Numatic HAS-750S Owner's Manual

Owner Instructions

Bedienerhandbuch

Mode d’emploi

Bedieningshandleiding voor de gebruiker

HAS - 750S

Hepa

Anti Static

Warning! Read instructions before using the machine.

Lesen Sie vor Gebrauch der Maschine das Handbuch.

Lisez la notice avant d’utiliser la machine.

Lees deze instructies voor u de machine gebruikt

Original Instructions

Warnhinweis

Attention

Waarschuwing

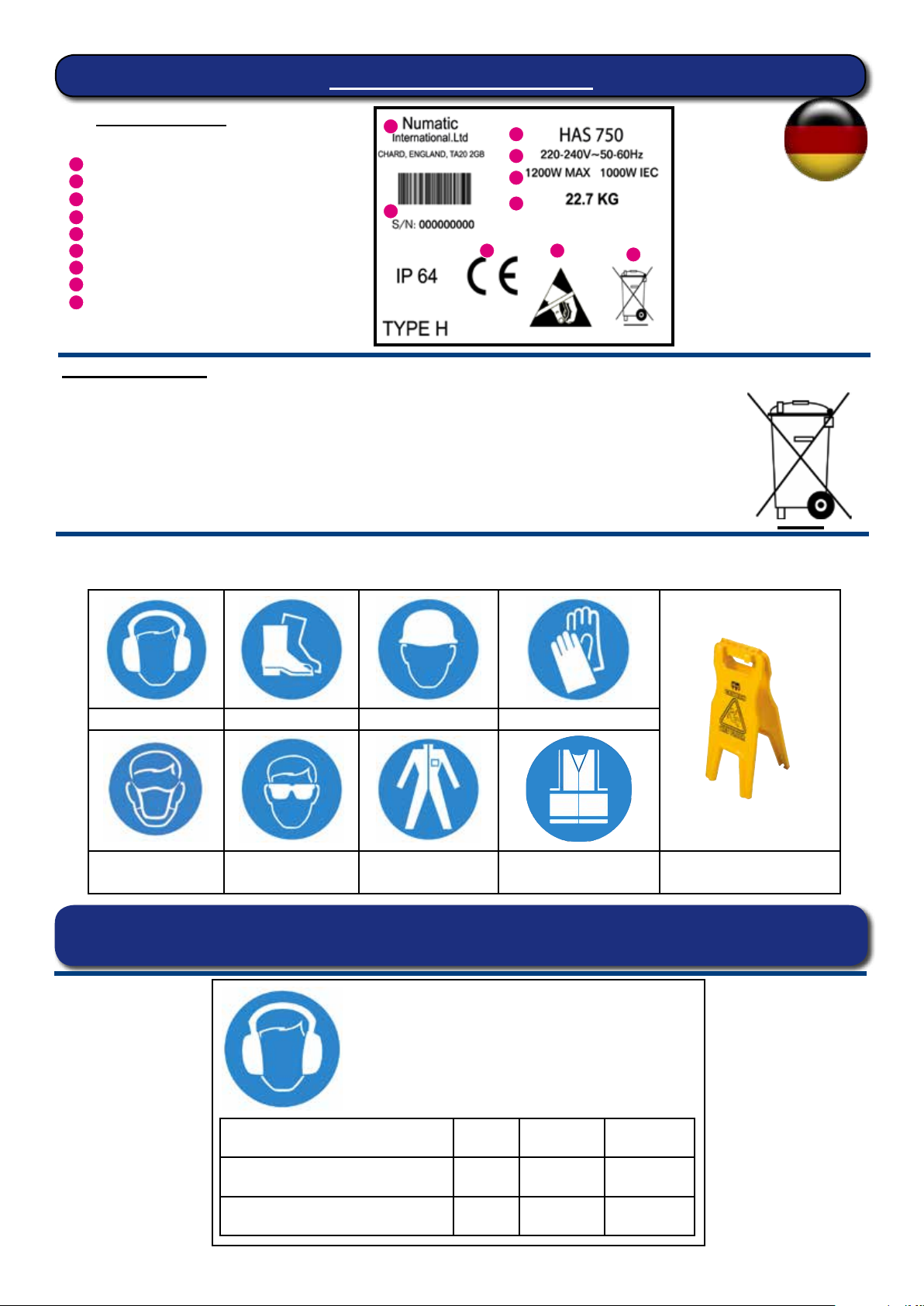

About the machine

Rating Label

Company Name & Address

1

Machine Description Voltage

2

Frequency

3

Power rating

4

Weight (ready to use)

5

Machine yr/wk Serial number

6

CE Mark

7

ESD Mark

8

WEEE Logo

9

1

6

2

3

4

5

7 8

9

WEEE (Waste, Electrical and Electronic Equipment)

Scrubber dryer Accessories and packaging should be sorted for environmentally- friendly recycling.

Only for EU countries.

Do not dispose of scrubber-dryer into household waste.

According to the European Directive 2002/96/EC on waste electrical electronic equipment and its

incorporation into national law.

Scrubber-dryers that are no longer suitable for use must be separated, collected and sent for

recovery in an Environmentally- friendly manner.

PPE

(Personal protective equipment) that may be required for certain operations).

Ear Protection Safety Footwear Head Protection Safety Gloves

Dust/Allergens

Protection

Eye Protection Protective

Clothing

Hi-Vis Jacket

Caution

wet oor sign

Note:

A risk assessment should be conducted to determine which PPE should be worn.

EAR DEFENDERS MUST BE WORN

WHEN USING THIS MACHINE

HAS 750 Uncertainty

Sound pressure level

Sound power level

Lpa

dB(A)

Lwa

dB(A)

70 dB 0.2 dB

78 dB 0.2 dB

2

Information for Dry USE Vacuum Cleaners

ORIGINAL INSTRUCTIONS

READ MANUAL BEFORE USE

Operators shall be adequately instructed on the use of these machines.

As with all electrical equipment, care and attention must be exercised at all times during use, in addition

to ensuring that routine and preventative maintenance is carried out periodically to ensure safe operation.

WARNING

could render this equipment unsafe and the manufacturer can accept no responsibility in this respect.

This machine is for DRY USE only and must not be stored outside or used in wet conditions.

The machine shall be disconnected from the mains by removing the plug from the supply socket during

cleaning or maintenance and when replacing parts or converting the machine to another function.

This machine is not a toy

CAUTION

NOTE

This machine is also suitable for commercial use, for example in hotels, schools, hospitals, factories,

shops, rental businesses and ofces for other than normal housekeeping purposes.

DO

● Replace any worn or damaged parts immediately.

● Regularly examine the power cord. If damage is found such as cracking or ageing the power cord

must be replaced by a qualied person using the correct Numatic original part.

● Change dust bag frequently.

● Keep diffuser lter (where tted) clean.

● Only use the brushes provided with the machine. The use of other brushes may impair safety.

● Only replace the power cord with the correct Numatic approved replacement part.

Failure to carry out maintenance as necessary, including the replacement of parts to the correct standard

Ensure that the ltration system tted to the machine is suitable for the material being collected.

This machine is for dry use only.

This machine is for use indoors only.

This machine should be stored indoors only.

● Keep your machine clean.

● Keep lters clean.

● Use lter bags, they will enhance performance and help keep machine clean.

● Use a Numatic Original lter bag under ne dust conditions.

● Keep hoses and tubes clear.

● Allow the rotating brush to come into contact with the supply cord (where rotating brushes are tted).

● Unreel the cable with one pull or pull on the cable to unplug the machine from the power supply.

● Use to suck up hot ashes or lighted cigarette ends.

DON’T

● Attempt machine maintenance or cleaning unless the power supply plug has been removed from the

supply outlet.

● Use steam cleaners or pressure washers to clean the machine or use in the rain.

● Immerse in water for cleaning.

TYPE HAS Vacuum cleaners

Extension cords shall be Class 1.

Type ESD vacuum cleaners are not suitable to pick up dusts or liquids of high explosion risk, nor mixtures of

combustible dust with liquids.

WARNING

Only use accessories approved for TYPE ESD use. The use of other accessories may cause electrostatic discharges.

The machine shall only be operated when all lters, including lters for motor cooling, are in position and undamaged.

NOTE:- National regulations may contain requirements for the installation of data lead wiring and

power sockets in ESD.

3

Important User Information

Before use operators shall be provided with information, instruction and training for the use of the machine and the

substances for which it is to be used, including the safe method of disposing of material collected.

The dust container has to be emptied not only when necessary, but also after each time it is used.

This vacuum cleaner has a lamp that will ash when air velocity drops below a preset level, which indicates that the

bag must be changed.

All lters including the bag must be undamaged and in correct position before this machine can be used safely.

Do not pick up glowing embers or dust or any other ignition hazard

Do not use the power cable as a method of moving the machine.

WARNING:

1. This machine must only be operated by suitably trained and authorised personnel.

2. This machine or its accessories must not be modied.

3. The machine must not be stored or used in a wet environment.

4. Do not allow the dust collection bag to become so full as to reduce the effective pick-up of the

vacuum. (Lamp will ash at preset air velocity levels).

5. Only use the dust collection bag once.

6. This machine must only be repaired by suitably trained and authorised personnel.

7. Only use genuine Numatic International Ltd spare parts, for repairs.

8. This machine must not be installed as a xed extraction system or run unattended.

Do not re-use the essential lter element after removal out of the machine.

Do not pick up glowing dust or other ignition hazards.

Operators should observe any safety regulations appropriate to materials being handled.

This machine is for dry use only.

PREPARATION FOR USE

Unpack and identify each item of equipment from the delivery note.

Check that the details given match the information on the “rating plate” mounted on the head assembly.

Installation / Removal / Disposal of the dust bag.

The dust bag holding the dust and debris must be removed and renewed by authorised personnel only, wearing

appropriate personnel protective equipment, in a specied de-contamination area.

Never operate without the full ltration system in place.

Process of disposal:

Disconnect the hose, t the dust cap on the hose ange, un-clip the bottom two toggle clamps.

(Upper two toggle clamps have split pins that should not be removed by un-authorised personnel).

Remove the cloth lter in the drum.

Remove the dust bag from the hose ange inside the drum and seal the dust bag hole.

Place the dust bag inside an impervious plastic bag and seal the bag.

Dispose of the plastic bag, depending on contamination, in an appropriate manner.

Fit a new dust bag over the hose ange inside the drum assembly.

Fit the cloth lter and the head, plus interceptor assembly, re-applying the two Toggle clamps.

Hepa Anti Static

Only use accessories approved for Type ESD use.

The use of other accessories may cause electrostatic discharges.

Ensure that the tted plug and power socket meets national regulations for EPAs and ESD.

The use of other accessories may cause an explosion hazard.

4

Maintenance

All machine parts should be regarded as contaminated when removed from the hazardous area and appropriate

action taken to prevent dust dispersal.

Disconnect from the power supply during cleaning, maintenance or when replacing parts.

Ensure the plug is removed from the socket outlet.

Maintenance must be carried out in a suitable non hazardous area with facilities for cleaning the area after servicing,

and with suitable ventilation.

Decontaminate before dismantling - Maintenance and cleaning work must always be carried out by competent

authorised personnel equipped with suitable personal protection.

The cloth lter must be taken out and checked for degree of contamination, and damage to cloth or seals.

If the cloth seal is found to be damaged or badly contaminated, you must replace. If only mildly contaminated, either

wipe clean or wash with a mild detergent (ensure it is dry before replacing).

Items that can not be satisfactorily cleaned (e.g. lters) need to be disposed of in an impervious plastic bag and

disposed of in accordance with current regulations.

Replace the items that cannot be satisfactorily cleaned using approved manufacturer parts.

Regularly examine the supply cord for damage, such as cracking or ageing.

If damage is found, replace the cord before further use.

All parts of this vacuum are safety critical only replace with the genuine Numatic spare parts.

For user servicing, the machine must be dismantled, cleaned and serviced, as far as is reasonably practicable, without

causing risk to maintenance staff and others.

Suitable precautions include decontamination before dismantling, provision for local ltered exhaust ventilation where

the machine is dismantled, cleaning of the maintenance area and suitable personal protection.

In class H machines the outside of the machine should be decontaminated by vacuum cleaning methods and wiped

clean or treated with a sealant before being taken out of the hazardous area and appropriate action taken to prevent

dust dispersal. (Risk Assessment needed).

A competent person shall perform a technical inspection at least annually, consisting of, for example, inspection of

lters for damage, air tightness of the machine and proper function of the control mechanism.

Also the ltration efciency should be tested at least annually, or more frequently as specied in national requirements.

The test methods that can be used to verify the machine’s lter efciency are specied in IEC/EN 60335-2-69 Annex

AA (AA22.201.2). If the test fails it should be repeated with a new essential lter.

5

Preparing the machine for normal use

The dust bag holding the dust and debris must be removed and renewed by authorised personnel,

wearing appropriate personnel protection, in a specied contamination area. Never operate without the

full ltration system in place.

Process of disposal: Disconnect the hose, t the Dust Cap on the Hose Flange, un-clip the bottom

three Toggle Clamps (Upper three toggle clamps have split pins that should not be removed by un-authorised

personnel).

Remove the cloth lter in the Drum. Remove the dust bag from the Hose Flange inside the drum

and seal the Dust Bag hole. Place the Dust Bag inside an impervious plastic bag and seal the bag.

Dispose of the plastic bag, depending on contamination, in an appropriate manner.

Fit a new Dust Bag over the Hose Flange inside the drum assembly. Ret the cloth lter, and the Head,

plus Interceptor assembly, re-applying the 3 Toggle clamps.

Ensure the dust bag (NVM-4B) has been properly tted over Hose Flange internally by unclipping

the three lower toggle clamps, and lifting off Head & Interceptor assembly. If not tted, fully insert

dust bag over Hose Flange and re-t the Head & Interceptor assembly

Fully unwind the mains cable and connect the HASmachine into an approved power supply

Unscrew the Dust Cap on the Hose Flange and t Hose assembly plus appropriate tools for the job

To run the machine, press the ON/OFF button in. Press once for ON, then press again for OFF

6

Replacing HEPA Filters Process

HEPA lter INLET (see gure 1)

Unclip the top three toggle clamps, removing the security split pins in advance. Remove the Head assembly

and place in a safe area. Unclip the lower three toggle clamps and remove the Interceptor assembly from the

drum assembly, and place the Interceptor on a good level working surface. Unscrew the 6, M5 x 10 screws

on the underside of the Interceptor assembly which will expose the HEPA lter.

Remove the contaminated HEPA lter and place in a suitably impervious plastic bag and dispose of in

accordance with current regulations. Replace the HEPA lter with an identical approved part

(ensure plastic lter grid that locates into the hole in the metalwork is not thrown away with HEPA lter).

Re-assemble the Interceptor assembly in reverse order. If the seal between the upper and lower metal parts

of the Interceptor assembly is damaged, replace with a manufacturer approved seal material

(there must be NO gap in the circular seal).

Re-assemble the machine in reverse order. (Screw torque 2.5Nm). Ensure new split pins are tted

and legs opened

During this process please look carefully at all seals between mating parts and check for any damage.

If seals have been damaged, please contact the machine manufacturer to obtain an approved replacement part.

HEPA lter EXHAUST (see gure 1)

Unscrew the 8, M5 X 10 screws holding the Filter Cover onto the Head assembly.

Remove Filter Cover to expose HEPA lter. Remove the contaminated HEPA lter and place in a

suitably impervious plastic bag and dispose of in accordance with current regulations. Replace

the HEPA lter with an identical approved part.

Re-assemble the Filter Cover onto the Head Assembly, trapping the HEPA lter,

tightening up all screws (Screw torque 2.5Nm)

7

HAS 750 ACCESSORY KIT LIST - 607661

1 x 602111 HOSE ASSEMBLY 38mm (HAS)

1 x 602112 BRUSH NOZZLE 400mm WIDE TRACK (HAS)

1 x 602919 TUBE BEND STAINLESS STEEL

2 x 602929 TUBE EXTENSION STAINLESS STEEL

1 x 602923 GULPER/SCRAPER 305mm STAINLESS STEEL

1 x 604019 DUST BAGS (NVM-4BH) (10 per packet)

1 x 629445 DISPOSABLE BAGS 120 LT (10 per packet)

1 x 602124 CONDUCTIVE BRUSH

1 x 602125 CONDUCTIVE RUBBER GULPER

1 x 602923 GULPER/SCRAPER

305mm STAINLESS STEEL

1 x 602111 HOSE ASSEMBLY 38mm HAS

1 x 629445 DISPOSABLE BAGS

120 Ltr (10 per packet)

2 x 602929 TUBE EXTENSION STAINLESS STEEL

1 x 602124

CONDUCTIVE BRUSH

1 x 602919 TUBE BEND

STAINLESS STEEL

1 x 602125 CONDUCTIVE

RUBBER GULPER

1 x 604019 DUST BAGS

(NVM-4BH) (10 per packet)

1 x 602112 BRUSH NOZZLE

400mm WIDE TRACK HAS

8

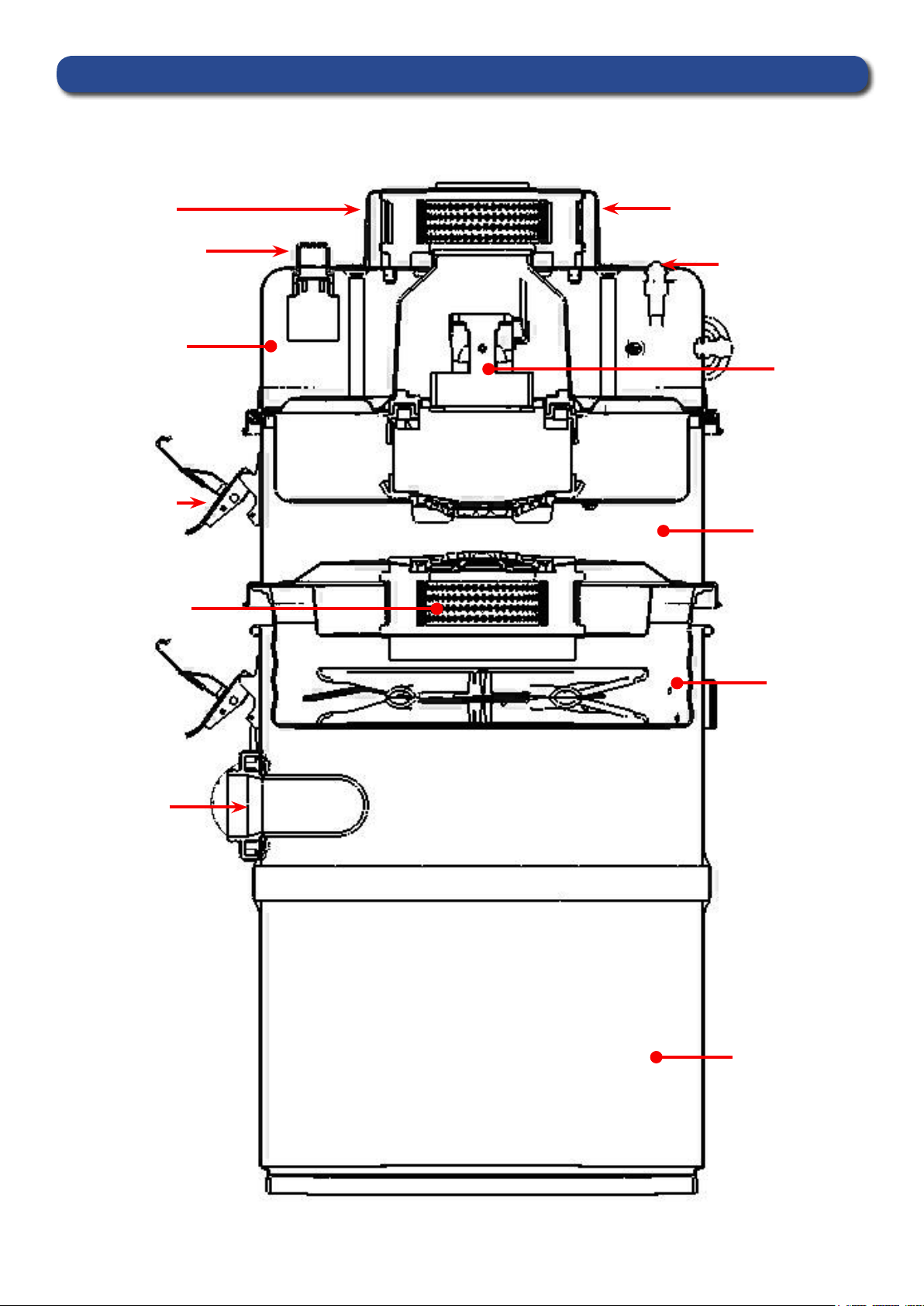

HAS 750 Sectional View

(Figure 1)

Filter Cover

Illuminated Lamp

Head Assembly

Toggle

(Split pin ftted)

Hepa Filter Inlet

Hepa Filter Exhaust

ON / OFF Switch

Motor

Interceptor

Assembly

Hose Flange

Dust Bag Compartment

Cloth Filter

Drum Assembly

9

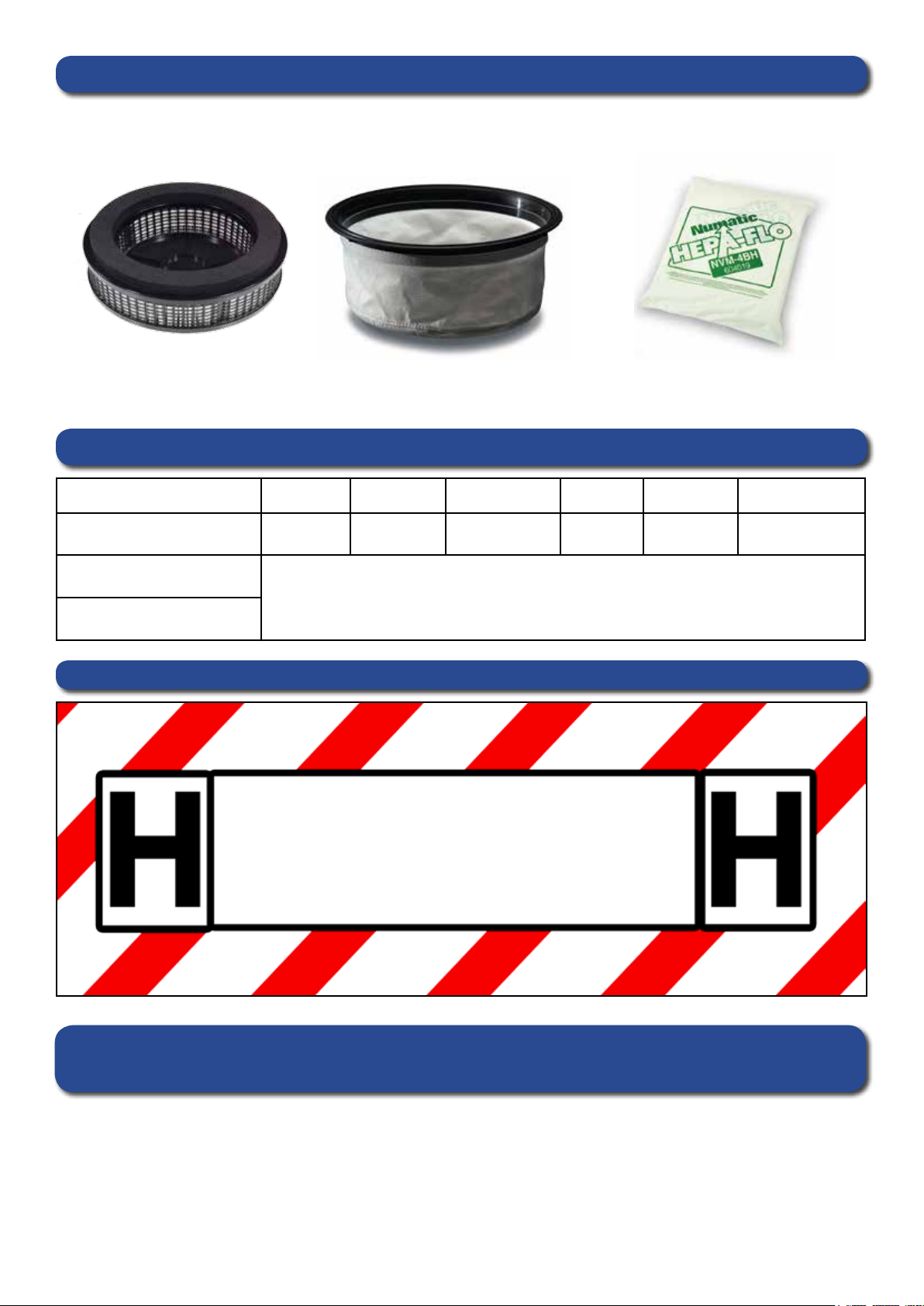

Spares

In order to ensure that maintenance work can be carried out without delay, we recommend that

stocks of the following parts are held:

HAS Hepa Filter

604124

Filter cloth assembly

(anti-static)

Filter bags (pack of 10)

604019

604144

Machine Data

Noise Suction Airow Dry Capacity Weight Size Cleaning Range

72.2dB @ 1m 2500 48 L/sec 35 Litres 23 Kg

Flow Data

Numatic International Ltd, Milleld Road, Chard, Somerset. TA20 2GB.

Tel: +44 (0) 1460 68600 Fax: +44 (0) 1460 68458. www.numatic.co.uk

40l/s = 144m3h

Warning:

This machine contains dust hazardous to health.

Emptying and maintenance operations, including removal of the dust

collection means, must only be carried out by authorised

personnel wearing suitable personal protection.

Do not operate without the full ltration system tted.

510 x 510 x

960

‘H Type’ Warning Label

25.6m

Failure to rectify the problem or in the event of a breakdown contact your

Numatic dealer or the Numatic Technical help line +44 (0)1460 269268

10

Angaben zum Gerät

Produktplakette

Name und Adresse Unternehmen

1

2

Gerätebeschreibung

3

Nennspannung/ Frequenz

4

Leistung

5

(Nutz-) Gewicht

6

Gerät Jahr/Woche Seriennummer

7

CE-Kennzeichnung

8

ESD Kennzeichnung

9

WEEE Logo

1

6

2

3

4

5

7 8

9

WEEE-Richtlinie

Staubsauger, Zubehör und Verpackung müssen getrennt entsorgt werden, um ein umweltfreundliches

Recycling zu ermöglichen.

Für EU-Länder gilt:

Entsorgen Sie Staubsauger nicht im Hausmüll!

Gemäß EU-Richtlinie 2002/96/EG über Elektro- und Elektronik-Altgeräte sowie ihrer Umsetzung in

nationales Recht. Staubsauger, die nicht mehr verwendet werden können, sind getrennt zu sammeln und zur

umweltfreundlichen Wiederverwertung abzugeben.

PSA

(Persönliche Schutzausrüstung) kann für bestimmte Verwendung des Geräts erforderlich sein.

Gehöschutz Sicherheitssdchuhe Kopfschutz Sicherheitshandschuhe

Staub/Allergieschutz Augenschutz Schutzkleidung

Warnweste

Hinweisschild

“Achtung Rutschgefahr”

Hinweis:

Eine Risikoauswertung ist vom Betreiber des Gerätes anhand der örtlichen Gegebenheiten vorzunehmen,

um die erforderliche Schutzausrüstung festzulegen.

Bei der Verwendung dieses

Geräts muss ein Gehörschutz

getragen werden.

HAS 750-2 Unsicherheit

Schallfeldgrößen des Geräts

Schallleistungspegel

11

Lpa

dB(A)

Lwa

dB(A)

70 dB 0.2 dB

78 dB 0.2 dB

Informationen für Trockensauger

Lesen Sie die Anleitung vor Inbetriebnahme

des Geräts gründlich durch.

Lesen Sie die Anleitung vor Inbetriebnahme des Geräts gründlich durch.

Benutzer müssen in den Gebrauch dieser Geräte ausführlich eingewiesen werden.

Wie bei allen elektrischen Geräten ist während der Benutzung jederzeit Vorsicht und Aufmerksamkeit

geboten. Darüber hinaus muss zur Gewährleistung eines sicheren Betriebs in regelmäßigen Abständen

WARNUNG

Bei Unterlassung notwendiger Wartungsarbeiten, einschließlich des ordnungsgemäßen Ersetzens von fehlerhaften

Teilen durch korrekte Standardteile, kann die Sicherheit des Geräts beeinträchtigt werden, und der Hersteller kann in

dieser Hinsicht keine Verantwortung oder Haftung übernehmen.

Das Gerät ist ausschließlich als TROCKENSAUGER einzusetzen. Stellen Sie das Gerät nicht im Freien ab, und

verwenden Sie es nicht in feuchten Umgebungen.

Bei Reinigung und Wartung, beim Ersetzen von Teilen oder beim Umschalten des Geräts auf eine andere Funktion

muss das Gerät durch Ziehen des Netzsteckers von der Stromversorgung getrennt werden.

VORSICHT

HINWEIS

eine laufende und vorbeugende Wartung durchgeführt werden.

Achten Sie darauf, dass das im Gerät verwendete Filtersystem für das aufgenommene Material

geeignet ist.

Das Gerät ist ausschließlich als Trockensauger zu verwenden.

Das Gerät ist nur in Innenräumen zu verwenden.

Das Gerät darf nur in Innenräumen abgestellt werden.

Dieses Gerät ist zusätzlich zu seiner Verwendbarkeit in privaten Haushalten auch für den gewerblichen Einsatz

geeignet, beispielsweise in Hotels, Schulen, Krankenhäusern, Fabriken, Läden,Mietgeschäft und Büros.

Was zu beachten ist...

● Halten Sie das Gerät sauber.

● Halten Sie die Filter sauber.

● Verwenden Sie Filterbeutel. Sie verbessern die Leistung und helfen, das Gerät sauber zu halten.

● Verwenden Sie bei Feinstaubeinsatz originale Numatic-Filterbeutel.

● Halten Sie Schläuche und Rohre sauber.

● Ersetzen Sie abgenutzte oder beschädigte Teile unverzüglich.

● Untersuchen Sie regelmäßig das Netzkabel. Wenn Sie eine Beschädigung feststellen, wie z. B. einen Bruch

oder Alterungserscheinungen, muss das Netzkabel durch eine qualizierte Person ausgetauscht und durch das

richtige Numatic-Originalteil ersetzt werden.

● Wechseln Sie die Staubbeutel regelmäßig.

● Halten Sie den Diffusor-Filter sauber (falls vorhanden).

● Verwenden Sie nur die Bürsten, Saugschläuche und Zubehör, die im Lieferumfang des Geräts enthalten sind.

Durch die Verwendung anderer Komponenten kann die Sicherheit beeinträchtigt werden.

● Reparaturen am Gerät ausschließlich durch qualiziertes Fachpersonal

Was zu unterlassen ist…

● Stossen Sie beim Arbeiten nicht mit der Saugdüse an das Netzkabel

● Zum Abrollen oder Trennen von der Steckdose nicht am Kabel ziehen

● Saugen Sie weder heiße Asche noch glimmende Zigarettenstummel auf

● Verwenden Sie keine Dampf- oder Druckreiniger zum Reinigen des Geräts, und verwenden Sie das Gerät nicht im

Regen.

● Tauchen Sie das Gerät zur Reinigung nicht in Wasser ein.

● Führen Sie keine Wartungs- oder Reinigungsarbeiten am Gerät durch, wenn der Netzstecker noch in der

Steckdose steckt.

Typ HAS Staubsauger

Zuleitungen müssen einen Schutzleiter (Klasse 1) enthalten.

Typ ESD Staubsauger sind nicht geeignet, um Stäube oder Flüssigkeiten mit hoher Explosionsgefahr, noch Mischungen von brennbarem Staub mit Flüssigkeiten aufzusaugen.

WARNUNG

Verwenden Sie nur Zubehör, das für Typ ESD zugelassen ist. Die Verwendung anderer Zubehörteile kann zu elektrostatischen Entladungen führen.

Die Maschine darf nur betrieben werden, wenn alle Filter, einschließlich des Filters für die Motorkühlung ordnungsgemäß eingebaut und unbeschädigt sind.

HINWEIS: -

Nationale Vorschriften können weitere Anforderungen an Verdrahtung und Steckdosen in ESD-Maschinen enthalten.

12

Loading...

Loading...