Page 1

MODELS VX475CC, VX550CC AND VX1040CC

INSTALLATION TIPS & USER GUIDE

BROAN-NUTONE CANADA INC.; MISSISSAUGA, ONTARIO WWW.NUTONE.CA 1-888-882-7626

30042320 rev. K

CENTRAL VACUUM POWER UNIT

REGISTER YOUR PRODUCT ONLINE AT: WWW.NUTONE.CA

FOR RESIDENTIAL USE ONLY

!

!

VISIT WWW.NUTONE.CA FOR THE CENTRAL VACUUM SYSTEM INSTALLATION INSTRUCTIONS

AB0002

Page 2

page 2

IMPORTANT

SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE

USING THIS APPLIANCE

WHEN USING AN ELECTRICAL APPLIANCE, BASIC PRECAUTIONS

SHOULD ALWAYS BE FOLLOWED

, INCLUDING THE FOLLOWING:

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY:

1. Do not use on wet surfaces or outdoors.

2. Do not vacuum liquids or fine powders (such as drywall dust).

3. Do not use to pick up flammable or combustible liquids

such as gasoline or use in areas where they may be present.

4. Do not pick up anything that is burning or smoking, such as

cigarettes, matches, or hot ashes.

5. Do not allow to be used as a toy. Close attention is

necessary when used by or near children.

6. Use only as described in this manual. Use only

manufacturer's recommended attachments.

7. Keep hair, loose clothing, fingers and all parts of body

away from openings and moving parts.

8. Turn off all controls before unplugging.

9. Use extra care when cleaning on stairs.

10. Do not handle plug or appliance with wet hands.

11. Do not use with damaged cord or plug. If appliance is not

working as it should, if it has been dropped, damaged, left

outdoors, or dropped into water, return it to a Service Center.

12. Keep your work area well lighted.

13. Connect to a properly grounded outlet only. See grounding

instructions shown on page 7.

14. When performing installation, servicing or cleaning the

unit, it is recommended to wear safety glasses and gloves.

CAUTION

1. Do not put any object into openings. Do not use with any

opening blocked; keep free of dust, lint, hair and anything

that may reduce air flow.

2. Ensure air flows freely to both side intake vents and

exhausts unobstructed from top outlet.

3. Do not use without filter in place.

4. Do not use to blow leaves or debris.

5. Do not put any object on the unit.

6. Do not install the unit horizontally.

7. Do not use the pail as a wash bucket.

8. Do not use the pail as a stool.

9. Avoid picking up sharp objects.

10. Do not unplug the unit by pulling on cord. To unplug, grasp

the plug, not the cord.

11. Store your cleaner indoors in a clean, dry area.

12. Any servicing other than that recommended in this manu-

al should be performed by an authorized service facility.

13. We recommend that your unit be inspected by a

specialized technician once a year.

OPERATION

The power unit is located away from the everyday living areas

of your home – usually in the garage, basement, or utility

room. Through a network of strong, lightweight tubing, the

power unit connects to inlets strategically placed throughout

your home. To clean, attach cleaning tools to the system's

hose and insert the hose into an inlet. The system is turned on

by a power switch on the hose. As you vacuum, dirt and dust

is transported to the power unit where it remains in a debris

pail until emptied.

This electrical appliance has been evaluated by the appropriate

listing agencies and is intended for household use only.

The system status indicator light(s) on the front of the power

unit indicate that the power unit is ready for use. Under normal

operation, the light(s) will be green. (A red light on NuTone

models VX550CC or VX1040CC indicates a need to empty

pail. See page 12 for instructions.)

When you are ready to clean, attach the wand and cleaning

tool onto the end of the hose. Open the inlet cover and insert

the end of the hose into the inlet.

For non-switched hoses, inserting the hose automatically

turns on the power unit; removing the hose shuts off the power

unit. Some hoses have switches which can be used to activate

power unit.

NOTE: The power unit will not turn automatically ON when

the hose is inserted into its own inlet. To turn the

power unit inlet ON, use the rocker switch located on

the side of the power unit.

Use the cleaning tools as you would for any other vacuum

cleaner. Avoid picking up pine needles, coffee sticks, and other

similar objects. These kinds of objects may become lodged in

the hose or tubing.

CAUTION

DO NOT REMOVE either of the TOP red cap plugs

that are glued to the unit. Removing these glued

plugs will damage the unit. Only remove and use

the outlets covered by the green BOTTOM plugs.

!

Page 3

page 3

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Tool Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Working with Plastic Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

WALL INLET INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

POWER UNIT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Fitting Main Line to Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INTERNAL WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

VX475CC, VX550CC & VX1040CC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

GROUNDING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

FOR MODELS: DLXKIT800, STDKIT400, STDKIT800 AND WHKIT700 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing Hose Hanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operating Hande Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

FOR MODEL: DLXKIT800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

How to Assemble Power Brush/Wand/Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wand and Hose Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

How to Use Power Brush/Wand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cleaning & Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintaining the Power Brush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Power Brush Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

FOR ALL MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

Vacuum Power Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

When to Empty the Debris Pail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Emptying the Debris Pail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SERVICE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

TABLE OF CONTENTS

CENTRAL VACUUM SYSTEM INSTALLATION INSTRUCTIONS

Please visit www.nutone.ca for the Central Vacuum System Installation Instructions; including System Planning and Layout,

General Installation, Installation in New Construction, Installation in Existing Construction, Tubing System Assembly, Final System Check.

Also including the practical and easy-to-use Vacusweep® Inlet Valve detailed installation instructions.

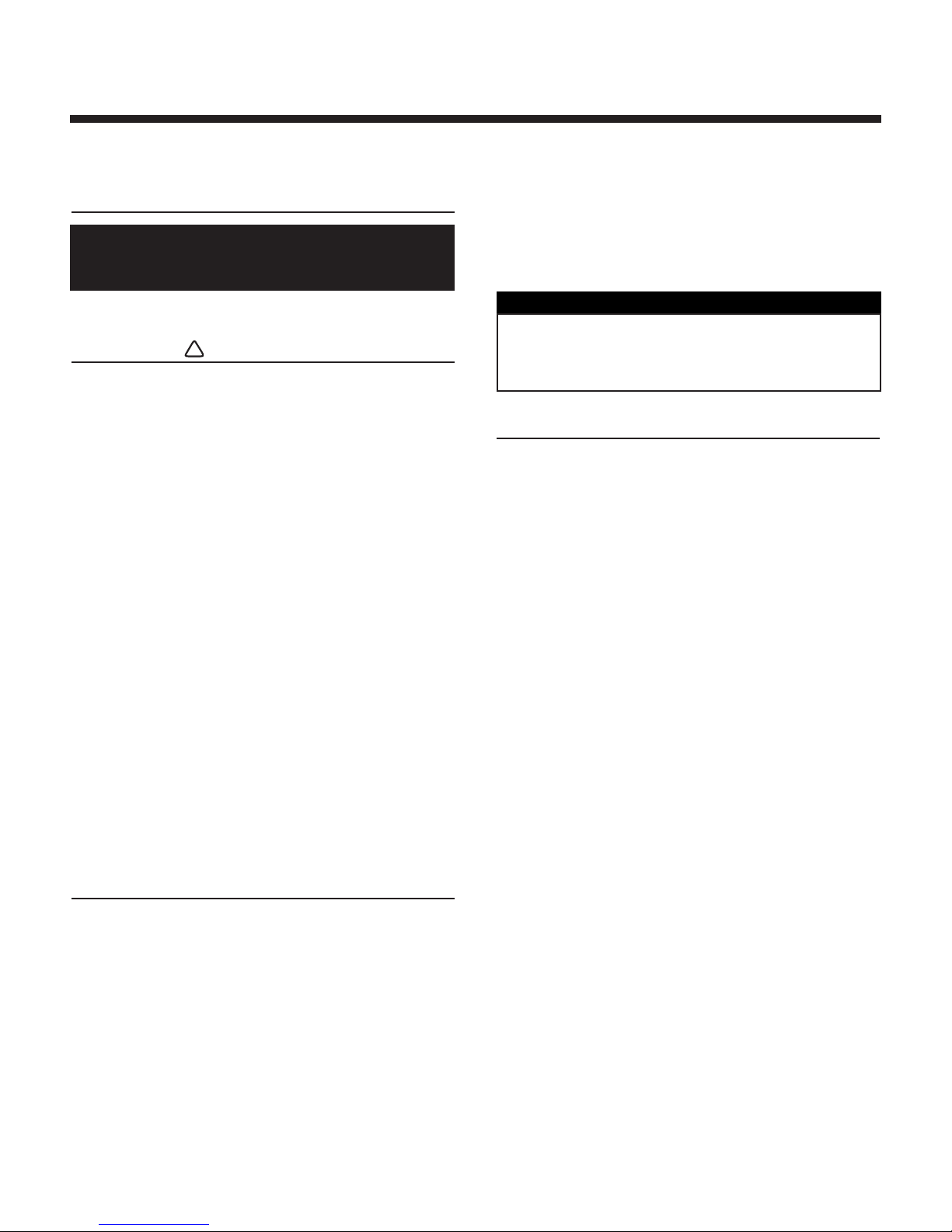

Practical

• Use in kitchens, mudrooms, workshops and any residential or

commercial sweepable areas

• Makes it easy for debris and dirt to be quickly swept and removed

from non-carpet surfaces

• Available in black, white and ivory

Easy-to-Use

• Fast and simple installation

• Rear access for piping permits connections from any direction

• Fits in the kick space of a cabinet or within a wall

• Toe operated: to activate, open the door by rasing the lever with

your toe; to turn off, close the door by pressing your toe on the

ribbed surface

AA0018

Page 4

page 4

TOOL LISTING

Depending on the installation, the use of the following tools

may be required. The power tools are recommended to make

the installation proceed quickly. A mask should be worn when

cutting ducting and gloves when using glue.

Wire strippers, 1/4’’ and 1/2” drill bits, utility knife, putty knife,

2½’’ hole saw, keyhole saw, hammer, cold chisel, level,

flashlight, drill, electrical tape, screwdriver, wrench, hacksaw,

tape measure, safety glasses.

WORKING WITH PLASTIC TUBING

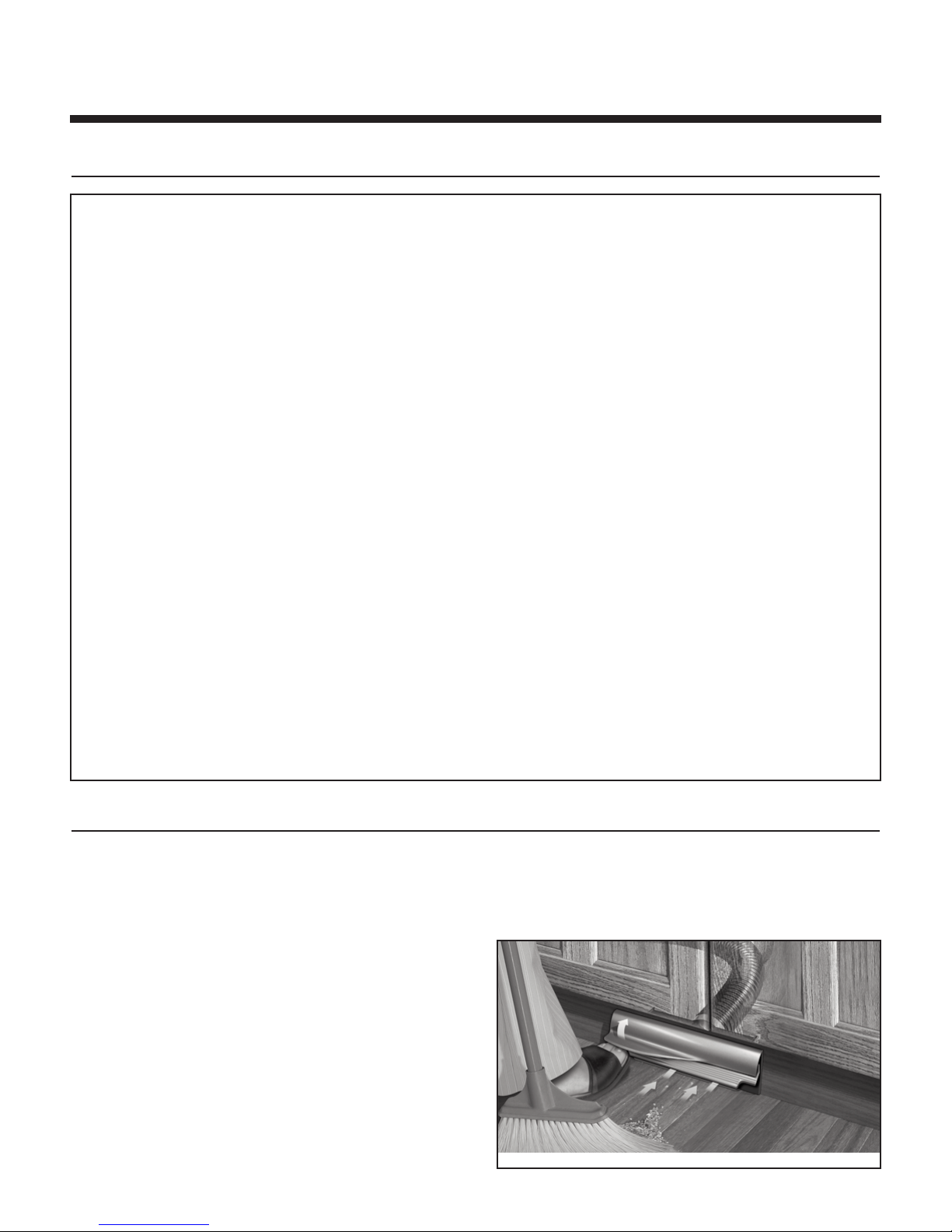

CUTTING TUBING

Measure the length of tube needed. Allow 5/8” of tubing for

inserting into fittings and 1½” for placing into flexible tubing.

Cut the plastic tubing with a hacksaw, ensuring that the cut is

exactly square. Use wire cutters or tin snips to cut flexible

tubing, 8” lengths of flexible tubing should not be cut.

Use a small knife or steel wool to remove any burrs from the

inside of the tube.

Use a file to slightly bevel the outside of the tube so that it will

easily slide into the fitting. Use steel wool or a light grained

sandpaper to buff the surface of the tube which will be glued.

MAKING A JOINT

Insert the tube into the fitting,

aligning both parts as they will be

installed. Mark the tube and the

fitting to quickly realign the joint.

Apply cement in an inch-wide

band to the outside of the tube.

Insert the tube into the fitting with

the alignment marks a quarter

turn apart, and then quickly push

and turn the fitting to align the

marks and spread the cement.

Allow 1 minute for the joint to dry.

CEMENTING FLEXIBLE TUBING

Ensure the ends of the flexible tubing are even. When joining

flexible tubing to plastic tubing or to an inlet mounting plate,

apply cement to both the inside of the flexible tubing and the

outside of the plastic tubing or mounting plate tubing ring.

Twist both pieces while joining them to evenly spread the glue.

Allow 5 minutes for the cement to set in flexible tubing.

SECURE WIRE

TO TUBING

The low-voltage power wiring is

run along with the tubing. Use

electrical tape to secure the wire

to the tubing. Tape the wire

approximately every 12" to 18".

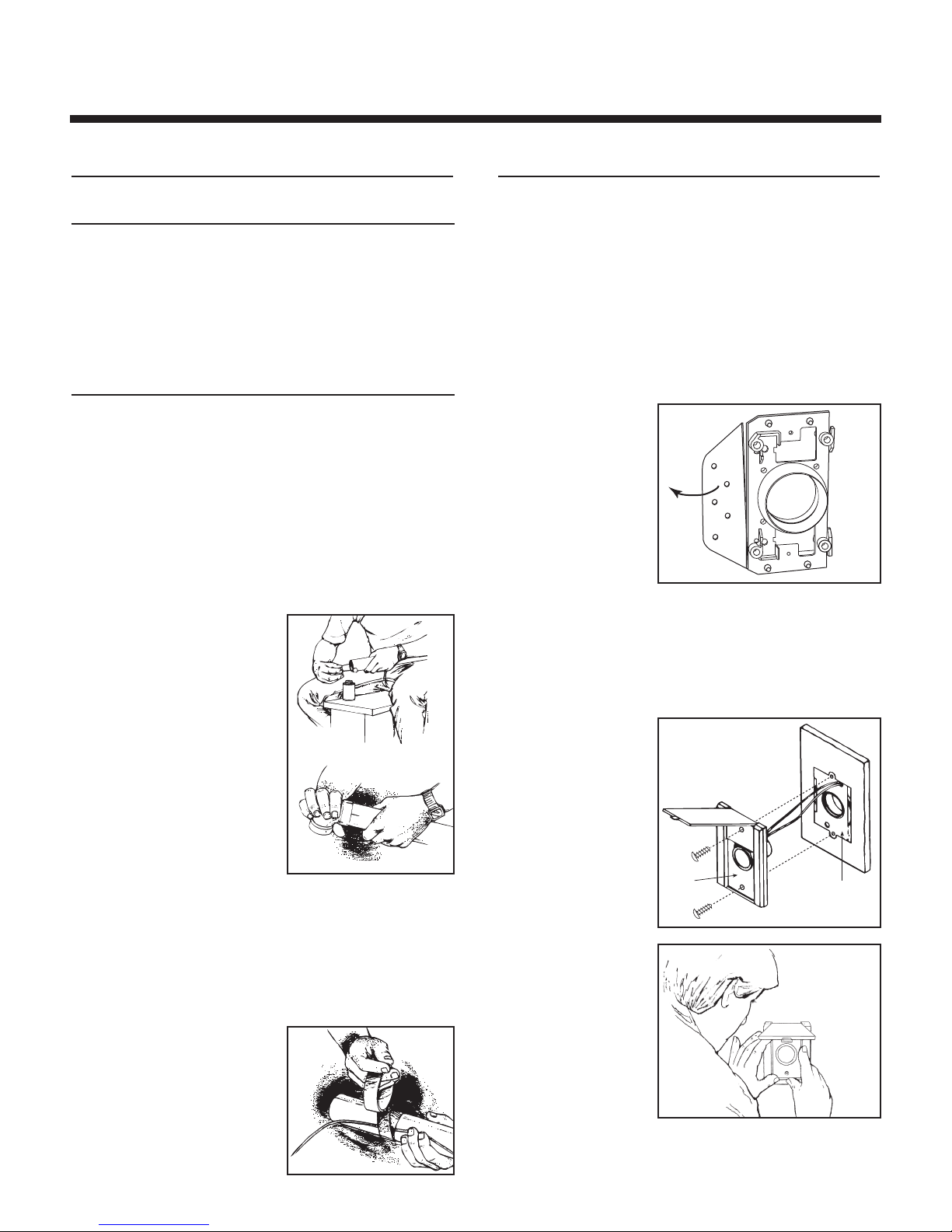

MAKING THE WALL INLET CUTOUT

The wall inlet should be located 18” on-center from the floor

and directly in line with the attic or basement inlet tubing hole

previously drilled in the wall plate or header. The wall inlet

cutout must be exactly 3⅞” high by 2⅞” wide.

ATTACHING THE INLET MOUNTING PLATE

Reach through the inlet hole and locate the inlet tubing. Pull

the flexible tubing through the inlet hole and remove the

low-voltage wiring from inside the tube.

Remove the nail flange

from the inlet mounting

plate (Fig. 1). Apply cement

to both the inside of the

flexible tubing and to the

outside of the mounting

plate’s tube ring. Insert

the mounting plate’s

tube ring in the flexible

tubing and twisting the

pieces as you join them to spread the cement, and align the

mounting plate in a vertical position.

Now, strip the ends of the two low-voltage wires, and then

connect the wires to the screw terminals on the back of the

inlet cover. When the wiring is complete, assemble the inlet

cover to the tube guard and mounting plate.

COMPLETING

THE INLET

ASSEMBLY

Once you have attached

the mounting plate to the

flexible tubing, pull the

low-voltage wire through

the top wiring hole in the

mounting plate.

INSTALLING

THE INLET

Place the inlet into the

wall cutout (the inlet

cover remains on the

outside). Hold the inlet in

place and gradually

tighten down each screw

a little bit at a time.

For more details on inlet installation, visit www.nutone.ca

for the Central Vacuum System Installation Instructions.

GENERAL INFORMATION WALL INLET INSTALLATION

AO0045

FIG. 1

AO0010

AO0011

AR0040

INLET

AE0024A

MOUNTING

PLATE

Page 5

page 5

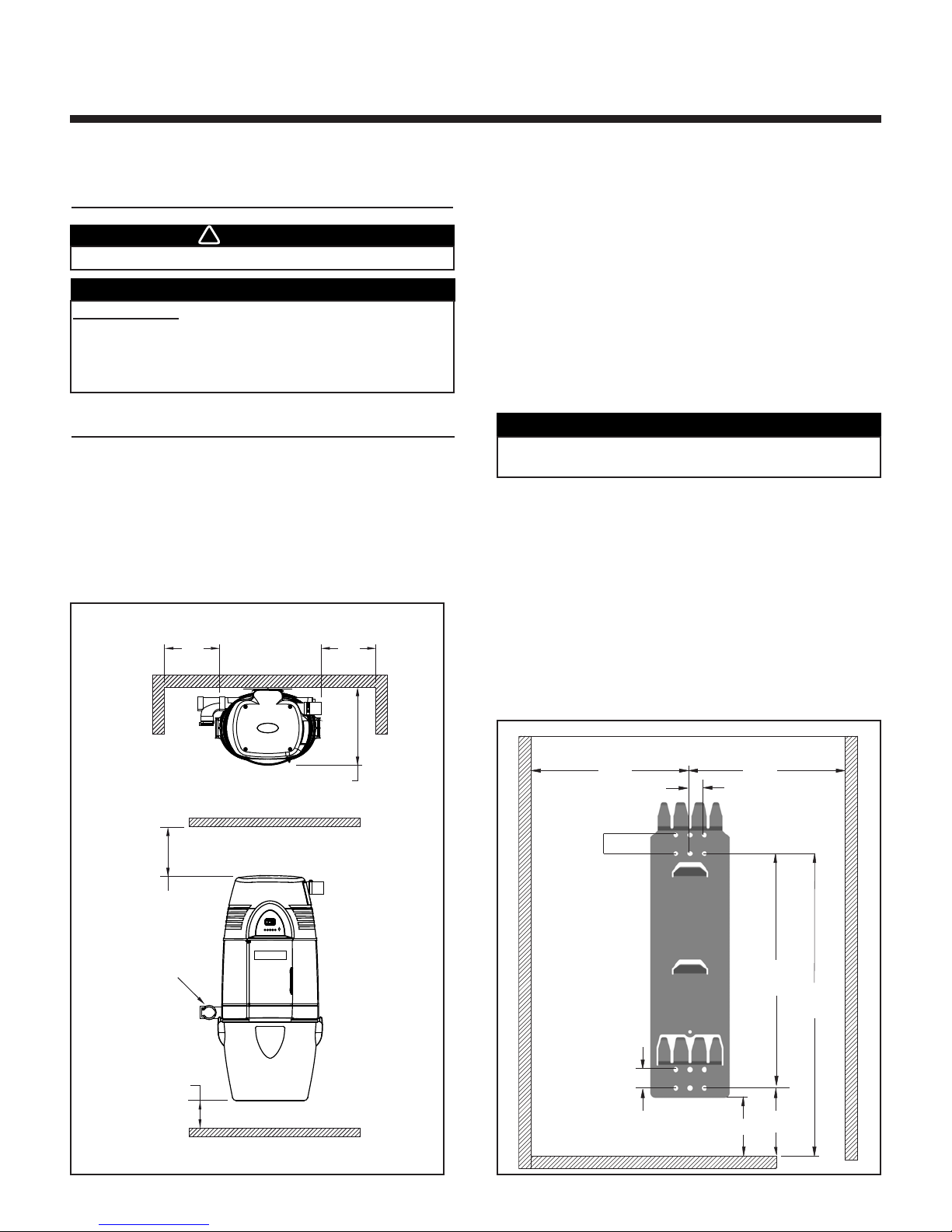

MOUNTING

Your power unit mounts to the wall using a mounting system.

The wall mounting bracket, provided with your power unit,

mounts to the wall. It has 4 fingers at the top and 4 more at the

bottom. The power unit has 4 upper openings and 4 lower

openings which are designed to slide onto the wall mounting

bracket fingers. Ensure to follow the instructions below for

proper installation.

1. Locate power unit within six feet (1.82 m) of a grounded

electrical outlet. NuTone VX475CC and VX550CC power

units require a 120 V, dedicated 15-amp branch-circuit with

a NEMA 5-15R receptacle or a dedicated 20-amp branch

circuit with a NEMA 5-20R receptacle. NuTone VX1040CC

power unit requires a 240 VAC, dedicated 20-amp branch

circuit with a NEMA 6-20R receptacle.

2. Refer to Fig. 2 to maintain minimum wall clearance

dimensions.

3. Position and install the wall mounting bracket with the

provided screws. Refer to Fig. 3 for proper mounting

dimensions.

4. Using the provided mounting screws, secure the mounting

bracket on the wall through two upper and two lower

mounting holes.

5. Hang power unit onto wall mounting bracket. Ensure both

upper and lower mounting openings on the back of the

power unit are engaged with corresponding wall bracket

fingers. Pull the power unit down to secure.

6. Open the door located on the front of the power unit.

Ensure the cyclonic filter is properly seated.

See page 13 for reference. Close the door.

12⅝”

3/4” TYP.

30¾”

1” TYP.

43

7

⁄16”

MIN.

HEIGHT

30¼”

30⅜” 30⅜”

MOUNTING

HOLES

MOUNTING

HOLES

AD0044A

CAUTION

Ensure to fix the wall mounting bracket with the

screws directly onto a stud for a solid installation.

CAUTION

For all models, DO NOT REMOVE either of the TOP

red cap plugs that are glued to the unit. Removing

these glued plugs will damage the unit. Only

remove and use the outlets covered by the green

BOTTOM plugs.

WARNING

Do not install outdoors.

!

WALL MINIMUM CLEARANCE DIMENSIONS

F

IG. 2

F

IG. 3

POWER UNIT

INSTALLATION

24”

TOP VIEW

24”

NuTone VX475CC: 11”

NuTone VX550CC and VX1040CC: 13¾”

18” MINIMUM

ABOVE FLOOR

AD0003A

24”

MINIMUM TO CEILING

UTILITY

VALV E

FRONT VIEW

Page 6

page 6

FITTING MAIN LINE TO POWER UNIT

Your power unit is capable of being connected to the intake

vacuum trunk line from either side. Select the intake

connection to be used. Some installations may require the

connection into both intakes. The power unit has 4 intake

connections, which 2 of them are factory capped.

1. Using rubber coupling and hose clamp provided, attach the

utility valve assembly to the vacuum trunk line feeding into

the power unit. The utility valve can be installed on the left

or right hand side.

2. Cap off the unused intake tube with the plastic cap provided.

3. Attach exhaust tube to power unit using rubber coupling

and hose clamp provided (if vented to the outside).

4. Make sure all tubing connections are air tight.

5. The exhaust should NOT be vented into a wall, ceiling or

concealed space in the house. It is recommended to vent

the vacuum exhaust air to the outside of the house.

Exterior vented exhaust lines should be terminated using

Model V142 wall caps.

DIMENSIONAL CHART

Models VX475CC VX550CC VX1040CC

A 369⁄16” 399⁄16” 399⁄16”

B 11” 11” 11”

C 107⁄8” 107⁄8” 107⁄8”

CAUTION

NuTone VX475CC, VX550CC and VX1040CC power

units will attach to the lower intake connections.

See Fig. 10. Utility valve can be installed on either

side.

INTERNAL

WIRING DIAGRAMS

• VX475CC • VX550CC

• VX1040CC

POWER UNIT

INSTALLATION (CONT’D)

EXHAUST

“B” CENTER OF EXHAUST

TO MOUNTING

BRACKET HOLES

“C”

“A”

OVERALL

INTAKE

HEIGHT

WHITE

BLACK

GREEN

120 VOLTS

BLUE

THERMAL

PROTECTOR

AE0005A

240 VOLTS

THERMAL

PROTECTOR

THERMAL

PROTECTOR

BLUE

CONTROL

RED OR WHITE

BLACK

GREEN

BLUE

BLUE

BLUE

BLUE

CONTROL

BOARD

YELLOW

YELLOW

CONTROL

BOARD

BLACK

WHITE

BLACK

RED OR WHITE

RED OR WHITE

GREEN

MOTOR

GREEN

GREEN

BLACK

MOTOR

GREEN

BLACK

AD0004A

AE0027A

YELLOW

CONTROL

YELLOW

MOTOR

Page 7

page 7

GROUNDING INSTRUCTIONS

WIRING

Grounding Instructions – This appliance must be grounded. If it should malfunction or break down, grounding provides a path of

least resistance for electric current, to reduce the risk of electric shock. This appliance is equipped with a cord having an

equipment-grounding conductor and grounding plug. The plug must be plugged into an appropriate outlet that is properly installed

and grounded in accordance with all local codes and ordinances.

This appliance is for use on a standard 120 VAC, dedicated 15-amp branch circuit with a NEMA 5-15R receptacle or a dedicated

20-amp branch circuit with a NEMA 5-20R receptacle for NuTone models VX475CC and VX550CC. For NuTone model VX1040CC,

a dedicated nominal 240 VAC, individual 20-amp branch circuit with NEMA 6-20R receptacle is required. Make sure that the

appliance is connected to an outlet and has a grounding attachment plug that looks like the plug shown in either Fig. 4 or Fig. 5

depending on the model. No adapter should be used with this appliance.

FIG. 4

F

IG. 5

WARNING

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with

a qualified electrician or service person if you are in doubt as to whether the outlet is properly grounded. Do

not modify the plug provided with the appliance – if it will not fit the outlet, have a proper outlet installed by

a qualified electrician.

!

NuTone VX475CC AND VX550CC

NOTE: INLET LEADS TO BE CONNECTED TO POWER UNIT

TERMINALS USING CRIMP CONNECTORS

NORTH AMERICA

AC ELECTRIC

OUTLET

120 VOLT GROUNDED

OUTLET BOX

AND LOW VOLTAGE WIRE HARNESS.

LOW VOLTAGE

WIRE HARNESS

LOW VOLTAGE WIRE

AE0030A

NORTH AMERICA

AE0008A

NEMA 5-15R

OR

NEMA 5-20R

AC ELECTRIC

OUTLET

NEMA 6-20R

GROUND PIN

POWER

CORD

TO

OTHER

INLETS

NOTE: INLET LEADS TO BE CONNECTED TO POWER UNIT

TERMINALS USING CRIMP CONNECTORS

AND LOW VOLTAGE WIRE HARNESS.

240 VOLT GROUNDED

OUTLET BOX

GROUND PIN

POWER

CORD

TO

OTHER

INLETS

POWER

MODEL V133 18/2 WIRE

NuTone VX1040CC

POWER

MODEL V133 18/2 WIRE

UNIT

UNIT

INLET

LEADS

LOW VOLTAGE

WIRE HARNESS

INLET

LEADS

CRIMP CONNECTORS

LOW VOLTAGE WIRE

CRIMP CONNECTORS

Page 8

page 8

INSTALLING HOSE HANGER

If not already done, install the hose hanger by following these

3 steps.

Place one loop of the hanger

over the other (as shown

beside).

Using a screwdriver, secure

the hanger to the wall with the

provided screw. Insert a

plastic anchor if necessary.

Wind hose around it’s hanger

when not in use.

AR0031

AR0029

AR0030

CONNECTING HOSE

LOW VOLTAGE HOSE

To ensure proper operation of

hose, insert hose into wall inlet

(as shown beside). Align tab up

with depression in wall inlet (A).

2

AO0022

OPERATING HANDLE SWITCH

LOW VOLTAGE HOSE

The switch will turn power unit

ON/OFF.

DUAL VOLTAGE HOSE

Switch on the right position:

Central vacuum mode with power

brush.

Switch on the left position:

Central vacuum mode without

power brush.

Switch in the center:

Power unit is turned OFF.

AD0025

A

A

AD0026

AD0033

AD0032

CONNECTING HOSE (CONT’D)

DUAL VOLTAGE HOSE

In addition to connecting into wall

inlet (A), dual voltage hose must

also be connected to a standard

electrical outlet (B).

If your new hose connection is

not compatible with the telescopic

handle of your unit, please call

1-888-882-7626.

IMPORTANT: Do not return the

hose to the store.

AO0023

B

B

A

A

FOR MODELS: DLXKIT800, STDKIT400, STDKIT800 & WHKIT700

1

3

Page 9

page 9

HOSE HANDLE TO WAND CONNECTION

HOW TO ASSEMBLE

POWER BRUSH/WAND/HANDLE

1. Read important safety instructions before installing power

brush.

2. Ensure hose is disconnected from power supply before

installing power brush.

3. Push wand into power brush neck so that the lock button

snaps in place.

4. Connect hose handle into wand quick connector and

ensure that the prongs are aligned with the receptacle

holes. Push until lock button snaps in place.

HOSE

HANDLE

POWER

BRUSH

LOCK

BUTTON

LOCK BUTTON

POWER BRUSH

NECK

WAND TO POWER BRUSH CONNECTION

HEIGHT

ADJUSTMENT

PEDAL

PRONGS

LOCK

BUTTON

LOCK

BUTTON

HOSE

HANDLE

PRONGS

WAND

WAND

RECEPTACLE

RECEPTACLE

WAND

GRIP

WAND

RELEASE

PEDAL

POWER BRUSH

NECK RELEASE

PEDAL

HOSE HANDLE

RELEASE BUTTON

QUICK

CONNECTOR

AO0019

AO0020

AO0021

WAND AND HOSE COMPATIBILITY

WAND PART NO. 08949

VACUUM HOSE PART NOS.

32DVB, 32DVN AND BN32DV

HOSE HANDLE

CAUTION

Always check underside of product for any

obstructions prior to use.

WARNING

Never leave electric power brush unattended while

it is plugged in.

!

FOR MODEL: DLXKIT800

NOTE: If your dual voltage hose is not compatible with

your new BN200 power brush, please contact

Broan-NuTone Customer service at 1-888-882-7626

to receive a free electrical cord (Part no. CRD400-01)

that will enable you to connect your new power brush

to your hose.

IMPORTANT: Do not return the brush to your retail store.

Page 10

page 10

HOW TO USE POWER BRUSH/WAND

WAND RELEASE

The power brush is not

recommended for use on

bare floors. Wand release

pedal (A) on power brush

allows you to quickly

disconnect wand and switch

to combination floor/rug tool

for use on bare floors.

POWER BRUSH NECK RELEASE

Push down power brush neck release pedal (B) to unlock

brush neck. Return the neck to the upright position for storage.

POWER BRUSH HEIGHT ADJUSTMENT

The icons (D) refer to the carpet pile

height. Select height by depressing

height adjustment pedal (C) to desired

position: (Extra-Low), (Low),

(Medium) or (High).

HEIGHT ADJUSTMENT LED INDICATORS

The LEDs show the carpet pile covered

by the selected height, e.g.: when

(High) is selected, all LEDs will be lit, since this height

covers all pile heights. So if (Extra-Low) is selected, only the

lowest LED will be lit.

WAND LENGTH ADJUSTMENT

Extend (E) or shorten (F)

the wand to comfortable

work position by holding

the wand grip (G) in one

hand and sliding the upper

section (the one with the

prongs) with the other

hand.

FLOOR HEIGHT

B

C

D

F

E

A

G

CAUTION

Always pick up hard or sharp objects by hand

before using your power brush. Items such as pins,

hairpins, tacks, crayons, etc., may damage the

brush roll or may break the belt.

CAUTION

Always unlock brush neck before use.

AO0020

AD0022

AD0023

AD0024

EDGE CLEANER

Brush extends full width for effective edge cleaning along both

sides of nozzle. To operate, simply run cleaner along edge

board. Rubber bumper protects furniture and baseboards.

ELECTRONIC CIRCUIT BREAKER

The power brush is equipped

with an electronic circuit breaker

that protects the motor and the

belt if a too large object is

picked up accidentally.

If the power brush stops while

vacuuming, turn the power unit

off using handle. Release the

power brush from the wand

and turn it over to see if there is an obstruction. When brush

roll jam has been cleared, press the reset button (H) and

connect the power brush back to the wand. Finally, turn the

power unit/power brush back on. If it fails to restart or continues

to trip without any apparent reason, the power brush must be

serviced by an authorized service center.

CLEANING AND STORAGE

CLEANING BRUSH ROLL

In order to keep high cleaning efficiency and to prevent

damage to your vacuum cleaner, the brush roll must be

cleaned every time the belt is changed.

The brush roll must also be cleaned according to the following

schedule:

V

ACUUM CLEANER USE CLEAN BRUSH ROLL

Heavy (used daily) Every week

Moderate (2-3 times per week) Every month

Light (1 time per week) Every 2 months

Check and remove hair, string and lint build-up frequently in

the brush roll and end cap areas. Remove any dirt or debris in

the belt path and in the brush roll areas.

CLEANING HOUSING

To keep the power brush housing clean, it can be wiped with

a damp cloth and a mild soap solution, then thoroughly dried.

Never use any type of chemical as they can damage the housing.

STORAGE

1. Ensure that hose and power cord are disconnected from

wall inlet before unplugging power brush.

2. Disconnect hose handle from wand.

3. Always keep hose neatly coiled when not in use.

4. When not in use, the power brush should be stored in a

clean, dry place.

WARNING

Disconnect electrical supply before servicing or

cleaning the unit. Failure to do so can result in

electrical shock or personal injury from cleaner

suddenly starting.

!

AD0030

H

Page 11

page 11

MAINTAINING THE POWER BRUSH

HOW TO CHANGE BELT

1. Turn power brush over and

using a Phillips no. 2 screwdriver,

remove the 3 brush roll cover

retaining screws (Fig. 6) and

set aside.

2. Remove brush roll cover.

(Fig. 7)

3. To free brush roll from

base, start by sliding the

belt side end and pull

brush roll sideways (1).

Once disengaged from

housing, lift brush roll (2)

out of its compartment

(Fig. 8).

4. Disengage brush roll from

worn belt and extract the belt

from motor shaft by a

twisting motion in the enlarge

area (I) specifically made for

that purpose (Fig. 9).

5. Install new belt by reversing steps 4 to 1.

NOTE: To ease belt replacement, start by inserting one end

around the motor shaft in the enlarged area (I). Insert

brush roll through belt until belt is seated in its place.

Push down brush roll back in place.

WARNING

Disconnect electrical supply before servicing or

cleaning the unit. Failure to do so can result in

electrical shock or personal injury from cleaner

suddenly starting.

!

FIG. 6

F

IG. 7

F

IG. 8

F

IG. 9

BELT

BRUSH ROLL

1

2

I

2

RETAINING

SCREWS

AB0010

AB0012

AB0013

WARNING

Motor shaft can become hot during normal use. To

prevent burns, avoid touching the motor shaft

when replacing the drive belt.

!

HOW TO CHANGE BRUSH ROLL

Replace brush roll when brush roll brissles are worn to the

base support bars level.

1. Turn power brush over and using a Phillips no. 2 screwdriver,

remove the 3 brush roll cover retaining screws (Fig. 6)

and set aside.

2. Remove brush roll cover. (Fig. 7)

3. To free brush roll from base, start by sliding the belt side

end and pull brush roll sideways (1). Once disengaged

from housing, lift brush roll (2) out of its compartment

(Fig. 8).

4. Disengage brush roll from belt. Discard worn brush roll.

5. Insert new brush roll through belt until belt is seated in its

place. Push down brush roll back in place.

6. Finalise the installation by reversing steps 2 to 1.

SERVICE INFORMATION

To avoid unnecessary service calls, check the belt and brush

roll often. Replace the belt if it is stretched or cracked. Clean

the brush roll bristles when they are wrapped with thread and

hairs. Build-up could cause the brush to rotate unevenly.

The model number and serial number are indicated on the rating

label located underneath the power brush. Always refer to

these numbers when inquiring about service.

NOTE: The motor is permanently lubricated and sealed. Do

not oil the motor at any time.

POWER BRUSH SERVICE PARTS

KEY NO. PART NO. DESCRIPTION

1 09234 Belt

2 09233 Brush roll

3 09236 Brush roll cover with screws

4 09235 Wand release pedal

5 18651 Wand

Order Service Parts by “Part No.”, not by “Key No.”

1

2

4

5

3

AB0011

Page 12

page 12

VACUUM POWER CONTROL

The wand end of the deluxe hoses is equipped with a control

ring to regulate suction. The control ring covers a “bleeder”

hole. Open the hole to reduce the suction for cleaning

draperies, small rugs, and other light fabrics. Some very thick,

plush carpets with high density yarns also require reduced

suction to make the nozzle easier to push. Be sure to close the

control ring completely over the hole to produce the maximum

power required for most other cleaning tasks.

WHEN TO EMPTY THE DEBRIS PAIL

NuTone model VX475CC has a single indicator light that

remains green. The level of pail fill for this model can be

determined by either viewing through the window on the pail or

releasing the carry handles and checking the level of debris in

the pail.

NuTone models VX550CC and VX1040CC have the LED

indicators that show the status of the level of debris in the pail.

The first three lights remain green as pail fills. The fourth light

is amber and will come on to alert you that the pail is nearly

full. When the fifth light turns red it is time to empty the pail

(see CONTROL PANEL DIAGRAM A below).

EMPTYING THE DEBRIS PAIL

Your power unit has a permanent filter that is self cleaning

under normal conditions. The filter protects the motor and

stops small dirt particles from escaping to the outside of the

power unit. The filter cleans itself by moving up when the

power unit starts, and dropping down when the unit is turned

off. The filter can be removed by means of a pull-tab for

cleaning if desired. Be sure to reinstall properly. Correct

placement is critical to insure proper protection for the motor.

1. Release both carry handles on side of the unit by pulling

out and then pushing up. (Fig. 10). Holding the pail by the

handles, lower it from unit (Fig. 11).

2. Carry pail to trash receptacle and empty.

3. Reattach pail using handles.

4. Push Reset button on control panel. Light on control panel

will change to green on NuTone models VX550CC and

VX1040CC.

Utility valve (circled in Fig. 11), next to power unit, can be

used to service area around where power unit is installed.

GREEN ONLY

NuTone VX475CC

Manually check

pail to determine

fill level.

GREEN AMBER RED RESET

NuTone VX550CC

and VX1040CC

Timed pail

full indicators

CONTROL PANEL DIAGRAM A

AR0001

AR0002

FOR ALL MODELS

FIG. 10 FIG. 11

AC0001

Page 13

EMPTYING THE DEBRIS PAIL (CONT’D)

CLEANING THE INTERNAL FILTER

When emptying the debris pail, it is a good idea to also clear

any dust and dirt that may have accumulated on the internal

filter media. To do this, simply open the direct door, reach in

and tap the top of the internal filter (Fig. 12). This will release

any loose debris into the pail. You may empty the pail again at

this point but it is not necessary as any amounts of dirt and

dust will be minimal. Close the door.

CLEANING THE SECONDARY FILTER

A secondary safety filter, located at the top of the vacuum

chamber, provides additional protection to the motor. This filter

should be checked and cleaned if necessary, when emptying

the debris pail. Simply brush filter clean. If the filter is

excessively soiled, wash in a mild detergent and let it dry

completely

before reinstalling.

A. FILTER REMOVAL

Open the door located on the front of the power unit.

Reach inside the unit and remove both locking sleeves

from the retaining hooks. Carefully pull filter down to

remove.

NOTE: NuTone model VX1040CC has two secondary

filters. Ensure to remove both filters.

B. FILTER REINSTALLATION

To reinstall the secondary filter, reverse the steps

described above.

A replacement secondary filter (part no. 10941310) may be

purchased from your local Broan-NuTone Sales Outlet. To

locate your nearest Broan-NuTone Sales Outlet, call toll

free 1-888-882-7626.

page 13

CAUTION

Operating the power unit without the secondary filter will

void the warranty.

AR0003

FIG. 12

SECONDARY

FILTER

RETAINING

HOOKS

LOCKING

SLEEVES

UNIT DOOR

AO0066

Page 14

page 14

TROUBLESHOOTING GUIDE

Read before calling Service Center.

PROBLEMS POSSIBLE CAUSES POSSIBLE REMEDY

1.Loss or decrease of

vacuum occurs.

• Debris pail is completely full.

• Obstruction in the hose. A blockage in the hose

can be determined by inserting the hose into any

wall inlet and, while power unit is running, check

each additional inlet for normal suction by holding

the palm of your hand over the open inlet. If normal

suction is felt at all other inlets, insert the hose

into a second inlet. If the blockage still exists it is

located in the hose. However, if the blockage

does not occur when the hose is changed, the

blockage is probably located in the tubing system

leading to the original inlet.

• Obstruction in the tubing system inside the walls.

• Wall inlet cover not properly sealed.

• Exhaust tubing or vent clogged.

• Empty debris pail as described on page 12.

• Insert handle end of hose into utility valve at

power unit. Turn unit on. This will reverse normal

air flow through the hose and dislodge any clogs.

• Insert hose end into any inlet with power unit running,

place the palm of your hand over the opposite

end of the hose. When you can feel the suction

increase, hold your hand over the hose end for a

few seconds and then quickly remove your hand.

This procedure repeated several times should

clear the obstruction. If the blockage is not

cleared, contact your nearest Service Center.

• Check all wall inlet covers to be sure they are

closed and sealed tightly.

• Inspect and remove any blockages.

2.Power unit does not

start, or shuts off during

normal operation with

no LED showing red or

illuminated.

• Defective inlet. Check other wall inlets.

• Thermoprotector has been activated OR there is

a tripped circuit breaker on the unit.

• Blown fuse or tripped circuit breaker on house

electrical panel.

• Defective hose.

• Microprocessor lockup.

NOTE:This applies only to NuTone VX550CC

and VX1040CC.

• Low line voltage.

• Replace defective wall inlet.

• Turn unit off for 20 minutes then plug unit back in.

If unit does not start, look for the tripped circuit

breaker behind the unit, a white button has

popped up, push it back to reset it. If circuit

breaker trips again, unplug your unit and contact

your local Service Center.

• Replace fuse or reset circuit breaker on house

electrical panel.

• Replace hose as required.

• 1) Push Reset button while unit is engaged OR

2) Unplug unit completely for 60 seconds.

• Contact your local Service Center.

3.Power unit fails to stop

when the hose is

removed.

• An electrical short has occurred somewhere in

the system.

• A complete check of all wall inlets and power unit

low voltage control lead connections.

Contact your authorized Service Center.

4.Power unit shuts off

during normal operation,

lights on unit, wall valve

and hose are all red.

• Debris pail full sensing has been activated. • Empty debris pail as described in page 12.

5.On NuTone VX550CC

and VX1040CC units

only, all lights on control

panel flash when unit is

first plugged in.

• Low line voltage. • Contact your local Service Center.

Page 15

page 15

1

2

3

4

6

7

5

8

9

AL0001

KEY

NO.

PART NO. DESCRIPTION VX475CC VX550CC VX1040CC

1

10941189

Pail assembly VS

X

10941191

Pail assembly TS

X X

2 10941192

Door assembly

X X X

3 10941199

Latch kit (with screws)

X X X

4

10941232

VS PCB’s assembly (including mother, daughter and screws)*

X

10941233

TS1 PCB’s assembly (including mother, daughter and screws)*

X

10941195

TS2 Motherboard/Daughterboard S/A incl. screws*

X

5

10941235

VS motor with motor harness, fuse with fuse harness, circuit breaker*

X

10941236

TS1 motor with motor harness, fuse with fuse harness, circuit breaker*

X

10941231

TS2 motor with motor harness, fuse harness, circuit breaker*

X

6

30100528

Pail gasket TS

X X

30100527

Pail gasket VS

X

7

30010272

Cyclonic filter VS

X

30010270

Cyclonic filter TS

X X

8

10941217

Motor Chamber VS with foam and logo*

X

10941218

Motor Chamber TS with foam and logo*

X X

9

10941211

Top cap VS with logo

X

10941213

Top cap TS with logo

X X

NOTE: Order service parts by “Part No.” — not by “Key No.”

*This part MUST be removed and installed by a qualified technician.

SERVICE PARTS

REPLACEMENT PARTS AND REPAIRS

In order to ensure your ventilation unit remains in good

working condition, you must use Broan-NuTone genuine

replacement parts only. Broan-NuTone genuine

replacement parts are specially designed for each unit

and are manufactured to comply with all the applicable

certification standards and maintain a high standard of

safety. Any third party replacement part used may cause

serio

us damage and drastically reduce the performance

level of your unit, which will result in premature failing.

Broan-NuTone also recommends to contact a

Broan-NuTone certified service depot for all replacement

parts and repairs.

Page 16

BROAN-NUTONE CANADA INC.

CENTRAL VACUUM POWER UNIT

LIMITED LIFETIME WARRANTY

Broan-NuTone Canada warrants to the original consumer purchaser that its central vacuum power unit will be free from defects in

materials and workmanship for as long as you own your home in which it was originally installed with the exception of the motor and electronic

components which will be warranted for five (5) years. The first year of this warranty covers the parts and labor in an authorized service center.

THERE ARE NO OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

During these time periods, Broan-NuTone Canada will, at its option, repair or replace the power unit or part without charge, which is found to

be defective under normal use and service. THIS WARRANTY DOES NOT APPLY TO THE INSTALLATION OR THE PARTS USED IN THE

INSTALLED TUBING SYSTEM. All central vacuum hoses, electric or air-driven brushes, filters, attachments and accessories are warranted for

one (1) year from the original purchase date with the exception to consumables such as light bulbs and belts.

This warranty does not cover (a) normal maintenance and service or (b) any products or parts which have been subject to misuse, negligence,

accident, improper maintenance or repair (other than by Broan-NuTone Canada or an authorized representative), faulty installation or installation

contrary to recommended installation instructions.

The duration of any implied warranty is limited to the period as specified for the express warranty.

BROAN-NUTONE CANADA’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN-NUTONE CANADA’S OPTION, SHALL BE THE

PURCHASER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROAN-NUTONE CANADA SHALL NOT BE LIABLE FOR

INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE.

Please do not return your unit to place of purchase. Please visit www.nutone.ca for your closest service center. You may also call 1-888-882-7626

for the name of an authorized representative in your area. This warranty supersedes all prior warranties.

Warranty service is to be completed by an authorized Service Center designated by Broan-NuTone Canada. Where applicable, in home service

will be made available only in areas where a contracted service provider offers service. If in home service is not available, the product will be

repaired or replaced, at Broan-NuTone Canada’s discretion, by the nearest authorized service provider. The unit removal and reinstallation works

are under the customer responsibility, and Broan-NuTone Canada cannot be charged for them.

To qualify for warranty service, you must notify Broan-NuTone Canada at the address or telephone number stated below. We will then forward

you the authorized service depot in your area. You will be required to present evidence of the original purchase date.

Date of Installation Builder or Installer

Model Number and Product Description

IF YOU NEED ASSISTANCE OR SERVICE

For the location of your nearest Broan-NuTone Canada Inc. dealer, dial toll free: 1-888-882-7626

Please be prepared to provide: Product model number ● Date and proof of purchase ● The nature of the difficulty

Broan-NuTone Canada Inc. 1140 Tristar Drive, Mississauga, Ontario L5T 1H9

Product specifications subject to change without notice. Printed in Canada.

WARRANTY

NUTONE MODELS VX475CC, VX550CC AND VX1040CC

page 16

Loading...

Loading...