Page 1

PRODUCT DATA

PureSound

SPEAKER TEST SYSTEM

Key features for a modern, state-of-the-art test system are speed, simplicity, reproducibility and

automation in a factory environment. The PureSound speaker test system exactly answers these

needs. The key element is the unique Rub & Buzz defects analysis with a 100% correlation to the

human ear. It replaces the subjective human ear perception against an objective, reliable and repeatable test feature.

The PureSound speaker test system is based on the FX100 Audio Analyzer, operated via the PCbased turnkey production software RT-Speaker. It is tailored for the total quality control of single

components, pre-assembled parts or finished products.

Key Features:

• Speed: Cycle time down to 1 second based on speaker

type.

• Accuracy: The FX100 Audio Analyzer is based on reliable technologies providing accurate and consistent test

results.

• Rub&Buzz: Superior Rub&Buzz defects detection with a

100% correlation to the human ear. Objective Rub&Buzz

testing replaces subjective golden ears.

• Noise Immunity: Maximum performance in noisy production environment using dedicated technologies.

• System Integration: Tailored for automated production

lines with PLC interface, barcode reader or remote control via TCP/IP commands; offering full data logging and

statistics (e.g. Cpk, Ppk).

• Multi-Channel Operation: Testing two DUTs in parallel or

multiple DUTs sequentially without any operator interaction.

Multimedia speaker testing

Mobile Devices

www.nti-audio.com

Pro Audio Loudspeaker

19Nov 20 Page 1

Page 2

PRODUCT DATA

INTRODUCTION

Electro-acoustical transducers naturally bear a particularly high error rate. Sorting out faulty devices

in an early production stage increases the overall yield and reduces the cost of waste material and

optimizes the quality of the manufactured goods. The FX100 Audio Analyzer and the production

software RT-Speaker form together the PureSound Speaker Test System comprising exactly the

required features for quality control and production line testing.

Basic Speaker Test Configuration

Test Functions:

• Frequency Response

• Sound Pressure Level dBSPL

• Rub & Buzz analysis with100% correlation to the human ear

• Impedance Response & Resonance Frequencies

• Distortion THD, THD+N, 2nd - 35th harmonics

• Speaker Polarities

• Thiele/Small Parameters

• DC Resistance

PureSound detects any audible manufacturing flaws of speakers or transducers, such as air-leaks,

misaligned coils, rubbing voice coils, loose particles, touching wires etc.

www.nti-audio.com

19Page 2

Page 3

PRODUCT DATA

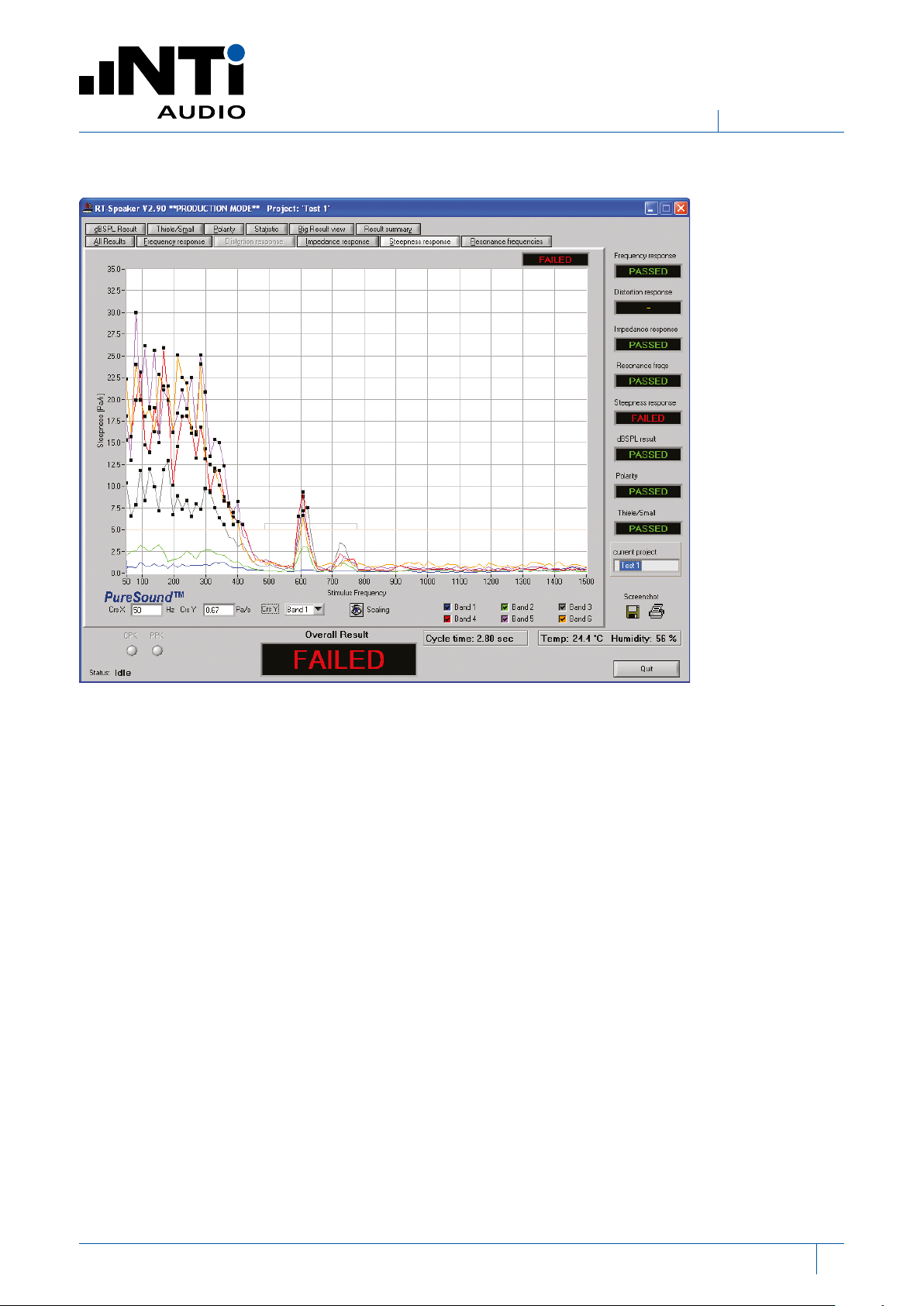

SIMPLE AND INTUITIVE OPERATION

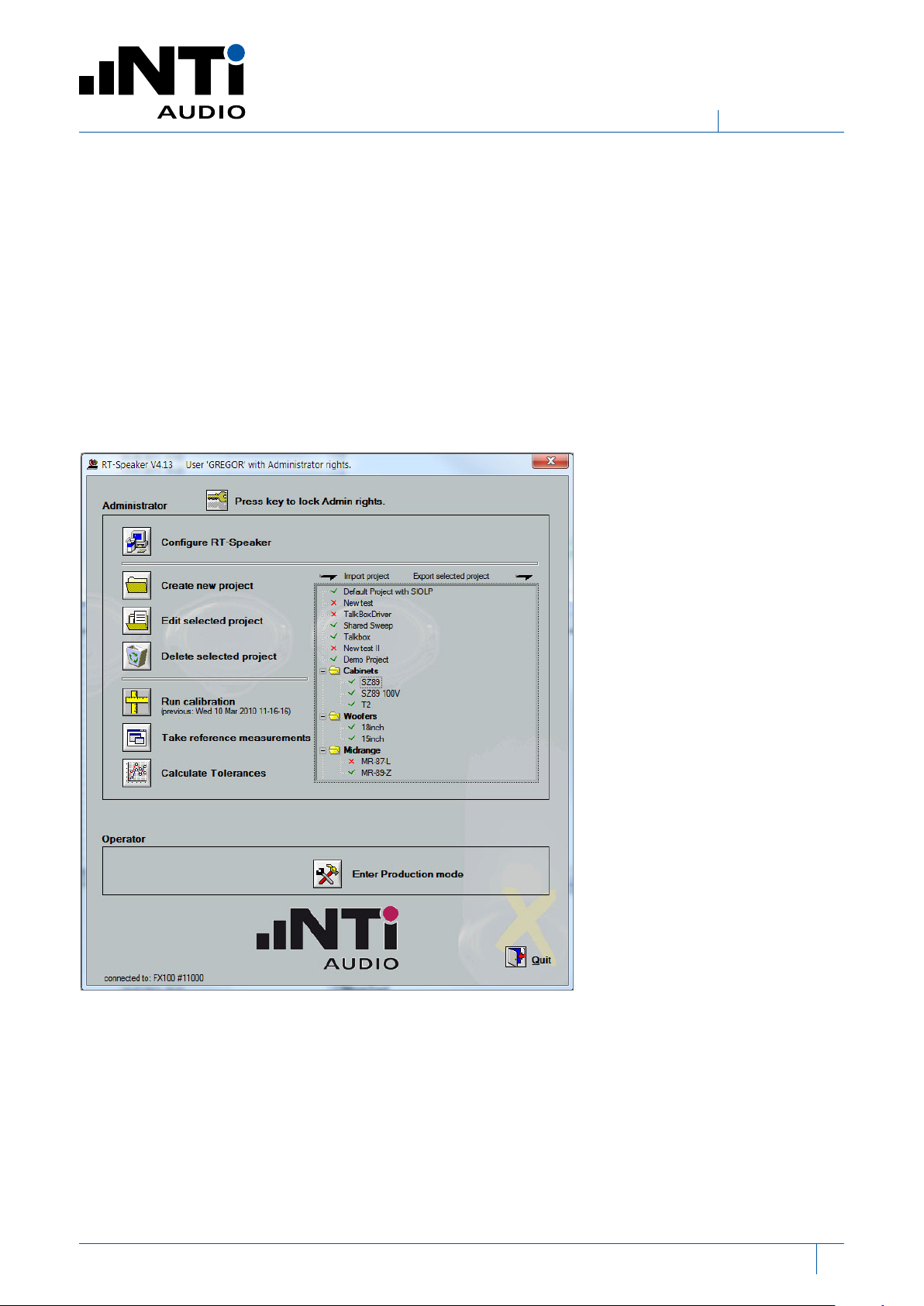

The PureSound speaker test system is setup and configured within a few minutes. The FX100 Audio

Analyzer communicates with the PC-software RT-Speaker via the USB interface. RT-Speaker provides an intuitive user interface for test setup and display of all measurement results.

The main menu guides the production administrator through the basic system configuration on to

the test parameter settings, which are contained in a single “Project“ folder. After an automated calibration sequence the reference measurements can be recorded, tolerances automatically calculated

and the Production Mode started. The RT-Speaker software provides a simple PASSED/FAILED

readout or a detailed view of all measured speaker parameters.

PC-Software RT-Speaker

The key element is the Rub&Buzz test technology with a unique and reliable defects analysis. The

cycle time may be set down to 1.0 second (based on the speaker type) for a complete test including

the outstanding Rub&Buzz analysis.

www.nti-audio.com

19Page 3

Page 4

PRODUCT DATA

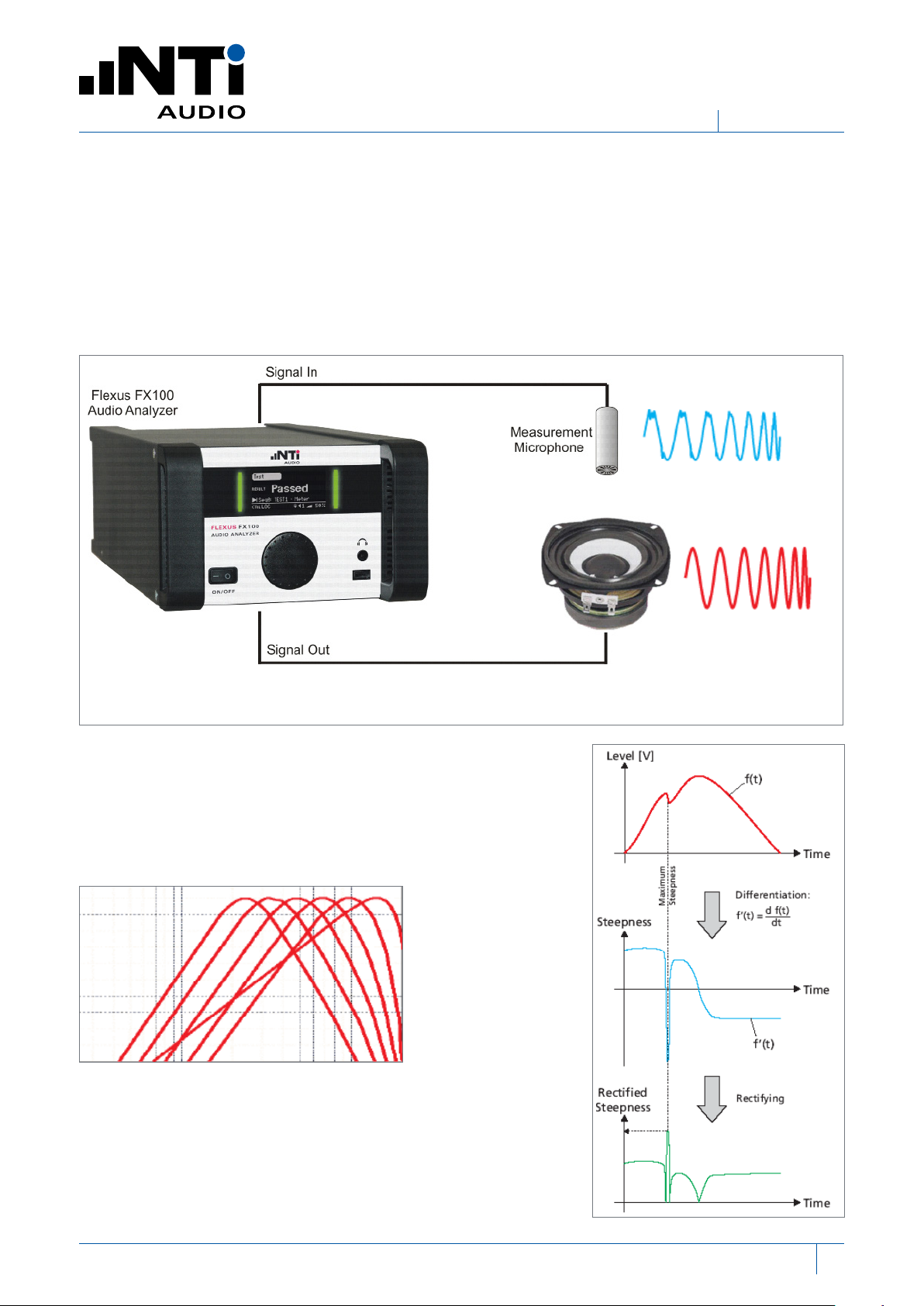

UNIQUE RUB & BUZZ TEST IN TIME DOMAIN

The patented measurement technology enables the PureSound speaker test system to conduct fast

and reliable Rub&Buzz tests with a perfect equivalence to the human “Golden Ear”.

TECHNOLOGY:

Gliding chirp triggers

all frequencies

The measured signal is first processed with a filter bank, simulating the psycho-acoustic perception of the human ear. Then

the Transient Steepness Analysis is carried out by differentiation and rectifying the time signal. The result displays all sound

energy changes audible to the human ear.

PureSound filters

www.nti-audio.com

19Page 4

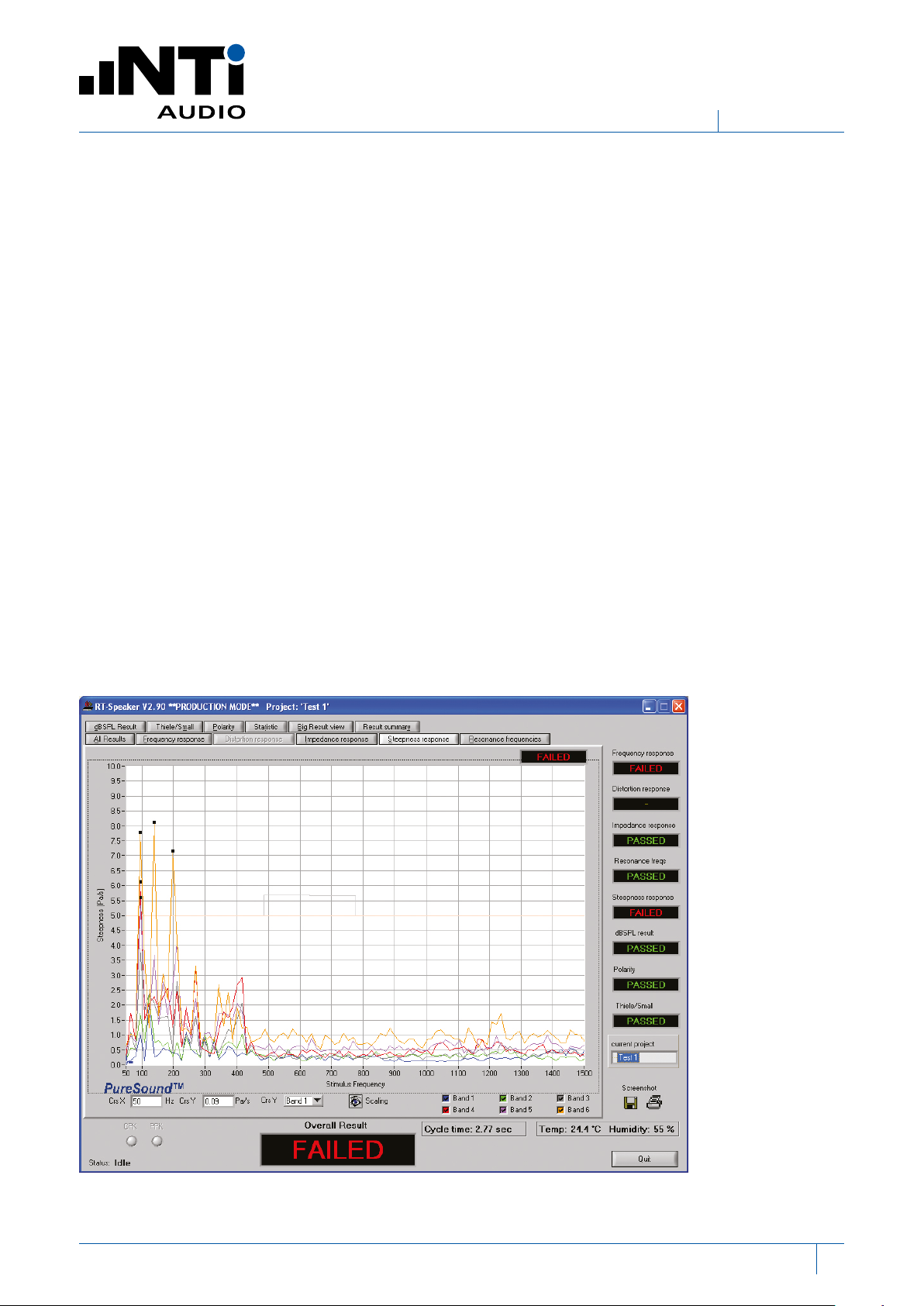

Page 5

100% CORRELATION TO HUMAN EAR

The NTi Audio Rub & Buzz test technology is the outstanding approach for perceptual audio testing in the time domain. The algorithms model the human ear

as a transient analyzer, effectively measuring every audible manufacturing imperfection with an unmatched correlation to the acuity of “Golden Ears” – “You

measure what you hear”. This correlation allows cost saving and much improved

test accuracy by replacing the subjective “Golden Ear“ with a successful and

objective Rub & Buzz test.

In the past “Golden Ear“ tests have been carried out based on the judgment of

individual persons, which may even vary over time as the human ears tire during

the day. PureSound offers a 100% repeatable, objective Rub&Buzz test at any

location around the globe.

PRODUCTION NOISE IMMUNITY

PRODUCT DATA

PureSound measures Rub&Buzz even in noisy factory environments. An effective, advanced noise cancellation algorithm eliminates non-correlating signal

components from the test signal, thus immunizing the measurement process

against factory noise. The typical test time is one second.

Rub & Buzz analysis: Loose particles

www.nti-audio.com

19Page 5

Page 6

PRODUCT DATA

Rub & Buzz analysis: Rubbing voicecoil

DETECTING SLIGHTEST RUB & BUZZ DEFECTS

PureSound provides a complete speaker or transducer characterization, detecting even the most subtle manufacturing flaws of speakers or transducers,

such as air-leaks, misaligned coils, rubbing voice coils, loose particles, touching

wires or defects from any other cause, also supporting the automatic qualification of the nature of these defects.

PURESOUND IN R&D

PureSound acquires “fingerprints” of speaker non-linearity’s to compare developments in every design stage over its entire life. Such a continuous Rub &

Buzz measurement monitors the objective quantification of design changes to

audible effects, minimizing design flaws. As lower the measured Rub & Buzz

is in the development stage as better are the test results of the final product.

Furthermore in the supplier selection process different speaker-samples can be

compared against each other in order to choose the sample with lowest Rub &

Buzz for the final product.

www.nti-audio.com

19Page 6

Page 7

PRODUCT DATA

Rub & Buzz analysis: PASSED loudspeaker

COMPARING PURESOUND AGAINST CONVENTIONAL METHODS

Rub & Buzz defects are audible for the human ear, but hard to measure with

older measurement techniques. Tests carried out in the frequency domain, such

conventional FFT spectrum analysis or high order harmonic tracking filters, typically fail to discriminate short instantaneous Rub&Buzz effects like loose particles. The test results may not correlate with the human hearing at all since the

energy content of the signal caused by the defect is not sufficient and consistent

for FFT measurements. PureSound is the solution for today’s quality control. It

ensures the delivery of final-branded units without audible defects, reduces warranty returns and prevents unnecessary shipping costs, missed deadlines and

customer claims.

Fast Measurements

The default measurements are carried out with a logarithmic sine sweep signal.

A dedicated technology ensures best noise immunity even in noisy production

environments.

www.nti-audio.com

19Page 7

Page 8

The fast sweep signal serves as stimulus for simultaneous measurements of:

• Frequency Response

• Sound Pressure Level dBSPL

• Impedance Response & Resonance Frequencies

• Distortion THD, 2nd - 35th harmonics

• Individual driver Polarities

• Thiele/Small Parameters

This highly accurate and repeatable set of measurements typically occupies the

device under test for one second. All completed measurements are compared

in real-time against user-defined tolerances for individual PASSED/FAILED decisions.

PRODUCT DATA

FREQUENCY SWEEP WITH TOLERANCE CLASSES

The smart “learn-mode” simplifies tolerance definition by feeding the system

with a representative set of one or more “Golden Samples”. The unique tolerance management derives its tolerance criteria automatically and supports up

to five different quality clusters, which may be user-defined in any language,

such as “Excellent”, “OK”, “Acceptable”, “Class 3” and “Reject”. This enables

the manufacturer e.g. to charge a premium for selected “Excellent” products or

match speaker pairs for stereo applications.

Frequency response measurement with absolute results

www.nti-audio.com

19Page 8

Page 9

Meeting individual customer requirements, the PureSound speaker test system

measures up to 5 different resonance frequencies, speaker polarities and sound

pressure levels at once. This is of great help e.g. for performance verifications

at speaker systems with woofer, mid-range or tweeters installed or ensuring a

minimum sound level at different frequencies or frequency ranges.

DISTORTION TESTING

The distortion measurement includes THD, THD+N, individual 2nd to 35th harmonic and sum of multiple harmonics. The non-linear behavior of the device

may be assessed simultaneously with the frequency response test or examined

via a separate sweep. All measurements are optimized for speed to maintain

maximized throughput for production lines.

Distortion measurements have been proven inadequate for reliable defects detection, its presence is not intended to replace the unmatched sensitivity and

accuracy of the PureSound Rub & Buzz measurement! Distortion is just another

useful tool valuable for correlation to R&D specifications, e.g. at sampling inspections.

PRODUCT DATA

Distortion analysis THD

www.nti-audio.com

19Page 9

Page 10

THIELE/SMALL PARAMETERS

The FX100 Audio Analyzer measures the Thiele/Small parameters DC-resistance

Rs, R, R0, Qms, Qes, Qts, C, L and df without extending test time. All parameters are tested with one very fast single sweep signal. The results are compared

against tolerance limits in real time for an accurate PASSED/FAILED test result.

The sensitive T/S parameters are an excellent monitoring base for the integrated

CPK/PPK module, effectively supervising the stability of the production process.

AUTOMATION IN PRODUCTION LINES

System integration into existing high volume production lines and connection

to host controllers is very simple, as the speaker test system supports remote

control via TCP/IP commands. The patented measurement algorithms have

been optimized for factory noise immunity. This maximizes your production line

yield and allows conducting the same measurement in R&D as well as in the

production floor. Measurements can be started by an external button or automatically as the speaker is connected. The FX100 Analyzer offers an integrated

DIO-Interface for automated operation, such as

PRODUCT DATA

• Connection to external PLC

• Test result indication to the operator

• External pre- or post-test actions independent of test result

• Automated splitting of PASSED/FAILED samples

• Individual bin splitting of different FAILED samples

Bins with

FAILED

SPL

Rub

Automated splitting in FAILED production bins

www.nti-audio.com

f0

19Page 10

Page 11

SERIAL NUMBER HANDLING

RT-Speaker offers manual and automatic serial number handling. Flexible bar

code interpretation extracts the model type and loads the corresponding project

file automatically. For example a widely varied mix of different speakers can be

tested sequentially without even touching the keyboard of the controlling PC.

ONLINE PRODUCTION MONITORING

Complete measurement setups can be exported from the customer or engineering PC and sent by e-mail to the assembly line reducing time and installation

efforts. The actual production test results can be monitored over the web around

the globe. An activated TCP/IP-link to a server gives direct access to measurements, pre-set tolerances and the production statistics.

PRODUCT DATA

DATA LOGGING

All test results are automatically stored as log-files, which can be opened with

e.g. MS Excel. This simplifies the utilization of spreadsheet or data-mining software. The user has the choice between single, batch, daily or weekly log-files

with individually specified logging data. This feature supports detailed quality

monitoring for after-sales service and simplifies data comparisons of returned

speakers, a valuable add-on for speaker manufacturers or rental companies.

STATISTICAL PROCESS CONTROL (SPC)

Statistical data is calculated on the fly while the production tests are running.

The detailed histogram, trend analysis and Cpk/Ppk values (=short/long term

production variation) provide a clear assessment of the currently manufactured

quality level.

Speaker parameters are very sensitive to changing environmental factors, such

as temperature and humidity. RT-Speaker offers detailed on-line correlation of

test results with the actual temperature & humidity using the optional Environmental Sensor. The trend monitor supports identifying failed speaker batches

due to environmental effects and highlights necessary calibrations or reference

sampling for maintaining reliable PASSED/FAILED test results at the same time.

www.nti-audio.com

19Page 11

Page 12

PRODUCT DATA

Statistical trend analysis correlated with the environmental temperature

Applications

BASIC SPEAKER TEST CONFIGURATION

The basic system configuration is quickly set up and ready

to go for measurements within a few minutes. For noisy production environments an acoustically shielded test-box is

recommended. The measurement microphone distance to

the speaker under test is commonly equal or higher than the

speaker diameter.

Regardless whether it is a passive or an active system, RTSpeaker evaluates the complete performance of the system

cabinet. All speakers can be tested at once or sequentially using various available test configurations.

In a passive system, the impedance measurement enables RTSpeaker to record the impedance plot and identifies multiple

resonance frequencies from several drivers.

M2010

FX100 Audio Analyzer with FX-SIP

www.nti-audio.com

19Page 12

Page 13

WOOFER TESTING

Woofers with large mechanical dimensions are challenging objects for quality control. The transfer function and acoustical

performance needs to be measured in axis from the front.

A woofer with its big membrane area and low frequency characteristics acts more or less like a piston with very large excursions. It is obvious that manufacturing defects are most audible close to the motor itself. The front microphone inside the

test box is somewhat shielded by the membrane and in some

cases not very effective. With a second microphone mounted

at the rear-side, any Rub & Buzz can be measured, which is

not audible from the front.

The offered DC resistance measurement ensures accurate

Thiele/Small parameter testing for all woofer types.

System includes:

PRODUCT DATA

M2010

M2010

FX100 Audio Analyzer with FX-SIH & FX-IS

• 1x FX100 Audio Analyzer

• 1x Speaker Impedance Module FX-SIH

• 1x Input Switcher Module FX-IS

• 1x RT-Speaker Software including PureSound Rub & Buzz

• 2x Measurement Microphone M2010

• 1x Audio Amplifier

STEREO CONSUMER PRODUCT TESTING

Automated testing of consumer products with multiple inputs

and electrical or acoustical outputs is supported by the PureSound speaker test system. The individual acoustical performance of Left/Right speakers is typically measured in sequential order.

Additional microphones or vibration sensors may probe for

housing vibrations or loose grids. Input- and Output Switcher

Modules may be integrated for such comprehensive matrix

testing.

System includes:

M2010

CH1

CH1

UNBAL

UNBAL

max.

200VAC

UNBAL

UNBAL

Analog Analyzer

Analog Generator

CH2

CH2

FX-GEN

FX-ANA

Auxiliary I/O

Power:

Fuse:

90 – 264 VAC

FX100 -1.6A

47 – 63 Hz

FX200 -3.15A

FX-CTRL

FX100 Audio Analyzer

M2010

USBUSBLAN

Controller

• 1x FX100 Audio Analyzer

• 1x RT-Speaker Software including PureSound Rub & Buzz

• 2x Measurement Microphone M2010

www.nti-audio.com

TV testing configuration

19Page 13

Page 14

Optional:

• 1x Input Switcher Module FX-IS

• 1x Output Switcher Module FX-OS

100 V SPEAKER TESTING

The PureSound speaker test system allows impedance response- & resonance frequency testing of 100 V speakers,

which are often used in public address systems. Lower speaker test voltages, such as 75 V, 50 V, 25 V are also supported.

In the past the speaker and the 100 V transformer had to be

tested separately as individual components. The complete assembly could not be tested. Assembling faults often have been

detected at the actual speaker installation on-site only.

PRODUCT DATA

M2010

LINE

Voltage Range:

85 - 264 VAC

Frequency Range:

47 - 63 Hz

Power Fuse:

RT-IB 100VRT-IB 100V

T2.5A / 250V

To Rapid Test

100V Impedance Box

+

(Measure OUT)

+

(Signal IN)

from Amplier

Fuse:

use only type

from NTI

F 3A F 1A F 175mA

FSF 6.3x32 (250V)

Fuses

F2F1

F3

to Speaker

(Signal OUT)

The PureSound speaker test systems offers the all-in-one solution for testing the completely assembled 100 V speaker with

transformer. The RT-IB 100V Impedance Box enables impedance measurements up to 30 kW, allowing to test all powertaps of a 100 V speaker transformer.

System includes:

CH1

CH1

UNBAL

UNBAL

max.

UNBAL

UNBAL

Analog Generator

CH2

CH2

FX-GEN

FX-ANA

• 1x FX100 Audio Analyzer

• 1x RT-Speaker Software including PureSound Rub & Buzz

• 1x RT-IB 100 V Impedance Box

• 1x M2010 Measurement Microphone

MOBILE PHONE SPEAKER & RECEIVER TESTING

Telecom transducers are very small yet important components in modern mobile

phones. Best performance over a wide frequency range and as small as possible is expected. Their naturally high problem rates may result in high costs

for waste goods from finished materials. Nowadays manufacturers increase the

production yield by a 100% quality control of the individual component, the preassembly and finally the completed phone. Especially the PureSound Rub&Buzz

test is of great help to filter out any products with abnormal noise as early

as possible, thus final testing of completed phones achieves close to a 100%

PASSED rate and best performance. Vibration motor testing is included!

100V Amplifier

USBUSBLAN

Auxiliary I/O

200VAC

Analog Analyzer

Controller

Power:

Fuse:

90 – 264 VAC

FX100 -1.6A

47 – 63 Hz

FX200 -3.15A

FX-CTRL

FX100 Audio Analyzer

The mobile phone test adapter TA2010 or artificial ears (type IEC 318 or IEC

711) are available, which simulate the acoustical conditions at the human ear.

www.nti-audio.com

19Page 14

Page 15

They are typically used for mobile phone receiver testing.

System includes:

• 1x FX100 Audio Analyzer

• 1x Speaker Impedance Module FX-SIP

• 1x RT-Speaker Software including PureSound Rub & Buzz

• 1x M2010 Measurement Microphone or Artificial Ear

• 1x Audio Amplifier

PRODUCT DATA

M2010

Microphone

FX100 Audio Analyzer

with FX-SIP

Telecom transducer test setup; FX100 Audio Analyzer with FX-SIP

www.nti-audio.com

19Page 15

Page 16

ORDERING INFORMATION

Basic Configuration

• FX100 Audio Analyzer

• Speaker Impedance Module

• FX-SIP (with built-in 30 W amplifier)

• FX-SIH (for high power speakers, requires external amplifier)

• RT-Speaker Software including PureSound Rub & Buzz

• Power Amplifier

• 1/2“ Measurement Microphone class 1 frequency response,

• M2010: SPL max = typ. 145 dB

• M2015, SPL max = typ. 155 dB

PRODUCT DATA

FX100 Modules

• Input Switcher Module FX-IS

• Output Switcher Module FX-OS

• Channel Extension 2CH -> 4CH

• FX-AES (for digital audio loudspeakers)

Accessories

• Input Switcher IS-1002

• Output Switcher OS-0210

• Environmental Sensor

• Class 1 Sound Calibrator

• RT-IB Impedance Test Box for 100 V speaker applications

Automation Accessories

• Digital I/O Adapter for FX100

• Digital I/O Card, 6503, 6528,

• Digital I/O 6501, USB

Artificial Ear

• Kit Artificial Ear

• ICP or 200 V Microphone, IEC318 or IEC711, including pre-amplifier and power supply

(available with special mounting fixture to test stand)

www.nti-audio.com

19Page 16

Page 17

Other Turnkey PC-Software

RT-Microphone

Microphone Production Testing

SPECIFICATIONS

Analog Generator

Test Signals Sine, StepSweep, GlideSweep, White Noise

Level Range 10 μV to 12.45 V (-100 dBV to 21.9 dBV)

PRODUCT DATA

Level

Accuracy

Level Flatness < ± 0.01 dB (10 Hz to 20 kHz)

Frequency

Range

THD+N • -104 dB @ 1 kHz, 0 dBV (typical)

Analog Analyzer

Measurement

Functions

Sweeps Frequency Sweep, Time Sweep, Level Sweep, Table Sweep

± 0.05 dB

5 Hz to 80 kHz

• ≤ -101 dB + 1.3 μV (20 Hz to 20 kHz fundamental, Lowpass 22 kHz)

• Level ( selective & wideband), Frequency, FFT, Gain,

THD, THD+N,

• Harmonics k2-k35, Phase, Crosstalk, Polarity, DC-Level, DC-Impedance,

• optional: PureSound™ Rub&Buzz

Speed Frequency response down to 200 ms from 20 Hz to 20 kHz

(GlideSweep)

Level Range <1.0 μV to 141 V (max 200 Vp), channel independent auto

ranging

Level

Accuracy

Level Flatness < ± 0.02 dB (20 Hz to 20 kHz)

Frequency

Range

www.nti-audio.com

± 0.1 dB @ 1 kHz

DC, 5 Hz to 80 kHz

19Page 17

Page 18

THD+N • -104 dB @ 1 kHz, 0 dBV (typical)

• ≤ -104 dB + 1.5 μV (20 Hz to 20 kHz fundamental, LP

22 kHz)

Residual Noise ≤ 1.5 μV (20 Hz to 20 kHz bandwidth)

Filters • A-Weighting, C-Weighting, AES17 Brickwall

• Highpass 22Hz, Highpass 400Hz, Lowpass 22kHz

Crosstalk ≤ –120 dB + 1 μV to 20 kHz

PRODUCT DATA

Input Bias

2 VDC, 48 VDC Phantom Power, ICP®

Supply

Input Coupling AC or DC

General

Channels • 2 or 4 Parallel Independent Inputs/Outputs Analog

• XLR and BNC connectors

Extension

3 empty slots @ Base Unit FX100 for modular extensions

Slots

Interfaces • USB 2.0 Communication to PC

• Headphone connector for audio out, 1/4”Jack Stereo

• LAN (prepared for later firmware extension)

Pass / Fail

Result

FX-Control

Suite

• Built in DIO-Interface controls external peripherals

• Dual color display with green/red indication

• PC Software with full access to all audio analyzer features

• Parallel measurements with internal/external triggering

• Calculation panels for mathematical processing of measurement data

• Result reporting: txt-files, csv-files or xlsx-files

• Full tolerance handling and hardware wiring diagram

Programming Supports .NET Assembly (e.g. C#.NET, Visual Basic.NET)

Design Desktop use or ½ size 19’’ rack mounting, 3 rack units high

www.nti-audio.com

19Page 18

Page 19

PRODUCT DATA

Overview test results

www.nti-audio.com

19Page 19

Loading...

Loading...