Page 1

Trin & Stor

ill

ndicates a hazardous situation which, if not avoided,

ndicates a hazardous situation

hazardous

ndicates a hazardous situation which, if not avoided,

Model Numbers: S, S-SR, SL Series

Version Date: 2010-06-01

INDIRECT WATER HEATERS

NEW PRODUCT LINE

Indirect Water Heaters

Stainless Steel Solar

Stainless Steel

Stone Lined

INSTALLATION AND OPERATION INSTRUCTIONS

To be installed in conjunction with a NTI Boiler

TABLE OF CONTENTS

INTRODUCTION................................................................................................................2

Trin & Stor Specifications....................................................................................................2

I.O.M. Checklists..................................................................................................................3

General Installation Requirements .......................................................................................4

Safe Temperatures for Potable Water...................................................................................5

WATER HEATER PIPING .................................................................................................7

Domestic Side Piping ...........................................................................................................7

Boiler System Piping............................................................................................................9

Solar System Piping..............................................................................................................9

FIELD WIRING.................................................................................................................14

TPI Thermostat Wiring.......................................................................................................14

TPI and Boiler Controls......................................................................................................16

START UP AND CHECK OUT........................................................................................18

ANNUAL MAINTENANCE AND INSPECTION...........................................................18

PARTS LIST......................................................................................................................19

TROUBLESHOOTING .....................................................................................................19

HAZARD SYMBOLS AND DEFINITIONS

Danger Sign: Indicates a hazardous situation which, if not avoided, w

result in serious injury or death.

Warning Sign: I

could result in serious injury or death.

Caution Sign plus Safety Alert Symbol: I

which, if not avoided, could result in minor or moderate injury.

Caution Sign without Safety Alert Symbol: Indicates a

situation which, if not avoided, could result in property damage.

Notice Sign: I

could result in property damage.

This Indirect Water Heater must be installed by a licensed and trained

Heating Technician or the Warranty is Void. Failure to properly

install this unit may result in property damage, serious injury to occupants, or possibly death.

S-SR Series

S Series

SL Series

Page 2

Trin & Stor

│

Installation and Operation Instructions Indirect Water Heaters

1.0 INTRODUCTION

NTI offers three (3) diversified series of Indirect Water Heaters: "S" Series consists of a high performance

stainless steel tank and heat exchanger coil, "SL" Series offers a high mass stone lined tank and finned copper

heat exchanger coil, and "S-SR" Series consists of a stainless steel tank with dual heat exchanger coils. The S-SR

Series comes equipped with a Solar Domestic Hot Water backup via a second heat exchanger coil for boiler

supply connections ("S-SR" models). The "S-SR" series can also be used with a single boiler as a normal indirect

or with a second boiler for increased recovery rate. For the complete NTI Trin & Stor line, visit

www.nythermal.com.

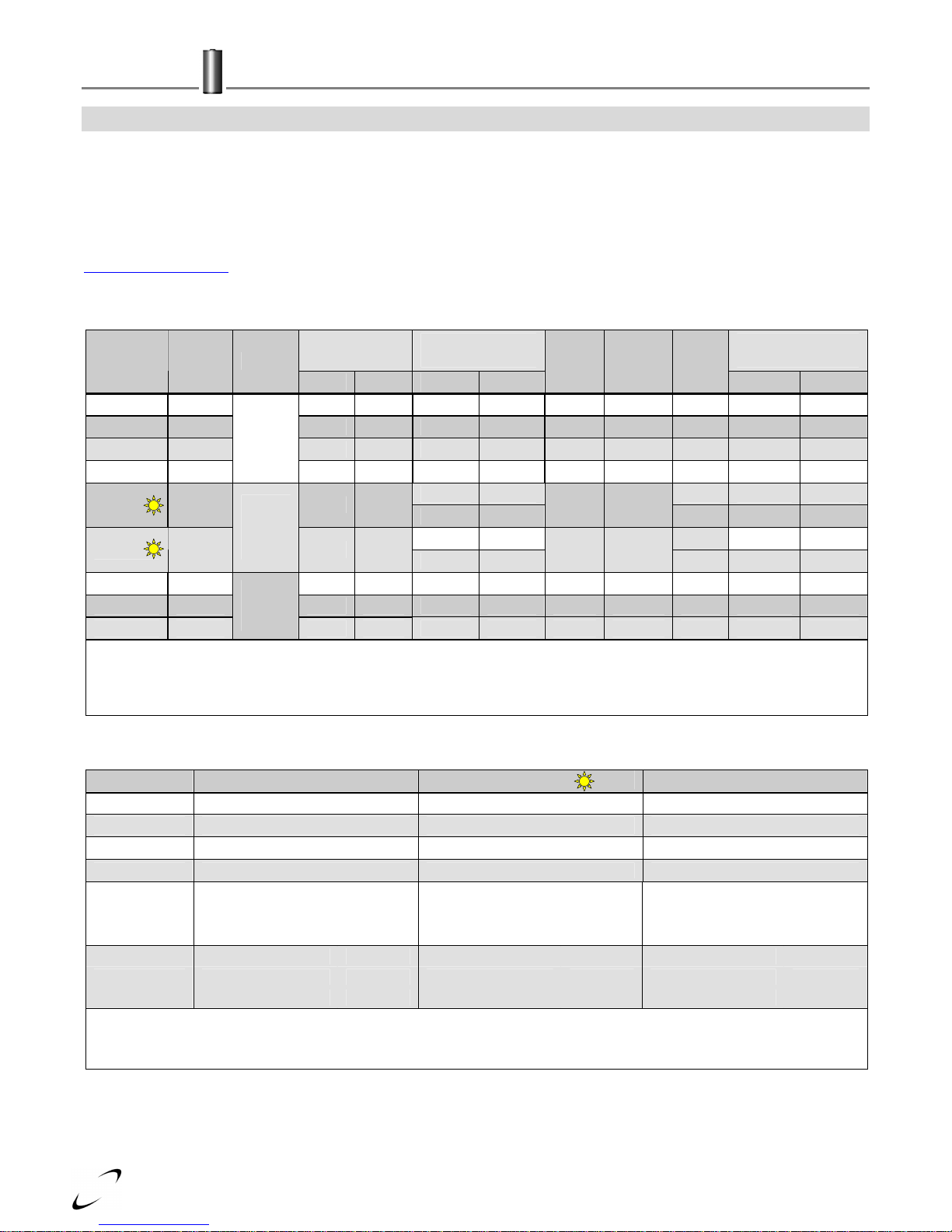

Trin & Stor Specifications

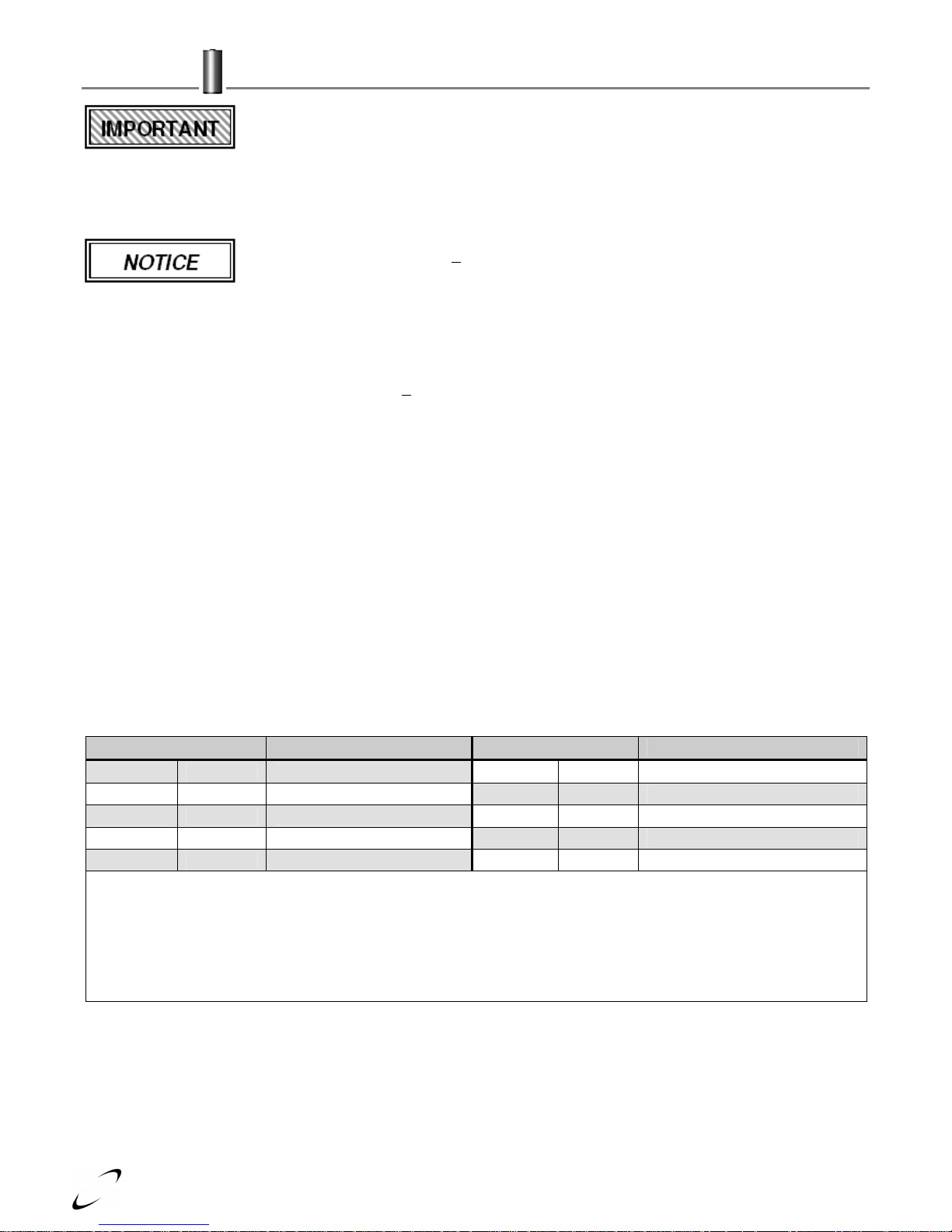

Table 1-1 Indirect Water Heater Specifications

Hour 1 Recovery

(Gal @ Outlet Temp)

1

140 °°°° F 115 °°°° F

Model

Storage

Capacity

(

US Gal

Type

)

Weight (lbs)

Empty

Filled

S40 40 66 485 228 303 146 6.9 4.1 196 271

S50 53 82 655 238 313 146 6.9 4.1 196 271

S80 79 170 995 356 468 210 10.4 11.3 292 404

S120

119

S80SR

S120SR

119

SL35 35 185 477 230 300 150 6.0 7.0 195 265

SL50 50 238 656 250 320 150 6.0 7.0 200 270

SL70 70

Notes:

1

Ensure the location chosen for the tank is capable of supporting the tank when filled with water.

2

Refer to Table 1-3 for a list of considerations when selecting a location for the tank.

3

Hour 1 Recovery based on 50oF inlet water temperature and 200oF boiler water outlet temperature.

Stainless

Steel

Indirect

183 1275 485 636 290 13.6 26.5 392 542

Stainless

79 180 840

Steel

Solar

Indirect

195 1190

Stone

Lined

Indirect

290 875 270 340 150 6.0 7.0 200 270

214 157 4.6 182 291

274 166

239 Upper 167 Upper

274 Lower 177 Lower

Table 1-2 Indirect Water Heater Characteristics

Attribute S Series

Tank 1

stainless steel stainless steel stone lined

Coil stainless steel stainless steel copper finned

Insulation EPS foam EPS foam EPS foam

Jacket gray plastic gray plastic gray plastic

Recommended

Service

Clearances

top 12" top 12" top 36"

connection side 12" connection side 12" connection side 12"

boiler connections as required boiler connections as required

MAWP 150 psi MAWP 150 psi MAWP 150 psi

Restrictions Max tank temp 190oF Max tank temp 190oF Max tank temp 190oF

Max boiler temp 210oF Max boiler temp 210oF Max boiler temp 210oF

Notes:

1

Water used in the tank must meet the water chemistry limits specified in Table 2-1. Levels outside the limits may

corrode the tank and shorten its life resulting to damage to tanks and voiding the warranty.

3

Boiler

Output

(

MBH

220 10.4

290 13.6

S-SR Series

Coil Flow

Rate

)

(

GPM)

Coil

Drop

(Feet)

Continuous Rate

(GPH @ Outlet Temp)

140 °°°° F 115 °°°° F

4.8 193 307

7.6 194 Upper 310 Upper

8.0 205 Lower 328 Lower

SL Series

boiler connections

as required

2

Page 3

Indirect Water Heaters

Installation and Operation Instructions

Trin & Stor

I.O.M. Checklists

The various Installation, Operation and Maintenance (IOM) Checklists contained in this manual are meant to be

read in conjunction with the details, drawings and safety information to ensure a complete and proper installation.

Pre-Installation Checklist

Inspection and Preparation

1. Remove packaging. Inspect for damage during shipping.

2. Package contents should contain the following:

Indirect Water Heater (verify correct model number)

Plastic lid, screws, and insulation (applicable to "SL" Series only)

Temperature and Pressure Relief Valve (150psi)

TPI Thermostat

Brass tee, ¾” (applicable to "SL" Series only)

Locating the Tank

1. Solid foundation, dry location, near boiler.

2. Leave room to service water heater and controls (coil can be removed from the top of the "SL" series tanks).

3. Sufficient room for boiler piping and servicing boiler.

4. Area free of flammable liquids or combustible vapors.

5. Install where leaks will not damage property.

6. Locate in room where temperature never drops below 50oF (10oC).

Water Damage Protection

1. Make provisions to protect the surrounding area from water damage should a leak occur from the tank, fitting

connections, or relief valve.

2. If the area surrounding the tank location is susceptible to water damage, install a catch pan c/w drain under the

tank.

General Information

1. Review system specifications and characteristics.

2. Know the Water Chemistry and Warranty requirements.

3. Be informed of potential hazards associated with DHW.

DOs & DON’Ts

1. DO NOT install water heater close to high temperature appliances or wood stoves as water heater jacket is

combustible.

2. DO NOT install where there is a risk of property damage in the event of an eventual leak at some

unpredictable time.

3. DO support the entire tank bottom with ¾" plywood (min) if elevating off the floor with blocks.

3

Page 4

Trin & Stor

│

Installation and Operation Instructions Indirect Water Heaters

General Installation Requirements

Generalized instruction and procedures cannot anticipate all situations. For this reason, only a qualified installer

should perform the installation.

Users Responsibility – This manufacturer anticipates the proper installation and care in use of the product. As

with any hot water system, there is a risk of property damage and personal injury inherent in the use. NTI cannot

supervise the installation and therefore makes it a specific condition for the warranty that the customer will

supervise the installation and use of the product to be sure they are performed in accordance with the instructions

and I.O.M. Checklists in this manual. It is the User’s responsibility to maintain the appliance by having it

inspected on an annual basis, serviced as required, and to use the product for the purpose it was intended.

Installers Responsibility – A qualified installer is a licensed person who has appropriate training and a working

knowledge of the applicable codes, regulations, tools, equipment and methods necessary to install an indirect

water heater and heating boiler required to heat it. The Installer assumes all responsibility for a safe installation

and that it meets the requirements of this document, as well as National and local codes.

Consider the following when selecting a location for the Indirect Water Heater: All tanks will eventually leak at

some unpredictable time, so take precautions and use a catch pan with a drain beneath the water heater to contain

potential leaks or install the tank in a location not susceptible to water damage. Do not install near a wood stove

where excessive heat could melt the water heater’s plastic jacket. Boiler supply piping, floor drain locations,

relief valve discharge will also need to be considered before selecting a location.

Scope of Instruction - This document pertains to the correct installation and operation of

the NTI Trin & Stor Indirect Water Heater line, exclusively series "S" and "SL". This

manual DOES NOT provide installation instructions for heating system boilers; therefore, installers must refer

to the boiler manufacturers instructions for boiler installation procedures.

Emergency Situation - Should the water heater be subject to flood, fire or other

damaging conditions, turn the power and water to the heater off. DO NOT place water

heater in operation again until it has been thoroughly checked by qualified service personnel.

Code Requirements - The installation of your NTI Trin & Stor Indirect Water Heater

must conform to the requirements in this manual, as well as National and local codes.

Intended Purpose - This appliance is not intended to convey or dispense water for

human consumption such as drinking or cooking.

Annual Service - Failure to have the Indirect Water Heater properly serviced and

inspected on a regular basis by a qualified service technician may result in property

damage, serious injury or death.

Flammable Vapors - Do dot install this appliance in any location where gasoline,

flammable vapors are air-born contaminants are likely to be present.

Warranty Requirements - Improper installation, use, neglect or abuse of this product

will not only jeopardize the safe operation of this appliance but also void the warranty.

Be Informed - Read and understand this manual prior to proceeding with the installation

of the Trin & Stor Indirect Water Heater. Failure to follow the instructions outlined in

this document will result in property damage, serious injury or death.

4

Page 5

Indirect Water Heaters

Installation and Operation Instructions

Trin & Stor

Safe Temperatures for Potable Water

Two factors used to determine safe hot water temperatures are Legionella and scalding. Potable water needs to

be stored at temperatures hot enough to limit the growth of Legionella, yet be cool enough to prevent scalding.

Since both hazards present a potential risk to the user, they must be monitored and controlled. Table 1-3

indicates how water temperature affects Legionella bacteria and contributes to scald injury. Use of a thermostatic

mixing valve in the indirect water heater plumbing system can help protect against both of these hazards. By

storing potable water at higher temperatures, bacteria growth is controlled, while still providing high temperature

water for dishwasher applications and low temperature water for bathing. Before proceeding, read the following

carefully and take all necessary pre-cautions to avoid potential illness and/or injury that can result from

Legionella or scalding hazards.

Legionella Hazard - This bacteria is naturally occurring in surface water and ponds. It

can also be found in man-made water systems around the world such as water storage

tanks, water distribution systems, fountains, hot tubs, humidification systems, refrigeration systems and grocery

produce misters. Health authorities agree that Legionella bacteria most often enter the lungs due to aspiration

when contaminated water spray is breathed in as opposed to ingesting drinking water contaminated with the

bacteria. Typical illnesses attributed to Legionella include flue like symptoms (Pontiac Fever) and a potentially

fatal type of pneumonia (Legionnaires’ disease). Failure to follow instructions may result in illness or death.

Contributing Factors to Legionella - Experts acknowledge that Legionella is an identified risk in most water

systems. Although eradicating Legionella is improbable, pre-cautions can be taken to control and monitor

conditions that promote bacteria growth. According to the World Health Organization (WHO); American

Society of Heating, Refrigeration, and Air-conditioning Engineers (ASHRAE); Canada Safety Council (CSC);

and Centers for Disease Control (CDC), contributing factors to the growth of Legionella in potable water

systems include:

• Minerals and nutrients present in the source water and systems materials

• Stagnation or low flow characteristic of dead ends in distribution piping systems and storage tanks

• Scale, corrosion, and bio film

• Tepid water in cold water lines

• Water storage temperatures optimal for bacteria growth

• Chlorine concentration

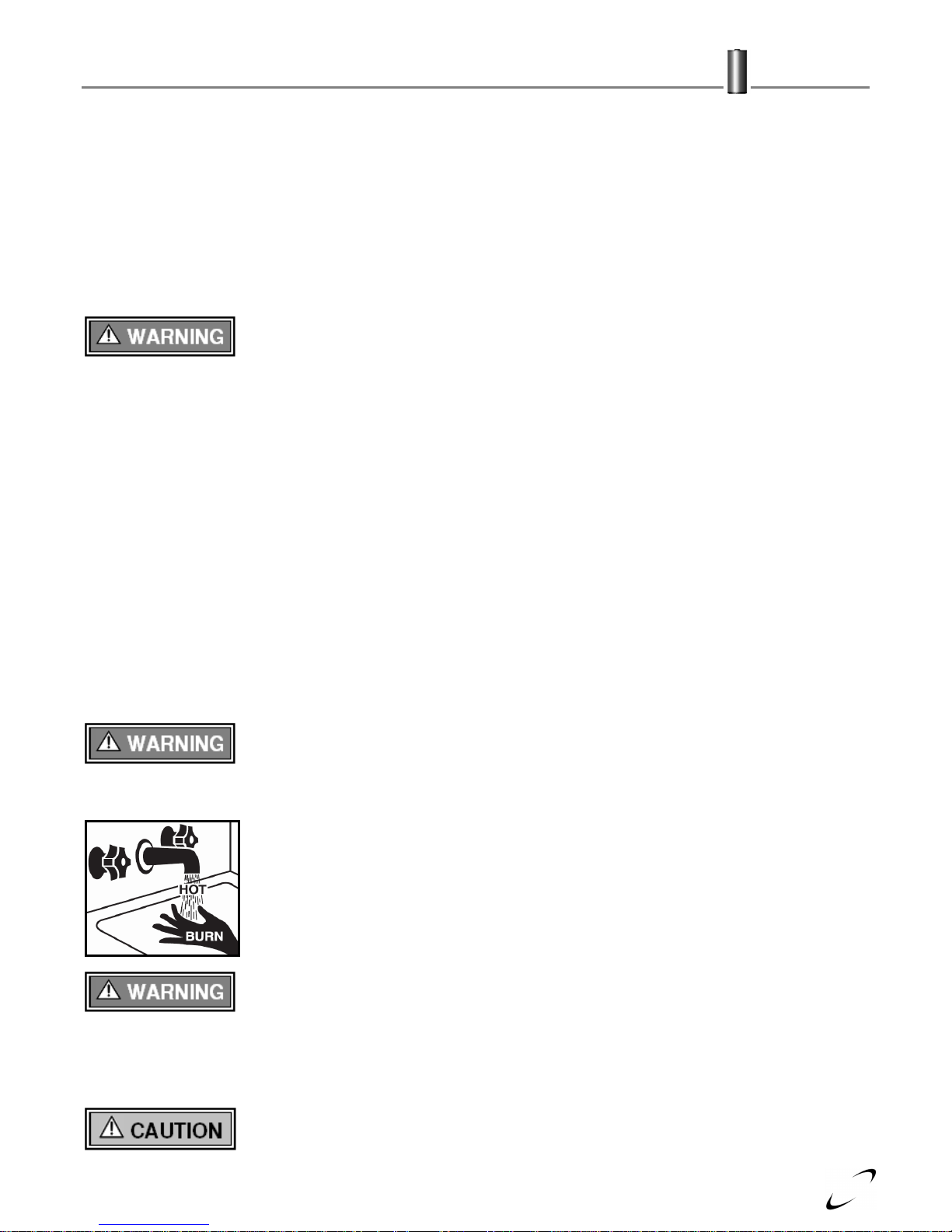

Scald Hazard - Hotter water increases the risk of scald injury. There is a hot water scald

potential if the storage tank thermostat is set too high. Before changing the temperature

setting on the tank thermostat, refer to the thermostat manufacturers recommended settings. Failure to follow

these instructions may result in serious injury or death.

A scald injury can occur when hot steam or liquid makes contact with one or more layers

of skin. Scald severity (degree of burn) is directly impacted by exposure time and

temperature. Refer to Table 1-4. The following basic precautions are common sense:

• Young children and elderly adults burn more quickly and should use cooler water.

• Never leave a child alone while drawing water in a bathtub.

• Test the water temperature before bathing or showering.

• Turn cold water on first, then add hot water until the temperature is comfortable.

Thermostatic Mixing Valve - When the system requires water at temperatures higher

than required for other uses, such as high temperature applications typically greater than

46oC (115oF), a means such as a thermostatic mixing valve shall be installed to temper the water for those uses

in order to reduce scald hazard potential. Anit-scald devices such as a thermostatic mixing valve allows potable

water to be stored at a higher temperature to limit bacteria growth, and allows water at the tap to be delivered at

a lower temperature to prevent scalds. Failure to follow these instructions may result in serious injury or death.

This appliance is not intended to convey or dispense water for human consumption such

as drinking or cooking.

5

Page 6

Trin & Stor

│

Installation and Operation Instructions Indirect Water Heaters

Legislation and Guidelines - At the time this document was written, standards and

guidelines regulating the prevention of Legionella in the United States and Canada were

mostly voluntary. The American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.

(ASHRAE) is currently in the process of converting its guideline entitled "Minimizing the Risk of Legionellosis

Associated with Building Water Systems" (ASHRAE Guideline 12-2000) into an official standard. Consult with

your local authorities as to recommended guidelines for controlling Legionella in potable water systems.

Storing water at temperatures >140°F may not be permitted in some States, so check with

the authorities having jurisdictions. In Canada, recent changes to the National Plumbing

Code requires that domestic hot water be stored at or above 61oC (140oF) and then mixed down to safe

temperatures at the tank outlet.

General Guidelines - In the absence of a National standard or local codes, the following are general guidelines

for “good practice” on maintaining, monitoring and operating your potable water system:

• Store domestic hot water at temperatures > 61oC (140oF).

• Store and distribute cold water at temperatures below 20oC (68oF).

• System supply for uses other than high temperature applications typically greater than 46oC (115oF) shall be

equipped with a thermostatic mixing valve on the hot water outlet to reduce potential scald hazards.

• Clean aerators and nozzles on water fixtures on a regular basis to reduce scale build-up.

• Clean storage tanks and remove sediment. Flush storage tanks and piping systems regularly for 10-30

minutes at high water temperatures (depending on guidelines used) to rid the system of sediment and scale

that develops, typically in the bottom of storage tanks where water temperature is coolest; and piping runs

where water can stagnate.

• Abandoned water lines should be capped off at the distribution main, not at the most convenient place.

• Avoid dead-ends in piping system. If unavoidable, provide a drainage port in these areas at the lowest point

to flush out stagnant water regularity.

• Insulate Domestic Hot Water recirculation lines and keep pipe runs as short as possible.

• Recommend annual water testing of water in your tank and piping system(s) to monitor water conditions.

• Keep a maintenance record of when your indirect water heater and storage tank were cleaned, piping

systems flushed and who did the service work.

Table 1-4 How Water Temperature relates to Legionella and Scald Hazard

Water Temperature

158-176oF 70-80oC Disinfection range 158oF 70oC 1 second - 2nd or 3rd degree burn

140-149oF 60-65oC Bacteria die within minutes 140oF 60oC 5 seconds - 2nd or 3rd degree burn

122-131oF 50-55oC Bacteria die within hours 131oF 55oC 5 seconds - 1st degree burn

68-113oF 20-45oC Bacteria thrive and multiply 122oF 50oC 1 minute - 1st degree burn

below 68oF below 20oC Bacteria is dormant 111oF 44oC 5 hours - 1st degree burn

Notes:

1

Published by Chartered Institute of Plumbing and Heating Engineering, Databyte series, "Safe Hot Water Temperatures".

2

The elderly and small children are susceptible to bad burns at shorter exposure times than listed in this table.

3

A thermostatic mixing valve should be installed on DHW storage tanks when outlet temperatures exceed 115oF [46oC].

4

Typical water temperature for bathing or showering range between 98-113oF [37-45oC].

5

Temperature-Time-Burn Chart published by John Hopkins University, excluding notes.

1

Legionella Bacteria 1

Water Temperature

2,5

Exposure Time vs Burn 5

3,4

6

Page 7

Indirect Water Heaters

Installation and Operation Instructions

Trin & Stor

2.0 WATER HEATER PIPING

Failure to follow the instructions provided in this section will void your NTI warranty

and may result in property damage, fire, serious injury or death.

Domestic Side Piping

The various series of NTI Trin & Stor indirect water heaters are dimensioned and connection ports marked in

Figures 2-1 and 2-2. Dimensioned drawings are to be read in conjunction with Table 2-3 and 2-4 which identify

the connection type and port size and illustrates typical domestic water piping for a single indirect water heater.

Basic system components are identified in Table 2-2 and their function described in detail below. For multiple

Indirects, pipe the tanks in parallel using equal pipe lengths between each tank and a common tee to ensure

equalized draw.

Energy Efficiency - Although the NTI Trin & Store Indirect Water Heater is an energy efficient appliance,

insulating long pipe runs can improve the system efficiency by conserving energy and reducing standby losses.

System Preparation - Prior to connecting plumbing to the indirect water heater, flush the entire system to

ensure it is free of impurities that may be harmful to the system or indirect water heater. Check the water

composition of the domestic water supply prior to filling the tank to ensure the water characteristics are within

the range specified in Table 2-1. Water used in the tank must meet the water chemistry limits specified in Table

2-1. Levels outside the limits may corrode the tank and shorten its life resulting in damage to the tank and

voiding the warranty. If levels are outside the acceptable limits, consult a qualified water treatment expert about

treatment options for domestic water.

Table 2-1 Water Chemistry Requirements

Characteristic "S" series "S-SR" series

PH

Chloride (ppm)

Notes:

1

The "SL" Series is not affected by abnormal PH or Chloride levels.

2

Residual solder flux can corrode stainless steel. Flush tank before heating

the domestic water in the tank or warranty will be void.

System Components - As a minimum, a properly installed system will include the following major components

identified in Table 2-2. It is the responsibility of the installing contractor and system designer to consider all

aspects of a proper system design including compliance with local codes, including additional components

required for prevention of thermal-siphoning (i.e. heat traps), isolation valves, drain and purge valves, etc.

Table 2-2 Domestic Side Major Component Checklist

Factory Supplied Components Field Supplied Components

Indirect Water Heater

Temp & Pressure Relief Valve (150PSI)

Tank Thermostat Control (TPI)

Drain Valve

Notes:

1

All NTI Indirect Water Heaters come standard with a TPI thermostat control (not applicable for solar applications).

2

Check if required by local codes.

3

E

xpansion Tank is mandatory if using a System Backflow Preventor.

Damage to tanks resulting from water chemistry levels outside the ranges specified in

Table 2-1 can cause corrosion, shorten the life of the tank, and will void the warranty.

Flushing the

Water Hater

"SL" Series

Min 6.0 Min 6.0 Min n/a

Max 8.0 Max 8.0 Max n/a

Min 0.0 Min 0.0 Min n/a

Max 80.0 Max 80.0 Max n/a

1

Many solder fluxes can severely

corrode stainless steel. Once piping

connections are completed, flush the

water heater by drawing at least

three (3) times the tank’s volume

through the water heater prior to

heating water in the tank. Failure to

flush the tank will void the warranty.

System Backflow Preventor

DHW (Potable Water) Expansion Tank

1

Thermostatic (Anti-Scald) Mixing Valve

2

2,3

7

Page 8

Trin & Stor

│

Installation and Operation Instructions Indirect Water Heaters

Indirect Water Heater - NTI Trin & Stor Indirect Water Heaters are equipped with a single-walled internal

heat exchanger coil. To maintain the efficient and reliable operation of the heat exchanger, and to avoid heat

exchanger failure, it is critical to ensure the rules and guidelines in this section are followed.

Locate the water heater in an area where leakage from the tank or plumbing connections

will not result in water damage to adjacent areas or lower floors. If such a location is

unavoidable, install a suitable catch pan with a drain under the appliance. This manufacturer is not responsible

for any water damage that may occur in connection with the indirect tank or any of its components.

Temperature and Pressure Relief Valve - Each Indirect comes standard with a factory supplied temperature

and pressure relief valve, sized to ASME specifications and compliant with Standard ANSI Z21.22•CSA 4.4

Relief Valves for Hot Water Supply Systems. The field installed relief valve and discharge piping is to be

mounted on the Indirect Water Heater in accordance with Figures 2-3 and 2-4 and must be accessible for

servicing or replacement. No valve is to be placed between the Relief Valve and the Indirect Water Heater or

Relief Valve and discharge pipe. Install discharge piping as shown in Figures 2-3 and 2-4 and in accordance with

Installation Checklist 2-1.

T&P Normal Operation - The relief valve is not intended for constant duty such as

repeated operation due to normal system expansion. If this occurs, correct the situation

by installing a properly sized domestic expansion tank as per the expansion tanks manufacturer’s instructions.

Location - Do not conceal, plug, or remove the relief valve from its designated point of

installation. Failure to comply may result in property damage, personal injury or death.

Tank Thermostat - The TPI immersion thermostat is intended to allow a conventional water heater or boiler to

monitor and control the Indirect Water Heater’s tank temperature, improve response time, and prevent short

cycles of operation. Install the TPI on the Indirect tank as per the TPI Thermostat Wiring Instruction in Section

3.0 of this manual. For the Solar "SR" series, the TPI is only applicable when used as a normal indirect. For

controllers suitable for Solar Indirect applications, refer to the NTI Sol-R-Therm manual.

Drain Valve - The Indirect water heater requires a field supplied drain valve to facilitate emptying the tank for

inspection and servicing. Refer to Table 2-4 for drain port size and type.

System Backflow Preventor - Check if a backflow preventor (BFP) is required by local codes. Most plumbing

codes require a thermal expansion control device be installed if a backflow preventor, pressure reducing valve or

check valve is installed on a domestic supply line. If a backflow prevention device is used, then an expansion

tank is mandatory (not optional) and must be installed downstream of any device used to control system thermal

expansion. When using multiple indirects, check if a single BFP is required on the domestic supply or if each

tank requires it’s own backflow preventor and respective expansion tank. See Figures 2-3 and 2-4.

DHW ( Potable Water) Expansion Tank - This manufacturer recommends installing an expansion tank in the

domestic hot water system for the purpose of absorbing the increase in water volume caused by rising water

temperature. If required by local codes, the expansion tank must be suitable for use with potable water and be

sized in accordance with the water volume of the system and the firing rate of the boiler connected to the indirect

water heater. Refer to the expansion tank manufacturer’s literature for proper sizing information.

Isolation Valves - Do not install any valves between the expansion tank and the tank

inlet. Failure to follow these instructions may result in discharge of the Relief Valve and

result in property damage or personal injury.

Thermostatic (Anti-Scald) Mixing Valve - A mixing valve is recommended on branches supplying low

temperature water to endpoint plumbing fixtures when domestic hot water is stored above 46°C (115°F).

Temperature Limiting Device - When the tank requires water at temperatures higher

than 46°C (115°F), a mixing valve shall be installed to temper the water and reduce the

risk of scalding. Failure to follow these instructions may result in serious injury or death.

8

Page 9

Indirect Water Heaters

Installation and Operation Instructions

Trin & Stor

Boiler System Piping

The NTI Trin & Stor line of high efficiency Indirect Water Heaters are intended to be heated by an external hot

water boiler where hot water supplied from the boiler is connected to ports 4 and 5 on the indirect tank, and

circulated through an internal heat exchanger coil in the tank. See Figures 2-3 and 2-4. The tanks are specifically

designed for low temperature applications [<100oC (210oF)] and are NOT intended to be used as a pool heating

system or in conjunction with steam boilers or other high temperature appliances where water temperatures could

potentially exceed 100oC (210oF). Refer to the Installation and Operation Manual included with the boiler for

detailed instructions on connecting boiler system piping to the indirect water heater.

High Temperature Applications - Trin & Stor Indirect Water Heaters are not to be used

for high temperture applications [greater than 100oC (210oF)] or in conjunction with

steam producing systems as this will void the warranty. Failure to follow these instructions may damage the tank

resulting in property damage, serious injury or death.

Solar System Piping

The NTI Trin & Stor "S-SR" line of high efficiency Solar Indirect Water Heaters is intended to be heated by a

solar thermal system where a propylene glycol mixture, heated by the solar collectors, is circulated through the

internal heat exchanger coil in the tank. This manual does not cover installation of solar thermal system piping. If

installing a Solar Indirect Water Heater as part of an NTI Packaged Solar Domestic Hot Water System, refer to

the NTI Sol-R-Therm Manual for detailed instructions regarding Solar System Piping.

Domestic side piping for solar thermal can be done in a number of configurations depending on the application.

Since solar tanks are specifically designed for high temperature applications in the event of collector stagnation

and overheating, tank sensors specifically designed for these high temperature applications must be used instead

of the TPI.

TPI Applications - The TPI thermostat control is compatible with any Trin & Stor tank,

including "S-SR" models, when used as normal indirect water heaters. The TPI is not

intended for use with Solar Domestic Hot Water Systems. An alternate sensor and thermostat control, normally

provided with the solar thermal system, should be used.

Pre-heat Option - The most common application is where the solar water heater is plumbed in series with an

auxiliary water heater which is used as the primary storage tank. The hot water out (connection port 2) of the

solar water heater is connected to the cold water inlet of the auxiliary water heater, so when there is a demand for

domestic hot water, the auxiliary water heater immediately brings in pre-heated water from the solar tank to

replace it instead of cold water directly from the potable water system. In this configuration the upper heat

exchanger coil is not required so connection ports 4 and 5 should be capped or plugged with a brass fitting. Refer

to Figure 2-4 and Table 2-1 respectively for location and sizes of connection ports for applicable solar models.

Back Up Option - This option is used when the solar water heater is the primary storage tank and solar water

heating alone is not enough to meet the domestic hot water demand. Hot water supplied from the boiler is

connected to ports 4 and 5 on the solar water heater and circulated through the upper heat exchanger coil in the

tank. See Figure 2-4. Refer to the Installation and Operation Manual included with the boiler for detailed

instructions on connecting boiler system piping to the indirect water heater.

Storage Option - This option is used when the solar water heater is the primary storage tank and is connected to

an additional storage tank for use as extra storage or as a dump zone for excess heat. In this method, hot water

from the solar water heater is transferred to the secondary storage tank using connections 4 and 5. Note that flow

direction is reversed for this application compared to the back up option. See Figure 2-4.

9

Page 10

Trin & Stor

│

Installation and Operation Instructions Indirect Water Heaters

Figure 2-1 Indirect Water Heater Dimensions

Table 2-3 Indirect Water Heater Dimensions

Model

S40

S50

S80

S120

S80SR

S120SR

SL35

SL50

SL70

10

A B C D E F G H I J K L M N

56

49

70 1/

4

-

1

70

/

4

- 64 3/

1

43

/

4

3

43

/

4

3

48

/

4

54

47

69

64

68 7/

40

40

45

3

3

3

1

3

3

/

4

/

4

/

4

8

4

/

4

/

4

/

4

3

46

/

46

4

3

39

/

4

7

60

/

8

5

53

/

8

1

59

/

2

3

52

/

8

1

43

/

2

44 44

49 49

3

/

4

3

39

/

8

60 35

1

53

/

4

1

59

/

2

3

52

/

8

1

43

/

2

29

29

44

35

31

1

/

5

/

5

/

1

/

3

/

-

-

-

25

8

8

29

40

8

56

8

49

8

43

43

48

Dimensions (inches)

1

26 27

5

5

1

1

1

5

5

1

/

26

/

8

9

8

9

5

/

30

/

8

/

41

8

/

21

2

/

22

4

/

13

8

13

/

8

13

/

8

10

8

5

/

12

8

3

/

42

4

1

/

35

2

7

/

43

8

7

/

43

8

7

/

48

8

3

/

7

/

3

1

1

1

3

7

7

2

8

8

/

4

/

4

/

4

/

8

/

8

/

8

/

8

1

/

2

8

2 2

3

2

/

8

3

2

/

8

2 2

2 2

1

43

/

4

3

43

/

4

3

48

/

4

1

/

3

2

/

3

2

/

7

7

/

7

7

/

7

7

/

20

8

8

8

22

8

8

8

23

23

28

23

28

26

28

1

/

- - -

8

7

/

- - -

8

7

/

- - -

8

7

/

- - -

8

7

3

1

1

/

26

8

5

/

57

4

/

- - -

4

- - -

- - -

7

/

9

/

8

1

/

11

8

50

8

/

2

46

1

/

2

1

/

8

Page 11

Indirect Water Heaters

Verify with local codes if a backflow preventor or

Figure 2-2 Solar Indirect Water Heater Dimensions

Installation and Operation Instructions

1.

Install domestic side piping as per National and

local codes. Refer to Figures 2-3 and 2-4.

2.

Do not over tighten brass threads on water supply

connections.

3.

Do not apply heat to the cold water inlet on the

indirect water heater.

4.

Mark the water supply for future reference.

5.

Install a mixing valve on the hot water outlet of

the water heater as shown in Figure 2-3 and 2-4.

6.

Install boiler water connections (if used) as per

the boiler manufacturer’s instructions.

7.

Cap (plug) any unused connection ports, such as

domestic hot water recirculation.

8.

Install T&P relief valve on tank in accordance

Installation Checklist

with local codes and Figures 2-1 through 2-4.

9.

Ensure no valve is installed between the relief

valve and indirect water heater or discharge pipe.

10.

Ensure discharge piping material used is rated to

withstand temperatures up to 250oF (120oC).

11.

Direct discharge to a safe area (drain) where hot

water or steam will not cause damage or injury.

12.

Terminate discharge pipe 6"-12" above the floor.

Do not connect discharge pipe directly to a drain.

13.

Typical discharge pipe diameter ¾". Maximum

pipe length is 15 feet with 2 or less elbows.

14.

Cut discharge end of pipe at a 45o angle to reduce

the risk of being blocked or capped.

15.

Install drain valve in the location and orientation

shown in Figures 2-3 and 2-4.

16.

thermal expansion control device is required.

17.

Install a domestic expansion tank downstream of

the backflow preventor (control device).

18.

Install the domestic expansion tank on the cold

water supply of the domestic side piping.

19.

Flush the tank thoroughly before filling to heat

water. Fill heat exchanger coil with heating fluid.

Trin & Stor

Table 2-4 Indirect Water Heater Connections

Model

S40

S50

S80

S120

S80SR

S120SR

SL35

SL50

SL70

* Connections are NPT unless noted otherwise. All Aquastat connections are friction fit immersion wells.

T&P RV Hot Out Recirc Boiler In Boiler Out A-stat Lw Cold In Drain Solar In Solar Out A-stat Up

1 2 3 4 5 6 7 8 9 10 11

3

/

" F

1

1

1" M

1" M

1

/

1

/

4

3

/

" F

4

3

/

" F

4

3

/

" F

4

1" F 1" F

1" F

1 ¼" M

3

-

-

-

/

4

3

/

4

3

/

4

2

2

" M

" M

" M

" M

" M

3

/

3

/

3

/

3

/

1

1

1

1

4

4

4

4

/

/

-

-

-

" F

" F

" F

" F

" F

4

" F

4

Connection Port Sizes

1" M 1" M Well 1" M - - - 1" M 1" M Well

1" M 1" M Well

1" M 1" M Well

3

/

" M

4

3

/

" M

4

3

/

" M

4

3

/

" M

4

3

/

" M

4

3

/

" M

4

3

/

" M

4

3

/

" M

4

3

/

" M

4

3

/

" M

4

Well

Well

Well

Well

Well

1" M - - - -

1

1

/

1

1

1" M

1

1

3

/

3

/

3

/

/

/

" M

4

" M

4

" M

4

" M

2

" M

2

" M

4

- - - -

- - - -

3

-

/

" M

4

3

-

/

" M

3

/

" F

4

3

/

" F

4

3

/

" F

4

4

- - -

- - -

- - -

3

/

" M

4

3

/

" M

4

Well

Well

11

Page 12

Trin & Stor

│

Installation and Operation Instructions Indirect Water Heaters

Figure 2-3 Indirect Water Heaters

Domestic Plumbing Schematic

12

Page 13

Indirect Water Heaters

Figure 2-4 Solar Indirect Water Heaters

Domestic Plumbing Schematic

Installation and Operation Instructions

Trin & Stor

13

Page 14

Trin & Stor

│

Installation and Operation Instructions Indirect Water Heaters

3.0 FIELD WIRING

Ensure all field wiring complies with this manual and is installed in accordance with the National Electrical

Code ANSI/NFPA 70 or Canadian Electrical Code CSA C22.1, and any applicable local codes.

TPI Thermostat Wiring

24VA Transformer (Hot, GND) - The TPI requires a 24VAC power supply to function. This power supply

may be provided directly from the boiler (check with boiler manufacturer’s instructions) or via a field provided

24VAC transformer. See Figured 3-6 to 3-9. Note the TPI may draw up to 0.6 W

Pump/TT Output Contacts - The TPI is equipped with a normally open isolated end switch (Pump/TT) that

closes when the tank temperature drops below the TPI setting. Connect the Pump/TT contact to the DHW

specific input on boilers equipped with DHW priority capabilities (Figures 3-6 to 3-7) or to the priority zone

input on zone controllers Figure 3-9. Alternately, the Pump/TT contact could be used to power a zone valve, see

Figure 3-8. Note the Pump/TT contact is rated for 125V@10A.

Install the TPI Thermostat in accordance with these instructions, the installation checklist(s) in this section, and

corresponding Figures 3-1 to 3-5.

TPI Applications - The TPI thermostat control is compatible with any Trin & Stor tank,

including "S-SR" models, when used as normal indirect water heaters. The TPI is not

intended for use with Solar Domestic Hot Water Systems. An alternate sensor and thermostat control, normally

provided with the solar thermal system, should be used.

Avoid Shocks - To avoid electrical shock, turn off electrical power prior to opening any

electrical box on the unit. Ensure the power remains off while any wiring connections are

being made. Failure to follow these instructions may result in component failure, serious injury or death.

Wire Protection - When passing 110VAC wiring through the TPI housing, the installer

must use appropriate conduit and a chase nipple to securing the wiring and prevent

chafing. Failure to follow these instructions

Component Damage - DO NOT use the TPI if it has been under water. Failure to replace

electrical damaged components may result in component failure, serious injury or death

14

Page 15

Indirect Water Heaters

immersion well, no special

self

Indicating light provides status of power, call

all the way into

the immersion well until it contacts the end.

or will measure temperature

adequately by resting against the bottom of

complete installation

to make intimate

entire well surface to work

sharply

Turn off electrical power supply to water

heater. Run all 24VAC wiring thru the

24VAC supply to 24VAC

Connect 24VAC PUMP/TT outgoing wiring

If using 110VAC PUMP/TT output wiring,

use knockout at bottom of TPI case with

and

TPI

Tank

Sensor

Screw A

PUMP

/

TT

Square

Notch

Incoming

Incoming

PUMP

/

TT

To Circulator

Close

Figure 3-1 Top Performer Immersion (TPI)

Indicator

Light

Differential

Adjustment

Temperature

Adjustment

Installation and Operation Instructions

Dimensions 5.0"H x 2.6"W x 1.7"D

Features

Control voltage 24VAC

Maximum control power 0.6 W

TT contact rating 125V, 10A

Adjustment increment 1oF.

Temperature set point range 110oF to 160oF.

Temperature differential range 5oF to 20oF.

10k sensor accurate to within 2 degrees.

Fits any standard

adapter required. Mounts to tank using

taping screw provided.

for heat, at temperature, normal operation.

Trin & Stor

Fit flush against the tank

(complete installation)

Wall

Terminals

(24VAC)

Terminals

(24VAC)

Figure 3-2 Installing the Sensor

Sensor

Figure 3-3 Wiring the Controls

Terminals

(110VAC)

Nipple

Conduit

1.

Installation Checklist

Place the hole located in the back of the TPI

over the immersion well.

2.

Mount the TPI flush against the tank.

3.

Use the self-tapping screw provided (Screw

A) to attach the TPI to the exterior of the

tank.

4.

Slide the temperature sensor

The sens

the immersion well. A

does not need the sensor

contact with the

properly. Sensor is soldered directly to TPI

so DO NOT bend sensor connection

or overwork it.

Terminals

(24VAC)

5.

square notch in bottom of TPI case.

Connect incoming

6.

Installation Checklist

Terminals on the bottom right corner of TPI.

7.

to terminals on the bottom left corner of TPI.

8.

appropriate chase nipple.

9.

Refer to Figures 3-6 through 3-9 for TPI

Boiler control configuration drawings.

15

Page 16

Trin & Stor

on the

Factory

To adjust the

temperature setting, slide the lever to the

desired setting using the indicator scale.

If domestic hot water is to be stored at

scald mixing valve shall be installed on the

tank’s hot water outlet to mix the water

read

"Safe Temperatures for Potable Water"

before removing the SCALD DANGER

erature slide. Higher water

may not

will close the output contact (call

for DHW) when the temperature drops

. A

water setpoints

can result in boiler cycling and reduce

Once wiring is complete, turn on electrical

power. Indicator light at the top of the case

place TPI cover and secure with Black

heck water temperature at faucet to verify

Figure 3-4 Adjusting the Temperature

│

Installation and Operation Instructions Indirect Water Heaters

SCALD DANGER

SEE MANUAL

10.

Installation Checklist

Locate the temperature setting slide

right-hand side of the TPI. The

setting is 120oF (49oC).

BEFORE REMOVING

Temperature

Normal range is 100oF to 140oF.

11.

temperatures above 115°F (46°C), an anti-

Setting Slide

down to safe temperature levels.

12.

If setting temperature above 140oF,

label on the temp

temperatures mandatory in Canada

Figure 3-5 Operation and Differential

be permitted in certain US jurisdictions.

13.

Installation Checklist

Locate the differential setting slide on the

left-hand side of the TPI. Factory setting is

10°. Slide the lever to the desired setting,

using the indicator scale.

14.

The TPI

below the setting minus the differential

small differential with high

Differential

Setting Slide

efficiency.

15.

will be solid green if powered.

16.

Re

Screw provided.

17.

C

desired temperature is achieved.

TPI and Boiler Controls

TPI connected to Boiler with DHW Input - TPI output contacts "Pump/TT" are connected to the boiler’s

dedicated DHW input. Typically the boiler will achieve DHW priority via circulator control (refer to boilers I&O

manual). 24VAC is provided by a field supplied transformer or via a 24VAC supply from the boiler (refer to

boiler I&O manual). See Figure 3-6.

TPI connected to NTI Trinity LX Boiler - The LX provides DHW priority. To connect the TPI to an LX boiler,

wire the TPI 24VAC input to LX contacts "COM" and "R"; connect TPI output contacts (Pump/TT) to LX DHW

input terminals, "DHW" and "Sensor COM". Refer to boiler application manual, Appendix B. See Figure 3-7.

TPI connected to Zone Valve - Typically used in applications where the boiler does not accept a dedicated

DHW input. 24VAC is provide by a field supplied transformer or via a 24VAC supply from the boiler (refer to

boiler I&O manual), TPI output contacts "Pump/TT" complete 24VAC to a zone valve. Zone valve end switch is

connected to boiler heat (T-T) input, refer to boiler I&O manual. See Figure 3-8.

TPI connected to DHW Priority Zone - 24VAC is provided via the transformer incorporated in the zone

controller, refer to zone controller I&O manual for details. TPI output contacts "Pump/TT" are connected to the

priority zone input (e.g. Zone 4). Priority for DHW is achieved via the zone controller when the priority switch is

activated. See Figure 3-9.

16

Page 17

Indirect Water Heaters

Figure 3-6 TPI wired to Boiler with DHW Input Figure 3-7 TPI wired to NTI Trinity LX Boiler

Installation and Operation Instructions

Trin & Stor

Figure 3-8 TPI wired to Zone Valve Figure 3-9 TPI wired to DHW Priority Zone Controller

17

Page 18

Trin & Stor

│

Installation and Operation Instructions Indirect Water Heaters

4.0 START UP AND CHECK OUT

Filling the Water Heater

1. Thoroughly flush the water heater so that three (3) times the tank’s volume has been drawn through it.

2. Verify water connections completed.

3. Close drain valve. Open highest hot water faucet.

4. Open cold water inlet valve and fill system.

5. Fill until a steady stream of water flows from the faucet.

6. Close the hot water faucet.

7. Ensure the boiler and domestic piping is free of leaks before proceeding to operational checklist.

Operational Checklist

1. Ensure all electrical connections are made correctly and no high voltage wires are exposed.

2. Set the TPI immersion thermostat (aquastat) to the desired temperature.

3. Verify that there is power to the TPI Thermostat Control.

4. Ensure that the tank is filled with water.

5. Ensure that the tank’s heat exchanger coil(s) are filled with water or heat transfer fluid (solar only).

6. Ensure piping system is free of leaks and that air has been purged from system.

7. Initiate a call for domestic hot water by opening hot water taps on domestic water fixtures.

8. Verify that the boiler starts when the aquastat calls for heat and shuts down when water heater is satisfied.

9. Verify circulator and zone valve operation during an aquastat call for heat and DHW priority. Allow zones to

operate long enough to purge any remaining air from the system.

10. Check for proper operation of relief valve by opening it manually.

11. If T&P relief valve functions continuously during normal thermal expansion, the expansion tank may need to

be upsized.

5.0 ANNUAL MAINTENANCE AND INSPECTION

Inspection Checklist

1. Perform a visual inspection of all valves, drains, and system piping for signs of leaks.

Maintenance Checklist

1. Verify maximum water temperature at hot water fixtures to verify mixing valve temperature settings.

2. Manually operate T&P relief valve by moving lever to open position until hot water is released and allow it to

snap close. If closed relief valve continues to leak, close cold water inlet, drain tank, and replace relief valve.

3. If T&P relief valve functions continuously during normal thermal expansion, the expansion tank may need to

be upsized.

4. Ensure that boiler and/or solar thermal system is maintained in accordance with their installation manuals.

5. Check function of field-installed controls, thermostats, and circulators.

6. Check tank PH and chloride levels to determine if water chemistry is within the specified range.

7. Any additional procedures required by local codes.

Draining the Water Heater

1. Disconnect the power supply to the heat source.

2.

Close the cold water supply shut off valve.

3.

Allow appliance to cool before servicing to avoid burns.

4. Open the drain valve and divert water in tank to alternate storage location or floor drain.

5. Open highest hot water faucet to allow air to enter the system.

Reinstalling the Heat Exchanger - The "SL" Series of indirect water heaters has a removable heat exchanger

coil which can be accessed from the top of the unit. Refer to Figure 4-1 and corresponding installation checklist

for instructions on reinstalling the coil.

18

Page 19

Indirect Water Heaters

All Series (S, S

-

SR,

All Series (S, S

-

SR,

directly

at 1-800-688-2575.

Figure 4-1 Reinstalling the SL Series Heat Exchanger

Installation and Operation Instructions

1.

2. Shut off water supply to tank and boiler.

3. Allow appliance to cool before servicing.

4. Remove heat exchanger coil from the tank.

Installation Checklist

Turn off power to unit and heat source.

5. Flush inside of heat exchanger with water.

6. Rinse outside of heat exchanger with water

and scrub with soft bristled brush.

7. Install heat exchanger. Ensure o-ring

housing is installed properly.

8. Insert and secure the bolts to the nuts one at

a time in the following manner:

9. Place the nut beneath the flange opening.

10. Hold the nut in place with one hand - insert

the bolt with the other.

11. Be sure to place bolts in all of the openings.

Trin & Stor

6.0 PARTS LIST

Table 6-1 Indirect Water Heater

Item Part # Models Description

1 84156

2 84158

3 84217 SL-35, SL-50 Coil, 35/50 Gal

4 84218 SL-70 Coil, 70 Gal

5 84219 SL Series O-ring 6 1/4" ID for Coil

6 84220 SL Series O-ring 6 3/4" ID for Coil

7.0 TROUBLESHOOTING

Locate the TPI indicator light at the top of the case as shown. Refer to Table 7-1 for TPI troubleshooting guide.

Figure 7-1 TPI Thermostat

Indicator Light

12. Thread the bolt into the nut and tighten in

13. Turn on water and bleed air from system.

Relief Valve, T&P, ¾", 150 psi

Controller, Water Heater, TPI

Unlit

Solid Green

Flashing Green

Flashing Red

proper order as shown (same as care tires).

Excessive force is not required to seal

properly.

Trin & Stor parts available

at any stocking wholesaler.

Installers needing technical

assistance can contact NTI

Indicator Light Status

No power to unit.

Powered.

Temperature is in range.

No demand. Demand satisfied.

Pump/TT output should be open.

Calling for heat.

Temperature is out of range.

Pump/TT output should be closed.

TPI has sensed failure.

Replace TPI module.

19

Page 20

NY Thermal Inc. 65 Drury Cove Road Saint John, NB E2H 2Z8 Canada

Technical Assistance: 1-800-688-2575

Website: www.nythermal.com

Fax: 1-506-432-1135

Loading...

Loading...