Numatic NHL 15, NLH 15 Owner's Manual

Owner Instructions

Original Instructions

Warning! Read instructions before using the machine

www.numatic.com

CleanTec

NHL 15

2

1.

Move furniture.

2.

Vacuum thoroughly.

3.

Test carpet for colour fastness (out of sight).

4.

Spot clean as necessary.

5.

Open window for ventilation.

6.

Always use a low foaming carpet cleaner.

7.

Always work backwards towards the Exit Door.

8.

Clean full carpet area - Hi pump setting for heavy soiling and Lo

pump setting for lightly soiled areas.

9.

Do not overwet remember

‘ What goes in, must come out again!’

10.

Leave windows open to help carpet dry naturally.

Product Features

* TriJet carpet extraction head.

* Lo pressure for lightly soiled areas.

* Hi pressure for heavy soiled areas.

* Quality upholstery tool supplied.

* Dump hose emptying option.

* 4 wheel mobility.

* 15 litres capacity.

* Full Aluminium tool head.

The Hi - Lo system puts you in complete control, when you need more, you get more and when you need

less, you are but a switch away.

Kit B26

Kit BS27

Good carpet cleaning is very much a team effort between operative and machine

and a few well established rules to be followed to get the best results.

Cleaning tips

Contents / Kits - B26 - BS27

3

Before continuing, please refer to Quick Set Up Guide on Page 8

!

!

Cleaning Tips / Kit B26 - BS27 ........................................................................................................ Page 2

Index ............................................................................................................................................... Page 3

Quick Set Up Guide ....................................................................................................................... Page 4

Machine Overview ........................................................................................................................... Page 5

Rating Label / PPE / Critical components / Specications ................................................................ Page 6

Information for wet machines ............................................................................................................ Page 7

Fault nding ...................................................................................................................................... Page 8

Machine Set up.

Fitting the handle .............................................................................................................................. Page 9

Removing the dome and waste water tank ..................................................................................... Page 10

Filling the Nuchem / water tank ....................................................................................................... Page 10

Chemical usage ................................................................................................................................ Page 11

Replacing waste water tank and the dome ........................................................................................ Page 12

Fitting vacuum hose ......................................................................................................................... Page 12

Connecting solution tube ................................................................................................................ Page 12

Assembling wands and oor tool ..................................................................................................... Page 13

Operating the machine

Controls and switches ....................................................................................................................... Page 14

Correct way to use the machine ...................................................................................................... Page 14

Using the hand tool .......................................................................................................................... Page 15

Cleaning the machine

Emptying the waste water ................................................................................................................ Page 16

Removing the wands and oor tool .................................................................................................. Page 16

Cleaning the Tanks and lters .......................................................................................................... Page 16

Blocked Nozzles ................................................................................................................................ Page 17

Warranty ............................................................................................................................................ Page 22

Declaration Documents .................................................................................................................... Page 23

Company Addresses ........................................................................................................................ Page 24

Maintenance

Maintenance .................................................................................................................................... Page 18

Replacing the vacuum lter ............................................................................................................... Page 18

Replacing vacuum or pump fuses ..................................................................................................... Page 18

Changing the cable ........................................................................................................................... Page 19

Troubleshooting ............................................................................................................................... Page 20

Recommended spare parts .............................................................................................................. Page 20

Technical helpline ............................................................................................................................. Page 20

Wiring Diagram ................................................................................................................................ Page 21

Documentation

4

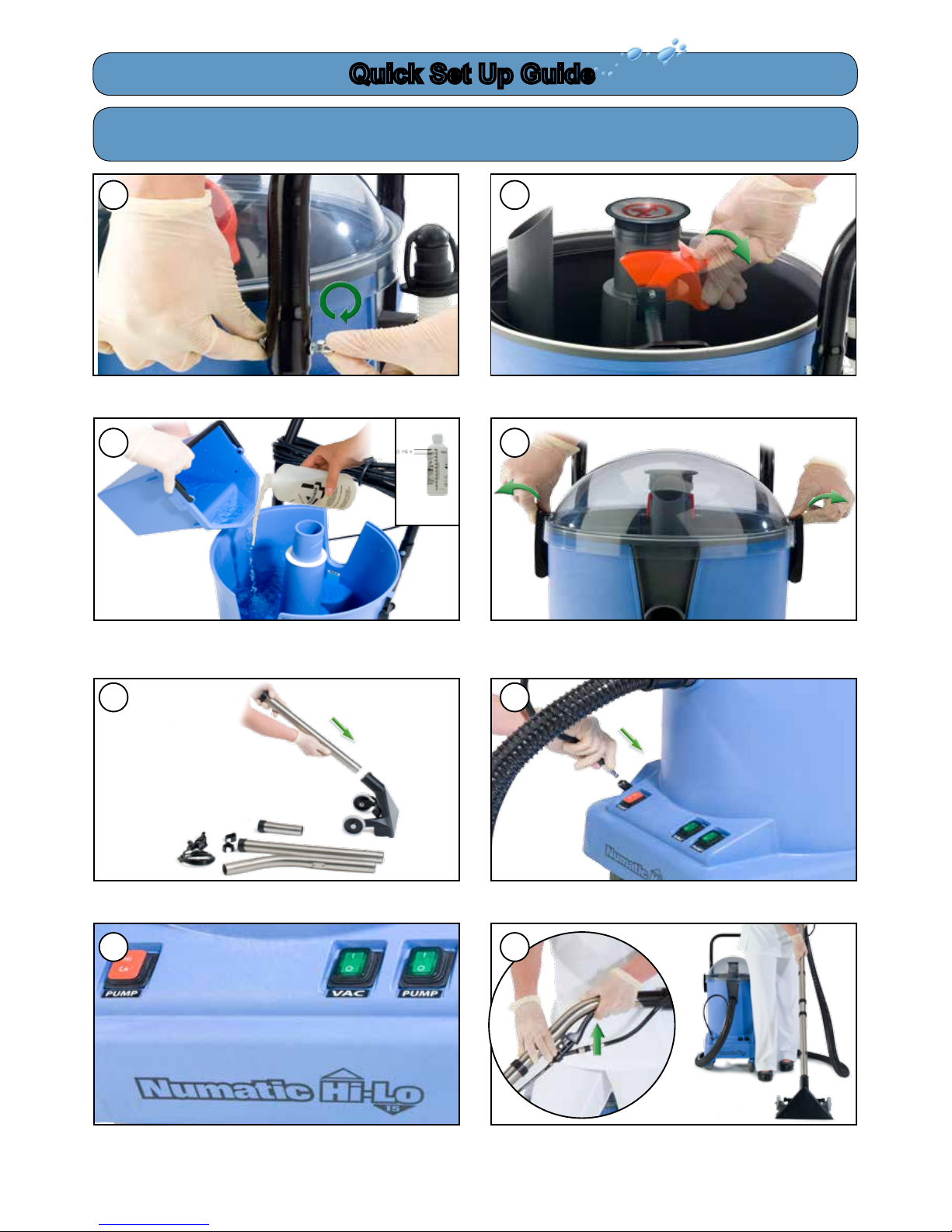

Quick Set Up Guide

Fit the handle to the machine using the xings supplied.

(Fig 1)

Remove the dome, unclip and remove the waste water

tank (Fig 2)

Fill the NuChem / water tank, up to the full level mark,

avoid pouring uids into the central tube as this leads

directly to the vacuum motor (Fig 3).

Replace the waste water tank, lock in place using the

red locking clamp and replace the dome. (Fig 4)

Assemble the wands and oor-tool and hose and

secure to the machine (Fig 5)

Connect the solution tube (Fig 6)

The switches on the front of the machine, control the

vacuum and pump operations. (Fig 7)

See page 15 for cleaning controls.

Operate the trigger (Fig 8) to apply water and vacuum

the carpet (Fig 9).

21

3 4

5 6

7

PLEASE READ BEFORE COMMENCING ANY OPERATION

After the removal of all the packaging, carefully open and check the contents.

8

Fig 1 Fig 2

Fig 3 Fig 4

Fig 5 Fig 6

Fig 7

Fig 9

Fig 8

5

14

15

16

17

13

Machine Overview

1. Plugged Cable cover

2. 6.3 amp time lag fuse x 2.

3. Plugged cable

4. Cable grommet

5. Vacuum lter cover

6. Vacuum lter

7. Castor wheels x 4

8. Quick release

9. Hi Lo Pump Switch

10. Vacuum Switch

11. Pump Switch

12.Dome

13. Waste tank locking toggle

14. Waste tank vacuum lter

15. Waste tank emptying hose

16. Handle

17. Cable strain relief

18. Solution tube quick release

1

3

4

5

6

7

2

9 10

11

12

For full easy to follow

Instructions on

the NHL 15 set up and use,

See quick set up guide

page 4

7

77

8

18

6

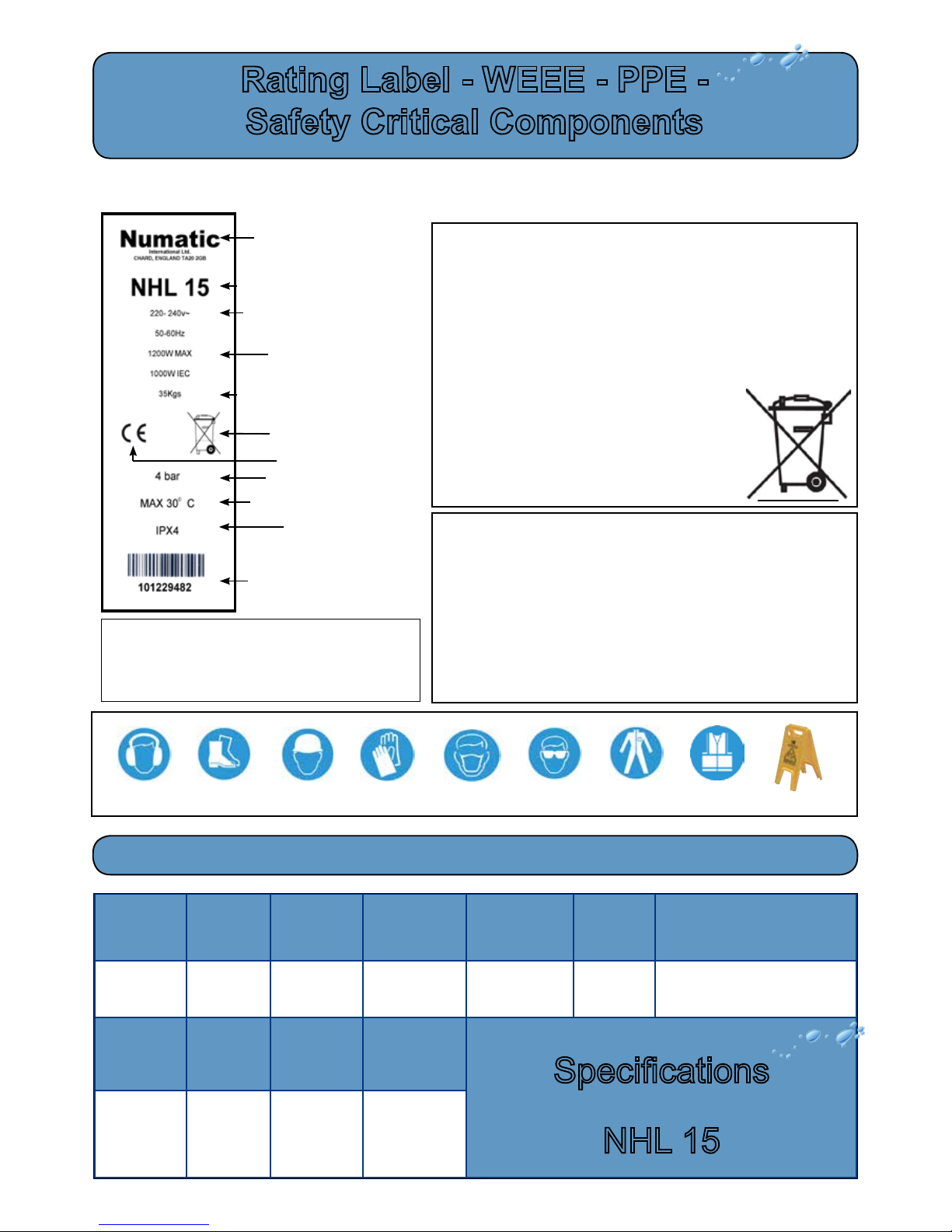

Model Motor Airow Suction

Cleaning

Range

Capacity

Wet

Noise

NHL 15 1200W 38 L/sec 2400mm 26.8m 15 Litres

75.6 dB(A)

uncertainty +/- 0.2 dB(A)

Pump

Solution

Tank

Size

H x W x D

Gross

Weight

(Full)

Specications

NHL 15

2 Bar

30psi

4 Bar 60

psi

15 Litres

890 x 420

x 530

35 Kgs

Company

name and address

Machine Description

Max Pressure

IPX Rating

WEEE Logo

Weight (Ready to use)

CE Mark

Voltage / Frequency

Power Rating

Yr / Wk / Serial Number

About the machine

WEEE Legislation

(Waste, Electrical and Electronic Equipment)

Vacuum cleaner, accessories and packaging should be sorted

for environmental-friendly recycling.

Only for EU countries:

Do not dispose of Vacuum cleaner into household waste!

According to the European Directive 2002/96/EC on waste

electrical and electronic equipment and its incorporation into

national law.

Vacuum cleaners that are no longer suitable for use

must be separately collected and sent for recovery

in an environmental-friendly manner.

Ear Protection Safety Footwear Head Protection Safety Gloves Dust / Allergens Protection Eye Protection Protective Clothing

Caution Floorsign

Hi Viz Jacket

Safety Critical Components

• Mains Lead

HO5VV-F - 3 x 1.00mm - 10m

• 6.3 amp time lag Fuse

Rating Label - WEEE - PPE -

Safety Critical Components

PPE

(personal protective equipment)

that may be required for certain operations.

NOTE:

A risk assessment should be conducted to determine which PPE should be worn.

Max cleaning agent temp

7

Information for Spray Extraction Vacuum Cleaners

WARNING

Read the instruction manual before using the machine.

Operators shall be adequately instructed on the use of these machines.

As with all electrical equipment, care and attention must be exercised at all times during use, in addition to ensuring

that routine and preventative maintenance is carried out periodically to ensure safe operation.

Failure to carry out maintenance as necessary, including the replacement of parts to the correct standard could render

this equipment unsafe and the manufacturer can accept no responsibility in this respect.

The machine shall be disconnected from the mains by removing the plug from the supply socket during cleaning or

maintenance and when replacing parts or converting the machine to another function.

The machine is not to be used by children or persons with reduced physical, sensory or mental capabilities, or lack of

experience or knowledge, unless they have been given supervision or instruction.

Children being supervised are NOT to play with the machine.

This appliance is intended to be assembled, cleaned and maintained by an adult.

This machine is not a toy.

CAUTION!

If foam/liquid comes out of machine exhaust, switch off immediately.

Allow the accumulated liquid to drain out through the machine exhaust, check the waste water level, empty the

waste water container if full.

Immediately upon start up there will be a certain amount of liquid issuing from the machine exhaust which will be the

residue of liquid still within the power head. This will be quickly discharged after which the machine should function

normally.

Liquid ejected from the machine could be hazardous as a result of its temperature, pressure or chemical

content.

This machine is not suitable for the collection of biological hazards, hazardous or explosive dust. You should contact

your local distributor if you require a machine capable of performing these tasks.

Ensure that the ltration system tted to the machine is suitable for the material being collected.

This machine is for indoor use only.

This machine shall be stored indoors only

NOTE: This machine is also suitable for commercial use, for example in hotels, schools, hospitals, factories, shops,

rental businesses and ofces for other than normal housekeeping purposes.

This machine can be used for cleaning carpet and upholstery.

DO

• Dry Vacuum the carpet before using wet extraction cleaner.

• Turn off pump and operate the trigger, to release pressure in the dosing system, before removing spray tube.

• Keep your machine clean.

• Keep lters clean.

• Keep hoses and tubes clear.

• Replace any worn or damaged parts immediately.

• Regularly examine the power cord, if damage is found, power cord must be replaced by a qualied person

Using the correct Numatic original part.

• Ensure that all components are assembled correctly before use.

DON’T

• Use steam cleaners or pressure washers to clean the machine or use the machine in the rain.

• Immerse in water for cleaning.

• Allow any inexperienced repairs. Call the experts.

• Use to suck up hot ashes, or lighted cigarette ends.

• Run the machine over the power cable during operation as a hazard may occur.

• Pull on the cable to unplug the machine from the power supply.

• Walk over-wet carpets, upholstery or fabrics.

• Walk on clean carpets until fully dry.

• Spray onto people or animals.

• Attempt machine maintenance or cleaning unless the power supply plug has been removed from the supply

outlet.

• Do not use as a dry vacuum

Information for wet machines

8

Spray extraction machines only

• Use only approved cleaning preparations.

• Use defoamer if necessary.

Use of detergents

When using any detergent with this machine, please ensure you have read the safety data on the container and you

are familiar with the procedures to clear up spills, inhalation, skin and eye contact.

This product complies with the requirements IEC 60335 -2.68.

When moving from one place to another, consider the weight of the machine.

Spray extraction maintenance/fault nding

If the vacuum cleaner stops working switch off and remove the plug from the wall, before investigating where the fault

lies.

If the vacuum cleaner has a blockage and will not pick up liquid, switch off and remove the plug from the wall.

Remove the dome and empty the liquid out of the waster water container.

If the waster water container is empty, check that the oor tool wands and hose are not blocked.

If no spray from nozzle the solution tank is empty, rell the solution tank.

Flush the system with clean water after use.

If the machine stops spraying then check the clean water tank level, empty the waste water tank and rell the clean

water tank as necessary.

If the spray nozzles are blocked, they have been designed to be easily cleaned. Undo the spray nozzle cap and clean

the nozzles.

A pin maybe used to clear the blockage.

After use always inspect the machine for damage.

Caution.

This machine has been designed to clean carpets and oors.

It must not be used when stood in water.

Fault Finding - Wet - Spray Extraction

Every time before use:-

Mains Cable.

Waste tank vacuum lter.

Hose, wands & tri jet assembly

Weekly

NuChem - water tank barrel lter (wash)

Vacuum lter (Check)

Visual inspection of Drum seal and bucket seal

Inspection schedule

Loading...

Loading...