Page 1

1

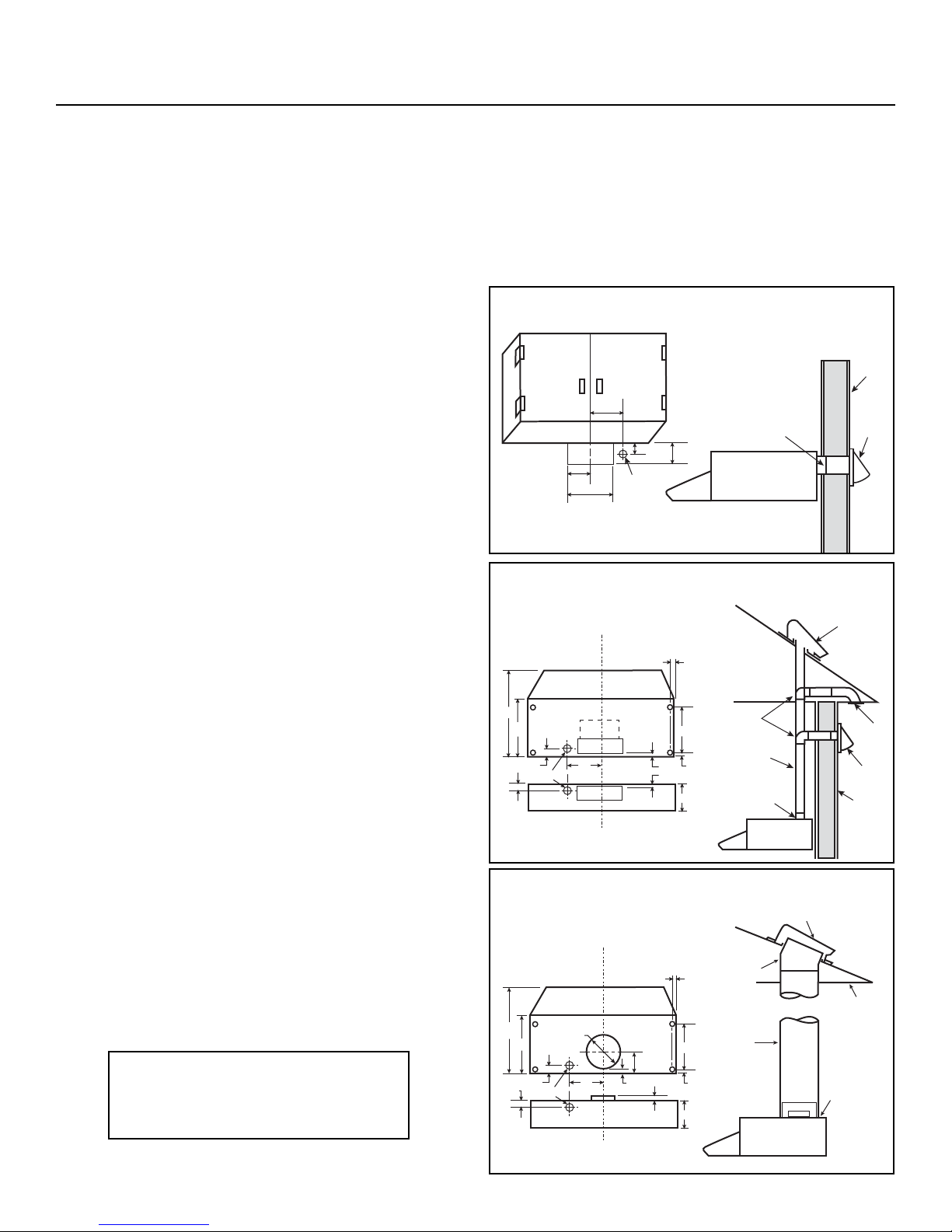

VERTICAL OR HORIZONTAL DISCHARGE

USING 3¼" x 10" DUCT

CUTOUT DIMENSIONS

TOP

VIEW

BACK

VIEW

18"

12"

6"

7⁄8"

3¼" x 10"

3¼" x 10"

ELEC. K.O.

9³⁄8"

17⁄16"

17⁄16"

7"

1"

1⁄2"

1⁄2"

SUPPLIED DUCT

TRANSITION

RANGE

HOOD

WAL L

WAL L

CAP

ELBOW

(

If required)

ROOF CAP

EAVE

CAP

3¼" x 10"

DUCT

C

L

INSTALLATION INSTRUCTIONS

GP AND SM6500 SERIES RANGE HOODS

READ & SAVE THESE INTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

1. For indoor use only.

2. For general ventilating only. Do not use to exhaust hazardous or explosive

materials and vapors.

3. To reduce the risk of fire or electrical shock, this range hood shoul not

be used with an additional solid-state speed control device.

4. To reduce the risk of shock, disconnect power before servicing.

5. To reduce the risk of fire and to properly exhaust air, be sure to duct

air outside. Do not vent exhaust air into spaces within walls or ceilings

or into attics, crawl spaces or garages.

IMPORTANT SAFETY INSTRUCTIONS

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you

have any questions, contact the manufacturer at the address or

telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel and lock

service panel to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked, securely

fasten a prominent warning device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by qualified person(s)

in accordance with all applicable codes and standards - including

fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of

gases through the flue (chimney) of fuel burning equipment to prevent

backdrafting. Follow the heating equipment manufacturer’s guidelines

and safety standards such as those published by the National Fire

Protection Association (NFPA), and the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE), and local

code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical

wiring and other hidden utilities.

6. This unit must be grounded.

7. Ducted fans must always be vented to the outdoors.

8. To reduce the risk of fire, use only metal ductwork.

9. When applicable local regulations comprise more restrictive installation

and/or certification requirements, the aforementioned requirements

prevail on those of this document and the installer agrees to conform

to these at his own expenses.

10. When performing installation, servicing or cleaning this unit, it is

recommended to wear safety glasses and gloves.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

1. Never leave surface units unattended at high settings. Boilovers cause

smoking and greasy spillovers that may ignite. Heat oils slowly on low

or medium setting.

2. Always turn hood ON when cooking at high heat or when flambeing

food (i.e.: Crêpes Suzette, Cherries Jubilee, Peppercorn Beef Flambé).

3. Clean ventilating fans frequently. Grease should not be allowed to

accumulate on fan or filter.

4. Use proper pan size. Always use cookware appropriate for the size of

the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF

A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING*:

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal

tray, then turn off the burner. BE CAREFUL TO PREVENT BURNS.

If the flames do not go out immediately, EVACUATE AND CALL THE

FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - you may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - a violent

steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher, and you already know

how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

*Based on “Kitchen Fire Safety Tips” published by NFPA.

KITCHEN

CABINET

CUTOUT DIMENSIONS

WIRING

CUTOUT

5

1

⁄8"

10¼"

3¾"

1

7

⁄16"

HORIZONTAL DISCHARGE THROUGH WALL

7"

SUPPLIED DUCT

TRANSITION

RANGE HOOD

REMOVE DAMPER FLAP

FROM TRANSITION FOR

THIS INSTALLATION

WAL L

WAL L

CAP

18"

12"

6"

7⁄8"

ELEC. K.O.

9³⁄8"

1

7

⁄16"

7"

1⁄2"

1⁄2"

7"

DIA

47/8"

RANGE HOOD

VERTICAL DISCHARGE USING 7” ROUND DUCT

(TRANSITION NOT INCLUDED)

ROOF CAP

ADJUSTABLE

ELBOW

7" ROUND

DUCT

ROOF

REMOVE BOTH

3¼" x 10" AND

4½" x 8"

KNOCKOUTS

FOR 7" DUCT

CUTOUT DIMENSIONS

TOP

VIEW

BACK

VIEW

C

L

17⁄16"

1"

FIGURE 1

FIGURE 3

30042422A

FIGURE 2

REGISTER YOUR PRODUCT ON LINE AT

• For Broan GP Series: www.broan.ca

• For Nutone SM6500 Series: www.nutone.ca

Page 2

INSTALLATION INSTRUCTIONS

GP AND SM6500 SERIES RANGE HOODS

PLANNING

• Mounting height MUST BE at a minimum of 22” and at a maximum of

30” above the cooking surface from the bottom edge of the range

hood.

• The hood shall be mounted to the bottom of a standard wall cabinet.

If the hood must be mounted directly to a wall, secure the hood to wall

studs.

• All wiring must comply with local codes and the unit must be properly

grounded. Connection should be made to a 110-120 VAC lighting

circuit (15A) in the circuit breaker or fuse box.

• This range hood is “Convertible”, it may be installed as a ducted or

as a non-ducted unit.

IF THE RANGE HOOD IS TO BE DUCTED:

• Ductwork can be installed vertically or horizontally.

• Duct runs should be as short as possible.

• Avoid the use of elbows.

• Use metal duct tape at all joints.

• Do not use duct smaller than the discharge on the hood.

NON DUCTED:

• Disregard instructions for knockout.

• Discard the transition, it will not be used.

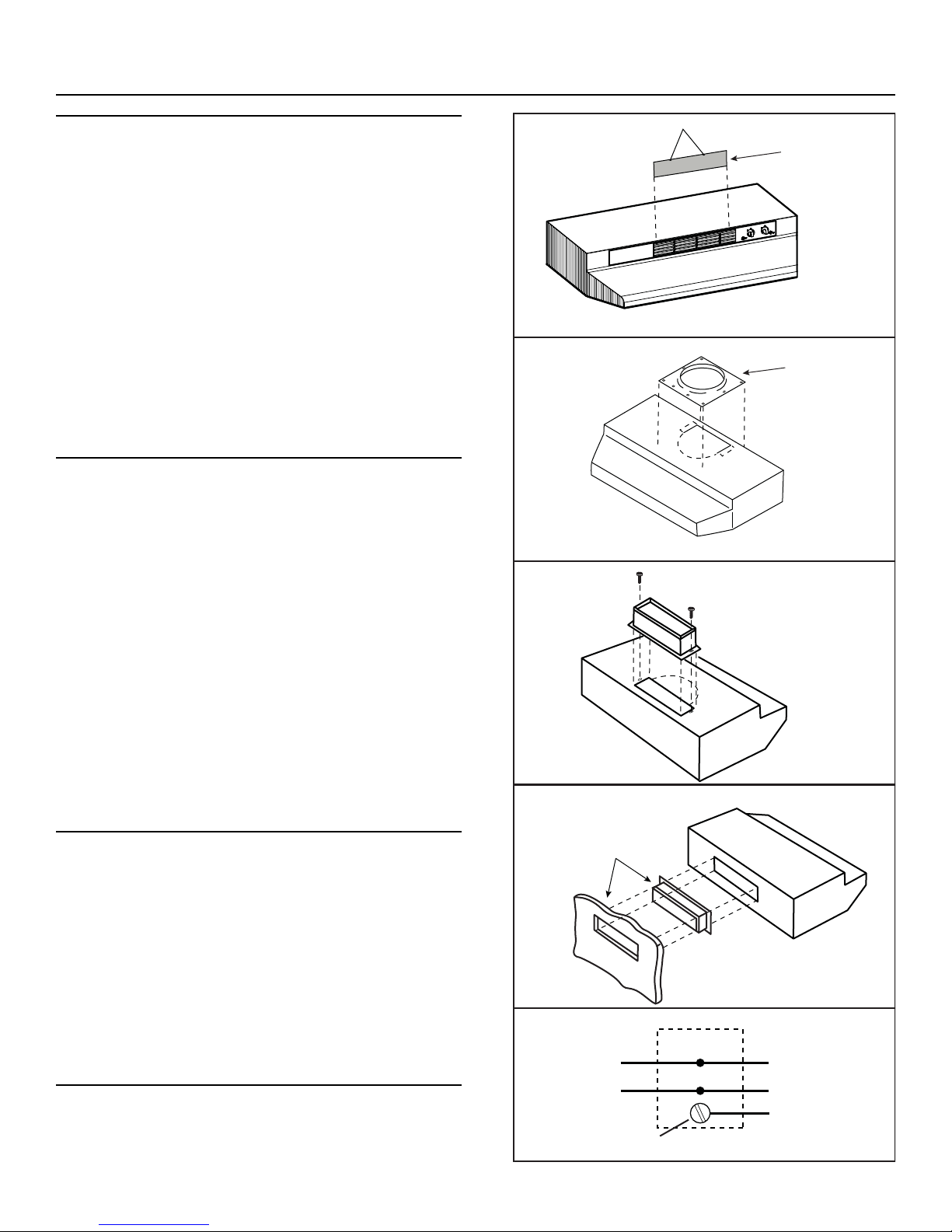

PREPARATION

1. Use the dimensional drawing to lay out the range hood’s mounting

holes, wiring access and ductwork.

2. Make cut-outs for wiring and ductwork.

3. If the hood is to be ducted, install the ductwork so that it is flush to the

range hood’s mounting surface.

• Refer to Figure 1 if the range hood is to be installed with a horizontal

discharge.

• Refer to Figure 2 if the range hood is to be installed with a vertical

discharge.

4. Remove the necessary duct opening and wiring knockout from the

range hood.

NOTE: If the range hood is to be installed as a ducted unit install

baffle (refer to Figure 4) by sliding into place behind grille.

Use locator bumps to orient in grille.

NOTE: If the range hood is to be installed as a ductless unit, do

not remove any knockouts.

5. Run two-conductor wires (with ground) from a power source to the

hood location. Bring approximately 12” of wiring through wiring hole in

cabinet.

6. Drill four 3/32” diameter pilot holes at points where mounting holes are

marked in the filler strips or cabinet bottom.

7. Insert four (4) mounting screw (not supplied), leaving approximately

1/4” of thread exposed. Use no. 8 or no. 10 round head screws.

INSTALLATION

1. Refer to Figure 6 for a vertical discharge installation.

Secure the 3¼” x 10” transition (if used) to top of hood.

Refer to Figure 7 for a horizontal discharge installation.

If using the supplied 3¼” x 10” duct transition, remove the damper from

the transition to prevent possible venting interference. Position transition

into wall cutout (the transition does not fasten to the hood).

Refer to Figure 5 for 7” round discharge installation.

Secure 7” round adaptor to top of hood using screws provided.

2. Feed the wiring through the access hole and into the electrical box.

3. Align hood’s keyhole mounting slots over the four (4) partially installed

screws.

4. Making sure the duct position over the hood’s duct transition (or adaptor),

push the hood against the rear wall. Secure hood by tightening screws.

5. Using a long blade screwdriver, reach into the discharge opening and

make sure the damper operates freely.

WIRING CONNECTIONS

All wiring connections must comply with local code and the unit must be

properly grounded.

1. Make sure box connector is secure.

2. Refer to Figure 8. Make wiring connections.

3. Replace electrical box cover and secure with screw.

LOCATORS

BAFFLE PLATE

7" ROUND

ADAPTER

(Not included)

SECURE TRANSITION

WITH SCREWS (included)

POSITION DUCT

TRANSITION IN

WALL CUTOUT

HORIZONTAL

WHITE

HOOD WIRING

SUPPLY WIRING

GROUND SCREW

BLACK

GREEN OR BARE

(GROUND)

BLACK

WHITE

FIGURE 4

FIGURE 5

FIGURE 6

FIGURE 7

FIGURE 8

2

Page 3

FILTER

CLIPS

FKM-65 FILTER

(FOR DUCTLESS

OPERATION ONLY)

ALUMINUM FILTER

Broan-NuTone Canada warrants to the original consumer purchaser of its products that such products will be free from defects in materials and

workmanship for a period of one year from the date of original purchase. THERE ARE NO OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone Canada will, at its option, repair or replace, without charge, any product or part which is found to be

defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS AND TUBES. This warranty does not cover (a) normal maintenance

and service or (b) any products or parts which have been subject to misuse, negligence, accident, improper maintenance or repair (other than by

Broan-NuTone Canada), faulty installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty.

BROAN- NUTONE CANADA’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN-NUTONE CANADA’S OPTION, SHALL BE THE PURCHASER'S

SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROAN-NUTONE CANADA SHALL NOT BE LIABLE FOR INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary by jurisdiction. This warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone Canada at the address or telephone number below, (b) give the model number and

part identification and (c) describe the nature of any defect in the product or part. At the time of requesting warranty service, you must present evidence

of the original purchase date.

Date of Installation Builder or Installer

Model No. and Product Description

IF YOU NEED ASSISTANCE OR SERVICE:

For the location of your nearest Broan-NuTone Canada Incorporated dealer

Dial Free 1-888-882-7626

Please be prepared to provide:

Product model number • Date and Proof of Purchase • The nature of the difficulty

Broan-NuTone Canada Incorporated

1140 Tristar Drive, Mississauga, Ontario, Canada L5T 1H9

www.broan.ca

www.nutone.ca

COMPLETING ASSEMBLY

1. Install a 75 W (maximum) light bulb in the receptacle.

2. Install filter and light lens assembly.

3. For ductless use with charcoal filter (FKM-65): Install 2 filter clips by

sliding into the receivers on the sides of the hood fan housing.

See Figure 9.

OPERATION AND MAINTENANCE

FILTERS

IMPORTANT: The aluminium filter should be removed once a week and

washed in hot detergent water. Rinse in clear, warm water and shake off

excessive moisture before replacing. The filter may also be cleaned in

your dishwasher. Always install the aluminium filter with the domed side

away from the fan.

IN A NON-DUCTED INSTALLATION

Refer to Figure 9. In non-ducted installations use FKM-65 filter and

replace every 3-6 months as needed. Always install the FKM-65 filter first

(nearest fan) with carbon side towards fan and the aluminium

filter second. Install filter clips by sliding into brackets on side of air chamber.

CLEANING

The hood should be wiped off occasionally both inside and outside using

warm water, mild dish detergent and a soft cloth. Never use scouring powders,

steel wool pads or any other abrasive cleaners, which will destroy the

hood’s finish.

BROAN-NUTONE CANADA ONE-YEAR LIMITED WARRANTY

FIGURE 9

3

Page 4

ÉVACUATION VERTICALE OU HORIZONTALE

AVEC DES CONDUITS DE 3¼ po x 10 po

DIMENSIONS DE LA DÉCOUPE

VUE

DU DESSUS

VUE

ARRIÈRE

18 po

12 po

6"

7⁄8 po

3¼ po x 10 po

9³⁄

8 po

1

7

⁄16 po

17⁄16 po

7 po

1 po

1⁄2 po

1⁄2 po

C

L

TRANSITION

INCLUSE

HOTTE

MUR

CAPUCHON

DE MUR

COUDE

(si requis)

CAPUCHON

DE TOIT

CAPUCHON

D’AVANT-TOIT

3¼ po x 10 po

OUVERTURE POUR

FIL ÉLECTRIQUE

CONDUIT DE

3¼ po x 10 po

DIRECTIVES D’INSTALLATION

HOTTES DE CUISINIÈRE SÉRIES GP ET SM6500

LIRE ET CONSERVER CES DIRECTIVES

IMPORTANTES DIRECTIVES DE SÉCURITÉ

1. Pour une utilisation à l’intérieur seulement.

2. Pour usage domestique seulement. Ne pas utiliser pour évacuer des

vapeurs ou des matières dangereuses ou explosives.

3. Afin de réduire les risques d’incendie ou d’électrocution, ne pas utiliser

cette hotte avec une commande de vitesse à semi-conducteur additionnelle.

4. Afin d’éviter les risques d’électrocution, couper le courant avant d’effectuer l’entretien.

5. Afin de réduire les risques d’incendie, assurez-vous d’évacuer l’air à

l’extérieur. Ne pas évacuer l’air dans des espaces restreints comme

l’intérieur des murs ou plafond ou dans le grenier, faux plafond ou garage.

IMPORTANTES DIRECTIVES DE SÉCURITÉ

AVERTISSEMENT - POUR RÉDUIRE LES RISQUES

D’INCENDIE, D’ÉLECTROCUTION OU DE BLESSURES,

OBSERVEZ LES DIRECTIVES SUIVANTES :

1. N’utilisez cet appareil que de la façon prévue par le manufacturier. Si

vous avez des questions, contactez le manufacturier à l’adresse et au

numéro de téléphone indiqués dans la garantie.

2. Avant de réparer ou de nettoyer l’appareil, couper l’alimentation électrique

en verrouillant le panneau de service afin d’éviter sa remise en marche

accidentelle. Si le panneau de service ne peut être verrouillé, y fixer un

avertissement en évidence, telle qu’une étiquette de couleur vive.

3. Les travaux d’installation et de raccordement électrique doivent être effectués

par une personne qualifiée, conformément aux codes et aux standards de

construction, incluant ceux concernant la protection contre les incendies.

4. Une quantité d’air adéquate est requise afin d’assurer une bonne

combustion et l’évacuation des gaz par la cheminée dans le cas des

équipements alimentés au gaz afin de prévenir les retours de cheminée.

Conformez-vous aux instructions et aux standards de sécurité des

manufacturiers d’équipement de chauffage, tel qu’ils sont publiés par

la

National Fire Protection Association

(NFPA) et l’

American Society

for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE)

ainsi que les responsables des codes locaux.

5. Lorsque vous coupez ou perforez un mur ou un plafond, prenez garde

de ne pas endommager les fils électriques ou autre installation qui

pourraient y être dissimulés.

6. Cet appareil doit être mis à la terre.

7. Les ventilateurs avec conduits doivent toujours évacuer l’air à l’extérieur.

8. Afin de réduire les risques d’incendie, n’utilisez que des conduits de métal.

9. Lorsqu’une réglementation est en vigueur et qu’elle comporte des

exigences d’installation et/ou de certification plus restrictives, lesdites

exigences prévalent sur celles de ce document et l’installateur entend

s’y conformer à ses frais.

10. Il est recommandé de porter des lunettes et des gants de sécurité lors

de l’installation, de l’entretien ou de la réparation de cet appareil.

AFIN DE RÉDUIRE LES RISQUES DE FEU DE CUISINIÈRE :

1. Ne jamais laisser les appareils de cuisson sans surveillance lorsqu’ils

sont réglés à feu vif. Les débordements engendrent de la fumée et des

déversements graisseux pouvant s’enflammer. Chauffez l’huile lentement,

à feu doux ou moyen.

2. Mettez toujours la hotte en marche lorsque vous cuisinez à feu vif ou

que vous cuisinez des mets flambés (par ex. : crêpes Suzette, cerises

jubilé, steak au poivre flambé).

3. Nettoyez régulièrement la roue du ventilateur. Ne laissez pas la graisse

s’accumuler sur le ventilateur ou les filtres.

4. Utilisez le bon format de casserole. Servez-vous toujours de casseroles

et d’ustensiles appropriés à la dimension de la surface chauffante.

AFIN D’ÉVITER TOUT RISQUE DE BLESSURES LORS D’UN FEU DE

CUISINIÈRE, SUIVEZ CES DIRECTIVES*:

1. Étouffez les flammes avec un couvercle hermétique, une tôle à

biscuits ou un plateau métallique et ensuite, éteindre le brûleur.

PRENEZ SOIN D’ÉVITER LES BRÛLURES. SI LES FLAMMES NE

S’ÉTEIGNENT PAS IMMÉDIATEMENT, ÉVACUEZ LES LIEUX ET

APPELEZ LES POMPIERS.

2. NE PRENEZ JAMAIS UNE CASSEROLE EN FLAMMES DANS VOS

MAINS – Vous pourriez vous brûler.

3. N’UTILISEZ PAS D’EAU, incluant un linge à vaisselle ou une serviette

mouillée, cela pourrait occasionner une violente explosion de vapeur.

4. N’utilisez un extincteur QUE DANS LE CAS OÙ :

A. Vous savez qu’il s’agit d’un extincteur de classe ABC et que vous en

connaissez le fonctionnement.

B. L’incendie est petit et limité à l’endroit où il a débuté.

C. Les pompiers ont été avisés.

D. Vous pouvez combattre l’incendie en ayant accès à une sortie de secours.

*Tirées du

Kitchen Fire Safety Tips

publié par la NFPA.

ARMOIRE

DE CUISINE

DÉCOUPE POUR

FIL ÉLECTRIQUE

5

1

⁄8 po

10¼ po

3¾ po

17⁄16 po

ÉVACUATION HORIZONTALE À TRAVERS UN MUR

7"

TRANSITION

INCLUSE

HOTTE

RETIRER LE CLAPET DE

LA TRANSITION POUR

CETTE INSTALLATION

MUR

CAPUCHON

DE MUR

DIMENSIONS DE LA DÉCOUPE

18 po

12 po

6 po

7⁄8 po

9³⁄8 po

7 po

1⁄2 po

1⁄2 po

7 po

DIA

47/8 po

HOTTE

ÉVACUATION VERTICALE AVEC CONDUIT ROND

DE 7 po (TRANSITION NON INCLUSE)

CAPUCHON

DE TOIT

COUDE

AJUSTABLE

CONDUIT

ROND

DE 7 po

TOIT

DÉFONCER LES

OUVERTURES

PRÉAMORCÉES

DE 3¼ po x 10 po

ET DE

4½ po x 8 po

POUR LE

CONDUIT

DE 7 po

DIMENSIONS DE LA DÉCOUPE

VUE

DU DESSUS

VUE

ARRIÈRE

C

L

1 po

1

7

⁄16 po

OUVERTURE POUR

FIL ÉLECTRIQUE

17⁄16 po

FIGURE 1

FIGURE 3

30042422A

FIGURE 2

ENREGISTREZ VOTRE PRODUIT EN LIGNE À :

• Pour la série GP de Broan : www.broan.ca

• Pour la série SM6500 de NuTone : www.nutone.ca

4

Page 5

DIRECTIVES D’INSTALLATION

HOTTES DE CUISINIÈRE SÉRIES GP ET SM6500

PLANIFICATION DE L’INSTALLATION

• Le bas de la hotte DOIT ÊTRE installé à un minimum de 22 po et à un

maximum de 30 po au-dessus de la surface de cuisson.

• La hotte doit être installée au bas d’une armoire de cuisine standard.

Si la hotte doit être installée directement au mur, la fixer aux montants.

• Le branchement doit être mis à la terre. La hotte doit être branchée à

un circuit d’éclairage de 110-120 V c.a. (15 A) qui se trouve dans le

panneau de distribution électrique ou la boîte de fusibles.

• Cette hotte de cuisine peut être installée avec ou sans conduit d’évacuation.

SI LA HOTTE EST INSTALLÉE AVEC UN CONDUIT D’ÉVACUATION

• Le conduit peut être installé à la verticale ou à l’horizontale.

• Réaliser un réseau de conduit le plus court possible.

• Éviter d’utiliser des coudes.

• Sceller hermétiquement les joints à l’aide de ruban à conduits en métal.

• Ne pas utiliser un conduit de format inférieur à celui de la sortie de la hotte.

SANS CONDUIT :

• Ne pas tenir compte des instructions pour les ouvertures préamorcées.

• Se défaire de la transition; elle ne sera pas utilisée.

PRÉPARATION

1. Utiliser les dessins dimensionels pour déterminer l’emplacement des

trous pour le montage, le passage des fils et le passage du conduit.

2. Découper les ouvertures pour le branchement et le conduit.

3. Si la hotte est installée avec un conduit, installer ce dernier pour qu’il

soit à égalité avec la surface de montage de la hotte.

• Voir la Figure 1 si la hotte est installée avec une évacuation horizontale.

• Voir la Figure 2 si la hotte est installée avec une évacuation verticale.

4. Enlever l’ouverture préamorcée appropriée pour le conduit ainsi que

celle pour le branchement électrique.

NOTE: Si la hotte es installée avec un conduit, installer le

déflecteur (voir la Figure 4) en le glissant en place derrière

la grille. Utiliser les repères pour orienter la grille.

NOTE: Si la hotte est installée sans conduit, n’enlever aucune

ouverture préamorcée.

5. Installer un fil à deux conducteurs (avec mise à la terre) de la source

d’alimentation à la hotte. Faire passer environ 12 po de fil dans

l’ouverture de branchement.

6. Percer quatre avant-trous de 3/32 po de diamètre à l’emplacement marqué

des trous de montage sur les languettes de bois ou au bas de l’armoire.

7. Insérer quatre (4) vis de montage (non fournies) dans les trous, en laissant

dépasser environ 1/4 po de filet. Utiliser des vis n°8 ou 10 à tête ronde.

INSTALLATION

1. Voir la Figure 6 pour une évacuation verticale. Fixer la transition de

3¼ po x 10 po (au besoin) sur le dessus de la hotte.

Voir la Figure 7 pour une installation à évacuation horizontale. Si

la transition de 3¼ po x 10 po est utilisée, retirer son clapet pour éviter

les interférences de ventilation. Placer la transition dans l’ouverture du

mur (la transition n’est pas vissée à la hotte).

Voir la Figure 5 pour l’installation de la sortie ronde de 7 po. Fixer

l’adaptateur rond de 7 po sur le dessus de la hotte à l’aide des

vis incluses.

2. Faire passer le fil électrique par l’orifice d’accès, puis dans la boîte de jonction.

3. Aligner les fentes de montage en forme de trous de serrure avec les

quatre vis partiellement vissées.

4. S’assurer que le conduit soit bien vis-à-vis la transition (ou

l’adaptateur) et pousser la hotte contre le mur arrière, puis la fixer en

place en serrant les vis.

5. Au moyen d’un long tournevis, vérifier que le clapet ouvre librement en

passant par la sortie de la hotte.

BRANCHEMENT ÉLECTRIQUE

Toutes les connexions électriques doivent être conformes aux codes

locaux en vigueur, et la hotte doit être correctement mise à la terre.

1. S’assurer que le connecteur de boîte soit bien fixé à la boîte de jonction.

2. Voir la Figure 8. Effectuer les connexions électriques.

3. Replacer le couvercle de la boîte de jonction et le fixer à l’aide de la vis.

REPÈRES

DÉFLECTEUR

ADAPTATEUR ROND

DE 7 po

(Non inclus)

FIXER LA TRANSITION

AVEC LES VIS (incluses)

PLACER LA

TRANSITION DANS LA

DÉCOUPE DU MUR

À L’HORIZONTALE

CÂBLAGE DE LA HOTTE

CÂBLAGE D’ALIMENTATION

VIS DE

MISE À LA TERRE

VERT OU NU

(MISE À LA TERRE)

BLANC

NOIRNOIR

BLANC

FIGURE 4

FIGURE 5

FIGURE 6

FIGURE 7

FIGURE 8

5

Page 6

Broan-NuTone Canada garantit à l’acheteur consommateur original de ses produits qu’ils sont exempts de tout défaut dans les matières premières ou

la main-d’œuvre pour une période de un an à compter de la date d’achat originale. IL N’Y A PAS D’AUTRES GARANTIES, EXPRIMÉES OU

IMPLICITES, INCLUANT MAIS NON PAS LIMITÉE AUX GARANTIES IMPLICITES POUR FIN DE COMMERCIALISATION ET DE CONVENANCE

DANS UN BUT PARTICULIER.

Pendant cette période de un an, Broan-NuTone Canada, à son choix, réparera ou remplacera gratuitement tout produit ou pièce qui s’avère défectueux

sous utilisation et service normaux.

CETTE GARANTIE NE COUVRE PAS LES STARTERS DE LAMPES FLUORESCENTES ET LES TUBES. Cette garantie ne couvre pas (a) l’entretien

et le service normal ou (b) tout produit ou pièce endommagé à la suite d’un mauvais usage, de négligence, d’un accident, d’un entretien inapproprié ou

d’une réparation (autre que par Broan-NuTone Canada), d’une installation inadéquate ou contraire au mode d’installation recommandé.

La durée de toute garantie implicite est limitée à une période de un an telle qu’elle est spécifiée pour la garantie exprimée.

L’ENGAGEMENT DE BROAN-NUTONE CANADA DE RÉPARER OU DE REMPLACER, AU CHOIX DE BROAN-NUTONE CANADA, SERA LA SEULE

OBLIGATION EXCLUSIVE SOUS CETTE GARANTIE. BROAN-NUTONE CANADA NE SERA PAS TENUE RESPONSABLE DES DOMMAGES

DIRECTS, INDIRECTS OU SPÉCIAUX SURVENANT À CAUSE DE OU EN RAPPORT AVEC L’UTILISATION OU LA PERFORMANCE DE SES

PRODUITS. Certaines juridictions ne permettent pas l’exclusion ou la limitation de responsabilité relative aux dommages directs ou indirects.

Par conséquent, l’exclusion ou la limitation énoncée ci-dessus peut ne pas s’appliquer à votre cas.

Cette garantie vous donne des droits légaux spécifiques et il se peut que vous ayez d’autres droits variant selon la juridiction. Cette garantie annule

toutes les garanties précédentes.

Pour le service sous garantie, vous devez (a) aviser Broan-NuTone Canada à l’adresse ou au numéro de téléphone ci-dessous, (b) donner le numéro

du modèle et l’identification de la pièce et (c) décrire la nature de tout défaut dans le produit ou la pièce. Au moment de demander le service sous

garantie, vous devez présenter une preuve de la date d’achat originale.

Date d’installation Entrepreneur ou installateur

N° de modèle et description du produit

POUR OBTENIR DE L’ASSISTANCE OU DU SERVICE

Pour connaître le Centre de services Broan-NuTone Canada Inc. autorisé indépendant le plus près de chez vous :

Composez le numéro sans frais : 1 888 882-7626

Garder à portée de la main le numéro du modèle, la date et la preuve d’achat, le type de problème.

Broan-NuTone Canada Incorporated

1140, Tristar Drive, Mississauga (Ontario) CANADA L5T 1H9

www.broan.ca

www.nutone.ca

ATTACHES

DE FILTRE

FILTRE FKM-65

(HOTTE SANS

CONDUIT SEULEMENT)

FILTRE EN ALUMINIUM

COMPLÉTER L’ASSEMBLAGE

1. Installer une ampoule de 75 W (maximum) dans la douille.

2. Installer le filtre et le couvercle de l’ampoule.

3. Pour les hottes sans conduit, utiliser un filtre à charbon FKM-65.

Fixer les deux attaches de filtre en les glissant dans les réceptacles de

chaque côté du boîtier du ventilateur. Voir Figure 9.

UTILISATION ET ENTRETIEN

FILTRES

IMPORTANT : Le filtre en aluminium doit être enlevé une fois par semaine

pour être nettoyé avec un détergent et de l’eau chaude. Rincer à l’eau

tiède, puis secouer pour enlever l’excédent d’eau avant de le remettre en

place. Le filtre va également au lave-vaisselle. Toujours installer le filtre en

aluminium avec la partie bombée à l’opposé du ventilateur.

HOTTE SANS CONDUIT

Voir la Figure 9. Avec une hotte sans conduit, utiliser le filtre à charbon

et le remplacer tous les 3 à 6 mois au besoin. Installer toujours le filtre à

charbon FKM-65 en premier (près du ventilateur), côté à charbon vers le

ventilateur, suivi du filtre en aluminium. Fixer les attaches de filtre en les

glissant dans les brides de chaque côté du boîtier du ventilateur.

NETTOYAGE

La hotte doit être nettoyée à l’occasion, à l’extérieur comme à l’intérieur

avec de l’eau tiède, un détergent doux et un chiffon doux.

Ne jamais utiliser de poudre à récurer, de tampon de laine d’acier ou de

nettoyants abrasifs, car cela endommagera le fini de la hotte.

FIGURE 9

GARANTIE LIMITÉE DE UN AN DE BROAN-NUTONE CANADA

6

Loading...

Loading...