Numatic TTV 678 Owner's Manual

Original instructions

Warning! Read instructions before using the machine

www.numatic.com

TTV 678

Ride-on

Scrubber Dryer

Owner Instructions

TTV 678

2

Page 2

Page 3

Page 4

Page 5

Page 6 / 7

Page 9

Page 9

Page 10

Page 11

Page 12

Page 12

Page 13

Page 13

Page 14

Page 14

Page 15

Page 15

Page 16

Page 16

Page 16

Page 17

Page 17

Page 18

Page 19

Quick Set-up Guide

Page 8

Before continuing, please refer to Quick Set Up Guide on Page 8

! !

Index

Machine Overview

Control Panel Overview

Rating Label / Personal Protective Equipment / Recycling

Safety Precautions

Machine set-up

Fitting the side pod skirts

Fitting the oor-tool

Fitting the hose Guide / Breakaway oor-tool feature

Fitting the brushes

Setting the width

Filling the clean-water tank

Chemical dosing system

Pre-cleaning advice

Machine Operation

Lowering the brush-deck

Lowering the oor-tool

Adjusting the seat

Setting the cleaning controls

Setting the operator pre-set buttons

Waste tank warning light

Brush pressure / load adjustment

Emergency stop button and horn

Machine usage advice

Machine Cleaning

Tanks and Filters

Changing the Floor-tool Blades

Machine Charging

Battery care

Free Wheel Function

Off-aisle Cleaning Function (optional)

Trouble Shooting / Specications

Recommended Spare Parts

Schematic Diagrams

Declaration document

Warranty

Company Address

Page 20

Page 21

Page 22

Page 23

Page 24 - 26

Page 27

Page 28

Page 30

Page 31

Page 32

3

1 Operator Control Panel (see page 4) 13 Gel batteries

2 Brush load-adjuster knob 14 Chemical dosing tank ( 5 litre )

3 Brush deck release lever 15 Charger

4 Brush deck foot pedal 16 Accelerator pedal

5 Clean-water tank ll point 17 Clean-water Tank Emptying Hose & Fill Level

6 Side Pod (adjustable) 18 Semi parabolic oor-tool

7 Brush deck motors x3 19 Vacuum hose

8 Brush deck cover adjustment / width lever 20 Waste-water emptying hose

9 Floor-tool raise / lower lever 21 Floor-tool vacuum hose

10 Seat adjustment lever 22 Air separator assembly

11 Separator release catches 23 Pedestrian warning light

12 40 Amp battery fuses x3 24 Water and detergent pumps

Machine Overview

1

3

4

5

6

7

8

9

10

12

13

15

16

17

18

19 20 21

22

6

11

2

23

24

14

4

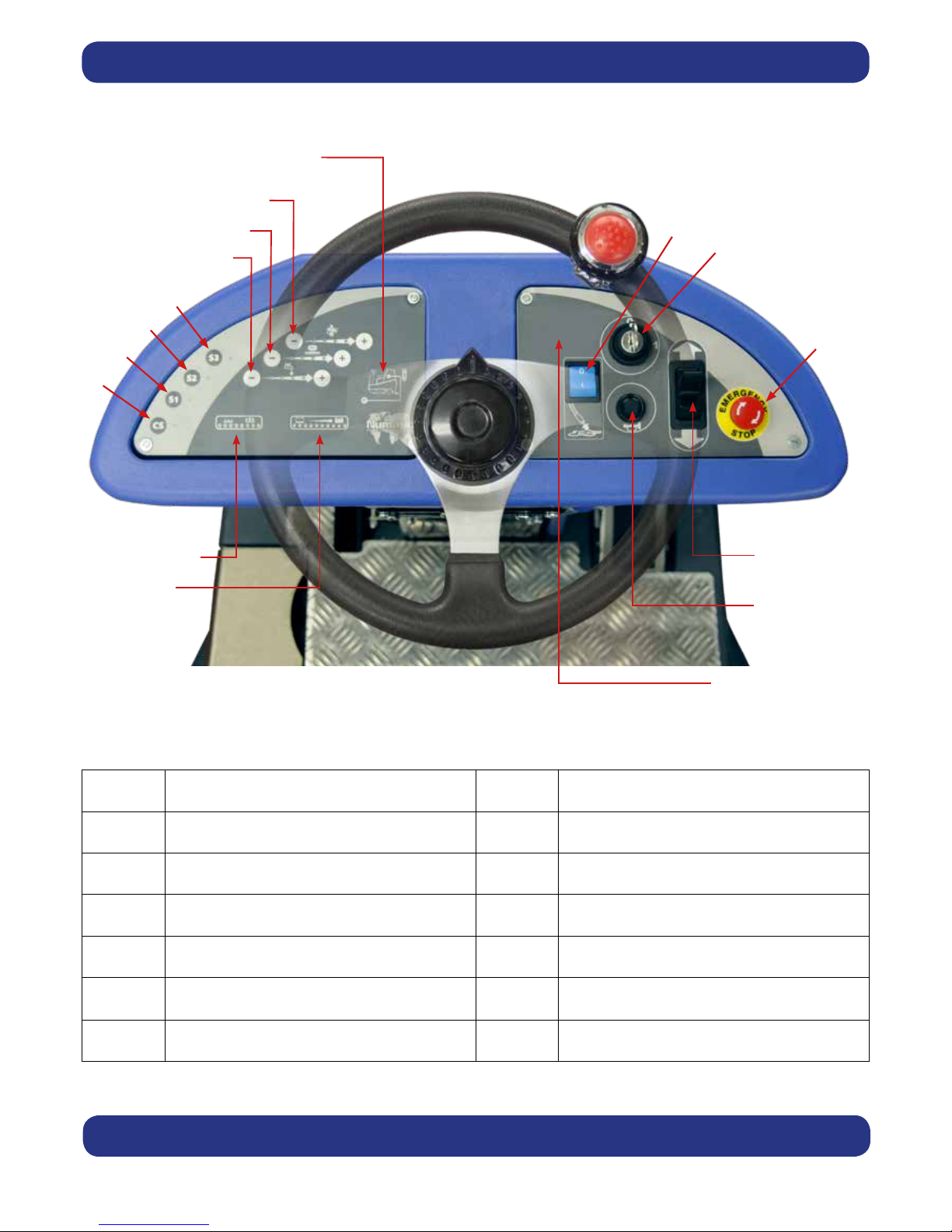

Control Panel Overview

For full easy to follow instructions on control panel set up and use, see machine operation page 15-17.

1 Battery Charge Level Meter 10 Waste-water ‘Full’ Indicator

2 Brush Operation / Load Indicator 11 Off Aisle Vacuum Button

3 Clean Speed Button 12 Main control On / Off key

4 / 5 / 6 Operator Pre-set Buttons 13 Emergency Stop

7 Water Flow Indicator 14 Forward / Reverse Switch

8 Brush Speed Indicator 15 Horn Button

9 Chemical Mix Indicator 16 Charging status light

9

10

1

2

3

4

5

6

7

8

11

12

13

14

15

16

5

About the Machine

WEEE (Waste, Electrical and Electronic Equipment)

Scrubber dryer Accessories and packaging should be sorted for environmentally-friendly recycling.

Only for EU countries.

Do not dispose of scrubber-dryer into household waste.

According to the European Directive 2002/96/EC on waste electrical electronic equipment and its

incorporation into national law.

Scrubber-dryers that are no longer suitable for use must be separated, collected and sent for

recovery in an environmentally-friendly manner.

Safety Critical Component

Charging Lead: H05VV-F x 1.0 mm

2

x 3 core

Motor Wheel & modied brake lead assembly (321450)

PG Controller (208169)

Battery Charger: 98A/H Stud Terminal Gel Type Battery

1

2

3

4

5 6

7

8

9

In the event of a breakdown contact your Numatic dealer or the

Numatic Technical help line +44 (0)1460 269268

10

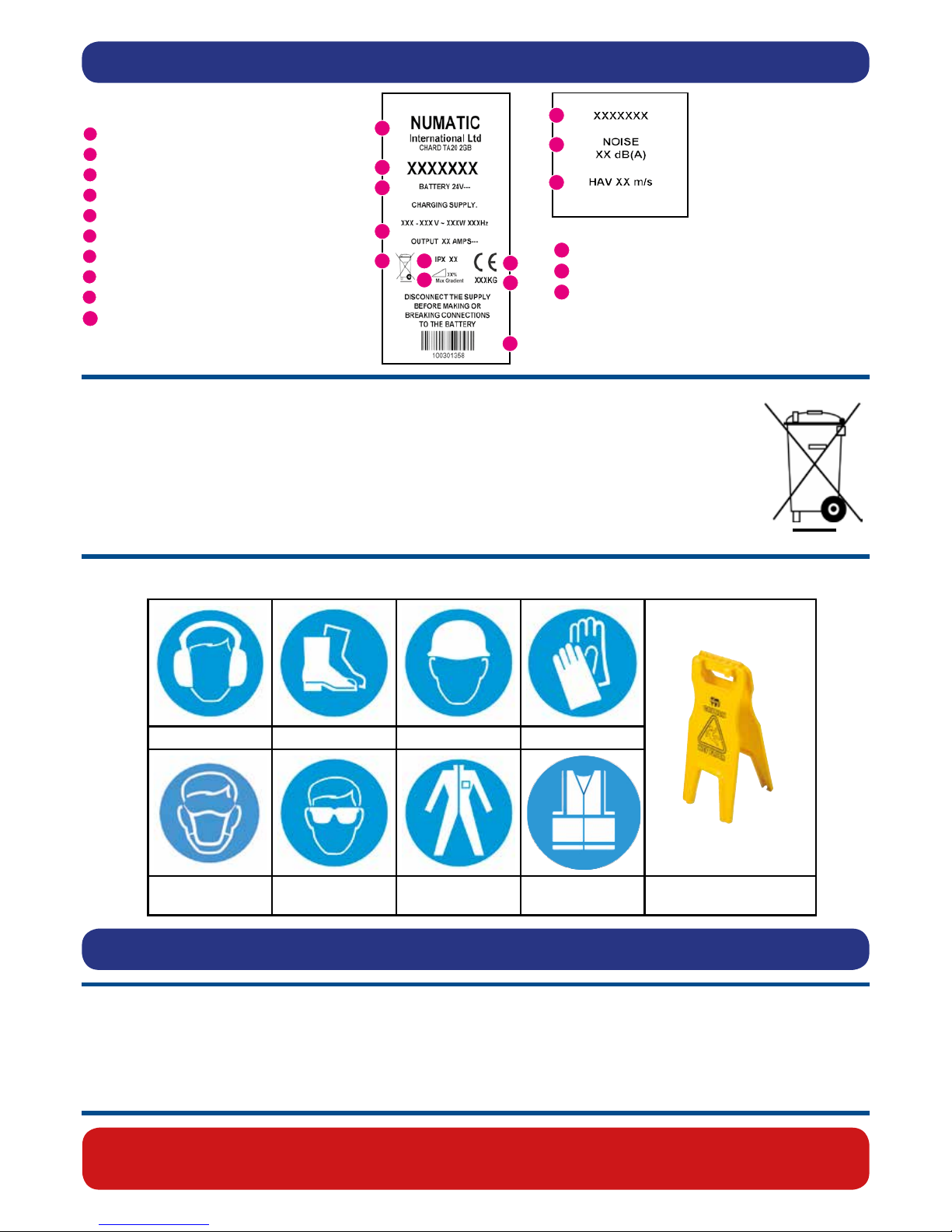

Rating Label

1

2

3

4

5

6

7

8

9

Company Name & Address

Machine Description

Voltage Frequency

Power Rating

WEEE Logo

Ingress Protection Rating

Max Gradient

CE Mark

Weight (ready to use)

Machine year/week Serial number

10

12

11

13

11

12

13

Machine Description

Noise Rating

Hand Arm Vibration

Ear Protection Safety Footwear Head Protection Safety Gloves

Dust/Allergens

Protection

Eye Protection Protective

Clothing

Hi-Vis Jacket

Caution

Wet Floor Sign

Note:

A risk assessment should be conducted to determine which PPE should be worn.

PPE (Personal protective equipment) that may be required for certain operations.

6

As with all electrical equipment care and attention must be exercised at all times during its use, in addition

to ensuring that routine and preventative maintenance is carried out periodically in order to ensure its safe

operation.

Failure to carry out maintenance as necessary, including the replacement of parts to the correct standard

could render this equipment unsafe and the manufacturer can accept no responsibility or liability in this respect. When

ordering spare parts always quote the Model Number / Serial Number specied on the Rating Plate.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

When detergents or other liquids are used, read the manufacturer’s instructions.

This machine is not suitable for picking-up hazardous dust.

Do not use on surfaces having a gradient exceeding that marked on the appliance.

The machine is not to be stored outdoors in wet conditions.

This machine is for indoor use only.

Read the instruction manual before using the appliance.

This product meets the requirements of IEC 60335-2-72, Sub Clause 20.1.

NOTES

This machine is also suitable for commercial use, for example in hotels, schools, hospitals, factories, shops and

ofces for other than normal housekeeping purposes.

• Ensure only competent persons unpack/assemble the machine.

• Keep your machine clean.

• Keep your brushes in good condition.

• Replace any worn or damaged parts immediately.

• Regularly examine the charger lead for damage, such as cracking or ageing.

If damage is found, replace the lead before further use.

• Only replace the charger lead with the correct Numatic approved replacement parts.

• Ensure that the work area is clear of obstructions and / or people.

• Ensure that the working area is well illuminated.

• Pre-sweep the area to be cleaned.

• Use steam cleaners or pressure washers to clean the machine or use in the rain.

• Attempt machine maintenance or cleaning unless the power plug has been removed from the supply outlet,

if the machine is in charge mode or remove the key if in normal use.

• Allow any inexperienced repairs. Call the experts.

• Strain charger lead or try to unplug by pulling on charger lead.

• Leave the brush pad on the machine when not in use.

• Allow the machine to be used by inexperienced or unauthorised operators or without appropriate training.

• Expect the machine to provide trouble-free, reliable operation unless maintained correctly.

• Run the machine over power cable during operation.

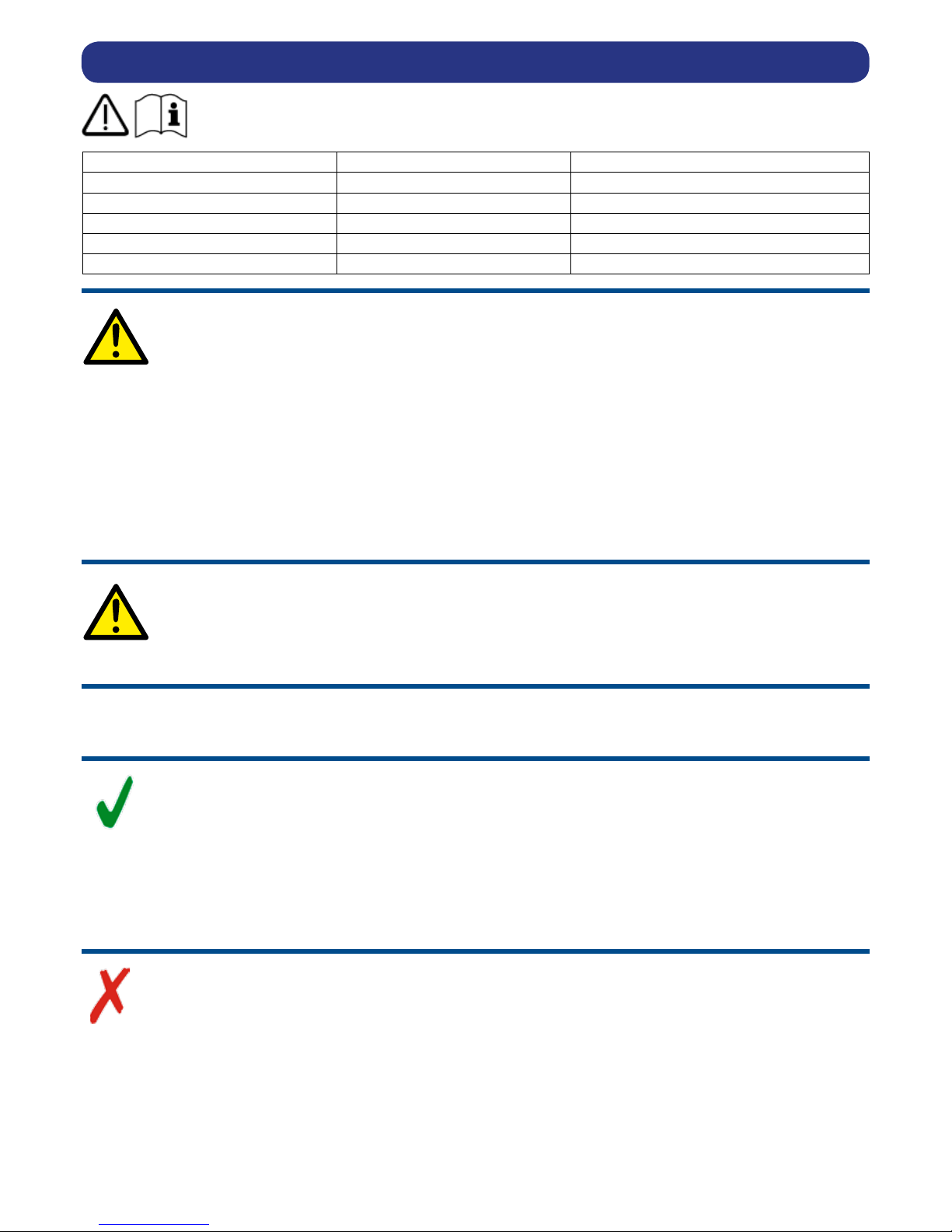

ORIGINAL INSTRUCTIONS

READ MANUAL BEFORE USE

Information for Scrubber Dryer

WARNING

CAUTION

DO

DON’T

Component Interval Inspect for

Charging Lead DAILY Scufng, cracks, splits, conductors showing

Brushes DAILY Bristle damage, wear, drive collar wear

Squeegee Blade BEFORE EACH USE Wear, cracks, splits

Filters BEFORE EACH USE Clogging and debris retention

Tanks AFTER EACH USE Rinse dirty water tank after use

7

Only use brushes provided with the appliance or those specied in the instruction manual.

The use of other brushes may impair safety.

A full range of brushes and accessories are available for this product.

Only use brushes or pads which are suitable for the correct operation of the machine for the specic task

being performed.

It is essential that this equipment is correctly assembled and operated in accordance with current safety regulations.

When using the equipment always ensure that all necessary precautions are taken to guarantee the safety of the operator

and any other persons who may be affected.

Wear non-slip footwear when Scrubbing.

Use a respiratory mask in dusty environments.

The machine, while charging, must be positioned so that the mains plug is easily accessible.

Remove the key from the ignition when cleaning and carrying out routine maintenance.

When replacing major components the ignition key and battery fuses MUST be removed.

In order to prevent unauthorized use of the machine, the power source shall be switched off or locked, for example by

removing the ignition key.

When detergents or other liquids are used, read the manufacturer’s instructions.

Operators shall be adequately instructed as to the correct use of the machine.

If this product does not have a factory installed Numatic battery charger, then it is the responsibility of the owner and user

of the product to ensure that the charging system and battery combination are compatible, t for purpose and safe to use.

WARNING

1. Always wear protective clothing e.g. face visor, gloves and overalls when working with batteries.

2. Whenever possible always use a properly designated and well-ventilated area for charging.

Do not smoke or bring naked ames into the charging area.

3. Remove any metallic items from hands, wrists and neck i.e. rings, chains etc. before working on a battery.

4. Never rest tools or metallic objects on top of the battery.

5. When charging is complete disconnect from the mains supply.

6. The machine must be disconnected from the supply when removing the battery.

7. To remove the batteries:- Disconnect machine from the mains supply (if charging), raise waste water tank and ensure

batteries are isolated by removing fuses. Disconnect hoses from separator and tanks, undo battery terminals and

remove batteries.

8. Only use genuine Numatic replacement batteries.

9. Do not allow the batteries to become fully discharged, it may not be possible to recharge them.

10. Do not allow one battery to be discharged separately to the other.

11. Do not mix batteries from different machines.

12. The batteries tted to this product are Valve Regulated Lead Acid (VRLA) gel electrolyte type.

The tting of any other type of battery may cause a safety hazard.

13. The batteries must be removed from the machine before it is scrapped.

14. Dispose of the batteries safely in accordance with local government regulations.

Precautions when working with batteries

1. Always recharge the batteries after use. This can be done at any time – it is not necessary to wait until they are fully

discharged; they do not develop a “memory”.

2. Leaving the charger to operate for a minimum of 4 hours after the green light has come on, at least weekly,

will prolong battery life.

3. Do not store the machine with the batteries discharged.

Battery care

Daily

Keep the machine clean.

Ensure brushes/ pads/ squeegee/ lters are in good condition.

Check for any worn or damaged parts and replace immediately.

Drain and rinse dirty water tank after every use.

Store machine with brush deck secured in tilted position.

Weekly – as daily and –

Check brush or pad and skirt and rinse.

Check oor tool blades for wear and wipe clean.

Clean separator assembly including lter and check condition of seal.

Flush out system with clean water and clean lters.

Do not steam clean or pressure wash.

Batteries

Always recharge the batteries after use.

Charge for a minimum of 4 hours after the green light has come on, this will prolong battery life.

TwinTec

Maintenance

8

Contents:

1 x Operator Manual

2 x Battery charging lead

2 x Keys

4 x 40 amp fuses (1 x spare)

2 x Side pod skirts

1 x Brake disengage key

1 x Maxi fuse-puller

Quick Set-Up Guide

PLEASE READ BEFORE COMMENCING ANY OPERATION.

AFTER THE REMOVAL OF ALL THE PACKAGING,

CAREFULLY OPEN AND CHECK THE CONTENTS OF THE START UP PACK FIG.1.

!!

Note: Ensure that no metal objects come into contact with battery terminals while the batteries are exposed.

When inserting the rst fuse you may notice a spark, this is normal.

Lift top tank assembly to reveal battery compartment.

Always lift between points as illustrated to ensure personal safety.

Fit battery fuses (contained in start-up pack) into the battery fuse holders as illustrated (Fig.1).

Remove transit block from pallet (Fig.2).

Insert key into main control (on / off) and turn quarter-turn clockwise to position (1) ‘On’ (Fig.3).

Ensure that the forward / reverse switch is set to forward (Fig.4).

Depress accelerator pedal with right foot and slowly drive machine off of the pallet using the ramp

provided (Fig.5).

Note: The seat is tted with a pressure sensor that disables the machine until

an operator is seated.

When the machine is removed and in a safe position, turn key back to the position (0) ‘OFF’ (Fig.6).

1

1a56

2

3

4

9

Machine Set-up

ALWAYS ENSURE THAT THE MACHINE IS SWITCHED OFF

BEFORE MAKING ANY ADJUSTMENTS

! !

Fitting the Floor-tool

To t the side pod skirts, rst remove the steel retaining strip already tted to the pod (Fig.7).

Align the steel retaining strip within the locating grooves of the rubber skirt and ret using existing screws (Fig.8)

Periodically the side skirts should be examined and checked for wear and damage. Replace as shown above.

Lower the oor-tool arm by moving the release lever to the upper position (Fig.9).

Push oor-tool onto the holder and secure with the easy-t securing pin (Fig.10).

Push waste collection pipe onto the oor-tool; ensure a tight t (Fig.11).

Note: Raise oor-tool again before driving to the cleaning area (Fig.12).

!

7

8

9

10

11

12

10

Machine Set-up

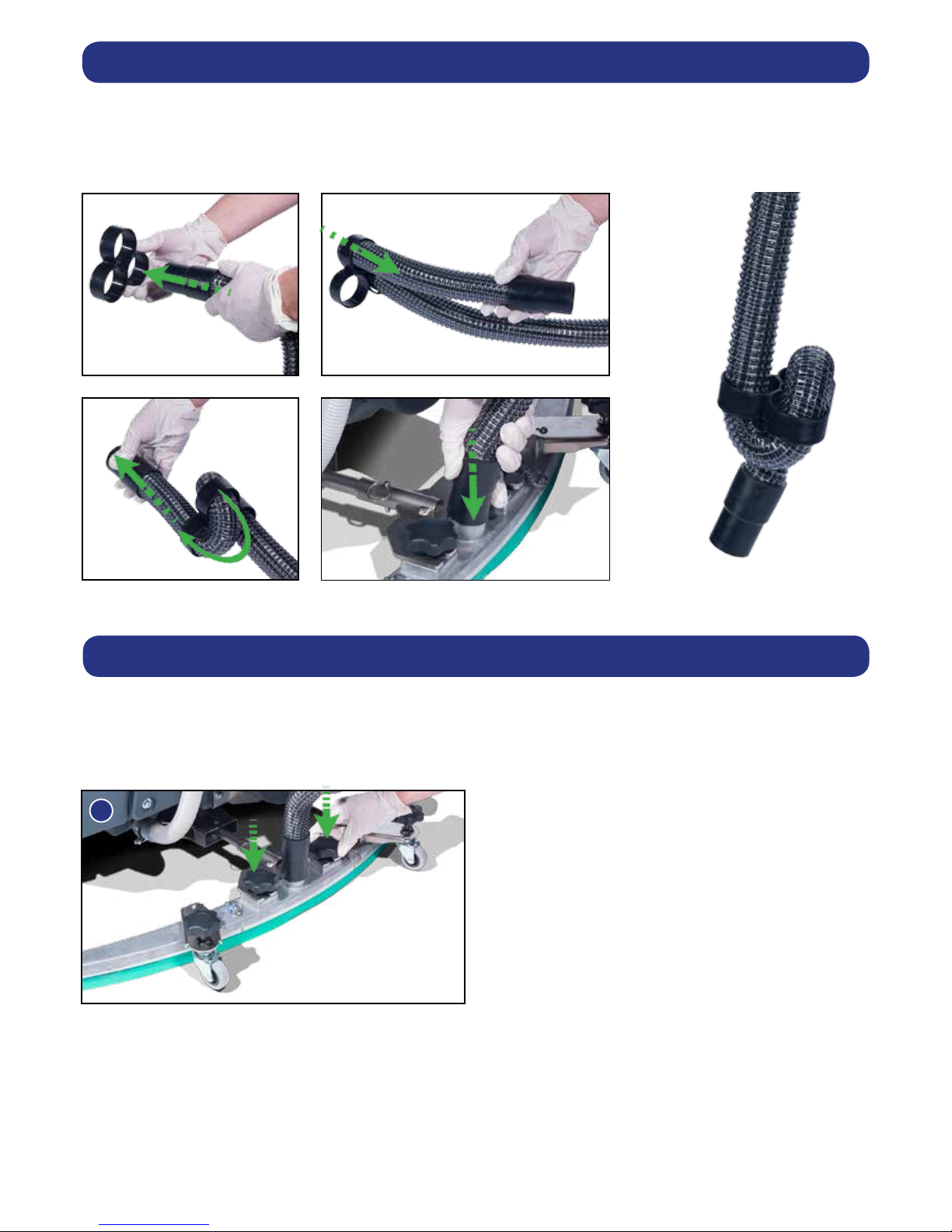

Breakaway Floor-tool

Ret vacuum hose to the Floor-tool when nished.

The vacuum hose has a U-bend clip which creates a U-bend in the hose preventing water spillage when the vacuum

is switched off. If you need to remove the U-bend clip for any reason always ensure it is retted correctly before you

resume operation.

Fitting the Hose Guide

Note:

DO NOT push the vacuum hose onto the Floor-tool with the Floor-tool in the raised position.

The oor-tool design incorporates a safety

knock-off feature.

Allowing it to safely disengage from its mounting

should it become caught on an obstruction, during

forward machine movement.

To re-attach the oor-tool blade to its holder.

First loosen the retaining knobs on the oor-tool body

and slide onto the holding bracket.

Tighten retaining knobs to nger tight. (See Fig.13).

13

Loading...

Loading...