Numatic TGB1620T, TGB 1620 Owner's Manual

Warning! Read instructions before using the machine

Owner Instructions

TGB 1620

TGB1620T

BATTERY SCRUBBER DRYER

www.numatic.co.uk

Machine Overview ................................ Pages 2-3

Control Panel Overview ................................ Page 4

Machine Set up Guide ................................ Page 5

Fitting the Brush / Pad ................................ Page 6

Fitting the Floor Tool ................................ Page 6

Fitting the Hose Guide ................................ Page 7

Filling the Clean Water Tank .......................... Page 7

Fill Level Indicator .............................. Page 8

Lowering the Floor Tool ................................ Page 9

Raise / Lower Brush Deck ............................... Page 9

Setting the Cleaning Controls .................... Page 9

Brush Pressure .............................. Page 10

Breakaway Floor Tool ................................ Page 10

Machine in Use ................................ Page 10

Machine Cleaning ................................ Page 11

Waste Water Tank Full ................................ Page 11

Changing Floor tool Blades ............................. Page 12

Machine Charging ................................ Page 13

Battery Care ................................ Page 14

Charging Lights Sequence .............................. Page 14

TGB6055T Operation ................................ Page 15 - 16

Specications ................................ Page 17

Trouble Shooting ................................ Page 17

Rating Label / Personal Protective

Equipment /Recycling ................................ Page 18

Safety Precautions ................................ Page 19-20

Recommended Spare Parts .......................... Page 21

Schematic Diagram ................................ Page 21

EU Declaration Document ............................. Page 22

Warranty ................................ Page 22

Company Address ................................ Page 24

TGB 1620

BATTERY SCRUBBER DRYER

Index

After the removal of all the packaging,

carefully open and check the contents

●

Owner Manual ● 2 x Ignition Keys

●

Battery Charging Lead ● 2 x 40 Amp Fuse

(Battery) ● 1 x 30 Amp Fuse (Brush)

●

1 x 20 Amp Fuse (Vac)

●

1 x 2.5 Amp Fuse ● Maxi Fuse-puller

For Charger-less Model, all the above plus:

●

1 x Charger Connector ● 2 x Charger

Connector Terminals ● 4 x Battery Terminal

Connectors ● 1 x Fuse Holder

PLEASE READ

BEFORE COMMENCING

OPERATION

1

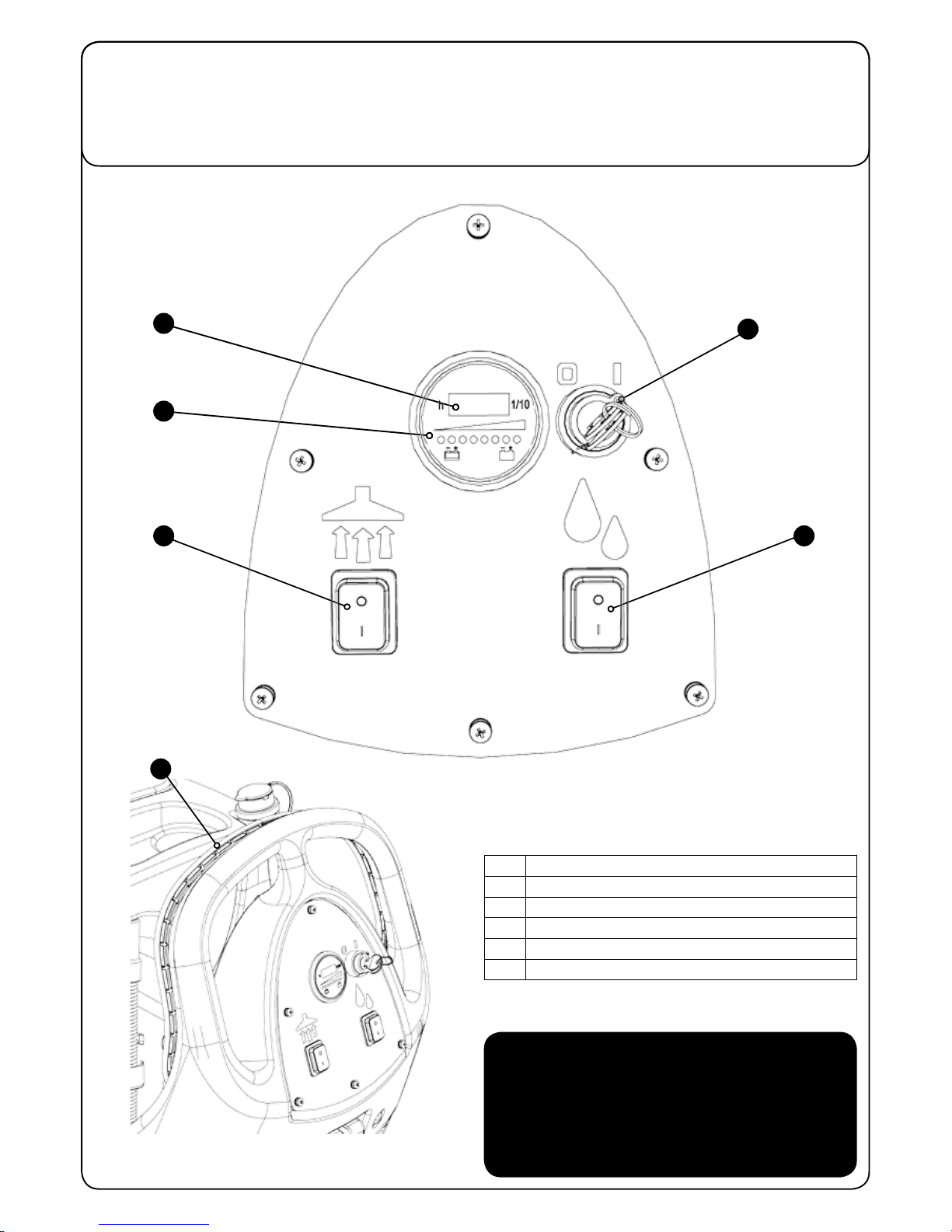

Operator control panel

2

Charging Socket / Point

3

Clean Water Fill Point

4

Floor Tool Raise / Lower Lever

5

Clean Water Tank Emptying Hose & Fill Level

6

Vacuum Hose

7

Charging Lights

8

Brush Deck Lifting Pedal

9

Extra Brush Load Pedal

10

Semi Parabolic Floor Tool

11

Brush On/O / Control Handle

12

Safety Fuse 2.5 Amp

13

Batteries

14

40 Amp Battery Fuse (50 Amp in Traction Machine)

15

Brush Motor Fuse 30 Amp

16

Vac Motor Fuse 20 Amp

17

Brush Deck

18

Clean Water Filter

19

Water Flow Tap

20

Waste Water Emptying Hose

21

Separator

22

Top Tank (Waste Water)

23

Bottom Tank (Clean Water)

24

Detent Pin

25

Key Ignition. On/O

6

4

2

1

3

14

15

16

17

9

8

7

11

Machine Overview

5

10

13

12

18

20

192122

23

24

25

For Traction Drive Twintec see pages 15 & 16

TGB 1620

BATTERY SCRUBBER DRYER

1

Key Ignition Switch

2

Hours Meter

3

Battery Charge Level Indicator

4

Vacuum Pick Up On / O

5

Water Flow On / O

6

Brush On / O / Control Handle

Control Panel Overview

In the event of a breakdown contact

your Numatic dealer or the

Numatic Technical

help line +44 (0)1460 269268

2

1

5

3

6

4

5

T 01460 68600

“

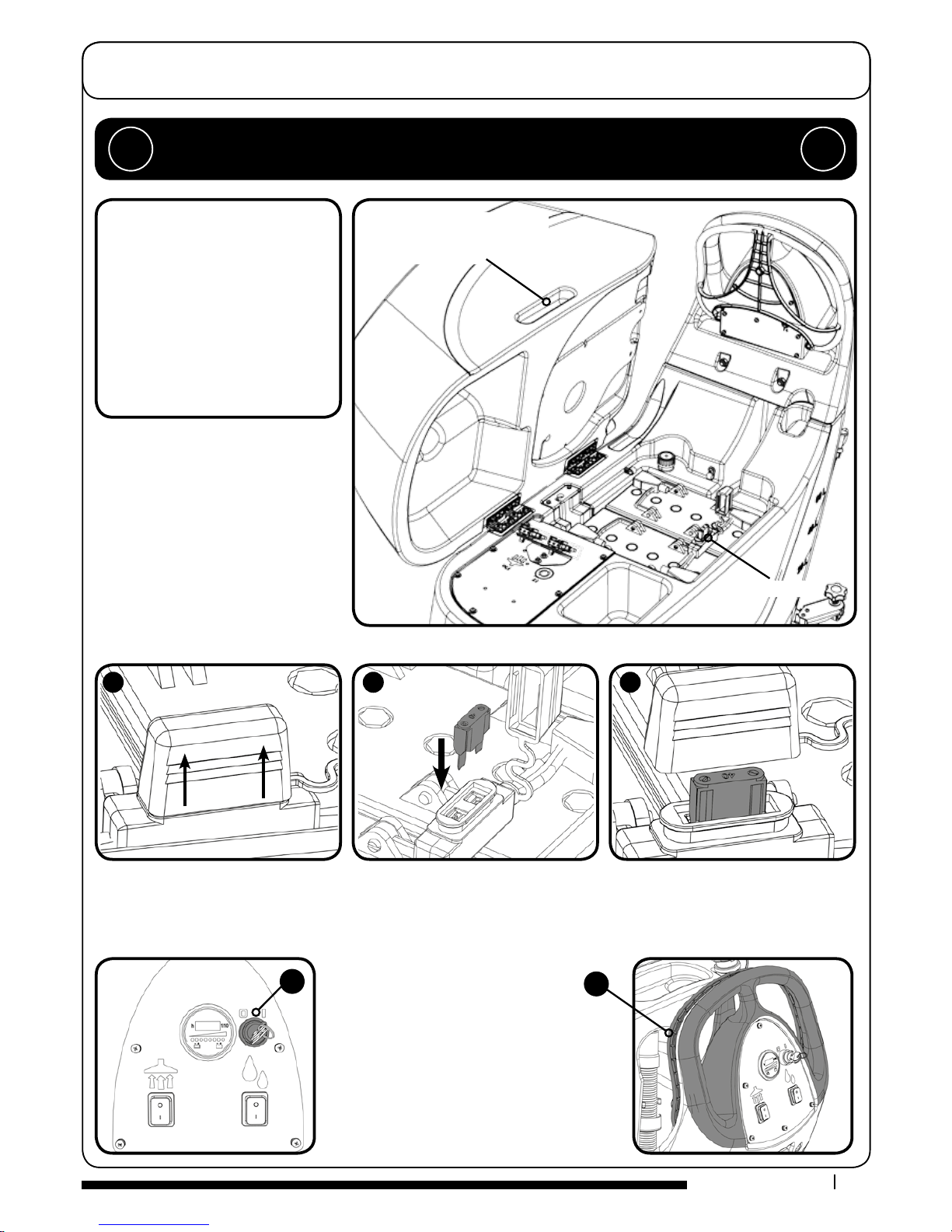

Ensure that no metal objects come into contact with

battery terminals while the batteries are exposed.

When inserting the rst fuse you may notice

a spark, this is normal.

”

Insert the Ignition key and

switch the machine on.

(Fig. A)

Use handle grip when

raising or lowering the

top waste-tank.

Fuse Location

Machine Set-up Guide

TGB

1620 CONTENTS

●

2 x Ignition Keys ● 2 x 40 Amp Fuse

(Battery) ● 1 x 30 Amp Fuse (Brush)

●

1 x 20 Amp Fuse (Vac)

●

1 x 2.5 Amp Fuse ● Maxi Fuse-puller

For Charger-less Model,

all the above plus:

●

1 x Charger Connector ● 2 x Charger

Connector Terminals

●

4 x Battery Terminal Connector

covers ● 1 x Fuse Holder

Lift top tank assembly to reveal battery

compartment, ensuring you use the handle

grip provided.

Fit battery fuse (contained in start-up pack)

into the battery fuse holder as illustrated.

(Fig. 1, 2, 3.)

Insert Key into ignition located on the

control panel (See below (Fig. A)

NOTE: Wear suitable gloves when

inserting fuses.

Using the control handle with both hands,

slowly push the machine o the pallet.

When the machine is removed and in a safe position,

release the control handle.

Note: Do not pull the RED trigger handle while in

transport mode (Fig. B)

During vehicular transportation ensure the product

is secured to avoid unnecessary movement.

PLEASE READ BEFORE COMMENCING ANY OPERATION AFTER THE REMOVAL OF ALL

THE PACKAGING, CAREFULLY OPEN AND CHECK THE CONTENTS.

!!

B

A

123

6

T 01460 68600

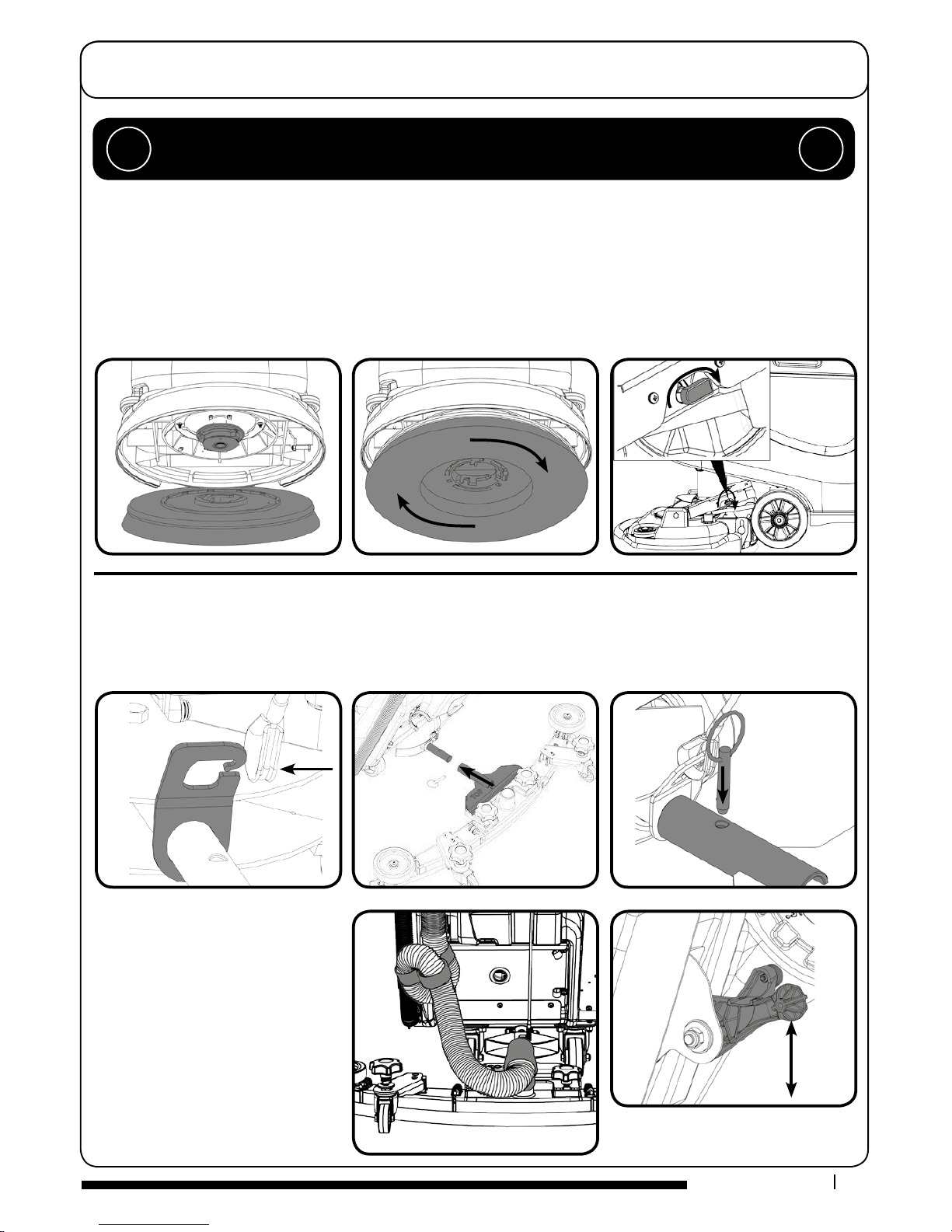

Fit the oor tool and retain using the

detent pin.

Push waste collection pipe onto the

oor tool; ensure a tight t.

Raise the oor tool for transit or

lower for cleaning operation using

the lifting handle tted to the back

of the machine.

For tting the oor tool blades

(See Page 12).

Machine Set-up Guide

ALWAYS ENSURE THAT THE MACHINE IS SWITCHED OFF

BEFORE MAKING ANY ADJUSTMENTS

!!

550mm Brush or a 500mm Pad on the TGB 1620.

Featuring the Nulock brush system.

The brush is simply pushed and twisted to lock, making

tting and removal a simple process.

Slide the brush / pad under the brush deck.

Fit the brush / pad onto the Nulock drive chuck, twist to lock the brush / pad in place.

Safety gloves are recommended for the changing of used brushes.

Turn on the clean water tap.

Fitting the Brush / Pad / Turn on water

Fitting the Floor Tool

The oor tool has been designed for quick tting, allowing easy squeegee blade replacement and a safety knock-o feature if the

oor tool gets snagged, whilst in transit.

NOTE: It is easier to t the oor tool if the weight of the machine is resting on the brush. Ensure the brush is tted rst.

7

T 01460 68600

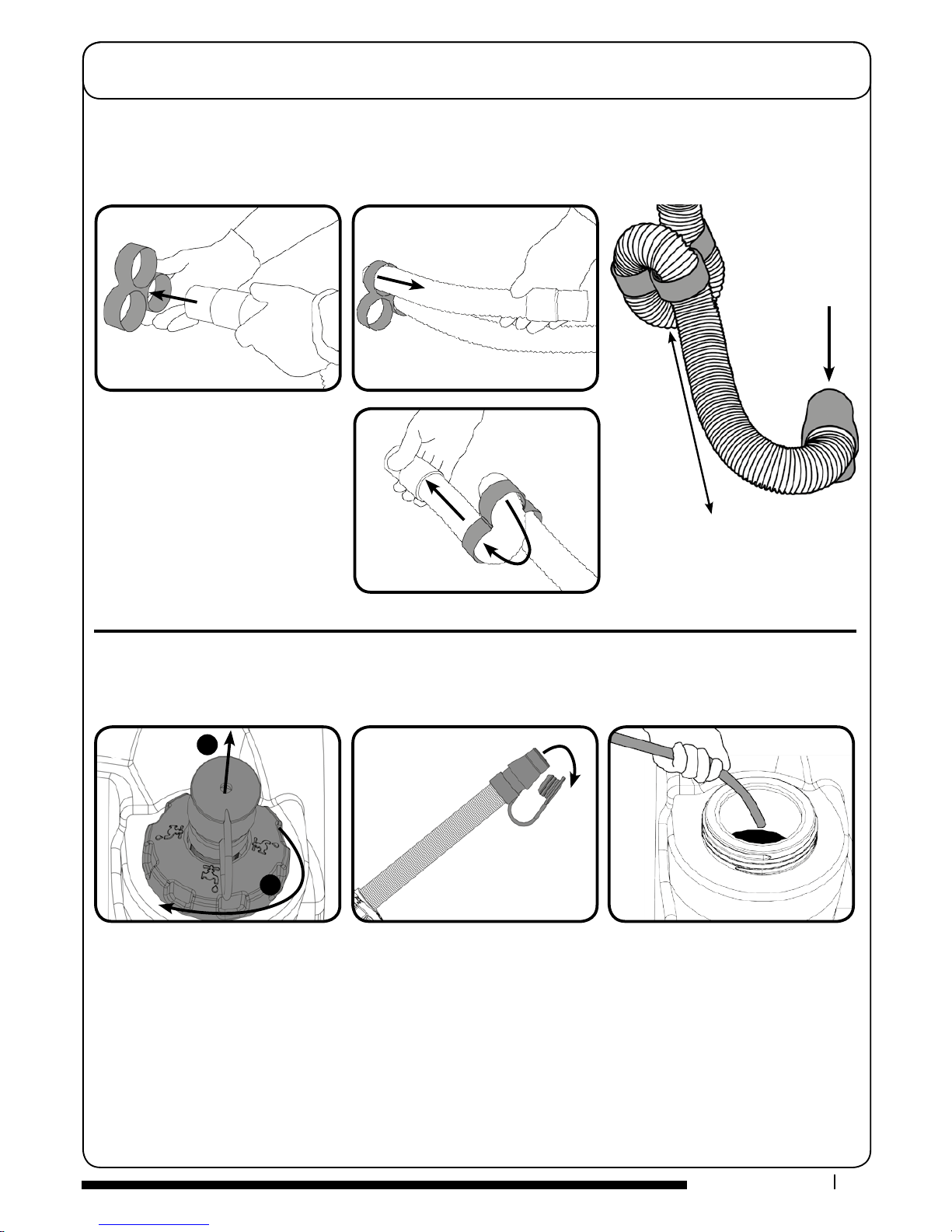

The vacuum hose has a U-bend clip which creates a U-bend in the hose preventing water spillage when the vacuum is switched

o. If you need to remove the U-bend clip for any reason always ensure it is retted correctly before you resume operation.

Fitting the Hose Guide

NOTE: DO NOT push the vacuum hose

onto the oor tool with the oor tool in

the raised position.

Machine Set-up Guide

Ret vacuum hose to the

Floor tool when nished.

250mm - 300mm

NOTE: Great care must be taken to ensure that contaminants (leaves, hair, dirt, etc.) are not allowed to enter the clean water

tank during the lling process. If using a bucket or similar, ensure it is always clean and free from debris.

F

illing the Clean Water Tank

The TGB 1620 is equipped with a large capacity clean water tank allowing for large areas to be covered in a single fill.

10

To ll the clean water tank, extend the hose located to the rear of the machine in the centre of the removable ller cap (1). Pull out

hose. Open the stopper and place hose under water tap, or use a hose to commence lling. The tank can also be lled by unscrewing

the ller cap and using a bucket or similar container (2).

1

2

8

T 01460 68600

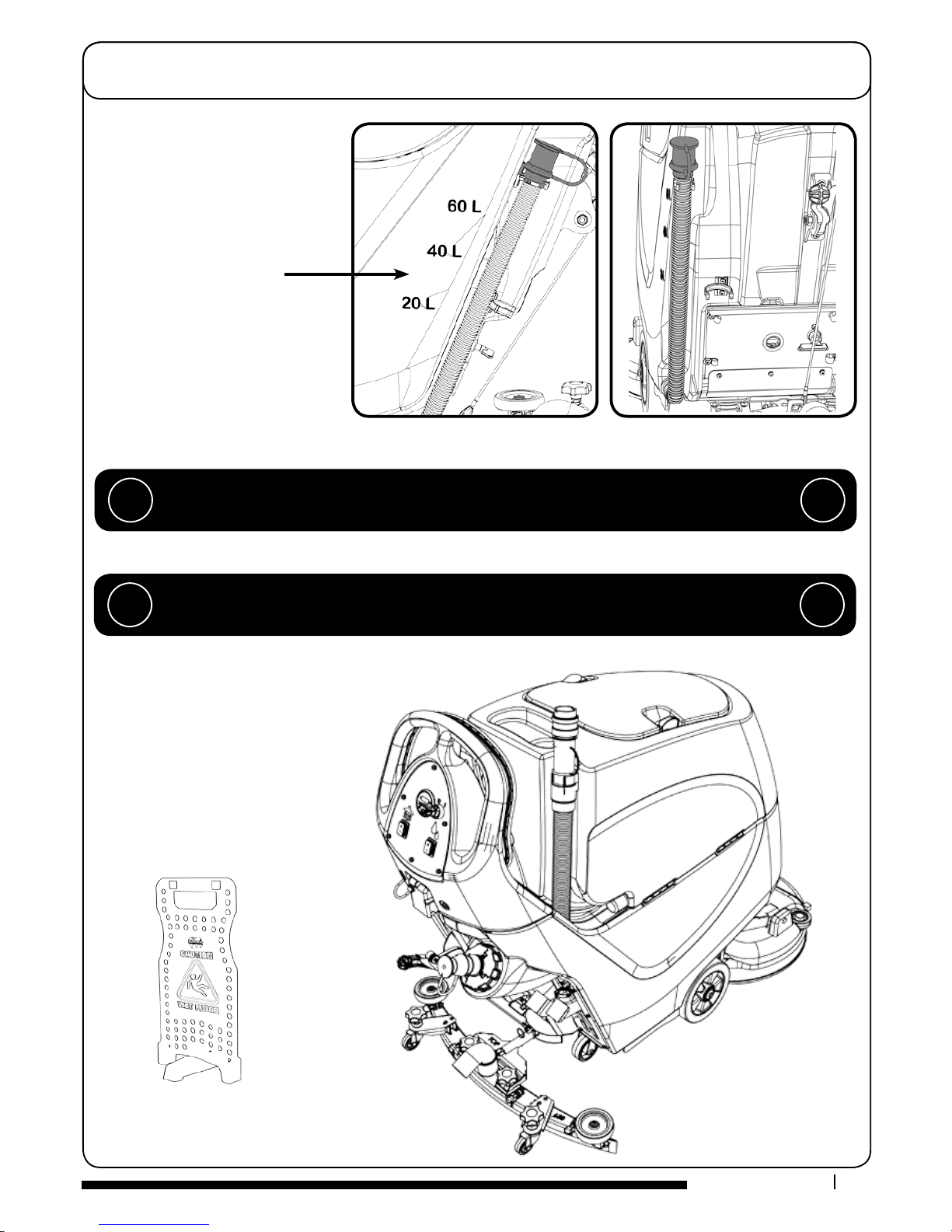

The water level in the clean-water tank

can be measured using the scale on the

left rear side of the machine. The clean

water bottom tank holds 60 litres.

NOTE: always ensure that the waste

water tank is empty before lifting.

Machine Set-up Guide

Fill Level Indicator

WHEN HANDLING AND MIXING CHEMICALS

Always ensure that chemical manufacturer’s safety guidelines are followed.

Only use chemicals recommended for use in auto scrubber-dryers.

!!

The machine is now ready to be moved to

the cleaning site.

Before performing the cleaning operation,

place out appropriate warning signs and

sweep or dust-mop the oor.

IMPORTANT

Do not operate machine unless the Operator Manual has been read and fully understood.

!!

Loading...

Loading...