Operation Manual

Nuvair Champion LP

Diesel/Electric

rev. 050112

Nuvair Champion LP

If you have any questions on this equipment please contact Technical Support at:

Nuvair

2949 West 5th St.

Oxnard, CA 93030

Phone: 1-805-815-4044

FAX: 1-805-815-4196

Email: info@nuvair.com

Hours: Monday through Friday

8:00 AM to 5:00 PM PST USA

This Operation Manual contains important safety information and should always be available to those

personnel operating this equipment. Read, understand, and retain all instructions before operating

this equipment to prevent injury or equipment damage.

Every effort was made to ensure the accuracy of t he information contained within. Nuvair, however,

retains the right to modify its contents without notice. If you have problem s or questions after reading

the manual, stop and call Nuvair at 1-805-815-4044 for information.

NUVAIR rev.010512

Champion LP Operation Manual

Page 2

Nuvair Champion LP

Table of Contents

Introduction

1.0 Introduction …………………………………….................................................................................. 4

2.0 Safety Warnings ……………………… …………………….............................................................. 5

3.0 Safety and Operation Precautions …………………………….......................................................... 6

4.0 Legal Precautions ……………………………………........................................................................ 7

5.0 System Components and Overview R15..………......................................………......………….... 8

System Components and Overview R30…………......................................………......………….... 9

6.0 System Components Identification Diesel….……....................................................……………..... 10

7.0 System Components Identification Electric…….......................................................……………..... 11

Setup, Operation, and Maintenance

8.0 Theory Of Operation …………..…………………………………….…………………………………… 12

9.0 Assembly Preparation …………………………………….................................................................. 12

10.0 Set-Up and Assembly ……………………………............................................................................. 12

10.1 Power Connections………………………...…....................................................................... 12

10.2 Proper Rotation ………………………………………………………………………………….. 12

11.0 Operation …………………………………………………………………………………………………. 13

11.1 Shutdown ………………………………………………………………………………………… 13

12.0 Operation Notes ………………………………………………………………………………………….. 14

13.0 Maintenance ……………………………………................................................................................. 14

13.1 Routine Maintenance …………………………….….............................................................. 14

13.2 Compressor Lubricant ………………………………….......................................................... 15

14.0 LP Filtration ……….……………………………………...................................................................... 16

14.1 Filtration Inspection ……………………………………………………………………………… 16

14.2 Changing Filtration Elements …………………………………………………………………… 17

14.3 Changing Air Intake Filtration …………………………………………………………………... 17

14.4 Air Intake Extension ……………………………………………………………………………… 17

15.0 Spare Parts List …………….……………………………................................................................... 18

16.0 Service Record Log …………………….……………..................................................……………… 19

Appendix ……………………………………..............................................................………………………… 20

Material Safety Data Sheets ……………………………………........................................................ 20

Warranty ……………………………………………………………………..……………..……………... 21

Options Available………………………………………………………………………………………..... 22

Separate Manuals Included:

Champion R15 or R30 Compressor Operation & Maintenance Instructions

Yanmar or Kohler Diesel Manual

WEG or Baldor Electric Motor Manual

NUVAIR rev.010512

Champion LP Operation Manual

Page 3

Nuvair Champion LP

1.0 Introduction

Nuvair has taken extreme care in providing you with the information you will need to operate this

system. However, it is up to you to carefully read this manual and make the appropriate decisions

about system safety.

This manual will assist you in the proper set-up, operation and maintenance of the Nuvair Champion

LP Breathing Air Compressor System. Be sure to read this entire manual and the included Champion

manual and engine or electric motor manuals included.

Throughout this manual we will use certain words to call your attention to conditions, pr ac t ices or

techniques that may directly affect your safety. Pay particular attention to information int r oduc ed by

the following signal words:

Indicates an imminently hazardous situation, which if not avoided, will result in serious personal injury

or death.

Indicates a potentially hazardous situation, which if not avoided, could result in serious personal injury

or death.

Indicates a potentially hazardous situation, which if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices.

Notifies people of installation, operation or maintenance information which is important but not

hazard-related.

NUVAIR rev.010512

Champion LP Operation Manual

Page 4

Nuvair Champion LP

2.0 Safety Warnings

This equipment is used to provide breathing gas for the purpose of underwater life support. Read this

manual in its entirety. Failure to heed the warnings and cautions contained in this document may

result in severe injury or death.

The equipment you will be using to manufacture air will expose you to both low and high-pressure gas.

Gas, even under moderate pressures, can cause extreme bodily harm. Never allow any gas stream to

be directed at any part of your body.

Any pressurized hose can cause extreme harm if it comes loose or separates from its restraint (or

termination) while under pressure and strikes any part of your body. Use appropriate care in making

and handling all gas connections.

Never mix the Compressor Lubricant with other lubricants. If unsure of

compressor lubricant remove all existing lubricant and replace with the proper

breathing air compressor lubricant prior to use. The use of improper lubricants can

lead to un-safe air quality, which may cause serious personal injury or death.

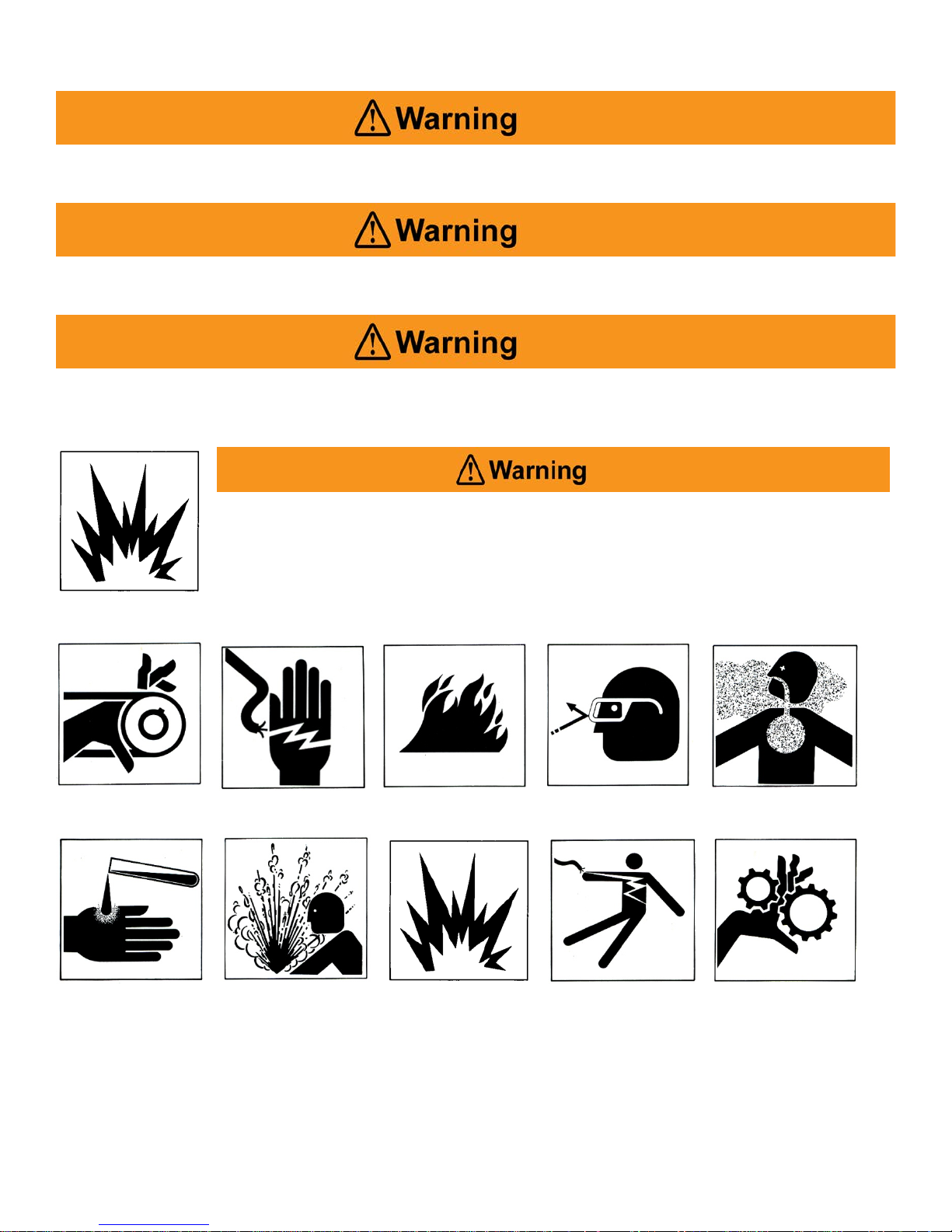

Warnings Graphics Defined:

Moving belts Electrocution Fire Eye protection Gas inhalation

Skin damage Explosion Explosion Electrocution Machinery

Abbreviations commonly used in this manual:

P.S.I. Pounds Per Square Inch C.F.M. Cubic Feet Per Minute

R.P.M. Rotations Per Minute L.P. Low Pressure

L/min Liters Per Minute CO Carbon Monoxide

CO2 Carbon Dioxide

NUVAIR rev.010512

Champion LP Operation Manual

Page 5

Nuvair Champion LP

3.0 Safety And Operation Precautions

Because a Compressor is a piece of machinery with moving and rotating parts, the same precautions

should be observed as with any piece of machi ner y of this type where carelessness in operations or

maintenance is hazardous to personnel. In addition to the many obvious safety precautions, those listed

below must also be observed:

1) Read all instructions completely before operating any compressor.

2) For installation, follow all local electrical and safety codes, as well as the National Electrical Code

(NEC) and the Occupational Safety and Hea lt h Administration (OSHA) standards.

3) Electric motors must be securely and adequately grounded. This can be accomplished by wiring with a

grounded, metal-clad raceway system to the compressor starter; by using a separate ground wire

connected to the bare metal of the motor f r ame; or other suitable means.

4) Protect all power cables from coming in contact with sharp obj ects. Do not kink power cables and

never allow the cables to come in contact with oil, grease, hot surfaces, or chemicals.

5) Make certain that power source conforms to t he requirements of your equipment.

6) Pull main electrical disconnect switch and disconnect any separate control lines, if used, before

attempting to work or perform maint enance. “Tag Out” or “Lock Out” all power sour ces .

7) Do not attempt to remove any parts without f irst relieving the entire system of pressure.

8) Do not attempt to service any part while Sys t em is in an operational mode.

9) Do not operate the System at pressures in ex c ess of it s rating.

10) Do not operate compressor at s peeds in excess of its rating.

11) Periodically check all safety devices for proper operation. Do not cha nge pressure setting or restrict

operation in any way.

12) Be sure no tools, rags or lo ose parts are left on the Compressor System.

13) Do not use flammable solv ents for cleaning the Air Inlet Filters or ele m ent s and other parts.

14) Exercise cleanliness during maintenance a nd when making repairs. Keep dirt away from parts by

covering parts and exposed openings with clean cloth or Kraft paper.

15) Do not operate the compressor without guards, shields, and screens in place.

16) Do not install a shut-off valv e in t he compressor discharge line, unless a pressure relief valve, of

proper design and size, is installed in the line between the compressor unit and shut-off valve.

17) Do not operate in areas where there is a possibility of inhaling carbon monox ide, c arbon dioxide,

nitrogen, or flammable or toxic fumes.

18) Be careful when touching the exterior of a recently run electric, gasoline, or diesel motor - it may be

hot enough to be painful or cause injury. With modern motors this condition is normal if o perated at

rated load - modern motors are built to operate at higher temperatures.

19) Inspect unit daily to observe and correct any unsafe operating conditio ns f ound.

20) Do not “play around” with compressed air, or direct air stream at body, this can cause injuries.

21) Compressed air from this machine absolutely must not be used for food process ing or breathing air

without the properly maintained downstream f ilters, purifiers, controls and periodi c air quality testing.

22) Always use an air pressure-r egulating device at the point of use, and do not us e air pressure greater

than marked maximum pressure.

23) Check hoses for weak or worn conditions before each use and make certain that all connections are

secure.

The user of any Compressor System manufactured by Nuvair is hereby wa r ned that failure to follow the

preceding Safety and Operation Precautions can result in injuries or equipment damage. However, Nuvair

does not state as fact or does not mean to imply that the preceding list of Safety and Operation

Precautions is all-inclusive, and further that the obs ervance of this list will prevent all injuries or equipment

damage.

NUVAIR rev.010512

Champion LP Operation Manual

Page 6

Nuvair Champion LP

4.0 Legal Precautions

It is highly recommended that a Dive log be maintained when using an Air Compressor on a job site

to document the following information. This log must be of permanent binding sty le with no loose

pages.

♦ Date and time of day

♦ Job Name & Number

♦ Supplier’s check of air quality plus signature and date

♦ MOD (Maximum Operating Depth) in user’s handwriting

Proper air analysis tested on a quarterly basis and comprehensive maintenance is the best way to assure

proper, safe, and economical air production.

While Nuvair manufactures LP compressors for commercial diving use, Nuvair does not determine

the regulations and or standards governing the use of “Air Compressor Systems”. Operators of Nuvair

compressors should consult your local and or national government and or managing bodies t o

determine the regulation obligations necessary to operate a Nuvair Compresso r for divers and

breathing air use.

In the U.S. and Canada regulators include, but are not limited to:

OSHA

US Coast Guard

US Military- Army, Navy, Marines, Air Force

CSA International

ANSI

ACDE

ADCI

USACE

ACDE

AAUS

NFPA

Some of the regulations in print pertain to the actual compressor equipment and others pert ain t o the

Contractors and Dive Team.

You should be clear of any regulations, standards and requirements that are present for your use of a

Nuvair Compressor before operating the compressor.

Nuvair can manufacture your Compressor package to meet any regulatory standards. Please provi de

us with the standards you operate under and we can provide you with the proper equipment to meet

those standards or regulations.

NUVAIR rev.010512

Champion LP Operation Manual

Page 7

5.0 System Overview

The Nuvair Champion LP Breathing Air Compressor system is designed to be open with good access to

components, yet good moving part protection while it is running. This package is for use to supply low

pressure surface supplied air direct t o divers.

The operator should be able to produce Air with a m inimum of start-up hassles.

Champion R15:

• Air Supply and Regulated Air Input Gauges

• 1 Air Intake Filters

• Hankison Serie s 20 LP Filtration to .003 PPM Oil Vapor for divers

• NUVAIR 455 FDA Ap proved Food Grade Compressor Lubricant in R15 block

• Open design 60 g allon tank mount standard

• Option: Heavy Duty Marine Grade Aluminum Frame with wheels, handles, lifting eye, and fork lift slots

• Vibration Isolati on Mounts

• 1 x Low-pressure T wo Stage Compressor

• Option: 1 x 1 Gallon ASME LP Surge Tank wit h ½” delivery ball valve

Yanmar or Kohler 10 HP diesel engine with electric start.

or

• WEG or Baldor Electric Motor 5hp

Air Compressor Technical Data:

• LP Compressor 5 or 10 HP 20.7cfm@175psi

Maximum Block Output Pressure: 200 PSI (13.75 BAR)

Final System Discharge Pressure: 200 PSI (13.75 BAR)

Dual Control Head Unloaders

Number of Stages: 2

Number of Cylinders: 2

Package Free Air Delivered Max: 20.7 CFM (586 L/Min)

Lubricant: NUVAIR 455

Condensate Drain Manual

Suggested Maintenance Intervals:

Replace Nuvair 455 Lubricant: in R15 200 Hours or yearly

LP Filtration Elements 100 Hours or yearly

(Nuvair recommends checking filter elements for moisture and proper operation daily.)

Typical Specification For Grade-D Air:

• O2 Percentage: 20-22

• CO2: 1000 PPM

• CO: 10 PPM

• Hydrocarbons: 25 PPM

• Odor: None

NUVAIR rev.010512

Champion LP Operation Manual

Nuvair Champion LP

Page 8

Nuvair Champion LP

Champion R30:

• Air Supply and Regulated Air Input Gauges

• 1 Air Intake Filters

• Hankison Serie s 24 LP Filtration to .003 PPM Oil Vapor for divers

• NUVAIR 455 FDA Ap proved Food Grade Compressor Lubricant in R15 block

• Open design 120 gallon tank mount standard

• Option: Heavy Duty Marine Gra de Aluminum Frame with wheels, handles, lift ing eye, and fork lift slots

• Vibration Isolati on Mounts

• 1 x Low-pressure Two Stage Compressor

• Option: 1 x 1 Gallon ASME LP Surge Tank with ½” delivery ball valve

Kohler 25HP diesel or Kohler 23 HP Gas engine with electric start.

•

or

• WEG or Baldor Electric Motor 15hp or20hp

Air Compressor Technical Data:

• LP Compressor 39-59 cfm@175psi

Maximum Block Output Pressure: 200 PSI (13.75 BAR)

Final System Discharge Pressure: 200 PSI (13.75 BAR)

Dual Control Head Unloaders

Number of Stages: 2

Number of Cylinders: 2

Package Free Air Delivered Max: 39-59 CFM (1104-1670 L/Min)

Lubricant: NUVAIR 455

Condensate Drain Manual

Suggested Maintenance Intervals:

Replace Nuvair 455 Lubricant: in R30 200 Hours or yearly

LP Filtration Elements 100 Hours or yearly

(Nuvair recommends checking filter elements for moisture and proper operation daily.)

Typical Specification For Grade-D Air:

• O2 Percentage: 20-22

• CO2: 1000 PPM

• CO: 10 PPM

• Hydrocarbons: 25 PPM

• Odor: None

NUVAIR rev.010512

Champion LP Operation Manual

Page 9

Nuvair Champion LP

See Yanmar Manual

for Yanmar Operation

R15 Oil Drain

Champion R15

Intake Filter

Diesel Exhaust.

(Optional) HF20-7

(optional) HF20-1

With Auto Drain

(Optional) HF20-5

With Auto Drain

Electric

option

Engine Fuel

Fill Cap

Belt Guard

Operation

Compressor

Available Options Necessary for Using the Champion

Over Pressure

Oil Fill

Oil Sight

6.0 System Component Identification:

The Champion R15 system is a self-contained, portable, low pressure delivery package capable of

supplying Air for the divers use.

The system utilizes a Champion R15 low-pressure compressor that is mounted together with 10hp

Yanmar or Kohler Diesel Engine or 5hp WEG or Baldor electric Motor in a rigid, aluminum frame or

on a volume tank. The system components include: Marine Grade Frame, Compressor and motor.

All of the component assemblies and parts are mounted to facilitate easy set-up, operation, and

transport.

Champion R15 Diesel Compressor System Components

Gauge

Relief

Air Pressure

Start

High Temp Sensor for Compressor Block

CO Analyzer- Shutdown, lights, Alarm

Be sure to check with your local agency for standards

that require options to be in place before using the

Champion Compressors for working divers.

Keep exhaust away

from compressor air

intakes.

Increase height if

necessary

CO in Exhaust Can Kill

Do Not

Remove while in

Coalescing Filter

Oil & Particulates

Oil Vapor Removal

No Auto Drain

Visually Check for Moisture

Daily

Compressors for Diving

LP Diver Air Filtration

Volume Tank

Regulator

Low Pressure Switch

Low Oil Level Switch

Low Pressure Switch

NUVAIR rev.010512

Champion LP Operation Manual

Page 10

Nuvair Champion LP

Diver Air

Diver Manifold

position

Air Pressure

Gauge

On/Off Switch

WEG Electric

Motor

*Volume

Volume Tank

Below Tank Here

Pictured with

(Optional) Analyzer

Available

Champion R30

Intake Filters

*3 stage low

Unloader

Oil Fill

Oil Drain

Oil Sight

7.0 Champion R30e Compressor System Component Identification with Options

Gauge

Drain is Located

pressure

breathing air

filtration

Shut Off Valve

Available Options to consider:

*Volume Tank- With pressure gauge, pressure relief valve, on/off valve and drain

*LP Diver Filtration- 3 stage filtration or 4 stage filtrat ion

**High Temp Sensor- To warn if compressor is running hot

**CO Analyzer- Will monitor CO levels of air supply being delivered to the diver manifold

* These items are required to use the compressor package for “Diver Breathing Air”

**Required to be compliant with some Diving standards

(Optional)

120 Gallon

Low Pressure Tank

O2 or CO

Shown in off

NUVAIR rev.010512

Champion LP Operation Manual

Page 11

Nuvair Champion LP

If any information in this manual conflicts with any of the other manuals call Nuvair before proceeding.

8.0 Theory of Operation:

Before Starting the Nuvair Champion LP system:

9.0 Assembly Preparation:

1. First familiarize yourself with the components of the system in the first section of the manual.

2. Please read and follow instructions for compressor and motor provided in additional manuals.

3. Unpack the System and remove from the pallet.

4. Visually inspect the system to make sure there has been no damage* during shipping.

5. Follow the remaining step by step instructions for initial set up and operation.

*If damaged, please call Nuvair to file a damage report. Please take photos and supply detailed

information about the damage.

10.0 Set-up and Assembly

10.1 Power Connection:

This package comes with a 12 volt battery for the Diesel electric start to function properly.

Red Is Positive! Connecting the wrong leads may damage circuitry.

Electric Option:

A WEG 5hp electric motor is supplied with the current and voltage specified at t im e of purchase.

The system must be properly wired according to national and local electrical

codes by a qualified electrician. Improper wiring may lead to fires, which can

cause serious personal injury or death.

10.2 Proper Rotation:

When the Weg electric motor is used to drive the system it is important that the power supply is

properly connected to prevent improper motor rotation. Running the compressor in t he wr ong

direction will damage the compressor and void warranty.

A. Yanmar or Kohler Engine Operation:

See engine Manual

B. WEG or Baldor Motor Operation:

See WEG Motor Manual and Electrical Schematic on page 30 of this manual.

NUVAIR rev.010512

Champion LP Operation Manual

Page 12

Nuvair Champion LP

11.0 Operation

Once you have read through this manual, the compressor manuals, the diesel manual, t he CO

analyzer manual, made the necessary set-up connections, and you understand how the system

functions; follow the steps below to operate the system:

1. Always check fluid levels before starting compressor and engine.

2. Open Diver tank on/off valve and Volume Tank valves for Air

3. Start diesel as per instructions or electric motor

4. Turn off diver Air Valves

5. Warm for a few minutes (Diesel engine)

6. Adjust throttle to run position (Diesel engine)

OSHA Regulations require an emergency backup source of breathing gas for the diver in case of an

emergency or compressor malfunction.

11.1 Shutdown:

Before shutting down any compressor, make sure all divers are no longer using the compressor t his

includes in water divers and decompressing divers.

Electric & Diesel: The Engine can be shut off by turning the power key off.

Diesel Engine Power Switch and Tach Electric Motor Power Switch and Tach.

NUVAIR rev.010512

Champion LP Operation Manual

Page 13

Nuvair Champion LP

12.0 Operation Notes:

• During the running of a Nuvair Champion LP Com pr es sor you should hear air escaping from

fittings, belt slap from a loose belt, knocking noise or any other audible concerns switc h t he

diver to back up source and stop operation of the compressor to prevent damage to the

compressor or faulty operation.

• The Nuvair Champion LP compressor s utilize 3 stage breathing air filtration to achieve Grade

“D” Air, Do NOT use any substitute filters.

• Bleed condensate drain on t he volum e tanks daily or every 8 hours of operation.

• Use only NUVAIR 455 compressor lubricant in the Champion piston compressor.

Do NOT substitute or Mix Lubricants.

13.0 Maintenance

Use only the specified Nuvair Lubricants in this system. The use of incompatible lubricants presents a

risk of fire and/or explosion, and may result in system damage. This can lead to severe personal injury

and death.

Be sure that all pressure has been relieved from the system prior to opening any filtration canister.

Failure to vent pressure from the system prior to opening the canister can lead to serious personal

injury or death.

If system is located in an area where there is high humidity and high heat, the life of all Filtration

Elements may be as little as 35% of rated operating capacity. Check the compressor manual and

Appendix for details on Filter Element Life Factors.

13.1 Routine Maintenance

1) Champion Compressor Lubricant: Change compressor lubricant after the first 50 hour break in

period and every 200 hours thereafter on the Champion. Only use lubricants rat ed f or use with

breathing Air systems such as NUVAIR455 TM. Never mix Compressor Lubricants. See LP

Compressor manual for details.

(Optional Diver 3 stage Filtration Package)

2) LP Filtration Inspection: On a daily basis, inspect each Filter Bowl for the presence of moisture

and each Element for any unusual degradation or wetness.

(Optional Diver 3 stage Filtration Package)

3) LP Filtration Elements: Change LP Filter Elements every 100 hours to maintain CGA Grade D air

standards. Visual differential pressure (DP) indicators on the HF7 and HF5 filters as sist with

monitoring replacement intervals. See Section 14.3 for details. If the Compressor System is

operated in high humidity and/or high temperature, Filter Elements must be changed more oft en.

4) (Optional) Low Volume tanks should be drained daily of Moisture.

5) 1 Gallon Surge tank should be drained regularly and at end of daily operation.

NUVAIR rev.010512

Champion LP Operation Manual

Page 14

Nuvair Champion LP

Compressor Oil

See manual

Refer to Supplied Engine manual for

proper oil and maintenance.

Oil Drain

Oil Fill

Pilot

Valve

Oil Sight

13.2 Compressor Lubricant:

Change Champion Compressor with NUVAIR 455 rated lubricant ever y 200 hour s or minimum

once per year. Do not mix brands.

1) Check oil and diesel levels before operation.

2) Drain (optional) Volume tanks daily. Check filters for moisture daily.

Dip Stick

Gauge

behind box

here

Use only the specified Nuvair Lubricants in this system. The use of

incompatible lubricants presents a risk of fire and/or explosion, and may result

in system damage. This can lead to severe personal injury and death.

Wear eye protection, gloves, and skin protection when performing oil changes.

Although the oil is not classified as a dangerous substance, the oil can be

irritating to your eyes and skin.

Both oil and oil filter are classified as “special wastes” and must be disposed of

properly according to applicable national and local laws. Failure to dispose of

these wastes properly can lead to death of wildlife as well as government

NUVAIR rev.010512

Champion LP Operation Manual

Page 15

Nuvair Champion LP

HF7-20

Removal

HF5-20

Air Flow

HF7 & HF5 Filters

Indicators.

Housing

Element

Bowl

HF1 Filter with

Contain Moisture

Do not carry out any maintenance tasks if the compressor has just shut down.

Wait for the compressor to cool to avoid skin burns.

Special attention needs to be given to the arrangement of the four LP Air Filtration Elements and

Bowls. Properly reinstall each Element and Bowl to the correct Housing. Improper sequence can

cause damage to downstream components

14.0 LP Filtration (Optional Diver 3 stage Filtration Package)

Three stages of Hankison LP filtration are used to produce Grade D air:

1) Particle Removal to 1 micron

2) Coalescing & Water/Oil Vapor Removal to 0.01 micron

3) Oil Vapor Removal to 0.003 PPM

14.1 Filtration Inspection

Open each Filter and inspect as follows:

1. Inspect Bowl for the presence of moisture. A high level of moisture build-up in the HF7 or HF5

Filter indicates improper operation of auto-drain floats. Any evidence of m oisture in t he HF1 Filter

indicates the air is not cooling properly and moisture is not properly being removed. Excess

moisture will prevent the final filter from operating properly.

2. Inspect Elements for any unusual degradation or wetness. Element degradation can indicate more

serious problems. Contact Nuvair for assistance.

with Auto-Drain

Floats & DP

Manual Drain –

Should not

Particle

Coalescing & Water/

Oil Vapor Removal

Be sure that all pressure has been relieved from the system prior to opening any

filtration canister. Failure to vent pressure from the system prior to opening the

canister can lead to serious personal injury or death.

NUVAIR rev.010512

Champion LP Operation Manual

Page 16

Nuvair Champion LP

DP Indicator

When Red.

14.2 Changing Filtration Elements (optional Breathing Air El em ents)

Change the LP Filter Elements every 100 hours or once per year*. If the Compressor System is

operated in high humidity and/or high temperature, Filter Elements must be changed more oft en.

Visual DP indicators on the HF7 and HF5 filters assist with monitoring replacement intervals.

1) Push up on the Bowl, rotate CCW, and lower to remove.

2) Gently rotate Filter Element and pull down off mounting post.

3) Replace Element and reassemble in reverse order.

Changes from

Green to Red.

Yellow indicates

filter needs to be

replaced.

Do Not Use

The interior of the Filter Bowls can be cleaned with a diluted solution of Simple GreenTM and flushed

thoroughly with clean water. This will assist to prolong the life of the element, bowl, and auto drain.

14.3 Changing Air Intake Filtration

Inspect and or change the air intake Filter Elements every 40 hours or once per year. If the

Compressor System is operated in high humidity or a dusty dirty environment, Filter Elements must

be changed more often. Inspect elements periodically to determine if the elements should be

changed sooner than recommended.

14.4 Air Intake Extension

The air intake filter housings are mounted on couplings. In the event that the compressor will be used

in a windy environment that may cause the diesel engine exhaust to be blown into the intake filters it

may be necessary to extend the elements vertically to prevent engine exhaust from entering t he

elements. Reinforced hose tubing can be purchased from Nuvair to extend the height of the

elements. By using a Nuvair PRO CO monitor you will notice changes in CO immediately and the

use of a CO monitor is highly recommended by Nuvair.

NUVAIR rev.010512

Champion LP Operation Manual

Page 17

Nuvair Champion LP

System Components

Type

Part Number

Compressor Lubricant, Food Grade

Nuvair 455, 1 Gal

(Other Sizes Available)

9406

LP Filtration Element – R15

Hankison HF 7-20 (blue housing)

E7-20

Hankison HF 5-20

E5-20

Hankison HF 1-20

E1-20

Norgren F74G (black housing)

4338-04

Norgren F74V

4341-01

Nirgren F74H

4344-02

Air Intake Filter Element

Champion

14

Related Equipment Components

Air Quality Analysis Kit

Specify: (1) CGA Grade Required

(2) Single Use or Program Use

Carbon Monoxide “CO” is a colorless, odorless, tasteless gas that will not support life.

Breathing gas mixtures containing CO will lead to unconsciousness and may cause death.

15.0 Spare Part s Li st

See Compressor manual for LP Compressor parts list. Other System components and relat ed it ems

are listed below.

NUVAIR rev.010512

Champion LP Operation Manual

Page 18

Date

Technician Name

Service Performed

16.0 Service Record Log

Nuvair Champion LP

NUVAIR rev.010512

Champion LP Operation Manual

Page 19

Nuvair™ 455 Premium Synthetic Food Grade Air Com pressor Lubricant

Effective Date: 03/19/2010

I. Product Identification:

Trade Name: …………………………………. Nuvair 455

Chemical Name: …………………………...... Polyalphaolefin

Chemical Family: ………………………...….. Synthetic hydrocarbons/Esters

II. Components & Hazard Statement:

This product is non-hazardous. This material is not considered hazardous by the OHSA Hazard Communicat i on

Standard (29 CFR 1910.1200).

III. Physical Data:

Viscosity: ...................................................... 100 cst. @40°C

Specific Gravity (Water = 1.0): ..................... 0.85

Boiling Point: ................................................ N.A.

Vapor Pressure: ........................................... Negligible

Appearance & Odor: .................................... Clear – with Mild odor

Solubility in Water: ....................................... Negligible

IV. Fire & Explosion Hazard Data:

Flash point: .................................................. 464°F / 24°0C/ COC

Auto ignition Temperature: ........................... Not Established

Flammability Limits: ..................................... Not Established

Extinguishing Media: ................................... Dry Chemical; CO2 Foam; Water Spray

Special Fire Fighting Procedure: ………….. Burning may produce irritating/noxious fumes. Firef i ghters should use

V. Reactivity Data:

Stability: ………………….…………………... This product is stable and will not react with water.

Materials to Avoid: ...................................... Avoid strong oxidizers

Hazardous Decomposition Products: …... ... Carbon monoxide, Carbon dioxide

VI. Health Information:

Eye Contact: ............................................... Flush eyes with water for 15 minutes. Call physician if irritation develops.

Skin Contact: ............................................... Wash skin with soap and water.

Inhalation: .................................................... Remove to fresh air.

Ingestion: ..................................................... First aid not normally required. If uncomfortable, call physician.

VII. Health Hazard Data:

Exposure Limit: ............................................ Not Applicable

Effects of Overexposure: ……………………. Low oral and dermal toxicity. Prolonged or repeated exposure may

VIII. Employee Protection:

For general personal hygiene, wash hands t horoughly after handling material. Avoid contact with skin and eyes.

Chemical impervious gloves are not required, but may be recommended for prolonged exposure. Use in a well

ventilated area.

IX. Storage, Spill, & Disposal Procedures:

Storage: ………………………………………. Store in clean, dry area.

Spills: …………………………………………. Use absorbent materials to soak up fluid.

Disposal: ……………………………………… Incinerate this product and all associated wastes in a licensed facility in

X. Hazard Rating Information:

NFPA Health: ………………………….. 0

Flammability: ……..................... 1

Reactivity: ……………….….….. 0

Personal Protection: ………….. B

This information contained herein is based on the data available to us and is believed to be true and accurate. Nuvair

makes no warranty, expressed or implied, rega rding the accuracy of this data or the results to be obtained from the use

thereof. Nuvair assumes no responsibility f or i nj ury from the use of this product.

NUVAIR rev.010512

Champion LP Operation Manual

Nuvair Champion LP

Material Safety Data Sheets

NIOSH/MNSA approved self-contained breathing apparatus. Use water

to cool fire-exposed containers to prevent pres sure build-up.

cause irritation, nausea, and vomiting.

accordance with Federal, state, and loc al regulations.

Page 20

Nuvair Champion LP

NUVAIR SYSTEM WARRANTY

NUVAIR extends a limited warranty, which warrants the System to be free from defects in materials and

workmanship under normal use and service for a limited period. All other Original Equipment Manufacturer

(OEM) components used in the system are warranted only to the extent of the OEM’s warranty to NUVAIR.

NUVAIR makes no warranty with respect to these OEM components, and only warrants the workmanship that

NUVAIR has employed in the installation or use of any OEM component. This warranty is not transferable.

NUVAIR will, at it’s discretion and according to the terms as set forth within, replace or repair any materials

which fail under normal use and service and do not exhibit any signs of improper maintenance, misuse,

accident, alteration, weather damage, tampering, or use for any other than the intended purpose.

Determination of failure is the responsibility of NUVAIR, which will work together with the customer to

adequately address warranty issues. When any materials are repaired or replaced during the warranty period,

they are warranted only for the remainder of the original warranty period. This warranty shall be void and

NUVAIR shall have no responsibility to repair or replace damaged materials resulting directly or indirectly from

the use of repair or replacement parts not approved by NUVAIR.

A warranty registration card, supplied with system documentation, must be filled out and submitted to NUVAIR

for the warranty to be in full effect. If the warranty registration card is not received within thirty (30) days of

installation, the thirty-six (36) month warranty will begin with the date of shipment from NUVAIR.

Maintenance Items:

Any materials which are consumed, or otherwise rendered not warrantable due to processes applied to them,

are considered expendable and are not covered under the terms of this policy. This includes maintenance and

consumable items listed as part of a suggested maintenance program included with system documentation.

Return Policy:

Application for warranty service can be made by contacting NUVAIR during regular business hours and

requesting a Return Material Authorization number. Materials that are found to be defective must be shipped,

freight pre-paid, to the NUVAIR office in Oxnard, California. Upon inspection and determination of failure,

NUVAIR shall exercise its options under the terms of this policy. Warranty serviced materials will be returned

to the customer via NUVAIR’s preferred shipping method, at NUVAIR’s expense. Any expedited return

shipping arrangements to be made at customer’s expense must be specified in advance.

Limitation of Warranty and Liability:

Repair, replacement or refund in the manner and within the time provided shall constitute NUVAIR’S sole

liability and the Purchaser’s exclusive remedy resulting from any nonconformity or defect. NUVAIR shall not in

any event be liable for any damages, whether based on contract, warranty, negligence, strict liability or

otherwise, including without limitation any consequential, incidental or special damages, arising with respect to

the equipment or its failure to operate, even if NUVAIR has been advised of the possibility thereof. NUVAIR

makes no other warranty or representation of any kind, except that of title, and all other warranties, express or

implied, including warranties of merchantability and fitness for a particular purpose, are hereby expressly

disclaimed. No salesman or other representative of NUVAIR has authority to make any warranties.

NUVAIR rev.010512

Champion LP Operation Manual

Page 21

Digital

Power Button

Calibrate Button

Relay

Program Button

Pro CO

Pro Co and High Temp Alarm

Alarm Light

Audible Alarm

Options for Champion Compressors from Nuvair:

• Pro CO Monitor- Audible, visual and shutdown capable

• Pro CO High Temp Combo

• 30 Gallon or Larger receiver tank

• Breathing Air Filtration – 3 Stage or 4 stage

• Low Oil Level Switch

• Low Oil Pressure Switch

• Low Tank Pressure Switch

• 4 Point Lifting Eyes

• Enclosed Frame

Display

Nuvair Champion LP

Together in Package

Output

NUVAIR rev.10512

Champion LP Operation Manual

Nuvair Champion LP

NUVAIR rev.10512

Champion LP Operation Manual

Nuvair Champion LP

Nuvair™ 2012 All Rights Reserved

Phone 1-805-815-4044

Fax 1-805-815-4196

2949 West 5th Street

Oxnard, CA 93030 USA

Email : info@nuvair.com

Web : www.nuvair.com

rev.10512

NUVAIR rev.10512

Champion LP Operation Manual

Loading...

Loading...