Page 1

512-Kbit, serial flash memory, 50 MHz SPI bus interface

Features

■ 512 Kbits of flash memory

■ Page program (up to 256 bytes) in 1.4 ms

(typical)

■ Sector erase (256 Kbits) in 0.65 s (typical)

■ Bulk erase (512 Kbits) in 0.85 s (typical)

■ 2.3 to 3.6 V single supply voltage

■ SPI bus compatible serial interface

■ 50 MHz clock rate (maximum)

■ Deep power-down mode 1 µA (typical)

■ Electronic signatures

– JEDEC standard two-byte signature

(2010h)

– RES instruction, one-byte, signature (05h),

for backward compatibility

■ More than 100,000 erase/program cycles per

sector

■ More than 20 years data retention

■ ECOPACK® packages available

M25P05-A

SO8 (MN)

150 mil width

VFQFPN8 (MP)

(MLP8)

TSSOP8 (DW)

UFDFPN8 (MB)

2x3mm

April 2008 Rev 11 1/52

www.numonyx.com

1

Page 2

Contents M25P05-A

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Signal descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Serial Data output (Q) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Serial Data input (D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Serial Clock (C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Chip Select (S

2.5 Hold (HOLD

2.6 Write Protect (W

2.7 V

2.8 V

supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CC

ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SS

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 SPI modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Operating features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Page programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Sector erase and bulk erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Polling during a write, program or erase cycle . . . . . . . . . . . . . . . . . . . . . 12

4.4 Active power, standby power and deep power-down modes . . . . . . . . . . 12

4.5 Status register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.5.1 WIP bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.5.2 WEL bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.5.3 BP1, BP0 bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.5.4 SRWD bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.6 Protection modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.7 Hold condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 Memory organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1 Write enable (WREN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 Write disable (WRDI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.3 Read identification (RDID) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2/52

Page 3

M25P05-A Contents

6.4 Read status register (RDSR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.4.1 WIP bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.4.2 WEL bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.4.3 BP1, BP0 bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.4.4 SRWD bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.5 Write status register (WRSR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.6 Read data bytes (READ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.7 Read data bytes at higher speed (FAST_READ) . . . . . . . . . . . . . . . . . . . 27

6.8 Page program (PP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.9 Sector erase (SE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.10 Bulk erase (BE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.11 Deep power-down (DP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.12 Release from deep power-down and read electronic signature (RES) . . 33

7 Power-up and power-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8 Initial delivery state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

10 DC and AC parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11 Package mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

12 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

13 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3/52

Page 4

List of tables M25P05-A

List of tables

Table 1. Signal names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 2. Protected area sizes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 3. Memory organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 4. Instruction set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 5. Read identification (RDID) data-out sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 6. Status register format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 7. Protection modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 8. Power-up timing and VWI threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 9. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 10. Operating conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 11. AC measurement conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 12. Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 13. DC characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 14. Instruction times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 15. AC characteristics (25 MHz operation). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 16. AC characteristics (40 MHz operation). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 17. AC characteristics (50 MHz operation). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

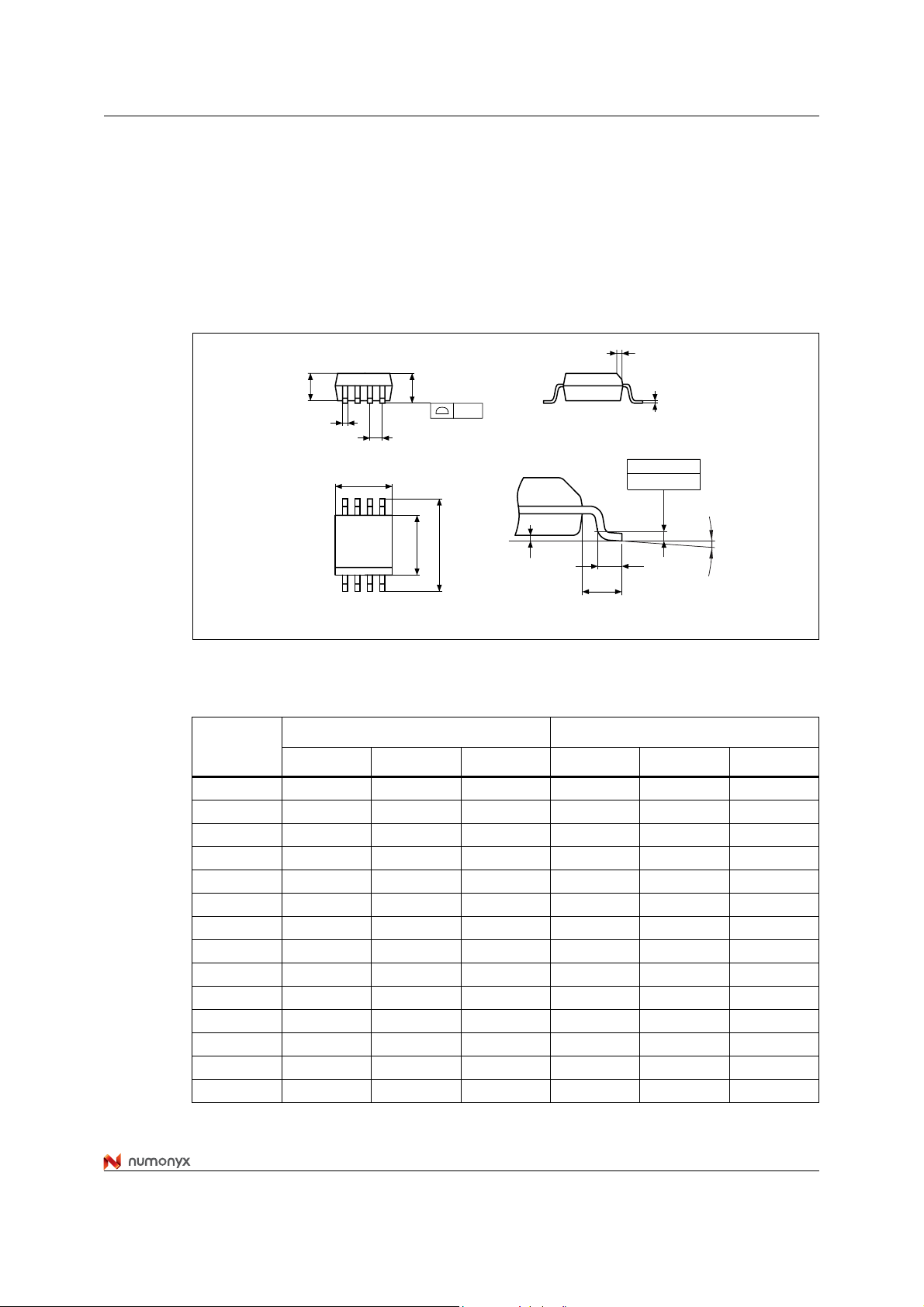

Table 18. SO8N – 8 lead plastic small outline, 150 mils body width, package mechanical data . . . . 45

Table 19. VFQFPN8 (MLP8) - 8 lead very thin fin e pitch quad flat package no lead,

6 × 5 mm, package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 20. TSSOP8 – 8 lead thin shrink small outline, package mechanical data. . . . . . . . . . . . . . . . 47

Table 21. UFDFPN8 (MLP8) – 8 lead ultra thin fine pitch dual flat package no lead,

2 x 3 mm package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 22. Ordering information scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 23. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4/52

Page 5

M25P05-A List of figures

List of figures

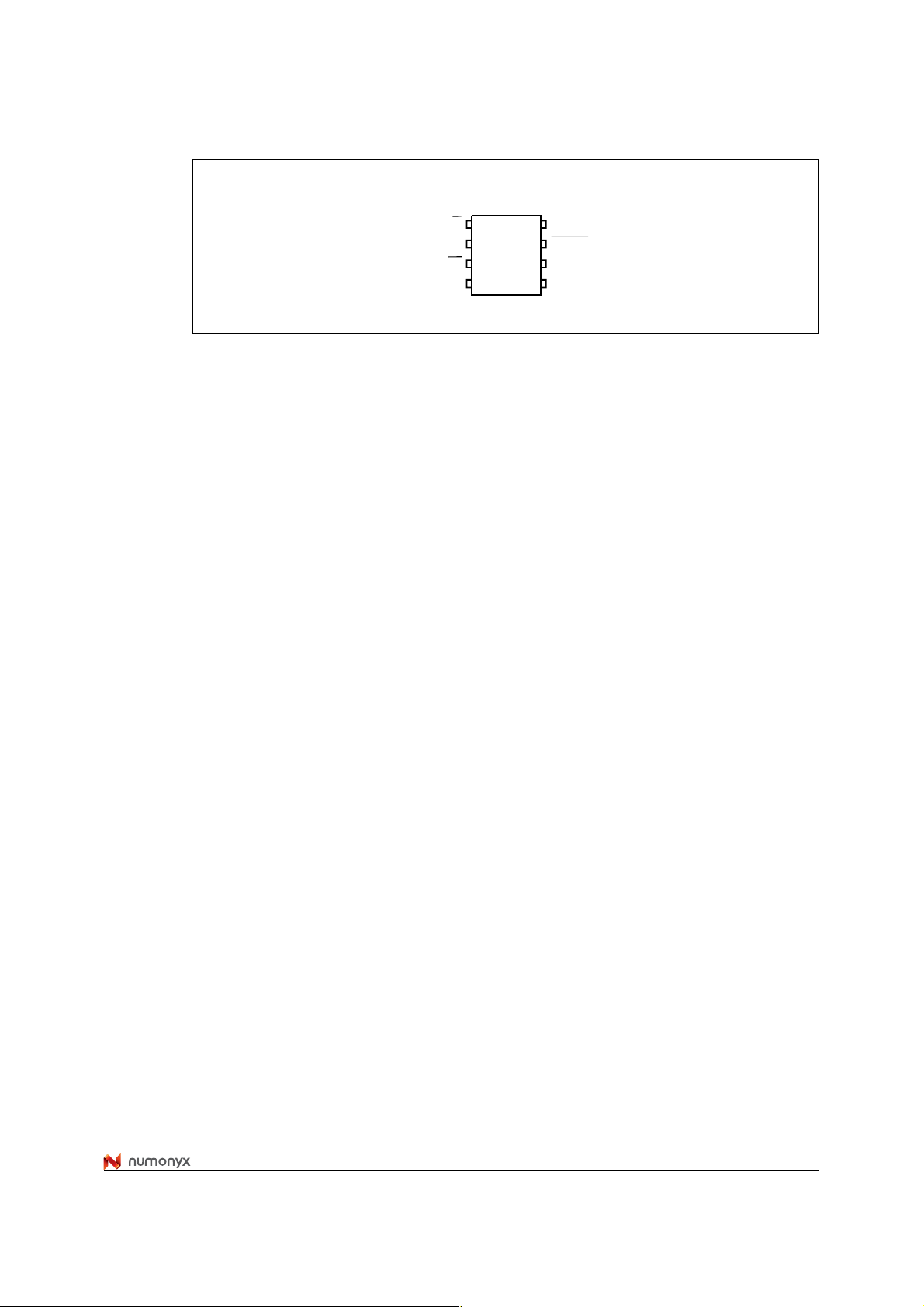

Figure 1. Logic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. SO, VFQFPN and TSSOP connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

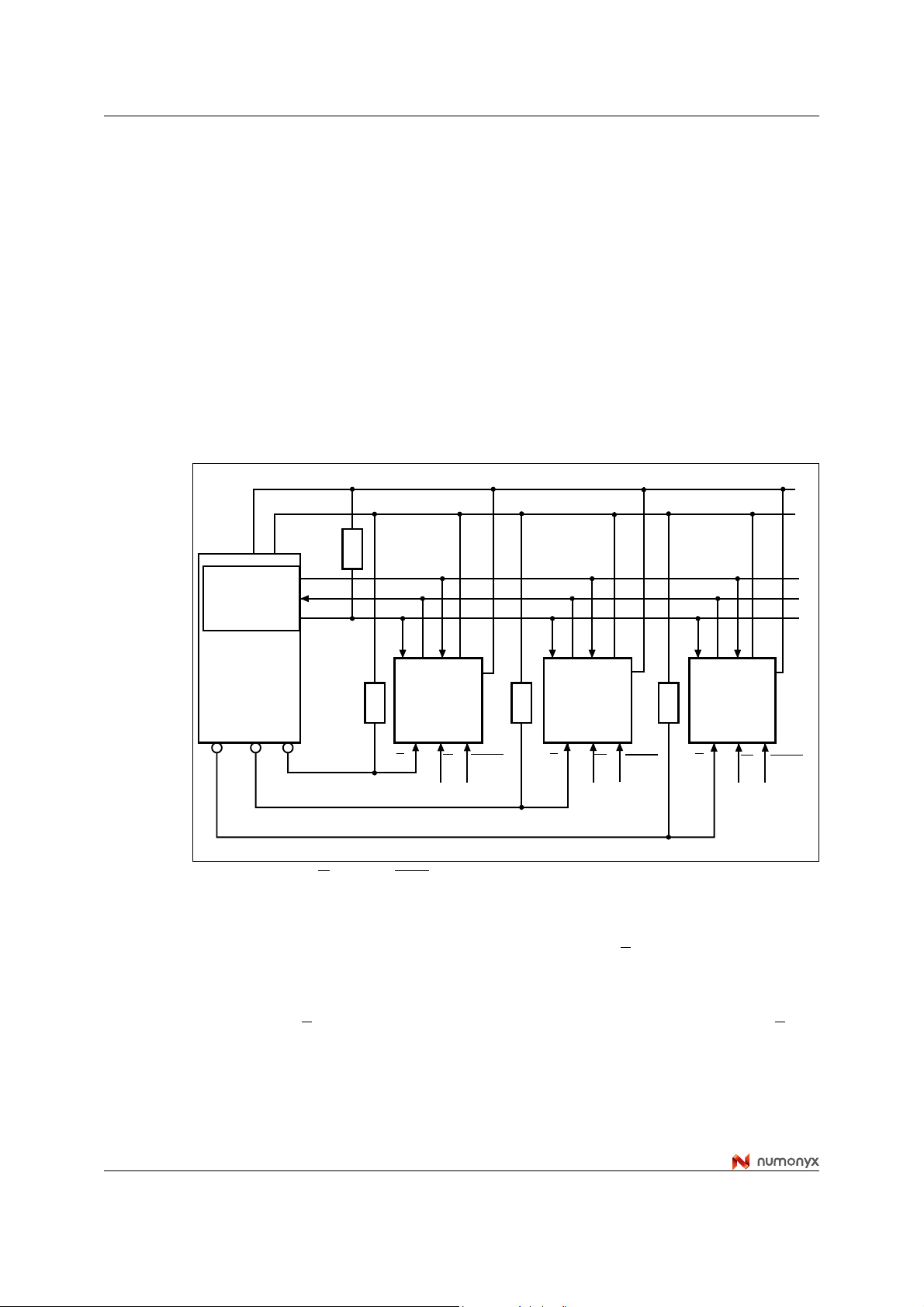

Figure 3. Bus master and memory devices on the SPI bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

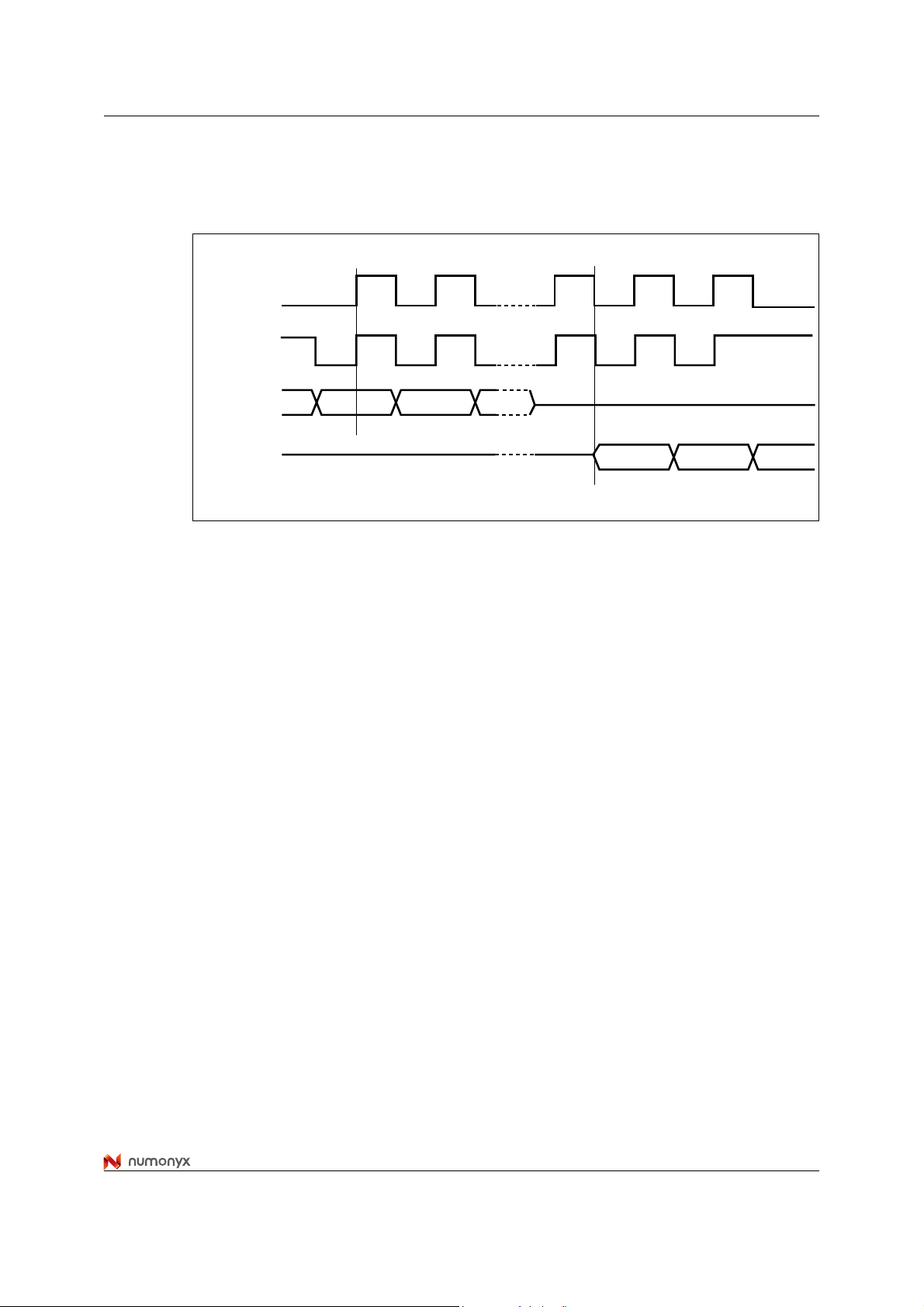

Figure 4. SPI modes supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 5. Hold condition activation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 6. Block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 7. Write enable (WREN) instruction sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 8. Write disable (WRDI) instruction sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 9. Read identification (RDID) instruction sequence and data-out sequence . . . . . . . . . . . . . 21

Figure 10. Read status register (RDSR) instruction sequence and data-out sequence . . . . . . . . . . . 23

Figure 11. Write status register (WRSR) instruction sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 12. Read data bytes (READ) instruction sequence and data-out sequence . . . . . . . . . . . . . . 26

Figure 13. Read data bytes at higher speed (FAST_READ) instruction sequence

and data-out sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 14. Page program (PP) instruction sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 15. Sector erase (SE) instruction sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 16. Bulk erase (BE) instruction sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 17. Deep power-down (DP) instruction sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 18. Release from deep power-down and read electronic signature (RES)

instruction sequence and data-out sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 19. Release from deep power-down (RES) instruction sequence . . . . . . . . . . . . . . . . . . . . . . 34

Figure 20. Power-up timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 21. AC measurement I/O waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 22. Serial input timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 23. Write protect setup and hold timing during WRSR when SRWD =1. . . . . . . . . . . . . . . . . . 43

Figure 24. Hold timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 25. Output timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 26. SO8N – 8 lead plastic small outline , 150 mils body width, package outline . . . . . . . . . . . . 45

Figure 27. VFQFPN8 (MLP8) - 8 lead very thin fine pitch quad flat package no lead,

6 × 5 mm, package outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 28. TSSOP8 – 8 lead thin shrink small outline, package outline . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 29. UFDFPN8 (MLP8) – 8 lead ultra thin fine pitch dual flat package no lead,

2 x 3 mm package outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5/52

Page 6

Description M25P05-A

1 Description

The M25P05-A is a 512-Kbit (64 Kbits ×8) serial flash memory, with advanced write

protection mechanisms, accessed by a high speed SPI-compatible bus.

The memory can be programmed 1 to 256 bytes at a time, using the page program

instruction.

The memory is organized as 2 sectors, each co ntaini ng 128 pages. Each page is 256 bytes

wide. Thus, the whole memory can be viewed as consisting of 256 pages, or 65,536 bytes.

The whole memory can be erased using the bulk erase instruction, or a sector at a time,

using the sector erase instruction.

Figure 1. Logic diagram

V

CC

D

C

S

W

HOLD

Table 1. Signal names

Signal name Function Direction

C Serial Clock Input

D Serial Data input Input

Q Serial Data output Output

S

Write Protect Input

W

Hold Input

HOLD

Chip Select Input

M25P05-A

V

SS

Q

AI05757

V

CC

V

SS

6/52

Supply voltage Supply

Ground Supply

Page 7

M25P05-A Description

Figure 2. SO, VFQFPN and TSSOP connections

M25P05-A

SV

1

2

3

W

4

SS

1. There is an exposed central pad on the underside of the VFQFPN package. This is pulled, internally, to

VSS, and must not be allowed to be connected to any other voltage or signal line on the PCB.

2. See Package mechanical section for package dimensions, and how to identify pin-1.

8

7

6

5

AI05758B

CC

HOLDQ

C

DV

7/52

Page 8

Signal descriptions M25P05-A

2 Signal descriptions

2.1 Serial Data output (Q)

This output signal is used to transf er data serially out of the de vice . Data is shifted out on the

falling edge of Serial Clock (C).

2.2 Serial Data input (D)

This input signal is used to transfer data serially into the device. It receives instructions,

addresses, and the data to be programmed. Values are latched on the rising edge of Serial

Clock (C).

2.3 Serial Clock (C)

This input signal provides the timing of the serial interface. Instructions, addresses, or data

present at Serial Data input (D) are latched on the rising edge of Serial Clock (C). Data on

Serial Data output (Q) changes after the falling edge of Serial Clock (C).

2.4 Chip Select (S)

When this input signal is High, the device is deselected and Serial Data output (Q) is at high

impedance. Unless an internal program, erase or write status register cycle is in progress,

the device will be in the standby mode (this is not the deep power-do wn mode). Driving Chip

Select (S

After power-up, a falling edge on Chip Select (S

instruction.

) Low enables the device, placing it in the active power mode.

2.5 Hold (HOLD)

The Hold (HOLD) signal is used to pause any serial communications with the de vice without

deselecting the device.

During the Hold condition, the Serial Data output (Q) is high impedance, and Serial Data

input (D) and Serial Clock (C) are don’t care.

To start the Hold condition, the device must be selected, with Chip Select (S

2.6 Write Protect (W)

The main purpose of this input signal is to freeze the size of the area of mem ory that is

protected against program or erase instructions (as specified by the values in the BP1 and

BP0 bits of the status register).

) is required prior to the start of any

) driven Low.

8/52

Page 9

M25P05-A Signal descriptions

2.7 VCC supply voltage

VCC is the supply voltage.

2.8 VSS ground

VSS is the reference for the VCC supply voltage.

9/52

Page 10

SPI modes M25P05-A

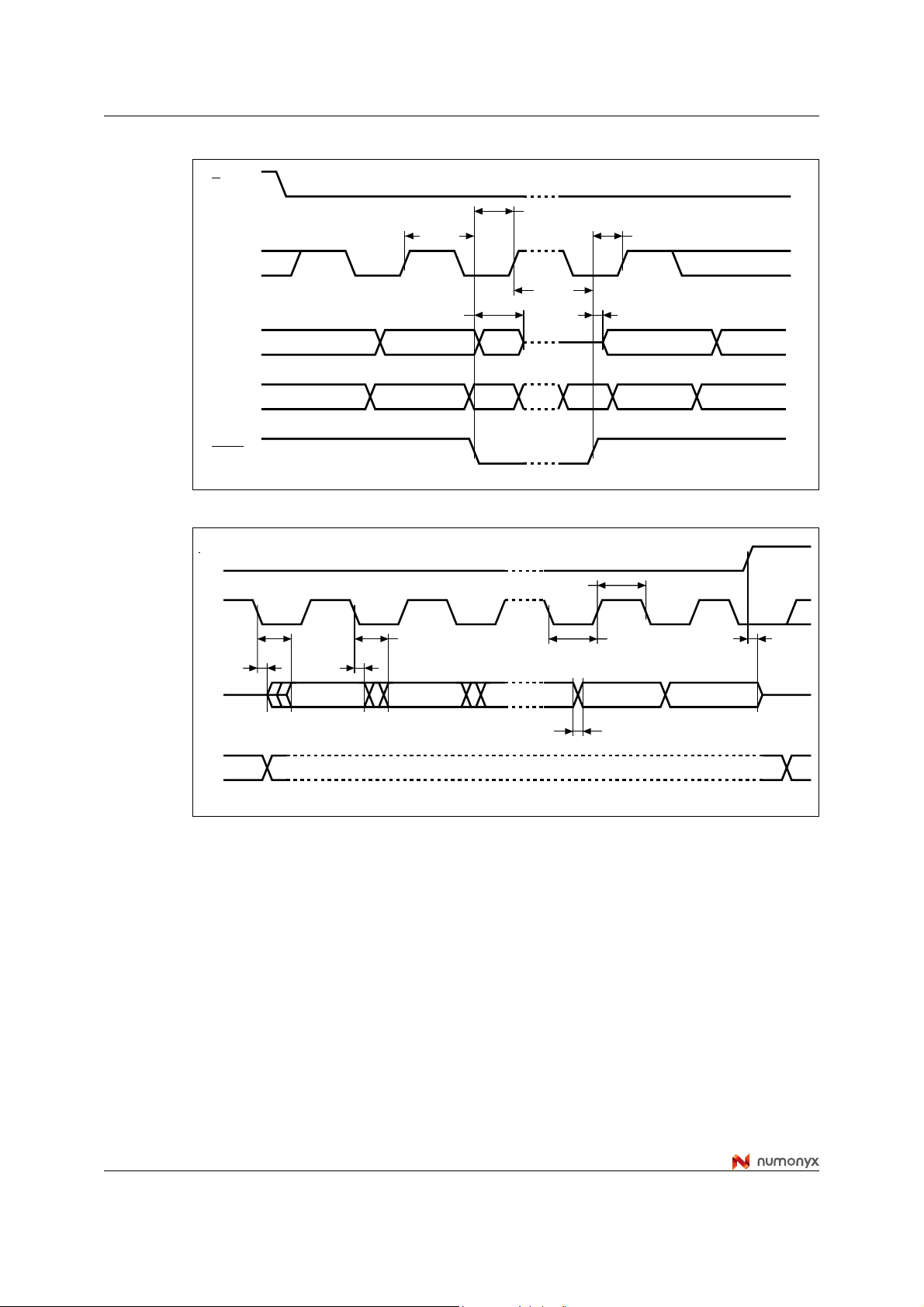

3 SPI modes

These devices can be drive n by a microcontroller with its SPI peripheral running in either of

the two following modes:

● CPOL=0, CPHA=0

● CPOL=1, CPHA=1

For these two modes, input data is latched in on the rising edge of Serial Clock (C), and

output data is available from the falling edge of Serial Clock (C).

The difference between the two modes, as shown in Figure 4, is the clock polarity when the

bus master is in standby mode and not transferring data:

● C remains at 0 for (CPOL=0, CPHA=0)

● C remains at 1 for (CPOL=1, CPHA=1)

Figure 3. Bus master and memory devices on the SPI bus

V

SS

V

CC

R

SPI interface with

(CPOL, CPHA) =

(0, 0) or (1, 1)

SPI bus master

CS3 CS2 CS1

1. The Write Protect (W) and Hold (HOLD) signals should be driven, High or Low as appropriate.

SDO

SDI

SCK

device

W

V

CC

HOLD

V

CQD

RR R

SPI memory

S

CQD

SS

SPI memory

S

device

W

V

CC

HOLD

V

CQD

SS

SPI memory

device

S

V

CC

V

SS

HOLD

W

AI12836b

Figure 3 shows an example of three de vices connected to an MCU , on an SPI bus . Only one

device is selected at a time, so only one device drives the Serial Data output (Q) line at a

time, the other devices are high impedance. Resistors R (represented in Figure 3) ensure

that the M25P05-A is not selected if the bus master leav es th e S

line in the high impedance

state. As the bus master ma y enter a state where all inpu ts/outputs are in high impedance at

the same time (for example, when the bus master is reset), the clock line (C) must be

connected to an external pull-down resistor so that, when all inputs/outputs become high

impedance, the S

C do not become High at the same time, and so, that the t

typical value of R is 100 kΩ, assuming that the time constant R*C

line is pulled High while the C line is pulled Low (thus ensuring that S a nd

requirement is met). The

SHCH

(Cp = parasitic

p

capacitance of the bus line) is shorter than the time during which the bus master leaves the

SPI bus in high impedance.

10/52

Page 11

M25P05-A SPI modes

Example: Cp = 50 pF, that is R*Cp = 5 µs <=> the application must ensure that the bus

master never leaves the SPI bus in the high impedance state for a time period shorter than

5µs.

Figure 4. SPI modes supported

CPHA

CPOL

C

0

0

1

1

C

D

Q

MSB

MSB

AI01438B

11/52

Page 12

Operating features M25P05-A

4 Operating features

4.1 Page programming

To program one data byte, two in structions are required: Write Enable (WREN), which is one

byte, and a page program (PP) sequence, which consists of four bytes plus data. This is

followed by the internal program cycle (of duration t

To spread this overhead, the page program (PP) instruction allows up to 256 bytes to be

programmed at a time (changing bits from 1 to 0), provided that they lie in consecutive

addresses on the same page of memory.

For optimized timings, it is recommended to use the page program (PP) instruction to

program all consecutive targeted bytes in a single sequence versus using several page

program (PP) sequences with each containing only a few bytes (see Section 6.8: Page

program (PP) and Table 14: Instruction times).

4.2 Sector erase and bulk erase

The page program (PP) instruction allows bits to be reset from 1 to 0. Before this can be

applied, the bytes of memory need to have been erased to all 1s (FFh). This can be

achiev ed either a sector a t a time, using the sector erase (SE) inst ruction, or t hroug hout the

entire memory, using the bulk erase (BE) instruction. This starts an internal erase cycle (of

duration t

The erase instruction must be preceded by a write enable (WREN) instruction.

or tBE).

SE

PP

).

4.3 Polling during a write, program or erase cycle

A further improvement in the time to write status register (WRSR), program (PP) or erase

(SE or BE) can be achiev ed by not waiting for the w o rst case d elay (t

write in progress (WIP) bit is provided in the status register so that the application program

can monitor its value, polling it to establish when the previous write cycle, program cycle or

erase cycle is complete.

, tPP, tSE, or tBE). The

W

4.4 Active power, standby power and deep power-down modes

When Chip Select (S) is Low, the device is selected, and in the active power mode.

When Chip Select (S

mode until all internal cycles have completed (prog ram, erase, write status register). The

device then goes in to the standby power mode. The device consumption drops to I

The deep power-do wn mo de is en tere d when th e specific in struction (the de ep power-down

(DP) instruction) is executed. The device consumption drops further to I

remains in this mode until another specific instruction (the release from deep power-down

and read electronic signature (RES) instruction) is executed.

While in the deep power-down mode, the device ignores all write, program and erase

instructions (see Section 6.11: Deep power-down (DP)). This can be used as an extra

software protection mechanism, when the device is not in active use, to protect the device

from inadvertent write, program or erase instructions .

) is High, the device is dese lected, b ut could rema in in the activ e pow er

.

CC1

. The device

CC2

12/52

Page 13

M25P05-A Operating features

4.5 Status register

The status register contains a number of status and control bits, as shown in Table 6, that

can be read or set (as appropriate) by specific instructions.

4.5.1 WIP bit

The write in progress (WIP) bit indicates whether the memory is busy with a write status

register, program or erase cycle.

4.5.2 WEL bit

The write enable latch (WEL) bit indicates the status of the internal write enable latch.

4.5.3 BP1, BP0 bits

The block protect (BP1, BP0) bits are non-volatile. They define the size of the area to be

software protected against program and erase instructions.

4.5.4 SRWD bit

The status register write disable (SRWD) bit is operated in conjunction with the Write

Protect (W

allow the device t o be put in the hardwar e protected mode . In this mode, the non- volatile bits

of the status register (SRWD, BP1, BP0) become read-only bits.

) signal. The status register write disable ( SRWD) b it and Write Protect (W) signal

13/52

Page 14

Operating features M25P05-A

4.6 Protection modes

The environments where non-volatile memory devices are used can be very noisy. No SPI

device can operate correctly in the presence of excessive noise. To help combat this, the

M25P05-A features the following data protection mechanisms:

● Power on reset and an internal timer (t

changes while the power supply is outside the operating specification

● Program, er ase and write status reg ister instructions are chec ked that they consist of a

number of clock pulses that is a multiple of eight, before they are accepted for

execution

● All instructions that modify data must be preceded by a write enable (WREN)

instruction to set the write enable latch (WEL) bit. This bit is returned to its reset state

by the following events:

–Power-up

– Write disable (WRDI) instruction completion

– Write status register (WRSR) instruction completion

– Page program (PP) instruction completion

– Sector erase (SE) instruction completion

– Bulk erase (BE) instruction completion

● The block protect (BP1, BP0) bits allow part of the memory to be configured as read-

only. This is the software protected mode (SPM)

● The Write Protect (W) signal, in co-ope ration with the status register write disable

(SRWD) bit, allows the block protect (BP1, BP0) bits and status register write disable

(SRWD) bit to be write-protected. This is the hardware protected mode (HPM)

● In addition to the low power consumption feature, the deep power-down mode offers

extra software protection, as all write, program and erase instructions are ignored.

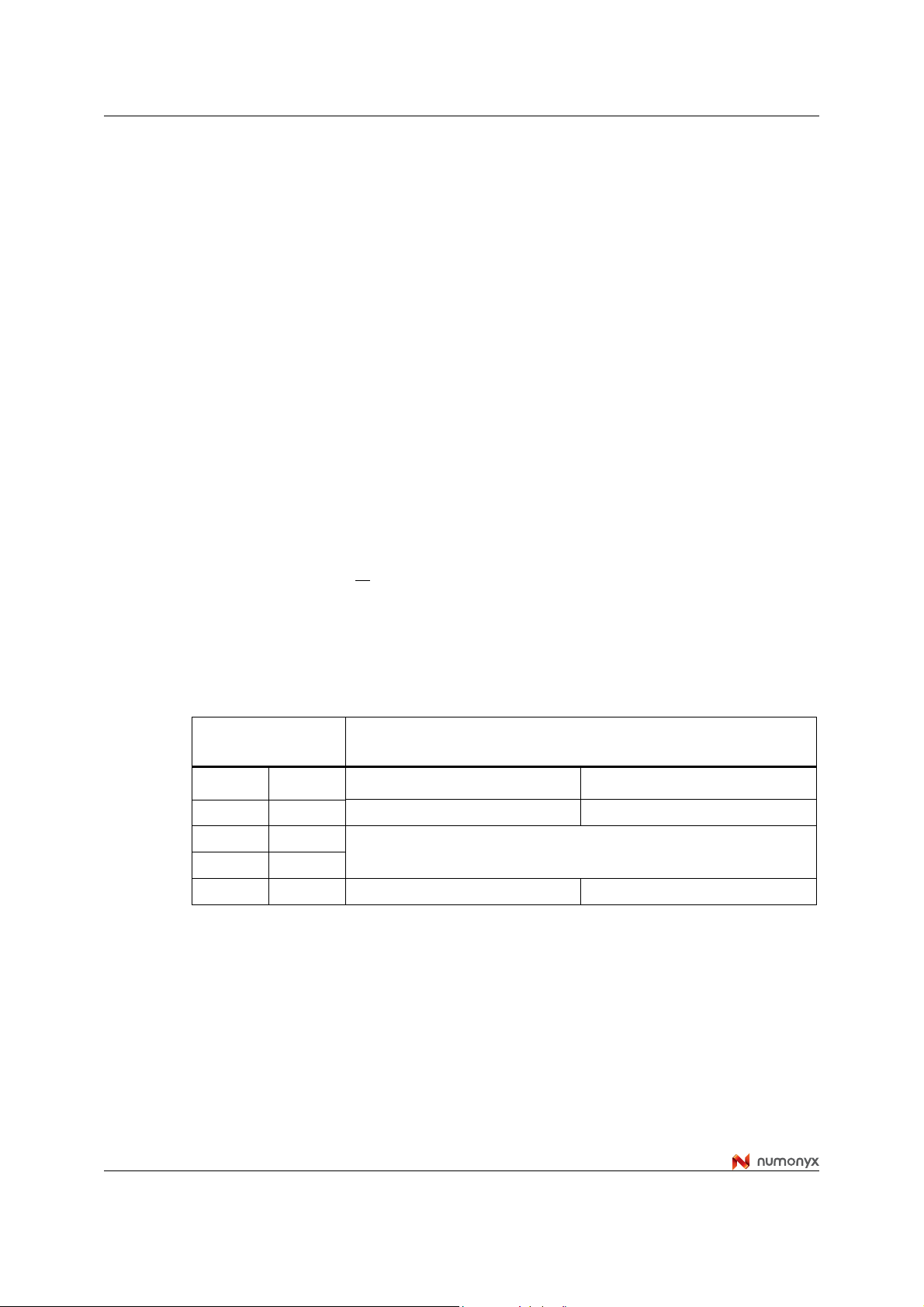

Table 2. Protected area sizes

) can provide protection against inadvertent

PUW

Status Register

content

BP1 bit BP0 bit Protected area Unprotected area

0 0 none All sectors (sectors 0 and 1)

0 1

1 0

1 1 All sectors (sectors 0 and 1) none

1. The device is ready to accept a bulk erase instruction if, and only if, both block protect (BP1, BP0) are 0.

14/52

No protection against page program (PP) and sector erase (SE)

All sectors (sectors 0 and 1) protected against bulk erase (BE)

Memory content

Page 15

M25P05-A Operating features

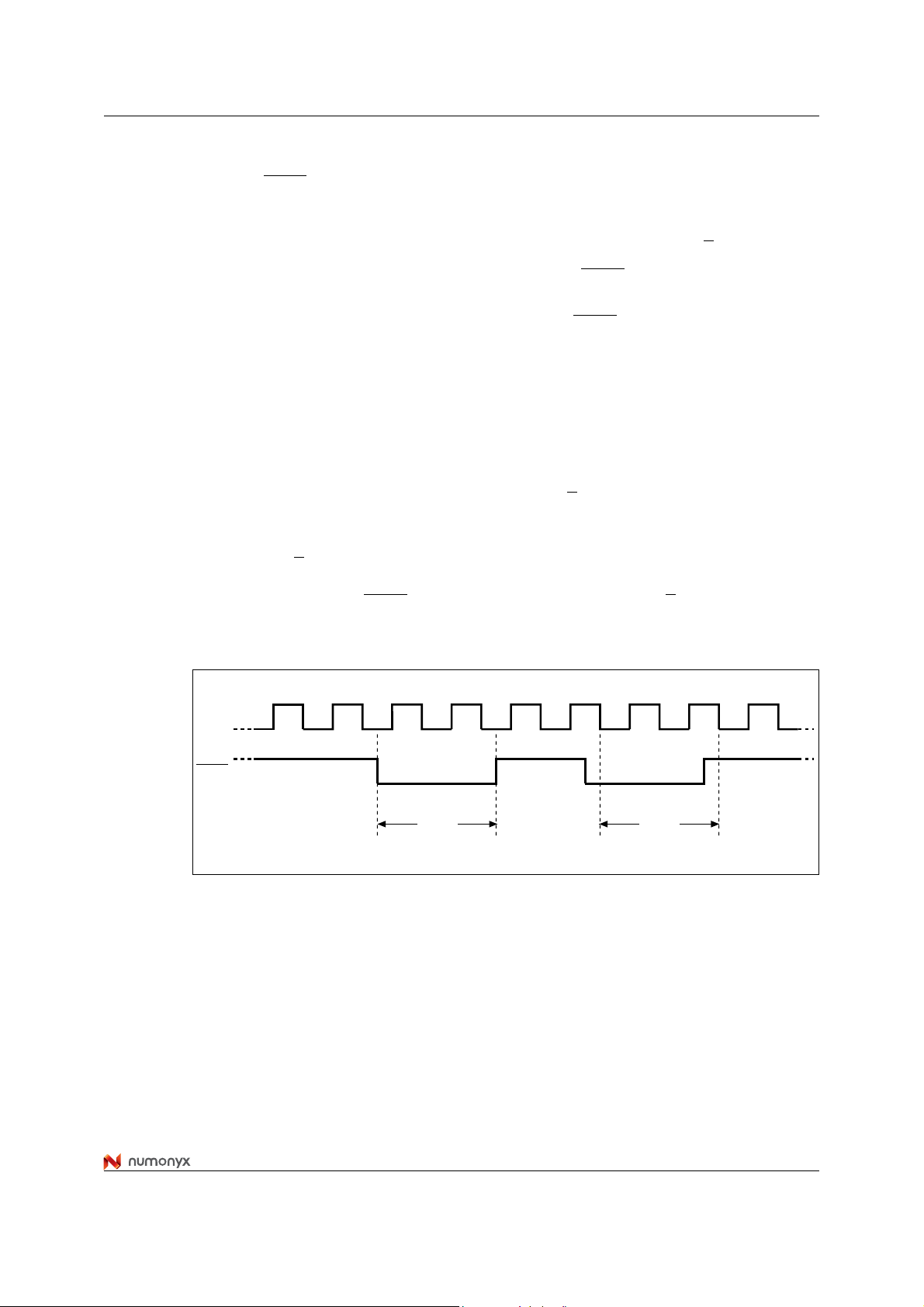

4.7 Hold condition

The Hold (HOLD) signal is used to pause any serial communications with the de vice without

resetting the clocking sequence. However, taking this signal Low does not terminate any

write status register, program or erase cycle that is currently in progress.

To enter the hold condition, the device must be selected, with Chip Select (S

The hold condition starts on the falling edge of the Hold (HOLD

) signal, provided that this

) Low.

coincides with Serial Clock (C) being Low (as shown in Figure 5).

The hold condition ends on the rising edge of the Hold (HOLD

) signal, provided that this

coincides with Serial Clock (C) being Low.

If the falling edge does not coincide with Serial Clock (C) being Low, the hold condition

starts after Serial Clock (C) next goes Low. Similarly , if the rising edge does not coincide

with Serial Clock (C) being Low, the hold condition ends after Serial Clock (C) next goes

Low (this is shown in Figure 5).

During the hold condition, the Serial Data output (Q) is high impedance, and Serial Data

input (D) and Serial Clock (C) are don’t care.

Normally , the de vice is k ept selected, with Chip Select (S

) driven Low, for the whole duration

of the hold condition. This is to ensure that the state of the inte rnal logic remains unchanged

from the moment of entering the hold condition.

If Chip Select (S

) goes High while the device is in the hold condition, this has the effect of

resetting the internal logic of the device. To restart communication with the device, it is

necessary to drive Hold (HOLD

) High, and then to drive Chip Select (S) Low. This prevents

the device from going back to the hold condition.

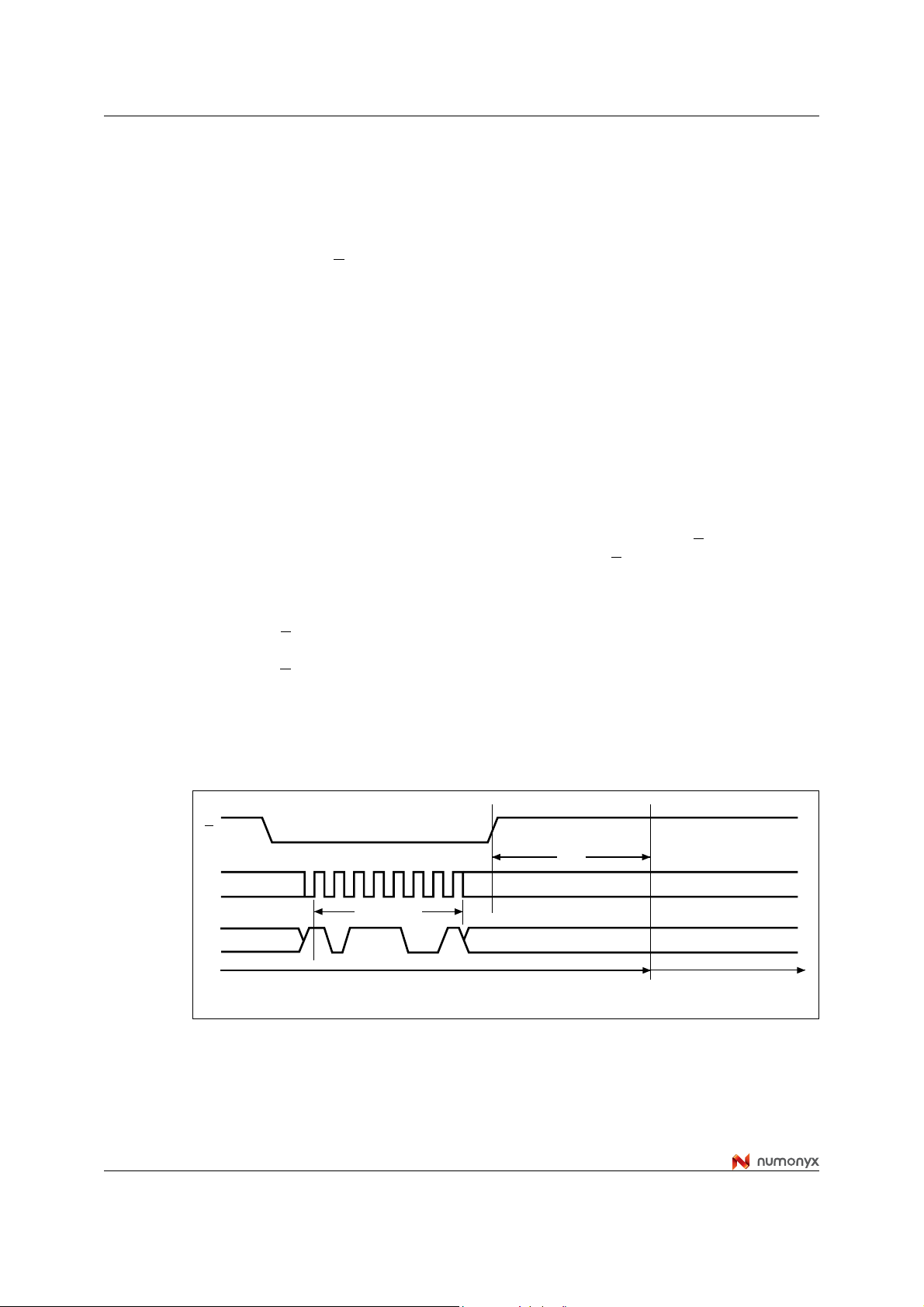

Figure 5. Hold condition activation

HOLD

C

Hold

condition

(standard use)

15/52

Hold

condition

(non-standard use)

AI02029D

Page 16

Memory organization M25P05-A

5 Memory organization

The memory is organized as:

● 65,536 b ytes (8 bits each)

● 2 sectors (256 Kbits, 32768 bytes each)

● 256 pages (256 bytes each).

Each page can be individually prog rammed ( bits are prog rammed from 1 t o 0). The de vice is

sector or bulk erasable (bits are erased from 0 to 1) but not page erasable.

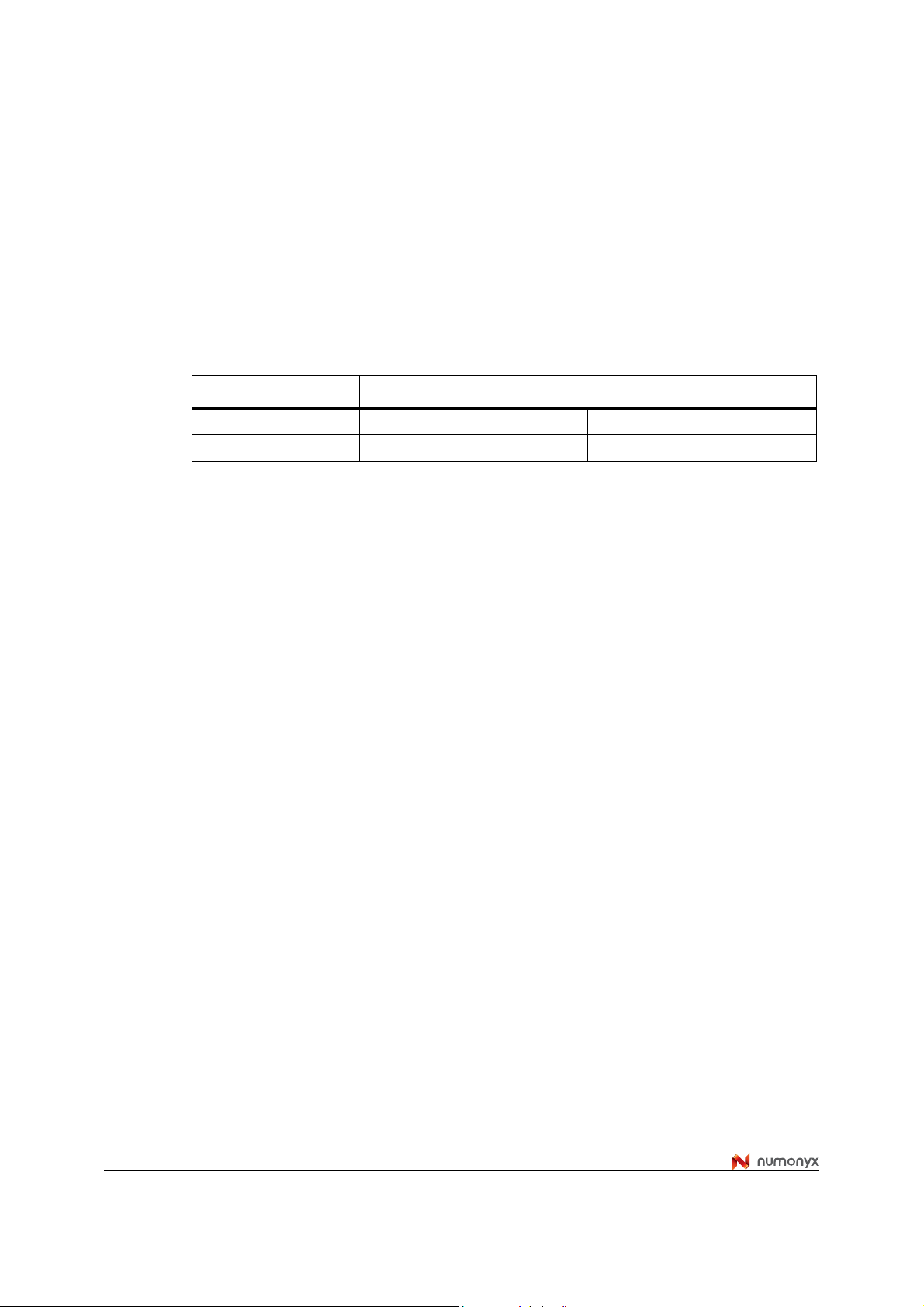

Table 3. Memory organization

Sector Address range

1 08000h 0FFFFh

0 00000h 07FFFh

16/52

Page 17

M25P05-A Memory organization

Figure 6. Block diagram

HOLD

W

S

C

D

Q

Control logic

Address register

and counter

08000h

Y decoder

High voltage

generator

I/O shift register

256 byte

data buffer

Status

register

0FFFFh

Size of the

read-only

memory area

00000h

000FFh

256 bytes (page size)

X decoder

AI05759

17/52

Page 18

Instructions M25P05-A

6 Instructions

All instructions, addresses and data are shifted in and ou t of the device, most significant bit

first.

Serial Data input (D) is sampled on the first rising edge of Serial Clock (C) after Chip Select

(S

) is driven Low. Then, the one-byte instruction code must be shifte d in to t he device, most

significant bit first, on Serial Data input (D), each bit being latched on the rising edges of

Serial Clock (C).

The instruction set is listed in Table 4.

Every instruction sequence starts with a one-byte instruction code. Depending on the

instruction, this might be followed by address bytes, or by data bytes , or by both or none.

Chip Select (S

shifted in.

In the case of a read data bytes (READ), read d ata bytes at higher speed (Fast_Read), read

identification (RDID), read status register (RDSR) or release from deep power-down, and

read electronic signature (RES) instruction, the shifted-in instruction sequence is followed

by a data-out sequence. Chip Select (S

sequence is being shifted out.

) must be driven High after the last bit of the inst ruction sequence has been

) can be driven High after any bit of the data-out

In the case of a page program (PP), secto r erase (SE), b ulk er ase (BE) , write status register

(WRSR), write enable (WREN), write disable (WRDI) or deep power-down (DP) instruction,

Chip Select (S

rejected, and is not e xecuted. That is, Chip Select (S

clock pulses after Chip Select (S

All attempts to access the memory array during a write status register cycl e, program cycle

or erase cycle are ignored, and the internal write status register cycle, program cycle or

erase cycle continues unaff ected.

) must be driven High exactly at a byte boundary, otherwise the instruction is

) must driven High when t he n umber of

) being driven Low is an exact multiple of eight.

18/52

Page 19

M25P05-A Instructions

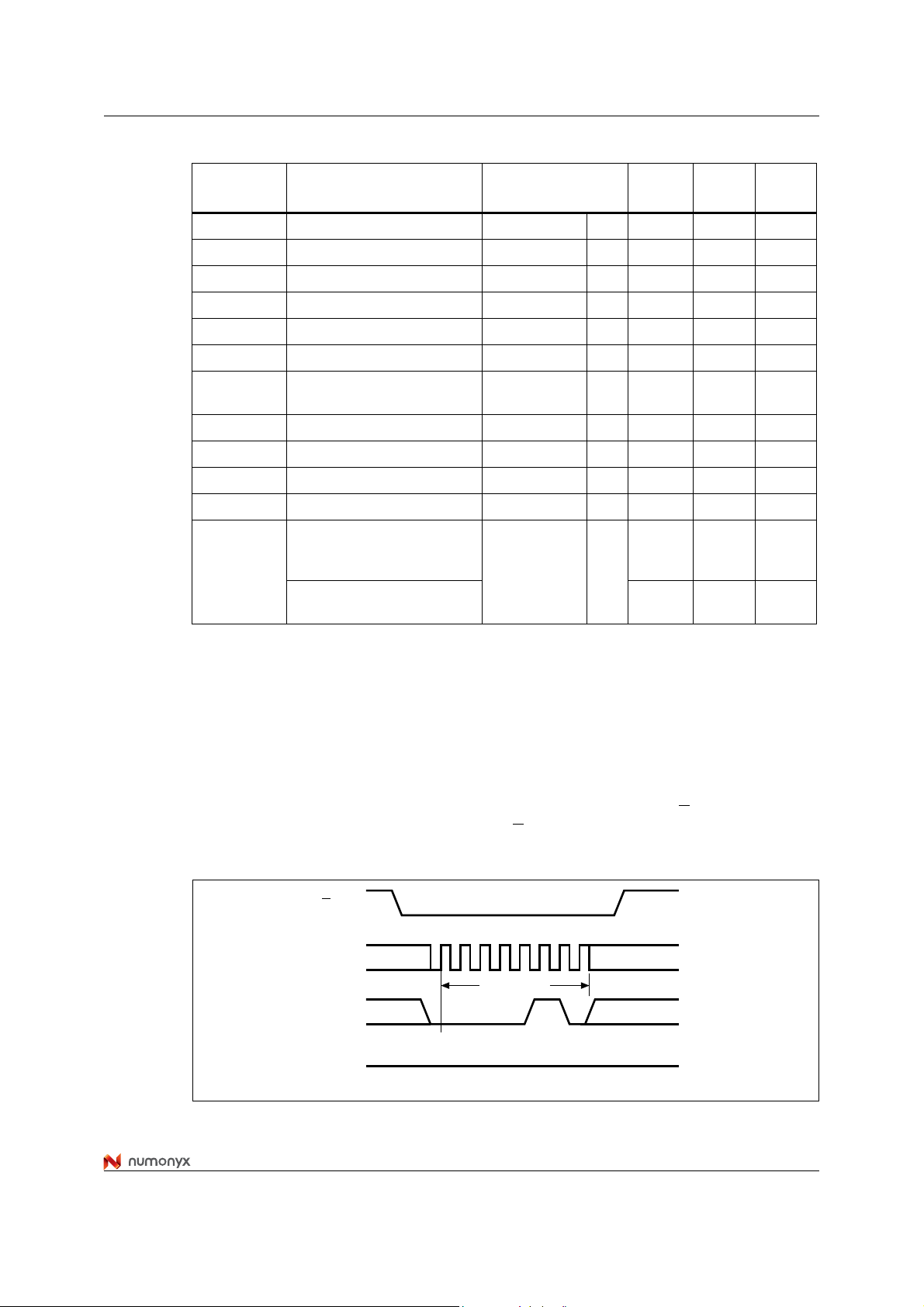

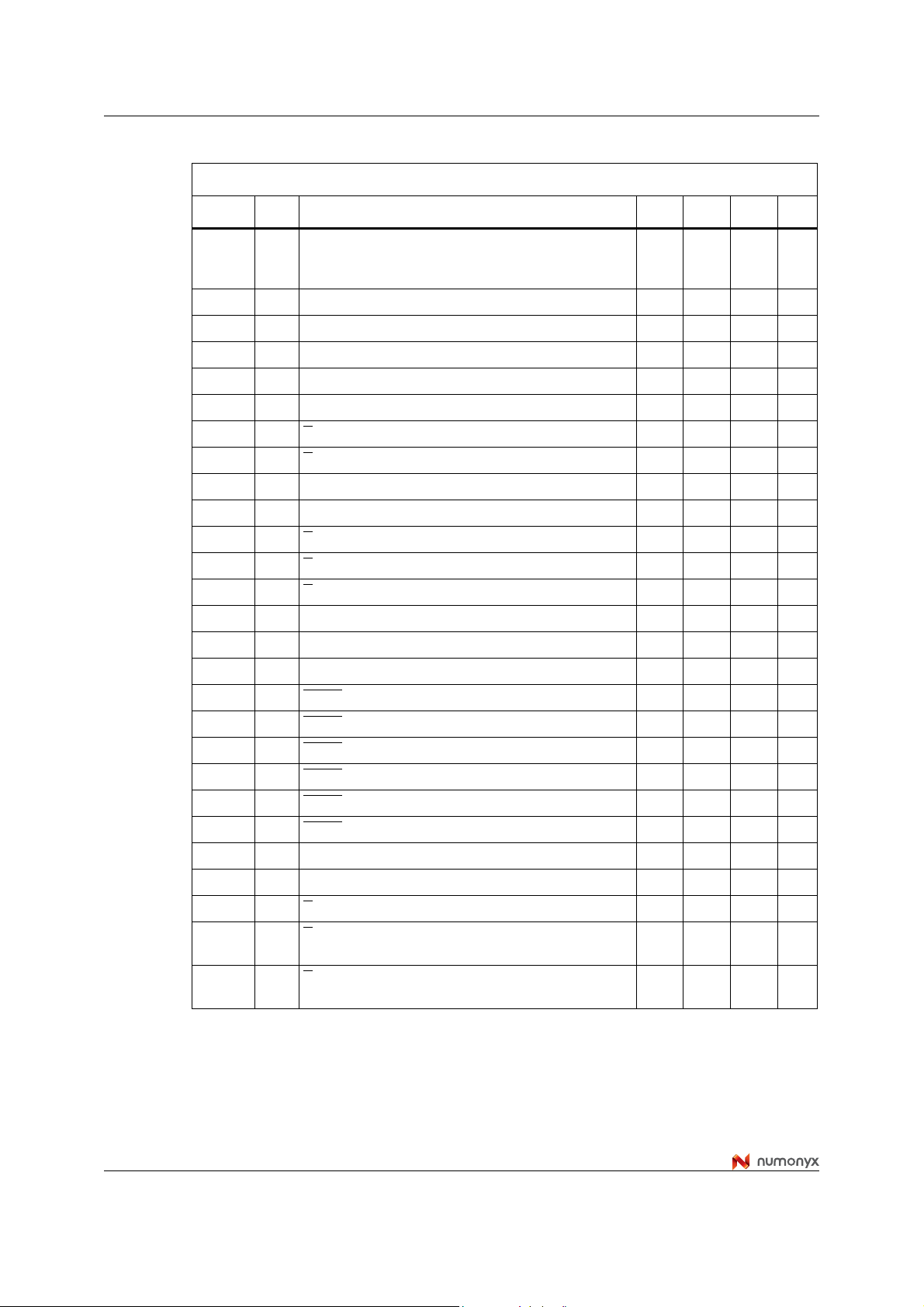

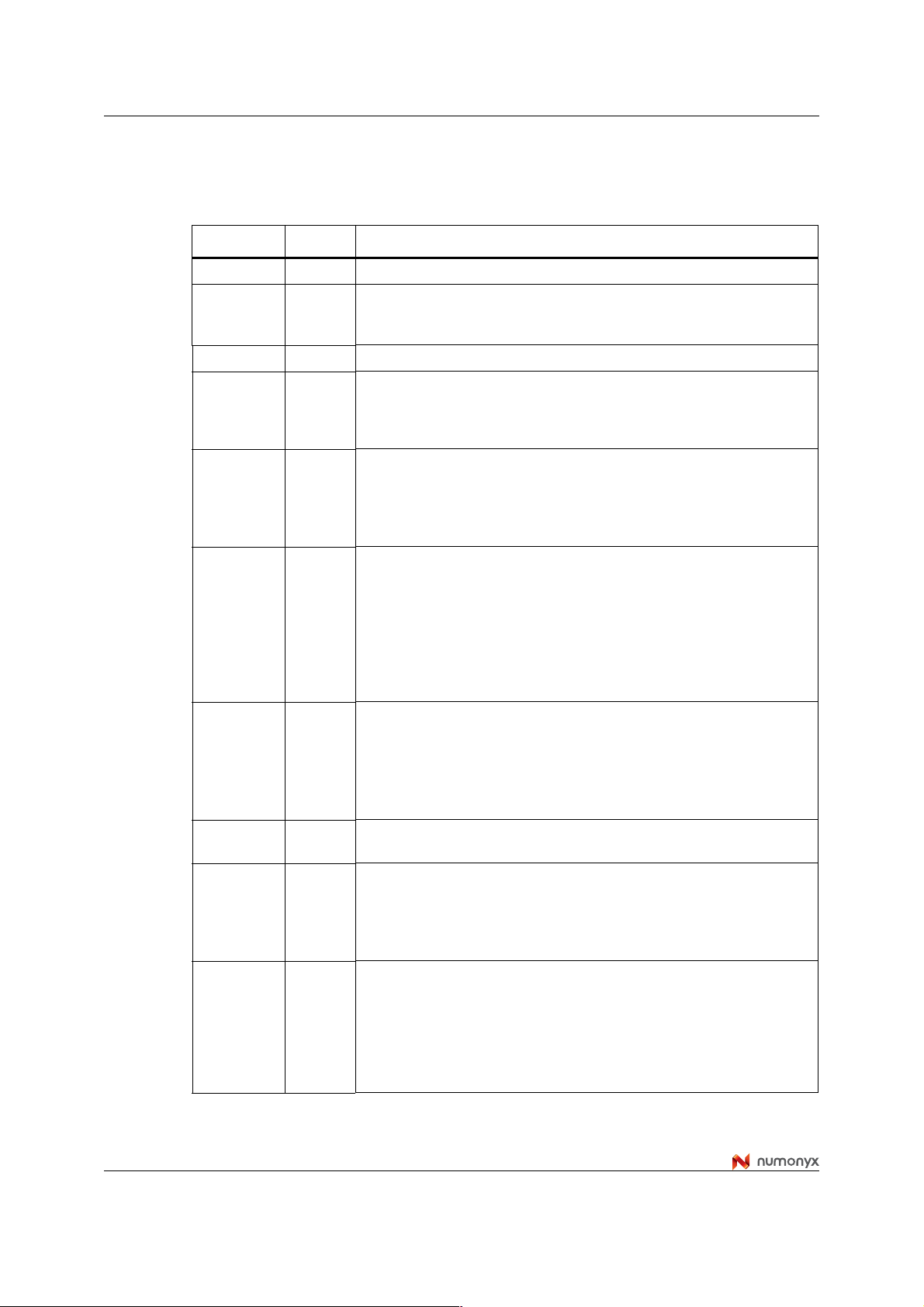

Table 4. Instruction set

Instruction Description

One-byte instruction

code

Address

bytes

Dummy

bytes

Data

bytes

WREN Write enable 0000 0110 06h 0 0 0

WRDI Write disable 0000 0100 04h 0 0 0

(1)

RDID

Read identification 1001 1111 9Fh 0 0 1 to 3

RDSR Read status register 0000 0101 05h 0 0 1 to ∞

WRSR Write status register 0000 0001 01h 0 0 1

READ Read data bytes 0000 0011 03h 3 0 1 to ∞

FAST_READ

Read data bytes at higher

speed

0000 1011 0Bh 3 1 1 to ∞

PP Page program 0000 0010 02h 3 0 1 to 256

SE Sector erase 1101 1000 D8h 3 0 0

BE Bulk erase 1100 0111 C7h 0 0 0

DP Deep power-down 1011 1001 B9h 0 0 0

Release from deep powerdown, and read electronic

RES

signature

1010 1011 ABh

Release from deep powerdown

1. The read identification (RDID) instruction is available only in products with process technology code X and

Y (see application note AN1995).

0 3 1 to ∞

0 0 0

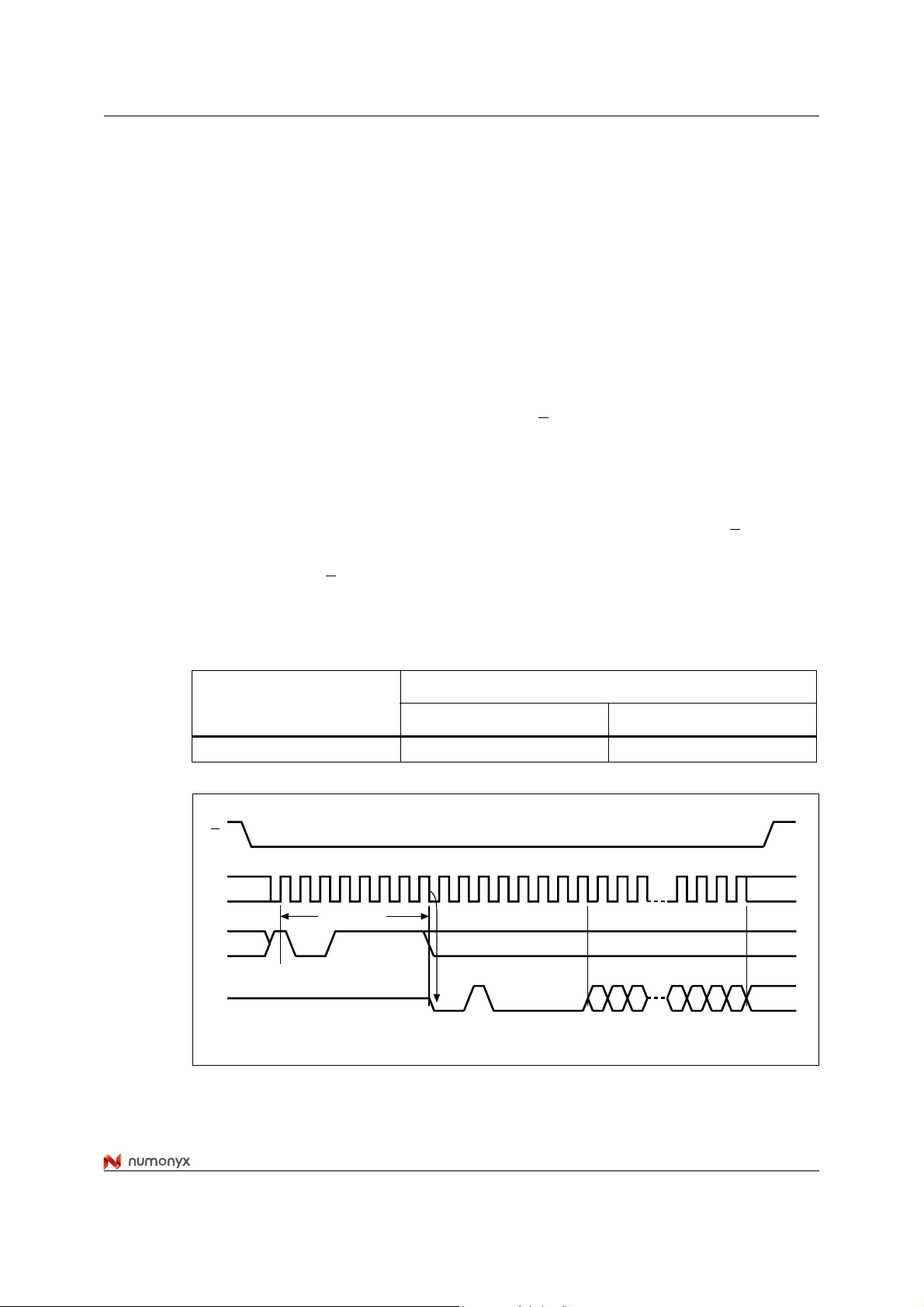

6.1 Write enable (WREN)

The write enable (WREN) instruction (Figure 7) sets the write enable latch (WEL) bit.

The write enable latch (WEL) bit mu st be set p rior to e v ery page progra m (PP), sector er ase

(SE), bulk erase (BE) and write status register (WRSR) instruction.

The write enable (WREN) instruction is entered by driving Chip Select (S

instruction code, and then driving Chip Select (S

Figure 7. Write enable (WREN) instruction sequence

S

C

D

Q

0

21 34567

Instruction

High Impedance

) Low, sending the

) High.

AI02281E

19/52

Page 20

Instructions M25P05-A

6.2 Write disable (WRDI)

The write disable (WRDI) instruction (Figure 8) resets the write enable latch (WEL) bit.

The write disable (WRDI) instruction is entered by driving Chip Select (S

instruction code, and then driving Chip Select (S

) High.

The write enable latch (WEL) bit is reset under the following conditions:

● Power-up

● Write disable (WRDI) instruction completion

● Write status register (WRSR) instruction completion

● P age program (PP) instruction completion

● Sector erase (SE) instruction completion

● Bulk erase (BE) instruction completion.

Figure 8. Write disable (WRDI) instruction sequence

S

0

21 34567

C

Instruction

D

High Impedance

Q

AI03750D

) Low, sending the

20/52

Page 21

M25P05-A Instructions

6.3 Read identification (RDID)

The read identification (RDID) instruction is available in products with process technology

code X and Y.

The read identification (RDID) instruction allows the 8-bit manufacturer identification to be

read, followed by two bytes of device identification. The manufacturer identification is

assigned by JEDEC, and has the value 20h for Numonyx. The device identification is

assigned by the device manufacturer, and indicates the memory type in the first byte (20h),

and the memory capacity of the device in the second byte (10h).

Any read identification (RDID) instruction while an erase or program cycle is in progress, is

not decoded, and has no effect on the cycle that is in progress.

The read identification (RDID) instruction should not be issued while the device is in deep

power-down mode.

The device is first selected by driving Chip Select (S

) Low. Then, the 8-bit instruction code

for the instruction is shifted in. This is followed by the 24-bit device identification, stored in

the memory, being shifted out on Serial Data output (Q), each bit being shifted out during

the falling edge of Serial Clock (C).

The instruction sequence is shown in Figure 9.

The read identification (RDID) instruction is terminated by driving Chip Select (S

) High at

any time during data output.

When Chip Select (S

) is driven High, the device is put in the st andby power mode. Once in

the standby pow er mode , the device waits to be selected, so that it can receive, deco de and

execute instructions.

Table 5. Read identification (RDID) data-out sequence

Device identification

Manufacturer identification

Memory type Memory capacity

20h 20h 10h

Figure 9. Read identification (RDID) instruct ion sequence and data-out sequence

S

21 3456789101112131415

0

C

Instruction

D

16 17 18 28 29 30 31

Q

High Impedance

Manufacturer identification

MSB

21/52

Device identification

15 1413 3210

MSB

AI06809b

Page 22

Instructions M25P05-A

6.4 Read status register (RDSR)

The read status register (RDSR) instruction allows t he status re gister to be read. The status

register may be read at any time, even while a program, erase or write status register cycle

is in progress. When one of these cycles is in progress, it is recommended to check the

write in progress (WIP) bit before sending a new instruction to the device. It is also possible

to read the status register continuously, as shown in Figure 10.

Table 6. Status register format

b7 b0

SRWD 0 0 0 BP1 BP0 WEL WIP

Status register write protect

Block protect bits

Write enable latch bit

Write in progress bit

The status and control bits of the status register are as follows:

6.4.1 WIP bit

The write in progress (WIP) bit indicates whether the memory is busy with a write status

register, program or erase cycle. When set to ‘1’, such a cycle is in progress, when reset to

‘0’ no such cycle is in progress.

6.4.2 WEL bit

The write enable latch (WEL) bit indicates the status of the internal write enable latch. When

set to ‘1’ the internal write enable latch is set, when set to ‘0’ the internal write enable latch is

reset and no write status register, program or erase instruction is accepted.

6.4.3 BP1, BP0 bits

The block protect (BP1, BP0) bits are non-volatile. They define the size of the area to be

software protected against program and erase instructions. These bits are written with the

write status register (WRSR) instruction. When one or both of the block protect (BP1, BP0)

bits is set to ‘1’, the relevant memory area (as defined in Table 2) becomes protected

against page program (PP) and sector erase (SE) instructions. The bloc k protect (BP1,

BP0) bits can be written provided that the hardware protected mode has not been set. The

bulk erase (BE) instruction is executed if, and only if, both block protect (BP1, BP0) bits are

0.

6.4.4 SRWD bit

The status register write disable (SRWD) bit is operated in conjunction with the Write

Protect (W

) signal. The status register write disable ( SRWD) bit and write protect (W) signal

allow the device to be put in the hardware protected mode (when the status register write

disable (SRWD) bit is set to ‘1’, and write protect (W

volatile bits of the status register (SRWD, BP1, BP0) become read-only bits and the write

status register (WRSR) instruction is no longer accepted for execution.

22/52

) is driven Low). In this mode, the non-

Page 23

M25P05-A Instructions

Figure 10. Read status register (RDSR) instruction sequence and data-out sequence

S

21 3456789101112131415

0

C

Instruction

D

Q

High Impedance

Status register out

7 6543210

MSB

6.5 Write status register (WRSR)

The write status register (WRSR) instruction allows new values to be written to the status

register . Bef o re it can be accepted, a write enab le (WREN) instruction must previously have

been executed. After the write enable (WREN) instruction has been decoded and executed,

the device sets the write enable latch (WEL).

The write status register (WRSR) instruction is entered by driving Chip Select (S

followed by the instruction code and the data byte on Serial Data input (D).

The instruction sequence is shown in Figure 11.

The write status register (WRSR) instruction has no effect on b6, b5, b4, b1 and b0 of the

status register. b6, b5 and b4 are always read as 0.

Chip Select (S

If not, the write status register (WRSR) instruction is not executed. As soon as Chip Select

(S

) is driven High, the self-timed write status register cycle (whose duration is tW) is initiated.

While the write status register cycle is in progress, the status register may still be read to

check the va lue of t he write in prog ress (WIP) bit. The write in progr ess (WIP) bit is 1 du ring

the self-timed write status register cycle, and is 0 when it is completed. At some unspecified

time before the cycle is completed, the write enable latch (WEL) is reset.

) must be driven High after t he eighth bit of th e data b y te has bee n latched in .

Status register out

7 6543210

MSB

7

AI02031E

) Low,

The write status register (WRSR) instruction allows the user to change the values of the

block protect (BP1 , BP0) bits, to define the siz e of the area that is to be tr eated as read-only,

as defined in Table 2. The write status register (WRSR) instruction also allows the user to

set or reset the status register write disab le (SR WD) bit in accordance with the Write Protect

(W

) signal. The status register write disable (SRWD) bit and Write Protect (W) signal allow

the device to be put in the hardware protected mode (HPM). The write status register

(WRSR) instruction is not executed once the hardware protected mode (HPM) is entered.

The protection features of the device are summarized in Table 7.

When the status register write disable (SRWD) bit of the status register is 0 (its initial

delivery state), it is possible to write to the status register provided that the write enable latch

(WEL) bit has previously been set by a write enable (WREN) instruction, regardless of the

whether Write Protect (W

) is driven High or Low.

23/52

Page 24

Instructions M25P05-A

When the status register write disable (SRWD) bit of the status register is set to ‘1’, two

cases need to be considered, depending on the state of Write Protect (W

● If Write Protect (W) is driven High, it is possible to write to the status register provided

):

that the write enable latch (WEL) bit has pre viously b een set b y a write enable (WREN)

instruction

● If Write Protect (W) is driven Low, it is not possible to write to the status register even if

the write enable latch (WEL) bit has previously been set by a write enable (WREN)

instruction (attempts to write to the status register are rejected, and are not accepted

for execution). As a consequence, all the data bytes in the memory area that are

software protected (SPM) b y the b lock protect (BP1, BP0) bit s of the status regist er , are

also hardware protected against data modification.

Regardless of the order of the two events, the hardware protected mode (HPM) can be

entered:

● by setting the status register write disable (SRWD) bit after driving Write Protect (W)

Low

● or by driving Write Protect (W) Low after setting the status register write disable

(SRWD) bit.

The only way to exit the hardware protected mode (HPM) once entered is to pull Write

Protect (W

) High.

If Write Protect (W

) is permanently tied High, the hardware protected mode (HPM) can

never be activated, and only the software protected mode (SPM), using the block protect

(BP1, BP0) bits of the status register, can be used.

Figure 11. Write status register (WRSR) instruction sequence

S

21 3456789101112131415

0

C

Instruction Status

D

High Impedance

Q

765432 0

MSB

register in

1

AI02282D

24/52

Page 25

M25P05-A Instructions

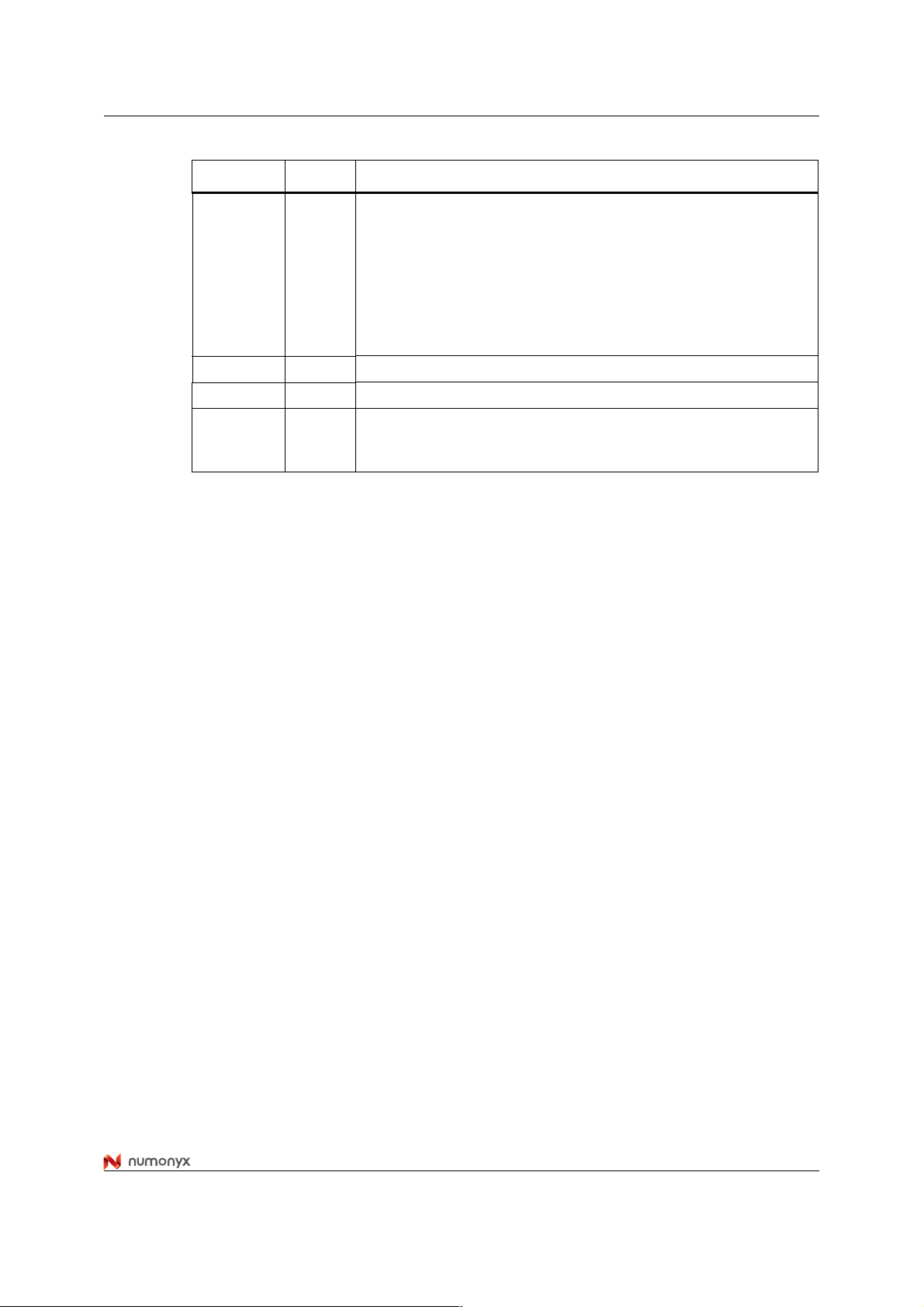

Table 7. Protection modes

Memory content

W

signal

SRWD

bit

Mode

Write protection of the status

register

Protected

(1)

area

Unprotected

area

(1)

10

00

11

Software

protected

(SPM)

Hardware

01

protected

(HPM)

1. As defined by the values in the block protect (BP1, BP0) bits of the status register, as shown in Table 2.

Status register is writable (if the

WREN instruction has set the WEL

bit).

The values in the SRWD, BP1 and

BP0 bits can be changed

Status register is hardware write

protected.

The values in the SRWD BP1 and

BP0 bits cannot be changed

Protected

against page

program, sector

erase and bulk

erase

Protected

against page

program, sector

erase and bulk

erase

Ready to

accept page

program and

sector erase

instructions

Ready to

accept page

program and

sector erase

instructions

25/52

Page 26

Instructions M25P05-A

6.6 Read data bytes (READ)

The device is first selected by driving Chip Select (S) Low. The instruction code for the read

data bytes (READ) instruction is followed by a 3-byte address (A23-A0), each bit being

latched-in during the rising edge of Serial Clock (C). Then the memory contents, at that

address, is shifted out on Serial Data output (Q), each bit being shifted out, at a maximum

frequency f

The instruction sequence is shown in Figure 12.

The first byte addressed can be at any location. The address is automatically incremented

to the next higher address after each byte of data is shifted out. The whole memory can,

therefore, be read with a single read data bytes (READ) instruction.

There is no address roll-over; when the highest address (0FFFFh) is reached, the

instruction should be terminated.

, during the falling edge of Serial Clock (C).

R

The read data bytes (READ) instruction is terminated by driving Chip Select (S

Select (S

) can be driven High at any time during data output. Any read data bytes (READ)

) High. Chip

instruction, while an erase, program or write cycle is in progress, is rejected without having

any effects on the cycle that is in progress.

Figure 12. Read data bytes (READ) instruction sequence and data-out sequence

S

21 345678910 2829303132333435

0

C

Instruction 24-bit address

23

D

High Impedance

Q

1. Address bits A23 to A16 must be set to 00h.

2221 3210

MSB

76543 1 7

MSB

36 37 38

Data out 1

39

Data out 2

2

0

AI03748D

26/52

Page 27

M25P05-A Instructions

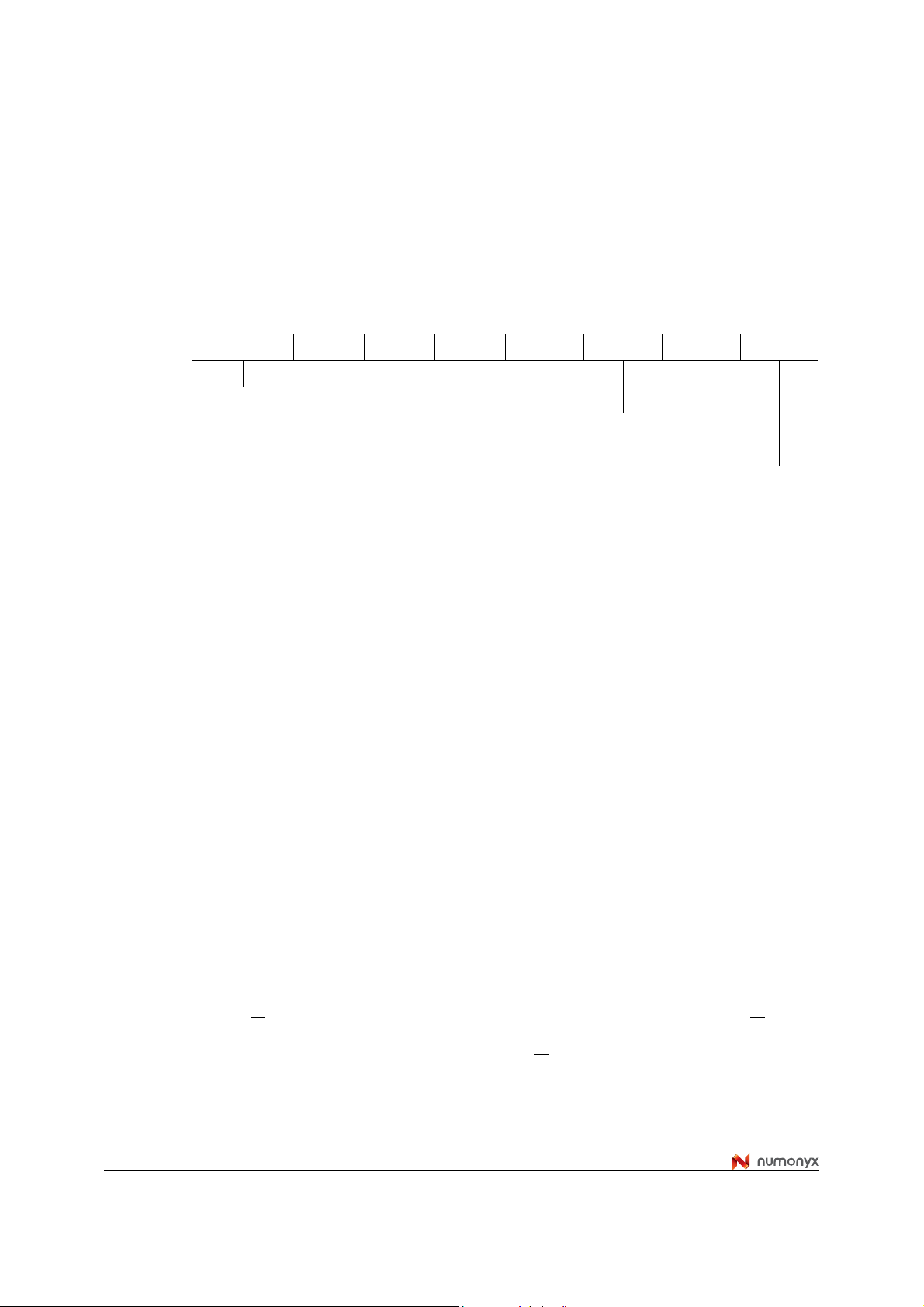

6.7 Read data bytes at higher speed (FAST_READ)

The device is first selected by driving Chip Select (S) Low. The instruction code for the read

data bytes at higher speed (FAST_READ) instruction is followed by a 3-byte address (A23A0) and a dummy byte, each bit being latched-in during the rising edge of Serial Clock (C).

Then the memory contents, at that address , is shifted out on Serial Data output (Q), each bit

being shifted out, at a maximum frequency f

The instruction sequence is shown in Figure 13.

The first byte addressed can be at any location. The address is automatically incremented

to the next higher address after each byte of data is shifted out. The whole memory can,

therefore, be read with a single read data bytes at higher spee d (FAST_READ) instruction.

There is no address roll-over; when the highest address (0FFFFh) is reached, the

instruction should be terminated.

The read data bytes at higher speed (FAST_READ) instruction is terminated by driving Chip

Select (S

) High. Chip Select (S) can be driven High at an y time during data output. An y r ead

data bytes at higher speed (F AST_READ) instruction, while an erase, program or write cycle

is in progress, is rejected without having any effects on the cycle that is in progr ess.

Figure 13. Read data bytes at higher speed (FAST_READ) instruction sequence

and data-out sequence

, during the falling edge of Serial Clock (C).

C

S

21 345678910 28293031

0

C

Instruction 24-bit address

23

D

High Impedance

Q

S

32 33 34 36 37 38 39 40 41 42 43 44 45 46

C

D

Q

765432 0

35

Dummy byte

2221 3210

1

DATA OUT 1

765432 0

MSB

47

DATA OUT 2

7 6543210

1

MSB MSB

7

1. Address bits A23 to A16 must be set to 00h.

AI04006

27/52

Page 28

Instructions M25P05-A

6.8 Page program (PP)

The page program (PP) instruction allo ws bytes to b e programmed in t he memory (changing

bits from 1 to 0). Before it can be acce pted, a write enable (WREN) instruction must

previously have been executed. After the write enable (WREN) instruction has been

decoded, the device sets the write enable latch (WEL).

The page program (PP) instruction is entered b y driving Chip Select (S

instruction code, three address bytes and at least one data byte on Serial Data input (D). If

the 8 least significant address bits (A7-A0) are not all zero, all transmitted data that goes

beyond the end of t he current page are programmed from the start address of the same

page (from the address whose 8 least significant bits (A7-A0) are all zero). Chip Select (S

must be driven Low for the entire duration of the sequence.

The instruction sequence is shown in Figure 14.

If more than 256 by tes ar e se nt t o the device, previously latched data are discarded and the

last 256 data bytes are guaranteed t o be progr ammed correctly within the same page . If less

than 256 data bytes are sent to device, they are correctly programmed at the requested

addresses without having any effects on the other bytes of the same page.

For optimized timings, it is recommended to use the page program (PP) instruction to

program all consecutive targeted bytes in a single sequence versus using several page

program (PP) sequences with each containing only a few bytes (see Table 14: Instruction

times).

Chip Select (S

latched in, otherwise the page progr am (PP) instruction is not executed.

As soon as Chip Select (S

duration is t

may be read to check th e value of the write in progress (WIP) bit. The write in progress

(WIP) bit is 1 during the self-timed page program cycle, and is 0 when it is completed. At

some unspecified time before the cycle is completed, the write enable latch (WEL) bit is

reset.

) must be driven High after the eighth bit of the last data byte has been

) is driven High, the self-timed page program cycle (whose

) is initiated. While the page program cycle is in progress, the status register

PP

) Low, f ollowed b y the

)

A page program (PP) instruction applied to a page which is protected by the bloc k protect

(BP1, BP0) bits (see Table 3. and Table 2.) is not executed.

28/52

Page 29

M25P05-A Instructions

Figure 14. Page program (PP) instruction sequence

S

21 345678910 2829303132333435

0

C

Instruction 24-bit address

D

S

4241 43 44 45 46 47 48 49 50 52 53 54 5540

C

Data byte 2

D

765432 0

MSB MSB MSB

765432 0

1

1. Address bits A23 to A16 must be set to 00h.

23

2221 3210

MSB

51

Data byte 3 Data byte 256

1

765432 0

MSB

2073

2072

765432 0

36 37 38

Data byte 1

2075

2074

2076

1

2077

1

39

2079

2078

AI04082B

29/52

Page 30

Instructions M25P05-A

6.9 Sector erase (SE)

The sector erase (SE) instruction sets to ‘1’ (FFh) all bits inside the chosen sector. Before it

can be accepted, a write enable (WREN) instruction must previously have been executed.

After the write enable (WREN) instruction has been decoded, the device sets the write

enable latch (WEL).

The sector erase (SE) instruction is entered by driving Chip Select (S

) Low, followed by the

instruction code, and three address bytes on Serial Data input (D). Any address inside the

sector (see Table 3) is a valid address f or the sector erase (SE) instruction. Chip Select (S

must be driven Low for the entire duration of the sequence.

The instruction sequence is shown in Figure 15.

Chip Select (S

) must be driven High after the eighth bit of the last address byte has been

latched in, otherwise the sector erase (SE) instruction is not executed. As soon as Ch ip

Select (S

) is driven High, the self-timed sector erase cycle (whose duration is tSE) is

initiated. While the sector erase cycle is in progress, the status register may be read to

check the va lue of t he write in prog ress (WIP) bit. The write in progr ess (WIP) bit is 1 du ring

the self-timed sector erase cycle, and is 0 when it is completed. At some unspecified time

before the cycle is completed, the write enable latch (WEL) bit is reset.

A sector erase (SE) instruction applied to a page which is protected by the block protect

(BP1, BP0) bits (see Table 3 and Table 2) is not executed.

Figure 15. Sector erase (SE) instruction sequence

S

21 3456789 293031

0

C

Instruction

24-bit address

)

D

1. Address bits A23 to A16 must be set to 00h.

30/52

23 22 2 0

MSB

1

AI03751D

Page 31

M25P05-A Instructions

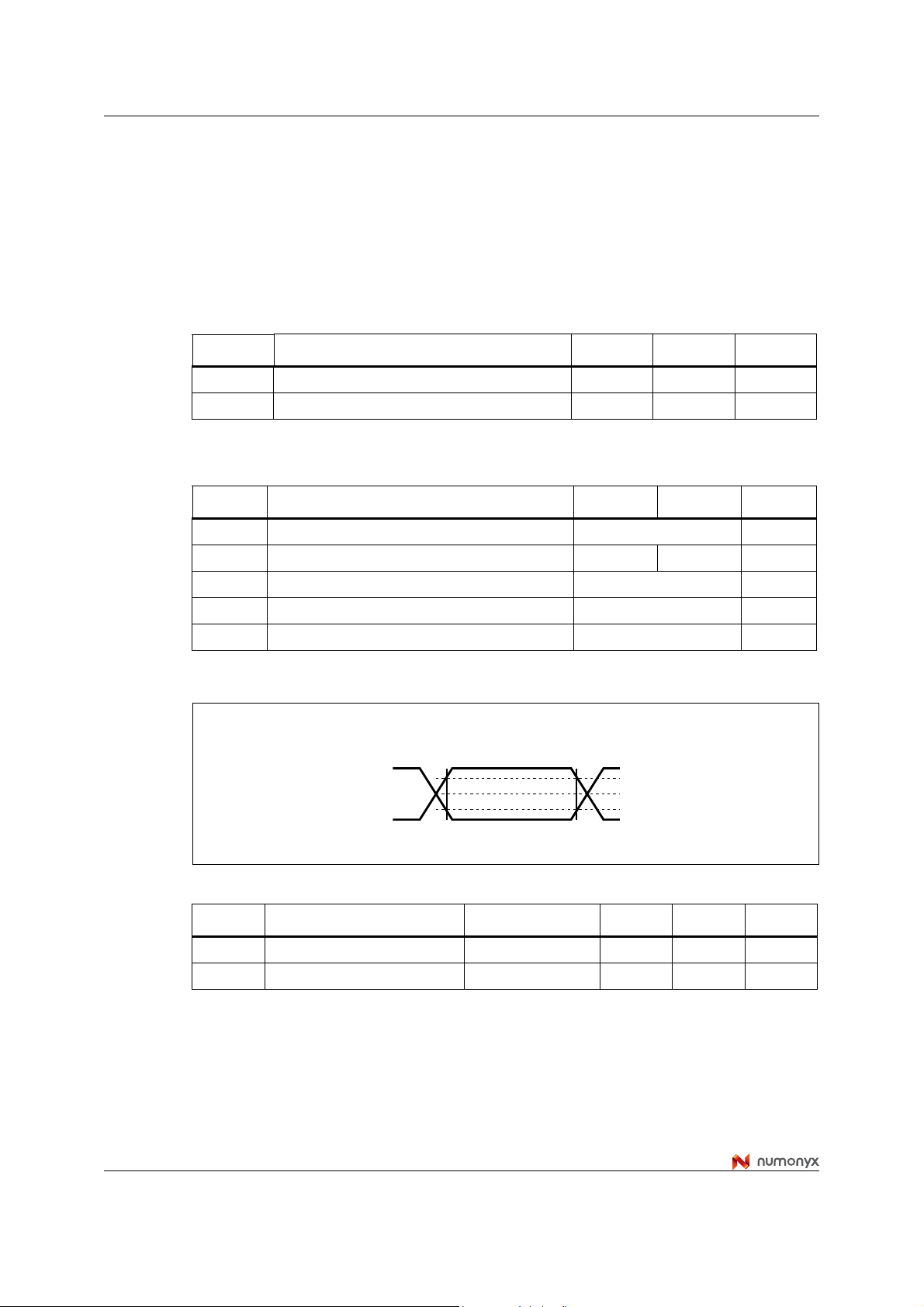

6.10 Bulk erase (BE)

The bulk erase (BE) instruction sets all bits to ‘1’ (FFh). Before it can be accepted, a write

enable (WREN) instruction must previously have been executed. After the write enable

(WREN) instruction has been decoded, the device sets the write enable latch (WEL).

The bulk erase (BE) instruction is entered by driving Chip Select (S

instruction code on Serial Data input (D). Chip Select (S

) must be driven Low for the entire

) Low, followed by the

duration of the sequence.

The instruction sequence is shown in Figure 16.

Chip Select (S

) must be driven High after the eighth bit of the instruction code has been

latched in, otherwise the bulk erase instruction is not executed. As soon as Chip Select (S

is driven High, the self-timed bulk erase cycle (whose duration is t

) is initiated. While the

BE

bulk erase cycle is in progress, the status register may be read to check the value of the

write in progress (WIP) bit. The write in progress (WIP) bit is 1 during the self-timed bulk

erase cycle, and is 0 when it is completed. At some unspecified time before the cycle is

completed, the write enable latch (WEL) bit is reset.

The bulk erase (BE) instruction is executed only if both block protect (BP1, BP0) bits are 0.

The bulk erase (BE) instruction is ignored if one, or more, sectors are protected.

Figure 16. Bulk erase (BE) instruction sequence

S

21 345670

C

Instruction

D

)

AI03752D

31/52

Page 32

Instructions M25P05-A

6.11 Deep power-down (DP)

Executing the deep power-down (DP) instruction is the only way to put the device in the

lowest consumption mode (the deep power-down mode). It can also be used as a software

protection mechanism, while the device is not in active use, as in this mode, the device

ignores all write, program and erase instructions.

Driving Chip Select (S

) High deselects the device, and puts the device in standby mode (if

there is no internal cycle currently in progress). But this mode is not the deep power-down

mode. The deep pow er-do wn mode can only be ente red b y e x ecut ing the deep po wer-do wn

(DP) instruction, subsequently reducing the standb y current (from I

CC1

to I

, as specified

CC2

in Table 13).

To take the device out of deep power-down mode, the release from deep power-down and

read electronic signature (RES) instruction must be issued. No other instruction must be

issued while the device is in deep power-down mode.

The release from deep pow er-down and read electron ic signature (RES) instruction, a nd the

read identification (RDID) instruction also allow t he electronic signature of the device to be

output on Serial Data output (Q).

The deep power-down mode automatically stops at power-down, and the device always

powers-up in the stan dby mode.

The deep power-down (DP) instruction is entered by driving Chip Select (S

by the instruction code on Serial Data input (D). Chip Select (S

) must be driven Low for the

) Low, followed

entire duration of the sequ ence.

The instruction sequence is shown in Figure 17.

Chip Select (S

) must be driven High after the eighth bit of the instruction code has been

latched in, otherwise the deep power-down (DP) instruction is not executed. As soon as

Chip Select (S

to I

and the deep power-down mode is entered.

CC2

) is driven High, it requires a delay of tDP before the supply cu rrent is r educe d

Any deep power-down (DP) instruction, while an erase, program or write cycle is in

progress, is rejected without having any effects on the cycle that is in progress.

Figure 17. Deep power-down (DP) instruction sequence

S

21 345670

C

Instruction

D

32/52

t

DP

Standby mode

Deep power-down mode

AI03753D

Page 33

M25P05-A Instructions

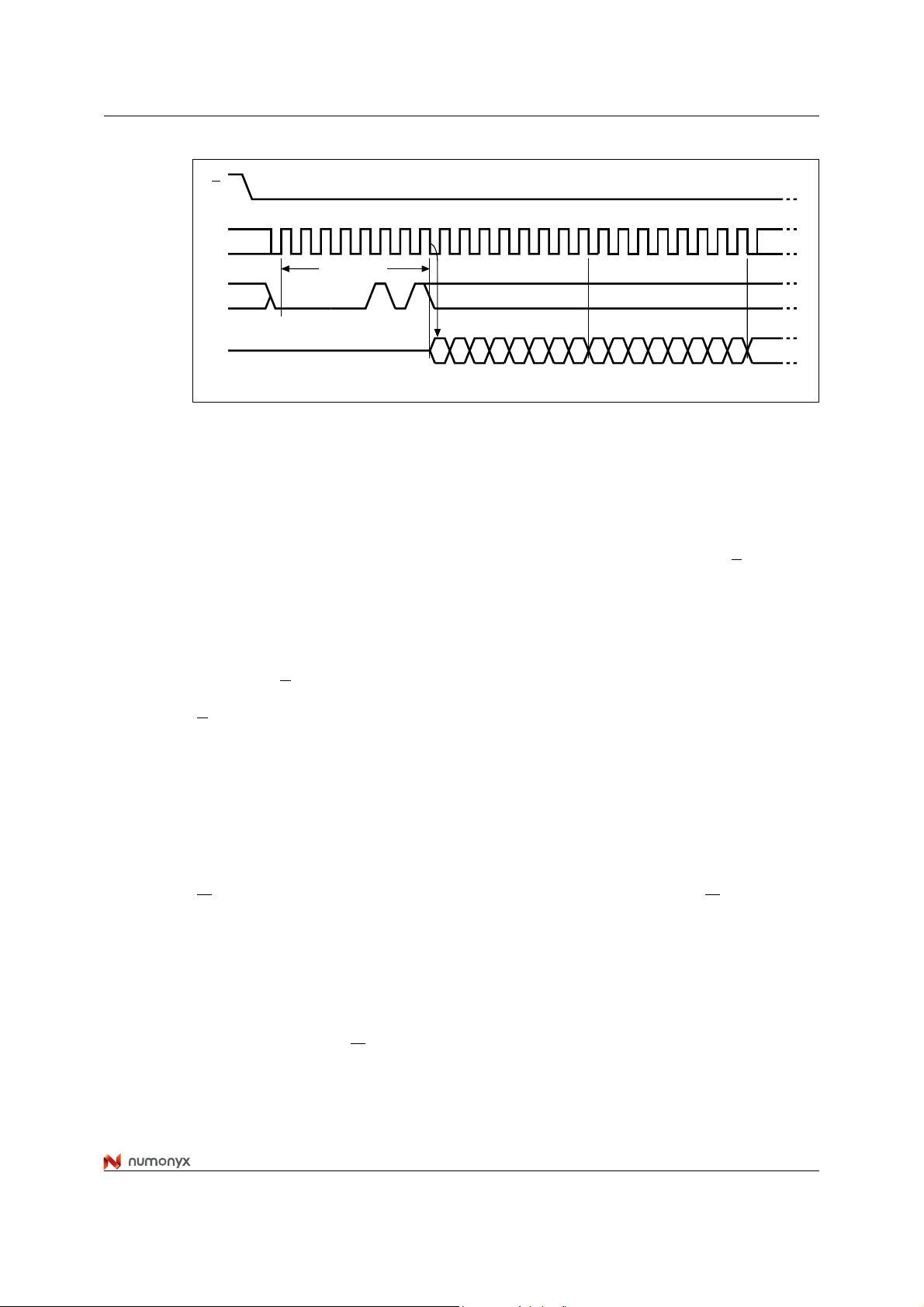

6.12 Release from deep power-down and read electronic signature (RES)

To take the device out of deep power-down mode, the release from deep power-down and

read electronic signature (RES) instruction must be issued. No other instruction must be

issued while the device is in deep power-down mode.

The instruction can also be used to read, on Serial Data output (Q), the 8-bit electronic

signature, whose value for the M25P05-A is 05h.

Except while an erase, program or write status register cycle is in pro gress , the release from

deep power-down and read electronic signature (RES) instruction always provides access

to the 8-bit electronic signature of the device, and can be applied even if the deep powerdown mode has not been entered.

Any release from deep pow er-down and re ad electronic signature (RES) instruction while an

erase, program or write status register cycle is in progress, is not decoded, and has no

effect on the cycle that is in progress.

The device is first selected by driving Chip Select (S

) Low. The instruction code is followed

by 3 dummy bytes, each bit being latched-in on Serial Data input (D) during the rising edge

of Serial Clock (C). Then, the 8-bit electronic signature, stored in the memory, is shifted out

on Serial Data output (Q), each bit being shifted out during the falling edge of Serial Clock

(C).

The instruction sequence is shown in Figure 18.

The release from deep power-down and read electronic signature (RES) instruction is

terminated by driving Chip Select (S

least once. Sending additional clock cycles on Serial Clock (C), while Chip Select (S

) High after the electronic signature has been read at

) is

driven Low, cause the electronic signature to be output repeatedly.

When Chip Select (S

) is driven High, the device is put in the standby power mode. If the

device was not pre viously in t he deep power- down mode , the transition to the st andby po wer

mode is immediate. If the de vice w as previously in the deep power-down mode, though, the

transition to the standby power mode is delayed by t

High for at least t

(max), as specified in Table 15. Once in the standby po wer mode, the

RES2

, and Chip Select (S) must remain

RES2

device waits to be selected, so that it can receive, decode and execute instructions.

Driving Chip Select (S

) High after the 8-bit instruction byte has been r eceiv ed b y t he de vice ,

but before the whole of the 8-bit electronic signature has been transmitted for the first time

(as shown in Figure 19), still ensures that the device is put into standby power mode. If the

device was not pre viously in t he deep power- down mode , the transition to the st andby po wer

mode is immediate. If the de vice w as previously in the deep power-down mode, though, the

transition to the standby power mode is delayed by t

High for at least t

(max), as specified in Table 15. Once in the standby po wer mode, the

RES1

, and Chip Select (S) must remain

RES1

device waits to be selected, so that it can receive, decode and execute instructions.

33/52

Page 34

Instructions M25P05-A

Figure 18. Release from deep power-down and read electronic signature (RES)

instruction sequence and data-out sequence

S

21 345678910 2829303132333435

0

C

Instruction 3 dummy bytes

23

D

High Impedance

Q

2221 3210

MSB

Electronic signature Out

765432 0

MSB

Deep power-down mode

36 37 38

1

1. The value of the 8-bit electronic signature, for the M25P05-A, is 05h.

Figure 19. Release from deep power-down (RES) instruction sequence

S

t

21 345670

C

Instruction

RES1

t

RES2

Standby mode

AI04047C

D

High Impedance

Q

34/52

Deep power-down mode

Standby mode

AI04078B

Page 35

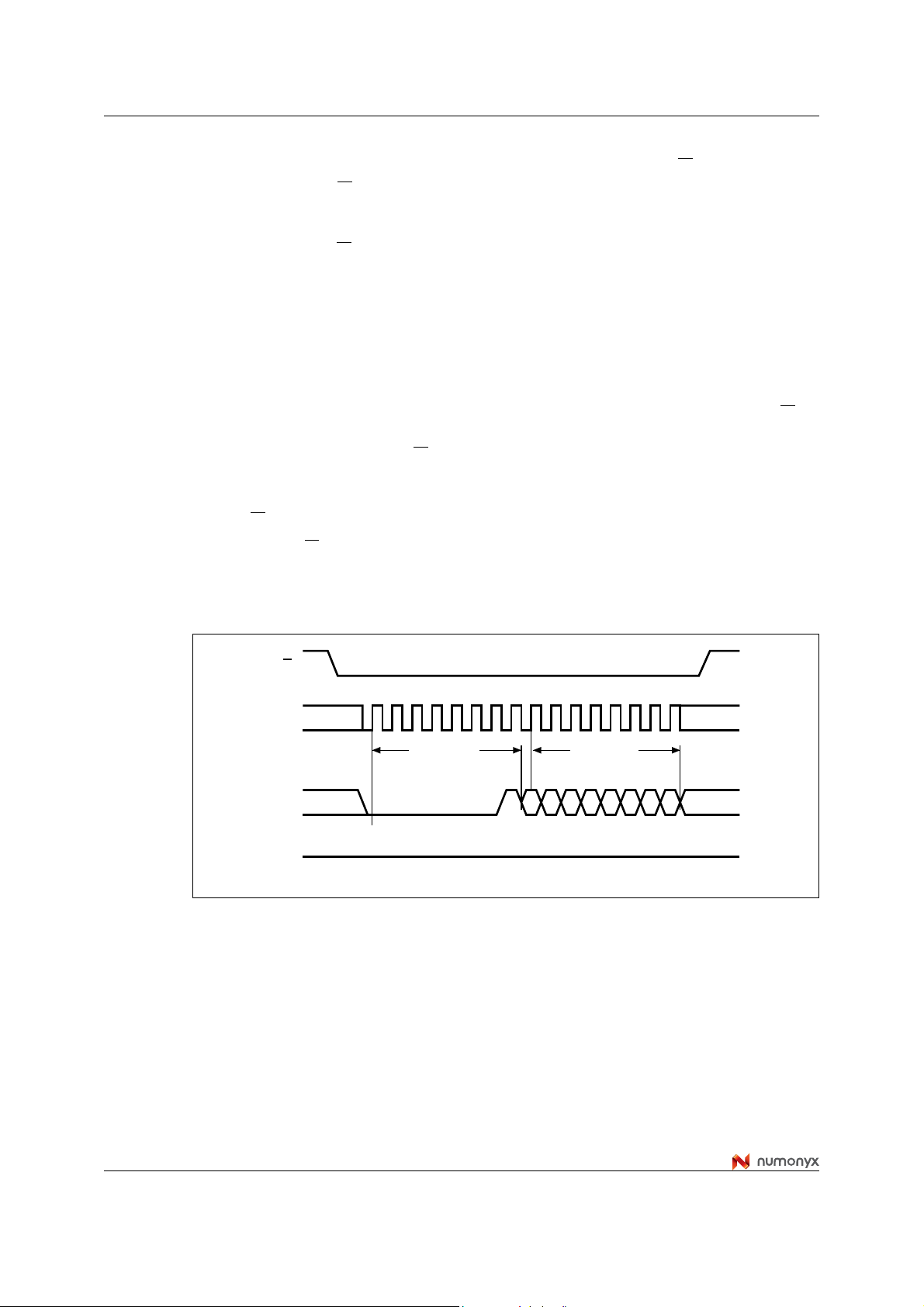

M25P05-A Power-up and power-down

7 Power-up and power-down

At power-up and po w er- down, the device must not be se lected ( that is Chip Select ( S ) m ust

follow the voltage applied on V

● V

●

(min) at power-up, and then for a further delay of t

CC

VSS at power-down

A safe configuration is provided in Section 3: SPI modes.

To avoid data corruption and inadvertent write operations during power-up, a power on reset

(POR) circuit is included. The logic inside the device is held reset while V

power on reset (POR) threshold voltage, V

does not respond to any instruction.

Moreover, the device ignores all write enable (WREN), page program (PP), sector erase

(SE), bulk erase (BE) and write status register (WRSR) instructions until a time de lay of

t

has elapsed after the moment that VCC rises above the VWI threshold. However, the

PUW

correct operation of the de vice is not guar a nteed if, by this time, V

No write status register, p rogram or erase instructions should be sent until the later of:

● t

● t

after VCC passed the VWI threshold

PUW

after VCC passed the VCC(min) level

VSL

These values are specified in Table 8.

) until VCC reaches the correct value:

CC

VSL

– all operations are disabled, and the device

WI

is less than the

CC

is still below VCC(min).

CC

If the delay, t

selected for read instructions even if the t

, has elapsed, after VCC has risen above VCC(min), the device can be

VSL

delay is not yet fully elapsed.

PUW

At power-up, the device is in the following state:

● The device is in the standby mode (not the deep po wer-down mode)

● The write enable latch (WEL) bit is reset

● The write in progress (WIP) bit is reset.

Normal precautions must be taken for supply rail decoupling, to stabilize the V

Each device in a system should ha v e the V

rail decoupled by a suitable capacito r close to

CC

supply.

CC

the package pins (generally, this capacitor is of the order of 100 nF).

At power-down, when V

(POR) threshold voltage, V

drops from the operating voltage, to below the power on reset

CC

, all operations are disabled and the device does not respond

WI

to any instruction (the designer needs to be aw are that if a power- down occurs while a write,

program or erase cycle is in progress, some data corruption can result).

35/52

Page 36

Initial delivery state M25P05-A

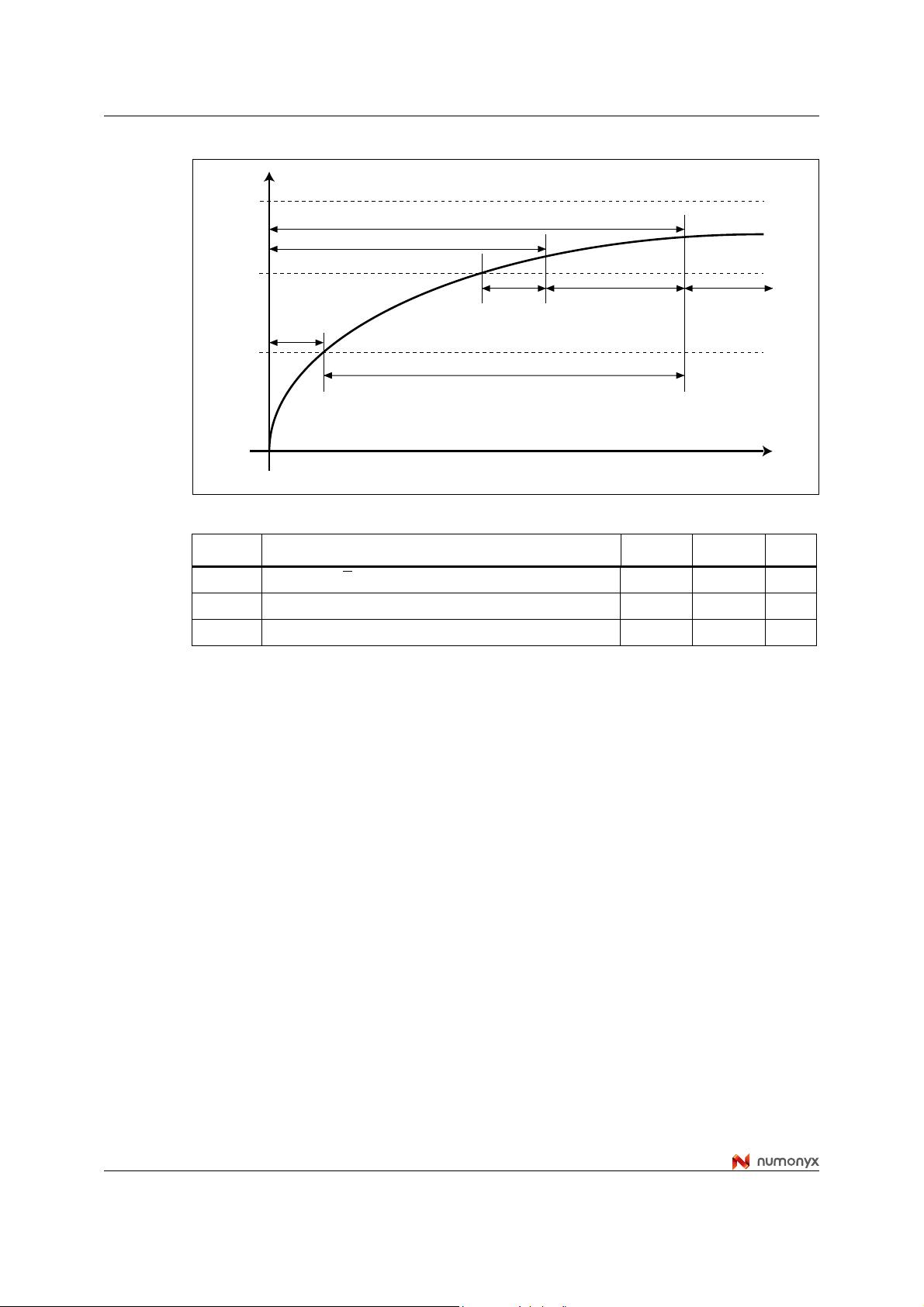

Figure 20. Power-up timing

V

CC

VCC(max)

Program, erase and write commands are rejected by the device

Chip selection not allowed

VCC(min)

Reset state

of the

device

V

WI

Table 8. Power-up timing and V

Symbol Parameter Min Max Unit

(1)

t

VSL

t

PUW

V

WI

1. These parameters are characterized only.

VCC(min) to S low 10 µs

(1)

Time delay to Write instruction 1 10 ms

(1)

Write inhibit voltage 1 2 V

8 Initial delivery state

threshold

WI

tVSL

tPUW

Read access allowed Device fully

accessible

time

AI04009C

The device is deliv ered with the memory array erased: all bits are set to ‘1’ (each byte

contains FFh). The status register contains 00h (all status register bits are 0).

36/52

Page 37

M25P05-A Maximum ratings

9 Maximum ratings

Stressing the device above the rating listed in Table 9: Absolute maximum ratings may

cause permanent damage to the device. These are stress ratings only and operation of the

device at these or any other conditions above those indicated in th e operating sections of

this specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may aff ect device reliability.

Table 9. Absolute maximum ratings

Symbol Parameter Min Max Unit

T

STG

T

LEAD

V

IO

V

CC

V

ESD

1. Compliant with JEDEC Std J-STD-020C (for small body, Sn-Pb or Pb assembly), the Numonyx

ECOPACK® 7191395 specification, and the European directive on Restrictions on Hazardous Substances

(RoHS) 2002/95/EU.

2. JEDEC Std JESD22-A114A (C1 = 100 pF, R1 = 1500 Ω, R2 = 500 Ω).

Storage temperature –65 150 °C

Lead temperature during soldering see

(1)

Input and output voltage (with respect to ground) –0.6 VCC+0.6 V

Supply voltage –0.6 4.0 V

Electrostatic discharge voltage (human body

(2)

model)

–2000 2000 V

°C

37/52

Page 38

DC and AC parameters M25P05-A

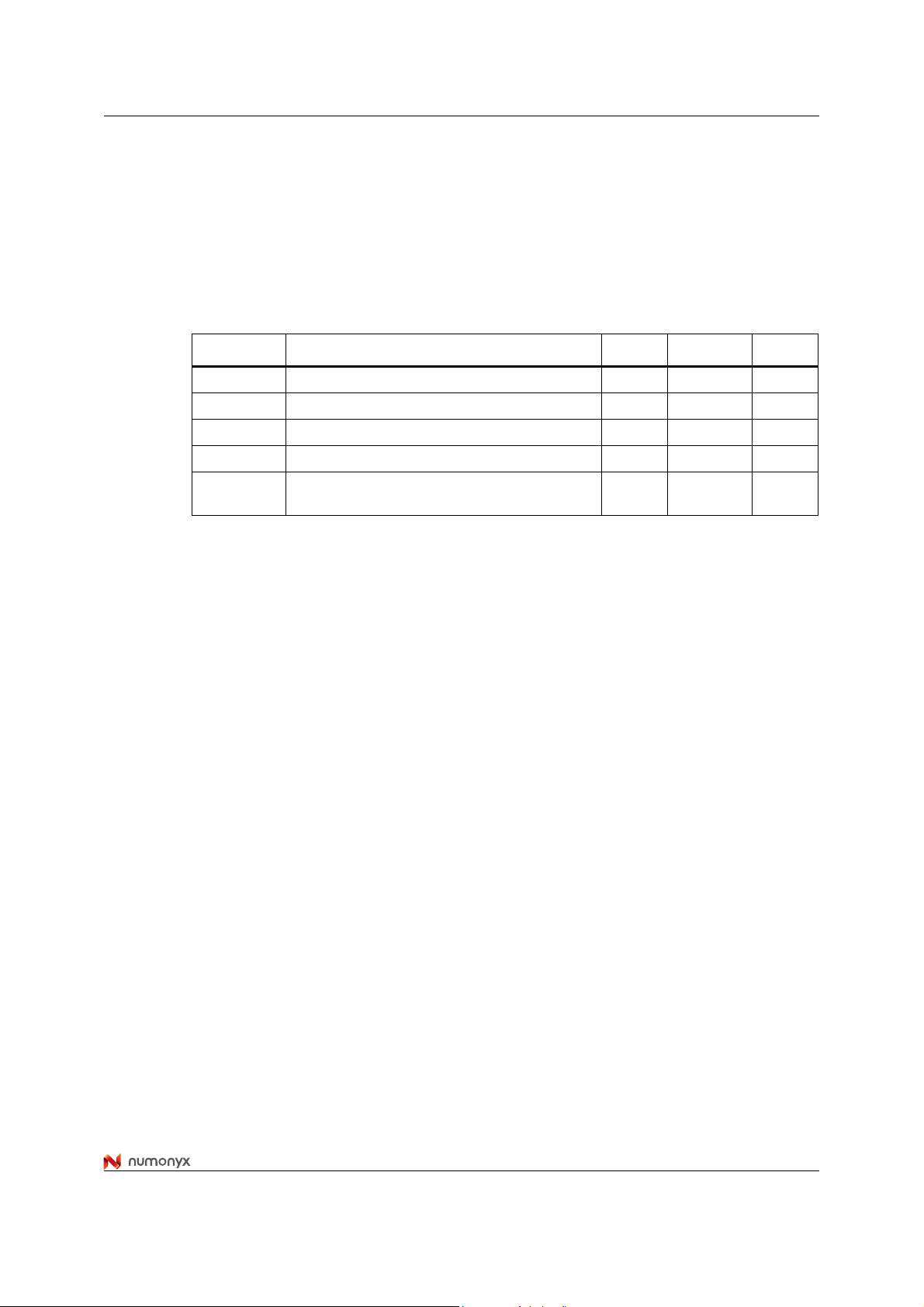

10 DC and AC parameters

This section summarizes the operating and measurement conditions, and the DC and AC

characteristics of the device. The parameters in the DC and AC characteristic tables that

follow are derived from tests performed under the measurement conditions summarized in

the relevant tables. Designers should check that the operating conditions in their circuit

match the measurement conditions when relying on the quoted parameters.

Table 10. Operating conditions

Symbol Parameter Min Max Unit

V

CC

T

1. Only in products with process technology code Y. In products with process technology code X, VCC(min) is

2.7 V.

Table 11. AC measurement conditions

Supply voltage 2.3

Ambient operating temperature –40 85 °C

A

(1)

Symbol Parameter Min Max Unit

(1)

3.6 V

C

Load capacitance 30 pF

L

Input rise and fall times 5 ns

Input pulse voltages 0.2VCC to 0.8V

Input timing reference voltages 0.3V

Output timing reference voltages V

1. Output Hi-Z is defined as the point where data out is no longer driven.

to 0.7V

CC

CC

CC

CC

/ 2 V

Figure 21. AC measurement I/O wavef orm

Input levels

0.8V

CC

0.2V

CC

Table 12. Capacitance

(1)

Symbol Parameter Test condition Min Max Unit

C

OUT

C

1. Sampled only, not 100% tested, at T

Output capacitance (Q) V

Input capacitance (other pins) VIN = 0 V 6 pF

IN

= 25 °C and a frequency of 25 MHz.

A

= 0 V 8 pF

OUT

Input and output

timing reference levels

0.7V

0.5V

0.3V

AI07455

CC

CC

CC

V

V

38/52

Page 39

M25P05-A DC and AC parameters

Table 13. DC characteristics

Symbol Parameter

I

Input leakage current ± 2 µA

LI

Output leakage current ± 2 µA

I

LO

I

I

I

I

I

I

I

V

V

Table 14. Instruction times

Standby current S = VCC, V

CC1

Deep power-down current S = VCC, V

CC2

Operating current (READ)

CC3

Operating current (PP) S = V

CC4

Operating current (WRSR) S = V

CC5

Operating current (SE) S = V

CC6

Operating current (BE) S = V

CC7

Input low voltage – 0.5 0.3V

V

IL

V

Input high voltage 0.7V

IH

Output low voltage IOL = 1.6 mA 0.4 V

OL

Output high voltage IOH = –100 µAV

OH

Test condition (in addition to

those in Table 10.)

= VSS or V

C = 0.1V

IN

= VSS or V

IN

/ 0.9.VCC at 50 MHz,

CC

CC

CC

Q = open

C = 0.1V

/ 0.9.VCC at 25 MHz,

CC

Q = open

CC

CC

CC

CC

Min Max Unit

50 µA

5µA

8mA

4mA

15 mA

15 mA

15 mA

15 mA

CC

CCVCC

–0.2 V

CC

+0.4 V

V

Test conditions specified in Table 10 and Table 11.

Symbol Alt. Parameter Min Typ Max Unit

t

W

(1)

t

PP

t

SE

t

BE

1. When using the page program (PP) instruction to program consecutive bytes, optimized timings are

obtained with one sequence including all the bytes versus several sequences of only a few bytes (1 ≤ n ≤

256).

2. tPP=2µs+8µs*[int(n-1)/2+1]+4µs*[int(n-1)/2]+2µs, only in products with process technology code X and Y.

Write status register cycle time 5 15 ms

Page program cycle time (256 bytes) 1.4

Page program cycle time (n bytes) 0.4+n*1/256

(2)

5ms

Sector erase cycle time 0.65 3 s

Bulk erase cycle time 0.85 6 s

39/52

Page 40

DC and AC parameters M25P05-A

Table 15. AC characteristics (25 MHz operation)

Test conditions specified in Table 10 and Table 11.

Symbol Alt. Parameter Min Typ Max Unit

Clock frequency for the following instructions:

f

C

f

F AS T_READ, PP, SE, BE, DP, RES, WREN, WRDI,

C

RDSR, WRSR

D.C. 25 MHz

f

R

(1)

t

CH

(1)

t

CL

(2)

t

CLCH

(2)

t

CHCL

t

SLCHtCSS

t

CHSL

t

DVCHtDSU

t

CHDXtDH

t

CHSH

t

SHCH

t

SHSLtCSH

(2)

t

SHQZ

t

CLQV

t

CLQXtHO

t

HLCH

t

CHHH

t

HHCH

t

CHHL

(2)

t

HHQX

(2)

t

HLQZ

(4)

t

WHSL

(4)

t

SHWL

(2)

t

DP

(2)

t

RES1

Clock frequency for read instructions D.C. 20 MHz

t

Clock high time 18 ns

CLH

t

Clock low time 18 ns

CLL

Clock rise time

Clock fall time

(3)

(peak to peak)

(3)

(peak to peak) 0.1 V/ns

0.1 V/ns

S active setup time (relative to C) 10 ns

S not active hold time (relative to C) 10 ns

Data in setup time 5 ns

Data in hold time 5 ns

S active hold time (relative to C) 10 ns

S not active setup time (relative to C) 10 ns

S deselect time 100 ns

t

Output disable time 15 ns

DIS

tVClock Low to Output Valid 15 ns

Output hold time 0 ns

HOLD setup time (relative to C) 10 ns

HOLD hold time (relative to C) 10 ns

HOLD setup time (relative to C) 10 ns

HOLD hold time (relative to C) 10 ns

tLZHOLD to Output Low-Z 15 ns

t

HOLD to Output High-Z 20 ns

HZ

Write protect setup time 20 ns

Write protect hold time 100 ns

S High to deep power-down mode 3 µs

S High to standby mode without electronic signature

read

3 µs

(2)

t

RES2

1. tCH + tCL must be greater than or equal to 1/ fC.

2. Value guaranteed by characterization, not 100% tested in production.

3. Expressed as a slew-rate.

4. Only applicable as a constraint for a WRSR instruction when SRWD is set to ‘1’.

S High to standby mode with electronic signature

read

40/52

1.8 µs

Page 41

M25P05-A DC and AC parameters

Table 16. AC characteristics (40 MHz operation)

40 MHz available for products marked since week 20 of 2004, only

Test conditions specified in Table 10. and Table 11.

Symbol Alt. Parameter Min Typ Max Unit

Clock frequency for the following instructions:

f

C

f

FAST_READ, PP, SE, BE, DP, RES, WREN, WRDI,

C

D.C. 40 MHz

RDSR, WRSR

f

R

(2)

t

CH

(2)

t

CL

(3)

t

CLCH

(3)

t

CHCL

t

SLCHtCSS

t

CHSL

t

DVCHtDSU

t

CHDXtDH

t

CHSH

t

SHCH

t

SHSLtCSH

(3)

t

SHQZ

t

CLQV

t

CLQXtHO

t

HLCH

t

CHHH

t

HHCH

t

CHHL

(3)

t

HHQX

(3)

t

HLQZ

(5)

t

WHSL

(1)

t

SHWL

(3)

t

DP

(3)

t

RES1

(3)

t

RES2

1. Only applicable as a constraint for a WRSR instruction when SRWD is set to ‘1’.

2. tCH + tCL must be greater than or equal to 1/ fC.

3. Value guaranteed by characterization, not 100% tested in production.

4. Expressed as a slew-rate.

5. Details of how to find the date of marking are given in application note, AN1995.

Clock frequency for read instructions D.C. 20 MHz

t

Clock high time 11 ns

CLH

t

Clock low time 11 ns

CLL

Clock rise time

Clock fall time

(4)

(peak to peak)

(4)

(peak to peak) 0.1 V/ns

0.1 V/ns

S active setup time (relative to C) 5 ns

S not active hold time (relative to C) 5 ns

Data in setup time 2 ns

Data in hold time 5 ns

S active hold time (relative to C) 5 ns

S not active setup time (relative to C) 5 ns

S deselect time 100 ns

t

Output disable time 9 ns

DIS

tVClock Low to Output Valid 9 ns

Output hold time 0 ns

HOLD setup time (relative to C) 5 ns

HOLD hold time (relative to C) 5 ns

HOLD setup time (relative to C) 5 ns

HOLD hold time (relative to C) 5 ns

t

HOLD to Output Low-Z 9 ns

LZ

t

HOLD to Output High-Z 9 ns

HZ

Write protect setup time 20 ns

Write protect hold time 100 ns

S High to deep power-down mode 3 µs

S High to standby mode without electronic signature

read

S High to standby mode with electronic signature read 1.8 µs

(1)

3µs

41/52

Page 42

DC and AC parameters M25P05-A

Table 17. AC characteristics (50 MHz operation)

50 MHz available only in products with process technology code Y

(1)(2)

Test conditions specified in Table 10 and Table 11.

Symbol Alt. Parameter Min Typ Max Unit

f

C

f

R

(3)

t

CH

(3)

t

CL

(4)

t

CLCH

(4)

t

CHCL

t

SLCH

t

CHSL

t

DVCH

t

CHDX

t

CHSH

t

SHCH

t

SHSL

(4)

t

SHQZ

t

CLQV

t

CLQX

t

HLCH

t

CHHH

t

HHCH

t

CHHL

(4)

t

HHQX

(4)

t

HLQZ

(6)

t

WHSL

(6)

t

SHWL

(4)

t

DP

(4)

t

RES1

(4)

t

RES2

1. Details of how to find the process on the device marking are given in application note AN1995.