Numatic TTB 2120/100T, TTB 2120/120T Owner's Manual

www.nacecare.com

Owner Instructions

Mode d’emploi

Original Instructions

Warning! Read instructions before using the machine.

Attention

Lisez la notice avant d’utiliser la machine.

TTB 2120/100T

TTB 2120/120T

Ride - On Scrubber Dryer

Autolaveuse à siège

2

Index Page 2 Index Page 2

Machine Overview Page 3 Description de la machine Page 27

Control Panel Overview Page 4 Description du panneau de commande Page 28

Rating label / Personal

Protective Equipment /

Recycling

Page 5

Plaque signalétique / Équipement de protection

individuelle /

Recyclage

Page 29

Safety Precautions Page 6 Précautions à prendre Page 30

Quick set-up guide Page 7 Guide d’installation rapide Page 31

Machine Set-up Préparation de la machine

Raise / Lower the Floor-tool Page 8 Relèvement / abaissement du suceur Page 32

Fitting the Floor-tool Page 8 Montage du suceur Page 32

Breakaway Floor-tool

feature

Page 8 Fonction de détachement du suceur Page 32

Raise / Lower the Brush

Deck

Page 9

Relèvement /abaissement

du plateau de brosses

Page 33

Fitting the Brush Page 9 Montage de la brosse Page 33

Floor-tool transit bracket Page 9 Support de transit du suceur Page 33

Filling the clean-water tank Page 10 Remplissage du réservoir d’eau propre Page 34

Fill Level Indicator Page 10 Indicateur du niveau de remplissage Page 34

Machine Operation Fonctionnement de la machine

Pre-cleaning advice Page 11 Conseils de pré-nettoyage Page 35

Setting the cleaning

controls

Page 11 Réglage des commandes de nettoyage Page 35

Waste water tank full Page 11 Réservoir d’eau sale plein Page 35

Brush pressure Page 12 Pression de la brosse Page 36

Emergency stop button and

horn

Page 12 Bouton d’arrêt d’urgence et klaxon Page 36

Anti-tip System Page 12 Système antibasculement Page 36

Machine usage advice Page 13 Conseils d’utilisation de la machine Page 37

Maximum Speed Control Page 13 Commande de la vitesse maximale Page 37

Hose U-Bend Clip Page 14 Collier de repli du tuyau Page 38

Off-aisle cleaning kit (op-

tional)

Page 14 Kit de nettoyage hors-allée (en option) Page 38

Machine Cleaning Nettoyage de la machine

Tanks and Filters Page 15 Réservoirs et ltres Page 39

Floor-tool cleaning and

blade replacement

Page 17 Nettoyage du suceur et remplacement des lamelles Page 41

Machine Charging Page 19 Charge de la machine Page 43

Free-wheel function Page 20 Fonction roues libres Page 44

Battery care Page 20 Entretien de la batterie Page 44

Trouble-shooting Page 22 Dépannage Page 46

Schematic Page 24 Schémas Page 48

Specications Page 25 Specications Page 49

3

Machine Overview

1

Operator control panel

10

On-board charger and charge indicator

2

Brush deck foot pedal

11

Accelerator pedal

3

Anti-tip buffers

12

Pedestrian warning light

4

Floor-tool raise / lower lever

13

Floor-tool transit bracket

5

Clean water tank ll point

14

Air separator assembly

6

Brush deck

15

Waste water emptying hose

7

40 Amp battery fuse

16

Vacuum hose

8

Gel batteries

17

Clean water tank emptying hose

9

Clean water tank lter

18

Floor-tool

10

9

8

7

6

5

4

3

2

1

11

12

13

14

15

16

17

18

4

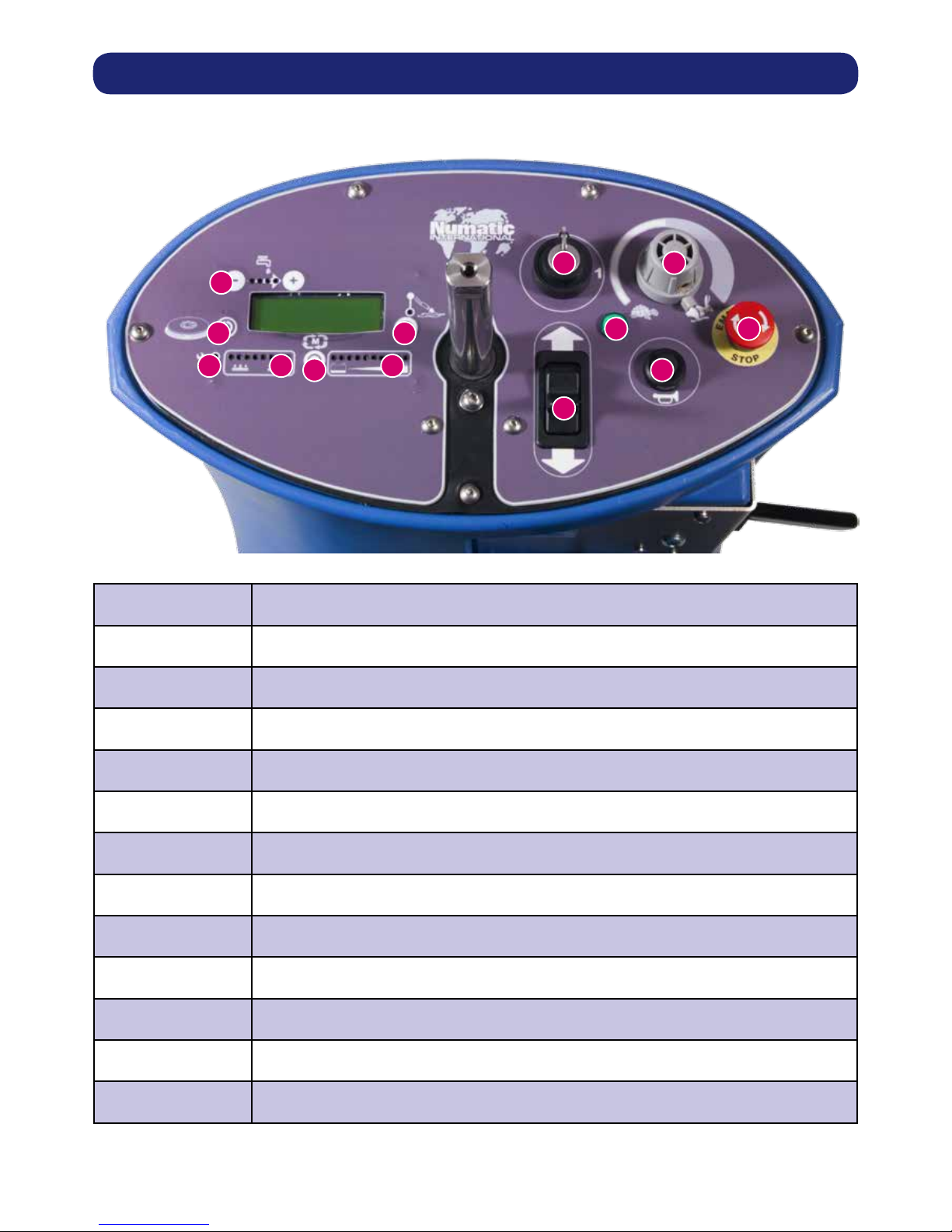

Control Panel Overview

10

9

8

654

3

2

1

1

Water Flow Rate Indicator and Selection Button

2

Brush Engage and Disengage Button

3

Service Indicator

4

Brush Pressure / Load Indicator

5

Run Time Selection Button

6

Battery Charge Level Indicator

7

Off Aisle Vacuum Button

8

On / Off Switch

9

Forward / Reverse Switch

10

LED Status Indicator

11

Maximum Speed Control

12

Horn Button

13

Emergency Stop Button

7

11

12

13

5

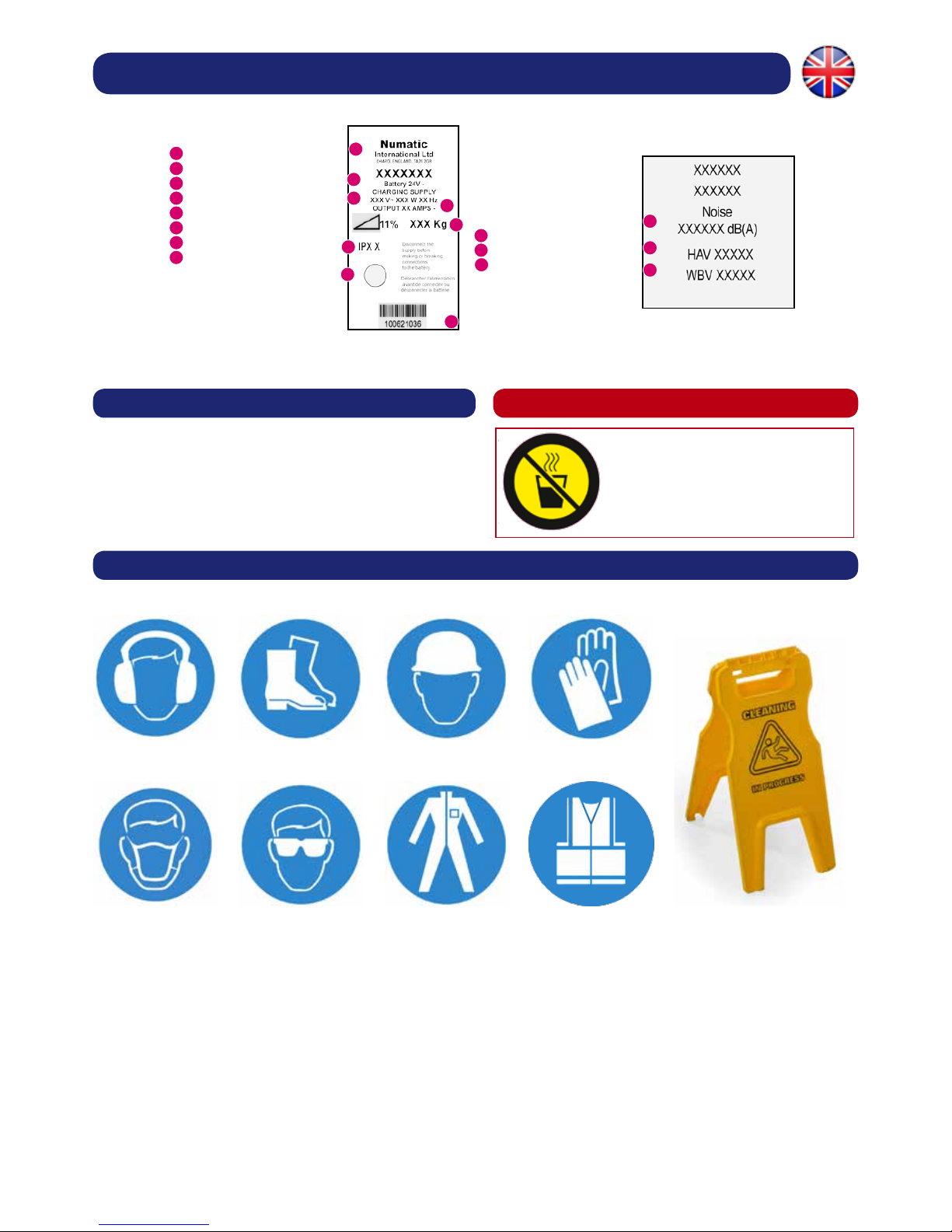

Rating Label / Personal Protective Equipment / Recycling

Safety Critical Components

PPE (Personal Protective Equipment) that maybe required for certain operations

Charging Leads: Ho5VV-F x 1.0 mm2 x 3 Core

Transaxle 205190

Battery Charger (230V)

(115V)

Ear Protection Safety HatSafety Footwear Safety Gloves

Face Mask Eye Protection Protective Clothing Hi Viz Jacket Caution Floorsign

NOTE: A risk assessment should be conducted to determine which PPE should be worn.

Caution

No HOT drinks

when operating this

machine.

1

2

3

4

5

6

7

8

Rating Label

Company Name & Address

Machine Description

Voltage Frequency

Power rating

Weight (ready to use)

Ingress Protection

Approval Mark

Machine yr/wk Serial number

1

2

3

4

5

6

7

8

9

9

Noise level

Hand arm vibration

Whole body vibration

10

11

11

10

6

Safety Precautions

Caution

Read the instruction manual before using the appliance.

The TTB is a class 1 product when tted with an AC supply lead, but a class 3 product during normal use.

Note

This product meets the requirements of CAN/CSA-C22.2 No. 60335-1-11. IEC 60335-2-72:2002

This machine is also suitable for commercial use, for example in hotels, schools, hospitals, factories, shops and ofces for other than normal

housekeeping purposes.

Never attempt to ll the machine’ s water tanks whilst it is charging.

Machines left unattended shall be secured against unintentional movement.

Care should be taken in the choice of chemicals, detergents and other liquids. Consult your supplier.

Do’s and Don’ts

DO ensure only competent persons unpack/assemble the machine.

DO keep your machine clean.

DO keep your brushes in good condition.

DO replace any worn or damaged parts immediately.

DO regularly examine the charger lead for damage, such as cracking or ageing. If damage is found, replace the lead before further use.

DO only replace the charger lead with the correct Numatic approved replacement part.

DO ensure that the work area is clear of obstructions and / or people.

DO ensure that the working area is well illuminated.

DO pre-sweep the area to be cleaned.

DON’T use steam cleaners or pressure washers to clean the machine or use in the rain.

DON’T Don’t attempt machine maintenance or cleaning unless the power plug has been removed from the supply outlet,

if the machine is in charge mode or remove the key if in normal use.

DON’T allow any inexperienced repairs. Contact your nearest service centre.

DON’T strain charger lead or try to unplug by pulling on charger lead.

DON’T leave the brush deck in the lowered position when not in use.

DON’T expect the machine to provide trouble-free, reliable operation unless maintained correctly.

DON’T run the machine over any power cables during operation.

Warning

This machine is not suitable for picking-up hazardous dust.

Do not use on surfaces having a gradient exceeding that marked on the appliance.

As with all electrical equipment care and attention must be exercised at all times during its use, in addition to ensuring that routine and

preventative maintenance is carried out periodically in order to ensure its safe operation. Failure to carry out maintenance as necessary, including

the replacement of parts to the correct standard could render this equipment unsafe and the manufacturer can accept no responsibility or liability in

this respect.

When ordering spare parts always quote the Model Number / Serial Number specied on the Rating Plate.

This machine is for indoor use.

The machine is not to be used or stored outdoors or in wet conditions.

Don’t allow the machine to be used by inexperienced or unauthorised operators or without appropriate training.

Only use brushes provided with the appliance or those specied in the instruction manual. The use of other brushes may impair safety. A full range

of brushes and accessories are available for this product. Only use brushes or pads which are suitable for the correct operation of the machine for

the specic task being performed.

It is essential that this equipment is correctly assembled and operated in accordance with current safety regulations. When using the equipment

always ensure that all necessary precautions are taken to guarantee the safety of the operator and any other persons who may be affected. Wear

non-slip footwear when Scrubbing. Use a respiratory mask in dusty environments.

The machine, while charging, must be positioned so that the mains plug is easily accessible.

Remove the key from the ignition when cleaning and carrying out routine maintenance. When replacing major components the ignition key and

battery fuses MUST be removed.

When detergents or other liquids are used, read the manufacturer’s instructions.

If this product does not have a factory installed Numatic battery charger and batteries then it is the responsibility of the owner and user of the

product to ensure that the charging system and battery combination are compatible, t for purpose and safe to use.

Precautions when working with batteries

1. Always wear protective clothing e.g. face visor, gloves and overalls when working with batteries.

2. Whenever possible always use a properly designated and well-ventilated area for charging. Do not smoke or bring naked ames into the

charging area.

3. Remove any metallic items from hands, wrists and neck i.e. rings, chains etc. before working on a battery.

4. Never rest tools or metallic objects on top of the battery.

5. When charging is complete disconnect from the mains supply.

6. The machine must be disconnected from the supply when removing the battery.

7. To remove the batteries:- Disconnect machine from the mains supply (if charging), raise waste water tank and ensure batteries are isolated by

removing fuses. Disconnect hoses from separator and tanks, Undo battery terminals and remove batteries.

8. Only use genuine Numatic replacement batteries.

9. Do not allow the batteries to become fully discharged, it may not be possible to recharge them.

10. Do not allow one battery to be discharged separately to the other.

11. Do not mix batteries from different machines.

12. The batteries tted to this product are Valve Regulated Lead Acid (VRLA) gel electrolyte type. The tting of any other type of battery may cause

a safety hazard.

13. The batteries must be removed from the machine before it is scrapped.

14. Dispose of the batteries safely in accordance with local government regulations.

BATTERY CARE

1. Always recharge the batteries after use. This can be done at any time – it is not necessary to wait until they are fully discharged; they do not

develop a “memory”.

2. Leaving the charger to operate for a minimum of 4 hours after the green light has come on, at least weekly, will pro-long battery life.

3. Do not store the machine with the batteries discharged.

7

Quick Set Up Guide

After the removal of all the packaging, carefully

open and check the contents of the start up pack (Fig.1).

!

!

Lift top tank assembly to reveal battery compartment.

Always lift between points as illustrated to ensure personal safety (Fig.1).

Fit battery fuse into the battery fuse holder as illustrated (Fig.2).

Remove transit block from pallet (Fig.3).

Ensure no metal objects come into contact with battery terminals while the batteries

are exposed. When inserting the fuse you may notice a spark, this is normal.

!

!

Insert key into ignition and turn quarter-turn clockwise to the ‘ON’ (1) position, make sure that the

forward / reverse switch is set to forward and the speed control is set to low (Fig.4).

DO NOT depress accelerator pedal while software initialises.

Depress accelerator pedal with right foot and slowly drive machine off of the pallet using the ramp

provided (Fig.5).

Make sure the ramp is central to the machine and drive off straight.

Note: The seat is tted with a pressure sensor that disables the machine until an operator

is seated.

When the machine is removed and in a safe position, turn key back to the off (0) position (Fig.6).

Contents:

1 x Operator Manual

2 x Battery Charger Lead

2 x Keys

1 x 40 Amp Fuse (1 x Spare)

1 x Maxi Fuse-puller

1

2

3

456

8

Machine Set Up

Lower the oor-tool arm by moving the oor-tool lever to the upper position (See above).

Loosen the retaining knobs on the oor-tool and slide onto the holding bracket (Fig.10).

Tighten the retaining knobs to nger tight. (Fig.11).

Push waste collection pipe onto the oor-tool; ensure a tight t (Fig.12).

Note: Raise oor-tool again before driving to the cleaning area (See Above).

Always ensure that the machine is switched off before making any adjustments

!

!

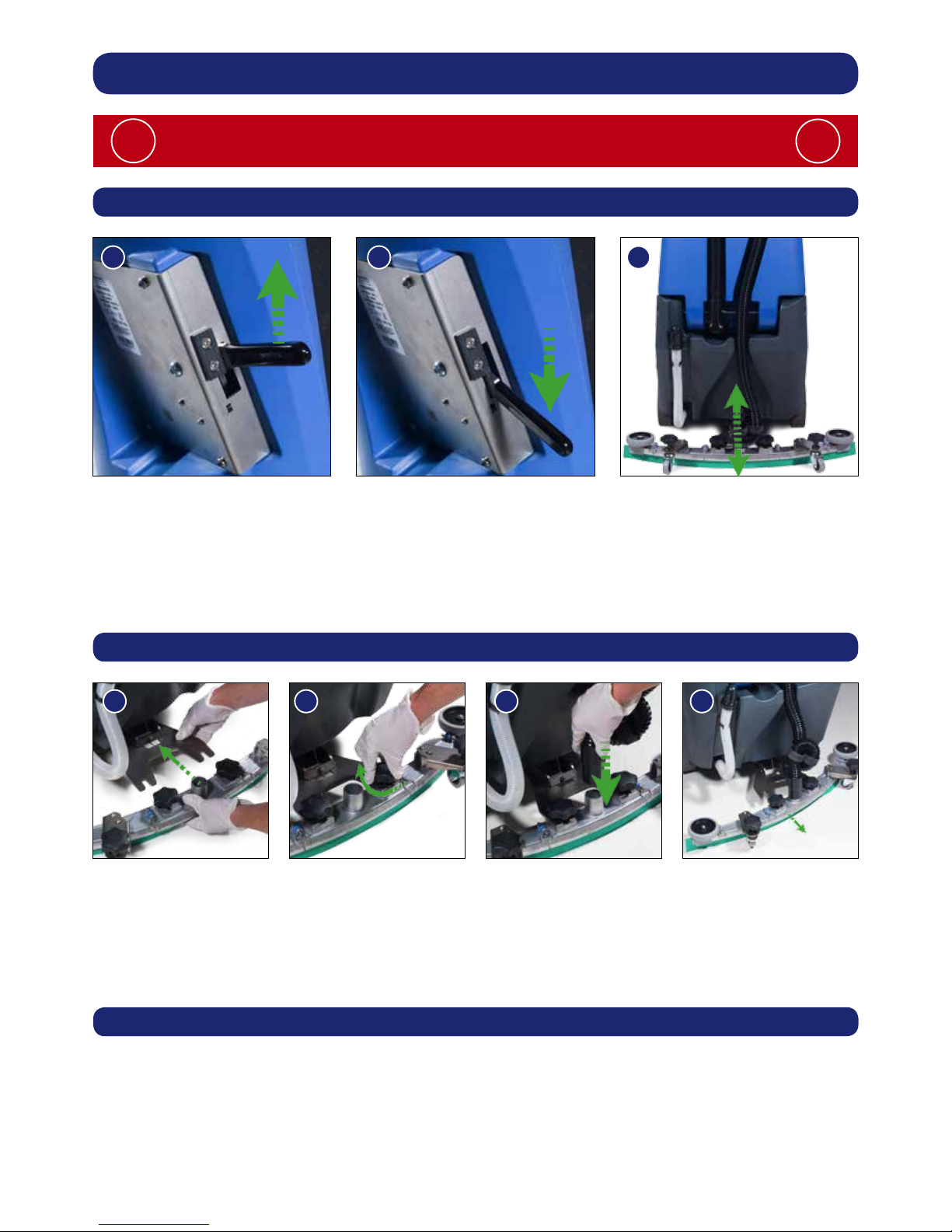

Raise / Lower the Floor-tool

To lower the oor-tool move the oor-tool lever into the upper position (Fig.7).

To raise the oor-tool move the oor-tool lever into the lower position (Fig.8).

Note: The machine will not operate in reverse with the Floor-tool lowered.

Note: The oor-tool lever guide is designed to be reversible and replaceable.

Fitting the Floor-tool

The oor-tool design incorporates a safety knock-off feature.

Allowing it to safely disengage from its mounting should it become caught on an obstruction during

forward movement (Fig.13).

Make sure you do not over tighten the retaining knobs to ensure correct operation.

Breakaway Floor-tool

798

101112

13

9

Machine Set Up

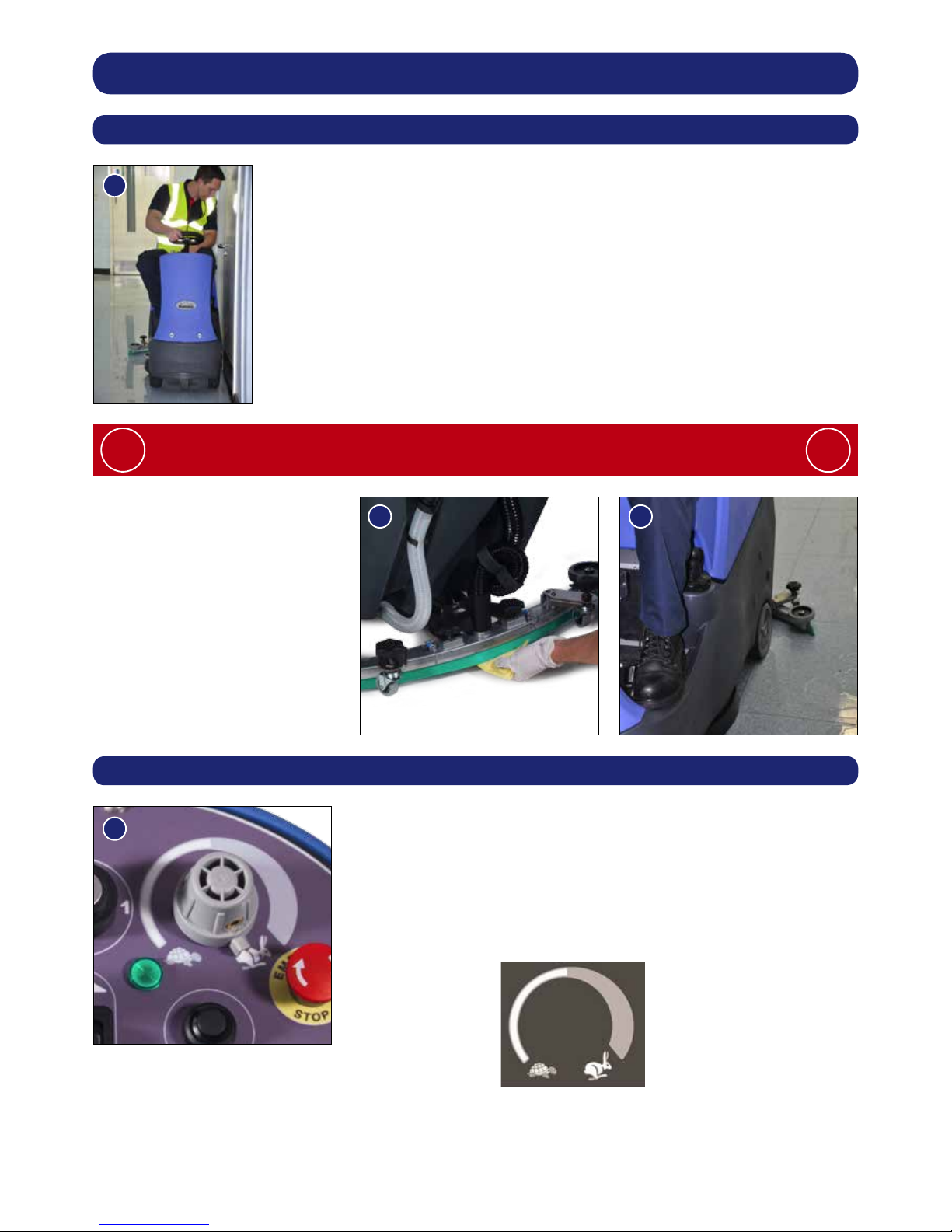

Raise / Lower the Brush Deck

To lower the brush deck slide the brush deck foot pedal forward with your foot (Fig.14) and gently

release the foot pedal (Fig.15). The brush deck is now in the lowered position.

To raise the brush deck slowly depress the foot pedal, ensuring it is in the forward position (Fig.16)

and slide your foot back to lock the pedal in place (Fig.17).

The brush deck is now in the raised position.

Fitting the Brush

Make sure the brush deck is in the raised position (see above) and place the brush under the

brush deck (Fig.18) ensuring it is central to the chuck (Fig.19), then lower the brush deck

(see above).

Turn on the machine by inserting the key and turning a quarter-turn clockwise.

Press the brush engage button and the machine will pick up the brush (Fig.21).

Turn off the machine by turning the key a quarter-turn anti clockwise.

To disengage the brush press the brush engage button with the brush deck in the raised position.

Note:

Do not lift the brush deck until the brush has stopped revolving or the brush will release.

Make sure you raise the brush deck before driving to the cleaning site.

Safety Gloves are recommended for the changing of used Brushes.

!

!

Always ensure that the machine is switched off before making any adjustments

!

!

Floor-tool Transit Bracket

When in transit, the Floor-tool can be placed on

the bracket at the rear of the machine.

Simply slot the retaining knob into the bracket.

141516

17

181920

21

10

Machine Set Up

Filling the Clean Water Tank

Always ensure that the machine is switched off before making any adjustments

!

!

The TTB 2120 is equipped with a large capacity (21 US Gall) clean water tank, allowing for large

areas to be covered in a single ll.

To ll the clean water tank extend the Flexill hose, remove the rubber seal and ll from a suitable

water outlet (Fig.22). Replace seal and hose to original position when nished.

Alternatively unscrew the ller cap completely (Fig.23) and ll the tank using a hose or preferred

method (Fig.24).

Note: Great care must be taken to ensure that contaminants (leaves, hair, dirt, etc.) are not

allowed to enter the Clean water tank during the lling process. If using a bucket or similar,

ensure it is always clean and free from debris.

Fill Level Indicator

When lling the clean water tank, do not ll above the clean water tank emptying hose retaining

clip (Fig.25). This can be found at the rear of the machine.

222324

25

Full

If you need to access the batteries, make sure that the waste water tank is

empty before lifting.

!

!

11

= No Flow

= 0.13 gpm

= 0.26 gpm

= 0.39 gpm

= 0.52 gpm

= 0.79 gpm

Machine Operation

Important

Do not operate machine unless the operator manual has been read and fully understood.

!

!

The machine is now ready to be driven to the cleaning site (see the quick set-up guide if

necessary).

Before performing the cleaning operation, place out appropriate warning signs and sweep or

dust-mop the oor.

When you have arrived at the cleaning site, lower the Floor-tool (see page 8) and the brush

deck (see page 9).

Setting the Cleaning Controls

Insert the key into the on / off switch and

quarter-turn it clockwise to the ‘ON’ (1) position

(Fig.26).

The battery charge-level indicator will illuminate

(Fig.27).

Set the water ow rate as required, depending

on oor type and level of soiling.

Waste Water Tank Full

The vac shut off system tted to your machine

stops the airow when the top tank is full!

It does not shut the power off to the vac motor,

the vac motor will continue to run, but there is an

audible difference in the sound when the shut off

system operates.

See Page 16 for more details on checking and

cleaning the shut off system.

Always ensure that the oor is pre-swept and

relevant safety signs are displayed.

!

!

26

27

12

Machine Operation

Brush Pressure

The machine is equipped with a brush-pressure load warning system

(Fig.28). As the load on the Brush increases the LEDs on the Load

Indicator will illuminate from left to right.

Note: The run-time of the machine may decrease if the load on the brushes is increased

The TTB 2120 is equipped with an electronic braking system.

Simply lift your foot from the accelerator and the machine will stop.

In an emergency, strike the emergency-stop button and the machine will

be disabled. To reset, turn emergency stop button clockwise (Fig.29).

After resetting the emergency stop button, to restart the machine,

turn the ignition key to the ‘Off’ then the ‘On’ position again.

The horn is located on the right-hand side of the operator control panel

(Fig.30).

Emergency Stop Button and Horn

Anti-tip System

The TTB 2120 is equipped with an Anti-tip system. If the operator

attempts to turn a corner when the machine is going at speed,

the machine will automatically slow down preventing the machine from

tipping over. Additionally the buffers at the front of the machine are

designed to prevent the machine tipping in the event of the operator

turning sharply (Fig.31).

Care must be taken to reduce speed when cornering or manoeuvring

!

!

28

29

30

31

The buffers are designed to be replaceable

when worn.

13

Machine Operation

Machine in Use

To operate, select forward, press the accelerator pedal.

Vacuum pick-up and water-ow will turn on if selected and the brush and

oor tool are in the lowered position, the machine will move forward.

Clean water is dispersed evenly via ‘THRU- FEED’ scrubbing brushes.

The waste water is then retrieved by the suction oor-tool (Fig.32).

Overlap each scrubbing path by 1/2” to ensure an even clean.

After stopping the Vac motor will run for a further 10 seconds to collect any

water left in the vacuum hose.

Do not operate the machine on inclines that exceed 11%.

!

!

If streaking occurs wipe

oor-tool blades clean (Fig.33).

On heavily soiled oors use a

‘double scrub’ technique.

First pre-scrub the oor with the

oor-tool in the raised position,

allow the chemicals time to

work then scrub the area a

second time with the oor-tool

lowered (Fig.34).

Maximum Speed Control

Use the maximum speed control knob and set desired traction

speed as required, depending on oor type and level of soiling

(Fig.35).

Keep speed setting within the white gradient on the dial for

optimum oor cleaning.

The grey gradient on the dial is for setting the transit speed.

32

34

33

35

Cleaning Transit

Once the Max speed has been set using the control knob on the

control panel, ne adjustments can be made using the variable

control speed pedal located on the right side of the footplate.

14

Machine Operation

Hose U-bend Clip

Ret vacuum hose to the Floor-tool when nished.

Off-Aisle Cleaning Kit (Optional Extra Accessory ) 606182

Return the hose to the oor-tool once nished using the off-aisle facility.

The vacuum hose has a U-bend clip which creates a U-bend in the hose preventing water spillage

when the vacuum is switched off. If you need to remove the U-bend clip for any reason always

ensure it is retted correctly before you resume operation (Fig 36-39).

363738

39

40

41

The optional off-aisle cleaning kit gives added exibility to the operator.

The kit can be used to clean hard to reach / inaccessible areas (Fig 40).

Remove the Vacuum hose from the Floor-tool and attach to the Off-aisle kit.

To operate the vacuum, press the Off-aisle vacuum button on the

control panel.

Pressing the Off-aisle Button again will switch the vacuum off (Fig 41).

30mm

MAX

Note:

DO NOT push the vacuum hose onto the Floor-tool with the

Floor-tool in the raised position.

15

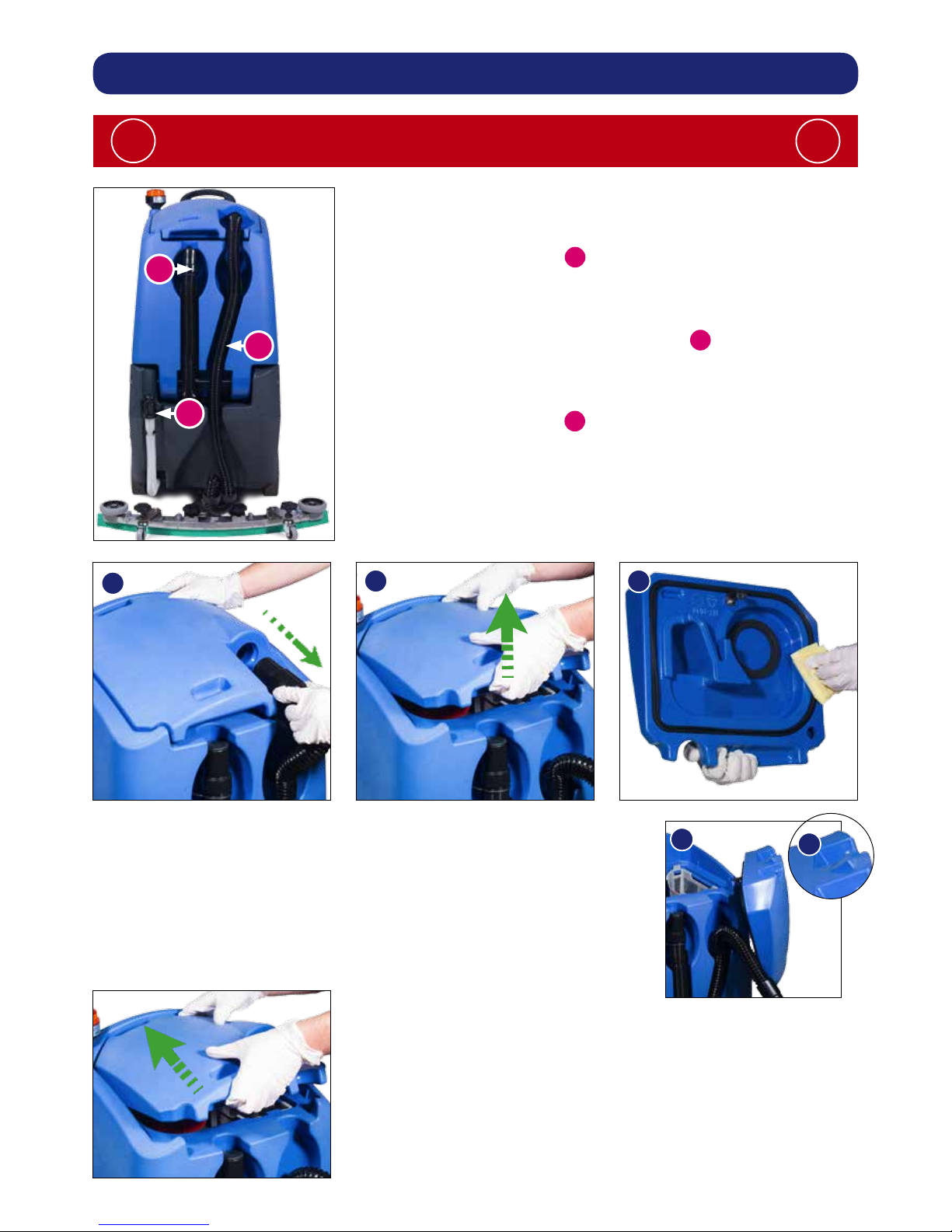

Machine Cleaning

Always ensure that the machine is switched off prior to any maintenance.

!

!

After use, empty waste-water tank using emptying hose and

ush-out with clean water.

Next remove oor-tool vacuum hose ensuring you remove the

U-bend clip and ush out with clean water.

Next empty clean water tank, using emptying hose and again

ush out with clean water.

Before removing the separator, rst pull off the connected hose (Fig.42).

Remove the separator and rinse using clean water (Fig.43).

The separator also has a sealing-rubber which should be examined at

every clean-down (Fig.44).

Note: The separator can be hung from either side of the top tank

while you maintain the machine using the clip on the front of the lid.

(Fig.45).

A

B

C

A

B

C

42

43

44

45

When retting the separator make sure you engage the tab (A) at

the front of the separator BEFORE pushing the separator down.

Ret the vacuum hose.

A

16

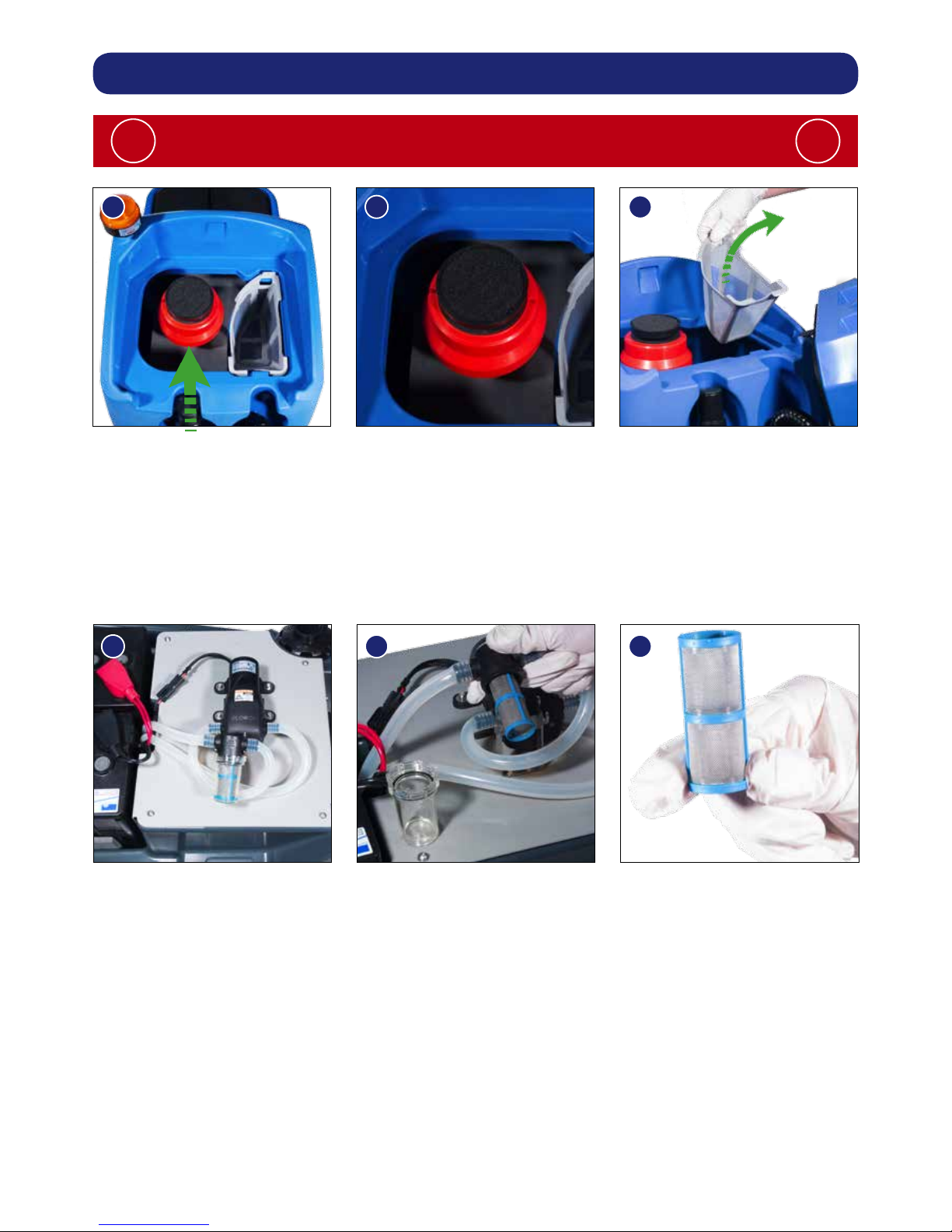

Located in your waste water (top) tank is a vacuum shut off system, this prevents suction when the

waste water tank is full. It also prevents foam created by high-foaming detergents from entering

the motor. Sometimes the oat vents get clogged and blocked, clean to ensure correct operation

(Fig.46-47) reguarlly check and clean the air lter in the top of the assembly.

Remove debris basket lter and rinse using clean water, and ret (Fig 48).

IMPORTANT: If the debris basket is allowed to become clogged, vacuum performance can

deteriorate.

The clean-water tank lter is located to the front of the battery compartment, and should be

checked at regular intervals (Fig.49).

Lift the lter off of the cradle, unscrew the bottom and remove (Fig.50). taking care not to spill any

liquid on to the batteries. Rinse using clean water and ret (Fig 51).

Re-assemble the lter and ret into the lter cradle.

Note: Any Spills should be wiped up before tank is lowered.

Machine Cleaning

Always ensure that the machine is switched off prior to any maintenance.

!

!

464748

495051

Loading...

Loading...