SERVICE MANUAL

SERVICE MANUAL

Edition Date Modifications

01 12/2015 First Edition

02 09/2016 Wiring diagram tank version updated

II

Ed. 02 of 09/2016

SERVICE MANUAL

MACHINE DESCRIPTION

FIRST INSTALLATION AND

PRELIMINARY OPERATIONS

REMOVAL OF THE EXTERNAL

SURFACE

INFUSION UNIT

HEATER

HYDRAULIC CIRCUIT

ELECTRIC COMPONENTS

TROUBLESHOOTING

1

2

3

4

5

6

7

8

DIAGRAMS

MAINTENANCE CHECKING

SPARE PART CATALOGUE

9

10

11

Ed. 02 of 09/2016

I

INDEX

SERVICE MANUAL

1. MACHINE DESCRIPTION ........1.1

1.1 DESCRIPTION ...................1.2

1.2 KEYBOARD DESCRIPTION

(Standard configuration)...........1.3

1.3 SAFETY REGULATIONS ...........1.4

1.4 MACHINE IDENTIFICATION ........1.7

1.5 TRANSPORT ....................1.8

1.5.1 HANDLING ..................1.8

2. FIRST INSTALLATION AND

PRELIMINARY OPERATIONS .....2.1

2.1 FIRST INSTALLATION .............2.2

2.1.1 WEIGHT AND DIMENSIONS ....2.2

2.1.2 CONNECTION TO THE

WATERLINE AND DRAINAGE

SYSTEM ....................2.3

2.1.3 TECHNICAL SPECIFICATIONS..2.4

2.1.4 CONNECTION TO THE POWER

LINE .......................2.4

2.1.5 PROCEDURE OF FIRST

INSTALLATION...............2.4

2.2 ACCESSORIES BOX . . . . . . . . . . . . . . 2.5

2.2.1 FITTING THE FILTER HOLDER..2.5

2.3 PROGRAMMING DOSES ..........2.6

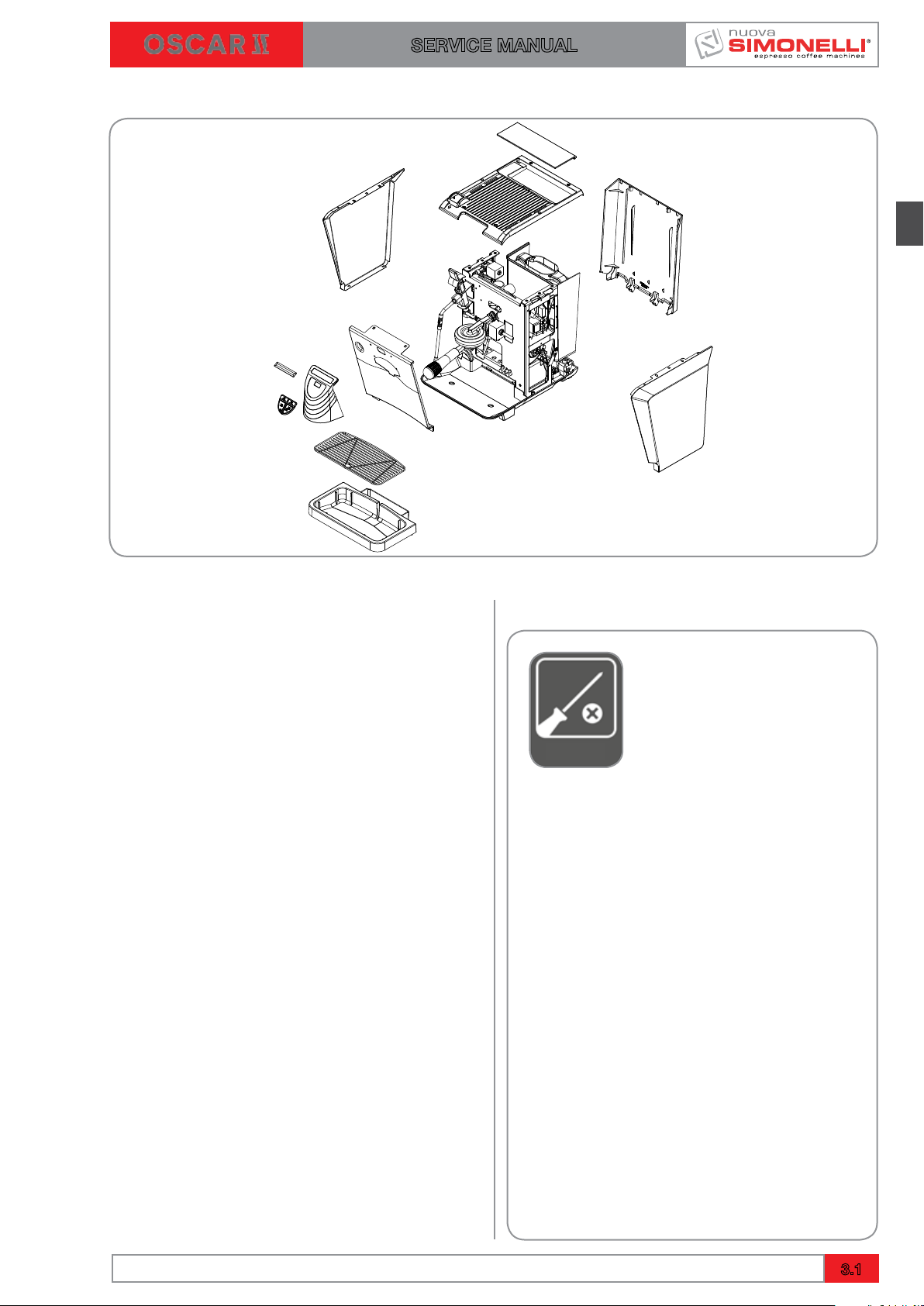

3. REMOVAL OF THE

EXTERNAL SURFACE ...........3.1

3.1 REMOVAL OF WATER TANK .......3.2

3.2 REMOVAL OF THE CUP

HOLDER SURFACE...............3.3

3.3 REMOVAL OF THE SIDE PANELS ...3.4

3.4 REMOVAL OF THE REAR PANEL ...3.4

3.5 TANK TO COLLECT WATER FILED ..3.4

3.6 REMOVAL OF THE FRONT PANEL ..3.5

3.6.1 REMOVAL OF KEYBOARD .....3.6

4. INFUSION UNIT ................4.1

4.1 REMOVAL OF SHOWER

AND SEAL ..................4.2

4.2 COFFEE VALVE ..............4.3

4.3 EXPANSION VALVE ...........4.5

5. HEATER.......................5.1

5.1 EMPTYING THE HEATER . . . . . . . . . . 5.2

5.2 REMOVAL OF THE HEATER ........5.4

5.3 HEATING ELEMENT AND

HEAT PROTECTION ..............5.5

5.4 REPLACEMENT OF THE

LEVEL GAUGE ...................5.6

5.5 ANTIVACUUM VALVE .............5.7

5.6 SAFETY VALVE ..................5.8

6. HYDRAULIC CIRCUIT ...........6.1

6.1 PUMP DISASSEMBLY .............6.2

6.2 REPLACING THE COFFEE VALVE ...6.4

6.3 STEAM NOZZLE .................6.6

6.4 WATER TANK...................6.11

6.4.1 REPLACEMENT OF

THE FLOAT.................6.11

6.4.2 REMOVAL OF THE

MAGNETIC SENSOR.........6.12

6.5 REMOVAL OF THE PRESSURE

SWITCH .......................6.12

7. ELECTRIC COMPONENTS .......7.1

7.1 CONTROL UNIT..................7.2

8. TROUBLESHOOTING............8.1

8.1 WATER LACK LIGHT..............8.2

8.2 HEATING ELEMENT LIGHT ........8.3

8.4 COFFEE DELIVERY ...............8.4

8.5 STEAM DELIVERY................8.4

8.6 HEATER ........................8.5

9. DIAGRAMS ....................9.1

9.1 HYDRAULIC DIAGRAM

TANK VERSION ..................9.2

9.2 HYDRAULIC DIAGRAM

DIRECT CONNECTION VERSION ...9.3

9.3 WIRING DIAGRAM TANK VERSION..9.4

9.4 WIRING DIAGRAM DIRECT

CONNECTION VERSION...........9.5

10. MAINTENANCE CHECKING .....10.1

10.1 DAILY MAINTENANCE ...........10.2

10.2 WEEKLY MAINTENANCE .........10.2

10.3 YEARLY MAINTENANCE .........10.3

10.4 BIENNIAL MAINTENANCE ........10.4

11. SPARE PART CATALOGUE ......11.1

11.1 CABINET PARTS ................11.2

11.2 COMPLETE POURING UNIT ......11.3

11.3 TANK - FRAME COMPONENTS ....11.4

11.4 STOVE FILED COLLECT WATER ...11.5

11.5 BOILER COMPONENTS ..........11.6

11.6 ELECTRICAL COMPONENTS .....11.7

Ed. 02 of 09/2016

III

SERVICE MANUAL

IV

Ed. 02 of 09/2016

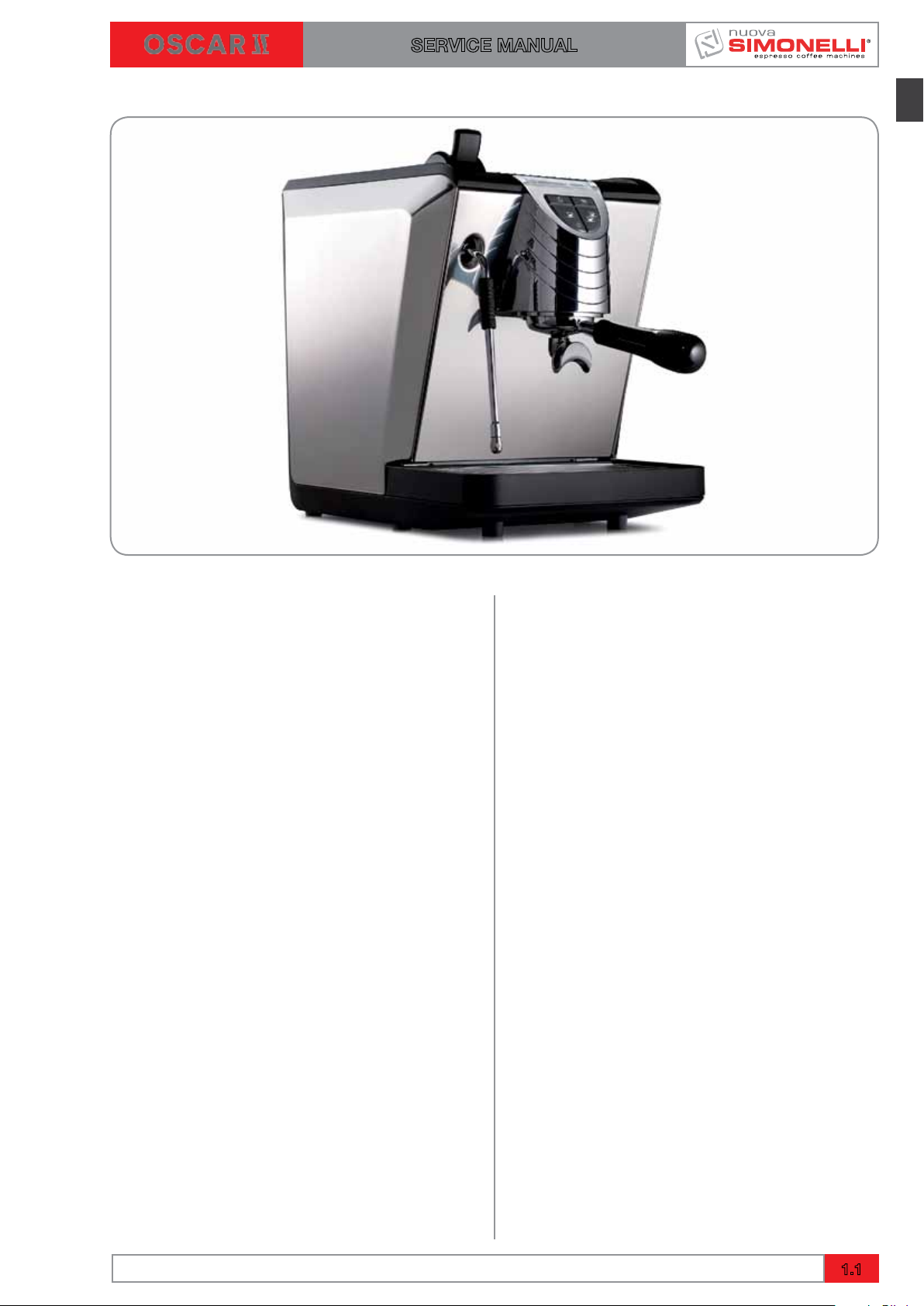

1. MACHINE DESCRIPTION

SERVICE MANUAL

INDEX

1. MACHINE DESCRIPTION ........1.1

1.1 DESCRIPTION ...................1.2

1.2 KEYBOARD DESCRIPTION

(Standard configuration)...........1.3

1.3 SAFETY REGULATIONS ...........1.4

1.4 MACHINE IDENTIFICATION ........1.7

1.5 TRANSPORT ....................1.8

1.5.1 HANDLING ..................1.8

Ed. 02 of 09/2016

1.1

1.1 DESCRIPTION

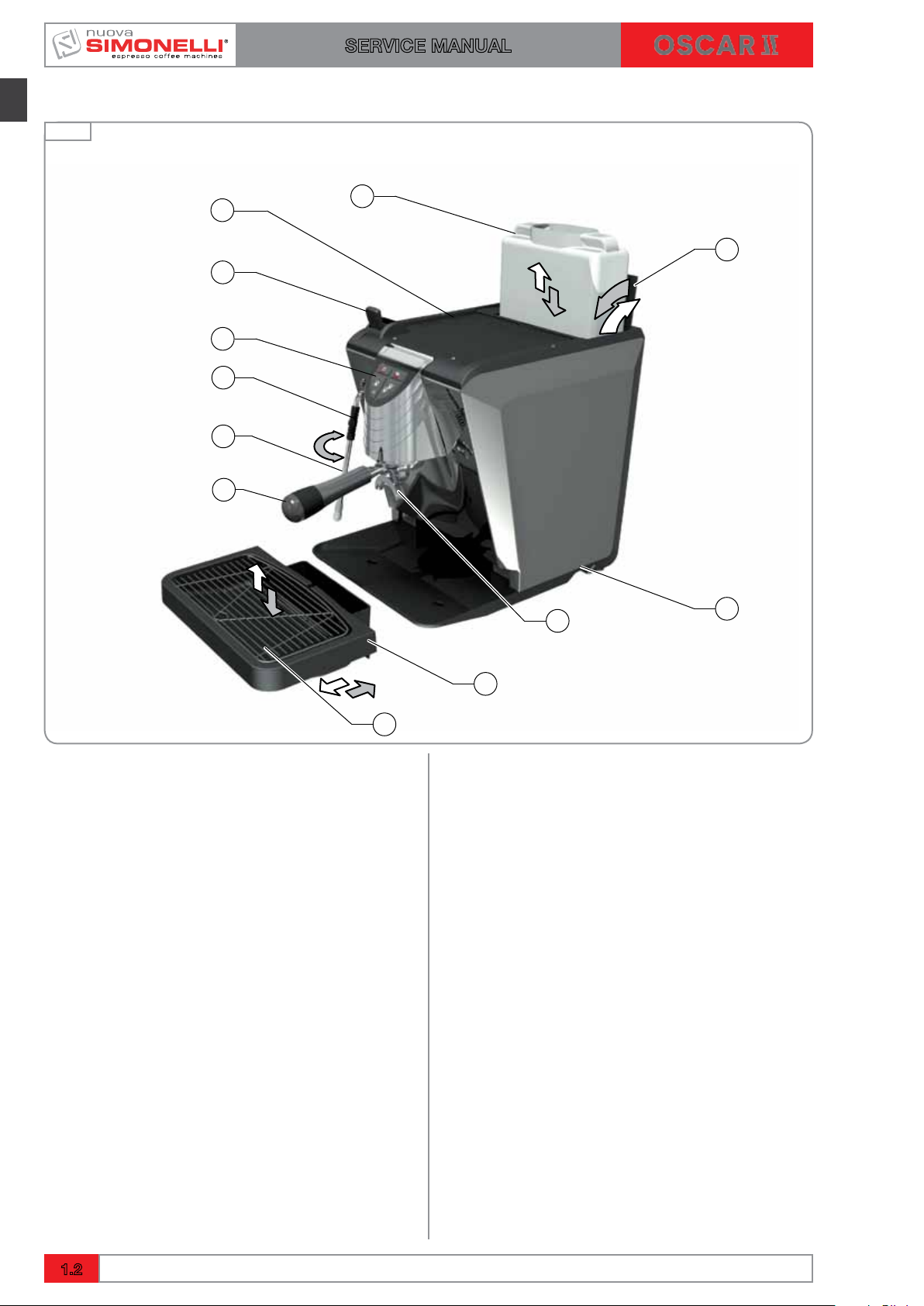

Fig. 1

SERVICE MANUAL

12

11

10

2

1

9

3

4

6

5

LEGEND

1 Steam lever

2 Cup warming grill

3 Water reservoir

4 Water reservoir hatch

5 Main switch

6 Dispensing unit

7 Water drain tank

8 Cup support grill

9 Filter holder

10 Steam wand

11 Steam wand insulating rubber

12 Control panel

7

8

1.2

Ed. 02 of 09/2016

SERVICE MANUAL

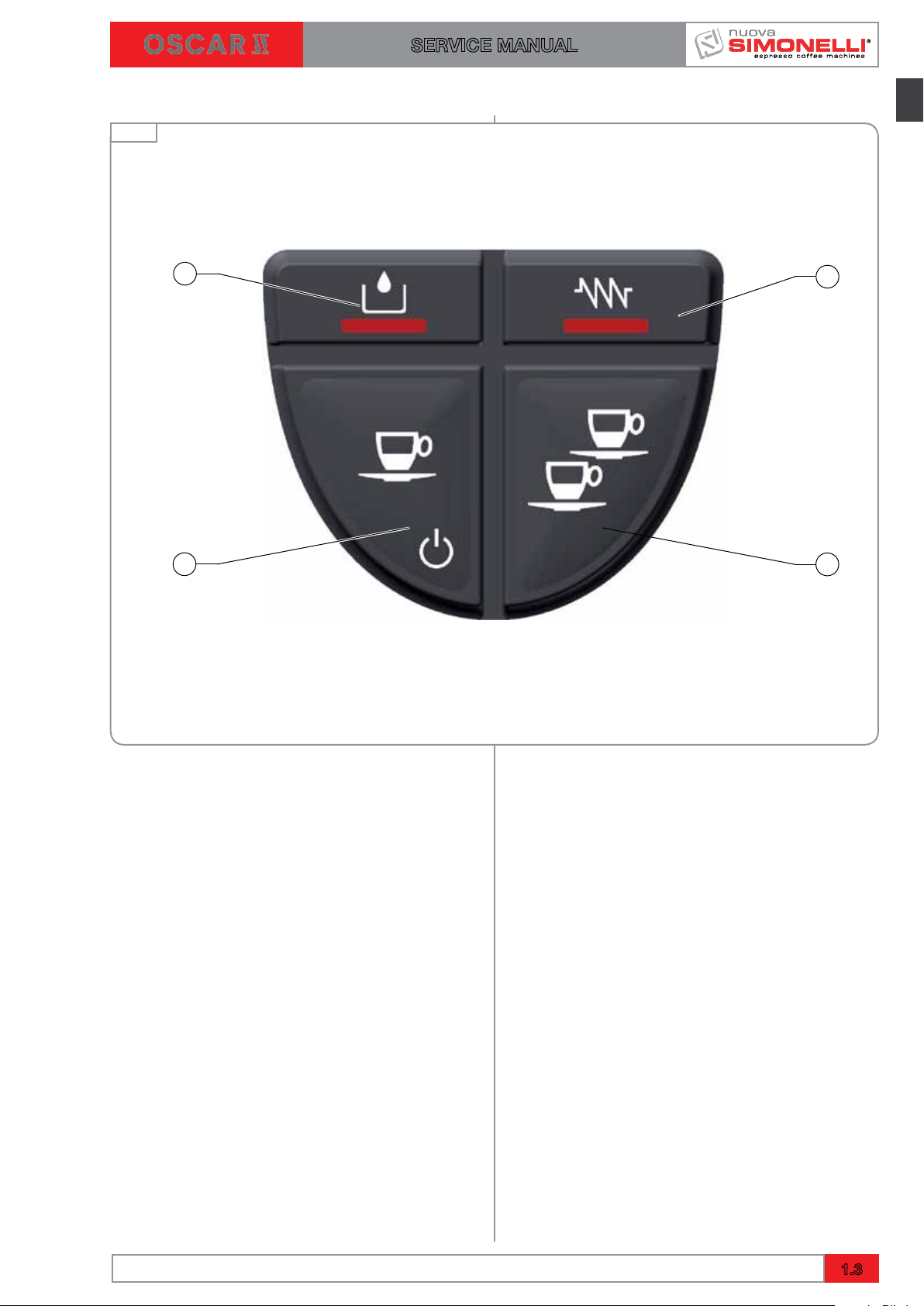

1.2 CONTROL PANEL DESCRIPTION (Configuration standard)

Fig. 2

1

4

2

3

LEGEND

1 Water level warning light

2 Heating resistance on warning light

3 Two coffee dispensing button / programming

entry

4 One coffee dispensing button / Standby

Ed. 02 of 09/2016

1.3

SERVICE MANUAL

1.3 SAFETY INDICATIONS

The present manual is an integral and essential part of the product and is to be delivered

to the user. Carefully read all warnings in

the manual as they provide important information required to install, use and maintain

the unit safely. Keep this manual in a safe

place for further consultation.

After having removed the packaging,

make certain that the unit is not damaged

in any way.

If you have any doubts, do not use the unit

and contact a professionally qualified person. Always keep all packaging (plastic

bags, polystyrene foam, nails, etc..) out of

the reach of children as they are a potential source of danger and never loiter the

environment with such materials.

DANGER OF POLLUTION

Fig. 3

The manufacturer cannot be held responsible for any damages incurred if the system is not grounded.

For electrical safety, this machine requires

a ground system. Contact a technically

certified electrician who must check that

the line electrical capacity is adequate for

the maximum capacity indicated on the

unit label.

Fig. 4

The qualified electrician must also check

that the section of the installation’s cables

is large enough for the absorbed power of

the appliance.

Never use adapters, multiple jacks or extension cords. When such items prove absolutely necessary, call in a qualified electrician.

The machine is can be installed in staff

kitchen areas in shops, offices and other

working environments, farm houses by

clients in hotels, motels and other residential type environments bed and breakfast type environments.

Before turning on the unit make certain

that the rating indicated on the label

matches the available power supply. The

nameplate can be seen inside the machine

when removing the water collection tray.

The machine must be installed according

to the applicable federal, state and local

standards (codes) in force with regard

to plumbing systems including backflow

prevention devices. For this reason, the

plumbing connections must be carried

out by a qualified technician.

The warranty expires if the characteristics

of the power supply do not correspond to

the nameplate data.

When installing the device, it is necessary

to use the parts and materials supplied with

the device itself. Should it be necessary to

use other parts, the installation engineer

needs to check their suitability for use in

contact with water for human consumption.

The installer must Make the hydraulic connections respecting the rules of hygiene

and water safety to environmental protection in force in the place of installation. So

for the hydraulic plant contact an authorized technician. Always utilise the new

hose supplied for connection to the water

supply. Old hoses must not be utilised.

The device needs to be supplied with

water that is suitable for human consumption and compliant with the regulations

in force in the place of installation. The

installation engineer needs confirmation

from the owner/manager of the system

that the water complies with the requirements and standards stated above.

This unit must only be used for the purposes described in the present manual.

The manufacturer cannot be held responsible for any damages caused by improper, mistaken and unreasonable use.

1.4

Ed. 02 of 09/2016

OK

SERVICE MANUAL

The appliance is not to be used by children

or persons with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they have

been given supervision or instruction.

Children must not play with the appliance.

Cleaning and maintenance must not be

carried out by children unless supervised.

This appliance is for professional use only.

The operating temperature must be within

the range of [+5, +35]°C.

At the end of installation, the device is

switched on and taken to rated operating

conditions, leaving it in a state in which it

is “ready for operation”.

After reaching the “ready for operation”

condition, the following dispensing operations are carried out:

• 100% of the coffee circuit through the

coffee dispenser (for more than one

dispenser, this is divided equally);

• Open the steam outlet for 1 minute.

Fig. 5

Fig. 6

At the end of installation, it is good practice to draw up a report of the operations.

CAUTION

Before using the machine, read this manual in its entirety or, at the very least, read

the safety and set up instructions.

There are some basic rules for the use of

any electrical appliance.

In particular:

• Never touch the unit with wet hands or

feet;

• Never use the unit with bare feet;

• Never use extension cords in areas

equipped with baths or showers;

• Never pull on the power supply cord to

unplug the unit;

• Never leave the unit exposed to atmospheric agents (rain, direct sunlight, etc.);

• Never let children, unauthorized personnel or anyone who has not read this

manual operate the unit.

Before performing any sort of maintenance, the authorized technician must

turn off the unit and unplug it from the

mains.

Before cleaning the unit set it in a state of

"0" energy: that is, "MACHINE SWITCHED

OFF AND UNPLUGGED". Follow the

instructions given in this manual carefully.

Refer to chapters 6 and 7 for periodical

cleaning and maintenance. The authorized technician must, before carrying out

any maintenance, disconnect the plug

after the switch off of the machine.

In case of breakdown or poor function,

turn off the unit. Never tamper with the

unit. Contact only professionally qualified

personnel.

Only the manufacturer or an authorized

service center can make repairs and only

using original spare parts.

Non compliance with the above can compromise machine safety.

On installation, the qualified electrician

must fit a circuit breaker switch as foreseen by the safety norms in force that has

a contact open distance that permits the

complete disconnection under conditions

of overload category III.

Ed. 02 of 09/2016

1.5

SERVICE MANUAL

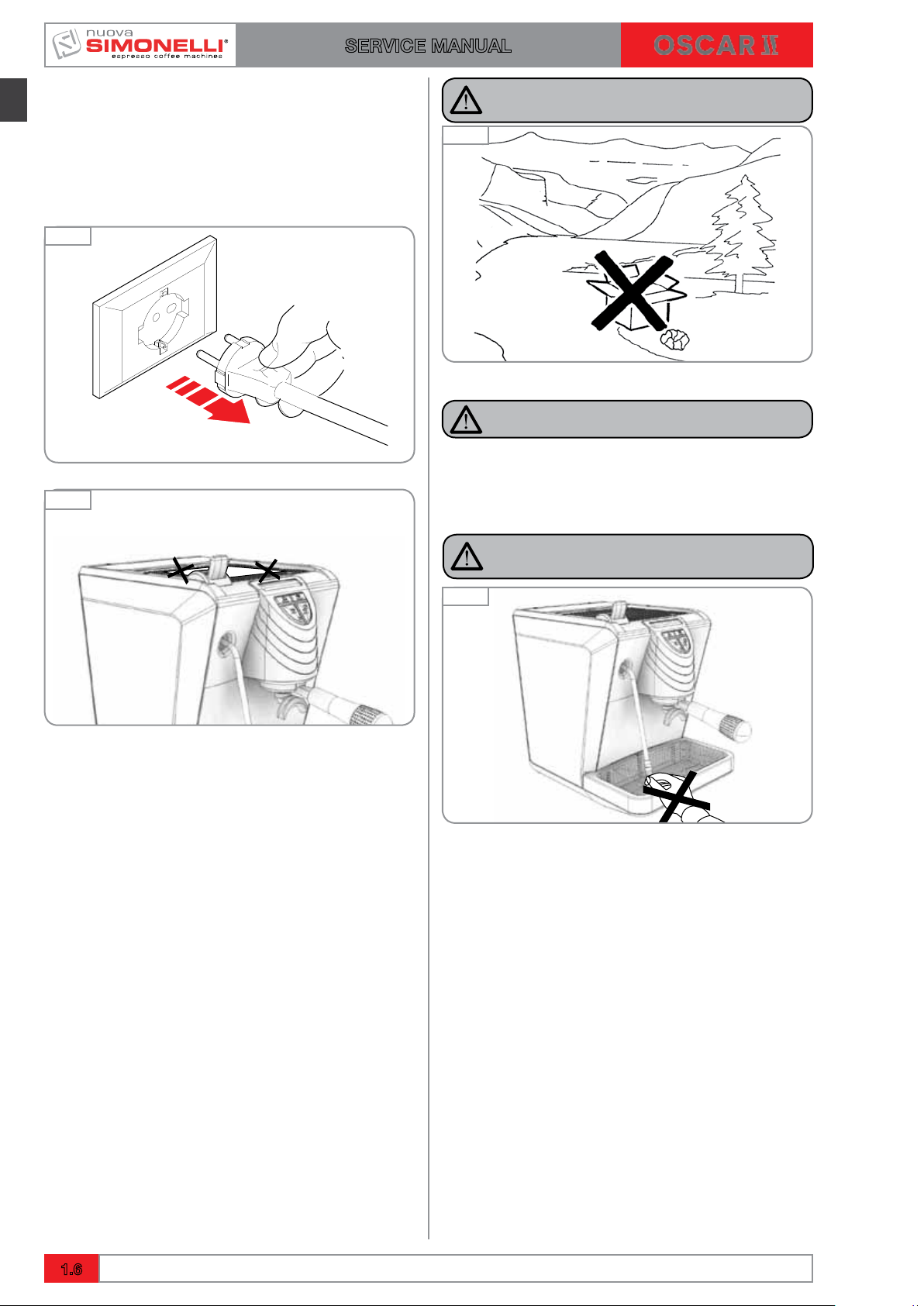

To prevent dangerous overheating, it is

advisable to fully extend the power supply

cord.

Never block the intake and/or heat dissipation grills, in particular those for the

cup warmer.

Fig. 7

OK

Fig. 8

WARNING

DANGER OF POLLUTION

Fig. 9

DANGER OF INTOXICATION

Once started the washing machine, do

not interrupt, the detergent residue may

remain inside the delivery unit.

The user must never replace the unit's

power supply cord. If this cord is damaged, turn off the unit and have it replaced

by a professionally qualified technician.

Should it be necessary to replace the

power cord, this replacement operation

must only be performed by an authorized

service centre or by the manufacturer.

Should you decide to stop using this type

of unit, we suggest you render it inoperable by unplugging it and cutting the power

supply cord.

Do not throw the machine in nature for the

Elimination contact an authorized center or

contact the manufacturer who will provide

you the necessary information about it.

Never dispose of the machine in the environment: to dispose of the machine, contact an authorized center or contact the

manufacturer for pertinent indications.

CAUTION

DANGER OF BURNS

Fig. 10

To facilitate aeration of the unit, position

the aeration portion of the machine 15 cm

from walls or other machinery.

Be extremely careful when using the steam

nozzle. Never place your hands under the

nozzle and never touch it right after use.

Remember that to install, maintain, unload

and regulate the unit, the qualified operator must always wear work gloves and

safety shoes.

When adding the coffee, the operator must

never put his hands into the container.

The noise level of the machine is less than

70db.

1.6

Ed. 02 of 09/2016

!

Mod. OSCAR II

S.N. SERIALE

220 - 240 V ~

50 Hz

Operating Pressure 0,166 MPa MAX Inlet Pressure 0,65 MPa

Date 01/01/0001

P= 1200 W

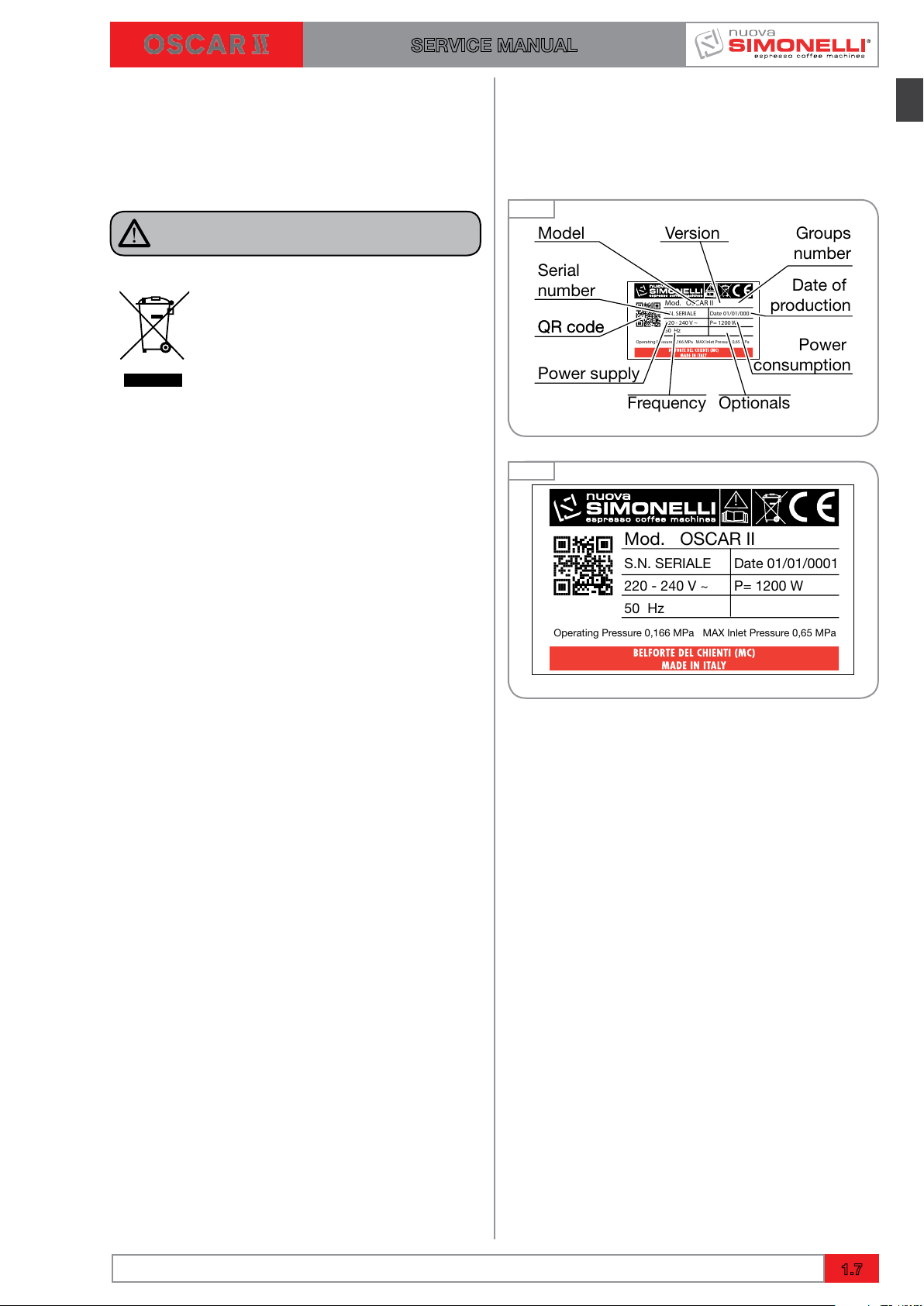

QR code

Version

Model

Serial

number

QR code

Power supply

Frequency Optionals

Groups

number

Date of

production

Power

consumption

!

Mod. OSCAR II

S.N. SERIALE

220 - 240 V ~

50 Hz

Operating Pressure 0,166 MPa MAX Inlet Pressure 0,65 MPa

Date 01/01/0001

P= 1200 W

SERVICE MANUAL

For machines connected to the mains

water supply, the minimum pressure must

be 2 bar and the maximum pressure

for correct machine operation must not

exceed 4 bar.

CAUTION

INFORMATION TO THE USERS

Under the senses of art. 13 of

Law Decree 25th July 2005,

n. 151 "Implementation of the

Directives/Guidelines 2002/95/

CE, 2002/96/CE and 2003/108/

CE, concerning the reduction

of the use of dangerous substances in electric and electronic equipment, as well as

the disposal of wastes".

1.4 MACHINE IDENTIFICATION

Always quote the machine serial number in all

communications to the manufacturer, Nuova

Simonelli.

Fig. 11

Fig. 12

The symbol of the crossed large rubbish container that is present on the machine points out

that the product at the end of its life cycle must

be collected separately from the other wastes.

The user for this reason will have to give the

equipment that got to its life cycle to the suitable

separate waste collection centres of electronic

and electro-technical wastes, or to give it back

to the seller or dealer when buying a new equipment of equivalent type, in terms of one to one.

The suitable separate waste collection for the

following sending of the disused equipment to

recycling, the dealing or handling and compatible environment disposal contributes to avoid

possible negative effects on the environment and

on the people's health and helps the recycling of

the materials the machine is composed of. The

user's illegal disposal of the product implies the

application of administrative fines as stated in

Law Decree n.22/1997” (article 50 and followings

of the Law Decree n.22/1997).

The machine internet page can be accessed

directly through the QR code.

By downloading and installing one of the apps to

read such codes on a mobile device.

Start the app and position the camera in front of

the code so that it can be clearly seen.

Wait some time while the app processes the result

and shows the internet page of the machine on

the display.

Ed. 02 of 09/2016

1.7

SERVICE MANUAL

1.5 TRANSPORT

The machine is transported on pallets which

also contain other machines - all boxed and

secured to the pallet with supports.

Before carrying out any transport or handling

operation, the operator must:

• putonworkglovesandprotectivefootwear,

as well as a set of overalls which must be

elasticated at the wrists and ankles.

The pallet must be transported using a suit-

able means for lifting (e.g., forklift).

1.5.1 HANDLING

WARNING

COLLISION OR CRUSHING HAZARD

During the entire handling operation, the operator must make sure no one or nothing is inside

the operating area.

Slowly lift the pallet to about 30 cm from the

ground and move to the loading area. After

making sure there are no obstacles, persons or

things, proceed with loading.

Once at destination, always using an adequate

lifting mechanism (e.g. fork-lift), after making

sure there is no one or nothing within the unloading area, lower the pallet to about 30 cm from the

ground and transport it to the storage area.

WARNING

COLLISION OR CRUSHING HAZARD

Before performing the following operation, make

sure the load is in place and is not likely to fall

when the straps are cut.

The operator, wearing safety gloves and footwear, must now cut the straps and store the

product. To perform this operation, check the

technical characteristics of the product to determine the weight of the machine to be stored and

take consequent precautions.

1.8

Ed. 02 of 09/2016

SERVICE MANUAL

2. FIRST INSTALLATION AND PRELIMINARY OPERATIONS

INDEX

2. FIRST INSTALLATION AND

PRELIMINARY OPERATIONS .....2.1

2.1 FIRST INSTALLATION .............2.2

2.1.1 WEIGHT AND DIMENSIONS ....2.2

2.1.2 CONNECTION TO THE

WATERLINE AND DRAINAGE

SYSTEM ....................2.3

2.1.3 TECHNICAL SPECIFICATIONS..2.4

2.1.4 CONNECTION TO THE POWER

LINE .......................2.4

2.1.5 PROCEDURE OF FIRST

INSTALLATION...............2.4

2.2 ACCESSORIES BOX . . . . . . . . . . . . . . 2.5

2.2.1 FITTING THE FILTER HOLDER..2.5

2.3 PROGRAMMING DOSES ..........2.6

Ed. 02 of 09/2016

2.1

2.1

SERVICE MANUAL

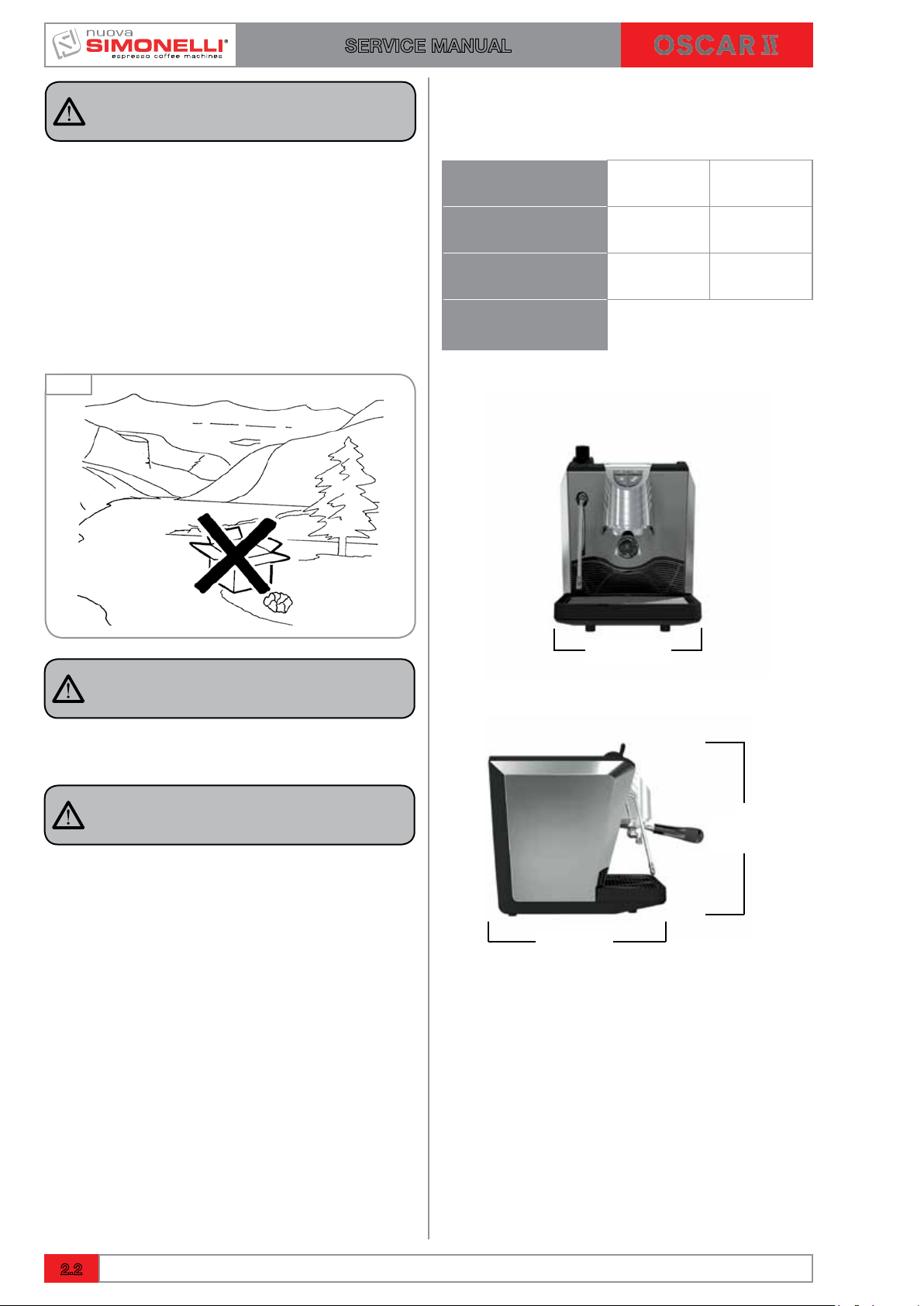

RISK OF POLLUTION

DO NOT DISPOSE PACKAGING in the environment.

2.1 FIRST INSTALLATION

2.1.1 WEIGHT AND DIMENSIONS

NET WEIGHT 14 kg 31 lb

Prior to installation please carefully read the

safety instructions in this manual. The company

cannot be held responsible for damage to persons or property arising from non-compliance

with safety regulations, either during installation

or maintenance of the machine described in this

manual.

Fig. 13

GROSS WEIGHT 17 kg 37 lb

POWER 1200 W 1200 W

DIMENSIONS

A

300 mm 12”

WARNING

Place the machine in an area where all risks of

malfunction can be avoided.

WARNING

Never install in areas where the machine may

be subject to jets of water.

C

400 mm

15,8”

B

408 mm

16”

2.2

Ed. 02 of 09/2016

SERVICE MANUAL

2.1.2 CONNECTION TO THE WATERLINE

AND DRAINAGE SYSTEM

The machine requires stringent specifications to

prevent the formation of limescale and to ensure

quality beverages. The main features required to

achieve high standards of performance are the

following:

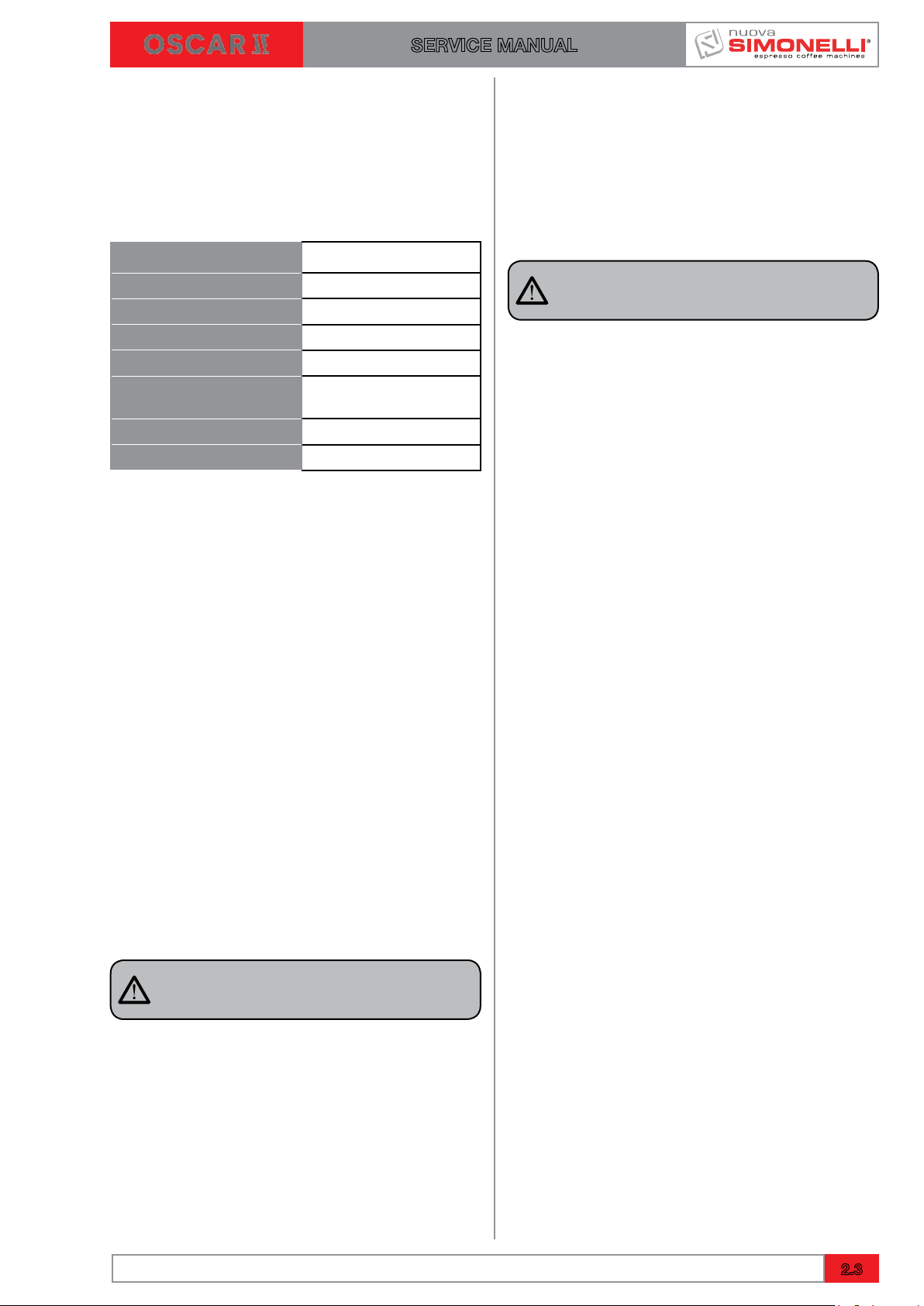

Total hardness

50 -60 ppm

Waterline pressure 2-4 bar, cold water

Minimum flow 200 l/hr

Filtration Less than 1.0 micron

Alkalinity

Total dissolved salts

10-150 ppm

50 -100 mg/L

(TDS)

Chloride < 0.5 mg/L

pH 6.5- 8.5

It is the task of a qualified technician to:

1 Adapt the water from the waterline to the

specifications required using filters and

water softeners;

2 Train the final user so that the equipment for

water treatment is constantly kept perfectly

operational.

The version with direct coupling is provided with

a loading tube 1,5 meters long with a 3/4 inch.

On one side is the fitting is straight and tapered,

the other angled at 90° with a gasket. The tube

is provided with tapered fittings therefore it is not

necessary to use Teflon tape on the fitting.

WARNING

If the water features do not comply, the warranty will automatically expire.

To connect the machine to the waterline, proceed as follows:

1 Remove the pipe from the upper door “A”

and connect one of its ends to fitting “B”

situated on machine base.

2 Connect the other end of the pipe to the

waterline using a 3/8 fitting.

NOTE

Dirty water drainage is carried out through the

drip tray both for version with connection to the

waterline and with tank.

Ed. 02 of 09/2016

2.3

SERVICE MANUAL

2.1.3 TECHNICAL SPECIFICATIONS

The machine is available in the following versions:

• single-phase 120 V 60 Hz (tank and waterline)

• single-phase 230 V 50 Hz (tank and waterline)

• single-phase 230 V 60 Hz (waterline)

The relative power absorbed is indicated on the

machine plate.

2.1.4 CONNECTION TO THE POWER LINE

Before utilising the machine, the operator must

have read and fully understood the safety instructions in this manual.

Connect the machine to the power socket.

The machine carries out the following checks.

Fig. 14

2.1.5 PROCEDURE OF FIRST

INSTALLATION

Before carrying out the installation carefully read

the safety instructions at the beginning of this

manual and particularly about how to put THE

MACHINE INTO ZERO ENERGY STATUS.

1 Once the machine has been removed from

the packaging, position it on a horizontal

surface and proceed with the installation as

illustrated in the following paragraphs.

Arrange the accessories as follows:

2 Insert the ring in its seat inside the filter

holder.

3 Insert one of the two filters.

4 Caution: danger of pollution.

DANGER OF POLLUTION

Fig. 16

Fig. 15

OK

Tank Model:

5 Open the hatch and take out the reservoir.

Especially the first time, wash the reservoir

with soap and water. Fill the reservoir with

water and make certain that the outside of

the reservoir is dry.

6 Return the reservoir to its housing and close

the hatch.

7 Make certain that the water drain tank has

been inserted.

NOTE

If the machine does not have enough water in the

tank or the pump stays on for more than 90 seconds, the machine will stop and all the buttons

flash. Getting on and off the machine: operation

of the filling boiler will run until the appropriate

level.

2.4

Ed. 02 of 09/2016

SERVICE MANUAL

NOTE

In the absence of load water at first boot:

1 Could be created air bubble between the

pump and reservoir and is preventing the

passage of water.

2 Make sure that the tank valve is working.

3 Remove and replace the tank filled with

water several times to facilitate removal of

the air bubble.

Direct attachment version:

5 Open the door of the tank and remove the

hose for direct attachment.

6 Connect the hose to the water supply and

open the tap upstream of the machine if present.

7 Make certain that the water drain tank has

been inserted.

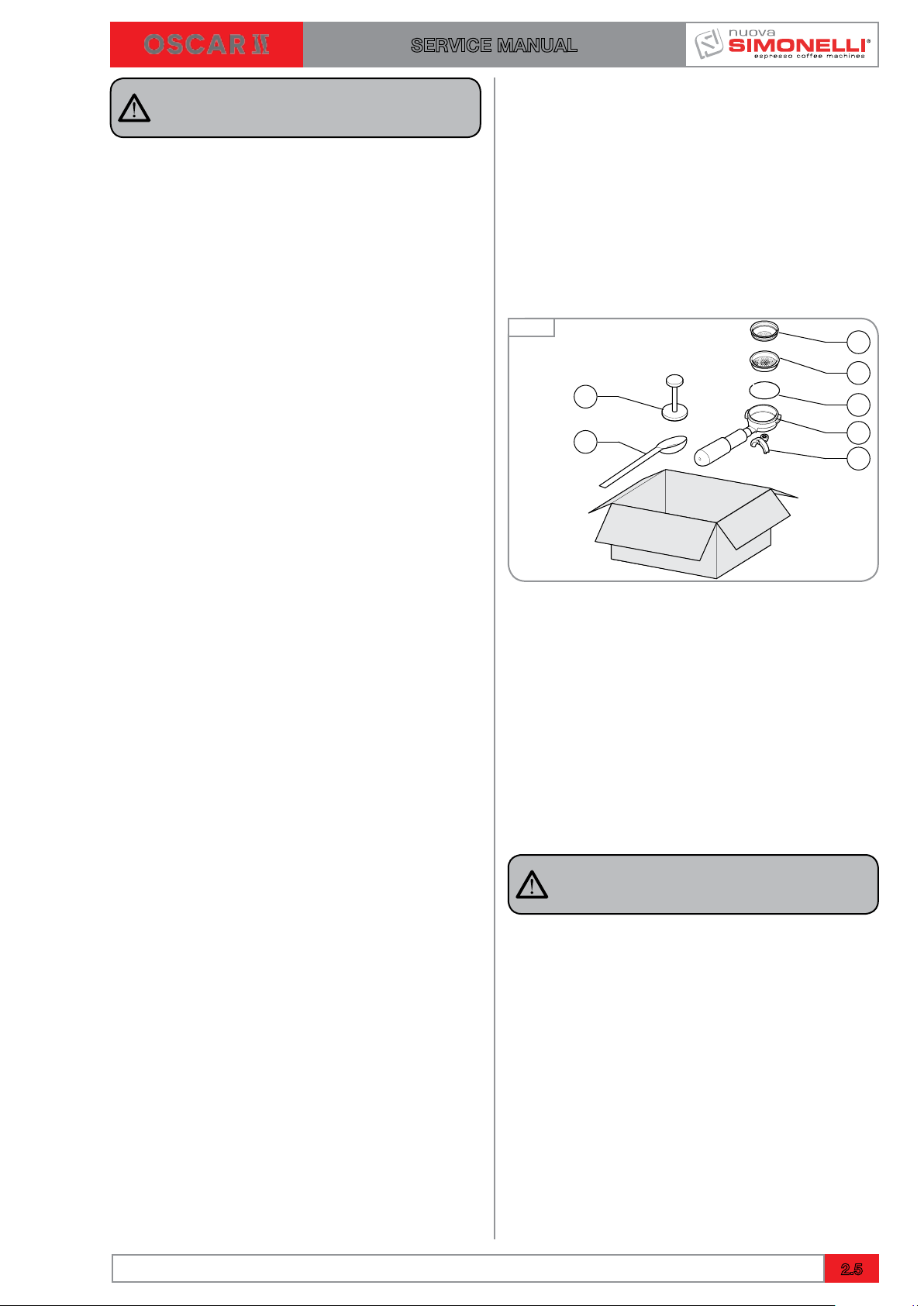

2.2 ACCESSORIES BOX

Machine is supplied with an accessories box

consisting of:

1 Single filter

2 Double filter

3 Spring

4 Filter holder

5 Dispensing nozzle

6 Coffee doser

Fig. 17

7

6

1

2

3

4

5

Make certain that the cup support grill is positioned squarely and is level:

8 Check that the steam lever is closed.

9 Make certain that the line voltage corre-

sponds to the requirements indicated on the

label.

10 The preliminary operations have been com-

pleted and the machine is ready to be set up.

2.2.1 FITTING THE FILTER HOLDER

To properly mount the filter holder:

1 Insert the spring inside the pay slot inside

the filter holder.

2 After selecting the appropriate filter (1 or 2),

insert the filter in the filter holder until you

hear the snap with spring.

3 Screw the dispensing spout up to place it

perpendicular to the handle.

NOTE

To change the filter inserted, pry up the edge with

one of the other filters.

Ed. 02 of 09/2016

2.5

SERVICE MANUAL

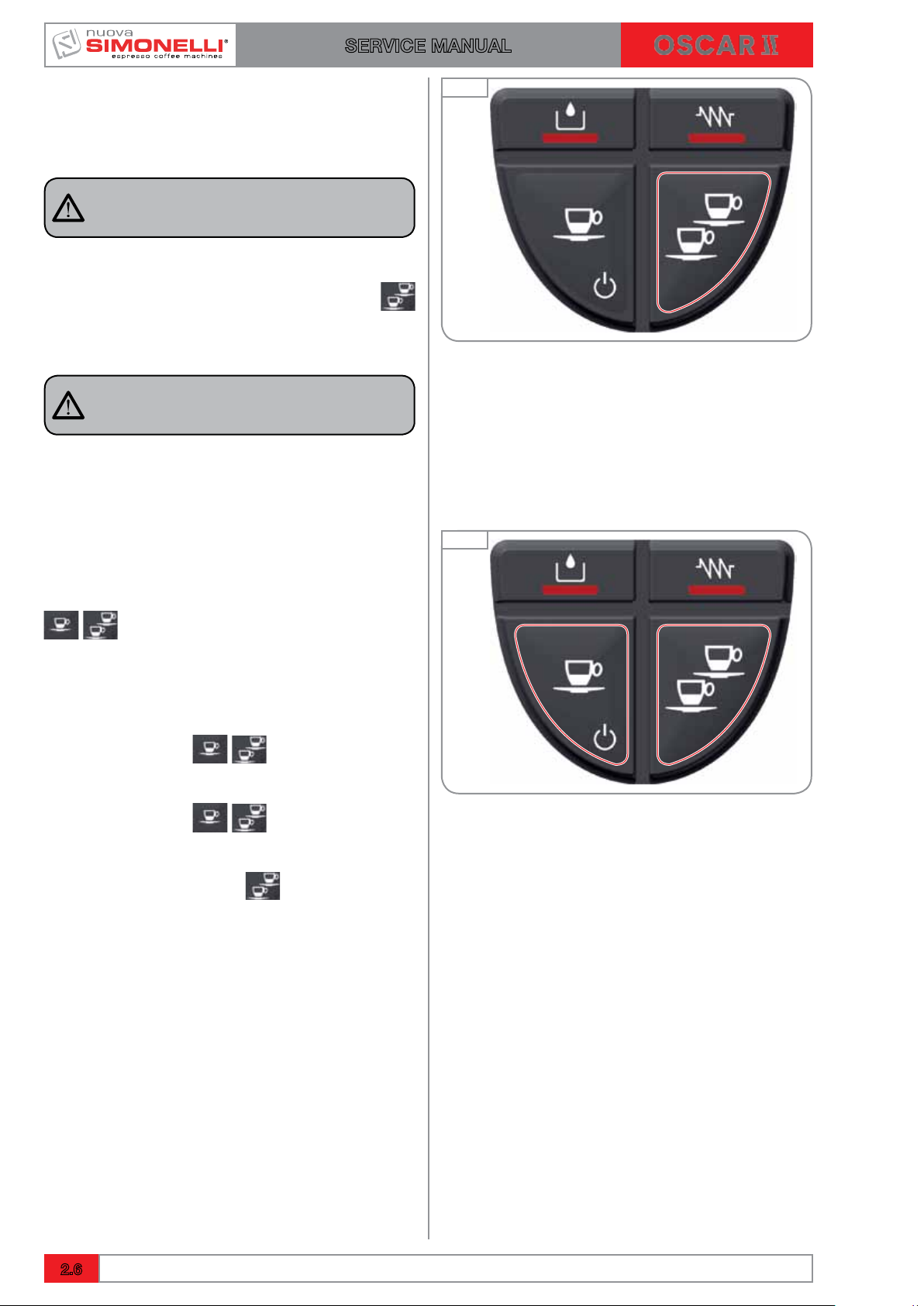

2.3 PROGRAMMING DOSES

Carry out the following operations to enter into

programming mode:

NOTE

Operation to be carried out with the machine

switched on.

To enter into programming mode, press the

two coffee dispensing button for 5 seconds.

The dispensing buttons start to flash.

NOTE

After 30 seconds of inactivity (no buttons pressed)

in programming mode, the machine returns to

normal mode and no data is memorised.

Fig. 18

PROGRAMMING COFFEE DOSES

To programme the dose of water relative to one of the

dispensing buttons, proceed as follows:

Fill the filter holder with the correct dose of coffee (the

filter holder can be single or double depending on the

button to be programmed).

Place the filter holder into the unit.

Press one of the dispensing buttons.

Dispensing starts; once the desired quantity has been

reached press the same button again.

To exit from the programming mode and memorise

the desired doses, keep the

at least 5 seconds; the buttons stop flashing.

button pressed for

Fig. 19

2.6

Ed. 02 of 09/2016

SERVICE MANUAL

3. REMOVAL OF THE EXTERNAL SURFACE

INDEX

3. REMOVAL OF THE

EXTERNAL SURFACE ...........3.1

3.1 REMOVAL OF WATER TANK .......3.2

3.2 REMOVAL OF THE CUP

HOLDER SURFACE...............3.3

3.3 REMOVAL OF THE SIDE PANELS ...3.4

3.4 REMOVAL OF THE REAR PANEL ...3.4

3.5 TANK TO COLLECT WATER FILED ..3.4

3.6 REMOVAL OF THE FRONT PANEL ..3.5

3.6.1 REMOVAL OF KEYBOARD .....3.6

TOOLS NEEDED:

Ed. 02 of 09/2016

3.1

CUTTING

AND

HOT

SURFACES

SERVICE MANUAL

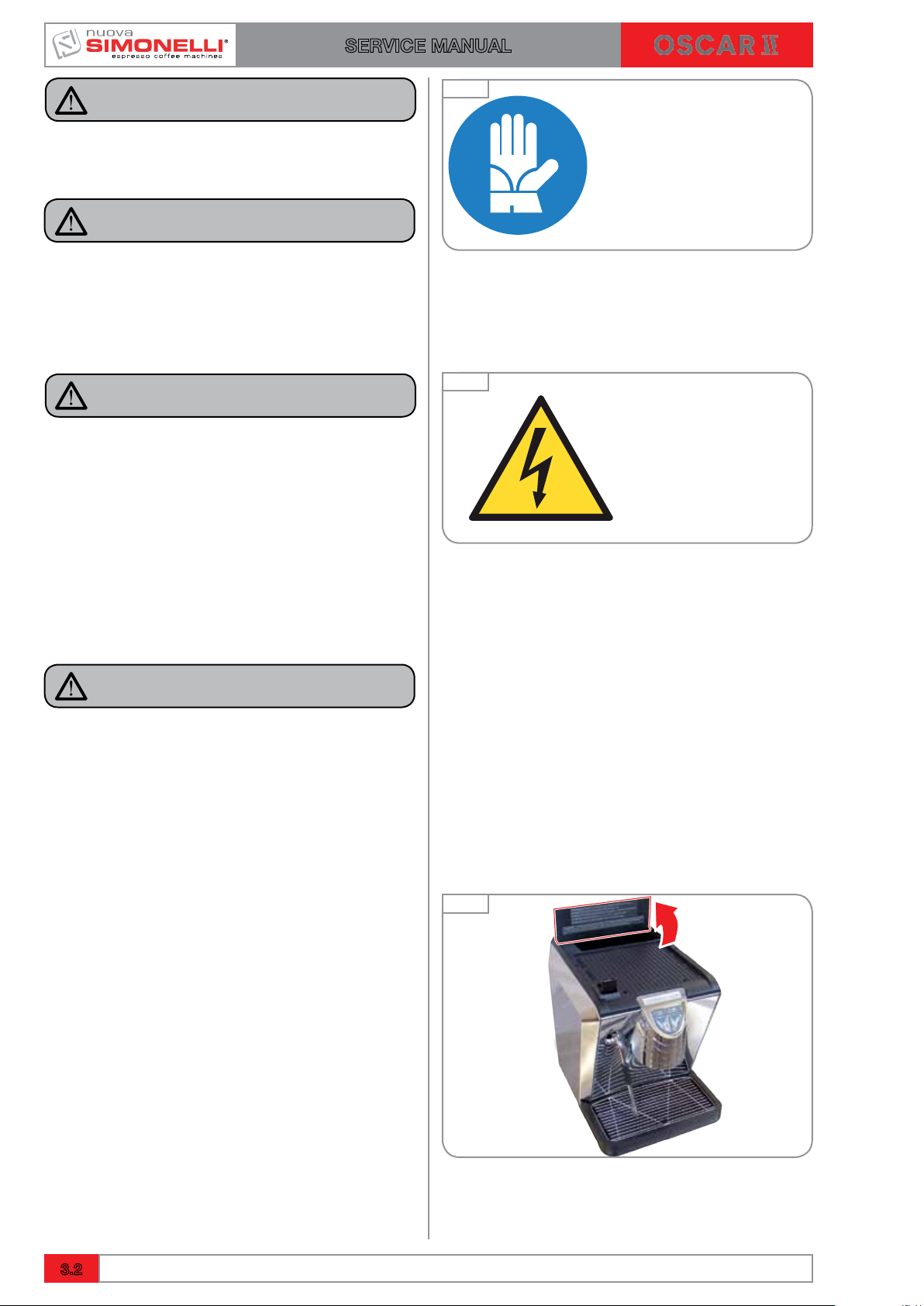

DANGER

Use gloves to protect against sharp or hot

surfaces that you can bump against involuntarily during operations.

NOTE

Before proceeding with the removal of the

panels it is advisable to clean and free up

enough space where the machine parts will

rest so that they are not be unintentionally

damaged.

DANGER

Before proceeding with the operations

described in the chapter make sure that the

machine is turned off and unplugged from the

mains. Discharge any residual pressure present in the heater.

Fig. 22

Fig. 23

DANGER

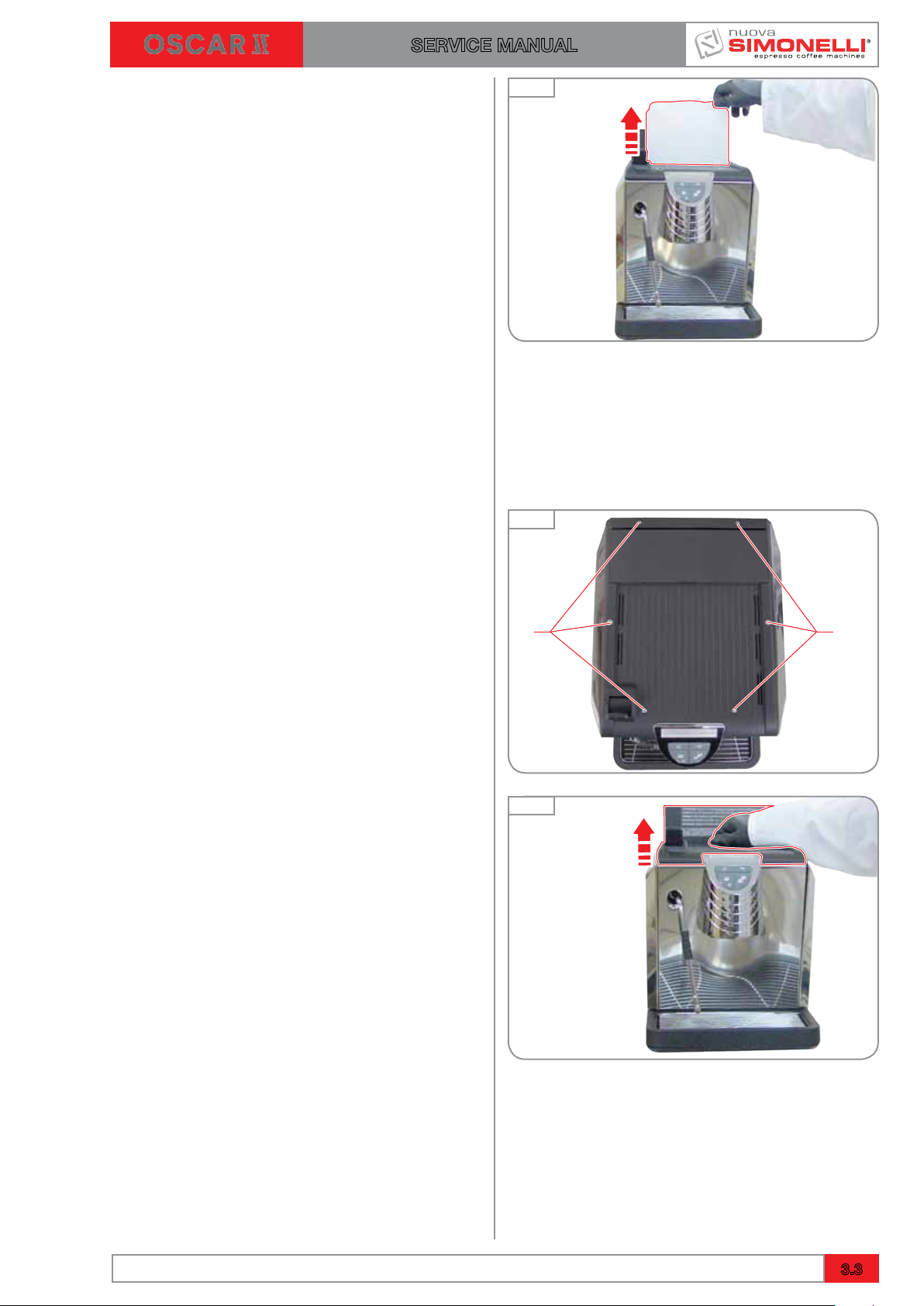

3.1 REMOVAL OF WATER TANK

To remove machine covers, take out the water

tank first:

NOTE

This operation is necessary only for the version with tank.

To remove the tank from its seat, proceed as follows:

1 Lift the water tank cap.

Fig. 22

3.2

Ed. 02 of 09/2016

A A

SERVICE MANUAL

2 Pull the water tank upward.

3.2 REMOVAL OF THE CUP HOLDER

SURFACE

To remove the bearing surface of the cup, proceed as follows:

1 Unscrew the screws "A" with a screwdriver.

Fig. 23

Fig. 24

2 Lift the panel and pull upwards.

Fig. 25

Ed. 02 of 09/2016

3.3

2

1

2

1

A

A

2

1

SERVICE MANUAL

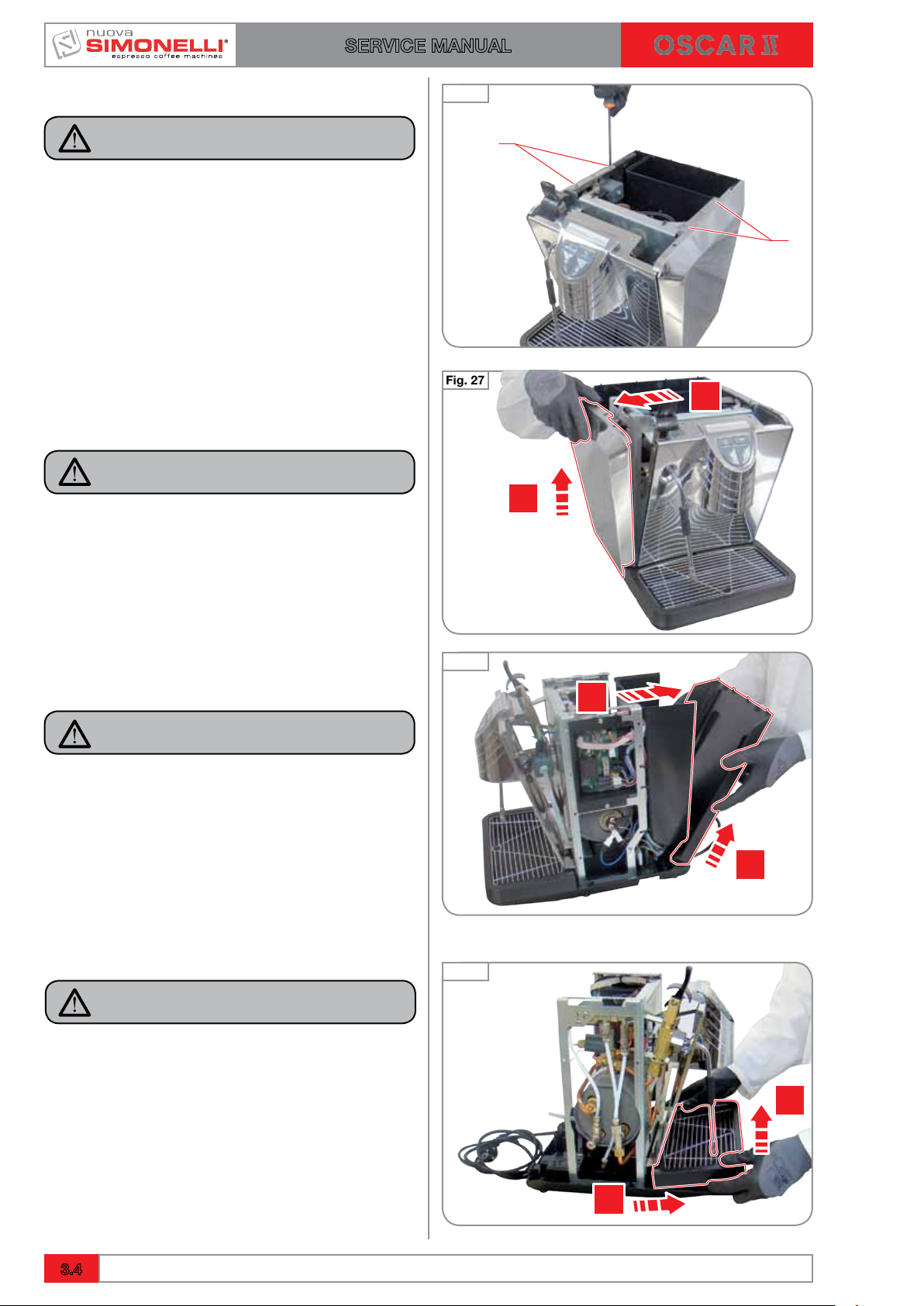

3.3 REMOVAL OF THE SIDE PANELS

NOTE

To remove the side panels, it is necessary to

remove the cup holding surface first.

1 Unscrew the "A" present on each panel

using a Phillips screwdriver.

2 Move outside the top of the panel and pull

up.

NOTE

Perform the same steps for the other side

panel.

Fig. 26

Fig. 27

3.4 REMOVAL OF THE REAR PANEL

NOTE

To remove the back panel it is necessary to

remove both side panels first.

Proceed as follows:

1 Move outside the top of the panel and pull

up.

3.5 TANK TO COLLECT WATER FILED

NOTE

To remove the tray with water you need:

1 Lift and remove the tray with water.

Fig. 28

Fig. 29

3.4

Ed. 02 of 09/2016

A

A

1

2

SERVICE MANUAL

3.6 REMOVAL OF THE FRONT PANEL

NOTE

To remove the front panel, you must remove

the top panels and water from the drain pan.

1 Disconnect the connection to the panel.

2 Unscrew the screws "A" with a Phillips

screwdriver.

Fig. 30

Fig. 31

3 Slight outside the steam nozzle, then slide

the front panel to the front of the machine.

Ed. 02 of 09/2016

Fig. 32

3.5

A

1

SERVICE MANUAL

3.6.1 REMOVAL OF KEYBOARD

NOTE

Separate the cover unit from the front panel.

1 Loosen the 4 screws “A” situated on the

back of the front panel using a Phillips

screwdriver.

2 Push in the connector located inside of the

support group to detach the panel.

Fig. 33

Fig. 34

3.6

Ed. 02 of 09/2016

4. INFUSION UNIT

SERVICE MANUAL

INDEX

4. INFUSION UNIT ................4.1

4.1 REMOVAL OF SHOWER

AND SEAL ..................4.2

4.2 COFFEE VALVE ..............4.3

4.3 EXPANSION VALVE ...........4.5

TOOLS NEEDED:

Ed. 02 of 09/2016

4.1

SERVICE MANUAL

The underpan seal prevents water from coming

out from the sides of the pavilion and reach the

capsule unevenly or spill from the filter holder.

Since the material is plastic and exposed to high

temperatures, replace the seal periodically, at

least once a year or according to machine operation, as it tends to deform, loosening elasticity

and sealing.

4.1 REMOVAL OF SHOWER AND SEAL

To remove the shower and pavilion it is sufficient

to loosen the central screw under the unit.

Fig. 35

Fig. 36

WARNING

If the machine was turned off recently, protect

yourself with thermal insulation gloves.

To change the seal use an awl or a slim flathead

screwdriver and at first remove one edge of the

seal and then remove it entirely.

If the unit is worn out just insert shims under the

seal so as to reduce the stroke of the filter holder.

Fig. 37

Fig. 38

4.2

Ed. 02 of 09/2016

SERVICE MANUAL

4.2 COFFEE VALVE

It is a solenoid valve that is normally closed and

opens when it received a command to dispense

coffee.

By closing the decompression removes any

excess water from the filter holder.

TYPICAL PROBLEMS

Check the operation of the valve, if the unit continues to drip continuously or if the coffee capsule is too wet.

Possible causes:

1 First check if the frame is too thin.

2 The third passage of the valve is obstructed,

therefore the final suction is less than it

should be.

3 Shower and pavilion are blocked because of

poor machine cleaning.

Fig. 39

DANGER

Before proceeding with the operations

described in the chapter make sure that the

machine is turned off and unplugged from the

mains. Discharge any residual pressure present in the heater.

HOW TO REPLACE THE COFFEE VALVE:

To remove the coffee valve proceed as follows:

1 Remove the right, side panel and the front

one, as explained in Chapter 3.

2 Disconnect power connections.

3 Disconnect the Teflon tube by removing the

cable holder “A” using the pliers.

Fig. 40

Fig. 41

Ed. 02 of 09/2016

4.3

B

A

C

SERVICE MANUAL

4 Remove the washer and the locking nut “B”

using a 14 mm wrench.

Remove the coil.

5 Loosen the coil support “C” with a 24 mm

wrench.

Fig. 42

Fig. 43

6 Use a 3 mm Allen key to remove the two

screws that fix the head to the unit.

Remove lime scale or oily residues that may

block the free circulation of water.

NOTE

In case of oily residues, properly instruct the

staff using the machine to perform a regular,

deep cleaning with suitable detergents.

Fig. 44

Fig. 45

4.4

Ed. 02 of 09/2016

A

SERVICE MANUAL

4.3 EXPANSION VALVE

To remove the expansion valve, proceed as follows:

1 Remove the front panel.

2 Disconnect the Teflon tube by removing the

cable holder “A” using the pliers.

Fig. 46

3 Loosen the valve with a 14 mm wrench.

4 Apply Teflon tape on the new valve before

screwing it.

Fig. 47

Fig. 48

Ed. 02 of 09/2016

4.5

SERVICE MANUAL

4.6

Ed. 02 of 09/2016

5. HEATER

SERVICE MANUAL

INDEX

5. HEATER.......................5.1

5.1 EMPTYING THE HEATER . . . . . . . . . . 5.2

5.2 REMOVAL OF THE HEATER ........5.4

5.3 HEATING ELEMENT AND

HEAT PROTECTION ..............5.5

5.4 REPLACEMENT OF THE

LEVEL GAUGE ...................5.6

5.5 ANTIVACUUM VALVE .............5.7

5.6 SAFETY VALVE ..................5.8

TOOLS NEEDED:

30 MM

19 MM

Ed. 02 of 09/2016

16 MM 12 MM 12 MM

5.1

A

SERVICE MANUAL

5.1 EMPTYING THE HEATER

DANGER

Before proceeding with the operations

described in the chapter make sure that the

machine is turned off and unplugged from the

mains. Discharge any residual pressure present in the steam heater.

WARNING

Before carrying out the heater emptying procedure, remove water inlet sources inside the

waterline:

• Waterline version: close the water inlet

tap and disconnect the pipe.

• Tank version:removethe tankfrom its

seat.

These operations are necessary to avoid any

water leakage inside the machine that may

cause damage.

Fig. 49

DANGER

Fig. 50

WARNING

Every time you work directly.

With the heater it is important to ensure that

the internal pressure is zero. Completely

remove the water inside for operations that

require it.

To empty the heater proceed as follows:

1 Turn off the machine and let out all the steam

by opening fully the steam outlets to lower

the temperature quickly.

2 Remove covers:

• Sidepanels;

• Rearpanel;

• Frontpanel.

3 Place the machine on the right side to pre-

vent water leakage and loosen the drain nut

“A” using a 13 mm wrench.

Fig. 51

Fig. 52

5.2

Ed. 02 of 09/2016

A

4 Connect the drain pipe and tilt the machine

on the left side to let the water out of the

heater.

5 After drainage of water from the heater,

tighten the drain nut “A” using a 13 mm

wrench.

Fig. 53

Fig. 54

Ed. 02 of 09/2016

5.3

B

B

A

C

SERVICE MANUAL

5.2 REMOVAL OF THE HEATER

In case of need, to remove the heater, it is necessary to discharge pressure.

Then, proceed as follows:

1 Remove machine covers:

• Rearpanel;

• Sidepanels;

• Frontpanel.

2 Empty water heater, as in the previous

section.

3 Disconnect the level probe.

4 Disconnect the pressure gauge capillary.

5 Remove the fittings on the upper part of the

heater with a 17 mm wrench:

A SteamNozzle;

B Coffeedeliverygroup;

C HotWaterNozzle.

6 Remove the remaining fittings that hold the

heater in place.

7 Remove the fittings on the left side:

A using a 12 mm wrench.

The heater can be extracted from the machine.

During the assembly phase of the new boiler, pay

close attention to the restoration of the connections to ensure proper operation.

Fig. 55

Fig. 56

5.4

Ed. 02 of 09/2016

B

B

C

A

B

5.3 HEATING ELEMENT AND

HEAT PROTECTION

To access the heating element, remove the right

panel of the cover.

The visible parts are:

A 167° heat protection.

B Electrical connections of heating element.

OSCARIIheaterfeaturesa1200Wheatingelement.

To remove the heating element, proceed as follows:

1 Empty the heater as described above.

2 Loose the nut “A” using a 30 mm wrench.

Fig. 57

3 Remove with care the panel out of its slot.

NOTE

Each time you replace the heating element,

it is also necessary to change the O-ring “B”,

which insulates it from the heater, as it is a

part subject to wear. This component must be

ordered along with the heating element.

Fig. 58

Fig. 59

Ed. 02 of 09/2016

5.5

A

B

SERVICE MANUAL

5.4 REPLACEMENT OF THE

LEVEL GAUGE

Water inside the heater is kept at a constant level

through the use of a level probe.

This probe is connected to the electronic unit,

which continuously checks water level.

Being always exposed to high temperatures and

steam/water it is subject to encrustations which

can inhibit operations.

WHEN TO INTERVENE

• In case it is verified that there are no prob-

lems upstream from the probe you can easily

access the component and perform careful

cleaning with abrasive or descaling agents.

• Make sure the Teflon coatingof the probe is

not damaged. In case of damage, steam leaks

occur and it is necessary to replace the probe.

Fig. 60

Fig. 61

To remove the probe, simply disconnect the red

wire “A” and unscrew the locking bolt “B” with a

16 mm wrench.

NOTE

When replacing the probe it is necessary to

cover the threads with Teflon tape or liquid

sealant.

Fig. 62

5.6

Ed. 02 of 09/2016

5.5 ANTIVACUUM VALVE

The antivacuum valve ensures that air enters the

heater during the machine cooling phase. In this

way the reduction of water volume due to cooling

does not create decompressions that may give

rise to drawbacks such as the suction of milk

throughthesteamnozzle.

WHEN TO REPLACE

You can assume that there are problems with the

antivacuum valve when water coming out from

heater is dirty.

The bad smell is generated from milk that has

been sucked into the heater.

In these cases the valve is closed and is locked

in this condition.

Fig. 63

If the valve blocked open because of limescale

the signs would be:

A Continuous slight whistling sound coming

from the valve.

B Condensation drops near the valve.

NOTE

We suggest that the valve be replaced annually to ensure proper function and excellent

sealing.

HOW TO REPLACE

Using a 19 mm cup hex wrench unscrew the

valve from its housing.

When inserting the new one, coat the threads

with Teflon tape or with a few drops of Loctite.

Fig. 64

Ed. 02 of 09/2016

5.7

A

A

SERVICE MANUAL

5.6 SAFETY VALVE

The heater safety valve “A” of heater serves to

discharge excess pressure that may form owing

to malfunctioning. The valve opens automatically

when inner pressure of heater exceeds 2.1 bar.

WHEN TO REPLACE

For safety reasons each time the valve comes

into operation it should be replaced to ensure

perfect operation.

Therefore, in case of heater flooding or excess

of steam, secure the machine by replacing the

entire valve.

HOW TO REPLACE

Remove the safety valve “A” by unscrewing it

with a 14 mm hex wrench.

Fig. 65

Fig. 66

5.8

Ed. 02 of 09/2016

6. HYDRAULIC CIRCUIT

SERVICE MANUAL

INDEX

6. HYDRAULIC CIRCUIT ...........6.1

6.1 PUMP DISASSEMBLY .............6.2

6.2 REPLACING THE COFFEE VALVE ...6.4

6.3 STEAM NOzzLE .................6.6

6.4 WATER TANK ...................6.11

6.4.1 REPLACEMENT OF

THE FLOAT.................6.11

6.4.2 REMOVAL OF THE

MAGNETIC SENSOR.........6.12

6.5 REMOVAL OF THE PRESSURE

SWITCH .......................6.12

TOOLS NEEDED:

Ed. 02 of 09/2016

6.1

A

SERVICE MANUAL

WARNING

Before carrying out the disassembly procedure of the hydraulic circuit, close water inlet

sources inside the waterline:

• Waterline version: close the water inlet

tap and disconnect the pipe.

• Tank version: remove the tank from its

seat.

Theseoperationsarenecessarytoavoidany

water leakage inside the machine that may

cause damage.

6.1 PUMP DISASSEMBLY

The pump is situated on machine bottom.

The duration depends on the amount of daily

work and the quality of water.

WHEN TO REPLACE THE PUMP

1 During delivery, no water comes out of the

unit.

2 In case the machine remains inactive for too

long, the pump does not delivers owing to

oxidation of fittings.

3 Continuous overheating even in the pres-

ence of water.

If the pump needs to be removed, it is necessary

to:

1 Remove the side and rear panels.

Fig. 67

2 Release the pump from its seat by loosening

the screws “A” of the bottom panel with a

Phillips screwdriver.

6.2

Fig. 68

Ed. 02 of 09/2016

C

D

B

A

SERVICE MANUAL

3 Disconnect the electrical connections of the

pump using the tweezers:

A: temperature probe.

B: power supply.

4 Disconnect the hydraulic connections of the

pump:

• Fromtheflowmeter,disconnecttheTeflon

pipe “C”.

• From the pump to the heater, unscrew

the fitting “D” using a 13 mm spanner.

Fig. 69

Flowmeter

Heater

Fig. 70

5 Take the pump out of the machine.

NOTE

Check the water inlet filter situated in the

heater connection and replace it, if necessary.

NOTE

When replacing the pump, replace the O-ring

code No. 02280007.V, too (see tables at the

end of the manual).

Ed. 02 of 09/2016

6.3

A

B

C

SERVICE MANUAL

6.2 REPLACING THE COFFEE VALVE

The coffee valve “A” is situated underneath the

upper panel, on the left side, and regulates the

amount of water flowing inside the heater during

all phases of machine operation.

WHEN TO INTERVENE

1 The system detects the absence of water

and the pump is set off but the pump sounds

like it’s straining badly: the valve is stuck.

2 There is a general short circuit: the coil may

be short-circuited due to micro leaks or electrical shock.

3 The heater flooded: the impurities have pre-

vented the valve from closing properly.

Fig. 71

HOW TO REPLACE THE COFFEE VALVE

To remove the coffee valve, it is necessary to:

1 Disconnect power connections using twee-

zers "B".

2 Using a 14 mm wrench, remove the bolt "C”

that holds the coil in place and ease it out

of its housing. Under optimal conditions,

the removal is immediate but if parts are

blocked, force removal as much as possible.

Fig. 72

6.4

Ed. 02 of 09/2016

D

E

C

SERVICE MANUAL

3 Using a 24 mm wrench, remove the fixed

part “C“.

4 Disconnect the hydraulic connections “D”

by using a 12 mm wrench.

5 Loose the locking screws “E” to release the

valve from the machine frame.

Fig. 73

Fig. 74

6 Make sure the plunger is clean and there are

no obstructions. Replace the valve if it is not

working.

Fig. 75

Ed. 02 of 09/2016

6.5

DANGER

SERVICE MANUAL

6.3 STEAM NOzzLE

The steam nozzle is composed of a piston actuated by the knob, which presses on a nut with

spring return. By pressing against the spring it

creates space for the steam to pass.

We suggest to replace the seals that keep the

piston perfectly aligned, every 4-6 months. Every

year it is advisable to replace the nut to prevent

the gasket that insulates the steam from drying

and letting seampass. Since these parts must

be changed, we suggest replacing all the seals

simultaneously.

WHEN TO INTERVENE

Problems related to the steam nozzle are:

• Continuouslossofsteam.

• Waterdrippingfromthesteamnozzle.

• Delayedclosure.

• Steamlevertooloose.

Fig. 76

Fig. 77

DANGER

Before proceeding with the operations

described in the chapter make sure that the

machine is turned off and unplugged from the

mains. Discharge any residual pressure present in the steam heater.

Fig. 78

6.6

Ed. 02 of 09/2016

A

SERVICE MANUAL

If there is a loss of steam or condensation, it is

necessary to:

1 Turn the machine off, let out all the steam

until there is no pressure in the heater.

2 Remove the left side panel and the front one.

3 Loose the steam nozzle by means of the nut

“A” using a 22 mm wrench, by levering the

nozzle locking nut with a 23 mm wrench, as

shown on the figure.

Fig. 79

Fig. 80

4 Loose the steam pipe fitting of the nozzle by

means of a 20 mm wrench, by levering the

locking nut with a 23 mm wrench, as shown

on the figure.

5 Unscrew the locking nut of the steam nozzle

with a 23 mm wrench, by levering the steam

valve block with a 22 mm wrench.

Fig. 81

Ed. 02 of 09/2016

6.7

C

B

2

1

D

A

SERVICE MANUAL

DISASSEMBLY OF THE STEAM LEVER

1 Remove screw "A" with an Allen key 3 mm.

2 Remove the clip "B" using pliers.

3 Pull the lever pin "C" to release the steam

lever "D".

Fig. 82

Fig. 83

4 To remove the dispensing nozzle it is suffi-

cient to unscrew the lower part of the nozzle

by hand. We recommend annual replacement O-ring seals.

MAINTENANCE OF STEAM NOzzLE

To carry out repairs and maintenance once the

steam nozzle is removed we can proceed with

the following steps:

1 Remove the piston which is actuated by the

lever. The seals that make it slide in its housing tend to wear out and must be replaced

depending on the use or every 4-6 months.

Fig. 84

Fig. 85

6.8

Ed. 02 of 09/2016

B

C

A

SERVICE MANUAL

2 Using a 22 mm wrench remove the steam

nozzle from its housing. We recommend

replacing the seal at least once a year.

3 Unscrew the fitting "A" with a 21 mm wrench

to reach the spring.

We recommend replacing the seal at least

once a year.

4 Remove the steam piston "C" behind the

spring "B".

Werecommendreplacingthepistonatleast

once a year.

Fig. 86

Fig. 87

The steam nozzle, in its simplicity, has components that must be replaced due to wear.

It is recommended to replace:

• The piston seals (code No. 02280014) to

avoid misalignment.

• The seals of the leverblock(02280011)and

the connection to the heater.

• Thepistonofinnerclosure(98008004).

RE-ASSEMBLY OF THE STEAM NOzzLE

During the reassembly phase it is important to

lubricate the seals of the piston in contact with

the lever, to ensure fluid movement inside the

housing.

Fig. 88

Fig. 89

Ed. 02 of 09/2016

6.9

A

SERVICE MANUAL

WARNING

Operation to be performed when the machine

is on.

Whenfixingthescrewthatholdstheleveronthe

stream nozzle it is necessary to:

1 Lightly press the lever upwards to let steam

come out.

2 Release the lever until the steam supply

stops.

3 Tighten the lever locking screw on the steam

nozzle.

In this way, there is a precise calibration of the

steam nozzle.

Fig. 90

6.10

Ed. 02 of 09/2016

A

SERVICE MANUAL

6.4 WATER TANK

To access the water tank, remove the rear panel.

NOTE

In case of a prolonged inactivity of the

machine, the tank valve may be blocked

owing to limescale.

To release the tank valve, use a screwdriver to

allow water discharge.

Check the valve for the presence of limescale

and the conditions of seal “A”. Replace the faulty

parts, if necessary.

6.4.1 REPLACEMENT OF THE FLOAT

1 Take out the water tank and remove the rear

panel.

2 Manually remove the tank float.

Fig. 91

Fig. 92

NOTE

During the assembly phase of the new float,

make surethe “+” mark on the float itself is

orientedtowardsthetankbottom.

Ed. 02 of 09/2016

6.11

A

B

SERVICE MANUAL

6.4.2 REMOVAL OF THE MAGNETIC

SENSOR

This sensor serves to detect the presence of

water inside the tank. In case of breakdown or

malfunctioning, it can be replaced.

1 Remove the side and rear panels.

2 Move the sensor down, pay attention to the

electrical connections.

3 Disconnect the sensor unit and replace.

6.5 REMOVAL OF THE PRESSURE

SWITCH

The pressure switch cuts off the circuit powering

the heating element. Therefore, it will read a voltage as the one of mains when heater pressure

is enough, while will read 0V when the heating

element is warming up.

Itisadvisabletoreplacethepressure(pressure)

every two years in order to avoid failure.

You need to replace when:

1 Cardoesnotheat(lightresistancestillis,but

the machine is cold and the heater works).

ThepressureislockedintheOFFstate.

2 The production of the steam engine of water

from the inside, because of the overheating

and the open safety valve. Pressure switch is

lockedintheONstate.

Fig. 93

Fig. 94

To remove the pressure switch “A”, it is necessary to:

1 Remove the right, side panel.

2 Disconnect the electrical connections.

3 Unscrew the fitting “B” with a 17 mm wrench.

Fig. 95

6.12

Ed. 02 of 09/2016

7. ELECTRIC COMPONENTS

SERvICE MaNUaL

INDEX

7. ELECTRIC COMPONENTS .......7.1

7.1 CONTROL UNIT..................7.2

TOOLS NEEDED:

Ed. 02 of 09/2016

7.1

A

A

A

A

2

1

3

4

6

5

7

8

9

10

SERvICE MaNUaL

7.1 CONTROL UNIT

To access the main board it is necessary to:

1 Remove the right side panel.

2 Disconnect the electrical connections using

the pliers.

3 Loosen the board locking screws “A” on the

support using a Phillips screwdriver.

Fig. 96

The control unit without connections appears as

shown in the figure.

1 Tank level

2 Keyboard

3 Heating element

4 The boiler

5 Heating element

6 Neutral

7 Phase

8 Valve group

9 Pump

10 Water level

Fig. 97

7.2

Ed. 02 of 09/2016

1

2

3

8. TROUBLESHOOTING

SERVICE MANUAL

INDEX

8. TROUBLESHOOTING............8.1

8.1 WATER LACK LIGHT..............8.2

8.2 HEATING ELEMENT LIGHT ........8.3

8.4 COFFEE DELIVERY ...............8.4

8.5 STEAM DELIVERY................8.4

8.6 HEATER ........................8.5

Ed. 02 of 09/2016

8.1

8.1 WATER LACK LIGHT

SERVICE MANUAL

Water lack light on. Lack of water in the tank.

Check the magnetic sensor. Replace, if necessary.

Water in the tank.

Float in the tank out of

place or faulty.

Check float positioning. Symbol “+” must

be oriented downward.

Replace, if necessary.

Check connections and

the electronic board.

Replace, if necessary.

Fill the tank with drinkable

water.

8.2

Ed. 02 of 09/2016

8.2 HEATING ELEMENT LIGHT

SERVICE MANUAL

Temperature light in

operating mode off (after

30 min.).

Check the conditions of

the pressure switch and

when locked in the open

state, and replace if necessary.

Check the heating element conditions. Replace,

if necessary.

Check connections and

the electronic board.

Replace, if necessary.

Heat protection on (operating temperature considerably exceeded). Check

the thermal protection and

replace it, if necessary.

The machine emits vapour

from inside the machine

regularly.

Check the status of the

pressure switch make

sure it is locked by measuring a voltage across it at

all times equal to 0V.

Replace the pressure

switch and the safety

valve.

Turn the machine off and

let it cool. Check again if

the offense occurs again.

Recheck pressure switch

and relay resistance of the

unit.

If necessary, replace the

control unit.

Ed. 02 of 09/2016

8.3

8.3 REMOVAL OF KEYBOARD

SERVICE MANUAL

Check connections and

the electronic board.

Replace, if necessary.

8.4 COFFEE DELIVERY

The pump is operating but

there is not water in the

tank.

When pressing the keys,

nothing happens.

Check the keyboard and,

if necessary, replace it.

The machine does not

deliver coffee.

Alarm enabled:

• Lack of water; the corresponding light is on.

• Machine not ready;

operating temperature

not reached; the corresponding light is off.

Check for any problems

due to keyboard.

Check the presence of air

between the tank and the

pump. Remove any limestone residue.

Replace, if necessary.

8.5 STEAM DELIVERY

Check for any problems

due to heater.

When pressing the steam

lever, the machine does

not deliver.

Check the condition of the

steam nozzle Eliminate

any residues of limestone

or milk. Unscrew spout

and if necessary, replace

the nozzle.

Check the shower and, if

necessary, replace it.

Check the presence of

limestone in the Gigler,

in the upper part of the

group.

Check for any problem

arising from heater warming up.

8.4

Ed. 02 of 09/2016

8.6 HEATER

SERVICE MANUAL

With the water tank full,

there is no water in the

heater.

Check the coffee valve.

Replace, if necessary.

Check the tank valve.

Remove any limestone

residue. Replace, if necessary.

Check the pump and, if

necessary, replace it.

When reaching the operating temperature.

The boiler emits more

noise than necessary.

Check the status of the

expansion valve. If necessary, replace.

Check the condition of the

safety valve. If necessary,

replace.

Odour from the heater.

Check the anti-vacuum

valve and, if necessary,

replace it.

If need be, carry out a

complete washing of the

heater with citric acid.

Check the valve and the

level probe. Replace, if

necessary.

Heat protection on (operating temperature considerably exceeded). Check

the thermal protection and

replace it, if necessary.

Operating temperature

not reached by the heater.

Check the heating element conditions. Replace,

if necessary.

Check connections and

the electronic board.

Replace, if necessary.

Ed. 02 of 09/2016

8.5

SERVICE MANUAL

8.6

Ed. 02 of 09/2016

9. DIAGRAMS

SERVICE MANUAL

INDEX

9. DIAGRAMS ....................9.1

9.1 HYDRAULIC DIAGRAM

TANK VERSION ..................9.2

9.2 HYDRAULIC DIAGRAM

DIRECT CONNECTION VERSION ...9.3

9.3 WIRING DIAGRAM TANK VERSION..9.4

9.4 WIRING DIAGRAM DIRECT

CONNECTION VERSION...........9.5

Ed. 02 of 09/2016

9.1

S

S

1 2

3

4

5

8

9

10

11

6

7

SERVICE MANUAL

9.1 HYDRAULIC DIAGRAM TANK VERSION

5 Steam valve

6 Safety valve

1 Pump

2 Calibrated orifice

3 1-way valve

4 Pressure switch

9 Water level valve

10 Maximum pressure valve

11 Delivery valve

circuit coffee

9.2

7 Anti-vacuum valve

8 Boiler

Ed. 02 of 09/2016

S

S

S

2

1

3

4

5

6

9

10

11

12

7

8

SERVICE MANUAL

9.2 HYDRAULIC DIAGRAM DIRECT CONNECTION VERSION

5 Pressure switch

6 Steam valve

7 Safety valve

1 Water supply valve

2 Pump

3 Calibrated orifice

4 1-way valve

10 Water level valve

11 Maximum pressure valve

12 Delivery valve

circuit coffee

Ed. 02 of 09/2016

8 Anti-vacuum valve

9 Boiler

9.3

LS

MS

LP

ER

TF

PS

MB

GR

PU LE

SERVICE MANUAL

9.3 WIRING DIAGRAM TANK VERSION

PS PRESSURE SWITCH

TF THERMAL FUSE

LE WATER LEVEL VALVE

GR GROUP VALVE

LP TANK SENSOR

MS MAIN SWITCH

PU PUMP

MB MAIN BOARD

LS TANK PRESENCE SENSOR

ER ELECTRICAL RESISTANCE

9.4

Ed. 02 of 09/2016

K

TL BL MS

LP

ER PS

LE PU

MB

TF

GR

SERVICE MANUAL

9.4 WIRING DIAGRAM DIRECT CONNECTION VERSION

TF THERMAL FUSE

LE WATER LEVEL VALVE

GR GROUP VALVE

TL TANK LEVEL SENSOR

BL BOILER LEVEL

K KEYPAD

LP TANK SENSOR

PU PUMP

MB MAIN BOARD

LS TANK PRESENCE SENSOR

PS PRESSURE SWITCH

Ed. 02 of 09/2016

9.5

SERVICE MANUAL

9.6

Ed. 02 of 09/2016

10. MAINTENANCE CHECKING

SERVICE MANUAL

INDEX

10. MAINTENANCE CHECKING .....10.1

10.1 DAILY MAINTENANCE ...........10.2

10.2 WEEKLY MAINTENANCE .........10.2

10.3 YEARLY MAINTENANCE .........10.3

10.4 BIENNIAL MAINTENANCE ........10.4

Ed. 02 of 09/2016

10.1

SERVICE MANUAL

10.1 DAILY MAINTENANCE

Time required 5 min:

Clean the machine;

Clean the unit with the blind filter and specific detergent (Pulycaff);

Empty the water collection tray.

10.2 WEEKLY MAINTENANCE

Time required 10 min:

Clean the machine;

Clean the unit with the blind filter and specific detergent (Pulycaff);

Empty the water collection tray;

Remove the filter from its holder and thoroughly clean it;

Immerse the filter holder into hot water with specific detergent (Pulycaff) and thoroughly clean all

parts;

Verify suitability of water used (total hardness F°< 6).

10.2

Ed. 02 of 09/2016

SERVICE MANUAL

10.3 YEARLY MAINTENANCE

Time required 45 - 60 min:

The skilled technician should take all the necessary precautions concerning safety measures to insulate the machine from the mains and to avoid pressure in the heater, waterline closure or tank removal

so as to prevent inconveniences or damages. Before proceeding, remove all machine covers and

check for any damage or leakage.

Before proceeding, remove all perimeter coverings and make sure there are no damages or leakages.

Check for any sign of leakage;

Check all wirings;

Check pump noise;

Check for any drip from the unit and the steam nozzle;

Check non-return valve;

Check self-level function;

Check heater pressure (______Bar);

Check the presence of limescale in the tank;

Check electrovalve for leakages;

Check heater for leakages;

Replace the group gasket (02280020.C);

Replace shower screen (03000066);

Insert or replace, if necessary, shims under the seal (02060014).

NOTES

The water hardness must be below 6°fr (French degree).

The chlorine content must not exceed 100 mg.

Necessary spare parts:

02280020.C

03000066

02060014

Ed. 02 of 09/2016

10.3

SERVICE MANUAL

10.4 BIENNIAL MAINTENANCE

Time required 60 - 90 min:

The skilled technician should take all the necessary precautions concerning safety measures to insulate the machine from the mains and to avoid pressure in the heater, waterline closure or tank removal

so as to prevent inconveniences or damages. Before proceeding, remove all machine covers and

check for any damage or leakage.

Check for any sign of leakage;

Check all wirings;

Check pump noise;

Check for any drip from the unit, the steam nozzle and the hot water nozzle;

Replace the non-return valve (01000023);

Check self-level function;

Check heater pressure (______Bar);

Check total production of beverages;

Check electrovalve for leakages;

Check heater for leakages;

Replace group gasket (02280020.C);

Replace shower screen (03000066);

Insert or replace, if necessary, shims under the seal (02060014);

Replace the pressure switch (09200014);

Replace the steam nozzle seals (05000001);

Replace the steam nozzle closing piston (98008004);

Replace the 2-coffee filter (03000073);

Replace the 1-coffee filter (03000072);

Replace the steam nozzle support seal (02280037);

Replace the nozzle support seal (02280011);

Replace the steam lever piston seals (2 x 02280014);

Replace the steam nozzle seal (02280036);

Replace the unit expansion valve (98120001).

NOTES

The water hardness must be below 6°fr (French degree).

The chlorine content must not exceed 100 mg.

Necessary spare parts:

01000023

02280020.C

03000066

02060014

09200014

05000001

98008004

03000073

03000072

02280037

02280011

2x02280014

02280036

98120001

10.4

Ed. 02 of 09/2016

SERVICE MANUAL

98120001

ANNUAL MAINTENANCE

02280037

02280020.C

03000066

02280036

O

S

C

A

R

II

98008004

02280011

09200014

03000073

03000072

01000023

Change every 12 months

Ed. 02 of 09/2016

Change every 24 months

10.5

SERVICE MANUAL

10.6

Ed. 02 of 09/2016

O

S

C

A

R

II

TAV 01

COMPONENTI GRUPPO CARENA

CABINET PARTS

05000758

05002406

00000009

05002412

05002410

03002452

03002454

00000011

00000175

00000175

00000011

05000185

03002460

31000700

00000175

00000050

05002400.C

03002450

00000232

05000185

00000089

05002404

00000174

00000231

04901090

03002462

00000204

00000204

05002408

01000268

01000268

01000268

*

*

*

*

*

SPECIFICARE COLORE (SPECIFY COLOR)

NOITPIRCSEDNOITPIRCSEDECNEREFER

END

VALIDETY

00000009 VIS AUTOF 3,5x8 Z.B. HILO TC TCR GALV. SELF-TAPPING SCREW 3,5x6,5 MUSTAD

SELNIATSA/2488INUEETELOM4MXONIELLEDNOR11000000 S STEEL KNURLED WASHER D4

00000047 VIS AUTOF 2,9x6,5 TC/T.CR. CROSS HEAD CAP SELF-TAPPING SCREW 2,9x6,5

00000050 VIS AUTOF 3,5x12 TC/T.CR. SCREW 3,5x12 TC/T.CR.

00000083 VIS AUTOF 3,9x16 TC/T.CR. CRO SS HEAD CAP SELF-TAPPING SCREW 3,9x16

00000089 VIS INOX M4x12 TC TCR DEN7985 SS CROSS HEAD CAP SCREW

M4x12

00000096 RONDELLE AQ M6 6,6X18X1.5 GALVANISE GALVANISED WASHER M6 6,6x18x1,5

00000112 VIS INOX M6x20 TCEI UNI 5931 SS SOCKET SCREW M6X20 UNI 5931

00000118 VIS INOX M4x12 TCEI 5931 SS HEX SOCKET CAP SCREW M4x12

00000155 VIS INOX TRUCIOL. 3x12 TSPTCR 18-8 DEN 750 A5057NEDRCTPST21x3WERCSSSA5

00000174 VIS INOX M4x16 TC TCR SS CROSSHEAD CAP SCREW M4x16

00000175 VIS INOX M4x10 TC TCR SS CROSS HEAD CAP SCREW M4X10

00000199 VIS POINTEAU INOX M4 MEDEO UNI 5588 NUT M4 MEDEUM STAINLESS UNI 5588

00000204 VIS AUTOF INOX 2,9x6,5 TC TCR DEN7981 SS SELF

-THREADENG SCREW 2,9x6,5 TC-TCR DEN7981

00000221 RONDELLE DE SECURITE INOX M6 SCHNORR CONIQUE SECURITY FLAT WASHER INOX M6 CONIQUEL

00000222 VIS INOX M6 LT=17.5 TE CH9 + TC x DOCCIA **AD EPUISEE SS SCREW M6 TE CH9 FOR GROUP SHOWER

00000231 VIS AUTOF INOX 3,9x19 TC /TCR SS SELF-THREADENG SCREW 3,9x22

00000232 VIS POINTEAU CAGE M 4 x EPAI. 0 TEEHSLATEMmm9,0-3,0ROFTUNEGAC9,0-3,

00200011 RONDELLE AQ M16 17X30X3 GALVANISE GALVANISED WASHER M16 17x30x3

00300002 VIS POINTEAU OT 1/4 EPAI.3 CH18 AGG. 3ROIAPE4/1TUNSSARB69.70.2

2

00300012 VIS POINTEAU OT 3/8 GAS CH22 EPAI.6 AGG. 22.07.96 BRASS NUT 3/8 GAS EPAIOR 6 HEX 22

00300021 VIS INOX M6x18 TSP TC DEN963 SS SLOTTED COUNTERSUNK SCREW M6X18 DEN963

00300026 BOUCHON CONIQUE 1/4 GAS CONIQUEL TAP 1/4"

00300040 VIS A TETE INOX M6x6 POINTE PLANE SS GRUB SCREW M6x6

01000023 PETITE VALVE MISE A L'AIR ANTI VACUUM VALVE

01000089 PETITE VALVE DE RETENUE CO14 RETAINING VALVE CO14

01000092 TUYAU ALIMENTATION EAU 1,5mt EPDM 3/8F OTT. - 3/4F90 3/8F-3/4F90° WATER CHARGE PIPE 1,5mt

01000265 ISOLANT CHAUDIERE OSCAR II BO

ILER THERMAL INSULATION

01000266 ISOLANT D.110 DX CHAUDIERE OSCAR II EDISXDNOITALUSNILAMREHTRELIOB

01000267 ISOLANT D.110 SX CHAUDIERE OSCAR II EDISXSNOITALUSNILAMREHTRELIOB

01000268 KIT ISOLANT CARENAGE OSCAR II SS HULL THERMAL INSULATION

AGECNALODONS658PE71.D511ROTNIOJ40008220 SKET OR 115 D17 EP 856 x SWIVEL STEAM PIPE

02280009 JOINT OR 139/4131 D.40 EP851 GASKET OR 139/4131 D.40 EP851

02280011 JOINT OR R11 D19 EP 851 GASKET O RING R11 D19 EP 851

TEKSAG5171LX7NOCILIS201RO/2NA7DROTNIOJ41008220 O RING D

.7 AN2/OR102 SILICON

DER07hSEGUORENOCILIS91D11RROTNIOJ81008220 SILICON GASKET O RING Sh70

02280020.C JOINT. SOUCOUPE 073X058X7 TYPE C 82/84 TEKSAGPUORGAhS

G07MDPE2.1x6ED.PAVECNALCEBxROTNIOJ63008220 ASKET OR x STEAM WAND NOZZLE

TEKSAG07RBN2x61ODONSERUTEMREFROTNIOJ73008220 OR JOINT LOCK 16x2

02290016 JOINT OR D 9,5 R5 SILICONE R. GASKET OR D 9,5 R5 SILICON RED

02590010 JOINT PISTON FKM NOIRE Sh80 GUARNIZ.PISTONCINO FKM NOIRE Sh80

OHS403isiAEEDUOS6x5,5x65XONIETTEHCUOD66000

030 WER INOX 056X05,5X6

03000072 FILTRE 1 CAFE' ALTO 7 gr. FILTER ONE COFFEE HIGH REPLACE 03000321

03000073 FILTRE 2 CAFE' ALTO 14gr. FILTER TWO COFFEE HIGH REPLACE 03000322

03000202 RESERVOIR RACC.CONDENSA MASTER AGG. 07.06.97 CONDENSATION TRAY MASTER

03002450 CARENAGE FRONTAL OSCAR II FRONT PANEL OSCAR II

03002452 CARENAGE FLANC DROIT OSCAR II RIGHT SIDE PANEL OSCAR II

03002454 CARENAGE FLANC GAUCHE OSCAR II LEFT SIDE PANEL OSCAR II

03002458 TOLERIE MACHINE OSCAR II M ACHINE FRAME OSCAR II

NSSIIRACSO.VALONAIPXONIOLIFAA

NITER06420030 ET WORK PLANE OSCAR II

AWPUCIIRACSOSESSATEFFUAHC.P.NOITCETORP26420030 RMER INTERNAL PROTECTION OSCAR II

04000075 CONNECTEUR PVC 2 POLES TERMINAL BLOCK 2 WAY

04000198 PRISE LAMELLAIRE M 6.3 d4.2 45 FOIL HOLDER M 6.3 D 4.2 45

BUOD542.4d3.6MELBUODERIALLEMALESIRP99100040 LE FOIL HOLDER M 6.3 D 4.2 45

04000566 UNITE' MAGNETIQUE FLOTTEUR D22X35 FLOATING UNIT

04000660 CABLE DE CONEXION CARTE/ DISTRIBUTEUR MUSICA CENTRAL UNIT/DESPENSING BOARD FLAT CABLE

04000685 CAPT

EUR REED 4X19 X OSCAR II T IIRACSOmm91x4ROSNESDEERLEVELKNATACINA

04000690 CABLAGE COMPLET OSCAR II COMPLETE ELECTRICAL CABLING OSCAR II

04060002 CABLE ALIM. UL AWG3x18 SJO 10A 90C 2mt PRISE USA DROITE POWER SUPPLY CABLE UL AWG 3x18 SJT + PLUG 730

04080043 CABLE ALIM. 2mt CE PRISE SCHUKO 90 H05VV-F 3x0,75 2 m POWER CORD EC PLUG

04100005 E.V. NC 2VOIES 1/4-1/4 220-230V 50/60Hz EPDM F2 CE NC 2-WAY SOLENOID 1/4-1/4

04100006 E.V. NC 2VOIES 1/4-1/4 110-120V 60Hz EPDM F2 UL NC 2-WAY SOLENOID 1/4-1/4 115

v

04100037 E.V. NC 3VOIES BAS VIDAGE PORTAG.115V 60Hz VITON F1.5 UL 3-WAY SOLENOID VALVE 115V 60Hz VITON F1.5 UL

04100038 E.V. NC 3VOIES BAS VIDAGE PORTAG.230V 50/60Hz VITON F1.5 3 WAYS SOLENOID VALVE 230V

04100060 E.V. NC 2VOIES 3/4-JG 6 DROITE REGUL+FILTR F.2,5 230V 50/60Hz 2-WAY SOLENOID VALVE 3/4-JG 6 230V 50/60HZ

04100061 E.V. NC 2VOIES 3/4-JG 6 DROITE REGUL+FILTR F.2,5 115V 60Hz UL 2-WAY SOLENOID VALVE 3/4-JG 6 115v 60HZ

04100062 E.V. NC 2VOIES 3/4-JG6 DROITE. UL REGUL+FILTR F.2,5 208/240V60Hz 2-WAY

SOLENOID VALVE 3/4-JG 6 230V 60HZ UL

04200112 INTERRUPTEUR BIPOLAIRE ROUGE 0/1 RECTANGULAIRE UL 16A 2 POLES SWITCH 16A OSCAR II

RBIVW84zH05V032.EUQINACEMORTCELEEPMOP50000840 ATION PUMP V230/50

RBIVW14zH06V021.EUQINACEMORTCELEEPMOP60000840 ATION PUMP 115V 60Hz

CELEW46zH06V022EUQINACEMORTCELEEPMOP70000840 TROMECHANICAL PUMP 220V 60Hz 64W

YEK2IIRACSOSEHCUOT2RUETUBIRTSIDETRAC09010940 KEYBOARD OSCAR II

04901094 CARTE ELECTRONIQUE. OSCAR II 230V CONTROL UN

IT OSCAR II 230V

04901095 CARTE ELECTRONIQUE. OSCAR II 115V CONTROL UNIT OSCAR II 115V

TSREBBUR8.DECNALNOITCETORPEDCUOHCTUOAC20000050 EAM PIPE PROTECTION 8

05000063 COUVRE VALVE DE SECURITE PA6 SAFETY VALVE COVER

05000082 DOSEUR CAFE' MOULU 1 DOSE 1 DOSE SPOON

05000083 SERRE CABLE SR 11-2 NOIRE CABLE BLOCK SR 11-2

05000185 PIED OSCAR FOOT OSCAR

05000186 INCERE NYLON GR. OSCAR h3 D.6,3/20 NOIR PUORGRACSOTRESNINOLYN2HE

YN1H02/3,6.D1HRACSO.RGNOLYNERECNI78100050 LON INSERT OSCAR GROUP

05000268 RESERVOIR EAU 3lt "MUSICA"

3LT WATER CONTAINER - MUSICA

INORTCELE"ACISUM"ELÔRTNOCEDETRACTROPPUS07200050 C CONTROL BOARD SUPPORT - MUSICA

05000758.N COUVERCLE RESERVOIR EAU 5LT PRONTOBAR NOIRE GRIS 5 LT WATER CHAMBER CO VER - PRONTOBAR BLACK

RCIMRABORCIMTL5UAERIOVRESERRUETCELLOC95700050 OBAR WATER CONTAINER MAINFOLD 5LT

05000840 MANETTE PORTE FILTRE 2003 NOIRE FILTER HOLDER KNOB 2003 BLACK

RETLIF3002ERTLIFETROPETTENAMERUTEMREF24800050 HOLDER KNOB LOCK 2003

05000844 REVETEMENT CAOUTCHOUC NOIRE

MANETTE PORTE FILTRE BLACK RUBBER COVER FILTER HOLDER KNOB

05002228 COLLECTEUR GROUPE D'ALIMENTATION POURING UNIT DRAIN MANIFOLD

D82220050xNOITATNEMILACUOHCTUOACNOHCUOB03220050 RAIN RUBBER PLUG

05002400 COUVRE GROUPE OSCAR II GROUP COVER OSCAR II

05002404 CARENAGE SUPERIEUR OSCAR II TOP COVER OSCAR II

05002406 CARENAGE ARRIERE OSCAR II BACK COVER OSCAR II

05002408 CARENAGE INFERIEUR OSCAR II BASE COVER OSCAR II

05002410 RESERVOIR RAC.EAU OSCAR II DRIP TRAY OSCAR II

C

R

II

11. SPARE PART CATALOGUE

SERVICE MANUAL

O

S

A

INDEX

11. SPARE PART CATALOGUE ......11.1

11.1 CABINET PARTS ................11.2

11.2 COMPLETE POURING UNIT ......11.3

11.3 TANK - FRAME COMPONENTS ....11.4

11.4 STOVE FILED COLLECT WATER ...11.5

11.5 BOILER COMPONENTS ..........11.6

11.6 ELECTRICAL COMPONENTS .....11.7

11.1

Ed. 01 of 12/2015

11.1 CABINET PARTS

SERVICE MANUAL

00000011

03002454

03002450

00000175

00000232

00000011

00000089

00000175

01000268

00000204

01000268

05000758

00000174

*

00000231

05002404

03002462

00000204

01000268

*

05002406

*

31000700

00000050

04901090

05002400.C

03002460

*

SPECIFICARE COLORE (SPECIFY COLOR)

00000175

05002410

05000185

*

05002408

00000009

03002452

*

05002412

05000185

*

11.2

Ed. 01 of 12/2015

11.2 COMPLETE POURING UNIT

SERVICE MANUAL

11600002

73004013

02280020.C

03000066

08000003

98120001

00000118

07300183

00000221

00300040

00000118

00300040

02290016

08000003

COMPLETE GROUP

980400000001000001 230V

980400000001000002 115V

04100038 230V

04100037 115V

11600002

00000217

05000082

03000107

05080035

03000072

08000017

03000073

06200086

07300212

07300601

05000840-G

05000843-C

05000844-G

98005050

Ed. 01 of 12/2015

07300092

06200008

11.3

SERVICE MANUAL

11.3 TANK - FRAME COMPONENTS

05000187

05000186

03002458

00000089

00000199

00000011

05000186

05002408

05002230

*

05000187

05180006

05180006

05002228

00000011

04000075

00000199

04100060 230V 50Hz

04100061 115V 60 Hz

04100062 208-240V 60Hz

00000089

04000604

05000083

04200112

09500007

07300714

07300860

05180005

05000185

*

SPECIFICARE COLORE (SPECIFY COLOR)

11.4

00000009

05002412

04800005 230V 50Hz

04800006 115V 60Hz

04800007 220V 60Hz

05180005

07300364

07300369

Ed. 01 of 12/2015

SERVICE MANUAL

11.4 STOVE FILED COLLECT WATER

05000759

00000155

00000155

08000015

00000231

00000231

05002414

04000685

05002416

98200000000020

*

02280018

07300355

07300295

98060030

05000002

02280036

02280037

07300293

02280004

00000118

02280014

02280014

08000027

07300110

00300012

07300810

07300221

07300354

98008004

08000005

02280011

00200011

04100005 230V

04100006 115V

07300218

98110001

07300720

07300138

07300450

07300364

07300364

75006038.1

*

SPECIFICARE COLORE (SPECIFY COLOR)

Ed. 01 of 12/2015

11.5

11.5 BOILER COMPONENTS

SERVICE MANUAL

01000265

01000266

01000267

98013021

07300227

09200014

09200006

98030444

01000023

03000202

09500014 (167°C)

07300365

09000006

07300362

00300026

05000063

07300459

02280009

00300002

14100040 230V

14100041 115V

07300382

98030440

00300002

07300091

00300002

07300365

98030446

11.6

98030442

98030448

Ed. 01 of 12/2015

11.6 ELECTRICAL COMPONENTS

05000270

SERVICE MANUAL

04000660

04901094 230V

04901095 115V

00000047

00000047

04200112

04000690

04080043

Ed. 01 of 12/2015

04060002

11.7

O

S

C

A

R

SERVICE MANUAL

NOITPIRCSEDNOITPIRCSEDECNEREFER

00000009 VIS AUTOF 3,5x8 Z.B. HILO TC TCR GALV. SELF-TAPPING SCREW 3,5x6,5 MUSTAD

00000047 VIS AUTOF 2,9x6,5 TC/T.CR. CROSS HEAD CAP SELF-TAPPING SCREW 2,9x6,5

00000050 VIS AUTOF 3,5x12 TC/T.CR. SCREW 3,5x12 TC/T.CR.

00000083 VIS AUTOF 3,9x16 TC/T.CR. CROSS HEAD CAP SELF-TAPPING SCREW 3,9x16

00000089 VIS INOX M4x12 TC TCR DEN7985 SS CROSS HEAD CAP SCREW M4x12

00000096 RONDELLE AQ M6 6,6X18X1.5 GALVANI

00000112 VIS INOX M6x20 TCEI UNI 5931 SS SOCKET SCREW M6X20 UNI 5931

00000118 VIS INOX M4x12 TCEI 5931 SS HEX SOCKET CAP SCREW M4x12

00000155 VIS INOX TRUCIOL. 3x12 TSPTCR 18-8 DEN 750 A 5057 NED RCTPST 21x3 WERCS SSA 5

00000174 VIS INOX M4x16 TC TCR SS CROSSHEAD CAP SCREW M4x16

00000175 VIS INOX M4x10 TC TCR SS CROSS HEAD CAP SCREW M4X10

00000199 VIS POINTEAU INOX M4 MEDEO UNI 5588 NUT M4 MEDEUM STAINLESS UNI 5588