Page 1

H

US Models

NTI # 82419

NTI – TRINITY Ti

INSTALLATION AND OPERATION INSTRUCTIONS

Ti100-200 Boilers and Ti150-200 Combi Models

VERSION DATE: 2013-05-21

TABLE OF CONTENTS

1.0 SPECIFICATIONS ........................................................................................... 4

2.0 BOILER LOCATION ....................................................................................... 5

3.0 GENERAL VENTING ...................................................................................... 6

4.0 VENT/AIR-INTAKE TERMINATION CLEARANCES ............................ 15

5.0 CONDENSATE DRAIN ................................................................................. 19

6.0 INSTALLING GAS PIPING .......................................................................... 20

7.0 LIGHTING THE APPLIANCE ..................................................................... 21

8.0 GAS VALVE AND BURNER SET-UP ......................................................... 23

9.0 BOILER AND HEATING SYSTEM PIPING .............................................. 26

10.0 COMBI BOILER DHW PLUMBING AND OPERATION ........................ 32

11.0 WIRING ................................................................ ................................ ........... 36

12.0 SENTRY 2100 CONTROLLER ..................................................................... 42

13.0 TROUBLESHOOTING .................................................................................. 46

14.0 SEQUENCE OF OPERATION ..................................................................... 49

15.0 WIRING SCHEMATIC ................................................................................. 50

16.0 INSTALLATION CHECKLIST .................................................................... 51

17.0 ANNUAL MAINTENANCE AND INSPECTION ....................................... 52

18.0 PARTS LIST .................................................................................................... 54

HAZARD SYMBOL DEFINITIONS

Danger Sign: Indicates a hazardous situation which, if not avoided, will

result in serious injury or death.

Warning Sign: Indicates a hazardous situation which, if not avoided, could

result in serious injury or death.

Caution Sign plus Safety Alert Symbol: Indicates a hazardous situation

which, if not avoided, could result in minor or moderate injury.

Caution Sign without Safety Alert Symbol: Indicates a hazardous situation

which, if not avoided, could result in property damage.

Notice Sign: Indicates a hazardous situation which, if not avoided could

result in property damage.

Page 2

2

Trinity │Installation and Operation Instructions Ti Series

0.0 INTRODUCTION

General Installation Requirements

The installation of the NTI Trinity Ti gas boiler must conform to the requirements of this manual, your local authority, and the

National Fuel Gas Code ANSI Z223.1 and or CAN/CGA B149 Installation Codes. Where required by the Authority Having

Jurisdiction, the installation must conform to the standard for “Controls and Safety Devices for Automatically Fired Boilers

ANSI/ASME CSD-1.

This document pertains to the correct installation and operation of NTI Trinity Ti boiler models Ti100, Ti150 and Ti200. The

instructions detailed in this document supersede any and all previous instructions provided by NTI, written or otherwise. Each

unit is provided with the following:

1) Installation and Operation Instruction Manual for Trinity Ti Series,

2) Trinity Users Manual and,

3) Trinity Natural to LP Conversion Kit *

* The conversion kit is required to convert the appliance so it will safely operate with Propane Gas.

Read and understand this entire document prior to proceeding with the installation of the Trinity Ti.

Failure to follow instructions outlined in this document will result in property damage, injury or death.

User Responsibilities

This appliance must be installed and serviced by a qualified installer or service technician. This appliance must be serviced and

inspected annually when operating in normal residential applications. Demanding applications or extreme conditions (i.e.

commercial) may require more frequent service and inspection. As the User/Owner of this equipment, you are responsible for

ensuring the maintenance is performed at the required intervals. It is also the Users responsibility to ensure the Vent and

Combustion-Air Intake termination is kept clear of ice and snow or any other obstruction. Failure to follow these instructions

could result in fire, serious injury, or death.

Failure to have the appliance properly serviced and inspected on a regular basis may result in property

damage, serious injury or death.

Failure to keep the Vent and Combustion Air Intake clear of ice, snow, and other debris may result in

property damage, serious injury, or death.

Installer Responsibilities

As the installing technician it is your responsibility to ensure the installation is performed in accordance with this instruction

manual as well as any applicable local or National installation codes. It is also your responsibility to inform the User/Owner of

their obligation with respect to the above description under “User Responsibilities”. Failure to follow this warning could result in

fire, serious injury, or death.

ATTENTION: LIQUEFIED PETROLEUM (LP) PROPANE

The Trinity Ti is factory set to operate with Natural Gas. BEFORE OPERATING WITH PROPANE, the specified LP

Conversion Kit must be installed to convert the appliance so it will operate safely with LP Propane. Listed below is the

correct Natural to LP Propane Conversion Kit number for Trinity Ti100-200 boiler models. Note: kit number 82650-1

contains two LP conversion orifices. The smaller orifice, labeled 34, must be used in the Ti100, while the larger orifice,

labeled 52, must be used in the Ti150 and Ti200.

Liquefied Petroleum (LP) propane gas is heavier than air; therefore, it is imperative that your Trinity Ti boiler is not

installed in a pit or similar location that will permit heavier than air gas to collect. Local Codes may require appliances

fueled with LP gas be provided with an approved means of removing unburned gases from the room. Check your local

codes for this requirement.

Natural to LP Propane Conversion Kit_

NTI Series Model Number Kit Number

Trinity Ti 100, 150, 200 82650-1

Refer to the above, ATTENTION: LIQUEFIED PETROLEUM (LP) PROPANE for correct conversion kit number.

Appliance Vent / Air-Intake Piping

in these instructions. Failure to follow instructions will result in serious injury or death.

Failure to use the appropriate Natural to LP Conversion Kit when operating the Trinity Ti with Propane

will result in extremely dangerous burner operation leading to property damage, serious injury or death.

The Trinity Ti is a “Direct Vent” appliance requiring a “Special Venting System”. Vent and

Combustion-Air Intake piping must be piped to the outdoors, using the vent material and rules outlined

Page 3

Ti Series Installation and Operation Instructions │Trinity

3

Energy Saving Feature - This boiler is equipped with a feature that saves energy by reducing

the boiler water temperature as the heating load decreases. This feature is equipped with an

override which is provided primarily to permit the use of an external energy management system that serves the

same function. THIS OVERRIDE MUST NOT BE USED UNLESS AT LEAST ONE OF THE FOLLOWING

CONDITIONS IS TRUE :

An external energy management system is installed that reduces the boiler water temperature as the heating load

decreases.

This boiler is not used for any space heating.

This boiler is part of a modular or multiple boiler system having a total input of 300,000 BTU/hr or greater.

This boiler is equipped with a tankless coil.

IN THE STATE OF MASSACHUSETTS ONLY

(a) For all horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or

in part for residential purposes, including those owned and operated by the Commonwealth and where the side wall

exhaust vent termination is less than seven (7) feet above finished grade in the area of the venting, including but not

limited to decks and porches, the following requirements shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS At the time of installation of the side wall

horizontal vented gas fueled equipment, the installing plumber or gas fitter shall observe that a hard wired

carbon monoxide detector with an alarm and battery back-up is installed on the floor level where the gas

equipment is to be installed and on each additional level of the dwelling, building or structure served by the

equipment. It shall be the responsibility of the property owner to secure the services of qualified licensed

professionals for the installation of hard wired carbon monoxide detectors.

a. In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl space or an

attic, the hard wired carbon monoxide detector with alarm and battery back-up may be installed on the next

adjacent floor level.

b. In the event that the requirements of this subdivision can not be met at the time of completion of

installation, the owner shall have a period of 30 days to comply with the above requirements; provided,

however, that during said 30 day period a battery operated carbon monoxide detector with an alarm shall

be installed.

2. APPROVED CARBON MONOXIDE DETECTORS Each carbon monoxide detector as required in

accordance with the above provisions shall comply with NFPA 720 and be ANSI/UL 2034 listed and IAS

certified.

3. SIGNAGE A metal or plastic identification plate shall be permanently mounted to the exterior of the building

at a minimum height of eight (8) feet above grade directly in line with the exhaust vent terminal for the

horizontally vented gas fueled heating appliance or equipment. The sign shall read, in print size no less than

one-half (1/2) inch in size, “GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”

(plate included with appliance).

4. INSPECTION The state or local gas inspector of the side wall horizontally vented gas fueled equipment shall

not approve the installation unless, upon inspection, the inspector observes carbon monoxide detectors and

signage installed in accordance with the provisions of 248 CMR 5.08(2)(a)1 through 4.

(b) EXEMPTIONS: The following equipment is exempt from 248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled “Equipment Not Required To Be Vented” in the most current

edition of NFPA 54 as adopted by the Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room or structure separate

from the dwelling, building or structure used in whole or in part for residential purposes.

(c) MANUFACTURER REQUIREMENTS – GAS EQUIPMENT VENTING SYSTEM PROVIDED: When the

manufacturer of Product Approved side wall horizontally vented gas equipment provides a venting system design

or venting system components with the equipment, the instructions provided by the manufacturer for installation of

the equipment and the venting system shall include:

1. Detailed instructions for installation of the venting system design or the venting system components; and

2. A complete parts list for the venting system design or venting system.

(d) MANUFACTURER REQUIREMENTS – GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED:

When the manufacturer of a Product Approved side wall horizontally vented gas fueled equipment does not provide

the parts for venting the flue gases, but identifies “special venting systems”, the following requirements shall be

satisfied by the manufacturer.

Page 4

4

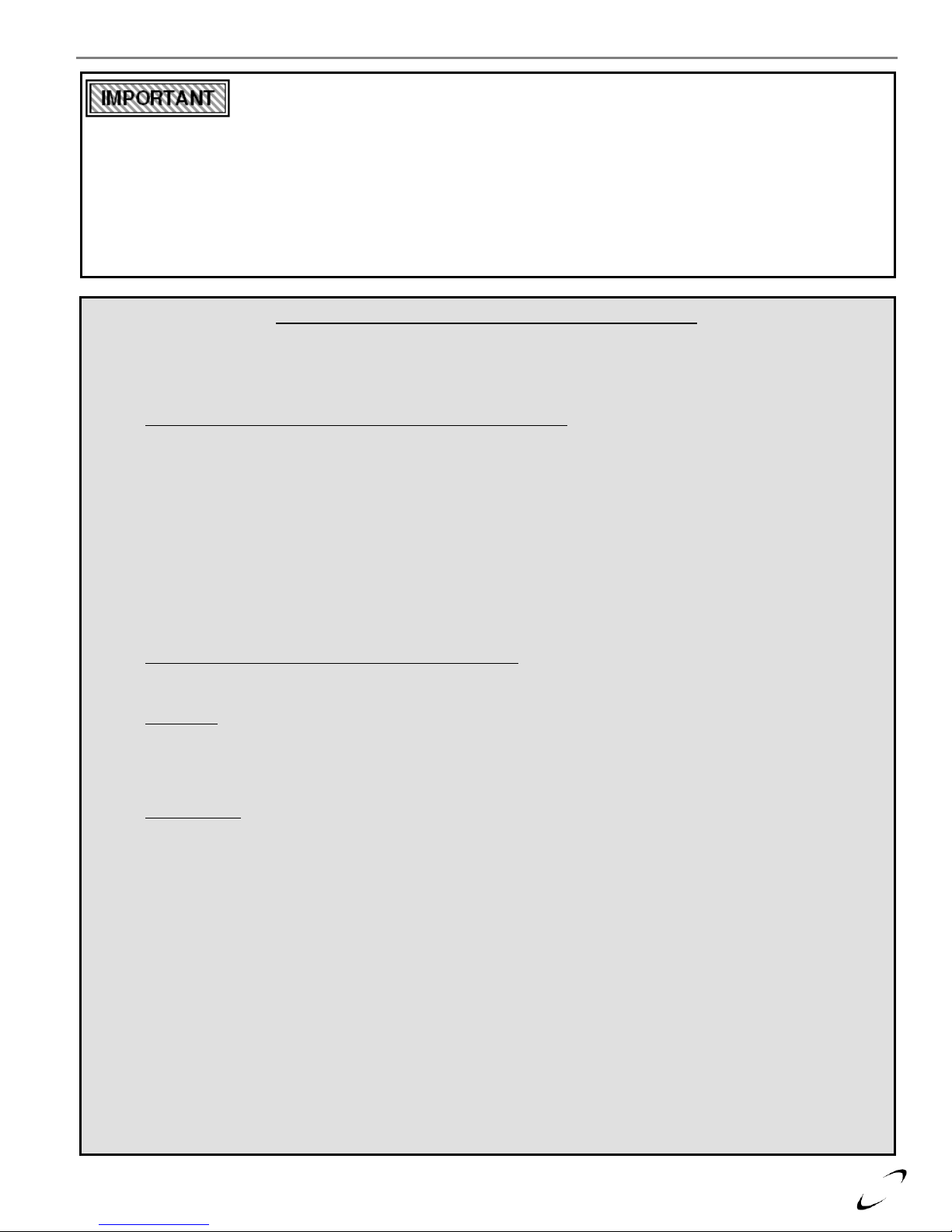

DESCRIPTION

Ti100

Ti150

Ti200

CSA Input Modulation

1

btu/hr [kw]

15,000 - 93,000

[4.4 – 29.3]

25,000 - 150,000 2

[7.3 - 44.0]

25,000 - 199,000

[7.3 - 58.3]

DOE Heating Capacity

1,3

btu/hr [kw]

84,000

[24.6]

136,000

[39.8]

181,000

[53]

Net I=B=R Rating

1,3

btu/hr [kw]

73,000

[21.4]

118,000

[34.8]

157,000

[46]

DOE AFUE %

3

93.5

Water Connections - NPT, in.

1 4

1

Gas Connection - NPT, in.

1/2

Vent/Air-Intake Pipe Diameter 5, in. [mm]

3 or 4 [76 or 102]

Vent/Air-Intake, Max. Length, NG / LP

ft. [m]

105 / 105

[32 / 32]

105 / 50

[32 / 15.2]

105 / 50

[32 / 15.2]

Dimensions H x W x D

in. [mm]

22.5 x 15.5 x 16.75

6

[571 x 394 x 425]

22.5 x 15.5 x 16.75

6

[571 x 394 x 425]

22.5 x 15.5 x 18.25

[571 x 394 x 464]

Approx. Appliance Weight with Water,

lbs [kg]

80 [36.3]

80 [36.3]

110 [49.9]

Notes:

1

Listed Input and Output ratings are at minimum vent lengths at Sea Level. Numbers will be lower with longer venting

and/or altitudes greater then 2000 feet [610 m].

2

The maximum output when operating on LP-Gas is limited to 145,000 Btu/hr [42.5 kW].

3

Based on rating plate input capacities, using standard test procedures prescribed by the U.S. Department of Energy.

Ratings have been confirmed by AHRI (GAMA).

4

Units sold in Canada are 3/4” NPT.

5

Trinity Ti units require a special venting system, use only vent materials and methods detailed in these instructions.

6

Ti100 and 150 units sold in Canada have a depth of 14.75”.

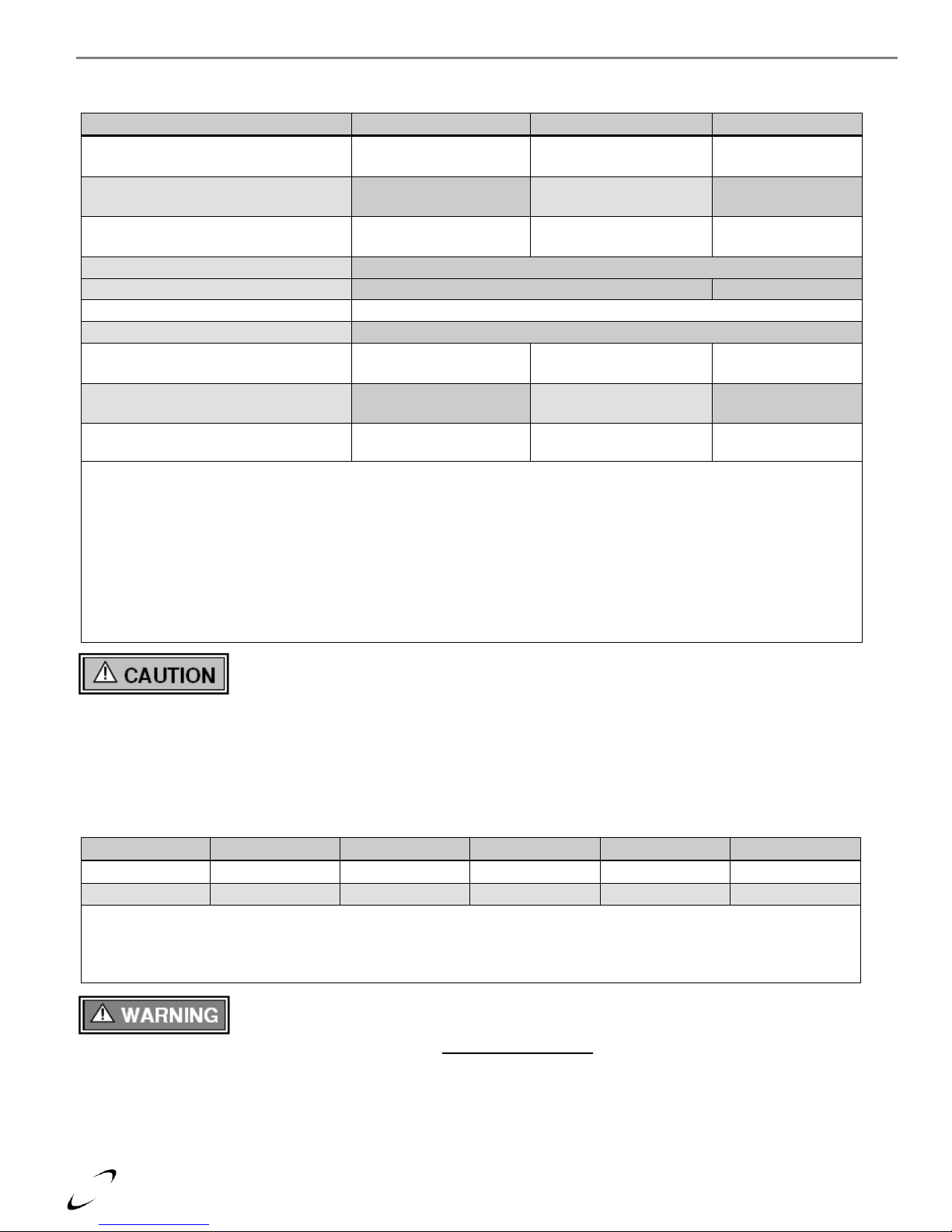

Elevations

2000 ft [610 m]

3000 ft [914 m]

4000 ft [1219 m]

4500 ft [1372 m]

5000 ft [1524 m]

In Canada 1

de-rate by 5%

de-rate by 5%

de-rate by 5%

de-rate by 5%

de-rate % may vary

In USA 2

-

de-rate by 4%

de-rate by 8%

-

de-rate by 12%

Notes:

1

Canada: Altitudes between 2000-4500 ft [610-1372 m], de-rate by 5%. Consult local authorities for de-rating capacities

for altitudes above 4500 ft [1372 m].

2

USA: De-rate capacity by 4% for every 1000 ft [305 m] over 2000 ft [610 m].

Trinity │Installation and Operation Instructions Ti Series

1.0 SPECIFICATIONS

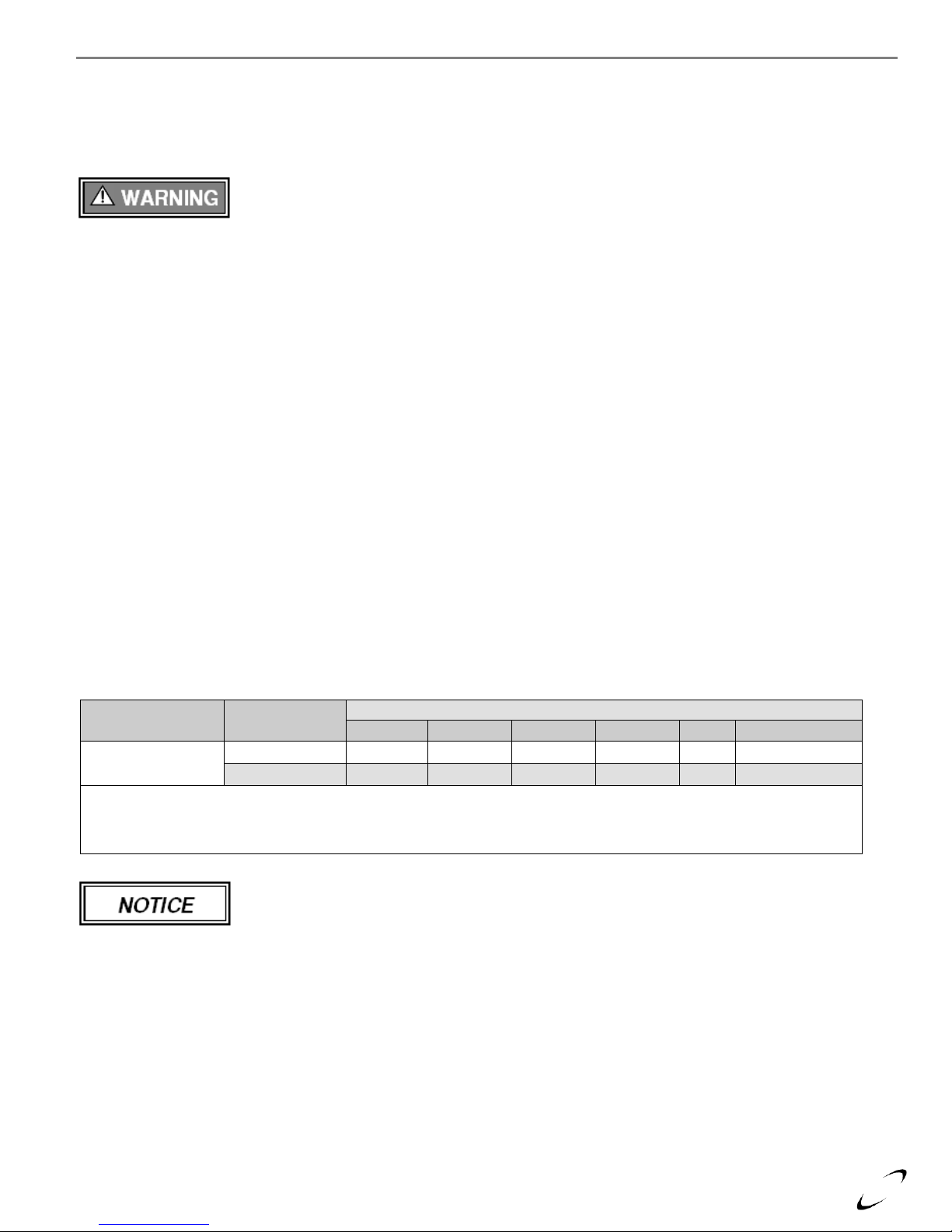

Table 1-1 Specifications

This unit requires two people to lift it or property damage and personal injury may result.

High Altitude Operation

The Trinity is designed to operate at its maximum listed capacity in installations less than or equal to 2000 ft [610 m] above Sea

Level. Since the density of air decreases as elevation increases, maximum specified capacity should be de-rated for elevations

above 2000 ft [610 m] in accordance with Table 1-2.

Table 1-2 De-rate % for High Altitudes

At elevations greater than 2000 feet, the combustion of the appliance must be checked with a calibrated

combustion analyzer to ensure safe and reliable operation. Consult Section 8.0 for instructions on

adjusting the input to provide proper operation. It is the Installers responsibility to check the combustion, and to adjust the

combustion in accordance with Section 8.0. Failure to follow these instructions may result in property damage, serious injury,

or death.

Page 5

Ti Series Installation and Operation Instructions │Trinity

5

Model No.

Clearances

Dimensions - inches [mm]

Front

Top

Sides

Bottom

Rear

Flue/Water Pipe

Trinity Ti100-200

Minimum

24 [610] 1

12 [305]

12 [305]

9 [229] 0 1 [25]

Recommended

24 [610]

24 [610]

24 [610] 2

9 [229] 0 1 [25]

Notes:

1

6” if surface is removable allowing 24” [610 mm] clearance (i.e. closet installation). See “Appliance Ventilation Air

Openings” above.

2

Clearances can be as low as 12” [305 mm] on one side if clearance on the other side is 24” [610 mm].

2.0 BOILER LOCATION

In all cases, the Trinity Ti must be installed indoors in a dry location where the ambient temperature must be maintained above

freezing and below 100F [38C]. Gas components must be protected from dripping, spraying water, or rain during operation and

servicing. Consider the proximity of system piping, gas and electrical supply, condensate disposal drain, and proximity to vent

termination when determining the best appliance location.

Water or flood damaged components must be replaced immediately with new factory-approved

components as failure to do so may result in fire, serious injury, or death.

Appliance Area Ventilation Air Openings

If appliance area clearances are less then the recommended clearances specified in Table 2-1, the appliance area must be

ventilated. Each ventilation air opening must meet the minimum requirements of 1 in2 per 1000 Btu/hr, but not less then 100in2.

The lower ventilation opening must be located within 6” of the floor while the upper opening must be located 6” from the top of

the space.

Closet Installations

For closet installations, it is necessary to provide two ventilation air openings, each providing a minimum area equal to 1 in2 per

1000 Btu/hr, but not less then 100 in2 and within 6” of the top and bottom of the closet door. All Vent and Air-Intake piping

within the closet must be CPVC for both Canada and the US. See Table 2.1 for Minimum and Recommended Clearances.

Alcove Installations

Alcove installations have the same minimum clearances as closet installations, except the front must be completely open to the

room at a distance no greater then 18” [457 mm] from the front of the appliance and the room is at least three (3) times the size of

the alcove. Provided these conditions are met, the appliance requires no extra ventilation air openings to the space. All Vent and

Air-Intake piping within the alcove must be CPVC for both Canada and the US. See Table 2-1 for Minimum and Recommended

Clearances.

Residential Garage Installations

When installed in a residential garage, mount the appliance a minimum of 18” [457 mm] above the floor. Locate or protect the

appliance so it cannot be damaged by a moving vehicle. Check with your local authorities for other possible regulations

pertaining to the installation of an appliance in a garage.

Table 2-1 Minimum Clearances for Installation and Service

The appliance area is considered to be a closet or alcove if the area does not provide the recommended

clearances listed in Table 2-1. See special instructions under Closet and Alcove Installations.

Page 6

6

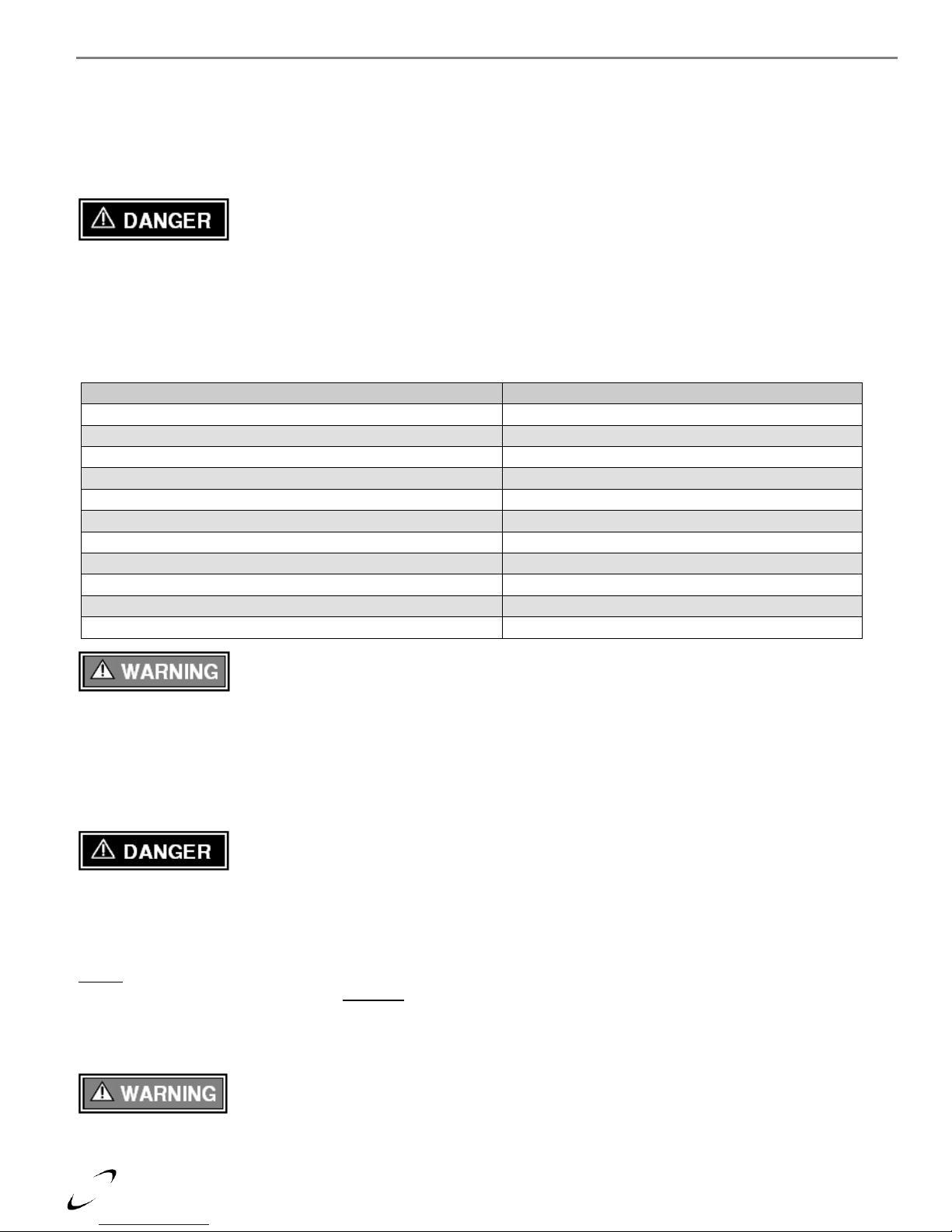

Products to Avoid

Contaminated Sources to Avoid

Antistatic fabric softeners, bleaches, detergents, cleaners

Laundry facilities

Perchloroethylene (PCE), hydrocarbon based cleaners

Dry cleaning facilities

Chemical fertilizer, herbicides/pesticides, dust, methane gas

Farms or areas with livestock and manure

Paint or varnish removers, cements or glues, sawdust

Wood working or furniture refinishing shops

Water chlorination chemicals (chloride, fluoride)

Swimming pools, hot tubs

Solvents, cutting oils, fiberglass, cleaning solvents

Auto body or metal working shops

Refrigerant charge with CFC or HCFC

Refrigerant repair shops

Permanent wave solutions

Beauty shops

Fixer, hydrochloric acid (muriatic acid), bromide, iodine

Photo labs, chemical / plastics processing plants

Calcium Chloride

De-Icing / Ice Melters

Cement powder, crack fill dust, cellulose, fiber based insulation

Concrete plant or construction site

Trinity │Installation and Operation Instructions Ti Series

3.0 GENERAL VENTING

The Trinity Ti is a “Direct Vent” appliance requiring a “Special Venting System” designed for pressurized venting. Both the

Vent and Air-Intake piping must be piped to the outdoors, using the vent material and rules outlined in this section. Under no

conditions may this unit vent gases into a masonry chimney, unless it is vacant, and utilizes the approved venting material and

rules described in this section. Installations must comply with the National Fuel Gas Code, ANSI Z223.1 (U.S.) or CSA B149.1

(Canada) and local requirements.

Vent and Air-Intake to be piped separately. The Trinity Ti cannot share a common vent or air-intake

with multiple appliances. Failure to comply will result in serious injury or death.

Combustion Air-Intake Contamination

Be careful not to locate the Air-Intake termination in an area where contaminants can be drawn in and used for combustion.

Combustion air containing dust, debris or air-borne contaminants will drastically increase the required maintenance and may

cause a corrosive reaction in the Heat Exchanger which could result in premature failure, fire, serious injury, or death. See Table

3-1 for a list of areas to avoid when terminating air-intake piping:

Table 3-1 Corrosive Products and Contaminant Sources

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance. Failure to follow instructions may result in serious injury or death.

Flammable Solvents and Plastic Piping

Due to the extremely flammable characteristics of most glues, cements, solvents and primers used in the process of joining plastic

vent and air-inlet pipe, explosive solvent vapors must be evacuated from the vent and air-intake prior to start-up. Avoid using

excess cement or primer that may lead to pooling inside the pipe assembly. Freshly assembled piping should be allowed to cure

for a minimum of 8 hours before applying power to the gas fired appliance. Refer to Mandatory Pre-commissioning Procedure

for Plastic Venting in this section.

Flammable Cements and Primers – It is the installers’ responsibility to familiarize themselves with

the hazards associated with explosive solvents and to take all precautions to reduce these risks. Failure

to follow these instructions can cause explosions, property damage, injury or death.

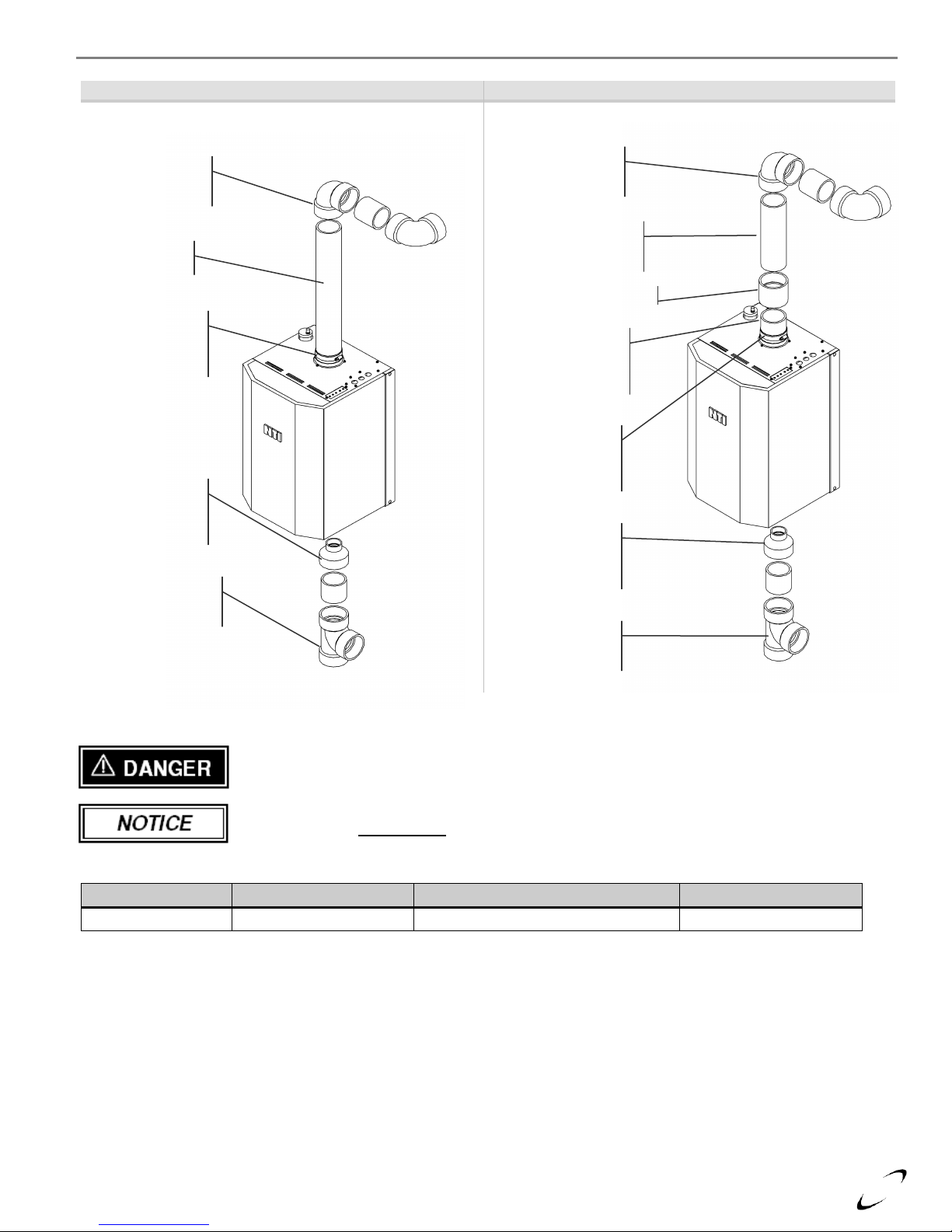

Near Boiler Vent/Air-Intake Piping

Each Trinity Ti is equipped with a short piece of approved CPVC vent pipe. Insert one end into the boiler flue outlet adapter and

cement the other to field venting (see Table 3-3 for approved venting material). The CPVC vent pipe should extend fully into the

boiler flue outlet adapter (see Table 3-2). DO NOT insert PVC pipe directly into the flue outlet connection as it can deform from

the clamping force of the gear clamp. Ensure that the venting system does not apply a load or strain on the boiler flue outlet

adapter. The manufacturer recommends using two elbows to create a “swing joint” to reduce potential strain on vent piping and

cemented joints. See Figure 3-1 for illustration.

Gasket Seating - Improper seating can cause leakage and eventual failure of the sealing gasket. Failure

to follow these instructions may result in serious injury or death.

Page 7

Ti Series Installation and Operation Instructions │Trinity

7

Swing Joint

to attain slope in

horizontal runs

Exhaust Vent

3”PVC, (check local

codes and Table 3-3)

Coupling - 3”PVC

Transition Piece

3” CPVC, minimum

5” long (factory

supplied)

Flue Outlet

Stainless Steel

Adapter (factory

supplied)

Air Inlet Adapter

Immediately

adapt from 1-1/2”

to 3”

Cleanout

Recommended on

Air Inlet Piping

Figure 3-1(a)

Figure 3-1(b)

Near Boiler Venting (CPVC)

Near Boiler Venting (PVC)

Model No.

CPVC Vent Pipe Size

CPVC Transition Vent Pipe Length

Full Insertion Depth

Trinity Ti100-200

3”

Minimum 5” [127 mm]

2-7/8” [73 mm]

Flue Outlet

Stainless Steel

Adapter (factory

supplied)

Swing Joint

to attain slope in

horizontal runs

Exhaust Vent

3”CPVC

Air Inlet Adapter

Immediately

adapt from 1-1/2”

to 3”

Cleanout

Recommended on

Air Inlet Piping

Air-Inlet - check with applicable local codes for acceptable pipe material.

Exhaust venting must be supported to reduce strain on piping joints. Failure to follow these instructions

may result in result in damage, serious injury or death.

In Canada, the first 3 ft (915 mm) of vent piping must be readily accessible for inspection.

Table 3-2 Mandatory Vent Pipe Transition Piece

Page 8

8

Items 1

Materials

2, 3

Installation Standards

All Vent and Air-Intake

materials installed on gas

fired appliances in CAN/US

must meet the Standards

listed in Table 3-3. Failure

to comply could result in

fire, serious injury or death.

United States

Canada 4

Vent Piping

and Fittings

PVC - DWV

ANSI/ASTM D2265

All venting material in

Canada must be

ULC S636 approved.

See Note 4 below for

appropriate temperature

applications.

PVC Schedule 40

ANSI/ASTM D1785

CPVC Schedule 40

ANSI/ASTM F441

AL29-4C

UL-1738

Polypropylene (PP)

n/a

Pipe Cement

PVC

ANSI/ASTM D2564

CPVC

ANSI/ASTM F493

Primers

PVC / CPVC

ANSI/ASTM F656

Notes:

1

Refer to Table 3-4 for Allowable Vent and Air-Intake Pipe Sizes and Lengths.

2

PVC venting (exhaust and air-intake) is not permitted within the Closet/alcove of a Closet/alcove installation.

3

The Air-Intake does not require high temperature pipe material. Check applicable local codes for acceptable materials.

4

ULC S636 PVC is approved for flue gas temperatures up to 149oF (65oC) and must only be used for low temperature

applications. High temperature applications requiring appliance supply water temperatures greater than 140oF (60oC)

must use ULC S636 CPVC, PP or AL29-4C.

Trinity │Installation and Operation Instructions Ti Series

Vent/Air-Intake Pipe Material

Table 3-3 Acceptable Vent and Air-Intake Pipe Material

The use of cellular core PVC (ASTM F891), cellular core CPVC, or Radel®

(polyphenolsulfone) in the exhaust venting system is prohibited. Failure to follow these

instructions may result in property damage, personal injury or death.

Covering non-metallic vent pipe and fittings with thermal insulation is prohibited. Failure to

follow these instructions may result in property damage, personal injury or death.

Mandatory Pre-commissioning Procedure for Plastic Venting

1) Working with the power turned off to the boiler, completely install the vent and air intake system, securely cementing joints

together. If possible, allow primers/cements to cure for 8 hours before firing the burner. If curing time is less than 8 hours,

proceed with Steps 2 through 6.

2) Maintain the boiler gas supply shut-off valve in the off position.

3) Disconnect electrical leads to the Hot Surface or Spark Igniter. Ensure the cables are placed in a fashion where they will not

arc to ground or other conductor.

4) Turn power on to the boiler and apply a heat demand.

5) Allow for 3 complete trials for ignition, consisting of pre and post purge of the combustion blower, until an ignition lockout

occurs. Repeat the process two more times (i.e. 9 complete ignition sequences in total).

6) Turn power off and reconnect the electrical leads to the Igniter.

Do not apply power to the boiler prior to Step 4 in the Mandatory Pre-commissioning Procedure for

Plastic Venting.

Page 9

Ti Series Installation and Operation Instructions │Trinity

9

Model

Pipe Size

Gas

Length

ft. [m]

Number of Elbows (90’s or 45’s) and Equivalent Feet [Meters]

1 2 3 4 5 6 7 8 9

Ti150

Ti200

3”

LP

50

[15.2]

45

[13.7]

40

[12.2]

35

[10.7]

30

[9.1]

25

[7.6]

20

[6.1]

15

[4.6]

10

[3.0]

5

[1.5]

3”

NG

105

[32]

100

[30.5]

95

[28.9]

90

[27.4]

85

[25.9]

80

[24.4]

75

[22.9]

70

[21.3]

65

[19.8]

60

[18.3]

4”

NG

& LP

105

[32]

100

[30.5]

95

[28.9]

90

[27.4]

85

[25.9]

80

[24.4]

75

[22.9]

70

[21.3]

65

[19.8]

60

[18.3]

Ti100

3” or 4”

NG

& LP

105

[32]

100

[30.5]

95

[28.9]

90

[27.4]

85

[25.9]

80

[24.4]

75

[22.9]

70

[21.3]

65

[19.8]

60

[18.3]

NTI

P/N

IPEX

P/N

Description

1,2,4

Vent Kit

Material

Kit

Connection

Vent Option

Roof

Wall

82666

196116

Concentric Vent Termination Kit (CAN)

4,5

ULC S636

PVC

3"

84355

196021

4"

n/a

197009

Concentric Vent Termination Kit (CAN)

4,5

ULC S636

CPVC

3"

84357

196985

Low Profile Termination Kit

(Flush Mount)

PVC

3"

84358

196986

4"

Notes:

1

Instructions included with termination kits contain more detailed assembly and installation instructions.

2

Clearance requirements in this manual supersede those of the instructions included with the vent terminal.

3

Terminal MUST be cemented together and to the vent pipes during installation.

4

Certified to ULC S636.

5

Vent Screen provided with boiler may be used with the IPEX Concentric Vent Kits; otherwise use IPEX vent screens (3"

vent screen P/N 196051; 4" vent screen P/N 196052).

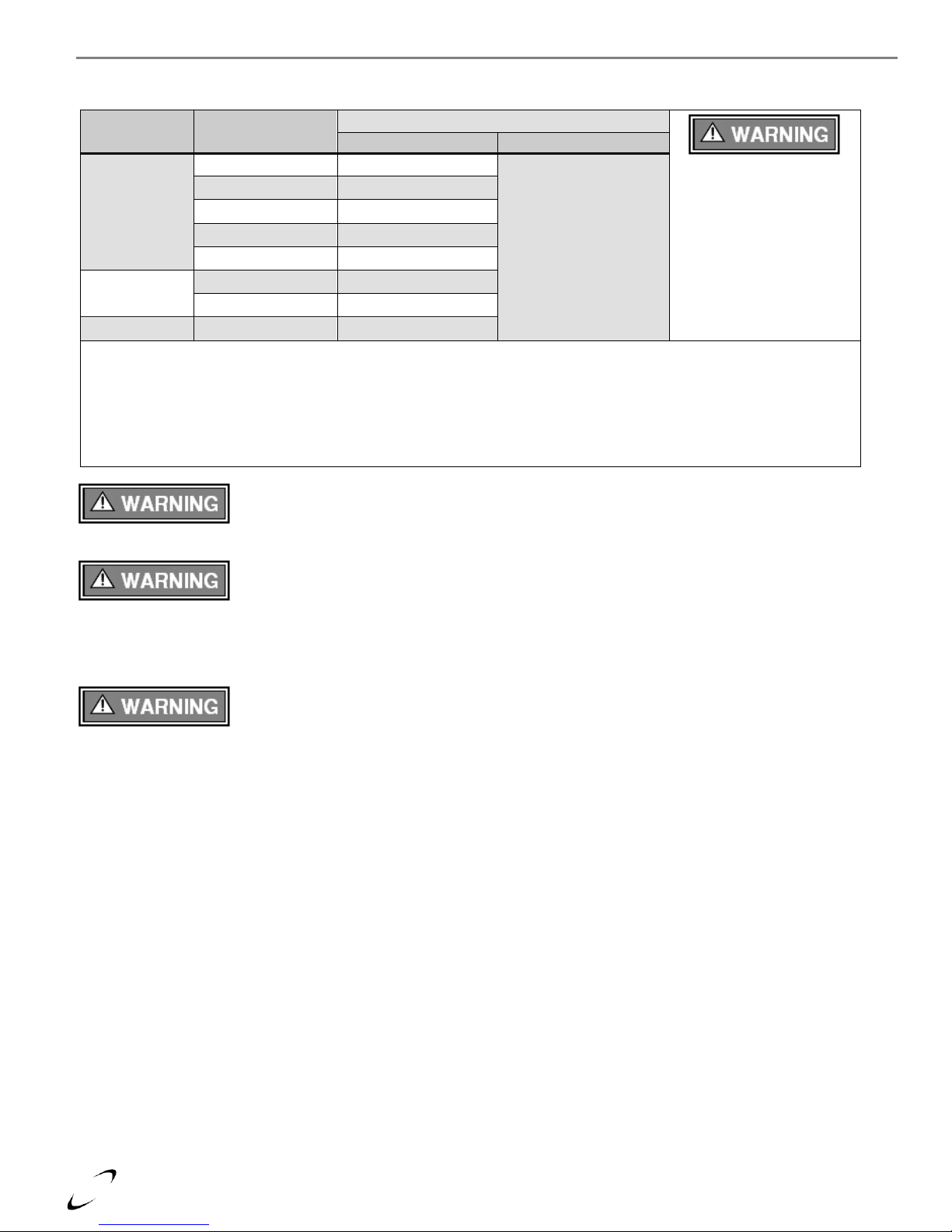

Vent and Air-Intake Pipe Length Determination

Use Table 3-4 to determine the maximum pipe length that can be used. The table calculates sweep, 90º elbows, and 45º elbows at

5 equivalent feet [1.52 m] each. Note: models Ti150-200 have limitations when operating with Propane Gas (LP).

Example: A Ti200 can be installed with 105 equivalent feet [32 m] of air-intake piping and 105 equivalent feet [32 m] of vent

piping when operating with Natural Gas. When operating with Propane Gas (LP), the maximum vent length in equivalent feet is

limited to 50’ (3” pipe).

The length of one vent pipe (intake or exhaust) may not exceed the length of the other vent pipe by

more than 20 equivalent feet (6.1 m).

Table 3-4 Allowable Vent and Air-Intake Pipe Size and Lengths

Termination Options

The venting system of the Trinity Ti may be terminated using field supplied piping to construct a “Two-Pipe” termination, see

Figures 3-3, 3-4a, 3-6, 3-9, 3-10 and 3-11. Alternatively, the venting may be terminated used a factory kit, either “Concentric”

(see Figures 3-2, 3-4b, 3-5 and 3-7) or “Low Profile” (see Figure 3-8). The Concentric Vent Termination Kit can be either Roof

or Sidewall terminated, while the Low Profile Termination Kit may only be Sidewall terminated. See Table 3-5 for details on the

optional termination kits.

Venting Options - Due to potential moisture loading (build-up) along the exterior wall, sidewall

venting may not be the preferred venting option. See Figs 3-2(b) and 3-3(b).

Optional Termination Kits

Kits certified with the Trinity Ti are listed in Table 3-5 and available from IPEX and/or NTI. For more information on System 636

Concentric Vent Kits or wholesaler locations contact IPEX directly. USA: 1-800-463-9572 or www.IPEXamerica.com │ CAN: 1866-473-9462 or www.ipexinc.com.

Table 3-5 Optional Vent Termination Kits

Page 10

10

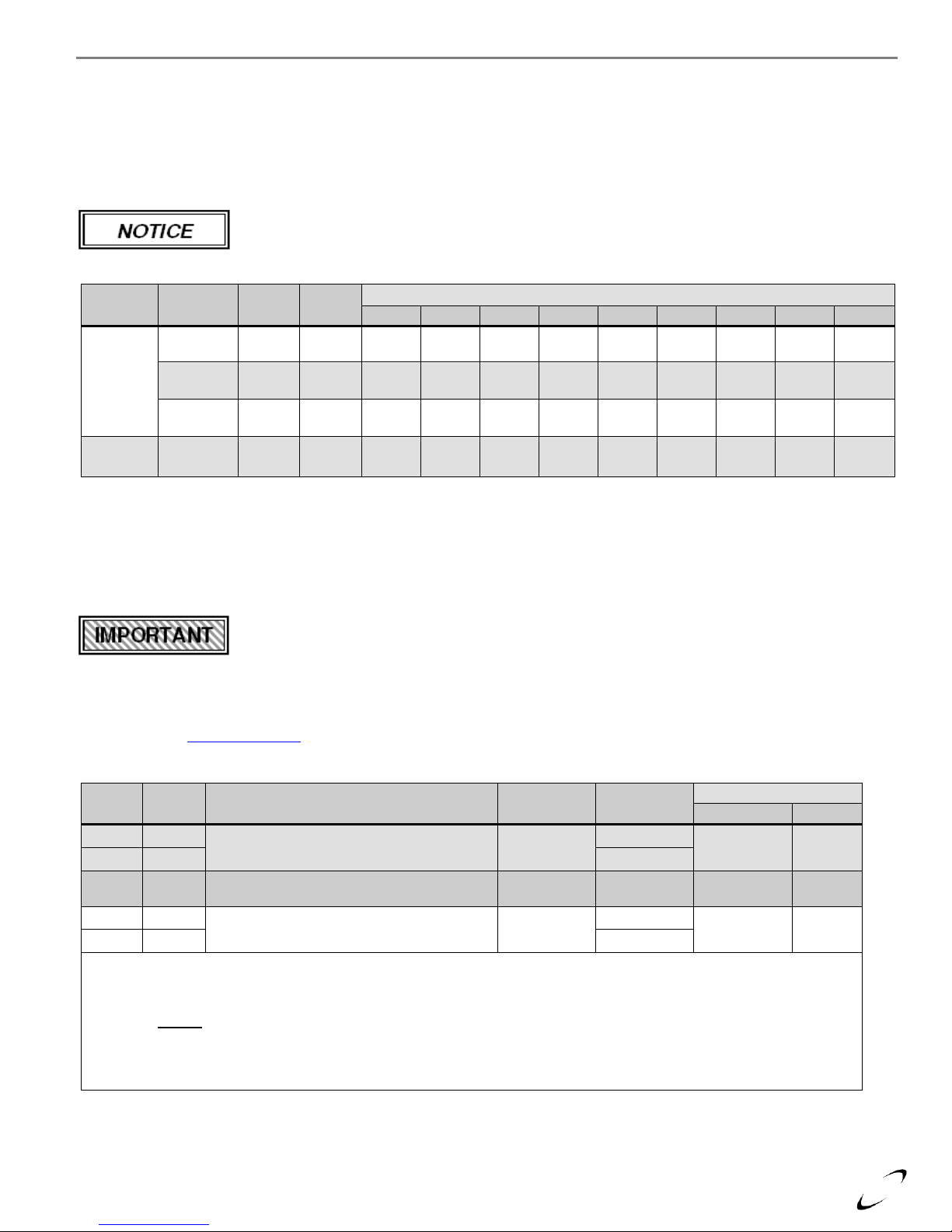

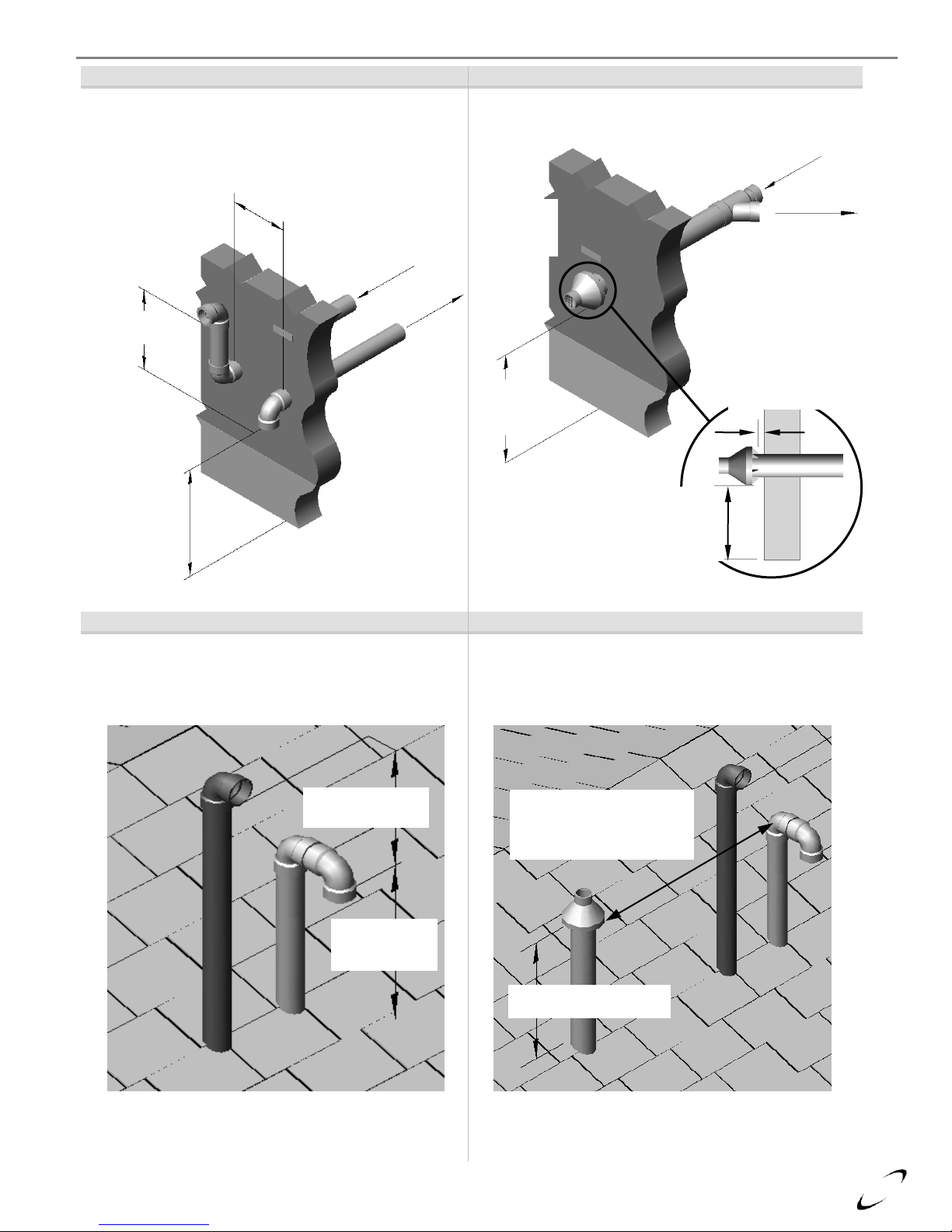

Figure 3-2(a)

Figure 3-2(b)

Concentric Side Wall Termination (Optional Kit)

Concentric Roof Termination (Optional Kit)

Figure 3-3(a)

Figure 3-3(b)

Two-Pipe Side Wall Termination

Two-Pipe Roof Termination

Trinity │Installation and Operation Instructions Ti Series

Page 11

Ti Series Installation and Operation Instructions │Trinity

11

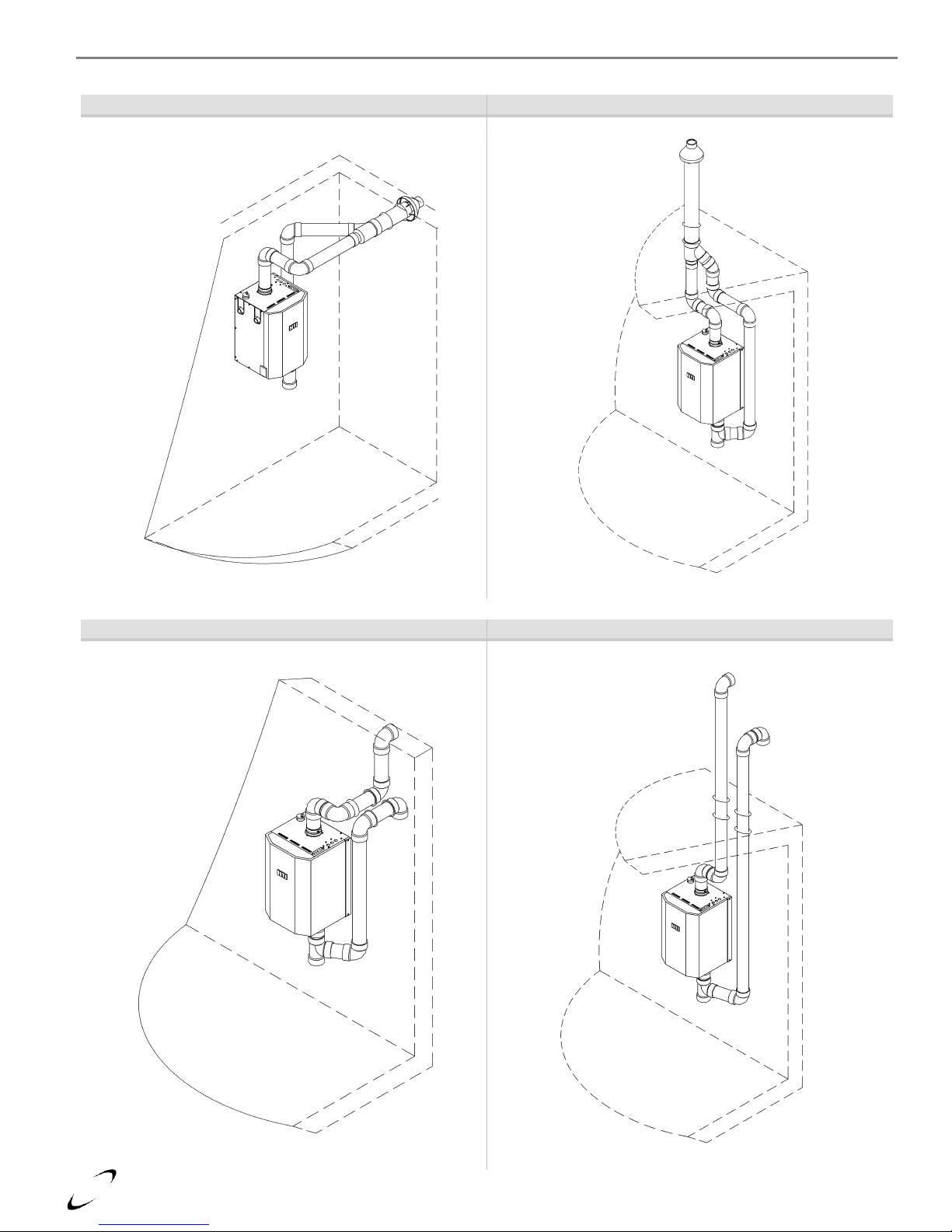

Labeling and Identification – Roof Top Terminations

Figure 3-4(a)

Figure 3-4(b)

Two-Pipe Roof Top Termination

Concentric Vent Roof Top Termination

Two-pipe terminations typically penetrate the roof surface.

An alternative is to use an existing chimney as a chase way.

See Figure 3-11 for more details.

To prevent water leakage, install adequate roof weather seal

flashing (not included) around roof penetration as shown.

Labeling and Identification – Concentric Vent Side Wall Terminations

Figure 3-5(a)

Figure 3-5(b)

Concentric Vent Side Wall Termination

Concentric Vent Detail

Insert vent screen between the end of the boiler exhaust vent

and the end cap as shown. The End Cap

Insert vent screen between the end of the boiler exhaust vent

and the end cap as shown. The End Cap must be secured to

the vent pipe via cement or stainless steel screws.

Warning Plate

From

boiler

To boiler airinlet

connection

Exhaust Vent

Outlet (center)

Gas Vent Directly Below

Keep Free of Obstructions

Concentric

“Y” Fitting

Combustion

Air-Inlet

(perimeter)

Support

(field

supplied)

To boiler

air-inlet

connection

From boiler

exhaust

Air-Inlet

Roof weather

seal flashing

(field supplied)

24” [610 mm]

from terminal

end cap vanes

Exhaust Vent

Exhaust

Vent

Air-Inlet

Chimney

Cap

Existing

Chimney

(used as a

chase way)

Flashing

Exhaust

Vent

Combustion

Air Inlet

End Cap

Vanes (typical)

End Cap

Exterior Wall

Page 12

12

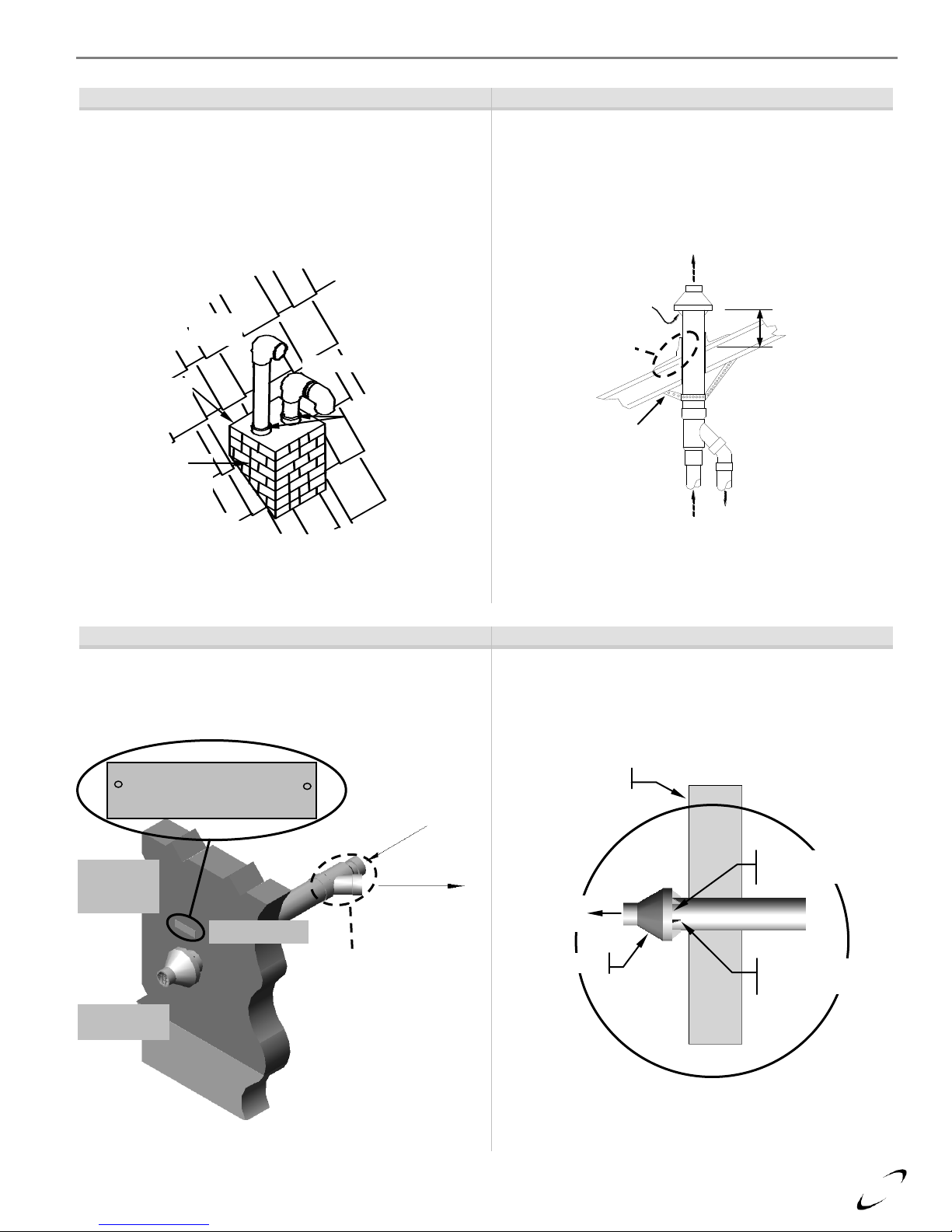

Labeling and Identification – Two Pipe Side Wall

Labeling and Identification – Optional Kit

Figure 3-6

Figure 3-7

Two-Pipe Side Wall Termination

Concentric Vent Termination Kit

Labeling and Identification – Low Profile Termination Kit

Figure 3-8

Low Profile Termination Kit

Warning Plate

Exhaust

Vent

Vent

Screen

Vent Screen

Insert vent

screen into

socket joint of

termination

elbow. Secure

by cementing

a short piece

of venting into

the socket.

Venting

Vent

Screen

Gas Vent Directly Below

Keep Free of Obstructions

Combustion

Air-Inlet

Venting

Fully Assembled

and Installed

Air-Inlet

Piping

Exhaust

Venting

Approved Orientation

Base

Cap

Low Profile Termination Kit

The vent /air-inlet pipes are field

supplied. Vent screens are build

in. Major components provided in

Low Profile Kit include: base, cap,

s.s. screws, and plastic anchors.

Concentric Vent Termination Kit

Insert Vent Screen into the End Cap from the outside,

followed by a short piece of vent pipe to retain the Vent

Screen in place. The End Cap must be secured to the

Exhaust Vent via cement or stainless steel screws. Refer to

Figure 4-12 for more details.

Air Inlet Pipe

Exhaust Vent

Vent Screen

(Included w. boiler)

End Cap

Retaining Exhaust

Pipe Piece

Trinity │Installation and Operation Instructions Ti Series

Page 13

Ti Series Installation and Operation Instructions │Trinity

13

Venting Rules and Guidelines

1. Prevailing Winds: Ensure the vent is located where it will not be exposed to normal prevailing winds.

2. Combustion Air-Intake Contamination: Air for combustion must be drawn from outdoors from an area free of dust and

contaminants. Combustion air containing chemicals such as chloride, fluoride, bromine or iodine or dust and debris will

cause corrosion damage of the heat exchanger voiding your NTI warranty. Refer to Table 3-1 for a list of corrosive

products and contaminants sources to avoid.

3. Vertical Separation: The exhaust must be a minimum of 18” [457 mm] above the air inlet, and the air inlet must always be

a minimum of 12” [305 mm] plus snow allowance above any surface that will support snow. (Two feet plus snow allowance

is highly recommended). Consult your weather office, for the maximum typical snowfall for your region.

Example: New Brunswick Canada - typical maximum snowfall is 19”, thus the inlet must be (12”+19”) = 31” above grade

and exhaust must be (31”+18”) = 49” above grade.

4. Horizontal Separation: The horizontal distance between the inlet and exhaust must be a minimum of 4” [102 mm] center

to center. When the horizontal distance between the inlet and exhaust is greater than 12” [305 mm], the difference in

horizontal distance must be determined and the vertical separation increased by the same amount.

Example: The horizontal distance (HD) = 24” [610 mm] and the vertical separation (VSmin) = 18” [457 mm], the new

vertical separation (VSnew) can be calculated using the following equation:

VSnew = (HD - 12”) + VS, where VSnew = (24” - 12”) + 18” = 30”.

(If the horizontal distance is greater than 6’ [1.83 m], no additional vertical spacing is required. Vertical separation is never

required to be greater than 36” [915 mm].

5. Wall Flashing: Under normal operating conditions this boiler will produce a plume of white gases, and should be taken into

consideration when selecting an adequate location. A 36” [915 mm] diameter stainless, plastic, or vinyl shield can be used to

flash the exterior of the residence.

6. Flue Gas Hazard: Position the vent termination where vapors cannot make accidental contact with people and pets or

damage nearby shrubs and plants.

7. Elbow Extensions: Elbows on outside of wall must be no more than ½” [13 mm] away from the wall.

8. Vent Sloping: All indoor exhaust piping must be on a slope back to the boiler a minimum of ¼” per linear foot of vent [6.25

mm per linear 305 mm]. For applications where excessive condensation is possible ½” per linear foot [13 mm per linear 305

mm] is recommended.

9. Vent Supports: Where required Vent and Air-intake piping shall be secured to the wall for more rigidity. All interior vent

pipe shall be supported a minimum of every 36” [915 mm].

10. Roof Exhaust: In all roof applications the discharge must point away from the pitch of the roof.

11. Roof Flashing: Install adequate flashing where the pipe enters the roof, to prevent water leakage.

12. Rain Cap: Install and seal a rain cap over existing chimney openings, in vacant chimney applications.

13. Venting Below Grade: For installations that exit the wall below grade refer to Figure 3-9.

14. Vent Screens: Install factory supplied vent screens on the outside of the last elbow for both the inlet and exhaust vent

terminal elbows. Install the screen into the female opening of the elbow. Then cut a small piece of pipe to sandwich the

screen into the elbow. NOTE be sure that the small piece of pipe cut, does not extend past the end of the elbow. Two

screens are provided in the package. See Figures 3-6 and 3-7. Vent screens are included in Optional Termination Kits.

15. Pipe Sizing: It is extremely important that the intake and exhaust vent piping be adapted to the appropriate size immediately

upon exiting the boiler cabinet. Refer to Figure 3-1 and Table 3-4.

16. Condensate Hazard: Do not locate vent over public walkways, driveways or parking lots. Condensate could drip and

freeze resulting in a slip hazard or damage to vehicles and machinery.

17. Warning Plate: Install the warning plate “Gas Vent Directly Below”, directly above (within 4 ft [1.22 m] vertically) the

location of the air inlet pipe, so it is visible from at least 8 ft [2.4 m] away. See Figures 3-5a and 3-6.

18. Wall Thickness: Direct vent terminations are designed to work with any standard wall thickness. Installation guidelines for

min/max wall thickness are as follows: Min.= 1” [25mm], Max.= 60” [1.52 m].

19. Venting Options: Due to potential moisture loading (build-up) along the exterior wall, sidewall venting may not be the

preferred venting option. Refer to Figures 3-2(b) and 3-3(b) for roof top venting options.

Page 14

14

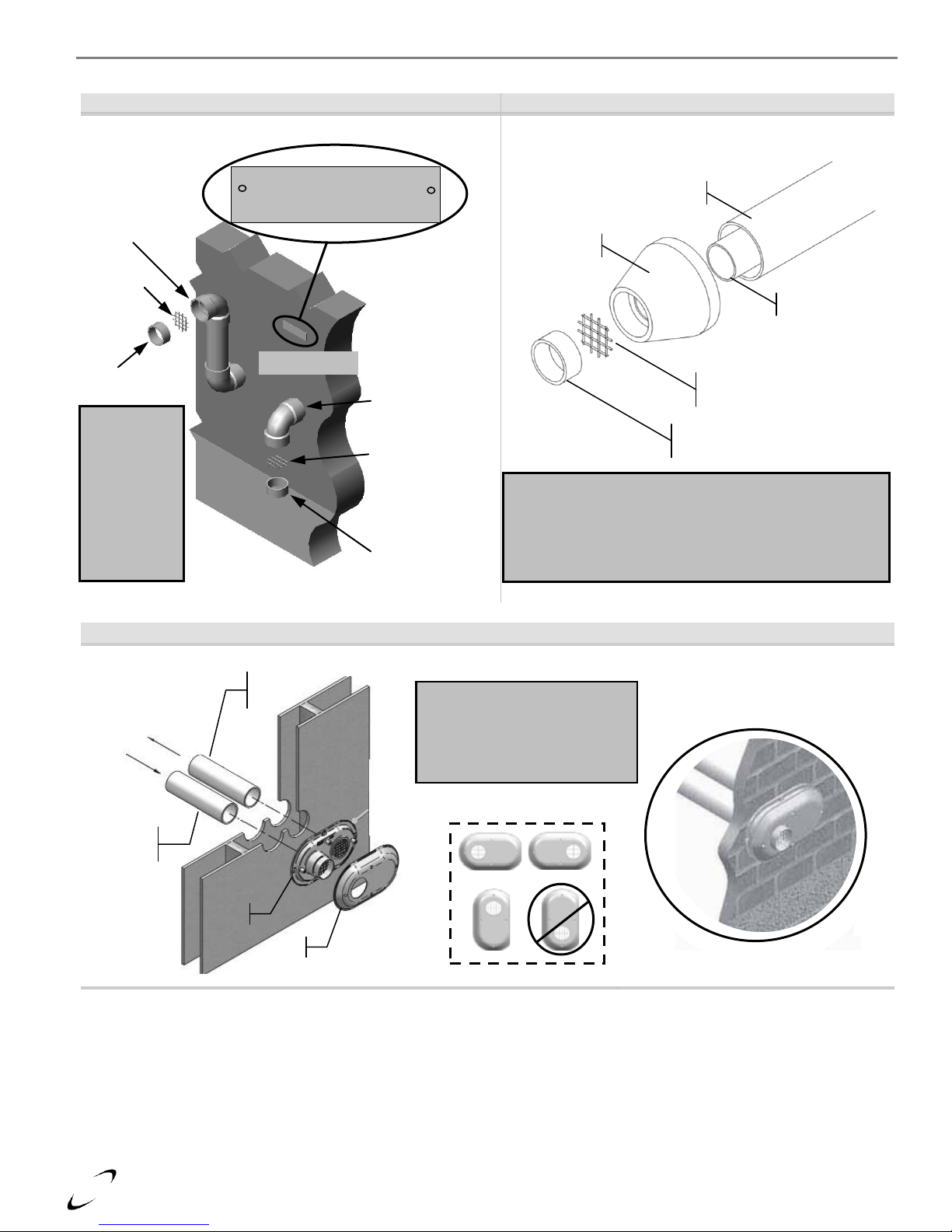

Figure 3-9

Venting Below Grade

For installations that exit the wall below grade:

1. Excavate site to a point below where the pipes are to

exit as shown.

2. Ensure that the wall is fully sealed where the pipes

penetrate the wall.

3. The Vent/Air-intake piping MUST be secured to the

side of the building above grade, as shown, to provide

rigidity.

4. NTI Provides a mounting bracket PN. 82075 for

securing the exhaust pipes.

5. Ensure that the Vent/Air-Intake clearances are

maintained, see Section 4.0 for details.

Figure 3-10

Outdoor Horizontal Venting

Vent piping outside the Building is permitted under the

following conditions:

1. The maximum length outside the building is 20 feet [6.1

m]. Note that outdoor length must be included in the

overall vent length calculation.

2. All normal termination clearances are maintained.

3. The pipe is supported every 24” [610 mm].

4. The exhaust and inlet are sloped back to the boiler ½”

elevation for every linear foot [13 mm for every linear

305 mm].

Figure 3-11

Existing Chimney Chase Way

It is permissible to use an existing chimney as a chase way to

run the Vent/Air-Intake piping as long as:

1. The chimney is not being used by any other boiler.

2. Flue gases don’t enter the vacant chimney.

3. Only Trinity certified venting materials are used, see

Section 3.0.

4. Vent lengths are within the maximums specified.

5. The top of the chimney is capped and the Vent/Air-Inlet

pipes are flashed to prevent leakage into the vacant

chimney.

Air-Inlet

Existing

Chimney

(used as a

chase way)

Chimney

Cap

Exhaust Vent

Exhaust Vent Min.

18” [457 mm]

above air-inlet

Air-Inlet

Min. 12” [305 mm]

above roof and

snow level

Supports every

24” [610 mm]

12” [305 mm] plus snow

allowance above grade

Air-Inlet

Maximum of 20 ft

[6.1 m] is permitted

for piping outside a

building.

Apply

Warning

Plate

here

Exhaust

Vent

Gas Vent Directly Below

Keep Free of Obstructions

Exhaust Vent

Air-Inlet

Mounting

Bracket

Trinity │Installation and Operation Instructions Ti Series

Page 15

Ti Series Installation and Operation Instructions │Trinity

15

Clearances to Air-Inlet Termination

Canada 1

USA 2

Min. Distance

Min. Distance

A

Above grade/roofline and snow level 8

12 in.

305 mm

12 in.

305 mm

B

Above roof line - Concentric Vent

6, 11, 13

24 in.

610 mm

24 in.

610 mm

C

To exhaust vent from any other boiler

36 in.

915 mm

12 in.

305 mm

Clearances to Exhaust Vent Termination

Min. Distance

Min. Distance

D

Minimum vertical separation above air inlet 9

18 in.

457 mm

18 in.

457 mm

E

Minimum horizontal separation from air inlet 3

4 in.

102 mm

4 in.

102 mm

F

Window, door or building opening

36 in.

915 mm

12 in.

305 mm

G

To combustion air inlet from any other boiler

36 in.

915 mm

12 in.

305 mm

H

Non-mechanical air supply inlet to building

36 in.

915 mm

12 in.

305 mm

I

Mechanical air supply inlet to building 4

6 ft.

1.83 m

3 ft.

915 mm

J

Soffit, overhang, eave or parapet

24 in.

610 mm

24 in.

610 mm

K

Soffit vent or vent opening in an overhang, eave or parapet

6 ft.

1.83 m

6 ft.

1.83 m

L

Outside corner 10

- - -

-

M

Inside corner of an L-shaped structure (including walls and fences)

36 in.

915 mm

36 in.

915 mm

N

Electric meters, gas meters, regulators and relief equipment

6 ft.

1.83 m

4 ft.

1.22 m

P

Each side of center line above or below meters, regulators and relief devices 5

36 in.

915 mm

36 in.

915 mm

Q

Above a paved sidewalk, driveway, or parking lot on public property if adjacent 12

7 ft.

2.13 m

7 ft.

2.13 m

R

Above a sidewalk, driveway, or parking lot on public property

X X X

X

S

Above a sidewalk, driveway on private property between / serving both dwellings

X X X

X

T

Under a concrete veranda, porch, deck, or balcony 7

24 in.

610 mm

24 in.

610 mm

U

Above, under or near exterior stairs

X X X

X

V

Into a canopy or carport

X X X

X

Notes:

1 - Canadian installations must comply with the current CSA B149.1 Natural Gas and Propane Installation Code and local

building codes.

2 - US installations must comply with current ANSI Z223.1/ NFPA 54 National Fuel Gas Code and local building codes.

3 - Horizontal separation center-to-center (c.c.) 4”-12” (102-305 mm). Refer to “Venting Rules and Guidelines” for

horizontal separation > 12” c.c. as it may impact vertical separation clearances.

4 - For US installations, an exhaust vent may be 3 ft above a mechanical air supply inlet if within 10 ft. [3 m] horizontally.

5 - Horizontal clearance must be observed up to a height of 15 ft. [4.6 m] above/below the meter, regulator, or relief devices.

6 - Concentric Vent must protrude from the roof precisely 24” [610 mm] measuring from the terminal end-cap vanes.

7 - Permitted if veranda, porch, deck, or balcony is made of concrete and a minimum of two sides are fully open beneath.

8 - 24” is the recommended snow level allowance above grade/roofline or any surface that will support snow, debris, or ice

(i.e. for roof venting clearances - roofline and snow level). If living in a snowfall region, consult your local weather

office for the maximum typical snowfall for your area.

9 - Note that the vent must maintain a minimum vertical distance above the air inlet. Example: Vent height = 18” (457

mm) above air inlet + 12” (305 mm) for air inlet above grade/roof line and snow level = 30” (762 mm) above grade and

snow level.

10 - Clearances to an outside corner to be in accordance with local installation codes.

11 - In Canada, concentric vent materials are subject to approval by local inspectors. See Termination Kits in Section 3.0.

12 - Above public walkways, driveways or parking lots if adjacent to it and condensate cannot drip, freeze, or create a hazard.

13 - Contact the manufacturer for special exemptions relating to multiple boiler installations using concentric vents.

4.0 VENT/AIR-INTAKE TERMINATION CLEARANCES

The quick reference table below is to be read in conjunction with the numbered notes as indicated,

Figures 4-1 through 4-6, and the Venting Rules and Guidelines in Section 3.0. The instructions detailed

in this section are a combination of Trinity Ti specific and National Gas Code restrictions. Compliance alone doesn’t insure a

satisfactory installation as good common sense must also be applied. Failure to follow these instructions may result in fire,

property damage, serious injury or death.

Table 4-1 Termination Clearances Quick Reference Table

Page 16

16

G – Letter represents a specific Termination Position. Refer to Table 4-1 for corresponding termination clearances.

Concentric Vent

Termination

Q

Two-Pipe

Termination

F

Clearance “Q”

Adjacent to Public

Walkway or Driveway

Minimum 7ft [2.13 m]

G

Clearances “F” and “G”

Canada – Minimum 3 ft [915 mm]

The US – Minimum 1 ft [305 mm]

Trinity │Installation and Operation Instructions Ti Series

Figure 4-1

Termination Clearances Quick Reference Diagram

Illustrations of Termination Clearances

Side Wall Termination - Clearances Above Grade

Figure 4-2

Page 17

Ti Series Installation and Operation Instructions │Trinity

17

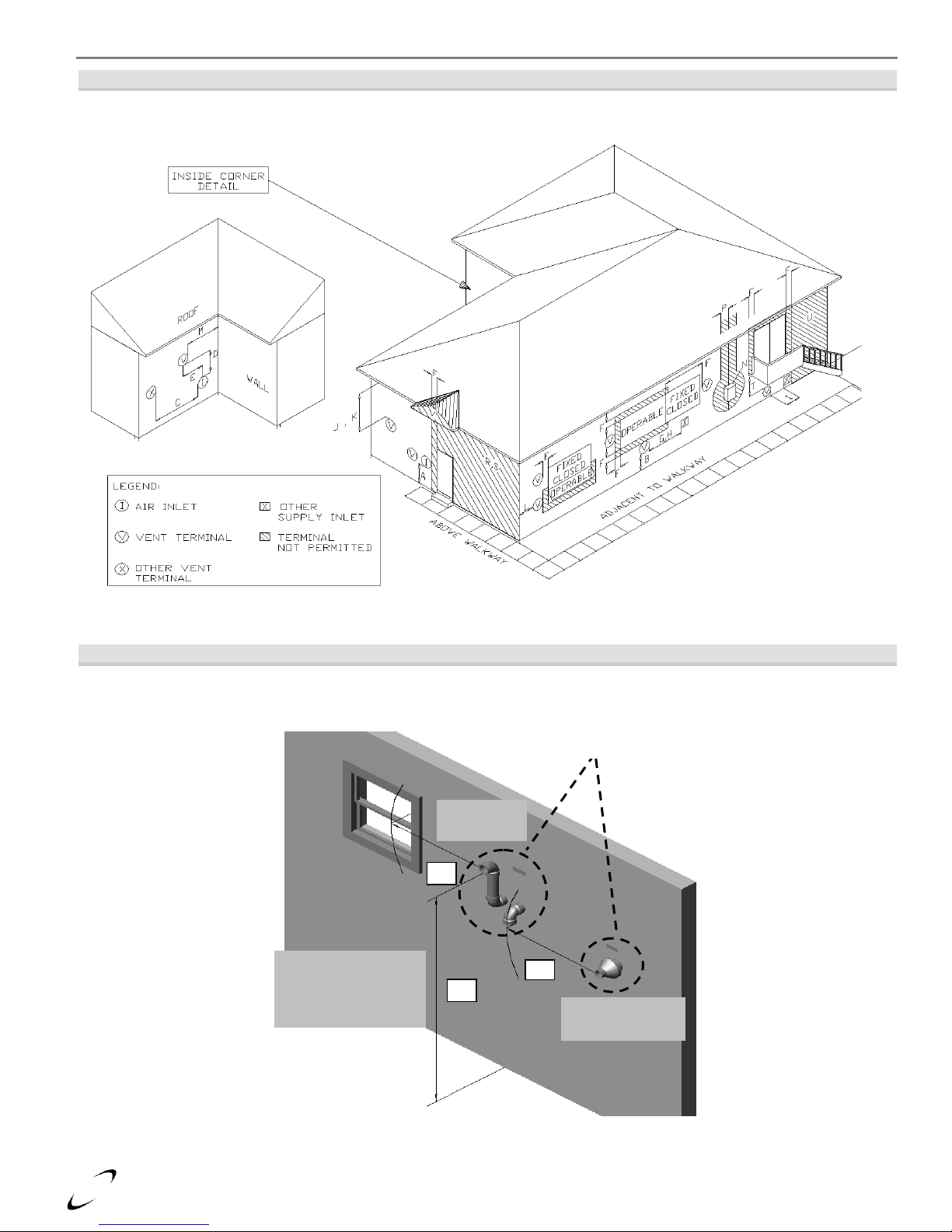

Figure 4-3 Typical

Figure 4-4

Two-Pipe Side Wall Clearances

Concentric Vent Side Wall Clearances

Figure 4-5

Figure 4-6

Two-Pipe Roof Top Clearances

Concentric Vent Roof Top Clearances

Two-pipe systems can be vented thorough the roof.

Minimum heights above snow level still apply.

The same clearances apply to roof-top terminations as for

two-pipe sidewall terminations.

Vertical

Separation

Horizontal Separation

4-12” [102 mm – 305 mm] or

greater than 36” [915 mm]

From boiler

exhaust

Minimum

12” [305 mm]

above grade

and snow level

To boiler

air-inlet

connection

Minimum 18”

[457 mm]

To boiler

air-inlet

connection

Exhaust from

boiler

Wall clearance

must be 1” [25

mm] from end

cap vanes to

outside of wall

Minimum

12” [305 mm]

above grade

and snow

Exhaust

Vent Outlet

(center)

Combustion

Air-Inlet

(perimeter)

Min. 12” [305 mm]

above grade and

snow level

MIN. 18” [457 mm]

above air-intake

MIN. 12”

[305 mm] above

snow level

24” [610 mm] above roof

from end cap vanes

Clearances from exhaust to

another combustion air inlet

Canada – Min. 3 ft [915 mm]

The US – Min. 1 ft [305 mm]

Page 18

18

Trinity │Installation and Operation Instructions Ti Series

Extra precaution must be taken to adequately support the weight of the Vent/Air-Intake piping in

applications using roof-top terminations. Failure to follow these instructions may result in venting or

boiler component failure resulting in flue gas spillage leading to property damage, serious injury or death.

Under no circumstances may an existing chimney or chase-way be used to vent or provide combustion

intake air to a Trinity Ti. Failure to follow instructions will result in fire, property damage, serious

injury or death.

Removing an Existing Boiler from Common Venting System

Do not install the Trinity Ti into a common venting system with any other boilers. Failure to comply

with this warning will cause flue gas spillage and leech carbon monoxide emissions into the

surrounding air resulting in serious injury or death.

When an existing boiler is removed from a common venting system, the common venting system is

likely to be too large for proper venting of the remaining boilers connected to it. Instructions have been

provided on how to remove the existing boiler and how to resize the remaining venting system. Failure to follow these

instructions may result in property damage, serious injury or death.

At the time of removal of an existing boiler, the following steps shall be followed with each boiler remaining connected to the

common venting system placed in operation, while the other boilers remaining connected to the common venting system are not

in operation.

Steps to Removing an Existing Boiler

1. Seal any unused openings in the common venting system.

2. Visually inspect the venting system for proper size and horizontal pitch. Verify that there is no blockage, restriction, leakage,

corrosion or other deficiencies which could cause an unsafe condition.

3. Insofar as is practical, close fireplace dampers, all building doors and windows and all doors between the space in which the

boilers remaining connected to the common venting system are located and other spaces of the building. Turn on clothes

dryers and any boiler not connected to the common venting system. Turn on any exhaust fans, such as range hoods and

bathroom exhausts, so they will operate at maximum speed. Do not operate a summer exhaust fan.

4. Place in operation the boiler being inspected. Follow the lighting instructions. Adjust thermostat so boiler will operate

continuously.

5. Test for spillage at the draft hood relief opening after 5 minutes of main burner operation. Use the flame of a match or

candle, or smoke from a cigarette, cigar or pipe.

6. After it has been determined that each boiler remaining connected to the common venting system properly vents when tested

as outlined above, return doors, windows, exhaust fans, fireplace dampers and any other gas burning boiler to their previous

condition of use.

7. Any improper operation of the common venting system should be corrected so the installation conforms with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54 and/or CAN/CSA B149.1, Natural Gas and Propane Installation Code. When

resizing any portion of the common venting system, the common venting system should be resized to approach the minimum

size as determined using the appropriate tables in Part 11 of the National Fuel Gas Code, ANSI Z223.1/NFPA 54 and/or

CAN/CSA B149.1, Natural Gas and Propane Installation Code.

Page 19

Ti Series Installation and Operation Instructions │Trinity

19

15"min.

Condensate

from Boiler

Bottom

Panel

Condensate

Trap & drain

White Siphon drainpipe must

terminate above any possible

water line in the house drain.

Make a water tight

connection to the

condensate-y fitting

exiting the bottom of

the boiler cabinet.

Condensate drainpipe

must not be sealed,

thus allowing overflow

if blocked.

Make a water tight

connection to the

condensate-y fitting

exiting the bottom of

the boiler cabinet.

Figure 5-1 Condensate Drain Kits

5.0 CONDENSATE DRAIN

This unit produces water as a product of combustion. Much of this water condenses on the heat exchanger and in the venting

system. All exhaust piping must be on a slope back to the boiler ¼” per linear foot of vent. Steps must be taken to ensure that

condensate does not collect in the venting system. Condensate must be drained from the boiler into a household drain.

Failure to properly connect the condensate trap and drain will cause combustion gases to enter the room

resulting in property damage, serious injury or death.

Note: check with your municipality, or local gas company to determine if disposal of combustion condensate is permitted.

In the State of Massachusetts the condensate must be neutralized prior to entering a drain.

The following are important notes that must be taken into consideration when constructing the condensate system:

DO NOT run condensate line outside. A frozen or blocked drain will cause the condensate to fill the combustion

chamber. This will result in a no heat condition, as the unit will shut down, and damage to the flame sensor, and

components can occur.

NEVER use copper, steel, or galvanized piping in the construction of the condensate system (condensate is very

corrosive and will rot most metals).

When a condensate pump is used or required, select a pump that is designed for residential furnaces.

If the condensate drain becomes blocked resulting in condensate backing-up into the heat exchanger, the

combustion chamber must be inspected and cleaned and internal refractory must be replaced; see

“Combustion Chamber Cleaning” in Section 17.0 for further details. Failure to follow these instructions will result in dangerous

boiler operation resulting in property damage, fire or loss of life.

The condensate drain kit supplied with each boiler is susceptible to flooding if the drain hose exiting the

kit is lengthened or inserted into a drain. If additional length is required, do not use the drain kit

provided, instead fabricate a 15” trap using tubing suitable for condensate disposal.

Page 20

20

It is highly recommended to use

flexible gas pipe, the gas valve and

blower cannot support the weight of

piping. If piping is used, ensure that

the valve supports NO WEIGHT

Gas cock shut Off

Valve to be "T"

type handle

Figure 6-1 Gas Connection

Trinity │Installation and Operation Instructions Ti Series

6.0 INSTALLING GAS PIPING

The Trinity Ti is factory equipped to operate with Natural Gas, the installation of a conversion kit is

required prior to operating with Propane Gas. The Natural to LP Conversion Kit must be installed prior

to installing the gas piping to the appliance. Failure to properly convert the unit to operate with Propane may result in property

damage, serious injury or death.

Liquefied Petroleum (LP)

propane gas is heavier than air;

therefore, it is imperative that your appliance is not

installed in a pit or similar location that will permit heavier

than air gas to collect. Check with Local Codes as they

may require appliances fueled with LP gas be provided

with an approved means of removing unburned gases from

the room. Failure to follow these instructions may result in

serious injury or death.

Installation

Refer to the current National Fuel Gas Code ANSI

Z223.1/NFPA 54 or CAN/CGA B149.1 installation codes,

and local codes for gas piping requirements and sizing.

Pipe size running to the unit depends on:

Length of pipe.

Number of fittings.

Type of gas.

Maximum input requirement of all gas appliances in the residence.

Ensure that:

The gas line connection to the appliance does not apply any weight to the gas valve. NTI recommends using approved

flexible gas piping (if acceptable by local codes) to connect the appliance to the gas supply (See Figure 6-1 for details).

You plan the installation so that the piping does not interfere with the vent pipe, or the removal of the valve, burner, and

serviceable components.

The Appliance shall be installed such that the gas ignition system components are protected from water (dripping, spraying,

rain etc.) during installation and servicing.

The gas piping is large enough for all the appliances in the home. No appreciable drop in line pressure should occur when

any unit (or combination of units) lights or runs. Use common gas-line sizing practices.

Always use a pipe-threading compound that is resistant to propane (LP) gas solvent action. Apply sparingly to all male

threads, starting at two threads from the end. Over doping or applying dope to the female end, can result in a blocked gas

line.

DO NOT TIGHTEN FITTINGS WITHOUT SUPPORTING THE GAS VALVE as damage to the valve or blower motor

can occur.

Install a manual “Equipment Shut-Off Valve” as shown in Figure 6-1. Valve must be listed by a nationally recognized

testing lab.

The gas line piping can safely be removed from the appliance for servicing, by strategically placing the gas line shutoff and

union; see example in Figure 6-1.

All gas piping, including gas components in the appliance, are checked for leaks using a “Bubble Test”, prior to operating

the appliance.

property damage, serious injury or death.

Strain on the gas valve and fittings may result in vibration, premature component failure and leakage

and may result in a fire, explosion, property damage, serious injury or death.

Flexible gas piping cannot be used within the appliance cabinet and cannot pass through the cabinet

wall, use rigid piping as shown in Figure 6-1. Failure to follow these instructions may result in fire,

Do not use an open flame to test for gas leaks. Failure to follow these instructions may result in fire,

property damage, serious injury or death .

When performing a pressure test on the gas line piping, be sure the appliance is disconnected or isolated

if the test pressure is expected to exceed 1/2 PSI (14” w.c.), as damage to the valve could occur

resulting in fire, property damage, serious injury or death.

Page 21

Ti Series Installation and Operation Instructions │Trinity

21

7.0 LIGHTING THE APPLIANCE

Before Start-up refer to Mandatory Pre-commissioning Procedure for Plastic Venting in Section 3.0.

Failure to follow these instructions can result in explosions, injury or death.

Prior to turning the gas supply on and lighting the appliance, ensure all aspects of the installation are

complete and in conformance with the instructions provided in this manual, including the Vent/AirIntake, Condensate Drain, and System Water Piping. Failure to precisely follow these instructions will cause a fire or explosion

resulting in property damage, serious injury or death.

Do not store or use gasoline or other flammable vapors & liquids in the vicinity of this or any other

appliance. Failure to follow instructions could result in explosion causing property damage, serious

injury or death.

If you do not follow these instructions exactly, a fire or explosion may result causing property damage,

serious injury or death.

If overheating occurs or the gas supply fails to shut off, turn off the manual gas control valve to the

boiler. Failure to follow instructions could result in explosion causing property damage, injury or death.

FOR YOUR SAFETY, READ BEFORE OPERATING_

A) This appliance does not have a pilot. It is equipped with an ignition device which automatically lights the

burner. Do not try to light the burner by hand.

B) BEFORE OPERATING smell all around the appliance area for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

C) Use only your hand to push in or turn the gas control knob. Never use tools. If the knob will not push in or

turn by hand, don't try to repair it, call a qualified service technician. Force or attempted repair may result in a

fire or explosion.

D) Do not use this appliance if any part has been under water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the control system and any gas control which has been under

water.

OPERATING INSTRUCTIONS_

1. STOP! Read the safety information above very carefully.

2. Set the thermostat to lowest setting. Turn off all electric power to the appliance.

3. This appliance does not have a pilot. It is equipped with an ignition device which automatically lights the

burner. Do not try to light the burner by hand.

4. Turn the manual gas valve to the OFF position. Remove front access panel.

5. Wait five (5) minutes to clear out any gas. Then smell for gas, including near the floor. If you smell gas,

STOP! Follow “B” in the safety information above. If you don't smell gas, go to the next step.

6. Turn the manual gas valve ON. Wait an additional five (5) minutes smelling for gas.

7. Replace the front access panel.

8. Set thermostat to highest setting. Turn on all electric power to the appliance.

9. Ignition sequence is automatic. Combustion will occur after a brief fan purge.

10. If ignition does not occur, follow the instructions “To Turn Off Gas To Appliance” and call your service

technician or gas supplier.

TO TURN OFF GAS TO THE APPLIANCE_

1. STOP! Read the safety information above very carefully.

2. Turn off all electric power to the appliance

3. Turn the manual gas valve to the OFF position

Page 22

22

Trinity │Installation and Operation Instructions Ti Series

The initial lighting of the appliance must be performed by a licensed Gas Technician. Failure to follow

instructions may result in property damage, serious injury or death.

Ensure the appliance is wired in accordance with this manual.

Ensure the gas shut-off valve is turned on, and that the gas system has been fully tested for leaks.

Ensure the system is completely filled with water, and that ALL the air is purged out.

Allow primers/cements to cure for 8 hours prior to Start-up. If curing time is less than 8 hours, first

perform Steps 2 through 6 of Mandatory Pre-commissioning Procedure for Plastic Venting in Section

3.0. Failure to follow these instructions can result in explosion, serious injury or death.

Initial Start-Up

1. Turn on power to the Trinity Ti and turn-up the Thermostat(s). The appliance should run through a purge, and combustion

should occur. (The control system has a built in ignition retry, allowing the system to try at least three times, before lockingout.)

2. With the unit operating at full capacity, verify that the gas line pressure is 4-10.5 inches w.c. for Natural gas, and 9-13 inches

w.c. for Propane (See Section 8.0 for details).

3. Using an appropriate Oxygen or Carbon Dioxide analyzer, take a sample of the flue gas. The sample must fall within the

acceptable ranges for Carbon Dioxide, which is 8.5% - 9.5% for Natural gas, and 9.5%-10.5% for propane (See Section 8.0

for details). Notice: unit shall be operating at maximum firing rate during the combustion test.

4. Perform at least three lights in succession to ensure proper operation.

5. After the three successive lights, unplug the flame probe, and allow the unit to cycle again. Ensure that it tries to light, and

locks out on safety reset. Once you have successfully activated the flame safety system, replace the wire on the flame sensor,

and reconfirm proper lighting.

If the unit fails to light consistently and smoothly, contact NTI for assistance at 1-800-688-2575.

Never allow the appliance to continue to operate if the ignition or operation of the burner is rough or

erratic. Failure to follow these instructions could result in serious injury or death.

Re-lighting Unit

1. Stop and read these instructions very carefully.

2. Set the thermostat to the lowest setting, and then turn off all power to the appliance.

3. This appliance does not have a pilot. It is equipped with an ignition device that automatically lights the burner. Do not try to

light the burner by hand.

4. Turn the gas shut-off valve to the off position, and then remove the front cover.

5. Wait five (5) minutes to clear out any gas. Then check for gas, including near the floor. If you smell gas “Stop” and follow

“B” above. If you don’t detect any gas proceed to the next step.

6. Turn the gas shut-off valve to the on position, wait an addition five (5) minutes and check for gas.

7. Replace the front cover.

8. Set the thermostat to the highest setting, and then turn on all power to the appliance.

9. Ignition sequence is automatic, combustion will occur after a brief fan purge. Ignition will retry 3 times.

10. If ignition does not occur, “Turn off the gas and electricity to the appliance” and contact a professional service technician,

or gas supplier.

Turning Off The Appliance

1. Set the thermostat to the lowest setting, and then turn off all power to the appliance.

2. Turn the gas shut-off valve to the off position.

Page 23

Ti Series Installation and Operation Instructions │Trinity

23

Gas

Line Pressure (inches wc)

CO2 (%)*

CO (ppm)

Max.

Nominal/Desired

Min.

Max.

Min.

Max.

Natural

7 4 10.5

8.5

9.5

175

Propane

11 8 13

9.5

10.5

175

Model

Minimum Gas Input Value

Maximum Gas Input Value

Ti100

50

240

Ti150

50

240

Ti200

40

240

8.0 GAS VALVE AND BURNER SET-UP

Set-up of the Trinity Ti gas valve must be performed by a licensed Gas Technician. Failure to perform

the set-up correctly may result in incorrect operation, component failure, property damage, serious

injury or death.

Gas Line Pressure

The appliance gas valve is equipped with a line pressure test port; see Figures 8-1. Use the following procedure to measure the

gas line pressure to the appliance to ensure if falls within the range given in Table 8-1:

1. Turn the supply of gas to the appliance off.

2. Open the bleed screw of the line pressure test port approximately 1-1/2 turns. This port is directly connected to the gas line

feeding the appliance.

3. Force 1/4 ID tubing over the housing of the line pressure test port; install the other end of the tubing to an appropriate line

pressure test gauge or manometer. Ensure both ends of the tubing make a tight connection.

4. Open the supply of gas to the appliance and check for gas leaks.

5. Observe the line pressure under static conditions and compare it to Table 8-1. The pressure will be greatest under static

conditions.

6. With all other gas appliances in the application running, operate the burner to the maximum firing rate (See Table 8-2) and

compare the observed line pressure with Table 8-1. The pressure will be lowest during the maximum flow of gas.

7. Adjust the gas line pressure to ensure the parameters in Table 8-1 are attained under all conditions. If possible adjust the

line pressure to the "Nominal/Desired" value listed in Table 8-1, while the unit is operating at the maximum modulation

rate, see Table 8-2.

8. Continue observing the gas line pressure until the completion of the combustion analyses, in case adjustments need to be

made.

9. Upon completion of the line pressure testing, return the bleed screw of the Line Pressure Test Port to the closed position.

The line pressure is a function of the gas supply and is affected solely by field provided parameters

such as line size and regulator settings. Under no circumstances can the appliance gas valve influence

or be used to adjust the gas line pressure.

Failure to close the bleed screw of the Line Pressure Test Port will cause a severe leakage of gas,

resulting in a fire or explosion causing property damage, serious injury or death.

Table 8-1 Line Pressure and Combustion Parameters

*Note: it is permissible to have higher CO2 values with the burner operating at the minimum modulation rate.

Table 8-2 Minimum and Maximum “Gas Input Values” (Modulation Rates)

Never leave the unit operating while producing Carbon Monoxide (CO) concentrations in excess of

175ppm. CO concentration will be greatest with the boiler operating at the highest firing rate, therefore

measure and make necessary adjustments with unit operating at the Maximum Gas Input Value, see Table 8-2. Failure to follow

this warning may result in serious injury or death.

DO NOT adjust or measure boiler Manifold Pressure as correct pressure is factory set. Field adjustment

could result in improper burner operation resulting in fire, explosion, property damage or death.

Page 24

24

Figure 8-1 Gas Valve Venturi Assembly

Gas Inlet

Gas Valve

Line Pressure

Manifold Pressure

Orifice Location

Gas Throttle / Input

Adjustment Screw

Venturi

Air Inlet

Throttle/Input Adjustment Screw

Increase gas

Turn Counterclockwise

Decrease gas

Turn Clockwise

Trinity │Installation and Operation Instructions Ti Series

Adjustment

Input Screw Adjustments - The appliance is equipped with a Throttle/Input Adjustment Screw, located on the Gas Valve and

Venturi Assembly. The Throttle screw is used to adjust the flow of gas leaving the gas valve, entering the Venturi and hence

entering the combustion air stream. By turning the adjustment screw in, clockwise, the flow of gas is reduced and the

combustion becomes leaner, thus reducing the concentration of CO2 in the flue gases. To increase the CO2 the Throttle screw

must be adjusted out, counterclockwise, thus increasing the flow of gas from the gas valve to the combustion air stream.

The Throttle/Input screw for models Ti100-200 is a multiple turn valve. Fully open to close is approximately 17 turns. Typical

adjustment for Natural Gas is 0-1 full turns in or out from its factory position. Typical adjustment for LP Gas is 0-3 full turns in

or out from its factory position. See Figure 8-1 for screw location.

Adjustments to the Throttle screw may only be made by a qualified gas technician, while using a

calibrated combustion analyzer capable of measuring CO2 and CO. Failure to follow these instructions

may result in serious injury or death.

Adjustments to the Throttle screw may only be performed if the gas line pressure is maintained above

minimum levels throughout the duration of the test, see Table 8-1. Failure to follow these instructions

may result in serious injury or death.

Page 25

Ti Series Installation and Operation Instructions │Trinity

25

Combustion Calibration - To calibrate burner operation, perform the following procedure using a calibrated combustion

analyzer capable of measuring CO2 and CO from Natural and Propane Gas burning appliances:

1. Operate the unit at the maximum modulation rate, see Table 8-2.

2. Ensure the gas line pressure is maintained within tolerance, see Table 8-1.

3. While at the maximum Gas Input Value, measure the CO2 and CO; adjust as necessary, using the Throttle Screw, to be

within the limits listed in Table 8-1.

4. Operate the unit at the minimum Gas Input Value (Table 8-2). Ensure the combustion remains smooth and CO2 and CO

remain within the limits (Table 8-1). If not, do not adjust further, contact NTI for assistance.

Maximum Modulation Rate – The Trinity Ti boiler is equipped with an electronic burner control that will modulate the firing

rate to match the demand placed on the unit. There is no way to force the appliance to operate at the maximum modulation rate;

the unit will automatically determine the modulation rate based on the water temperature and the temperature set points. To help

obtain the maximum modulation rate the following steps should be taken:

1. Remove the Outdoor sensor wires from the boiler (see Figure 11-1).

2. Change the HI setting to the maximum safe water temperature that the heating system can handle (see Section 12.0).

3. Turn on all heating zones and set thermostats to their maximum setting.

Failure to reconnect the Outdoor Sensor may increase fuel consumption. Failure to return the HI setting

to the heating system maximum desired working temperature may result in property damage or excessive

fuel consumption.

Alternate method (DHW with Combi or Indirect Fired Water Heater):

1. Turn on several hot water fixtures

2. Set boiler LO setting to 190 (see Section 12.0)

3. If using a Combi boiler the unit will run and stay at high fire until the taps are turned off.

4. If using an indirect hot water tank, allow the tank to cool off before turning the boiler on.

Failure to return the LO setting to the desired working temperature may result in excessive fuel

consumption.

See Table 10-3 for recommended settings.

Minimum Modulation Rate – Like the maximum modulation rate, there is no way to force the Trinity to operate at the minimum

modulation rate. To help obtain the minimum modulation rate follow the steps above for the maximum modulation rate, but

slowly reduce the system water flow rate until the minimum modulation rate is achieved. When using the alternate method (DHW