Page 1

INSTALLATION INSTRUCTIONS

READ & SAVE THESE INSTRUCTIONS!

Bulb Heaters & Bulb Heater/Fans

MODELS: 9417DNM, 9420WHC, 9425WHC

IMPORTANT SAFETY INSTRUCTIONS

WARNING – TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer.

If you have questions, contact the manufacturer at the address

or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service

panel and lock service panel to prevent power from being

switched on accidentally. When the service disconnecting

means cannot be locked, securely fasten a prominent warning

device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by a qualified person(s) in accordance with all applicable codes and standards, including fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting

of gases through the flue (chimney) of fuel burning equipment

to prevent backdrafting. Follow the heating equipment

manufacturer's guideline and safety standards such as those

published by the National Fire Protection Association (NFPA),

and the American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

6. Do not install this unit over a tub or shower.

7. Never place a switch where it can be reached from a tub or

shower.

8. Do not operate unit with dimmer switch or speed control.

CAUTION

1. For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

2. This product is designed for installation in flat ceilings only.

DO NOT MOUNT THIS PRODUCT IN A WALL.

3. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off power

unit.

4. Please read specification label on product for further information and requirements.

PLAN THE INSTALLATION

Choose the location for your heater. Refer to Warnings and Cautions.

MODELS 9417DNM & 9425WHC ONLY – The unit will operate

most efficiently when located where the shortest possible duct run

and minimum number of elbows will be needed. Units are designed for use with standard 4" round duct.

Note that two-bulb units can be fitted with one infrared bulb (for

heat) and one reflector bulb (for light). Dual or multi-controls can be

used for separate control of bulbs and/or exhaust fan. Purchase

controls separately.

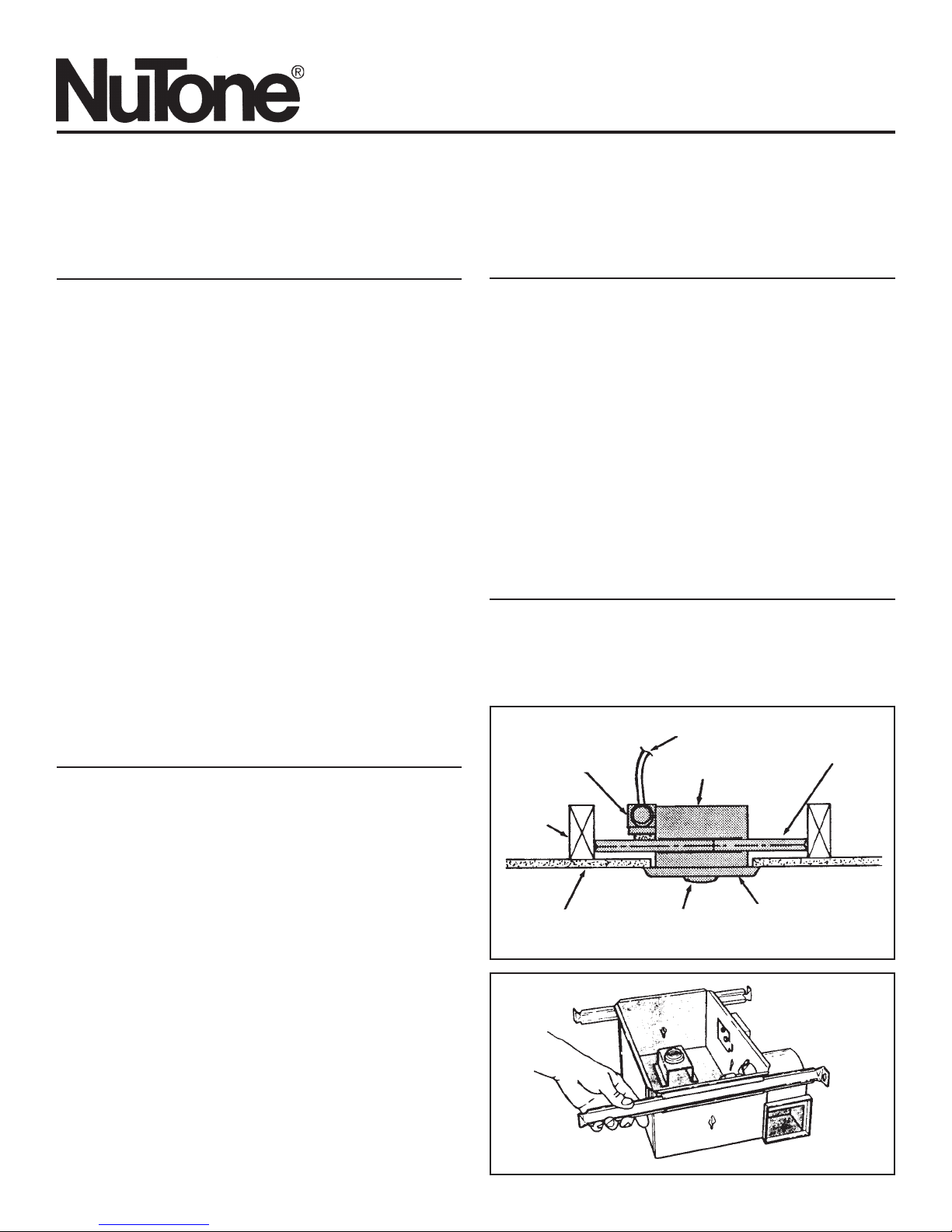

Refer to FIGURE 1

Follow these basic steps when installing this unit:

1. Nail unit to joists.

2. Attach ductwork (Models 9417DNM & 9425WHC only).

3. Connect power cable.

4. Fasten grille to housing.

PREPARE THE HEATER

1. Remove the unit from carton. Save carton for use as plaster

shield in rough-in installations.

Refer to FIGURE 2

2. Slide adjustable mounting brackets into bracket channels on

housing.

DAMPER/DUCT

CONNECTOR

CEILING

JOIST

CEILING MATERIAL BULB(S)

HOUSING

POWER CABLE

GRILLE

MOUNTING

BRACKET

FIGURE 1

FIGURE 2

1

Page 2

INSTALL THE HEATER

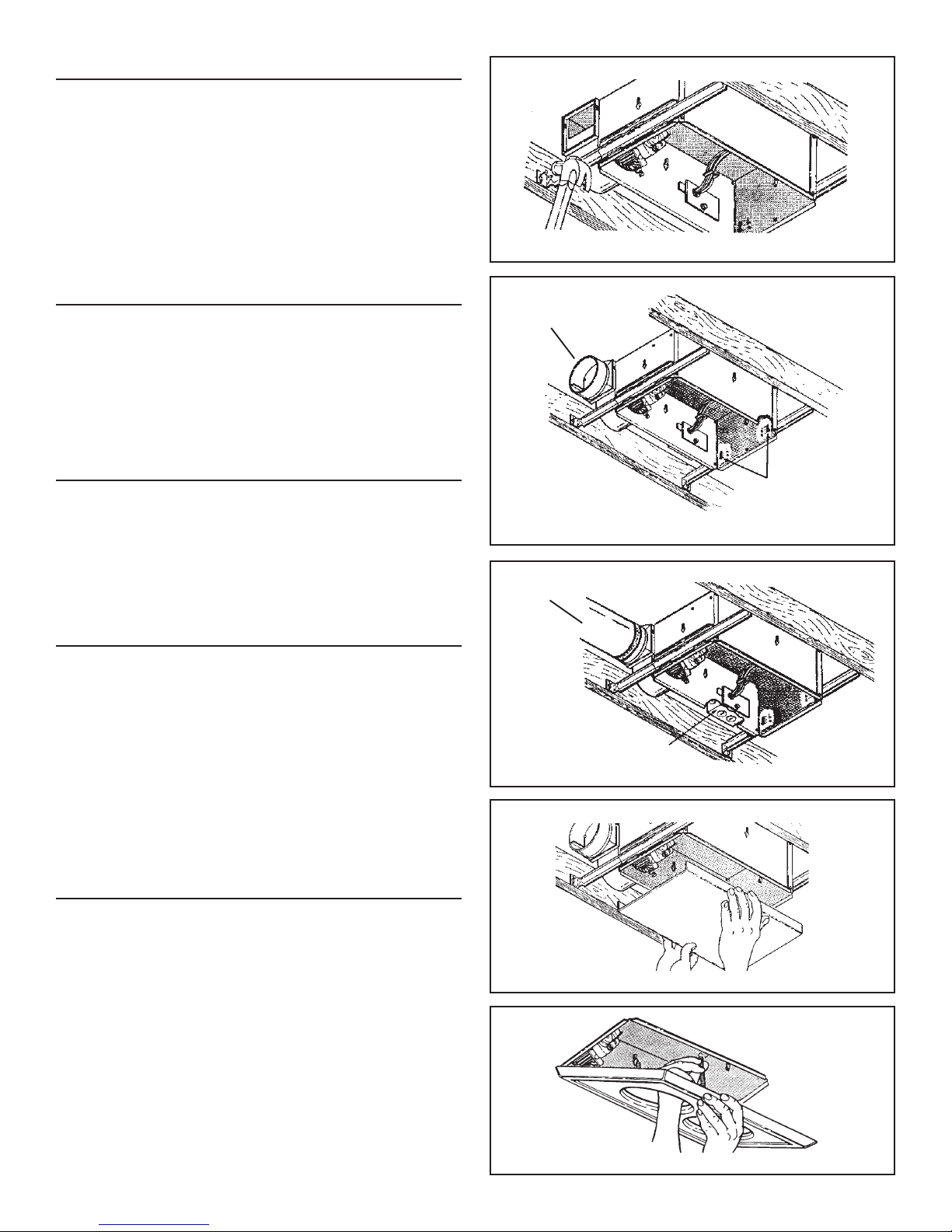

Refer to FIGURE 3

1. Position unit between joists and extend mounting brackets.

2. Nail brackets firmly to joists. Bottom of brackets should be

positioned flush with joist bottom.

Refer to FIGURE 4

3. Brackets are factory-set for ½" thick ceiling material. For thicker

ceilings, loosen 4 vertical adjusting screws and lower housing

to appropriate thickness on gauges. Tighten vertical adjusting

screws firmly.

ATTACH DUCTWORK

(MODELS 9417DNM & 9425WHC ONLY)

Refer to FIGURE 4

1. Snap the damper/duct connector onto housing. Make sure

that tabs on the connector lock in housing slots and that gravity closes damper.

2. Attach 4" round duct to damper/duct connector and run

ductwork to the outside through a roof or wall cap. Check

damper to make sure it opens freely. Tape all joints to make

them secure and air tight.

WIRE THE HEATER

Refer to FIGURE 5

1. Remove wiring box from side of housing. Remove knockout(s)

and connect power cable(s) to wiring box using proper CSA

approved connector.

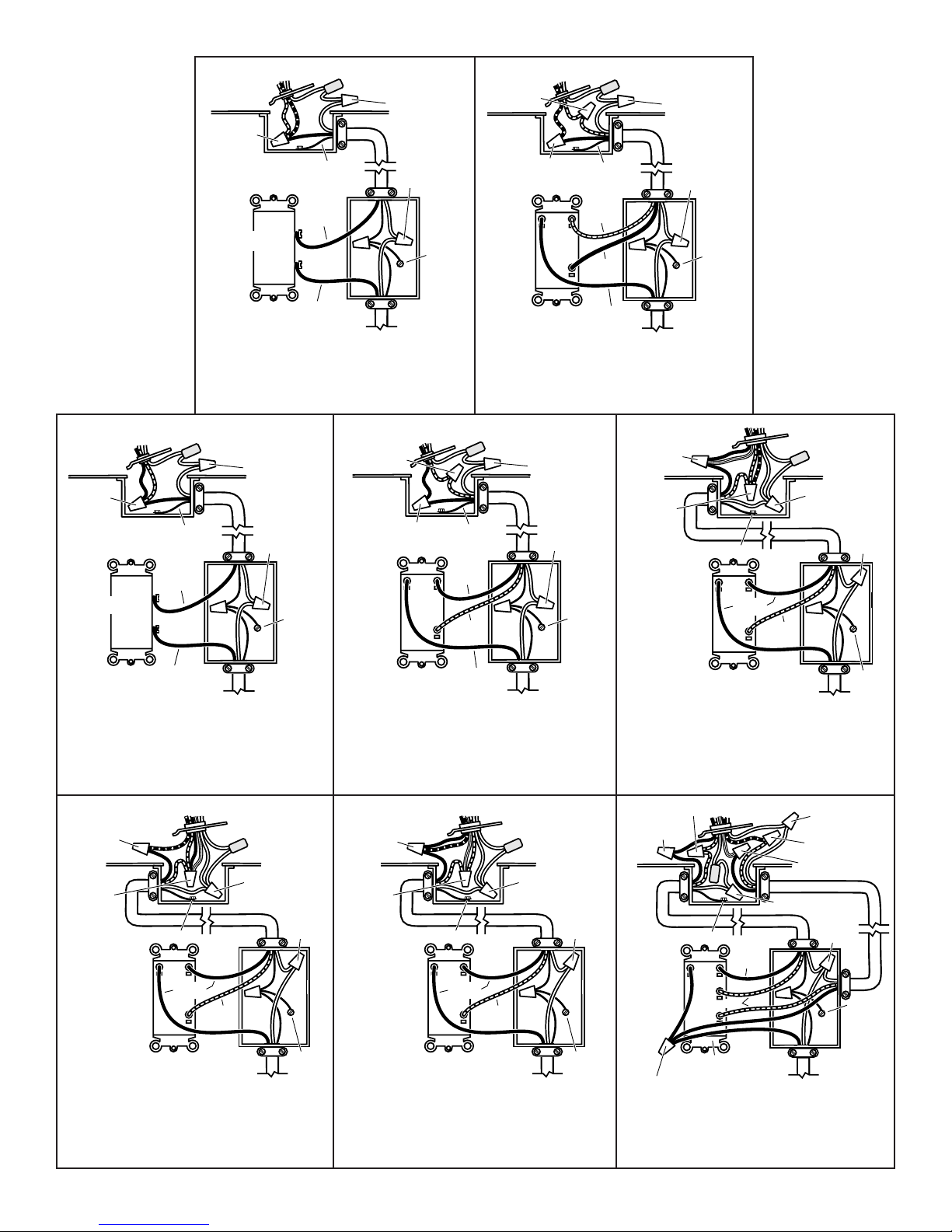

Refer to FIGURE 6 (on page 3)

2. Wire unit as indicated in appropriate diagram. Push all wiring

into wiring box and replace wiring box onto housing.

FIGURE 3

DAMPER/DUCT

CONNECTOR

VERTICAL ADJUSTING

SCREWS

FIGURE 4

4” ROUND

DUCT

FINAL ASSEMBLY

Refer to FIGURE 7

1. Protect motor, bulb sockets and wiring from construction dust,

drywall spray, paint, etc. by using the plaster shield. Cut it from

the carton and follow directions printed on it.

2. Finish all ceiling work as necessary.

3. Remove plaster shield and check if bottom of housing is flush

with finished ceiling. If not, loosen vertical adjusting screws,

reposition housing, and retighten screws.

Refer to FIGURE 8

4. Attach grille by hooking springs onto clips on side of housing.

5. Install BR40 or R40-size 250W infrared bulb(s). Center grille

around bulb(s).

USE AND CARE

MODELS 9417DNM & 9425WHC OPERATION NOTE: These units

are designed with a thermostat which senses excess heat and

may start the blower automatically. This is normal and is no cause

for concern.

DISCONNECT ELECTRIC POWER SUPPLY AND LOCK OUT

SERVICE PANEL BEFORE CLEANING OR SERVICING THIS

UNIT.

To clean fan assembly: Remove bulb(s). Unhook springs and remove grille. Loosen motor assembly mounting screws and rotate

assembly to remove it from housing. Gently vacuum fan, motor and

interior of housing. Reverse steps to replace fan assembly.

To clean grille assembly: Remove bulb(s). Unhook springs and

remove grille. Clean grille with mild soapy water. Use a mild detergent, such as dishwashing liquid. Dry with a soft cloth. DO NOT

USE ABRASIVE CLOTHS, STEEL WOOL PADS OR SCOURING

POWDERS.

Motor is permanently lubricated — Do not oil or disassemble motor.

WIRING BOX

FIGURE 5

FIGURE 7

FIGURE 8

2

Page 3

BLACK to

RED & BLUE

WHITE to

WHITE / GRAY

RED TO RED

WHITE to

WHITE / GRAY

BLACK to

BLACK

& RED

SWITCH OR TIMER

GROUND

BLACK

GROUND

BLACK

SWITCH OR TIMER

BLACK

120 VAC LINE IN

MODEL 9417DNM

Lamp & Vent operate together

WHITE to

WHITE / GRAY

WHITE to

WHITE

GROUND

RED to RED

BLACK to BLACK

LIGHT

HEAT

WHITE

to WHITE

GROUND

GROUND

BLACK

BLACK TO BLUE

HEAT

VENT

DUAL CONTROL

GROUND

RED

BLACK

BLACK

MODEL 9417DNM

Lamp & Vent operate separately

WHITE to

WHITE / GRAY

WHITE to

WHITE

RED

GROUND

120 VAC LINE IN

BLACK to BLACK,

& YELLOW

RED to RED

& BLUE

LIGHT

VENT & HEAT

WHITE to

WHITE

GROUND

GROUND

BLACK

3 WHITE / GRAY WIRES

RED

WHITE to

WHITE

BLACK

MODEL 9420WHC

Lamps operate together

BLACK to

BLUE

RED to RED,

BLACK &

YELLOW

GROUND

VENT

HEAT & LIGHT

BLACK

DUAL CONTROL

MODEL 9425WHC

Lamps operate together –

Vent separately

120 VAC LINE IN

3 WHITE / GRAY WIRES

RED

120 VAC LINE IN

WHITE to

WHITE

GROUND

DUAL CONTROL

BLACK

120 VAC LINE IN

MODEL 9420WHC

Lamps operate separately

BLACK to

BLACK, & BLUE

RED to RED

& YELLOW

GROUND

LIGHT

& VENT

HEAT

BLACK

RED

DUAL CONTROL

MODEL 9425WHC

Light & Vent operate together –

Heat separately

3 WHITE / GRAY WIRES

WHITE to

WHITE

GROUND

120 VAC LINE IN

DUAL CONTROL

120 VAC LINE IN

MODEL 9425WHC

Vent & Heat operate together –

Light separately

RED to RED

BLACK to BLACK

LIGHT

HEAT

VENT

3 BLACK WIRES

GROUND

BLACK

RED

3-FUNCTION CONTROL

WHITE to WHITE

RED to BLUE

BLACK to YELLOW

WHITE to WHITE / GRAY

3 WHITE

WIRES

120 VAC LINE IN

MODEL 9425WHC

Light, Vent & Heat operate separately

GROUND

GROUND

3

FIGURE 6

Page 4

PARTS LIST

9420WHC-R01 9425WHC-R01 9417DNM-R01

REF. PART NO. PART NO. PART NO. DESCRIPTION

1 97010320 97010320 97010319 Grille Assembly

(Includes Ref. No. 2)

2 06170-00 06170-00 06170-00 Grille Spring (2 Req.)

3 97009724 97010254 97010254 Motor

4 76230-00 98007352 98007352 Motor Mounting Bracket

5 99770033 99770033 99770033 Bulb Holder

6 99770037 99770037 - - - - Bulb Holder

7 - - - - 97010255 97010255 Blower Wheel

97009762 - - - - - - - - Fan Blade

MODEL 9420WHC-R01

MODEL 9417DNM-R01

3

4

5

2

MODEL 9425WHC-R01

7

WARRANTY

BROAN-NUTONE ONE YEAR LIMITED WARRANTY

Broan-NuTone warrants to the original consumer purchaser of

our products that such products will be free from defects in

materials or workmanship for a period of one year from date of

original purchase. THERE ARE NO OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING, BUT NOT LIMITED

TO, IMPLIED WARRANTIES OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone will, at our option,

repair or replace, without charge, any product or part which is

found to be defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT

LAMP STARTERS AND TUBES. This warranty does not cover

(a) normal maintenance and service or (b) any products or parts

which have been subject to misuse, negligence, accident, improper maintenance or repair (other than by us), faulty installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year

period as specified for the express warranty. Some states do

not allow limitation on how long an implied warranty lasts, so

the above limitation may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR REPLACE,

AT OUR OPTION, SHALL BE THE PURCHASER'S SOLE AND

EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROANNUTONE SHALL NOT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR

IN CONNECTION WITH PRODUCT USE OR PERFORMANCE. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitations

or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights, which vary from state to state. This warranty

supersedes all prior warranties.

To qualify for warranty service, you must (a) notify us at an address stated below or telephone 1-888-882-7626, (b) give the

model number and part identification and (c) describe the nature of any defect in the product or part. At the time of requesting warranty service, you must present evidence of the original

purchase date.

Broan-NuTone Canada, Inc.

1140 Tristar Drive

Mississauga, Ontario L5T 1H9

(1-888-882-7626)

Product specifications subject to change without notice.

1140 Tristar Drive, Mississauga, Ontario L5T 1H9

Printed in U.S.A., 3/02, Part No. 99043014D

4

1

Page 5

INSTRUCTIONS D’INSTALLATION

LISEZ ET CONSERVEZ CES INSTRUCTIONS

Ventilateurs à Lampe Chauffante

et à Éclairage

MODÈLES: 9417DNM, 9420WHC, 9425WHC

IMPORTANTES INSTRUCTIONS

DE SÛRETÉ

AVERTISSEMENT – POUR RÉDUIRE LES RISQUES D’INCENDIE, DE

CHOC ÉLECTRIQUE OU DE BLESSURE, VEUILLEZ OBSERVER LES

CONSIGNES SUIVANTES :

1. N’utilisez cet appareil que de la façon prévue par le fabricant. Pour

toute question, contactez le fabricant à l’adresse ou au numéro de

téléphone figurant dans la garantie.

2. Avant d’effectuer toute réparation ou nettoyage, coupez le courant au

panneau électrique et verrouillez le disjoncteur afin d’éviter que le

courant ne soit rétabli accidentellement. Si le disjoncteur ne peut être

verrouillé, accrochez une affiche ou une étiquette bien en vue sur le

panneau.

3. L’installation et les branchements électriques doivent être effectués

par un personnel compétent, conformément aux normes et aux codes

en vigueur, y compris les normes et les codes du bâtiment relatifs à la

résistance au feu.

4. Assurez un apport d’air suffisant pour la combustion et l’évacuation

adéquates des gaz par la cheminée de tout appareil de chauffage au

mazout et pour éviter les refoulements d’air. Suivez les instructions

du fabricant de l’appareil de chauffage et respectez les normes de

sécurité telles que celles publiées par la National Fire Protection

Association (NFPA), l’American Society for Heating, Refrigeration and

Air Conditioning Engineers (ASHRAE) et les autorités locales.

5. Lors du perçage ou du découpage d’un mur ou d’un plafond, prenez

garde de ne pas endommager le câblage électrique ni aucun élément

dissimulé.

6. N’installez pas cet appareil au-dessus d’une baignoire ou d’une

douche.

7. Ne placez jamais un interrupteur à un endroit accessible d’une

baignoire ou d’une douche.

8. N’actionnez pas cet appareil avec un gradateur ou un variateur de

vitesse.

ATTENTION

1. Cet appareil convient à des fins de ventilation générale uniquement.

Ne l’utilisez pas pour l’évacuation de matières ou de vapeurs

dangereuses ou explosives.

2. Ce produit est concu pour l’installation dans les plafonds plats

seulement. NE PAS POSER CE PRODUIT SUR UN MUR.

3. Pour éviter que les roulements du moteur soient bruyants ou s’abîment,

ou que la roue à ailettes soit déséquilibrée, assurez-vous qu’ils sont

exempts de poussière de plâtre ou de construction.

4. Veuillez lire l’étiquette des caractéristiques techniques du produit pour

de plus amples informations quant aux exigences.

PLANIFICATION DE L’INSTALLATION

Choisissez l’emplacement du ventilateur. Consultez les avertissements et

mises en garde ci-dessus.

MODÈLES 9417DNM ET 9425WHC SEULEMENT – L’appareil sera plus

efficace s’il est raccordé à un minimum de conduits et de coudes. Il est

conçu pour être utilisé avec un conduit rond standard de 4 po (10 cm).

Les appareils à deux ampoules (9420WHC et 9425WHC) peuvent être

équipés d’une lampe infrarouge (pour la chaleur) et d’un projecteur (pour

l’éclairage). Une commande double ou multiple peut commander

séparément les ampoules et le ventilateur. Ces commandes sont vendues

séparément.

Voir FIGURE 1

Lors de l’installation, suivez les étapes ci-dessous :

1. Clouez l’appareil aux solives.

2. Fixez les conduits de ventilation (modèles 9417DNM et 9425WHC

seulement)

3. Raccordez le câble d’alimentation électrique.

4. Fixez la grille au boîtier.

PRÉPARATION DU VENTILATEUR

1. Sortez l’appareil de son emballage. Conservez le carton pour protéger

les lieux contre la poussière de plâtre.

Voir FIGURE 2

2. Glissez les brides de montage réglables dans les rails du boîtier.

CLAPET/

RACCORD DE

CONDUIT

SOLIVE DU

PLAFOND

MATÉRIAU DE

PLAFOND

CÂBLE ÉLECTRIQUE

BOÎTIER

AMPOULE(S)

GRILLE

BRIDE DE

MONTAGE

FIGURE 1

FIGURE 2

5

Page 6

INSTALLATION DU VENTILATEUR

Voir FIGURE 3

1. Positionnez l’appareil entre les solives et allongez les brides de montage.

2. Clouez solidement les brides sur les solives. Assurez-vous que le

bas des brides est à égalité avec le bas des solives.

Voir FIGURE 4

3. Les brides sont réglées à l’usine pour des plafonds de 1/2 po (12 mm)

d’épaisseur. Pour des plafonds plus épais, desserrez les quatre vis

de réglage vertical et abaissez le boîtier à l’épaisseur appropriée

selon les marques de repère. Resserrez fermement les vis.

FIXATION DES CONDUITS

(MODÈLES 9417DNM ET 9425WHC SEULEMENT)

Voir FIGURE 4

1. Enclenchez le clapet/raccord de conduit sur le boîtier. Assurez que

les languettes du raccord sont bien bloquées dans les fentes du

boîtier et que le clapet se referme par gravité.

2. Fixez un conduit rond de 4 po (10 cm) au clapet/raccord de conduit et

acheminez-le jusqu’à l’extérieur à un chapeau de toit ou de mur.

Assurez-vous que le clapet s’ouvre librement. Appliquez du ruban

adhésif sur les joints pour qu’ils soient solides et étanches.

CÂBLAGE DU VENTILATEUR

Voir FIGURE 5

1. Retirez la boîte de connexion du côté du boîtier. Enlevez les pastilles

nécessaires et raccordez les câbles électriques à la boîte de connexion

à l’aide d’un connecteur approprié homologué CSA.

Voir FIGURE 6 (page 7)

2. Branchez les fils tel qu’indiqué dans le diagramme correspondant.

Repoussez tous les fils dans la boîte de connexion et replacez celleci dans le boîtier.

FIGURE 3

CLAPET/RACCORD

DE CONDUIT

VIS DE RÉGLAGE

VERTICAL

FIGURE 4

CONDUIT ROND 4 po (10 cm)

ASSEMBLAGE FINAL

Voir FIGURE 7

1. Protégez le moteur, les réceptacles d’ampoule et les fils contre la

poussière de construction, le plâtre ou la peinture à l’aide de l’écran

protecteur inclus. Découpez celui-ci dans la boîte de carton et suivez

les instructions imprimées sur l’écran protecteur.

2. Effectuez si nécessaire les travaux de finition du plafond.

3. Enlevez l’écran protecteur et vérifiez si le dessous du boîtier est au

ras du plafond fini. Dans le cas contraire, desserrez légèrement les

vis de réglage vertical, repositionnez le boîtier et resserrez les vis.

Voir FIGURE 8

4. Fixez la grille en accrochant les ressorts sur les attaches du côté du

boîtier.

5. Installez une ou deux lampes à infrarouge BR40 ou R40 de 250W.

Centrez la grille autour des lampes.

UTILISATION ET ENTRETIEN

FONCTIONNEMENT DU MODÈLES 9417DNM ET 9425WHC: Ce modèle

comporte un thermostat pour détecter les excès de chaleur et actionner

automatiquement le ventilateur. Il s’agit d’un fonctionnement normal et il n’y

a pas lieu de s’en inquiéter.

COUPEZ LE COURANT ET VERROUILLEZ LE PANNEAU ÉLECTRIQUE

AVANT DE NETTOYER OU DE RÉPARER CET APPAREIL.

Nettoyage du ventilateur : Enlevez les ampoules. Décrochez les

ressorts et retirez la grille. Desserrez les vis de montage du groupe

moteur et tournez-le pour le sortir du boîtier. Passez doucement l’aspirateur

sur le ventilateur, le moteur et l’intérieur du boîtier. Replacez le ventilateur

en inversant la marche à suivre.

Nettoyage de la grille : Enlevez les ampoules. Décrochez les ressorts

et retirez la grille. Nettoyez la grille à l’eau et au savon. Utilisez un détergent

doux, tel que du liquide à vaisselle. Essuyez-la avec un chiffon doux.

N’UTILISEZ PAS DE CHIFFONS ABRASIFS, DE LAINE D’ACIER OU DE

POUDRES À RÉCURER.

Le moteur est lubrifié à vie – Ne pas huiler ou démonter le moteur.

BOÎTE DE CONNEXION

FIGURE 5

FIGURE 7

FIGURE 8

6

Page 7

ENTRÉE

120 VCA

TERRE

LUMIÈRE

COMMANDE

DOUBLE

3 FILS

BLANCS / GRISS

VENT. et

CHALEUR

NOIR au

NOIR et

JAUNE

ROUGE au

ROUGE et

BLEU

TERRE

ROUGE

BLANC au

BLANC

NOIR

NOIR au

ROUGE et

BLEU

TERRE

BLANC au

BLANC / GRIS

BLANC

au

BLANC

ROUGE au

ROUGE

NOIR au BLEU

TERRE

BLANC au

BLANC / GRIS

BLANC

au

BLANC

NOIR au

NOIR

et ROUGE

INERRUPTEUR OU

MINUTERIE

TERRE

NOIR

INTERRUPTEUR ou

MINUTERIE

MODÈLE 9417DNM

Lampe et ventilateur

fonctionnant ensemble

BLANC au

BLANC / GRIS

BLANC au

BLANC

TERRE

NOIR

NOIR

ENTRÉE

120 VCA

ROUGE au

ROUGE

NOIR au NOIR

LUMIÈRE

CHALEUR

TERRE

TERRE

NOIR

ROUGE

CHALEUR

VENT.

COMMANDE

ROUGE

NOIR

NOIR

DOUBLE

MODÈLE 9417DNM

Lampe et ventilateur

fonctionnant séparément

BLANC au

BLANC/GRIS

BLANC au

BLANC

TERRE

ENTRÉE

120 VCA

TERRE

NOIR

ENTRÉE

120 VCA

MODÈLE 9420WHC

Lampes fonctionnant ensemble

NOIR au

BLEU

3 FILS

ROUGE

BLANCS / GRIS

BLANC au

BLANC

ENTRÉE

120 VCA

TERRE

ROUGE au

ROUGE, NOIR

et JAUNE

TERRE

VENT.

NOIR

CHALEUR et

LUMIÈRE

Lampes fonctionnant ensemble –

ventilateur séparément

COMMANDE

DOUBLE

MODÈLE 9425WHC

COMMANDE

DOUBLE

NOIR

ENTRÉE

120 VCA

MODÈLE 9420WHC

Lampes fonctionnant séparément

NOIR au

NOIR et BLEU

ROUGE

3 FILS BLANCS / GRIS

ENTRÉE

120 VCA

ROUGE au

ROUGE et

JAUNE

LUMIÈRE

et

VENT.

CHALEUR

TERRE

NOIR

COMMANDE

DOUBLE

MODÈLE 9425WHC

Lampe et ventilateur fonctionnant

ensemble – chaleur séparément

7

BLANC au

BLANC

TERRE

MODÈLE 9425WHC

Ventilateur et chaleur fonctionnant

ensemble – lampe séparément

ROUGE au ROUGE

NOIR au NOIR

LUMIÈRE

CHALEUR

VENT.

3 FILS NOIRS

TERRE

ROUGE

COMMANDE

TRIPLE

NOIR

BLANC au BLANC

ROUGE au BLEU

NOIR au JAUNE

BLANC au BLANC / GRIS

BLANCS

ENTRÉE

120 VCA

MODÈLE 9425WHC

Lampe, ventilateur et chaleur

fonctionnant séparément

3 FILS

TERRE

FIGURE 6

Page 8

PIÈCES DE RECHANGE

O

9420WHC-R01 9425WHC-R01 9417DNM-R01

N

REP. NUM. PIÈCE NUM. PIÈCE NUM. PIÈCE DESCRIPTION

1 97010320 97010320 97010319 Ensemble de grille

2 06170-00 06170-00 06170-00 Ressort de grille (2 Req.)

3 97009724 97010254 97010254 Moteur

4 76230-00 98007352 98007352 Support de montage du

5 99770033 99770033 99770033 Réceptacle d’ampoule

6 99770037 99770037 - - - - Réceptacle d’ampoule

7 - - - - 97010255 97010255 Roue à ailettes

97009762 - - - - - - - - Hélice

(inclut no de rep. 2)

moteur

MODÈLE 9417DNM-R01

5

MODÈLE 9420WHC-R01

MODÈLE 9425WHC-R01

3

4

7

GARANTIE

GARANTIE LIMITÉE D’UN AN BROAN-NUTONE

Broan-NuTone garantit à l’acheteur original que ses produits

sont exempts de tout défaut de matériel ou de fabrication pour

une période d’un an à compter de leur date d’achat initiale. IL

N’Y A PAS D’AUTRES GARANTIES EXPRESSES OU

IMPLICITES, Y COMPRIS, NOTAMMENT, LES GARANTIES

IMPLICITES DE QUALITÉ MARCHANDE OU D’ADÉQUATION

À UN USAGE PA RTICULIER.

Pendant cette période d’un an, Broan-NuTone, à son choix,

réparera ou remplacera gratuitement tout produit ou pièce

s’avérant défectueux dans des conditions normales

d’utilisation et de service.

CETTE GARANTIE NE COUVRE PAS LES DÉMARREURS DE

LAMPES FLUORESCENTES NI LES TUBES. Cette garantie

ne couvre pas (a) l’entretien et le service normal ou (b) les

produits ou les pièces endommagés par suite d’un mauvais

usage, d’une négligence, d’un accident, d’un entretien ou d’une

réparation inadéquat s (autre que p a r Broan-NuTone), d’une

installation inadéquate ou contraire aux instructions. La durée

de toute garantie implicite est limitée à une période d’un an,

tel que stipulé pour la garantie expresse.

L’ENGAGEMENT DE BROAN-NUTONE À RÉPARER OU

REMPLACER LE PRODUIT, À SON CHOIX, CONSTITUE

EXCLUSIVEMENT SA SEULE OBLIGATION DANS LE CADRE

DE CETTE GARANTIE. BROAN-NUTONE NE PEUT ÊTRE

TENUE RESPONSABLE DES DOMMAGES ACCESSOIRES,

CONSÉCUTIFS OU PA RTICULIERS DÉCOULANT

DIRECTEMENT OU NON DE L’UTILISATION OU DU

RENDEMENT DE SES PRODUITS.

Cette garantie vous confère des droits légaux spécifiques

auxquels peuvent s’ajouter d’autres droits. Cette garantie

remplace toutes les garanties antérieures. Pour recourir au

service de garantie, vous devez (a) aviser Broan-NuTone à

l’adresse ci-dessous ou, par téléphone, au 1-888-882-7626,

(b) indiquer le numéro du modèle et de la pièce et (c) décrire

la nature de la défectuosité du produit ou de la pièce. T oute

demande de garantie doit être accompagnée de la facture

originale.

Broan-NuTone Canada, Inc.

1140 Tristar Drive

Mississauga, Ontario L5T 1H9

(1-888-882-7626)

Caractéristiques de produit sujet au

changement sans communication préalable.

1140 Tristar Drive, Mississauga, Ontario L5T 1H9

Printed in U.S.A., 3/02, Part No. 99043014D

8

2

1

Loading...

Loading...