Q-390/MCH 36 Nitrox System Component Identification

LP Compressor

LP Oil Drain

LP Oil Filter

LP Oil

Compressor

Volume

LP Quincy

HP Coltri

HP Compressor

HP Auto

HP Oil

HP Oil Fill Port

HP Oil Gauge

HP Motor Control

HP Motor

Intake Filter

390

Check and

Fill Port

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Tank

Intake Plumbed

to Membrane

Drains

Page

Q-390/MCH 36Electric Nitrox System

Control

Panels

MCH36

Electric Box

Drain

14

LP Feed Air

LP Motor

Box

Membrane

Heater

HP compressor

HP compressor

Condensate

Power cable for

LP Compressor

Electric

Volume

Tank

LP Electric Motor

HP & LP Collective

Ball Valve

filter canisters

Moisture

Separator

Container with

Muffler & Drain

total package

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Q-390/MCH 36Electric Nitrox System

Control Electric

Page

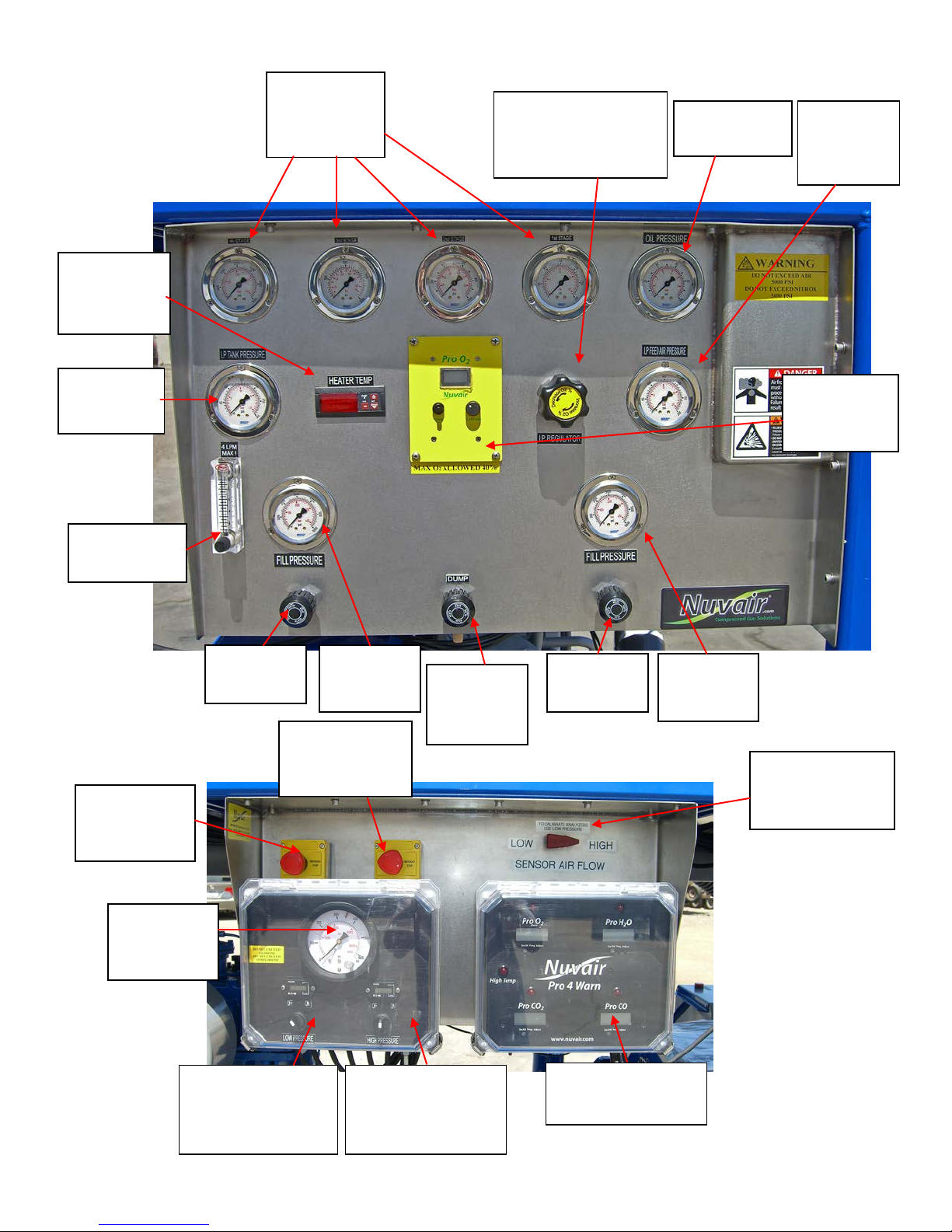

15

Transformer

Filtration

(4 Stage)

Aftercooler

Condensate Drain

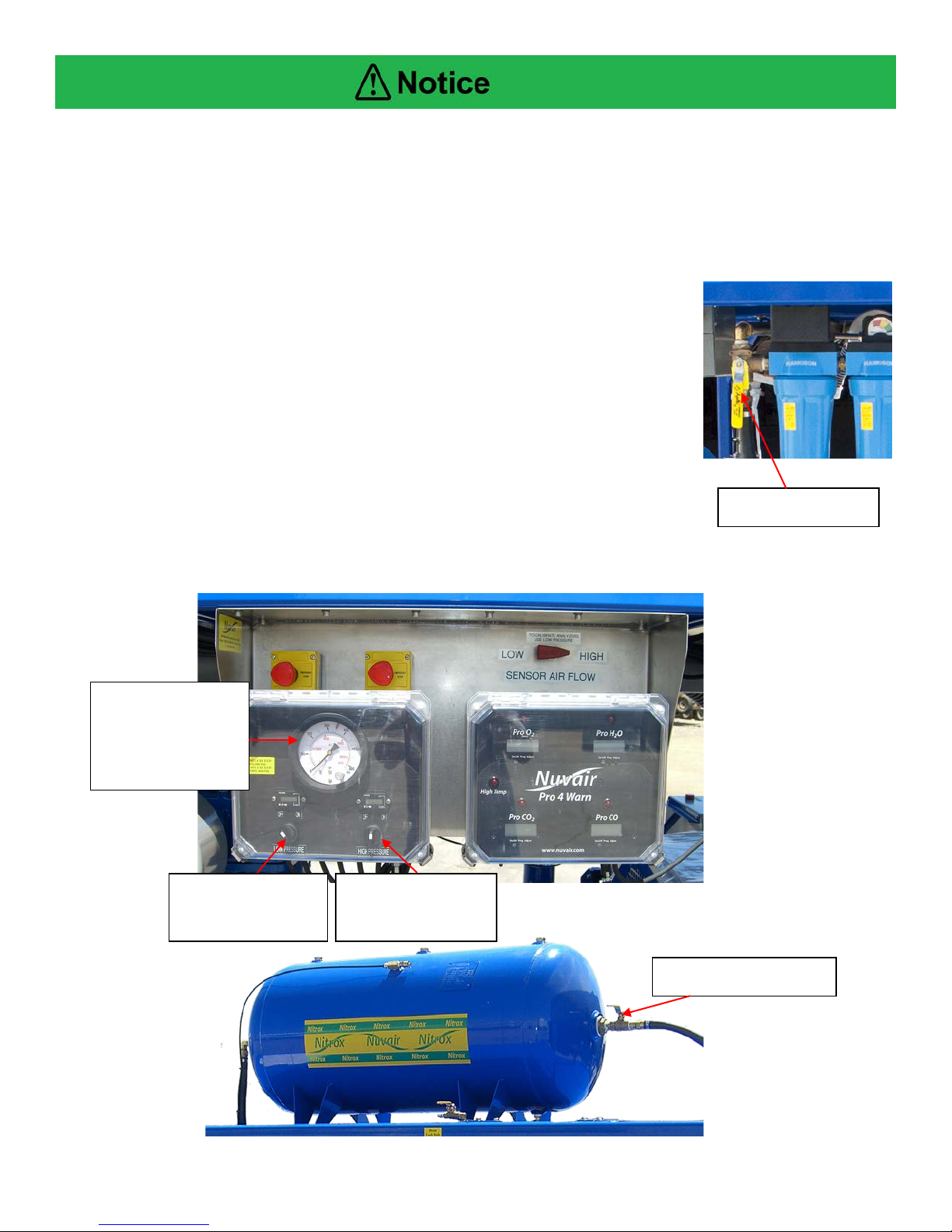

Control Panel

Stage

LP Back Pressure

2

Heater

Permeate

Fill

Gauge

HP Oil

On/Off

Membrane

Gauge

Fill

Gauge

On/Off

LP Tank

Gauge

Dump

Flow Meter

High Pressure

Low Pressure

Dial-A-

Emergency

Emergency

Pro 4 Warn

Gas flow switch

Pressure

Gauges

Thermostat

Control

Pressure

4LPM Max.

Valve

Stop HP

Compressor

Stop LP

Compressor

Pressure Fill

Gauge

Compressor

On/Off Switch &

Hour Meter

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Pressure

Compressor On/Off

Switch & Hour

Meter

Valve for

O2%

Page

16

Q-390/MCH 36Electric Nitrox System

Regulator Adjustment

Knob - Adjust Nitrox

% Here

O

Valve

Multi Gas Monitor

Pressure

Pressure

Feed

Pressure

Oxygen

Analyzer

for Monitoring

LP or HP Gas

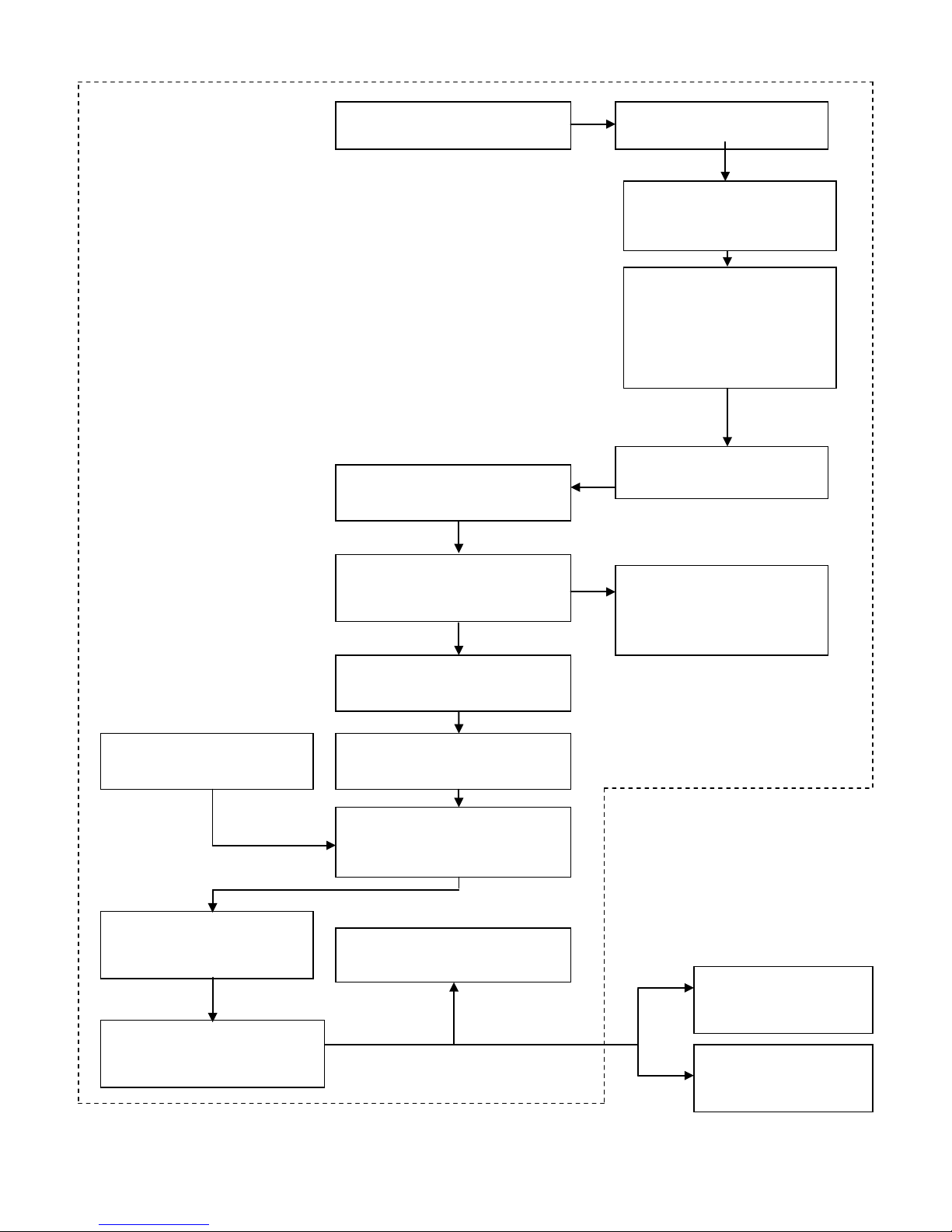

Q390/MCH36

Shown Within Dashed Lines

11.0 System Drawing / Schematic

nitrox system Components

Q-390/MCH 36Electric Nitrox System

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

17

12.0 System Flow Chart

LP aftercooler removes

moisture

LP feed air filtration

B.P./ LP regulator controls

Desired Nitrox %

Thermostat controlled heater

Membrane separates supply

nitrogen rich gas

Permeate exits membrane

Nitrogen rich gas exits

Mixing tube mixes air &

Air intake delivers filtered

Permeate O2 analyzer

compression to +/- 2% O2

HP compressor with

compresses nitrox

Fill diver O2 analyzer monitors

HP nitrox delivered to

HP nitrox delivered to

- OR -

Optional vacuum pump or

LP compressor produces LP

feed air (supply air)

LP Volume Tank Collects

Nitrox system components

Q-390/MCH 36Electric Nitrox System

Moisture and Delivers

Feed Air

shown within dashed lines

the amount of feed air

pumped by the

compressor. Reducing

Pressure Adjusts to

heats air to 110ºF (43ºC)

produces Grade D air

air into permeate and

through fixed orifice

located by exhaust cooling

air vent

ambient air to mixing tube

blower

monitors nitrox before

moisture removal & filtration

NUVAIR

Q-390/MCH36 Nitrox system User Manual

permeate to create nitrox

18

2

containing 24-40% O

nitrox mixture to +/- 1% O2

Page

scuba cylinder

storage

Q-390/MCH 36Electric Nitrox System

13.0 Installing the Q-390/MCH36 Nitrox System

If any information in this manual conflicts with any of the other manuals call Nuvair before

proceeding.

The Nuvair System should never be operated in a facility where the room temperature exceeds

104o F (40o C) while the system is in use. Operation at higher temperatures may lead to system

damage and malfunction. A damaged membrane will not produce the correct nitrox mixture

which can lead to severe personal injury if the gas is used for diving purposes wi thout proper

analysis.

13.1 Precautions

1. Please read all information supplied before physically installing the nitrox system.

2. Unpack the system and remove from the pallet. Visually inspect the system to make sure there

has been no damage during shipping. If damaged, please call Nuvair to file a damage report.

Please take photos and supply detailed information about the damage.

3. Place the system in a location that allows a minimum spacing of 18 inches from adjacent walls.

Select a location where ambient room temperature will never exceed 104o F (40o C).

4. The heater thermostat has been set in the factory. Do not

adjust.

13.2 Attaching Nitrogen Discharge Hose (option)

The nitrogen discharge from the membrane on the system exits

at the fitting in the picture. The open frame should not require a

discharge hose, unless installed in an improperly

vented room.

Pure nitrogen is a colorless, odorless, tasteless gas that will not support life.

Breathing gas mixtures containing more than 84% nitrogen at surface

pressures will lead to unconsciousness and may cause death.

The nitrogen discharge from the membrane should be vented to a wellventilated room or to open air with good circulation. Failure to isolate the

discharge from the air intake of the membrane system or LP compressor could

lead to incorrect nitrox mixtures, resulting in se rious personal injury or death.

If you allow this pure nitrogen to accumulate in an enclosed space, anyone entering this

space will quickly lose consciousness and will die if not immediately resuscitated.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

19

Q-390/MCH 36Electric Nitrox System

HP On/Off

Switch

HP compressor Shown

LP Hour

Meter

HP Hour

Meter

LP On/Off

Switch

13.3 Electrical Power Connection

Never use extension cords to provide power to your nitrox system. The system

must be properly wired according to national and local electrical codes by a

qualified electrician. Improper wiring may lead to fires, which can cause serious

personal injury or death.

The electrical power to the Nuvair Nitrox System must be off while wiring this

system for service. Failure to ensure that the electrical power is off can lead to

severe personal injury and death by electrocution.

Prior to making the electrical power connection, check all system specifications provided in this

manual. When working on the nitrox system, the main breaker at the power source must be “locked

out” and “tagged out” in the “Off” position. The nitrox system has electrical protection for the

compressor Motor an d membrane system Heater located inside the motor starter compartment.

Amperage Load for System

♦ Approximately 54 Amps for 440 V three phase service

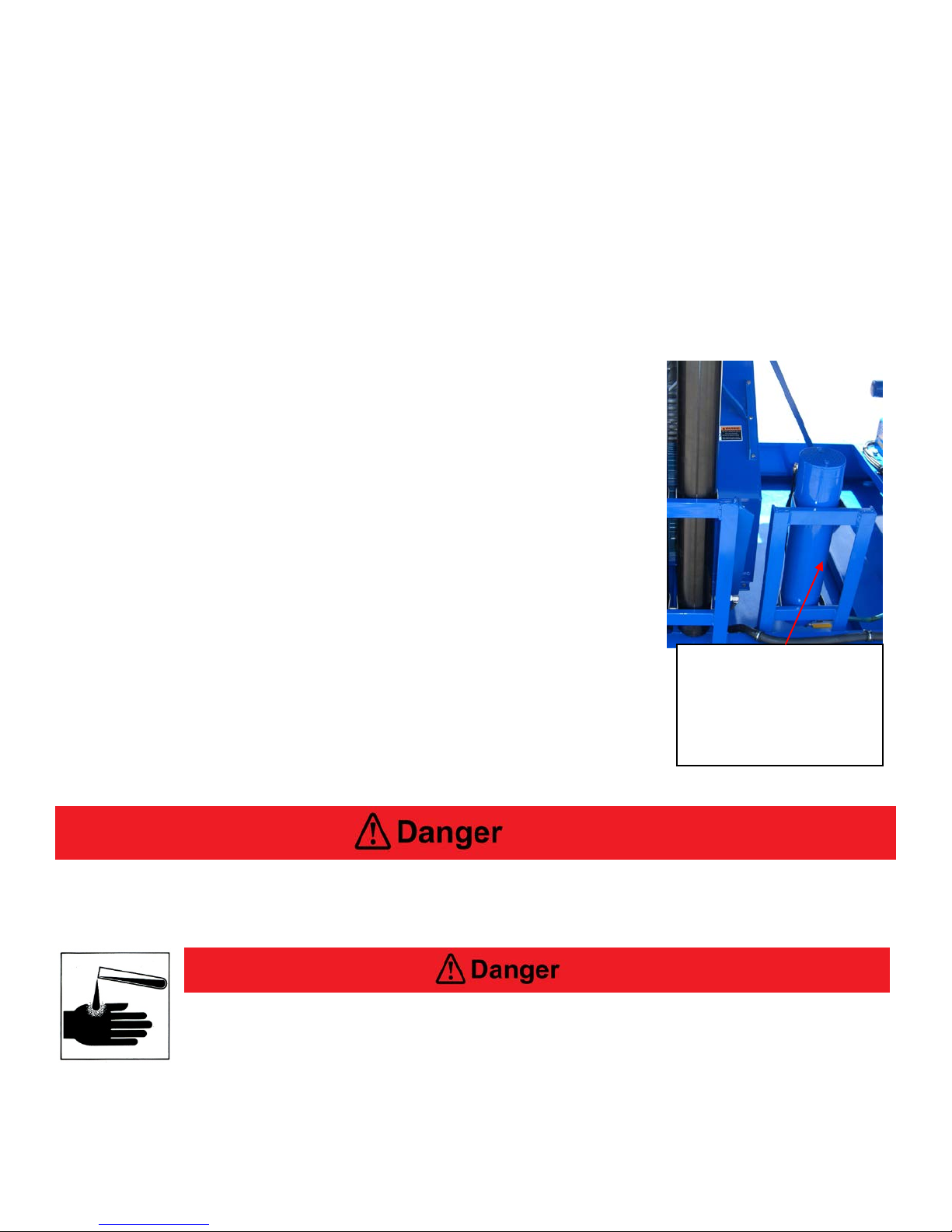

Compressor Rotation Check

Always turn on (bump) starter for both LP and HP compressors and run motor very briefly to check for

proper direction of rota ti on (see arrow on belt guar d and flywheel).

Note Proper Direction

of Rotation

Operation in reverse direction for extended periods of time will cause a reciprocating

compressor to run hot and perform poorly and may cause permanent damage. Reverse

rotation for a rotary screw compressor for even a short period of time will cause damage.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

20

HP

gauge

LP oil fill &

13.4 Check Compressor Lubricant Levels

Check lubricant levels before starting the LP

and HP compressors and add lubricant as

required. Use only the lubricants specified by

Nuvair.

Q-390/MCH 36Electric Nitrox System

dip stick

Compressor

lubricant

level sight

Do not allow nitrox to be discharged into the air storage system. Nitrox

introduced into the air storage system could cause a diver to suffer from oxygen

poisoning at depth. Oxygen poisoning is extreme ly dangerous and can lead to

death by drowning.

Do not allow air to be discharged into the nitrox storage system. Air introduce d into the nitrox

storage system could cause a diver to suffer decompression sickness if the nitrox mixture is

not analyzed properly and is used underwater under the assumption it is a different mix.

13.5 Control Panel Identification

See Page 16

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

21

Q-390/MCH 36Electric Nitrox System

14.0 Pre-Operation Instructions

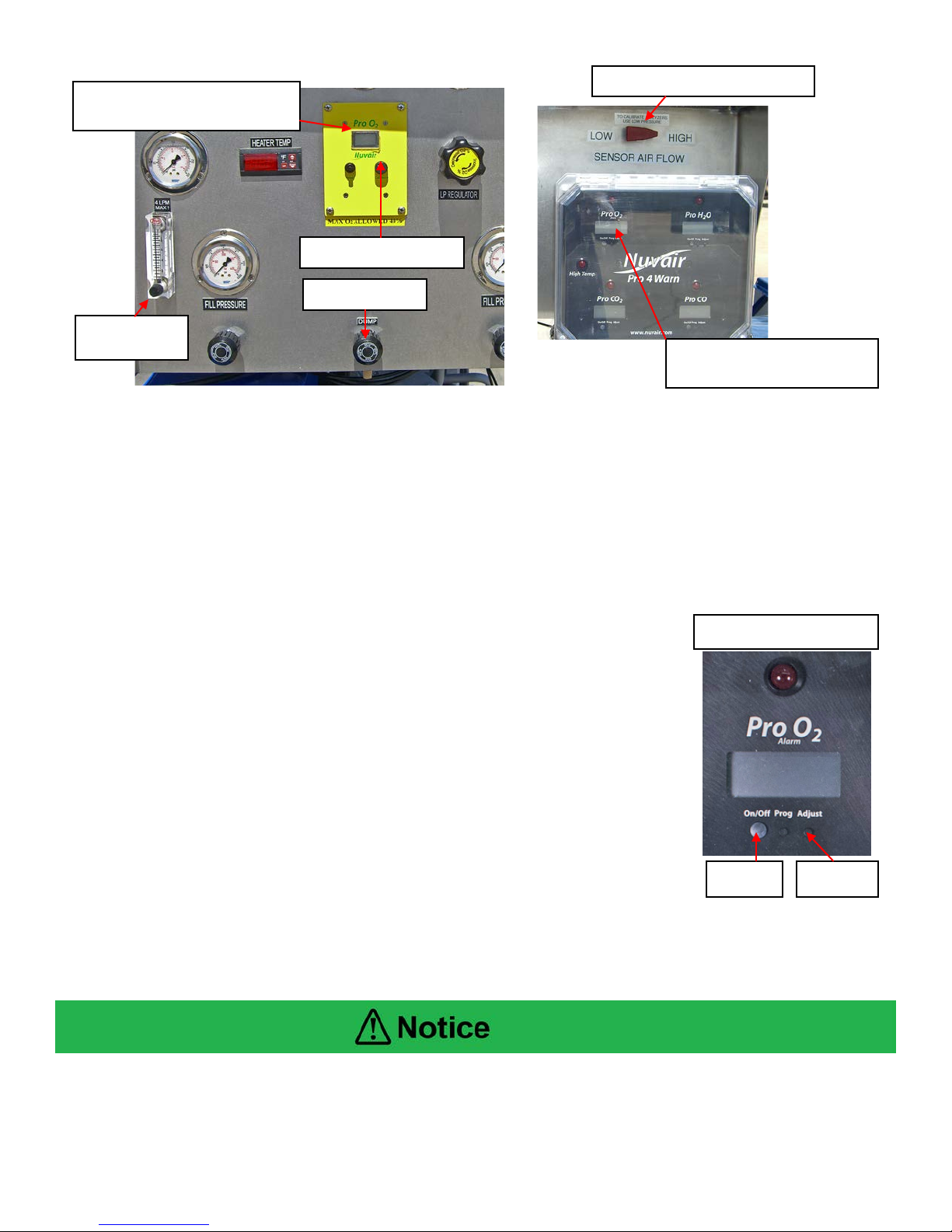

14.1 Calibrate Oxygen Analyzers

Gas production is monitored with the permeate oxygen analyzer before the compressed gas enters

the HP compressor to obtain a rough estimate of O2% (+/- 2%). Do not rely on this reading as a

proper indication of percentage of oxygen at the HP compressor outlet. Prior to pumping nitrox from

the compressor, it must be monitored with the fill oxygen analyzer to obtain a precise measurement of

O2% (+/- 1%). Both oxygen analyzers must be calibrated prior to each use.

Oxygen Analyzers must be calibrated before each use. See Oxygen Analyzer manuals for

correct calibration procedures. Improper calibration of the Fill Oxygen Analyzer may result in

the use of incorrect nitrox mixtures, which may cause serious injury or death to the diver

using the gas mixture.

At altitudes above sea level, a correction factor must be used when calibrating the fill oxygen

analyzer. It may not be possible to achieve all desired mixtures at altitude. See fill oxygen

analyzer manual for correcting analyzer readings at various altitudes. Imprope r calibration of

the fill oxygen analyzer may result in the use of incorrect nitrox mixtures, which may cause

serious injury or death to the diver using the gas mixture.

The permeate oxygen analyzer supplies oxygen readings that can vary +/- 2% O2 due to heat,

humidity, and pressure changes experienced in the nitrox flow and therefore should only be

used for rough estimates of O2%. The fill oxygen analyzer supplies more accurate oxygen

readings, within +/- 1% O2. For cylinder nitrox fills, the user must always verify the final fill

with a third independent oxygen analyzer.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

22

Q-390/MCH 36Electric Nitrox System

On/Off

Adjust

Fill Oxygen Analyzer

Calibration knob

Permeate oxygen analyzer

provides rough reading

Fill oxygen analyzer

provides precise reading

Low High Flow Valve

Dump Valve

Flow Meter

14.1 Calibrate Oxygen Analyzers - Continued

1) Turn on the high pressure compressor and analyzers.

2) Crack open the dump valve on the Control Panel so that the running HP compressor maintains

1500-2000 psi (100-136 bar) outlet pressure. Air will now be flowing past both oxygen

analyzers for calibration purposes; allow warm up 1-2 minutes.

3) Turn on low pressure compressor (make sure Feed air ball valve on tank is closed)

4) Monitor all gauges for proper operating range and check all connections for leaks.

5) Calibrate permeate oxygen analyzer while the HP compressor is pumping air. Refer to the

oxygen analyzer manual included with the nitrox system for details. Note that special

calibration procedures may be required when operating at altitudes above sea level.

6) Fill oxygen analyzer (Pro 4 Warn)

a. Open feed air ball valve on tank.

b. Change Low High Flow Valve on control panel to Low

c. Adjust flow meter to 4 LPM

d. Expose the sensor to ambient air for approximately 1-2

minutes.

e. Push the On/Off and Adjust buttons simultaneously to calibrate

fill analyzer.

f. Change Low High Flow Valve switch to High.

g. The fill oxygen analyzer is now ready for use.

Different settings may be used depending on heat, humidity and

altitude verify your actual ambient conditions and refer to

the oxygen analyzer manual for details.

7) Increase the low pressure compressor to a minimum of 90 psi

8) Allow the compressors to run for a 10 minute warm up period for

the membranes to warm up and stabilize. Check the heater

temperature gauge to verify air temperature rises and is between 105-120 ºF (40-49 ºC).

9) Now that the system temperature has stabili zed, you must recalibrate the fill O2 analyzer.

See step (6) above for cal i br ati on.

The oxygen analyzers may require re-calibration after 10-20 minutes of operation due to

humidity and temperature change effects on the sensor. To recalibrate, turn off the LP feed

air and follow calibration instructions.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

23

Q-390/MCH 36Electric Nitrox System

Fill oxygen analyzer

15.0 Producing Nitrox

Before using your nitrox system to pump nitrox, test a sample of the nitrox produced using the

air/nitrox quality analysis kit provided to verify compliance with CGA standards or applicable

standards for intended us e. Quarterly testing is mandatory once the system is operational.

The equipment you will be using to manufacture nitrox (oxygen rich air) will expose you to

both low and high-pressure gas. Gas, even under moderate pressures, can cause extreme

bodily harm. Never allow any gas stream to be directed at any part of your body.

Do not change the temperature setting on the thermostat control without contacting Nuvair.

Changes in temperature settings may cause membrane damage. A damaged membrane will

not produce the correct nitrox mixture which can lead to severe personal injury if the gas is

used for diving purposes without proper analysis.

15.1 Flow to Membrane and Setting Proper Pressure

The membrane system feed air pressure determines the oxygen percentage of the nitrox mixture. As

pressure is increased, a higher oxygen percentage of nitrox is pumped. As pressure is decreased, a

lower percentage of oxygen is pumped.

1) Increase pressure by slowly turning the back pressure LP regulator knob clockwise while

monitoring the LP pressure gauge and permeate oxygen analyzer. As the pressure rises, watch

the corresponding increase in the analyzer O

2) Increase or decrease pressure slowly until the permeate oxygen analyzer displays the percentage

of oxygen desired in the final nitrox mixture.

• Regulated membrane system pressure range should be

90– 175 psi (6-12 bar), depending on nitrox O2%being

produced.

• Heater temperature range should be 105-120º F (40-49º C).

15.2 Final Adjustments Before Pumping nitrox

1) As the nitrox initially makes its way through the running HP

compressor, the O2% reading on the fill oxygen analyzer will slowly

increase to read approximately the same O2% as the permeate

oxygen analyzer. This should happen within 3-5 minutes.

2) When the two analyzers read within +/- 1%, make any final

adjustments to the membrane system f eed air pressure necessary to

obtain the exact nitrox O2% desired as indicated on the fill oxygen

analyzer.

3) The system is now ready to pump nitrox.

4) Now you’re ready to close the dump valve and open the on/off fill

valve to the storage system.

% reading.

2

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

24

Q-390/MCH 36Electric Nitrox System

The use of enriched air nitrox does not eliminate the risk of decompression sickness (DCS) in

diving. Decompression sickness can lead to permanent disability or death.

The permeate O2 analyzer supplies oxygen readings that can vary +/- 2% O2 due to heat,

humidity, and pressure changes in the nitrox flow and should only be used for rough

estimates of O2%. The fill O2 analyzer supplies more accurate readings, within +/- 1% O2. For

scuba cylinder fills, the user must always verify the fill with a third independent O2 analyzer.

Do not use this system to produce nitrox mixtures containing more than 40%

oxygen. Pumping nitrox mixtures with higher concentrations of oxygen may

lead to fires or explosions, which can cause serious personal injury or death.

Do not pump nitrox mixtures at pressures above the HP compressor rating, and

never above 3600 psi (250 bar). The system is not rated for pressures above

3600 psi (250 bar). Higher pressures may lead to explosions which may cause

serious personal injury or death.

No oxygen cleaning of standard cylinders or plumbing is mandatory when using the nitrox

system to produce nitrox containing a maximum of 40% oxygen. When filli ng oxygen clean

cylinders, hyper-purification of the nitrox is required using an optional oxygen compatible air

purification system available from Nuvair.

This nitrox system does not produce nitrox mixtures acceptable for 100%

oxygen service. Mixing nitrox mixtures with 100% pure oxygen may lead to fires

and / or explosions, which may cause serious personal injury or death.

Never fill a cylinder that is marked, “For Oxygen Service,” with nitrox that has

been produced by anything other than 100% oxygen clean system. Filling an

oxygen clean cylinder with breathing gas containing hydrocarbons can lead to

explosions if the cylinder is subsequently filled with gas mixtures containing gas mixtures

containing greater than 40% oxygen. Explosions may cause serious i nj ur y or death.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

25

Q-390/MCH 36Electric Nitrox System

Only provide scuba cylinder nitrox fills to customers who have proof of nitrox training and

certification. Improper use of nitrox can cause severe personal injury or death.

This system is not cleaned for oxygen service and not all components are

compatible with gas mixtures containing greater than 40% oxygen. Pumping

gas mixtures containing greater than 40% oxygen will lead to explosions which

may cause severe personal injury or death.

Each scuba cylinder belonging to a customer must be analyzed by tha t customer at the nitrox

filling facility, using an oxygen analyzer independent of those used with the nitrox system. An

employee must witness that the customer has properly analyzed the gas in each cylinder,

noted the maximum operating depth for that mi xture, and signed and dated the fill log. The

time of day must also be included with the date, since some customers may fill the same

cylinder more than once a day.

15.3 Pumping Nitrox

1) When filling a scuba cylinder, follow all industry standards. Do not exceed rated pressure of

cylinder, and do not exceed 360 0 psi (250 bar) under any condition.

2) With fill whip bleed valve open and nitrox flowing, verify that fill oxygen analyzer O2% reading

equals the desired nitrox O2%.

3) Close bleed valve, open cylinder valve, and fill cylinder. Monitor system for proper operation:

a) Monitor oxygen analyzers and recalibrate as required

b) Listen for proper operation of automatic condensate drains every 10-15 minutes.

c) Monitor all system gauges as shown in the table below.

The Oxygen Analyzers may require re-calibration after 10-20 minutes of operation due to

humidity and temperature change effects on the Sensor . To recalibrate, turn off the LP feed

air switch and follow calibration instructions.

When the HP compressor auto drain engages and dumps condensate, the fill oxygen analyzer

reading will decrease momentarily due to the pressure drop in the system. It will return to its

previous reading within seconds after the auto drain sequence stops.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

26

Q-390/MCH 36Electric Nitrox System

GAUGE

RECOMMENDED SETTING

Compressor Gauges

According to manufacturers recommendations

Heater Temperature

105 - 120o F (40 - 49o C)

Cabinet Temperature

Less than 100o F (38o C)

Membrane Feed Air Pressure

90 – 175 P.S.I. (6 - 12 bar) depending on Nitrox O2%

Fill Oxygen Analyzer

Showing the proper reading for intended fill

Nitrox Storage Pressure

DO NOT

exceed rating of tank or 3600 P.S.I (250 bar)

Use independent oxygen

15.3 Pumping Nitrox (continued)

4) Aft er filling is complete, close the cylinder valve, vent the bleed valve,

and remove the cylinder.

5) Test the nitrox O2% in the cylinder using an independent oxygen

analyzer such as the Nuvair O2 QuickstickTM. Calibrate the analyzer

before use in accordance with manufacturer’s instructions.

6) Repeat steps 1-5 until you have filled all scuba cylinders.

7) Mark each tank with fill date, O2%, fill pressure, and MOD

(Maximum Operating D epth) .

8) Log every nitrox fill to document the following information:

• Fill date and time of day

• Tank serial number

• Supplier’s check of oxygen content O2% plus signature and dat e

• User’s check of oxygen content O2% plus signature and date

• Fill pressure

• MOD (Maximum Operating Depth) in user’s handwriting

• Nitrox certifying agency and card number

9) When filling a HP nitrox storage tank, verify that fill oxygen analyzer O2% reading equals the

desired nitrox O2%. Open applicable line valves and tank valve, and fill with nitrox. Do not

exceed rated pressure of cylinder, and do not exceed 3600 psi (250 bar) under any condition.

After filling is complete, close all valves and allow nitrox system to shut down.

analyzer for verification

High-pressure cylinders that are filled quickly will become hot and due to the increased

internal temperature the cylinder pressure will increase. This will leave a diver with less

pressure inside the cylinder once cooling has occurred. This will decrease the amount of time

the diver may spend underwater which may be critical during a deep dive. Customers must be

warned of this possibility if cylinders are delivered for use while warm. Always fill all breathing

gas cylinders slowly to avoid overheating.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

27

Always use Oxygen Analyzers to monitor oxygen content of any gas flowing through the

High Pressure

Switch

Low Pressure

On/Off

Dial-A-Pressure

Ball Valve LP Tank

3 way Ball Valve

system. Both air and nitrox are subject to variations in oxygen content.

15.4 Pumping Air

To use the system to pump HP air, simply turn off the LP compressor and close ball valve on tank.

No nitrox will be supplied to the HP compressor, and it will pump air only. When the HP compressor

is pumping air, the permeate oxygen analyzer and the fill oxygen analyzer

should both read 20.9 O2%.

The LP compressor can pump Grade D breathing air only by turning the

three way valve to bypass the three stage breathing air filtration.

15.5 Shutting Down

1) When the storage banks are finished filling and tank valves are closed,

the nitrox system will automatically shut down at the pres sur e set on the

dial-a-pressure switc h ( 3600 psi) (250 bar).

2) Close ball valve on LP Tank

3) Turn off LP Compressor

4) The system will automatically drain all filters, compressor, and volume tank condensate.

Switch & Gauge.

Adjust Shut Off

Pressure Here

Compressor

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Compressor On/Off

Page

Q-390/MCH 36Electric Nitrox System

28

Q-390/MCH 36Electric Nitrox System

16.0 Nitrox Operation Notes

• Ensure all personnel who operate the system are properly trained in its use.

• Keep a log with details of each cylinder filled with nitrox, including the time and date,

name of operator of system, name and certification number of diver, gas analysis,

MOD, and cylinder pressure.

16.1 Correlation of Feed Air Pressure to Oxygen Content

After the 10 hour break-in period for your nitrox system, you will notice that specific nitrox oxygen

percentages always match specific feed air pressures once the system has warmed up. These

pressures and percentages will be repeatable. If you find that the fill oxygen analyzer reads 36% O2

when the feed air pressure is at 125 psi (9 bar), record this pressure or make a mark on the feed air

pressure gauge indicating the O2%. Do this for each O2% that you normally make, making sure

system has warmed up first. The next time nitrox with 36% O2 is needed, adjust the regulator to 125

psi (9 bar) and wait for the oxygen analyzer reading to stabilize. You will find the analyzer reading to

be very close to 36% O2, requiring only minor adjustments of the regulator to achieve the exact

desired O2%.

Use the fill oxygen analyzer to verify the nitrox oxygen percentage prior to pumping. When

using the feed air pressure reading to obtain speci fic oxygen percentage, minor adjustments

of the feed air pressure regulator may be required to obtain the exact percentage desired.

16.2 Hot Fills

While in the process of filling HP nitrox storage tanks, you may have a need to supply a walk-in

customer with a scuba cylinder fill of a different nitrox mix. You can change mixes as follows:

1) With the nitrox system operating, isolate the HP nitrox storage tanks from the HP compressor by

closing the appropriate valves.

2) Record the membrane system feed air pressure reading.

3) Slightly open fill whip valve on the HP compressor, and adjust so the running compressor

maintains 1500-2000 psi (100-136 bar) outlet pressure.

4) Adjust the back pressure feed LP air regulator to the pressure corresponding to the desired nitrox

O2% for the scuba cylinder fill.

5) Allow the fill oxygen analyzer reading to stabilize, make any minor adjustments necessary to

achieve the desired O2%, and then fill cylinder in normal manner.

6) When finished retur n LP regulator to previous setting, and allow the fill oxygen analyzer reading to

stabilize. Make any minor adjustments necessary to achieve the desired O2%, and then resume

filling storage tanks.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

29

Q-390/MCH 36Electric Nitrox System

Condensate Drain

Check & Drain Weekly

17.0 Maintenance

The following list of daily and routine maintenance items is intended as a guide. Refer to LP and HP

compressor manuals for complete maintenance requirements.

17.1 Daily Maintenance

Be sure to check compressor lubricant levels prior to each day of operation. Failure to ensure

the proper lubricant level will lead to system damage.

1) Check lubricant levels of both LP and HP

compressors and add proper lubricants as

required. See Section 17.3 and compressor

manuals for details.

2) Slightly open each HP and LP manual condensate

drain valve to verify that no condensate is present.

3) Check LP air filtration for condensate and

proper operation of condensate drains.

Container.

Use only the specified Nuvair lubricants in this system. The use of

incompatible lubricants presents a risk of fire and/or explosion, and may resul t

in system damage. This can lead to severe personal injury and death.

Be sure that all pressure has been relieved from the system prior to opening

any filtration canister. Failure to vent pressure from the system prior to opening

the canister can lead to serious personal injury or death.

If system is located in an area where there is high humidity and high heat, the life of all

filtration elements may be as little as 35% of rated operating capacity. Check the compressor

manual and appendix for details on filter element life factors.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

30

Q-390/MCH 36Electric Nitrox System

Condensate drain

as needed.

17.2 Routine Maintenance

1) LP Compressor Lubricant: Change compressor lubricant every 100 hours or annually, whichever

comes first. Only use lubricants rated for use wit h nitrox, such as Nuvair 455 TM. Never mix

compressor lubricants. See Section 17.3 and LP compressor manual for details.

2) HP Compressor Lubricant: Change compressor lubricant every 100 hours or annually, whichever

comes first. Only use lubricants rated for use with nitrox, such as Nuvair 455 TM. Never mix

compressor lubricants. See Section 17.3 and HP compressor manual for details.

3) LP Air Filtration Inspection: On a weekly basis, inspect each filter bowl for the presenc e o f

moisture and each Element for any unus ual degradation or wetness. See Section 17.5 for details.

4) LP Air Filtration Elements: Change LP filter elements every 100 hours or annually to maintain

CGA Grade D air standards. Visual liquid level and service life indicators assist w i th moni t or i ng

replacement intervals. See Section 17.5 for details. If the nitrox system is operated in high

humidity and/or high temperature, filter elements must be changed mor e o ften. See appendix for

details on filter element life factors.

5) HP compressor Filtration Element: Change HP Filter Element

every 60,000 cubic feet (about 50 hours) of air or nitrox

processing to maintain CGA Grade E air standards. See

Section 17.7 for details. If the nitrox system is operated in high

humidity and/or high temperature the filter element must be

changed more often. See appendix for details on filter element

life factors.

6) Condensate Drain Container with valve open: Chec k level of

attached bucket and drain weekly or as needed.

7) Semi-Permeable Membrane: No maintenance required.

Service life exceeds 20 years if LP air filtration is properly

serviced to maintain oil free Grade D air standards.

8) Membrane System Air Intake Filter: Inspect filter element

every 3 months for visible particles. Change every 12 months

or sooner if particles are visible.

9) Oxygen Analyzers: Replace oxygen sensor and battery as

required. See manual included with nitrox system.

10) Air/nitrox Quality Analysis: Take breathing air/nitrox samples quarterly

for analysis to assure compliance with CGA Grade E breathing air s tand ar ds .

container must be

attached to a drain bucket

and left open. Check and

drain the bucket weekly or

Do not swallow (ingest) either the electrolyte from the oxygen sensor or the sensor itself. The

Potassium Hydroxide chemical contained in the sensor can cause severe injury or death. If

electrolyte or the Sensor is swallowed, seek medical attention immediately.

If after handling the oxygen analyzer or sensor, you find that your fingers or

other parts of your body feel “slippery” or the skin or eyes sting, immediately

flush affected area with clean, fresh water for at least 15 minutes. The stinging

or slippery sensation is an indication of a leaking Sensor. The Potassium

Hydroxide chemical contained in the sensor can cause severe injury or death. Seek immediate

medical attention if eye contact is made or skin stinging persists.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

31

Q-390/MCH 36Electric Nitrox System

Use only the specified Nuvair lubricants in this system. The use of

incompatible lubricants presents a risk of fire and/or explosion, and may result

in system damage. This can lead to severe personal injury or death.

17.3 Compressor Lubricants (see page 40 for Material Safety Data Sheets)

• The LP compressor in your nitrox system comes standard with Nuvair 455 synthetic food

grade compressor lubricant. Customers may specify different lubricants, check lubricant

page at the back of manual for accepted lubricants.

• The HP compressor comes with the Nuvair 455 synthetic food grade lubricant. Customers

may specify different lubricants, check lubricant page at the back of manual for accepted

lubricants.

• Check lubricant levels at sight gauge on HP and dip stick of LP Compressor and add

lubricant as required through the appropriate lubricant fill plug.

• Lubricant is removed through the drain plugs. See LP and HP compressor manu al s for

details on servicing lubricant

Never mix different lubricants together because equipment damage may occur when

machinery is operated with improper lubricant.

Do not carry out any maintenance tasks if the compressor has just shut down.

Wait for the compressor to cool to avoid skin burns.

Pressure must be properly drained from the system before opening the LP fill

plug. Failure to drain pressure may result in severe personal injury.

Any oil spilled during the oil and oil filter change coul d cause personnel to slip

and fall. Wear anti-slip footwear. Remove any traces of spilled oil immediately.

Slips and falls may cause severe personal injury or death.

Wear eye protection, gloves, and skin protection whe n performing

oil changes. Although the oil is not classified as a dangerous

substance, the oil can be irritating to your eyes and skin.

Both oil and oil filter are classified as “special wastes” and must be disposed

of properly according to applicable na tional and local laws. Failure to dispose

of these wastes properly can lead to death of wildlife as well as government

fines and penalties.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

32

Lubricant fill plugs

HP compressor

LP compressor

Lubricant drain plugs, right side of pumps

Lubricant sight gauge

Lubricant dip stick

All maintenance work must be carried out with the compressor off and the

power supply lead unplugged from the main socket. Appropriate steps must be

taken to tag out and lock out the electrical power. Failure to isolate this

equipment from the power source while performing maintenance may result in

severe personal injury or death.

• The LP compressor in your nitrox system comes standard with Nuvair 455 synth et ic food

grade compressor lubricant.

• The HP compressor comes with the Nuvair 455 synthetic food grade lubricant.

• Check lubricant levels at sight gauge on HP compressor and dip stick on LP compressor,

add lubricant as required through the appropriate lu br i cant fill plug.

• Lubricant is removed through the drain plugs. See LP and HP compressor manu als for

details on servicing .

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

Q-390/MCH 36Electric Nitrox System

33

Q-390/MCH 36Electric Nitrox System

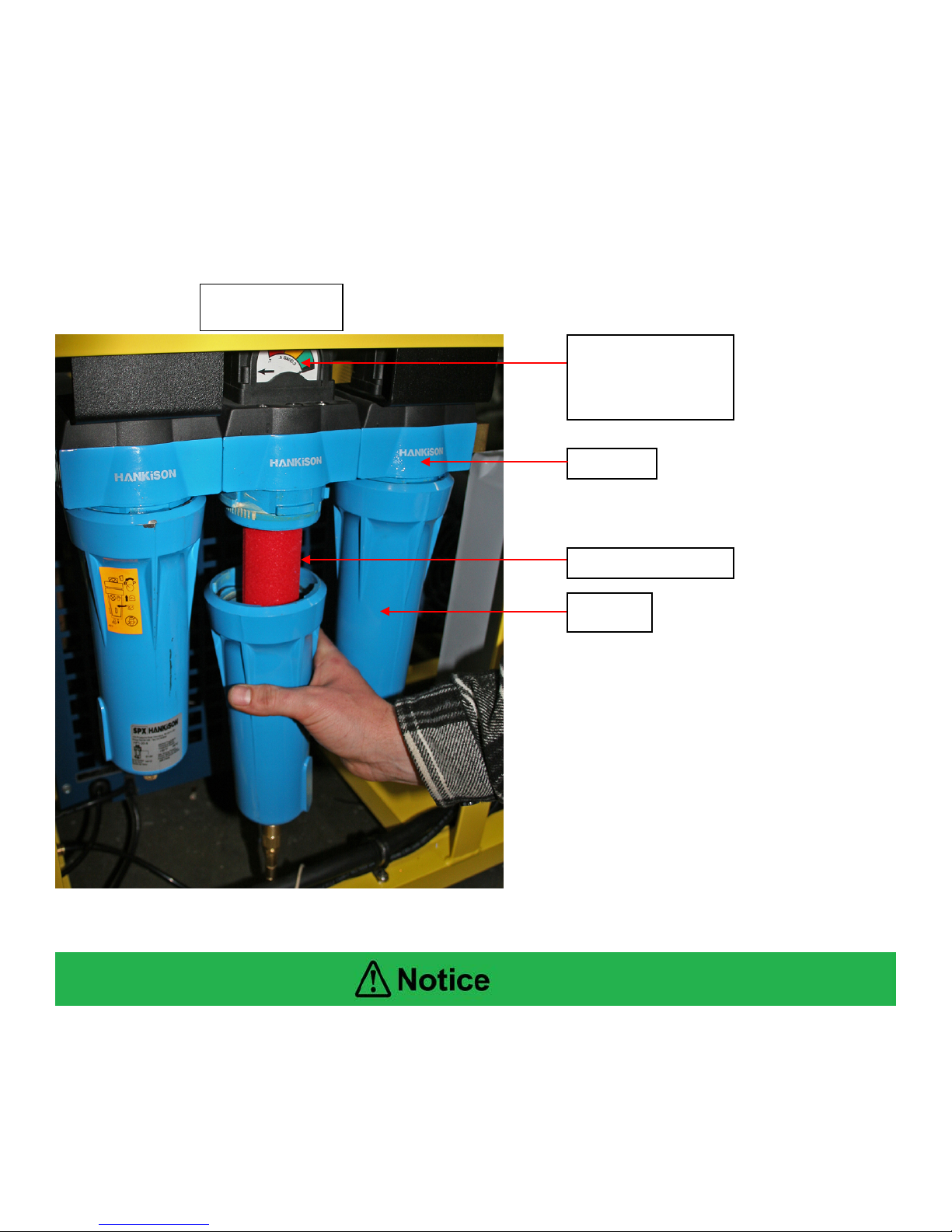

HF1-24

HF5-24

HF7-24

HF11-24

Replacement Element Part Number

E1-24

E5-24

E7-24

E11-24

Air Flow

HF5-24

Housing

Element inside bowl

HF1-24

moisture

HF7-24

Bowl

HF11-24

17.4 LP Feed Air Filtration and Bowls

Special attention needs to be given to the arrangement of the four LP feed air filtration

elements and bowls. Properly reinstall each element and bowl to the correct housing.

Improper sequence can cause damage to downstream components

The use of Grade D or better feed air is critical to prevent the passing of any residual oil vapor into

the membrane system. Four stages of Hankison LP filtration are used to produce Grade D air:

1) Coalescing filter (HF11-24)

2) Coalescing & water/oil vapor removal to 1 Particulate micron (HF7-24)

3) Coalescing & water/oil vapor removal to 0.01 Particulate micron (HF5-24)

4) Fina l s tage - oil vapor removal to 0.003 PPM (HF1-24)

17.5 LP Filtration Inspection

Open each Filter and inspect as follows:

Inspect the bowl for the presence of moisture. A high level of moisture build-up in the HF11-24 or

HF7-24 filter indicates improper operation of auto-drain floats. Evidence of any moisture in the

HF1-24 filter indicates air is not cooling properly and moisture is not properly being removed.

Check HF1 canister weekly for moisture. Moisture indicates possibl e aut o drai n problem. Excess

moisture will prevent the final filter from operating properly and can lead to damage of the

membrane.

Filter with

auto-drain

should not

contain

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Filter with

auto-drain

float & liquid

level indicator &

service indicator

Filter with

auto-drain

float & liquid

level indicator &

service indicator

Page

34

Filter with

auto-drain

float & liquid

level indicator

Q-390/MCH 36Electric Nitrox System

Changing LP

filtration element

Housing

Element inside bowl

Bowl

Differential pressure

should be changed

17.6 Changing LP Filtration Elements

Change filtration elements every 100 hours. If the nitrox system is operated in high humidity and / or

high temperature, filter elements must be changed more often. See appendix for details on filter

element life factors. Visual service indicators on the HF7 & HF5 filters assist with monitoring

replacement intervals.

1) Push up on filter bowl, rotate counter-clockwise, and lower to remove.

2) Gently unscrew filter element and pull down off mounting post.

3) Replace filter element and reassemble bowl in reverse order.

indicators. Color

indicates when filter

The interior of the Filter Bowls can be cleaned with a diluted solution of Simple GreenTM and

flushed thoroughly with clean water. This will assist to prolong the life of the element, bowl,

and auto drain.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

35

Q-390/MCH 36Electric Nitrox System

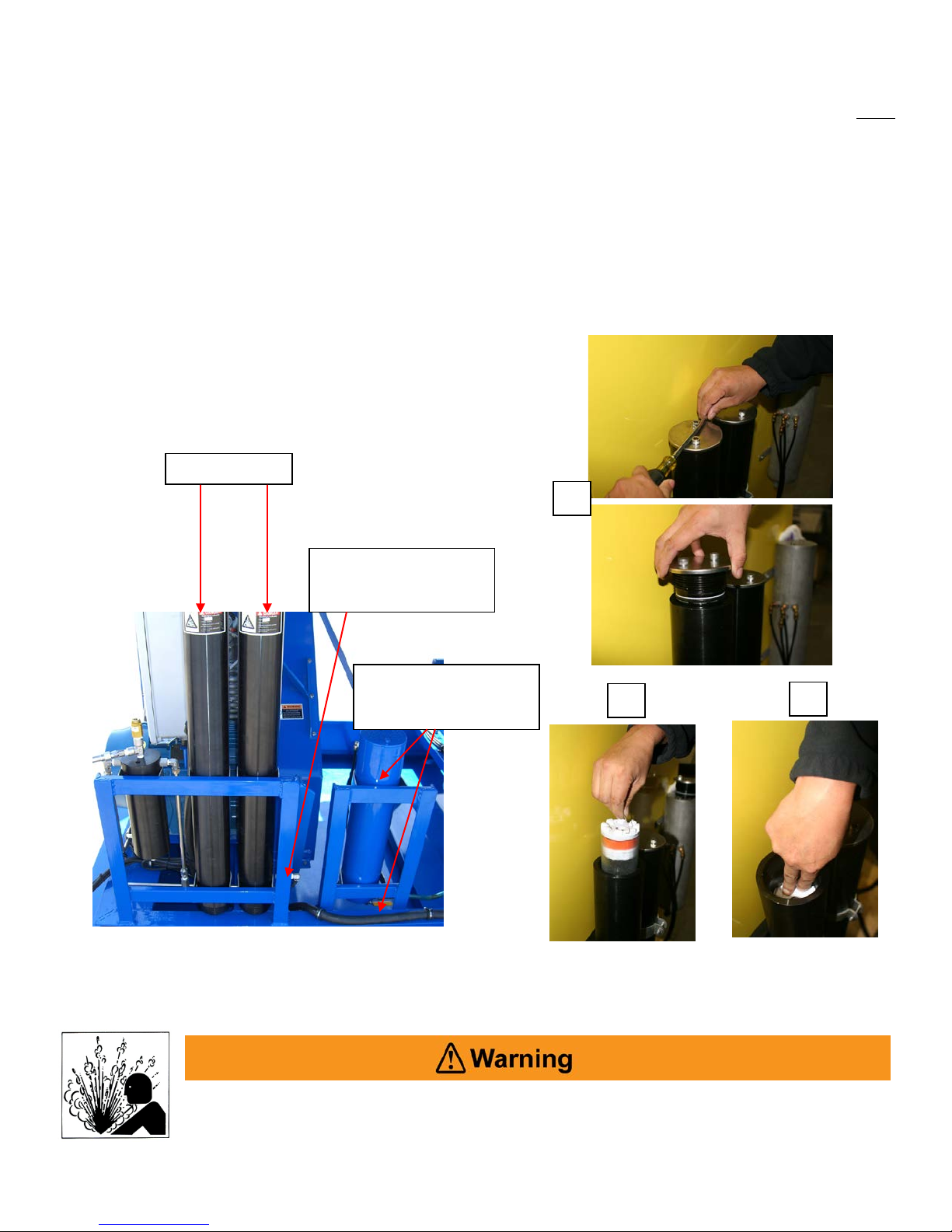

Filter canisters

3 4 5

Condensate Drain

Check & Drain Weekly

2) Manual Bleed Valve

17.7 HP Compressor Filtration

The HP compressor comes standard with triplex filtration, utilizing a single filter element. Do NOT

use any substitute. Change filtration elements every 60,000 cubic feet (about 50 hours) of air or nitrox

processing. If the nitrox system is operated in high humidity and / or high temperature, filter elements

must be changed more often. See appendix for details on filter element life factors.

1) Shut down the nitrox system

2) Open manual bleed drain valve to drain pressure. Leave valve open.

3) Unscrew the filter canister cap.

4) Remove expended element from filter canister.

5) Install new element place pressure on element to seat the element.

6) Reinstall cap to canister.

7) Close manual condensate valves.

at base of tower.

Container.

Be sure that all pressure has been relieved from the system prior to opening

any filtration canister. Failure to vent pressure from the system prior to opening

the canister can lead to serious personal injury or death.

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

36

Q-390/MCH 36Electric Nitrox System

Nitrox System Components

Type

Part Number

LP Compressor Consumables

Hankison HF11-24

E11-24

Hankison HF7-24

E7-24

Hankison HF5-24

E5-24

Hankison HF1-24

E1-24

HP Compressor Consumables

HP compressor lubricant, food

grade, nitrox compatible

Breathing air filter, Grade E

X65247

Heater assembly

2400 Watt, 28" length

H2400

220V Fahrenheit gauge

220V Centigrade gauge

Heater pressure switch

B16-947

Pro O2 Remote

9462

Pro O2 Remote

9506

1-1/4"-1-1/2" to 1-1/2"

RDTC40X32

Related Equipment Components

Specify: (1) CGA Grade

required

18.0 Spare Parts List

See LP and HP compressor manuals for compressor parts lists. Other nitrox system components

and related items are listed below.

LP compressor lubricant, food

grade, nitrox compatible

Nuvair 455, 1 Gal 9406

LP filtration elements

Nuvair 455, 1 Gal 9406

Gas drying filter X65677

HP compressor filtration elements

Heater thermostat control

(standard)

TS-13020 F

TS-13021 C

Membrane 250 Series PPA250

Air intake filter element 10-20 CFM 18P

Mixing tube assembly 2 in diameter, specify length Call for price

Oxygen analyzers

Oxygen sensors

Compressor hose couplers

Air / nitrox quality analysis kit

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Pro 4 Warn Pro4Warn

1-1/4"-1-1/2" to 1-1/4"-1-1/2" 018578000476

(2) Single use or program Use

Page

37

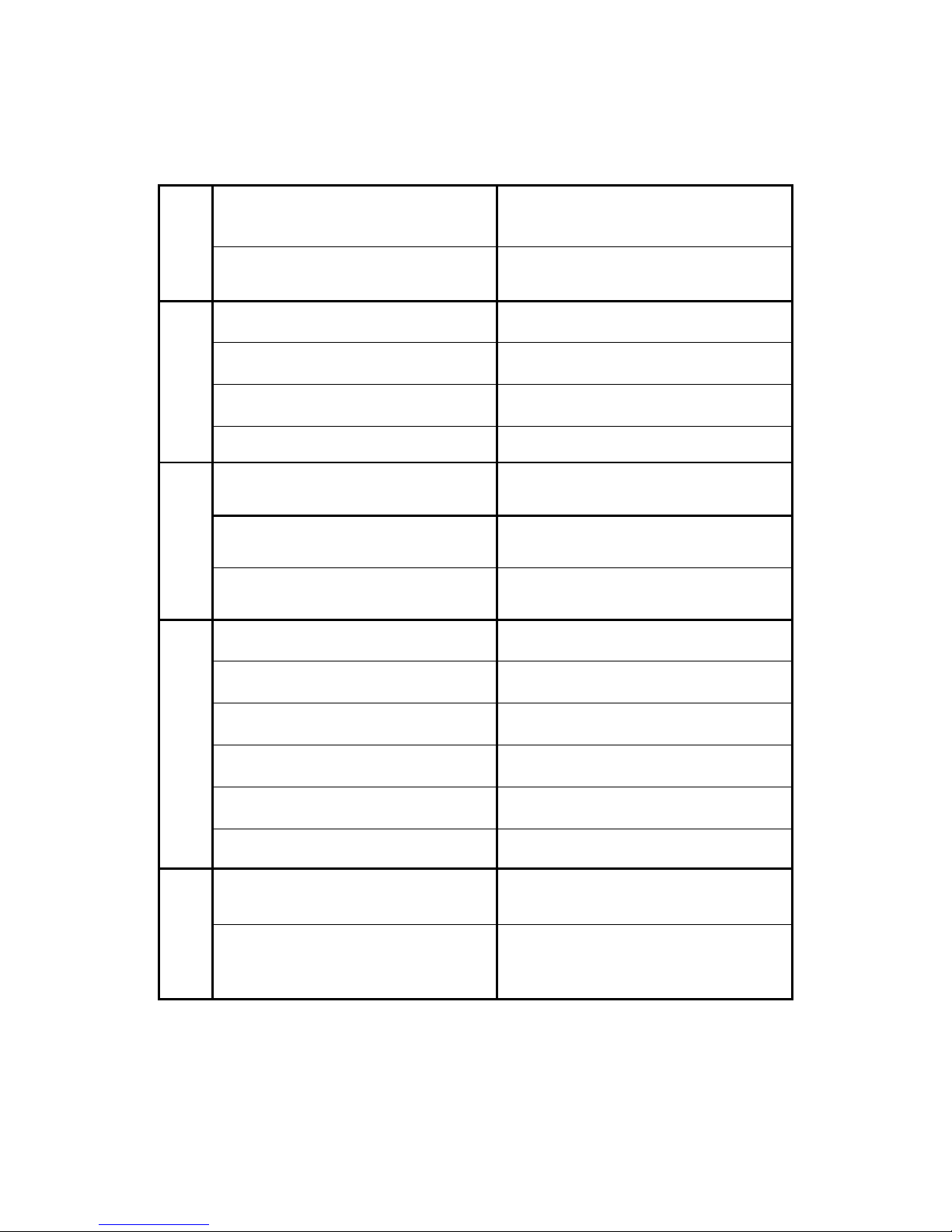

19.0 Service Record Log

Date

Technician Name

Service Performed

Q-390/MCH 36Electric Nitrox System

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

38

Q-390/MCH 36Electric Nitrox System

Item

Grade D

Grade E

O.C.A

Oxygen

19.5-23.5%

20-22%

20-22%

Carbon Dioxide (maximum)

1000 PPM

1000 PPM

1000 PPM

Carbon Monoxide (maximum)

10 PPM

10 PPM

2 PPM

Hydrocarbons (maximum)

Not specified

25 PPM

25 PPM

Water Vapor (maximum) (3)

67 PPM

67 PPM

67 PPM

Dew Point (maximum) (1)

-50ºF

-50ºF

-50ºF

Oil & Particles (maximum) (2 )

5 mg/m3

5 mg/m3

5 mg/m3

Odor

None

None

None

Filter

Temperature

Ambient

Temperature

Filter Element

Life Factor

53ºF (12ºC)

41ºF (5ºC)

2.6 x Life

62ºF (17ºC)

50ºF (10ºC)

1.8 x Life

71ºF (23ºC)

59ºF (16ºC)

1.35 x Life

80ºF (27ºC)

68ºF (20ºC)

1 x Life

89ºF (32ºC)

77ºF (25ºC)

0.8 x Life

96ºF (36ºC)

84ºF (29ºC)

0.55 x Life

105ºF (41ºC)

93ºF (34ºC)

0.45 x Life

114ºF (46ºC)

102ºF (39ºC)

0.35 x Life

20.0 Appendix

20.1 Supply and Breathing Air Specifications

All supply and breathing air must meet the following requirements of CGA G-7.1-1997. Supply air

delivered to the membrane system must be purified to meet oil f ree Grade D, Grade E, or O.C.A. as

specified below and periodic air quality testing to assure compliance is mandatory. All breathing air

for diving produced by the downstream compressor must be purified to meet Grade E quality, and

periodic air quality testing to assure compliance is mandatory.

Notes: (1) Dew Point of supply air must be >10

o

F (6oC) colder than coldest ambient air expected

(2) Supply air delivered to the membrane system must contain <0.003 PPM Oil Vapor

(3) May Vary with intended use.

All breathing nitrox produced for diving must be purified to meet these same requirements, except for

oxygen content. Nitrox oxygen content must measure within +/- 1% O2 of the specified value of the

mixture using a properly calibrated oxygen analyzer (i.e. nitrox produced with a target content of 32%

O2 must measure in the range of 31-33% O2). Periodic air quality testing to assure compliance is

mandatory.

20.2 Filter Element Life Factors

Breathing air filter element life is typically rated by manufacturer based on an air temperature of 80ºF

at the filter inlet. Under normal operation this temperature is 12ºF (5ºC) warmer than the ambient air,

resulting in an equivalent ambient temperature rating at 68ºF (20ºC).

To determine element life at a different ambient temperature, multiply the rated life by the life factor

listed below:

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

39

Q-390/MCH 36Electric Nitrox System

OWNER’S WARRANTY RESPONSIBILITIES

Failure of the owner to prevent equipment damage by complying with the procedures outlined below and in the

operation manual will void the nitrox system warranty.

Installation:

• All set up requirements and procedures provided in the nitrox system operation manual must be

followed in their entirety including supply air cleanliness, compressor preparation, and installation of the

nitrox system.

• Supply air to the membrane must be properly filtered to oil free CGA Grade D air quality or better to

prevent damage to the membrane. Air quality testing of the supply air should be performed periodically

and documented to assure compliance.

• If there is any doubt regarding the suitability of a HP or LP compressor for compressing nitrox, contact

Nuvair or the compressor manufacturer before you connect your nitrox system.

• If an existing HP or LP compressor is to be used for compressing nitrox, all traces of the old lubricant

must be removed and replaced with a nitrox compressor lubricant approved by Nuvair.

• Electrical wiring and connections should be made by a qualified electrician in accordance with all

national and local electrical codes.

• Do not change the temperature setting on the heater thermostat control. Changes in temperature

settings may cause membrane damage.

• To prevent compressor damage, only use the compressor Intake Hose provided. If a longer hose is

required, contact Nuvair for assistance.

• Compressors must be provided adequate ventilation to operate properly and prevent heat damage.

This requires an ambient temperature below 104

and proper rotation direction.

Operation:

• Do not use the nitrox system to supply a HP or LP compressor with nitrox mixtures containing more

than 40% oxygen. Compressing higher concentrations of oxygen may cause severe compressor

damage.

• Do not pump nitrox mixtures at pressures above the compressor manufacturer’s rating, and never

above 3600 psi (250 bar). Compressing nitrox at higher pressures may cause severe HP compressor

damage.

• To prevent membrane damage, drain all low pressure filters and condensate tanks on a daily basis.

• If you become aware of an operational fault, stop using the equipment immediately and contact Nuvair

for assistance.

Maintenance:

• Change low pressure filter elements on a schedule determined by filter capacity and ambient

temperature and humidity. Contact Nuvair if you need assistance establishing a schedule for your

equipment and location.

• Replace membrane system air intake filter on a regular basis to prevent flow obstruction.

• Keep all nuts, bolts, fittings, connectors, and clamps tight.

• Keep a service record book showing that regular maintenance work has been carried out. If a warranty

claim becomes necessary, it will aid in demonstrating that damage has not been caused by insufficient

maintenance. Proof of maintenance may be required prior to determining the validity of a warranty

request.

o

F (40 o C), sufficient clearance from adjacent walls,

NUVAIR

Q-390/MCH36 Nitrox system User Manual

Page

40

NUVAIR NITROX SY STEM WARRANTY

NUVAIR extends a limited warranty, which warrants the nitrox system to be free f rom defects in materials and

workmanship under normal use and service for a limited period. The specific membrane component of the

nitrox system is warranted according to the pro-rated t erms as set forth below. All other Original Equipment

Manufacturer (OEM) components used in the system are warranted only to the extent of the OEM’s warranty to

NUVAIR. NUVAIR makes no warranty with respect to these OEM components, and only warrants the

workmanship that NUVAIR has employed in the installation or use of any OEM component. This warranty is

not transferable.

NUVAIR will, at its discretion and according to the terms as set forth within, replace or repair any materials

which fail under normal use and service and do not exhibit any signs of improper maintenance, misuse,

accident, alteration, weather damage, tampering, or use for any other than the intended purpose.

Determination of failure is the responsibility of NUVAIR, which will work together with the customer to

adequately address warranty issues. When any materials are repaired or replaced during the warranty period,

they are warranted only for the remainder of the original warranty period. This warranty shall be void and

NUVAIR shall have no responsibility to repair or replace damaged materials resulting directly or indirect ly from

the use of repair or replacement parts not approved by NUVAIR.

Pro-Rated Terms:

NUVAIR warrants the membrane component of the nitrox system to be free from defects in material and

workmanship for a period of thirty-six (36) months from date of installation or forty-two (42) months from date of

shipment by NUVAIR, whichever may occur first. The warranty covers parts only and is prorated as follows:

• First Year Repair or replacement free of charge

• Second Year Warranty allowance of 70% of the current membrane component list price

• Third Year Warranty allowance of 40% of the current membrane component list price

A warranty registration card, supplied with system documentation, must be filled out and submitted to NUVAIR

for the warranty to be in full effect. If the warranty registration card is not received within thirty (30) days of

installation, the thirty-six (36) month warranty will begin with the date of shipment from NUVAIR. For warranty

service to be considered, customer’s account must be current or paid in full.

Maintenance Items:

Any materials which are consumed, or otherwise rendered not warrantable due to processes applied to them,

are considered expendable and are not covered under the terms of t his policy. T his includes maintenance and

consumable items listed as part of a suggested maintenance program included with system documentation.

Return Policy:

Application for warranty service can be made by contacting NUVAIR during regular business hours and