Nuova Venus Bar 2 Installation Manual

13

Congratulations, you have chosen an unique in its kind machine.

Read carefully what is advised in the instruction manual for “setting-up” of your

“Venus Family”. You will see how easy it is to make delicious coffee and creamy

cappuccinos. With the passing of time, you will also realise how little maintenance is needed.

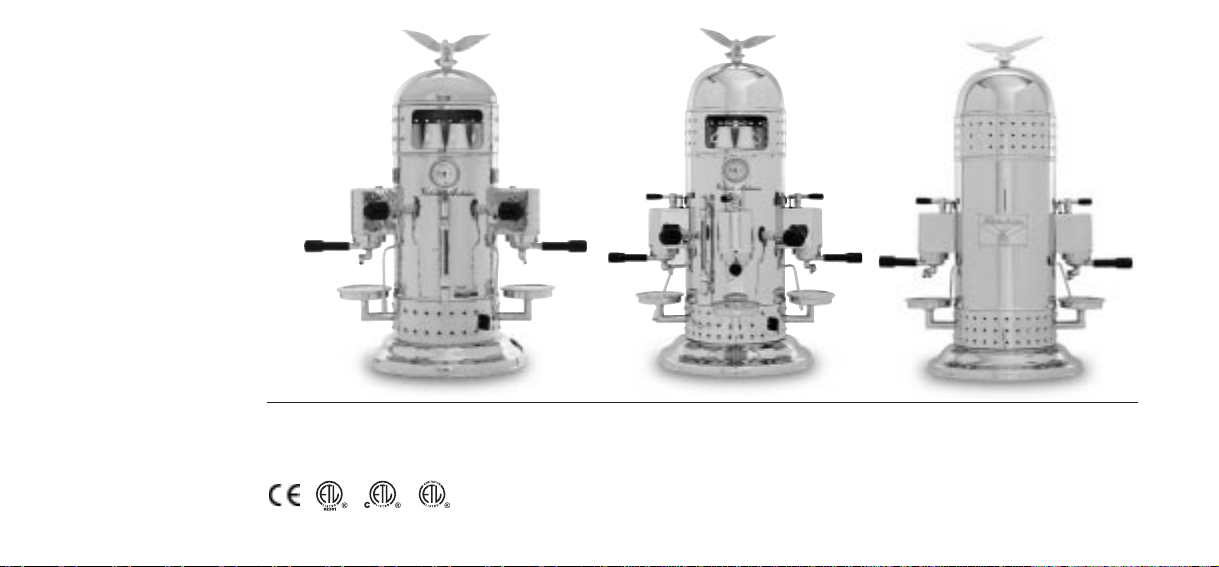

Victoria Arduino

VENUSBAR

14

fkajfasjf

15

Model:

Venus Bar 2 Groups - Net weight: 60 Kg - Gross weight: 70 Kg - Thermal power: 2000 W - Boiler capacity 7,6 lt Volts 208-240V 50/60Hz

Dimensions: L 420 mm H 920 mm W 420 mm -

Finishing in beaten sheet metal: copper, chrome, brass

Model:

Venus Bar 3 Gruoups -

Net weight:

76 Kg -

Gross weight:

86 Kg -

Thermal power:

2600 W -

Boiler capacity

14,8 lt Volts 208-240V 50/60Hz

Dimensions: L 490 mm A 1070 mm W 490 mm -

Finishing in beaten sheet metal: copper, chrome, brass

The international approval labels certify that all the machines have regularly undergone expert checks

and tests

VENUSBAR

16

SAFETY REGULATIONS

1 The present manual is an integral and

essential part of the product and will have to be

handed over to the user. Read carefully the

written warnings in the present manual as they

give important suggestions concerning the safety

of installation and set-up, use and maintenance.

Keep this manual in a safe place for further

information.

2

After removing the packaging, check the

integral parts of the machine are intact. If in

doubt, do not use the machine and contact the

professionally qualified personnel. The

elements of the packaging must be kept out of

children’s reach as they can be potential

sources of danger and they mustn’t be

disposed of in the environment.

m

POLLUTION DANGER

3

Before connecting the machine, make sure

that the data of the plate correspond to those of

the electrical distribution network. The plate is

located under the machine’s base. The

installation has to be carried out in compliance

with the regulations of the Country where the

machine is set-up, according to the instructions

by the manufacturer and qualified personnel.

The manufacturer can’t be considered

responsible for possible damage caused by

failure in earthing the plant. For the electrical

safety of this machine it is obligatory to arrange

the earthing plant, contact an electrician with

proper and certified technical suitability, to check

the electrical capacity of the plant is adequate to

the maximum power of the machine, stated on

the plate. In particular the electrician will

have to make sure that the section of the

plants’ cables is suitable to the power

absorbed by the machine.

The use of adaptors, multi-sockets and

extensions is forbidden. If their use is

necessary, it is compulsory to call a licensed

electrician.

4

The machine must be set-up according to the

sanitary and health regulations valid for hydraulic

plants. For the hydraulic plant contact an

authorised technician.

GENERAL REMARKS ON THE CONSIGNMENT

Loading...

Loading...