SPL 3200

Automotive lift date: 07/2000

Manual date: 07/2000

Operating instruction and documentation

s e r i a l - n u m b e r : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

retailer addresse / phone

Nußbaum Hebetechnik GmbH & Co. KG || Korker Straße 24 || D-77694 Kehl-Bodersweier ||

Tel: +49 (0) 78 53/89 90 || Fax +49 (0) 78 53/87 87 ||

E-mail: info@nussbaum-lifts.de || http://www.nussbaum-lifts.de ||

Instruction and Documentation

SPL 3200

Table of contents

Record of Installation............................................................................................. 3

Record of handing over...........................................................................................4

1. Introduction........................................................................................ 5

2. Master Document of the automotive lift.......................................... 6

Attestation of conformity....................................................................................... 7

3. Technical Information........................................................................ 8

Data Sheet over floor..............................................................................................9

Foundation plan ..................................................................................................... 10

Electrical diagram drawing (standard version).......................................................11

Electrical clamped connection drawing..................................................................12

Electrical diagram drawing (single phase Canada version)....................................13

Electrical diagram drawing (three phase Canada version).....................................14

Electrical diagram drawing (single phase USA version)........................................15

Hydraulic diagram drawing.................................................................................... 16

4. Safety regulations............................................................................... 17

5. Operating instructions....................................................................... 17

6. Troubleshooting...................................................................................19

Emergency lowering...............................................................................................20

Torn rope.................................................................................................................21

7. Maintenance........................................................................................ 22

8. Security check......................................................................................22

9. Installation and Initiation...................................................................23

Installation of the lift...............................................................................................23

Regulations for installation.....................................................................................23

Erection and doweling of the lift........................................................................... 23

Initiation..................................................................................................................26

Changing of the installation place.......................................................................... 26

Appendix

Document ”First security check before Installation”

Document ”Regular security check”

Document ”Extraordinary security check”

Spare parts list

2

Send this record, filled in and undersigned, to the

automotive manufacturer after the installation

Otto Nußbaum GmbH & Co.KG

Korker Straße 24

777694 Kehl-Bodersweier

Germany

Record of installation

Instruction and Documentation

SPL 3200

The automotive lift SPL 3200 with the

serial number.: ................................... was installed on .........................................................

at the firm........................................... a t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the safety was checked and the lift was startet.

The installation was effected from the operating authority / competent (please delete as applicable)

The safety of the automotive lift was checked from the competent before the initial operation

The operating authority attest the installation of the automotive lift, the competent attest the correct

initial operation.

.............................. ................................................ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

date name of the operating authority signature of the operating authority

.............................. ................................................ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

date name of the competent signature of the competent

3

Instruction and Documentation

SPL 3200

Record of handing over

The automotive lift SPL 3200 with the

serial number.: ................................... was installed on .........................................................

at the firm........................................... a t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the safety was checked and the lift was startet.

The persons below were introduced after the installation of the automotive lift. The introduction

was carried out from an erector of the lift-manufacturer or from a franchised dealer (competent).

.............................. ........................................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

date name signature

.............................. ........................................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

date name signature

.............................. ........................................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

date name signature

.............................. ........................................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

date name signature

.............................. ........................................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

date name signature

.............................. ........................................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

date name of the competent signature of the competent

4

1 . I n t ro d u c t i o n

Instruction and Documentation

The document ”Operating Instructions and Documentation” contains important

infomation about installation, running and preserving of the automotive lift.

To furnish proof of installation of the automotive lift the form ”Record of Installation”

must be sent undersigned to the manufacturer.

To furnish proof of the single, regular and special security checks this documentation

contains forms. The forms should be used to document the checks. They should also be

left in this documentation.

Every Changes in the construction and changing place of the automotive lift must be

registered in the ”Master document” of the lift.

Installation and check of the automotive lift

Only specialist staff is allowed to do the works concerning safety and to hold the safety

checks of the lift. They are called experts and competents in this document.

Experts are persons (for example self-employed engineers, TÜV-experts) which have

got an instruction and experience to check and to test automotive lifts in an

e x p e r t ’s report. They know the signified regulations for protection of labour and

prevention of accidents.

Competents are persons which have got enough knowledge and experience with

automotive lifts. They took part in a training from the lift-manufacturer

(servicing erectors of the manufacturer and the franchised dealer are

Competents)

Information of danger

To show danger and to show important information the three symbols below with the

special meanings are used. Pay attention of those passages, which are marked with these

symbols

D a n g e r !

This sign marks a danger to life. Inexpert handling of the marked series of

event ist dangerous to life

C a u t i o n !

This sign marks a caution against possible damage of the automotive lift or

other material defects in case of inexpert handling .

I n d i c a t i o n !

This sign marks an indication for an important function or for another

important note.

5

Instruction and Documentation

SPL 3200

2 . Master document of the automotive lift

Lift designation SPL 3200

Lift-manufacturer Otto Nußbaum GmbH & Co.KG

Korker Straße 24

77694 Kehl-Bodersweier

Germany

Application

The automotive lift SPL 3200 is a lifting stage for lifting vehicles with a laden weight of

3200 kg and a max. load sharing of 2:1 in and against drive-on direction. The lift is

equipped for working under the load. It is not allowed to enter the load or to carry persons

with it.

Changes of construction, repairings and changes of place must be registered

in this master document

Changes of the construction, expert checking, resumption of work (date, kind of

change, signature of the expert)

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . .

...........................................................................................................................................

name, address of the expert

............................................................ .................................................................

place, date signature of the expert

Change of automotive-lift-place, expert checking, resumption of work (date, address

and signature of the competent)

...........................................................................................................................................

name, address of the competent

............................................................ .................................................................

place, date signature of the competent

6

Instruction and Documentation

SPL 3200

7

3 . Technical Information

Technical ratings

Lifting capacity: 3200 kg

Load sharing: max. 2:1 in or against drive-on

Lifting time: ca. 32 sec

Lowering time: ca. 41 sec

lifting capacity: 1740 mm

Line voltage: 3 x 400V, 50 Hz (standard)

Driving voltage: 220 V

Power rating: 3.0 kW (standard)

Instruction and Documentation

SPL 3200

direction

(observe the power supply of your state)

Motor speed: 2800 revolution/minute

Output oil-pump: 3 ccm/revolution

Hydraulic pressure: 185 bar

Responsing pressure of pressure relief valve: 215 bar

Hold-up oil tank: ca. 8 Liter

Sound level (measured at operating panel) ≤ 75 dBA

Safety devices

1. Ratchets

safety device of the load against unintentional lowering when the

hydraulic system isn’t tight any more

2. Screens at hydraulic cylinder

safety device for slow lowering in case of pipe breaking

3. Lockable main switch

safety device against unauthorized using

8

Data sheet

Instruction and Documentation

SPL 3200

command unit

9

Foundation plan

Instruction and Documentation

SPL 3200

1 0

Quality of the concrete B25

Instruction and Documentation

Electrical diagram drawing(standard version)

fuse

3xT 16 A

by customers

by customers

automotive lift

SPL 3200

Parts list for electrical diagram

A1: reversing switch for lifting

M1: motor 3,0 kW

F1: thermofuse in motor

K1: up contactor

A1, A2: clamped connections

1-6: clamped connections

U;V;W: clamped connections

1 1

Clamped connection drawing

Instruction and Documentation

SPL 3200

1 2

Instruction and Documentation

SPL 3200

Electrical diagram drawing (single phase Canada version)

1 3

Instruction and Documentation

SPL 3200

Electrical diagram drawing (Canada version 3 Phase)

1 4

Instruction and Documentation

Electrical diagram drawing (single phase USA)

SPL 3200

A1 main switch

M1 motor

1 5

Hydraulic diagram drawing

Instruction and Documentation

SPL 3200

Parts list of hydraulic diagram

0.1: oil-tank

0.2: motor

0.3: pump

0.4: oil-filter

0.5: oil-level gage

0.6: hydraulic block complete

0.7: holding valve

0.8: pressure relief valve

0.9: ball valve (lowering)

0.10: flow control holding valve

1.0: hydraulic cylinder

1 6

Instruction and Documentation

SPL 3200

4 . Safety r e g u l a t i o n s

Using automotive lifts for working the regulations of accident prevention EN1493/Aug.98

(CEN/TC 98“automotive lifts“ “european regulation“) must be observed.

Especially the following regulations are very important

• The laden weight of the lifted vehicle mustn’t be more than 3200 kg. The max. load

sharing is 2:1 in or against drive-on direction.

• During working with the lift the operating instructions must be followed.

• Only trained personnel over the age of 18 years old are to operate this lift.

• During lifting or lowering the vehicle it must be observed from the operator.

• It’s not allowed to stay under the lifted or lowered vehicle (except for the operator).

• It’s not allowed to transport passengers on the lift or in the vehicle.

• I t ’s not allowed to climb onto the lift during lifting or lowering or onto a lifted

vehicle.

• The Automotive Lift must be checked from an expert after changes in construction

or after repairing carrying pads.

• I t ’s not allowed to start with operations at the lift before the main switch is switched

off.

• Switching on or switching off the lift you have to take care that the lifting and

lowering movement are steady.

• It’s not allowed to install the standard-automotive lift in hazardous location.

5 . Operating instructions

The Safety Regulations must be observed during working with the automotive

lift. Read the safety regulations in chapter 4 carefully before working with the

lift!

The operating elements are shown in picture 1.

Lifting the vehicle with the SPL 3200

• Drive vehicle between the two columns, longitudinal directon and transverse

direction in centre.

• Safe the vehicle against rolling away, switch ino gear, activate parking brake

• Slew carrying arms under vehicle and position pads at the points which are provided

from the vehicle-manufacturer

• Control the dangerous places of the lift and be sure that there are no objects or

people in the immediate area of the lift or on the lift

• Turn operating (reversing) switch to position "↑" and hold position "↑" until the

wheels of the vehicle are free

1 7

Instruction and Documentation

SPL 3200

(front view)

(side view)

(side view)

pic. 1: operating elements

• When the wheels have been lifted free, stop with lifting; let go of operating

(reversing) switch and check safety sit of the pads under the vehicle.

The sit of the pads under the vehicle is very important. If the position

of the pads isn’t all right the vehicle might fall down!

Lifting great vehicles (transporter, cross country cars) pay attention that the roof

d o e s n ’t touch the traverse of the lift. In case the vehicle touches the traverse of

the lift, a switching off strip is pressed upside, which pulls the operating switch

via rod assembly to position ”0” , so the lift doesn’t lift any more. Afterwards the

operating switch can not be turned to position "↑"any more. However the lift can

still be lowered by pulling the operating lever (refer to ”lowering of the lift”).

After lowering the lift to the position where the switch off strip is free, the

operating switch is released and the lift can be lifted again.

• Lift vehicle on height for working; turn operating switch to position "↑", keep it

until height for working or top position is reached

1 8

Instruction and Documentation

SPL 3200

When the lift is lifted to top position the operating switchis pulled to

position ”0” with the help of a rod assembly. So lifting stops. Afterwards

the operating switch can not be turned to position "↑"any more. The lift

can only be lowered (as described in section ”lowering of the lift”). When

top position is left the operating switch is released and the lift can be lifted

again.

In case the operating switch is not pulled to position ”0” at top position

automaticly the ratchet -rope is slack or torn. Refer to chapter

”Troubleshooting” section ”torn rope”!

Lowering the vehicle with the automotive lift

• Control the dangerous places of the lift and be sure that there are no objects or

people in the immediate area of the lift or on the lift

• Lower the vehicle at the height for working or until the carrying arms reach the

lowest position; Pull operating lever ”lowering” (= lever left side) until height for

working or until lowest position.

Attention! while using lever ”lowering”, both levers (”lowering” and

”lowering in ratchet” will be activated!)

• When the lift is in lowest position, slew carrying arms inside and drive vehicle out

of the lift

Lowering the the automotive lift in ratchet

• Control the dangerous places of the lift and be sure that there are no objects or

people in the immediate area of the lift or on the lift

• Lower the vehicle in ratchet; pull operating lever ”lowering in ratchet” (= lever right

side).

Attention! Before going on with ”lowering” , lift the lift first a little bit

until the ratchet is not engaged any more, then go on with lowering!

6 . Tro u b l e s h o o t i n g

If the lift does not work properly, the reason for this might be quite simple. Please check

the lift for the potential reasons mentioned on the following pages. If the cause of

trouble cannot be found, please call the technical service.

Repairs at the lift’ s security devices as well as repairs and examinations of the

electrical fittings may only be performed by specialists.

1 9

Instruction and Documentation

SPL 3200

Problem: Motor does not start, lift is neither lifting nor lowering!

Potential causes • Fuse is defective: replace fuse

of trouble: • Feed line is cut

• Motor is overheated: let it cool down for app. 10 min.

Problem: Lift is not lifting!

Potential causes • Level of hydraulic oil is too low

of trouble: • In case of cold weather the hydraulic oil is too viscous

• ball-valve defective or dirty

• coupling between motor and pump is defective

• oil-filter in tank is dirty

• things (nuts, screws...) are in the columns and block the low lift

platform truck

• height limit switch is activated

Problem: lift cannot be lowered!

Potential causes • lift is driven onto an obstacle

of trouble: • equalisation ropes are too tight. Make sure that the ropes are fastened

(refer to capter ”Installation and Initiation”)

• Ratchets are engaged: move the lift up before lowering.

• In case of cold weather the hydraulic oil is too viscous

• ratchet-rope is torn; (refer to emergency lowering)

roblem: lift lowers by itself until the ratchet is engaged

Potential causes • holding valve isn’t tight or dirty

of trouble: • ball-valve is leck or dirty

Problem: lift is jerked while lowering

Potential causes • equalisation ropes are too tight, check course of the ropes

of trouble: (refer to ”installation and initiation”)

• air is in oil circulation;deaerate (refer to ”installation and initiation”)

Problem: operating (reversing) switch is not pulled back

mögliche Ursachen: • safety-rope is torn (refer to ”torn-rope”)

• safety-rope is slack (refer to ”torn-rope”)

Emergency lowering

If the ratchet-rope is torn the lift can not be lowered any more because one or two ratchets

are engaged. In this case there is the possibility to lower the lift by unlocking the ratchets

manually.

The emergency lowering must only be performed by persons instructed to use

the lift. Please refer to the regulation ”Lowering”.

2 0

Instruction and Documentation

SPL 3200

Emergency lowering

• In case the ratchets are engaged turn operating switch to position "↑", lift it a little

bit until the ratchets are unlocked.

• Let go of operating switch and lock it in position "0"

• Take off coverings from ratchets and look which of the ratchet-ropes is torn.

• Pull back the relevant ratchet and lay a suitable support between ratchet-strip and

ratchet or fix the pulled back ratchet with the help of a wire to avoid reengaging of

the ratchet-tooth in the ratchet-strip. This measure is to do at this ratchet where the

ratchet-rope is torn.

• Lower vehicle to lowest position (as described in chapter ”operating instructions”).

Refer to the regulations ”Lowering”

• Take off support or wire from ratchets that the can engage again.

To guarantee the safe running of the lift the supports must be removed

from the ratchet to bring the ratchet in its normal function

• After finishing with emergency lowering reinstall coverings.

• When the lift is in lowest position, slew carrying arms inside and drive vehicle out

of the lift

After finishing with emergency lowering the lift must shut down until the

defective ratchet has been replaced.

Torn rope

In case the safety-rope is torn the height limit switch and the switch off strip under the

traverse is witchout function. The lift must shut down until the defective rope has been

replaced. The new safety-rope must be installed as described in the following instruction.

• Disconnect power supply (disconnect feed line)

• Hang up safety-rope at topside (see pic. 5) and pull it through the empty rope

guidance tube

• Hang up safety-rope in boring of the flat rolled steel (backside at operating switch).

Turn operating switch to position "↑" and adjust length of the rope that the rope is

streched not too much.

Streching of the safety-rope: a small activation of the switch-rod or of the

switch-off strip must pull the operating switch to position ”0”.

• Connect power supply

In case the safety-rope in not torn, only slack, the rope must only be adjusted again after

disconnecting the lift from power supply

2 1

Instruction and Documentation

SPL 3200

7 . M a i n t e n a n c e

A regular service has to be performed every three months by the lift’ s operator

according to the following schedule. If the lift is in continuous operation or dirty

environment, the maintenance rate has to be increased.

During daily operation the lift has to be watched carefully for its correct function. In

case of any malfunction or leakage the technical service has to be informed.

Maintenance schedule for the lift

• Clean and grease all moving parts (pull-outs of the carrying arms, rollers of the

lifting carriage guidances, hinge bolts of carrying arms)

• Check rubber supports of pads. in case they are worn change them.

• control ratchets: easy and smooth latching, lubricate striking surfaces

• check level of hydraulic oil

• Check the ropes.

• Check the welding of thelift.

The hydraulic oil has to be changed at least once a year. To change the oil lower the lift

into its lowest position. Empty the tank and replace the oil, approximately 8 litres are

needed. A high quality hydraulic oil is recommended, its viscosity should be 32 cst.

8 . Security check

The security check is necessary to guarantee the safety of the lift during use. It has to be

performed in the following cases:

1. Before the initial operation, after the first installation.

Use the form ”First security check”.

2. In regular intervals after the initial operation, at least annually.

Use the form ”Regular security check”.

3. Every time the construction of that particular lift has been changed.

Use the form ”Extraordinary security check”.

The first and regular security checks must be performed by a competent. It is

recommended to service the lift at this occasion.

After the construction of the lift has been changed (changing the lifting height

or capacity for example) and after serious maintenance works (welding on

carrying parts) an extraordinary security check must be performed by an expert.

This manual contains form with a schedule for the security checks. Please use the

adequate form for the security checks. The form should remain in this manual after they

have been filled out.

Instruction and Documentation

9 . Installation and Initiation

Installation of the lift

Regulations for the installation

• The installation of the lift is performed by trained technicians of the manufacturer

or its distribution partner. If the operator can provide trained mechanics, he can

install the lift by himself. The installation has to be done according to this

regulation.

• The standard lift must not be installed in hazardous locations or washing areas.

• Installing the lift you need at least a reinforcement of 3,5 cm2/m Fe, quality B 25

(DIN 1045) in both directions at the upper and lower side of the plate. The thickness

of the carrying concrete should be at least 200 mm. In case of other foundation or

ground conditions a foundation according to foundation plan (refer to foundation

plan) has to be provided: An even installation place has to be provided. The

foundations must be based in a frost resistance depth, both outside and indoors,

where you must reckon with frost

SPL 3200

• An electric supply (observe the power supply of your state) has to be provided. The

supply must be protected by customers (fuses). The electrical connection is located

in command unit.

• All cable ducts have to be equipped with protective coverings to prevent accidents.

Erection and doweling of the lift

• Install the lift according to the data sheet and the foundation plan and line it up.

• Put both synchronizing ropes over the rolls at the top and insert them from the upper

side in column. The ropes must not be crossed!

• Connect hydraulic hose between the two columns. Don’t fix connection at opposite

side too tight and don’t fasten the connection. Be sure that hydraulic hose doesn’t

hinder the course of the synchronizing ropes.

• Put traverse topside on columns and fix it with enclosed cylinder screws and

washers

• Connect oil-return line (synthetic material) at both columns (see pic. 4)

• Check position of the lift

• Bore holes to fix the dowels through the borings of the base plates. Clean holes with

pressure air. Put in safety dowels with washers in borings. The manufacturer

demands LIEBIG safety dowels type B 20 or equal dowels of another manufacturer.

Before doweling check concrete floor with quality B 25 if the concrete floor goes to

the top edge of the floor. In this case the dowels have to be chosen according to

picture 2. If the ground is covered with floor tiles, the dowels have to be chosen

2 3

Instruction and Documentation

SPL 3200

according to picture 3.

• Check line-up of the columns and look if they are vertical. If they aren’t vertical

correct with suitable bases.

• Tighten the Liebig-dowels with a dynamometric key (M = 80 Nm).

Each Liebig-dowels must be tightened with a torque of 80 Nm. The normal

function of the lift cannnot be guaranteed (Liebig = german dowel

manufacturer).

• Connect power supply. The cable entry is at topside of operating column (standard

version).

• Fill oil-tank with oil: viscosity 32 cst, hold-up: approximatly 8 litre.

• pull ratchet back and lay a suitable support between ratchet strip and ratchet or fix

theratchet, which is pulled back with a wire, to avoid engaging of the ratchet tooth

in ratchet strip.

• Turn operating switch to position "↑": Only one side of the lift is lifted. Lift the lift

until oil comes out of the loosen threaded joint at topside of opposite column.

• Fasten threaded joint at top of opposite side.

• Load this carriage which has got a higher position (stand on it) and turn

simultaneously operating switch to position "↑". Only that carriage without load is

lifted. That carriage must be lifted until the carriage at the operating side is 10 cm

higher than the carriage at the opposite side.

• Dismount pulley at lower side in column (opposite side) by loosing the circlip. Lay

loosen synchronizing rope from topside round the pulley and remount pulley with

rope.

Secure pulley with washer and circlip while installing it.

• Insert synchronizing rope from lower side in ratchet strip which is fixed at lower

side of carriage. Insert thread bolt at end of the rope through bore-hole which is

located at hang up of the rope topside at ratchet strip.

• Screw self-locking nut approximatly 4 turns on thread bolt to fix the rope safely at

carriage.

• Load carriage of operating side (stand on it) and turn operating switch to position

"↑". Only the opposite side of the lift is liftet.

• Lift opposite side until carriage of operating side is lifted.

• Mount second rope in operating column as well.

• Fasten self-locking nuts at upper side in both carriages regulary until both ropes are

tighten lightly. If the thread at upper side of carriage is too short, the self-locking nut

at the other side carriage (lower side) must be fastened accordingly.

2 4

Instruction and Documentation

SPL 3200

• Lower automotive lift to lowest position and lift it afterwards 500 - 600 mm. Both

ropes must be tightened lightly. In any other case the self-locking nuts at the upper

side ob both carriages must be adjusted again.

Pay attention that each of the two ropes is tightened regulary and that it is

not too slack, otherwise exactly synchronization can not be guaranteed.

Pay attention that the ropes are not too tight, otherwise there is the

possibility that the lift jerks, or that the lift is too slow while lowering

The ropes don’t carry load. They must regulate an exactly synchronization

of the lift.

• Install carrying arms (refer to data sheet Power-Lift), lubricate bolts and secure

them with enclosured circlips at both ends.

The bolts of the carrying arms must be secured at both ends, otherwise a

safe connection between carriage and carrying arm can not be

guaranteed.

• Deaerating the lift: lower the lift to lowest position. loosen thread joint at lower side

of cylinder which must be deaerated. Lift the lift until oil comes out of the thread

joint. Now close the thread joint and fasten it.

In case the lift jerks while lowering there are two posibilities: the

synchronizing ropes are too tight or oil is in oil circulation (deaerate

according to instruction ahead)

• Loosen ratchet (now it the tooth of the ratchet can engage in ratchet strip again)

• Hang up long ratchet-rope with end nipple in ratchet at column of opposite side.

Take free end of the rope through rope-guidance tube to topside and afterwards take

it through the rope-guidance tubes at traverse and at column of operating side to

lower side again (see pic. 5).

• Mount thimble at end of the rope.

• Hang up ratchet-ropes with accompanying spring in operating lever ”lowering”;

operating lever is in initial position.

• The short ratchet-rope with end-nipple is already preassembled.

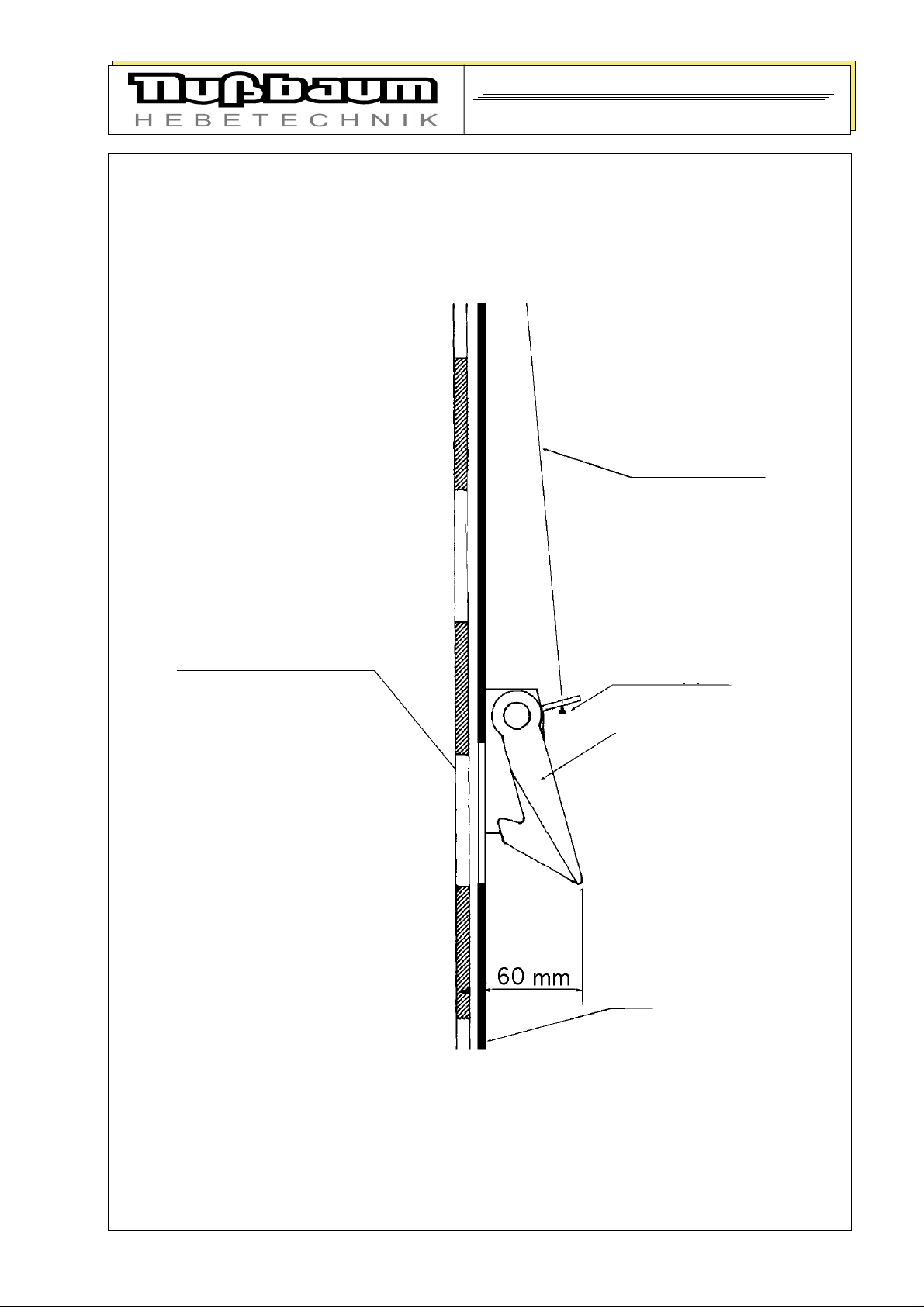

• Installing of the ratchet-ropes: Both ratchets mustn’t be engaged when operating

lever is completly pulled. The difference between backside of the ratchet and

column should be approximatly 60 mm (refer to pic. 6).

• For adjusting it might be necessary to loose one ratchet-rope and to strech the other

one to guarantee same position of both ratchets.

The ratchets must be free and their function must be guaranteed in any

case.

Instruction and Documentation

SPL 3200

Pay attention, that the ”switch-off covering” is smooth and that the lift is

switched off when the covering is pressed up. This covering is for

switching off the lift while lifting the lift the same time a vehicle drives

against it from upper side.

• Lift and lower the lift with vehicle several times, tighten dowels a second time (M

= 80 Nm).

Initiation

Before the initiation a security check must be performed. Therefore use form:

First security check.

If the lift is installed by a competent, he will perform this security check. If the operator

installs the lift by himself, he has to instruct a competent to perform the security check.

The competent confirms the faultless function of the lift in the installation record and

the form for the security check and allows the lift to be used.

Please send the filled installation record to the manufacturer after installation.

Changing of the installation place

If the place of installation shall be changed, the new place has to be prepared according

to the regulations of the first installation. The changing should be performed in accordance with the following points:

• lift carriage to medium height

• disconnect operating switch

• Take away current supply from lift

• Dismount carrying arms (remove circlips from carrying arm bolts, pull out carrying

arm bolts and take off carrying arm)

• Loosen long ratchet-rope

• Separate hydraulic connections between columns

• Dismount traverse support between the columns

• Empty oil-tank

• loosen dowels between base plate and floor and take off columns

• Transport lift to new installation place

• Install lift in accordance with chapter ”Installation and Initiation” of the lift.

Use new dowels, The used dowels cannot be used any more.

A security check must be performed before reinitiation by a competent. Use

form ”Regular security check”.

Instruction and Documentation

pic. 2: choice of dowel lengths (without floor pavement or tile surface)

SPL 3200

table to picture 5:

Liebig-safety dowels

type of dowel B20/175

Drilling depth a 225

min. anchorage depth b 1 7 0

thickness of concrete c 260

diameter of bor d 20

thickness of the Lift-piece e 0-65

You can use equivalent dowels from another manufacturer with licence, but observe their

regulations.

2 7

Instruction and Documentation

pic. 3: Choice of dowel lengths (with floor pavement or tile surface)

SPL 3200

table to picture 3:

type of dowel B20/175 B20/225

Drilling depth a 225 275

min. anchorage depth b 1 7 0 1 7 0

thickness of concrete c 260 260

diameter of bor d 20 20

thickness of the Lift-piece e+f 0-65 65-115

+ thickness of floor pavement

You can use equivalent dowels from another manufacturer with licence, but observe their

regulations.

2 8

pic. 4: course of the hoses

Instruction and Documentation

SPL 3200

return line hydraulic

service pipe

hydraulic

synchronizing

ropes

pulley

hydraulic cylinder

hang up of the rope

lower side carriage

hang up of the rope

upper side carriage

pulley

fixing at carriage

operating side

opposite side

2 9

pic. 5: ratchet-rope

Instruction and Documentation

SPL 3200

3 0

pic. 6: ratchet

Instruction and Documentation

SPL 3200

ratchet-rope

lifting carriage with

ratchet strip

end-nipple

ratchet

column

3 1

security check

SPL 3200

First security check before installation

kind of check

a l l

r i g h

d e f e c t

l a c k i n g

v e r i -

f i c a t i o n Remark

to fill in and to leave in

this document

Type plate ................................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Short operating instructions........................ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning designation................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Detailed operating instructions................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Designation Lifting/Lowering .................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating switch lockable........................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function limit switches ............................. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety device hinge bolt ............................. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Security of pads .......................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition rubber support of pads .. ............ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function fixing of carrying arms .. ............. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Construction (deformation, cracking) ....... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fixed seat of the carrying screws ............... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function, condition ratchet-system............. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

guidance of carriage in column................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition synchronizing rope, hang-up...... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition pulleys........................................ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition coverings ................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition hydraulic hoses........................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil level gage.............................................. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Closeness of hydraulic system.................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

surface of piston-rod .................................. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition electrical wires, earth contactor... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test: lift with vehicle ................................ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition concrete floor (cracks) ............... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

( mark where applicable, in case of verification mark in addition to the first mark! )

security check carried out: .................................................................................................................

Name, address of the competent...........................................................................................................

Result of the Check:

Initation not permitted, verification necessary

Initation possible, repair failures until .............................................................

No failings, Initation possible

Signature of the expert:................................. Signature of the operator:..............................

If failures must be repaired

Failures repaired at: ...................................... Signature of the operator:..............................

( Use anather form for verification! )

security check

SPL 3200

Regular security check

a l l

r i g h t

d e f e c t

l a c k i n g

v e r i -

f i c a t i o n Remarkkind of check

to fill in and to leave in

this document

Type plate ................................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Short operating instructions........................ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning designation................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Detailed operating instructions................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Designation Lifting/Lowering .................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating switch lockable........................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function limit switches ............................. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety device hinge bolt ............................. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Security of pads .......................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition rubber support of pads .. ............ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function fixing of carrying arms .. ............. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Construction (deformation, cracking) ....... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fixed seat of the carrying screws ............... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function, condition ratchet-system............. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

guidance of carriage in column................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition synchronizing rope, hang-up...... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition pulleys........................................ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition coverings ................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition hydraulic hoses........................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil level gage.............................................. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Closeness of hydraulic system.................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

surface of piston-rod .................................. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition electrical wires, earth contactor... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test: lift with vehicle ................................ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition concrete floor (cracks) ............... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

( mark where applicable, in case of verification mark in addition to the first mark! )

security check carried out: ...................................................................................................................

Name, address of the competent...........................................................................................................

Result of the Check:

Initation not permitted, verification necessary

Initation possible, repair failures until .............................................................

No failings, Initation possible

Signature of the expert:................................. Signature of the operator:..............................

If failures must be repaired

Failures repaired at: ...................................... Signature of the operator:..............................

( Use anather form for verification! )

security check

SPL 3200

Extraordinary security check

kind of check

a l l

r i g h t

d e f e c t

l a c k i n g

v e r i -

f i c a t i o n Remark

to fill in and to leave in

this document

Type plate ................................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Short operating instructions........................ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning designation................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Detailed operating instructions................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Designation Lifting/Lowering .................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating switch lockable........................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function limit switches ............................. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety device hinge bolt ............................. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Security of pads .......................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition rubber support of pads .. ............ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function fixing of carrying arms .. ............. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Construction (deformation, cracking) ....... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fixed seat of the carrying screws ............... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function, condition ratchet-system............. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

guidance of carriage in column................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition synchronizing rope, hang-up...... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition pulleys........................................ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition coverings ................................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition hydraulic hoses........................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil level gage.............................................. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Closeness of hydraulic system.................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

surface of piston-rod .................................. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition electrical wires, earth contactor... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test: lift with vehicle ................................ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condition concrete floor (cracks) ............... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

( mark where applicable, in case of verification mark in addition to the first mark! )

security check carried out: ...................................................................................................................

Name, address of the competent...........................................................................................................

Result of the Check:

Initation not permitted, verification necessary

Initation possible, repair failures until .............................................................

No failings, Initation possible

Signature of the expert:................................. Signature of the operator:..............................

If failures must be repaired

Failures repaired at: ...................................... Signature of the operator:..............................

( Use anather form for verification! )

Spare parts list

SPL 3200

Spare parts list drawing: columns, coverings, cylinder, ropes

operating side

opposite side

Spare parts list

SPL 3200

Spare parts list drawing: columns, coverings, cylinder, ropes

Number Description Code

1 column operating side 235SPL05003

2 column opposite side 235SPL05039

3 hydraulic cylinder 232POW22003

4 hydraulic cylinder 232POW22002

5 head plate operating side 232POW25020

6 head plate opposite side 232POW25056

7 bolt of pulley 232POW05026

8 traverse 235SPL05074

9 pulley 232NSTL05063

10 distance bush 232NSTL05034D

11 cylinder screw 9Z912M10*110ZN

12 hexagon nut 9MU934M10ZN

13 switch off covering 232POW09016

14 pan-head screw 9F921M06*012ZN

15 hexagon head cap screw 9S933M10*020ZN

16 lock washer 9FR127M10ZN

17 hexagon head cap screw 9S933M10*016ZN

18 AS-washer 970022

19 Seeger circlip ring 9SR030*1.5

20 aggregate backside, welding piece 235SPL05092

21 countersunk screw 9S7991M08*16ZN

22 hydraulic tube 232POW01030

23 countersunk screw 9SE7991M08*12ZN

24 Male Stud branch Tee 980020

25 Male Stud coupling 980018

26 Male Stud branch Tee 960024

27 banjo elbow 960023

28 oil-return line 232POW01041

29 oil-return line 232POW01042

30 hexagon nut self-locking 9MU985M18*1.5ZN

31 set of control ropes 970405

32 hexagon nut self-locking 9MU985M12ZN

33 washer 9SC125M12ZN

34 covering 235SPL49024

35 covering of column opposite side 235SPL09020

36 covering of cylinder 235SPL09003

37 countersunk screw 9SE7991M05*12ZN

38 rosette 970010

39 cover band 232POW09006

40 cable cover 232POW09008

Spare parts list

SPL 3200

Spare parts list drawing: columns, coverings, cylinder, ropes

Number Description Code

41 hexagon nut 9MU934M06ZN

42 countersunk screw 9SE7991M05*08ZN

43 cylinder screw 9Z912M06*010ZN

44 lock washer 9FR7980M06ZN

45 ratchet 232SPL10003

46 leg spring 970251

47 bolt of bearing 232POW10008

48 Seeger circlip ring 9SR012*1

49 guidance 232POW10020

50 cylinder screw 9Z912M08*025ZN

51 switching-rod 232SPL10021

52 pressure spring 9DFD-187ZN

Spare parts list

SPL 3200

Spare parts list drawing: carriages, standard carrying arms

Spare parts list

SPL 3200

Spare parts list Power-Lift: carriage, carrying arms

Number Description Code

1 carriage, operating side 232POW06003

2 carriage, opposite side 232POW06039

3 sliding block topside 232POW06014

4 sliding block, lower side 232POW06015

5 sliding block bottom frontside 232POW06030

6 countersunk screw 9SE7991M06*20ZN

7 carrying arm (long) 232POW28003D

8 tooth lock washer 232NSTL08013

9 hinge bolt 232NSTL08016

10 shaft ring 970006

11 cylinder screw 9Z912M08*025ZN

12 carrying arm (short) 232POW28039

13 pad 232HEL08075

14 elastomer support 901103031

15 countersunk screw 9SE963M06*20ZN

16 hexagon nut 9MU934M06ZN

17 pull-handle 232NSTL08096

18 protecting cap 970008

19 compression spring 9DFD-222SLZN

20 heavy clamping sleeve 9SH1481DM03*16ZN

Spare parts list

SPL 3200

Spare parts list drawing: hydraulic-aggregate

Spare parts list

SPL 3200

Spare parts list: hydraulic-aggregate

Number Description Code

1 pump carrier 232POW21003

2 cylinder screw 9Z912M08*012ZN

3 lock washer 9FR7980M08ZN

4 countersunk screw 9SE7991M08*16

5 coupling 970290

6 pump 980243

7 cylinder scres 9Z912M08*085ZN

8 lock washer 9FR7980M08ZN

9 motor 3.0 KW (standard version) 990303

10 cylinder screw 9Z912M06*016ZN

11 lock washer 9FR7980M06ZN

12 cylinder screw 9Z912M08*016ZN

13 washer 9SC125M08ZN

14 Male Stud coupling 980135

15 Male Stud coupling 980014

16 suction pipe 232POW01028

17 hydraulic tube (pump to hydraulic block) 232POW01029

18 hydraulic tube (hydraulic block to T-piece) 232SPL01050

19 hydraulic tube(ball valve to hydraulic block) 232SPL01055

20 hydraulic tube (T-piece to cylinder) 232SPL01034

21 deaerate screw 980006

22 oil-filter 980201

23 Male Stud coupling 960025

24 ball valve 980512

operating lever 235SPL22033

25 hydraulic block complete 232SPL22037

26 hexagon nut 9MU934M08ZN

27 Adjustable Male Stud Run Tees 980071

28 pressure relief valve, complete 232NSTL02082

29 USIT-ring 980240

30 holding valve 980480

31 operating (reversing) switch (small) 990391

32 steel cord for operating switch 235SPL10014

33 steel cord for unlocking the ratchet 235SPL10012

34 steel cord for unlocking the ratchet 235SPL10013

35 luster terminal 990037

36 tension spring 9ZFZ-141ZN

37 tension spring 9ZFZ-092ZN

38 ratchet-lever 235SPL02020

Gebrauchsanweisung und

B Ü H N E N T Y P

4 2

Gebrauchsanweisung und

B Ü H N E N T Y P

4 3

Loading...

Loading...