Page 1

R

ACKMUXSeries

RACKMUX-T15-N-Sx

Rack Mount Terminal

Drawer with Secure SSH

Console Switch

Quick Start Setup Guide

Introduction

The RACKMUX® Terminal Drawer with Secure SSH Console Switch combines a Terminal Drawer and an integrated SSH

Console Switch delivering secure management of up to 32 serial devices via the Internet, TCP/IP network, or dial-up modem

connections in only 1RU of space.

The main purpose of the Console Switch is to provide secure management of several serial devices from local or remote locations

(using Ethernet or external modems). Devices include routers, DSU's, servers, switches or any other equipment allowing serial

operation using RS232 interface. Users can work locally using the integrated Terminal Drawer or from remote locations via

Ethernet connection (Web Interface, SSH, Telnet).

Each SERIMUX port has to be configured for serial communication (baud rate, parity, etc) within the specifications of the attached

serial device, but the configurations of the two devices linked by the SERIMUX do not need to match. Various parameters

(communication speed, hardware and/or software flow control, timeout, etc) can be selected for each SERIMUX port. Devices

may be either locally connected or connected through attached modems.

Each SERIMUX port can be configured as either a host or user port. Serial hosts (such as servers, switches etc.) are connected to

host ports, while serial user devices (such as a terminal or serial console) are connected to user ports.

This guide describes the basic installation and configuration procedure. For further details, please see the SERIMUX-S-x

Installation and Operation Manual (go to

http://www.networktechinc.com/pdf/man107.pdf).

1

Page 2

Hardware Installation

Hardware installation consists of the following steps:

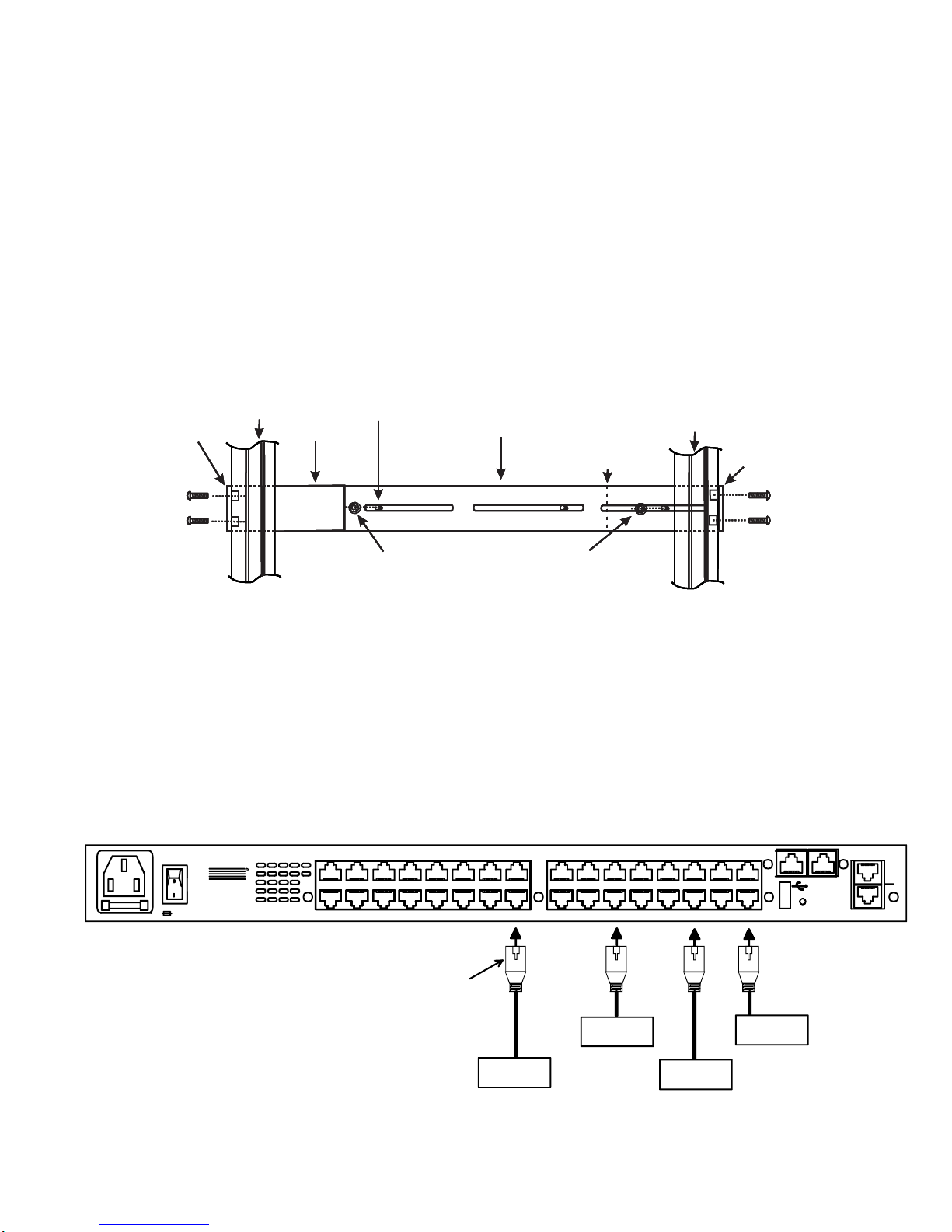

1. Determine the mounting height in the rack for the drawer. It should be a height comfortable to use the keyboard and see the

LCD display. Mark holes in each of the 4 corner cabinet rails at points all level with each other.

2. Secure the rear brackets to the rear rack cabinet rails at the holes marked in step 1 using #10-32x3/4” screws and cage nuts

(supplied). Be sure to tighten the screws securely.

3. Lift the keyboard into position and line the studs on the left and right sides up with the slotted openings in the rear br acket.

Apply the nuts (supplied) to the studs but do not tighten the nuts yet.

FYI: There are 5 mounting studs provided on each side of the RACKMUX. Depending on the depth of the rack and

distance apart of the cabinet rails, the position of the rear bracket may make all 5 studs available for use. In this case,

apply the 2 nuts to the studs furthest apart from each other on each side.

4. Slide the drawer in until the top holes in the front bracket flanges line up with the holes marked in step 1. Secure the front

brackets on the drawer to the front cabinet rails using #10-32x3/4” screws and cage nuts (supplied). Be sure to tighten the

screws securely. Then tighten the nuts applied in step 3.

Front Cabinet

Front Cabinet

Front Cabinet

Front bracket

Front bracket

Front bracket

Front bracket

flange on drawer

flange on drawer

flange on drawer

flange on drawer

Front Cabinet

Rail

Rail

Rail

Rail

Drawer

Drawer

Drawer

Drawer

Stud on drawer

Stud on drawer

Stud on drawer

Stud on drawer

Rear bracket overlapping

Rear bracket overlapping

Rear bracket overlapping

Rear bracket overlapping

drawer

drawer

drawer

drawer

(Rear edge

(Rear edge

(Rear edge

(Rear edge

of drawer)

of drawer)

of drawer)

of drawer)

Rear Cabinet

Rear Cabinet

Rear Cabinet

Rear Cabinet

Rail

Rail

Rail

Rail

Rear bracket

Rear bracket

Rear bracket

Rear bracket

flange

flange

flange

flange

Secure bracket

to rail using two

screws and nuts

(supplied)

Apply nuts (supplied) to studs and

Apply nuts (supplied) to studs and

Apply nuts (supplied) to studs and

Apply nuts (supplied) to studs and

secure rear brackets to drawer.

secure rear brackets to drawer.

secure rear brackets to drawer.

secure rear brackets to drawer.

Secure bracket

to rail using two

screws and nuts

(supplied)

Note: Very deep racks may require the back of the rails to be bolted to an internal mid-rail within th e rack, in which

case the rear rail extensions should be reversed so as to present the appropriate mounting holes to the rack midrails.

Cable Connections

1. Connect each serial user device or host device to be connected by the SERIMUX to any serial port (1-4/8/16/24/32) using a

serial cable with an RJ45 male connector (image below). It may be necessary to add one of the cable adapters (supplied)

detailed in Appendix C of the manual between the device port on the user device or host device and the RJ45 connector.

2. Connect the power cord to the IEC connector.

3. Connect the Console Switch to the Ethernet for remote system management using the “ETHERNET1” or “ETHERNET 2” port

and CAT5/5e/6 patch cable.

AC INPUT

100-240VAC

20W

2A,250V

NTI

1275 Danner Dr

Aurora, OH 44202

Tel:330-562-7070

Fax:330-562-1999

www.networktechinc.c om

R

16

Rear View of SERIMU X-T15 -N- S32

3132

12

131415

252627282930

91011

RJ45

Male

Connector

Ethernet cable

FIREWALL

2324

8

ROUTER

567

4

SERVER

RESET

RJ45 SENSORS

ETHERNET

171819202122

123

PBX

2

1

2

Page 3

(

)

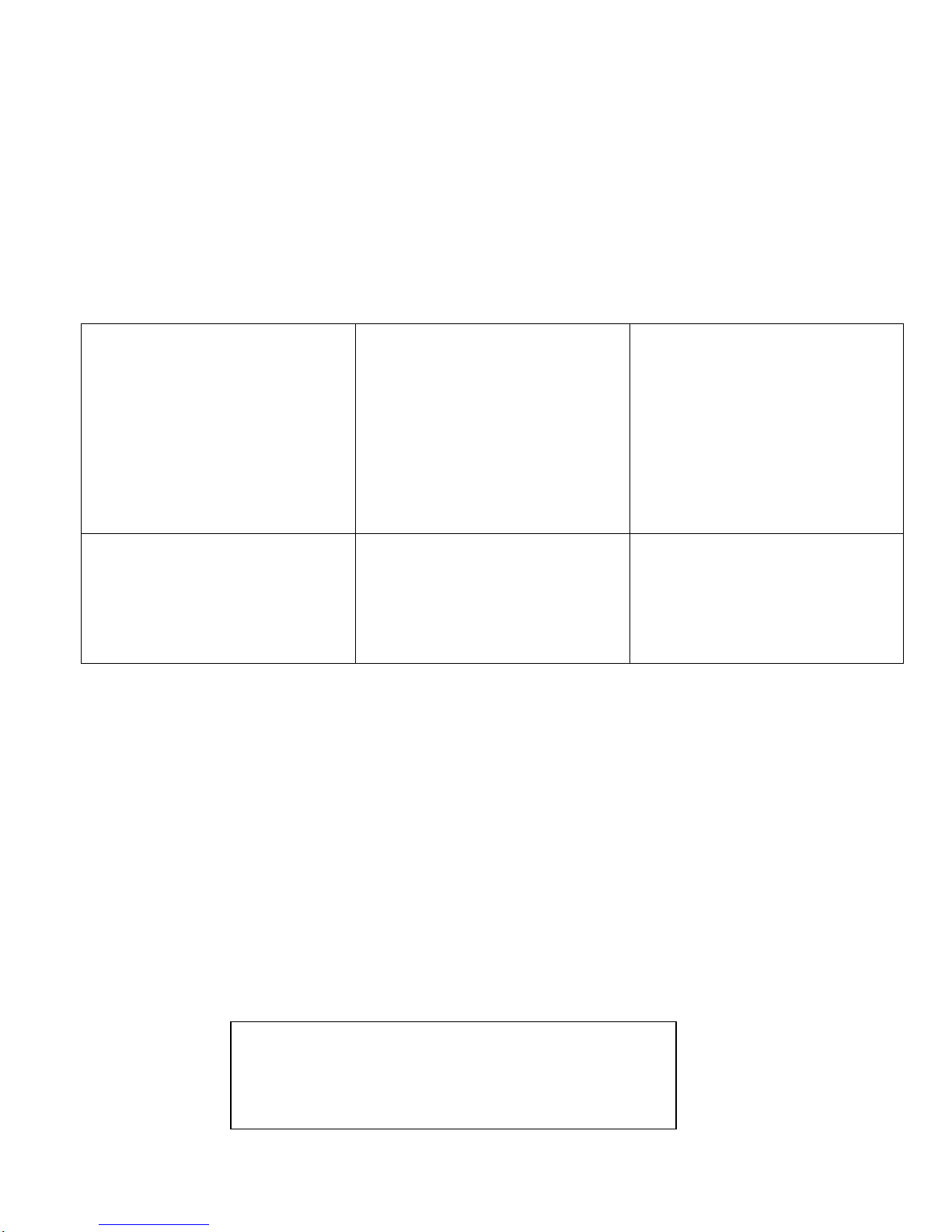

Configuration

The terminal is delivered pre-configured. For your reference, this section describes configuration for connection to the integrated

Console Switch.

• Switch ON the terminal using the power switch located at the rear of the keyboard.

• Hold down the <ALT> key and then depress the <Esc> key to enter Setup Mode.

• Adjust the screen's brightness and image position as described under “Displa y Functions” on page 5.

• To navigate the setup menus, use a function key to enter a setup menu, and then use the arrow keys to highlight the field to be

changed. Use the space key to change the value of a parameter. Use <F12> to return to the top level menu, and <F12> again

to leave setup mode. The user will be prompted at this point if the setup parameters are to be saved for future sessions. Select

Yes by pressing space and then press <F12> again to exit setup mode.

The terminal is delivered pre-configured with the follo wing settings suitable for connection to the SERIMUX SECURE Console

Switch at 9600 baud using VT-100 emulation.

Disp SETUP Menu

Columns = Econ-80

Cursor = Blink Block

Screen Saver = Off

Lines = 24

Background = Dark

Page Length = 1 x Lines

Auto Page = Off

Width change clear = Off

ANSI Reverse = Off

Display= LCD

F4 Comm SETUP Menu

Baud rate = 9600

Data / Stop Bits = 8/1

Parity = None

Rcv Hndshake = none

Xmt Hndshake = none

Login and Use the SERIMUX Secure Console Switch

The following instruction will enable the user to quickly make port connections using the integrated terminal. For

instruction to make quick connection using the Ethern et port and Web Interface, see “Web Interface” in the SERIMUX-Sx instruction manual on page 43.

The terminal should already be pre-configured as follows:

9600 bps

8 bits

no parity

1 stop bit

no flow control

1. Power ON the RACKMUX-T15-N-S32. When the terminal bootup is complete (text will stop scrolling and the cursor will

stop), press the <Enter> key to be provided with a login prompt.

2. At “login “ type the user name <root> (all lowercase letters) and press <Enter>.

3. At “password” type <nti> (all lowercase letters) and press <Enter>.

4. A shell prompt will be displayed “-sh-2.05b# “

DEFAULT USERNAME = root

DEFAULT PASSWORD = nti

all lowercase letters

F2 General SETUP Menu

Personality = VT 100

Enhance = On

Status Line = Standard

Scroll Speed = Jump

Auto Scroll = On

End of Line Wrap = On

Rcvd CR = CR

Monitor = Off

Attribute = Char

F5 Misc SETUP Menu (not applicable)

3

F3 Keybd SETUP Menu

Keyclick = Off

Key Repeat = 5

Xmt Limit = None

Margin Bell = Off

Language = US

Keycode = ASCII

NRC = Off

Bell Volume = 2

NUM Start = Off

DEL Keypad = Dot/Del

F9 Lan Setup Menu (not applicable)

Page 4

To access the configuration menu:

Type <serimuxconfig> to open Serimux Secure Configuration Menu. Use menu structure to configure

SERIMUX.

-OR-

To make a connection with a serial device:

connection with a serial device.

Note: To connect to a host, the host must first be configured with the same communication settings as the port (default

serial settings = 9600 baud, 8 bits, no parity, 1 stop bit, no flow control). If needed, see “Serial Settings” on page 16 of

the SERIMUX-S-x manual to change the SERIMUX port serial settings.

For more details, specifications, and troubleshooting tips, see the SERIMUX-S-x Installation and Operation Manual (man107.pdf

on this CD) or go to www.networktechinc.com

Type <portmenu> to open a port connection menu. Then type a port number and press <Enter> to make a

.

4

Page 5

Display Functions

An NTI RACKMUX with a 15” monitor supports resolutions up to XGA (1024 x 768) with a refresh rate at between 55 and 76Hz.

The quality of the image on the LCD monitor is adjustable using an On Screen Display (OSD) menu using the control buttons on

the RACKMUX.

Standard Controls

The RACKMUX has 5 standard control buttons and a power LED. The 5 standard control buttons o perate as follows:

The Power button turns the RACKMUX LCD and backlight ON and OFF as desired.

The Power LED located immediately below the Power button is a dual color

LED. It will illuminate with a green color when the RACKMUX is powered

ON and working properly. It will illuminate with a red color if the RACKMUX

is powered ON but there is no input signal detected.

The Menu button is used to bring up the OSD menu where the various

settings of the LCD display can be adjusted. See "OSD Control Menu"

(below) for more on LCD display settings.

The Up and Down Arrow buttons are used to navigate through the menus.

Move the cursor up or down as desired to highlight an item for selection.

Once an item is highlighted, pressing the Menu button will select it.

OSD Controls

The Select button is used to make selections within the OSD menus when the OSD menu is ON. When the OSD menu is

OFF, the Select button will act as an Auto Adjust button to keep the user from having to use the menus to adjust the quality

of the image on the monitor.

OSD Control Menu-

The OSD (On Screen Display) Menu enables the user to select the desired characteristics of the LCD display. To activate the

OSD Menu, press the Menu button (above). To turn the Menu back OFF, either select "EXIT" from the main menu or just wait

10-60 seconds and it will automatically be cleared from the screen.

Power

ON/OFF

Power LED

Menu

Up Arrow

Down Arrow

Select/

Auto Adjust

Controls for the

OSD Menus

OSD Main Menu

Selection Purpose Range

Brightness/Contrast Increase/decrease panel brightness/contrast level 1-100

Color R,G,B color temperature control 1-100

Position

Setup

Exit Exit from the OSD control menu

Video Image horizontal and vertical position control

Clock setting

Phase control

Control OSD Image position on screen

Set time OSD will stay on screen before auto shutoff

Select the language of the OSD menu

1-100

-10 to 60 seconds

Several languages (see page 8)

5

Page 6

Brightness/Contrast Menu

Selecting the Brightness/Contrast menu will bring up a screen in which the user can adjust the brightness and contrast levels of

the LCD display. Using the Up or Down arrows to navigate the menu, highlight either the BRIGHTNESS or CONTRAST sections

and press the Select button to choose the option to adjust. Then use the Up or Down Arrow to adjust the setting.

Select EXIT when finished to return to the Main Menu.

Color Menu

Selecting the Color menu will bring up a screen in which the user can adjust the Red, Green, and Blue color levels (values from 1-

100) of the LCD display. With the RED, GREEN, or BLUE sections highlighted, (use the Up or Down arrow to move between

them), press the Select button to choose the option to adjust. Then use the Up or Down Arrow to adjust the setting.

Select EXIT when finished to return to the Main Menu.

Position Menu

Selecting the Position menu will bring up a screen in which the user can select AUTO ADJUST to automatically adjust the

horizontal and vertical position of the displayed image on the monitor, as well as adjust the clock and phase settings if they are not

correct. The user can also individually adjust these settings if so desired. With any of the sections highlighted, (use the Up or

Down arrow to move between them), press the Select button to choose the option to adjust. Then use the Up or Down Arrow to

adjust the setting as needed. Select EXIT when finished to return to the Main Menu.

6

Page 7

Setup Menu

Selecting the Setup menu will bring up a screen in which the user can adjust

OSD POSITION-the position of the OSD menus on the LCD display

OSD TIME-the length of time the user can be idle before the OSD menu automatically exits (adjustable from 10

to 60 seconds)

LANGUAGE-the language that the OSD menus will be presented in

With the item highlighted, (use the Up or Down arrow to move between them), press the Select button to choose the option to

adjust. Then use the Up or Down Arrow to adjust the setting as needed. Select EXIT when finished to return to the Main Menu.

OSD Image can be moved

to different points on the

display

7

Page 8

Keyboard Drawer and Monitor Technical Specifications

Physical

Size (In.) WxDxH

Weight 26 lbs.

OperatingTemperature

Storage Temperature

Humidity

Power Supply (Standard) 110/220VAC, 50-60Hz

Power Consumption 60W (max), <25W (standby)

Cables Included IEC Power cord (country specific)

LCD Panel Specifications

Screen size 15.1” visible diagonal

Resolution 800x600

Controls contrast, brightness, auto-adjust, color temperature

Brightness

Contrast 500:1 (typical)

Viewing Angle

Keyboard Specifications

Type 104 key

Terminal Emulation

Emulations VT52, VT100, VT220, Console ANSI, PC TERM, TVI910+/925, WY-50+, WY-60, WY-100, WYCharacter matrix 7x12 dot matrix in 10x16 cell with 3 dot descenders

Screen size 80x25

Page length 1, 2, or 4 screens

Cursor Blink or steady, block or underline

Modes Full duplex, half duplex, block mode, half block mode

Color modes 16 foreground and 16 background colors

Console Switch

Connectors RJ45 Fema le DTE configuration via RS232

Regulatory Approvals

19x28.4x1.75

32°F - 100°F (0°C - 38°C)

-20°F -140°F (-30°C - 60°C)

17-90% non-condensing RH

250cd/m

2

(Nits)

140 H / 125 V

120, WY-325, PCG Alpha

CE, RoHS

Man112 Rev 5/29/2009

8

Loading...

Loading...