NTI Trinity Lx 600, Trinity Lx 500, Trinity Lx 700, Trinity Lx 800 Replacement Instructions Manual

Page 1

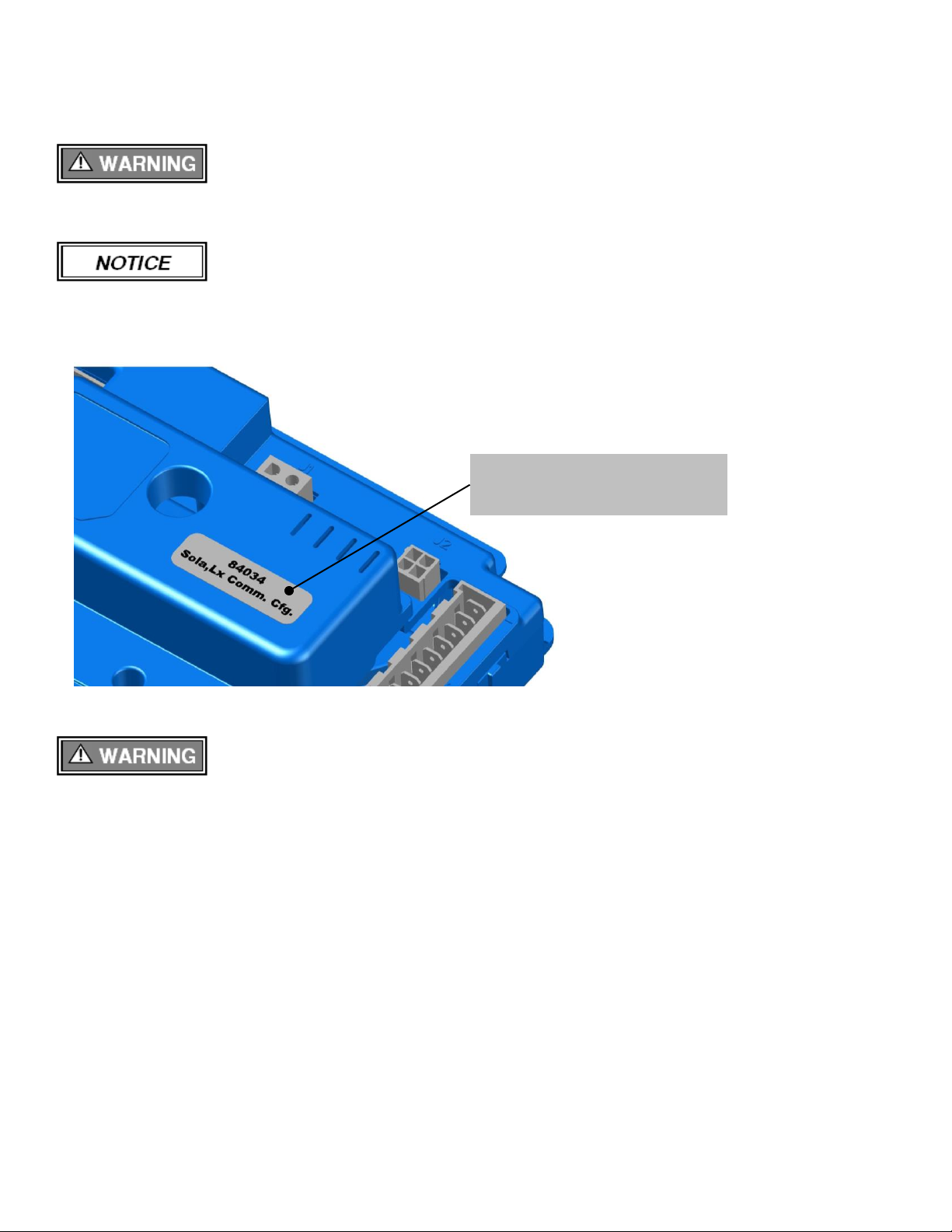

#84034 Trinity Lx Commercial Controller Issue date: 2012-Jan-11

Contact NTI if the replacement

controller does not have this

exact decal on the Controller.

Replacement Instructions Revision date: 2012-Jan-11

#84034 - Trinity Lx Commercial Controller Replacement Instructions

The commercial controller (part number 84034) is configured specifically for use with Trinity Lx

Commercial series boilers only, Lx500-800 inclusive. This controller shall NOT be used with

non Lx Commercial-series boilers. Use of this controller on boiler models other than Trinity Lx Commercial-series will

override some saftey features and may lead to unsafe operation resulting in fire, explosion, property damage or death.

Check the contents of the parts received to ensure the controller is labeled “84034 Sola,Lx

Comm. Cfg.”, signifying that it is for use with Lx Commercial-series Trinity boilers; see

illustration below. If the controller is not labeled, or has a different label, it is not intended for use with a Trinity Lx

Commercial-series boiler. Note: all commercial Sola controllers have a blue case, if the controller case is not blue return

to NTI.

Controller Replacement Instructions

Instructions may result in fire, explosion, property damage or loss of life.

These instructions describe the steps necessary to replace a controller from any model of the Trinity Lx Commercial

series, sizes 500 to 800 inclusive, with a “generic” controller. Be sure to thoroughly read and understand these

instructions before attempting a controller replacement.

Note: Before replacing an existing controller, record (if possible) the settings specific to the particular installation from

the old controller, so they may be transferred to the new replacement controller.

Replace the Trinity Lx Commercial controller:

1) Turn off power to the appliance via the circuit breaker, remote switch or local On/Off switch.

2) For Lx500-600 units remove the top panel. For Lx700-800 units, remove the top rear panel.

3) Remove the control panel cover.

4) Unplug all electrical connections from the controller. All wiring is connected to the controller by means of quick-

connect plugs, each of which is uniquely keyed to its mating receptacle to prevent incorrect electrical connections.

5) Remove the old controller from the panel. The controller is secured to the panel by four screws, #8 w/ ¼” hex drive.

6) Installation procedure is in reverse order.

7) Use the display to adjust the control parameter settings to the values specific to the boiler model (see instructions

below).

S:\NTI2001_N_Drive (1-20-09)\R&D\PARTS - ENGINEERING\Parts Department Stickers and Instructions\Current Parts Instructions (doc)\84034 instructions Trinity Lx Commercial Controller.doc

The instuctions provided in this document are a supplement to the Installation and Operating

Instructions originally provided with the boiler. Failure to follow the Installation and Operating

1/3

Page 2

Parameter

Description

Settings

CH max. modulation

rate

Maximum permissible blower speed during CH demand. Setting

is model dependent.

Lx500 = 6400 rpm

Lx600 = 4350 rpm

Lx700 = 4300 rpm

Lx800 = 5300 rpm

DHW max.

modulation rate

Maximum permissible blower speed during DHW demand.

Setting is model dependent.

Minimum modulation

rate

Minimum permissible blower speed. Setting is model dependent.

Lx500 = 1400 rpm

Lx600 = 1050 rpm

Lx700 = 1250 rpm

Lx800 = 1250 rpm

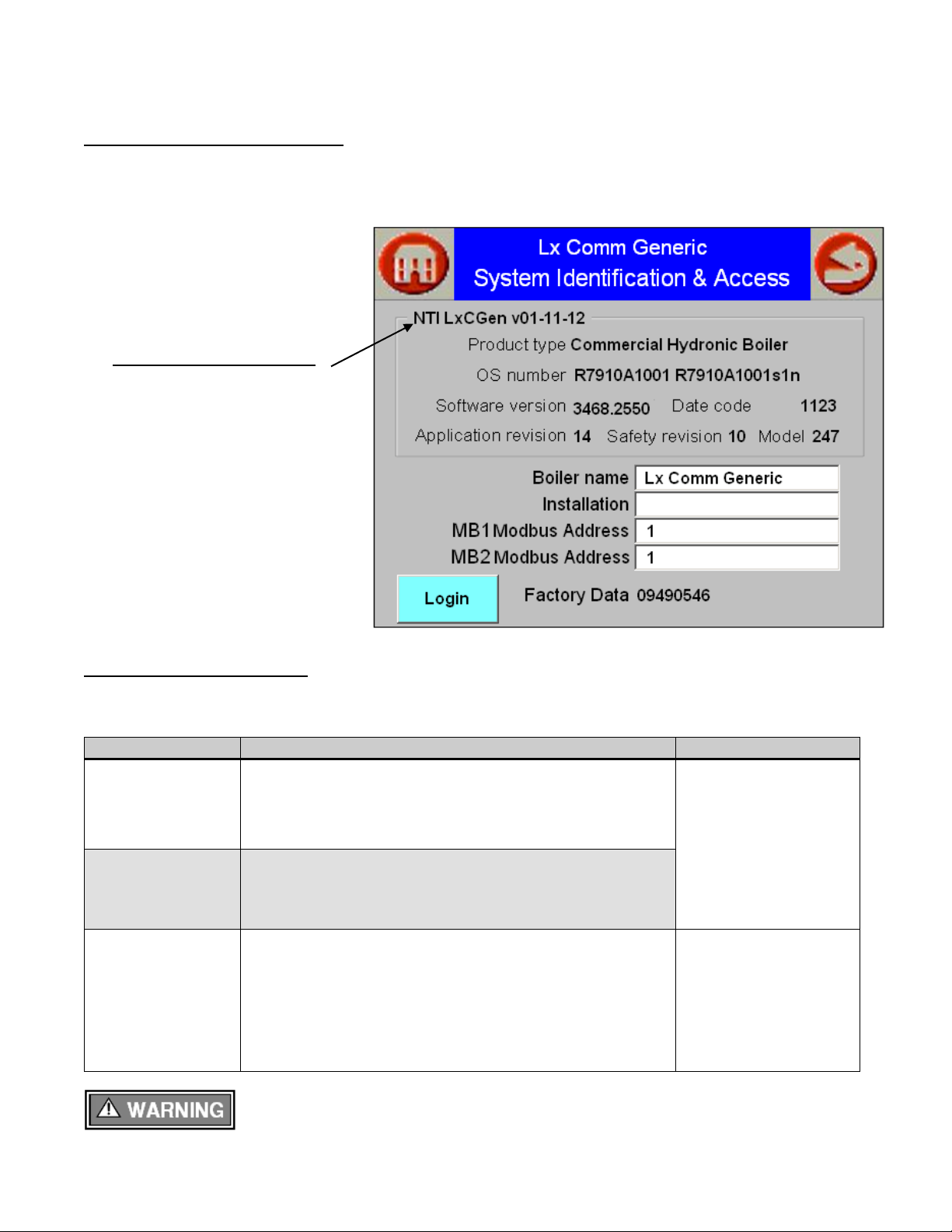

Configuration Identification

Must begin with “NTI LxCGen”

#84034 - Trinity Lx Commercial Controller Replacement Instructions

Control Settings Verification and Adjustments:

1) Control Configuration Verification – From the “Configuration” menu, select “System Identification and Access”.

Check to ensure the control is equipped with the correct configuration – see illustration below. Replacement

controllers intended for use on Lx Commercial-series boilers will begin with “NTI LxCGen”. At this time the

installer may choose to modify the “Boiler name” to reflect the boiler model the control is installed on, i.e. Lx500.

2) Modulation Rate Adjustments – Since the replacement control is generic to all Lx Commercial boiler models, the

minimum and maximum modulation rates must be set to the applicable values. Select “Modulation Configuration”

from the “Configuration” menu and adjust the settings according to the following table:

Failure to set the modulation rates appropriate to your specific boiler model according the

S:\NTI2001_N_Drive (1-20-09)\R&D\PARTS - ENGINEERING\Parts Department Stickers and Instructions\Current Parts Instructions (doc)\84034 instructions Trinity Lx Commercial Controller.doc

table above may result in fire, explosion, property damage or loss of life.

2/3

Page 3

Parameter

Description

Settings

Pulses per revolution

Number of feedback pulses produced for each revolution of the

combustion blower impeller.

Lx500 = 2

Lx600 = 3

Lx700 = 3

Lx800 = 3

#84034 - Trinity Lx Commercial Controller Replacement Instructions

3) Pulses Per Revolution Adjustment – Since the replacement control is generic to all Lx Commercial boiler models,

the blower tachometer feedback “Pulses per revolution” setting must be set to the appropriate value for the specific

boiler. Select “Fan Configuration” from the “Configuration” menu and adjust the settings according to the following

table (see the illustration below):

S:\NTI2001_N_Drive (1-20-09)\R&D\PARTS - ENGINEERING\Parts Department Stickers and Instructions\Current Parts Instructions (doc)\84034 instructions Trinity Lx Commercial Controller.doc

3/3

Loading...

Loading...