P.O. Box 2758 Windsor, Nova Scotia, B0N 2T0

Phone: 902-798-2261 Fax: 902-798-2557

www.nu-airventilation.com Email: nuair@nu-airventilation.com

CONTRACTOR EDITION HRV’S

OOPPEERRAATTIINNGG,, MMAAIINNTTAAIINNIINNGG && IINNSSTTAALLLLIINNGG YYOOUURR HHEEAATT RREECCOOVVEERRYY

FOR MODELS CEA15-R, CEA18-C, AND CEA20-D

* LEAVE THIS DOCUMENT WITH THE HOMEOWNER

Specifications, dimensions and ratings may change without notice

as a result of ongoing product development and improvements.

Rev. December 19, 2008

VVEENNTTIILLAATTOORR

TABLE OF CONTENTS

1. HOW THE NU-AIR SYSTEM WORKS ......................................................................................................................... 3

2. INSTALLATION............................................................................................................................................................. 3

2.1. Installer's Responsibilities...................................................................................................................3

2.2. Installation System Options ............................................................................................................... 3

2.3. Ducting to The Outside........................................................................................................................5

2.4. Mounting & Noise Control..................................................................................................................6

2.5. Port Configurations ............................................................................................................................. 6

2.6. Ductwork .............................................................................................................................................. 7

2.7. Drain Connections ............................................................................................................................... 7

2.8. Balancing the System........................................................................................................................... 8

3. CONTROLS..................................................................................................................................................................... 9

3.1. Features: ...............................................................................................................................................9

3.2. Machine ON/OFF Switch..................................................................................................................11

3.3 Standard Dehumidistat - Part # DSTAT-1...........................................................................................11

3.4. Windsor Control (Part # WIN-1) .....................................................................................................11

3.5. Windsor Timer (WIN-20)..................................................................................................................11

3.6 Spring Wound Timers ............................................................................................................................ 12

3.7 Remote On/Off Switching ...................................................................................................................... 12

3.8 Furnace Interlock....................................................................................................................................12

4. Arctic Defrost Mode ...................................................................................................................................................... 12

5. START-UP..................................................................................................................................................................... 12

6. OPERATING HINTS.................................................................................................................................................... 13

7. MAINTENANCE .......................................................................................................................................................... 13

7.1. Filters:.................................................................................................................................................13

7.2. Fans .....................................................................................................................................................13

7.3. Condensate Drain ..............................................................................................................................13

7.4. Core.....................................................................................................................................................13

7.5. Exterior Hoods ................................................................................................................................... 13

7.6. Grills & Duct Work ........................................................................................................................... 14

8. ANNUAL SERVICING................................................................................................................................................. 14

9. TROUBLE SHOOTING ............................................................................................................................................... 15

10. ELECTRICAL SCHEMATICS .................................................................................................................................... 16

10.1. WINDSOR Wall Controls Wiring Diagram....................................................................................16

10.2. 24V Standard D-Stat Wiring Diagram (Part#DSTAT-1) ..............................................................17

10.3. Damper Defrost and Re-circulation Defrost ...................................................................................18

11. WARRANTIES.............................................................................................................................................................. 19

Rev. December 19, 2008

1. HOW THE NU-AIR SYSTEM WORKS

A. Powerful, centrifugal

blowers bring fresh air into

your home while an equal

amount of stale, humid air is

exhausted to the outside.

This is NU-AIR’s balanced

central ventilation system.

B. Incoming fresh air is filtered

before flowing through the

heat exchange core.

C. Stale, humid air flows

through the cross-flow heat

exchanger and transfers the

heat to the incoming fresh

air.

D. Warm fresh air is distributed to each room of the house through an independent ductwork system.

2. INSTALLATION

2.1. Installer's Responsibilities

Installers are responsible for the performance of the ventilation system and for ensuring that all codes

and standards are met.

Do not mount the fresh air supply near a source of contaminated air such as automotive exhaust, gas

or propane exhaust or oil tanks.

Do not hook a dryer exhaust to an HRV.

Combustion appliances such as furnaces and hot water heaters must not draw combustion air directly

from an HRV.

Do not connect a range hood to any part of this system.

Do not install in attics or other unconditioned spaces (min. 16º C).

Do not install in enclosed garages.

2.2. Installation System Options

Before installing your HRV, please read these

instructions for correct installation. The Nu-Air HRV

is a self-contained system that is ready to be installed.

There are three commonly used and approved

methods of installation.

2.2.1. The Fully Ducted System

This system uses an independent duct system for

supply and exhaust air. The HRV is controlled

independently of all other equipment.

The best results are achieved when:

Rev. December 19, 2008 Page 3 of 19

• Each room of the space is serviced with a vent mounted in the ceiling or high on an interior wall

(within 12" of the ceiling).

• Vents are located deep within a room, where they will not short circuit or create an

uncomfortable draft.

Areas typically serviced by Exhaust Air: Laundry Rooms, Kitchens, Bathrooms, other wet rooms.

Note. Kitchen exhaust grills should be equipped with a grease filter and must be located

at least 3 ft. horizontally in all directions from the surface of the range extended to the

ceiling.

Areas typically serviced by Fresh Air: Bedrooms, Living Rooms, Dining Areas, and Recreation Areas.

2.2.2. The Extended Exhaust System

This system uses the HRV in conjunction with a

forced air furnace distribution system. In this

system the HRV supply air to the house is

introduced into the return duct of the forced air

furnace. Separate, additional ductwork is used to

transfer stale air from the wet rooms to the HRV.

2.2.2.1. Extended System, Continuous Ventilation

The furnace fan may not need to run continuously with this system. Check local code requirements. For

improved supply air distribution during continuous ventilation mode, the furnace may be interlocked to

the HRV. See Section 3.9

2.2.2.2. Extended System, Intermittent Ventilation

If the HRV is operated intermittently, the furnace fan should be interlocked with the HRV for good

distribution of supply air during high-speed ventilation conditions.

2.2.3 The Simplified System

This system uses the furnace's return

duct for both supply air distribution and

exhaust air collection. The exhaust air

connection must be a minimum of 40

inches upstream of the supply air

connection to avoid short-circuiting of

the fresh air.

Rev. December 19, 2008 Page 4 of 19

2.2.3.1. Simplified System - Continuous Ventilation & Intermittent Operation

For proper supply air distribution with this system, and to prevent short circuiting in the return air duct,

the furnace fan must run during ventilation mode. Interlock the furnace and HRV in accordance with

Section 3.7.

NOTES:

1) When selecting an installation option, consideration should be given to the increased electrical

consumption of the furnace fan.

2) The HRV fresh air supply duct to the return air plenum shall be connected at a sufficient distance

upstream of the plenum connection to the furnace. This allows proper mixing and ensures appropriate

air temperature at the furnace heat exchanger in cold weather. For fuel-fired mid and high efficiency

furnaces a minimum temperature of 15.5º C (60º F) is recommended at the heat exchanger. (Check the

furnace manufacturer’s specifications).

2.2.4 Installation Supplies, Standard Issue Items

The HRV comes equipped with:

Filters

Anti-Vibration Straps

Heat Recovery Core

Drain Hose Assembly

Connections for timers, remote controls, furnace interlock

2.2.5. Control Options (sold separately)

Windsor mechanical control (WIN-1)

Windsor 20 minute timers -up to 6 each system (WIN-20)

2.3. Ducting to The Outside

Between the weather hoods and the HRV you must use fully insulated ducting with an integrated

vapour barrier. Insulated ducting with an integrated vapour barrier must also be used on all runs

passing through unheated areas. This will avoid condensation problems and energy losses.

The minimum RSI value of insulation should equal that of the local building codes.

2.3.1. Weather Hood Installation

1. Insulated flex duct slides over the

galvanized sleeve of the weather hood.

2. Use sheathing tape (red) to join the inner

duct to the hood's sleeve.

3. Tape the vapour barrier to back of the

hood without compressing the insulation.

Caulk or foam seal around the collars and

hoods to eliminate air and water leaks.

4. Locate the hoods for easy access to the

bird screen for cleaning purposes.

Make the insulated duct that connects the weather

Rev. December 19, 2008 Page 5 of 19

CEA15

-R

hoods to the HRV as short as possible to minimize airflow restrictions. Avoid sharp bends and stretch

out the inner lining of the flex duct as much as possible to reduce static pressure and maximize airflow.

For runs over 12’, increasing flex diameter 1” to next size up will reduce pressure drop in the duct.

2.3.1.1. Locating the Weather Hoods

There should be a minimum of 6’ (feet) of separation between the fresh air and exhaust hoods. Supply

hoods should be a minimum of 18” (inches) above the ground level. Exhaust hoods should be at least 4

“(inches) above the ground level. Holes through the wall should be 1” larger than the collar on the

hood. Fresh air hoods must be 3’ away from any other appliance exhaust vent or furnace vent.

In addition ASHRAE Standard 62-99 recommends the following. Ventilation systems should be

designed to prevent the reintroduction of exhaust contaminants, condensation or freeze-ups and growth

of microorganisms. Make-up air inlets and exhaust air outlets shall be located to avoid contamination of

the makeup air. Contaminants from sources such as cooling towers, sanitary vents, vehicular exhaust,

and street traffic should be avoided.

2.4. Mounting & Noise Control

For maximum efficiency, the HRV should be installed in a heated area. The HRV is designed to be hung

from the ceiling by way of the anti-vibration straps supplied. Avoid hanging the HRV directly below a

bedroom or other quiet area.

2.5. Port Configurations

1. FROM OUTSIDE - Insulated flex pipe

2. TO SPACE - Non insulated pipe

3. FROM SPACE - Non insulated pipe

4. TO OUTSIDE - Insulated flex pipe

5. DEFROST IN (CEA18 ONLY)

6. DEFROST OUT (CEA18 ONLY)

Rev. December 19, 2008 Page 6 of 19

CEA20-D

Connecting To Other Equipment - Residential Applications

Your Nu-Air HRV is not intended to be connected to other equipment or appliances. Interconnection

with a forced air furnace duct system is permissible; refer to sections 2.2.2 through 2.2.3.1 and section

3.7.

2.6. Ductwork

Duct runs should be straight with a minimum of bends and elbows. Joints should be tight fitting and

sealed with duct tape or duct sealer. Install the two balancing dampers (supplied) in the supply air and

return air ducts close to the unit and 12” from an elbow or flow collar.

RECOMMENDATION: Use galvanized duct

whenever possible. Although flexible duct can be used,

its use should be restricted to areas indicated (outside

hoods and unheated spaces).

Ducting must be supported according to the manufacturers

specified hanger system and intervals.

RECOMMENDATION: An engineer or other qualified

person should design the duct system.

2.7. Drain Connections

Access to a drain or sump is required to handle the HRV condensate. Care should be taken to run the

condensate tube where it cannot freeze.

For best results, Nu-Air recommends the following steps be followed when installing drain kits on residential

HRV's.

1. Apply the O-ring supplied to the flange of each drain spout (A)

2. Insert the drain spouts through the holes in the drain pan (B)

3. Use the speed nut to tightly secure the drain spout

4. Cut two lengths of drain hose (E) long enough to avoid kinking

5. Attach the hose to the drain spout by sliding it over the spout until it is tight to the bottom of the speed nut.

Repeat for the other side

6. Secure the hose to the spout with the plastic tie wraps (D)

7. Install the Tee (F) in either of the two ways shown in the drawings below

8. Attach the free end of the hose to the left fitting. Repeat for the other side

9. Use the remaining hose to form a "P" trap and terminate at the top of the tee

10. Pour approximately one cup of water into the drain assembly to form an air seal. This prevents gasses

from being drawn into the HRV

Rev. December 19, 2008 Page 7 of 19

2.8. Balancing the System

Balanced air flow between the supply and exhaust air streams is essential to the

performance of an HRV. The equipment we recommend for balancing your system is

easy to use, reliable and one of the most cost efficient flow balancing, measuring

systems available.

Once the HRV system is installed and the vapour barrier is completed, ensure the

following:

Close all windows, doors and fireplace dampers

Turn off any exhaust systems such as dryers, range hoods, bath fans and central

vacuums.

The forced air furnaces should operate at continuous low speed.

Use set-screws to lock both balancing dampers to the fully open position.

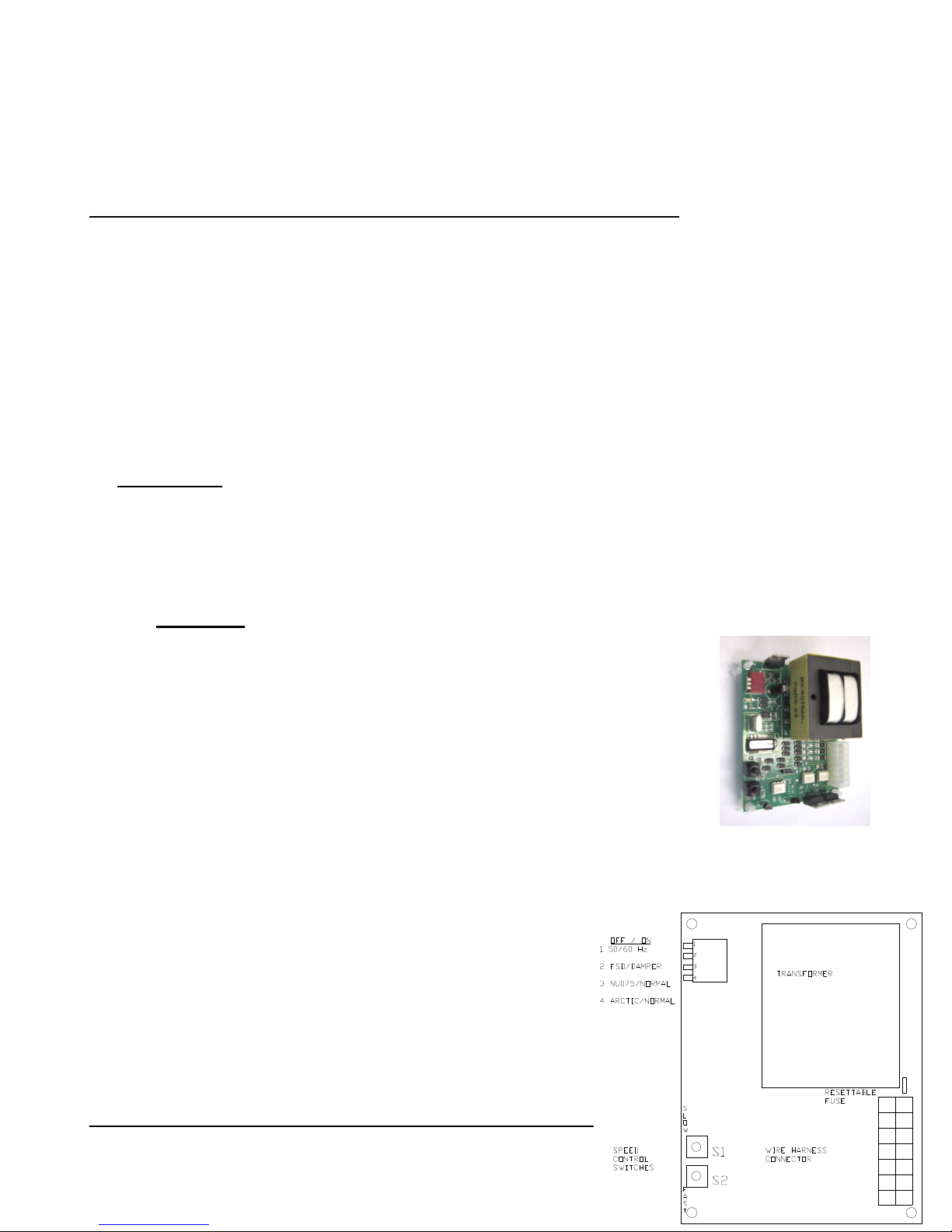

To balance the HRV, you will need a device to measure air flow. It is recommended to

use either a magnehelic gauge or an air meter, both of which are available from NuAir. Depending on the device you are using, follow one of the two procedures below:

Magnehelic Gauge

1. Disengage one end of the exhaust flexible duct connector in the main duct before any branch ducts

and push the duct back into itself. Insert the flow grid and tape the joint between the flow grid and

ductwork.

2. Set the HRV on high speed. Mount the magnehelic gauge level and plumb. Join the hoses from the

flow grid to the magnehelic gauge. The needle of the magnehelic gauge should read positively.

Switch hose connections if the needle falls below zero.

3. Ensure again that the balancing dampers are fully open. Record reading from gauge. Repeat the

procedure for the supply duct.

4. Go back to the duct with the higher reading and adjust the balancing damper until

the supply air is equal to the exhaust air reading.

Air meter

1. Drill a ¼” hole in both the supply and exhaust ducts on the warm-side of the

machine at least 12” away from the HRV and any elbows, tees, etc.

2. Set the HRV on high speed and ensure once again that both balancing dampers

are set in the fully open position with a set-screw.

3. Take a pressure reading in each duct and record the results.

4. Go back to the duct having the higher reading, and damper the airflow down until

the pressure reads to within 10% of the other air flow.

5. Use tape to reseal the holes.

6. To convert pressure readings to airflow (cfm or L/s) refer to the instructions and

table included with the air meter.

Rev. December 19, 2008 Page 8 of 19

For residential applications you should have a minimum ventilation capacity of 10 cfm (5 L/s) per room.

The chart that accompanies the flow grid calibrates pressure readings to airflow.

Refer to ASHRAE Standard 62 for acceptable ventilation rates in commercial buildings.

Calculating TVC (Total ventilation Capacity) for Residential Applications

• 20 cfm for the master bedroom

• 20 cfm for an unfinished basement

• 10 cfm for each other room in the house

Add these together to arrive at your TVC.

This method is called the “Room Count Method” and is part of CSA F326 (Residential Mechanical

Ventilation Systems). 0.3 air change per hour is no longer used.

Air meter available from Nu-Air wholesalers. (Part #100460)

Balance the HRV in less than five minutes.

3. CONTROLS

Your machine is equipped for remote controls. Options include humidity sensing, off-on control,

intermittent & continuous modes, as well as high speed control from the dehumidistat or timer(s). You

can also interlock the furnace blower to the HRV. Various means of controlling the system are described

below.

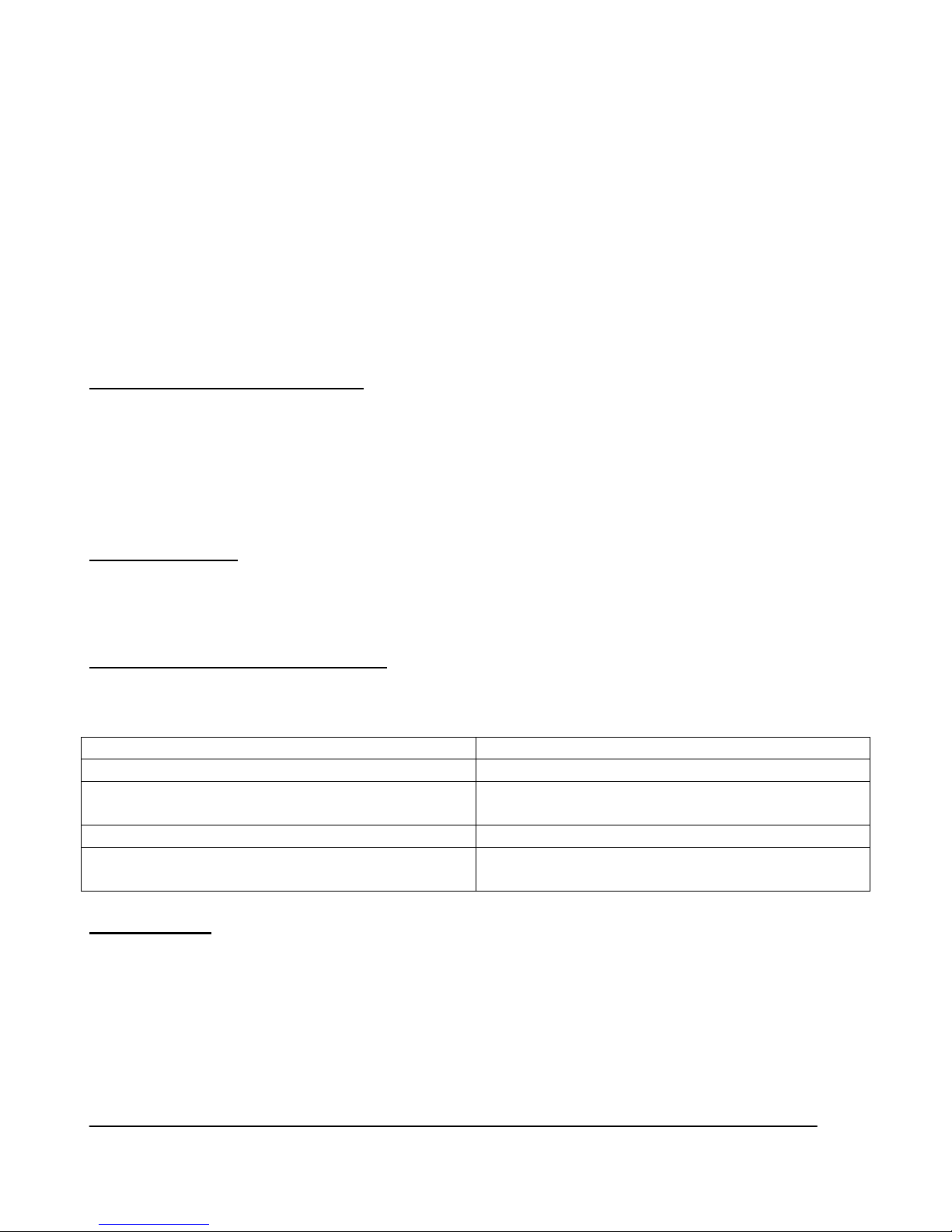

3.1. Features:

• Powerful transformer – up to six (6) WIN-20 Timers can be connected in

parallel

• Field selectable defrost cycle for northern applications

• Self-resetting fuse to protect the board against mis-wiring

• Variable low speed control – HRV low speed can be adjusted between a

minimum of 40% and a maximum of 70% of high speed. See below for

explanation.

• Optional setting for 220V/50Hz geographic areas

The following sections outline the features and explain the board in greater

detail. In most applications, the factory settings for speed control, defrost, electrical service and

fan/motor type will never need to be changed. A qualified technician must do any service work done

within the electrical panel of the HRV.

DIP Switches:

An array of four (4) two position switches are located at the top

left corner of the board. The "On" position for each switch is

labeled and corresponds to down (i.e. towards the board surface).

The "Off" position is up or away from the board surface. The

switches are labeled 1-4 and their settings determine the

following conditions.

Rev. December 19, 2008 Page 9 of 19

# 1 Frequency Setting - Set to ON (down) for 60 Hz service. This includes all of North America. Set to

OFF (up), for electrical grids using 50 Hz.

#2 Defrost Type - ON (down) is for damper/recirc. models. OFF (up) is for fan shut down defrost

models.

#3 Fan Selector - OFF (up) is for the NU075 machine only. All other models are set to ON (down).

#4 Arctic Mode Selector - for design temperatures of -30 0C (-22 F) and colder for Damper/recirc.

defrost machines, or design temperatures of –20 0C (-4 F) and colder for FSD defrost machines, set to

Off (up). Otherwise set to ON (down). When the machine is set to operate in arctic mode, the machine

will increase the amount of time spent in defrost.

Variable low-speed motor control:

For field adjustment of the low (continuous) ventilation rate, pushbutton switches S1 & S2 are used.

These are located on the bottom left of the board. S1 is labeled DEC (decrease) and S2 is labeled INC

(increase). Each push of S1 or S2 decreases or increases low speed by increments of 3%. Low speed is

set at 40% of high speed in the factory by default and cannot be lowered beyond this point. The

maximum low speed setting is approximately 70% of high speed. Settings are stored in the board’s

memory, eliminating the need to reset the speed after a power failure for instance.

Self-resetting fuse:

Field mis-wiring of timers or dehumidistats may cause the fuse to trip. If this happens, remove the

control wires and allow the fuse to reset. This may take a few minutes. Check your manual for proper

wiring connections.

Troubleshooting using the PCB light:

There is a small green light on the board located just below the DIP switches. This light will either be

solid or pulsing and is an indicator of machine status. It can be used to assist in troubleshooting.

Machine State Light Status

Machine has no power Off

Power to the board, but main power switch is off

or the door switch is tripped

Machine running normally in low speed Pulsing – on for one second, off for one second

Machine running in high speed due to a call from

dehumidistat, timer, or defrost cycle

Defrost Cycles:

Fan Shutdown Defrost – On FSD machines, the temperature sensor is located in the fresh air stream

before the core. When this air is measured to be below freezing, a timed defrost cycle is initiated. The

fresh air fan motor is stopped for 4 minutes (both normal and arctic modes). The exhaust fan motor

continues to operate, drawing warm air from the building through the core. After 4 minutes, the fresh air

fan motor is started again and runs for 20 (normal mode) or 12 (arctic mode) minutes. This cycle is

repeated until the temperature of the exhaust air stream is measured to be above freezing.

Two short pulses approximately every 5 seconds

Solid

Rev. December 19, 2008 Page 10 of 19

|

|

|

COM

Damper Defrost – On damper/recirc. models, the temperature sensor is located in the fresh air stream

before the core. When the outdoor air temperature is measured to be below freezing, a timed defrost

cycle is initiated. The machine runs normally for 36 (normal mode) or 20 (arctic mode) minutes and then

shuts off the fresh air by closing a damper for 4 (normal mode) or 5 (arctic mode) minutes. This timed

cycle repeats until the temperature of the outdoor air is measured to be above 0 C. Note: When the

machine has power but is not turned on the damper automatically closes off the fresh air port to prevent

unwanted drafts while the machine is not in operation.

Change from previous board-versions: When in defrost mode, the fans operate in high-speed. A call from the timer now lasts

20 minutes total, even if the machine is in defrost (previous versions would wait until defrost was complete and then resume

the timer).

3.2. Machine ON/OFF Switch

Switch to the ON position " | " to enable operation of the HRV.

HUM

LED

3.3 Standard Dehumidistat - Part # DSTAT-1

With this standard basic control the system is designed to operate

on a low speed for continuous ventilation with intermittent high

speed for moisture on air quality control. The dehumidistat will

switch the HRV to high speed when the relative humidity of the air

around it exceeds its set point. When the humidity falls below the

set point, the machine drops out of high speed.

INT"

CONT"

SWITCH

24 V

3.4. Windsor Control (Part # WIN-1)

The Windsor Dehumidistat Control incorporates a 3-position switch from which the operator can select

three operating modes.

1. OFF - disables all functions.

2. STANDBY - HRV is on stand-by (intermittent). High speed ventilation on demand from the

dehumidistat, or remote timers. i.e. Auto-Off

3. CONTINUOUS - continuous low speed ventilation. HRV cycles to high speed on demand

from the dehumidistat or timers.

The two position switch:

Constant - locks the motors in High speed

Standard – normal operating mode enables functions 2 and 3 above.

Wires from the control are colour coded as follows: black/HUM, green/INT, yellow/CONT, red/24V

COM. Remove factory installed jumper wire at CONT and 24 V COM. Four-conductor wire is used.

3.5. Windsor Timer (WIN-20)

Install in bathrooms, kitchens, workstations or other locations where high-speed ventilation control is

needed. The machine will run at high speed for twenty (20) minutes and then return to its normal

operating condition.

Rev. December 19, 2008 Page 11 of 19

Up to six (6) timers can be connected in series or parallel. Match terminals on back of switch to

terminals on HRV. "SWITCH", "LED" and "24 V COM (PWR)". When engaged, the HRV will run in

high speed for twenty minutes. Three-conductor wire is needed.

3.6 Spring Wound Timers

Connect to "HUM" and "24 V COM" using two-conductor wire. To select between continuous low

speed operation or intermittent high speed when no other control is being used, use a jumper wire

connection as described in 3.2 above.

3.7 Remote On/Off Switching

Basic RNC type control can be achieved using a standard light

switch. Add a jumper to 24 V COM and CONT for

continuous low speed. For manually switched high speed,

connect a switch between HUM and 24 V COM.

Remote On/Off Switching With Internal Dehumidistat

For continuous low with automatic humidity control, connect the on/off switch to "CONT" and "24V

COM".

3.8 Furnace Interlock

To interlock the furnace blower with the HRV, supply 24 V in and out from

the furnace controls R & G lines to HRV terminals labeled R&G.

NOTE - For a furnace connected to a cooling system: When using the built-in

furnace interlock relay on the HRV in conjunction with certain older mercury bulb

thermostats, energizing the R and G terminals will also cause 24 volts to be sent

through the Y terminal which will initiate the outdoor condenser. If this is the case,

there are two possible solutions. Either upgrade the thermostat to a digital type

which does not have Y connected to G internally, or install the isolation

relay as shown in the wiring diagram at right.

4. Arctic Defrost Mode

A field selectable Arctic Defrost Mode is available on all models and

should be used for temperatures below -20 0C (-4 F) for fan

shutdown defrost models and areas with temperatures reaching

below -30 0C (-22 0F) for damper defrost or recirculation models. Consult Nu-Air Ventilation Systems

Inc. or your nearest wholesaler for more information.

5. START-UP

• Ensure the controls are connected in accordance with Section 3.

• For electrical hook-up, plug into a 120 volt receptacle.

• Ensure that the machine is piped to an adequate drainage source, i.e. through the drain hose

supplied.

IN (R) OUT (G)

FURNACE INTERLOCK

Rev. December 19, 2008 Page 12 of 19

6. OPERATING HINTS

Set the dehumidistat at the desired level. Look for signs of excessive humidity or dryness. Let your

windows be your guide. As outdoor temperatures decrease – the comfortable humidity level also

decreases.

Winter Operation – 40% - 50% is recommended. Lower settings may be necessary in colder zones to

keep windows free of condensation.

Spring/Fall Operation- 50% - 60% is recommended

Summer Operation – On extremely humid days it is best not to run the HRV during the day. At night

turn the machine on high speed using the dehumidistat. This will help keep your home cool and

your basement fresh. In the morning, turn the machine off again. The normal summer setting is 55%

- 75%. Alternatively plug the HRV into an electrical timer set to switch on/off at desired intervals.

7. MAINTENANCE

CAUTION: Disconnect power before servicing.

7.1. Filters:

Dirty filters can reduce ventilation efficiency, result in unbalanced airflow and damage or shorten the

life of the motors. Clean every three months. Polyester filters should be replaced annually. Permanent

electrostatic filters are available from your Nu-Air dealer. Filters remove easily by opening the front

cover.

7.2. Fans

When cleaning the filters, take the opportunity to vacuum any interior surfaces including the fan blades.

No other service is required as these fans are designed to operate continuously without lubrication.

7.3. Condensate Drain

Twice per year wipe clean the condensate drain pan. Check the condensate drain and tubing to ensure

they are free flowing. The tubing must have an "S" or loop that traps a quantity of water to prevent air

from entering the HRV via this tubing.

7.4. Core

The core (located behind the cover) should be removed and cleaned at least once a

year, using a mild detergent in cold water (i.e. Arctic Power). To remove the cover of

the machine, unlatch the two latches; slide the door to right to release from hinges.

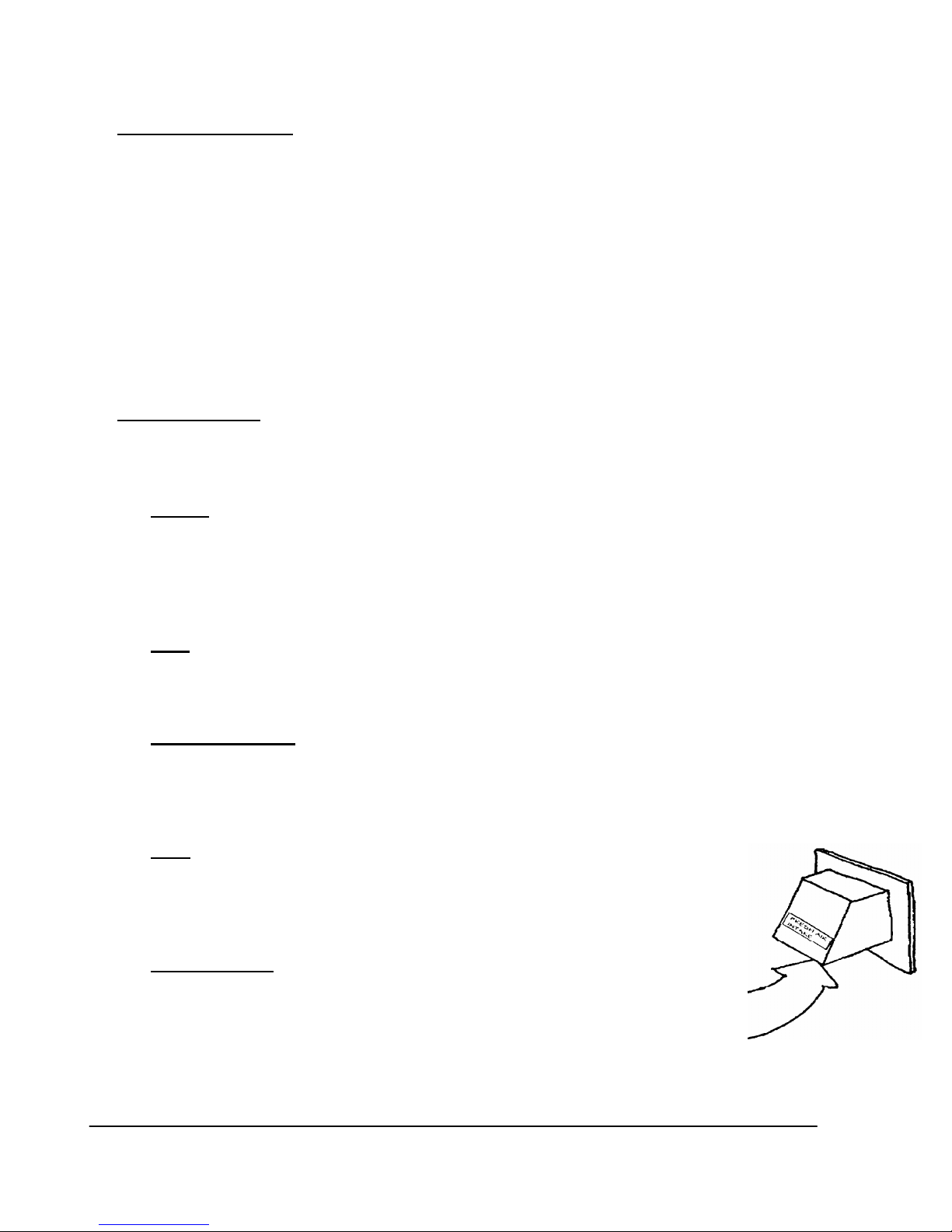

7.5. Exterior Hoods

Regularly check the outside vents and clean any obstructions such as grass, leaves or

other debris. Do not replace the screen with mesh smaller than 1/4" as this will restrict

airflow. During winter operation, ensure snow and frost does not build up and restrict

or block openings.

Rev. December 19, 2008 Page 13 of 19

7.6. Grills & Duct Work

Clean the grills when they are dusty or greasy with soap and water. Check for punctures in the

insulation jacket on the fresh air and exhaust air ducts. Repair any punctures using foil tape.

8. ANNUAL SERVICING

Your HRV should undergo annual general servicing by an accredited contractor. This servicing should

include the following:

a) The six maintenance items above.

b) A general check for proper operation. Controls and electrical connections should be inspected.

c) Verification that intake and exhaust air flows are properly balanced.

d) Re-balancing as necessary.

Rev. December 19, 2008 Page 14 of 19

9. TROUBLE SHOOTING

SYMPTOM EXPLANATION ANSWER

Humidity levels too low.

Humidity levels too high.

House dry/basement wet.

Dehumidistat is not

working.

Frosting up of HRV and/or

Duct(s).

Supply air feels cool.

Outside duct has ice build

up or condensation.

Water in the bottom of

HRV.

Poor air flow(s)

•••• HRV air flows incorrectly balanced.

•••• Dehumidistat control set too low.

•••• Lifestyle of the resident(s).

•••• HRV air flows incorrectly balanced.

•••• HRV not properly sized for the application

•••• High humidity areas not ventilated properly.

•••• Lifestyle of resident(s).

•••• Dehumidistat is not working.

•••• High humidity during summer months

•••• Incorrect connection of outside low voltage

wiring between HRV and Dehumidistat.

•••• HRV air flows incorrectly balanced.

•••• HRV defrost system is not working.

•••• HRV air flows incorrectly balanced.

•••• Improper location of supply grills.

•••• Extremely cold outside temperatures.

•••• Moving air feels cooler than it actually is.

•••• Improperly installed vapour barrier around

insulated duct.

•••• Drain pans are plugged.

•••• Incorrect connections of HRV’s drain lines.

•••• HRV is not level.

•••• Drain lines plugged.

•••• HRV heat exchange core improperly

installed.

•••• HRV airflow incorrectly balanced.

•••• Filters need to be cleaned.

•••• Mesh on outside hoods needs to be cleaned.

•••• Grills are closed.

•••• Inline dampers are closed.

•••• Low power supply.

•••• Wrong-size ducting.

•••• Under-sized HRV.

•••• HRV is not working.

•••• Balance Air Flow(s).

•••• Increase Dehumidistat.

•••• Humidifiers may need to be added.

•••• Balance airflow.

•••• Set dehumidistat.

•••• Cover pools etc. when not in use.

•••• Avoid hanging clothes to dry, storing wood and

venting clothes dryer inside.

•••• Install a programmable timer on 12-hour cycle. On

at night. Off during the day.

•••• Partially close some grills upstairs, open grills in

basement.

•••• Check control wiring for short

•••• Check wall switch for correct connection.

•••• Check wires are connected to proper terminals at the

HRV

•••• Balance HRV.

•••• Install back draft dampers.

•••• Check defrost system.

•••• Note minimal frost build up is expected on cores

before unit initiates defrost cycle function.

•••• Balance HRV.

•••• Locate grills high on walls or in ceiling.

•••• If supply air is installed into return line of furnace,

furnace fan must run continuously on low speed.

•••• Tape all joints.

•••• Ensure that vapour barrier is completely sealed and

insulated.

•••• Look for kinks in the line.

•••• Check water drain connections.

•••• Ensure that water drains from pan.

•••• Tape all joints.

•••• Use proper air flow measuring equipment.

•••• Open grills.

•••• Remove obstructions in duct(s), hoods(s), and

grill(s).

•••• Balance air flows.

•••• Clean filter.

•••• Have a professional look at the system.

IMPORTANT!

QUALIFIED TECHNICIANS SHOULD DO ALL OTHER SERVICING.

Rev. December 19, 2008 Page 15 of 19

10. ELECTRICAL SCHEMATICS

10.1. WINDSOR Wall Controls Wiring Diagram

WIN-20

WIN-1

Rev. December 19, 2008 Page 16 of 19

10.2. 24V Standard D-Stat Wiring Diagram (Part#DSTAT-1)

NOTE: Jumper must be removed if WIN-20 timers are installed

Rev. December 19, 2008 Page 17 of 19

10.3. Damper Defrost and Re-circulation Defrost

Rev. December 19, 2008 Page 18 of 19

11. WARRANTIES

Your NU-AIR Contractor Edition Heat Recovery Ventilator Transferable Warranty

For Canada and United States

Should your NU-AIR Contractor Edition Heat Recovery Ventilator (HRV) cease to function within two

(2) years for models CEA15-R, CEA18-C, CEA20-D of the date of original purchase (effective January,

01, 2007) due to defective material or workmanship of the product, NU-AIR Ventilation Systems Inc.

will supply a new or rebuilt part FOB Factory to replace the defective part. Delivery, installation, and

labour cost would be your responsibility.

Fifteen Year HRV Core Warranty

If the aluminum core in your NU-AIR CEA Series Heat Recovery Ventilator fails due to a defect in

material or workmanship NU-AIR Ventilation Systems Inc. will supply a new core FOB Factory to

replace the defective part. Delivery and labour costs are your responsibility.

Nu-Air warrants its ERV core to be free from manufacturing defects for a period of one year.

Warranty Limitations

The above warranty does not cover damage to the unit while in your possession (other than damages

caused by defective parts or material) due to the following: 1) improper installation or unreasonable use

of unit: 2) failure to provide reasonable and necessary maintenance. If the unit is put to commercial use

or application other than residential use, warranty is for a period of one (1) year.

P.O. Box 2758 Windsor, Nova Scotia Canada B0N 2T0

Phone: 902 798 2261 Fax: 902 798 2557

Email: nuair@nu-airventilation.com Website: www.nu-airventilation.com

Rev. December 19, 2008 Page 19 of 19

IIMMPPOORRTTAANNTT

READ AND FILL OUT REGISTRATION

CARD IMMEDIATELY

THIS IS YOUR WARRANTY REGISTRATION CARD

In order to properly validate your warranty, you must fill

out and return this card. Failure to register unit will

require you to present proof of purchase should the unit

This information provides us the means of proving the

date you purchased the product and also enables us to

notify you in the unlikely event of a service notification

or recall of the product.

IIMMPPOORRTTAANNTT

require service.

LISEZ ET REMPLISSEZ CETTE

CARTE D’INSCRIPTION

IMMÉDIATEMENT

VOICI VOTRE CARTE D’INSCRIPTION DE LA

Afin de valider votre garantie, vous devez remplir et

renvoyer cette carte. A défaut d’inscrire votre produit,

vous devrez présenter une prevue de la date d’achat si

le produit nécessite des réparations.

Les renseignements ci-joints nous fourniront la prevue

de votre date d’achat du produit et nous permettront

également de communiquer avec vous si, pour une raison

fortuite, nous devoins vous faire parvenir un avis de

réparation ou de rappel du produit.

GARANTIE

PPRROODDUUCCTT WWAARRRRAANNTTYY RREEGGIISSTTRRAATTIIOONN

CCAARRTTEE DD’’IINNSSCCRRIIPPTTIIOONN DDEE LLAA GGAARRAANNTTIIEE DDEE VVOOTTRREE

PPRROODDUUIITT

FIRST NAME LAST NAME

NOM DU PRÉNOM ________________________ NOM DE FAMILLE______________________________

ADDRESS

ADRESSE _________________________________________________________________________________

CITY

VILLE ____________________________________________________________________________________

PROVINCE POSTAL CODE DATE PURCHASED

PROVINCE ___________ CODE POSTAL ______________ DATE D’ACHAT __________________

MO/MOIS DAY/JOUR YEAR/AN

TELEPHONE

TÉLÉPHONE (___________) _______________________________________________________________

DEALER’S NAME

NOM DU VENDEUR ________________________________________________________________________

MODEL NUMBER

NO. DU MODÈLE __________________________________________________________________________

SERIAL NUMBER

NO. DE SÉRIE ______________________________________________________________________________

P.O. Box 2758

Windsor, Nova Scotia

Canada B0N 2T0

Ph: 902-798-2261

Fax: 902-798-2557

Loading...

Loading...