Page 1

OPERATING MANUAL

MEASUREMENT MICROPHONES

Page 2

Contact NTi Audio at

Headquarters +423 239 6060 info@nti-audio.com

Americas +1 503 684 7050 americas@nti-audio.com

China +86 512 6802 0075 china@nti-audio.com

Czech +420 2209 99992 czech@nti-audio.com

Germany +49 201 6470 1900 de@nti-audio.com

Japan +81 3 3634 6110 japan@nti-audio.com

South Korea +82 2 6404 4978 korea@nti-audio.com

United Kingdom +44 1438 870632 uk@nti-audio.com

www.nti-audio.com

NTi Audio AG

Im alten Riet 102, 9494 Schaan

Liechtenstein, Europe

is an ISO 9001:2015 certified company.

Version April 2021

All information is subject to change without notice.

© All rights reserved.

® Minirator is a registered trademark of NTi Audio.

™ XL2, XL2-TA, EXEL, M2230, M2211, M2215, M4261, MA220 M2230-WP, M4261-WP,

WP30 and WP61 are trademarks of NTi Audio.

Made in

Switzerland

Page 3

Table of Contents

Overview ............................................................................4

Measurement Microphones .........................................4

Outdoor Measurement Microphones ............................ 5

Scope of Delivery ..........................................................6

Description ..........................................................................8

Integrated Preamplifier ..................................................8

Electronic Data Sheet ................................................... 8

Connecting to XL2 .........................................................9

Capsule Replacement Instruction ................................ 10

Outdoor Microphones ......................................................12

Assembling .................................................................. 14

Calibration .................................................................... 16

Disassembling the Top Section .................................... 18

Accessories ........................................................................19

Further Information .......................................................... 22

My NTi Audio ...............................................................22

Notes ...........................................................................23

Calibration Certificate ...................................................23

Service and Repairs ..................................................... 23

Warranty Conditions ....................................................24

Declaration of Conformity ............................................ 24

Index

Technical Data Measurement Microphones ...................26

Technical Data PreAmplifier .............................................34

3

Page 4

Overview

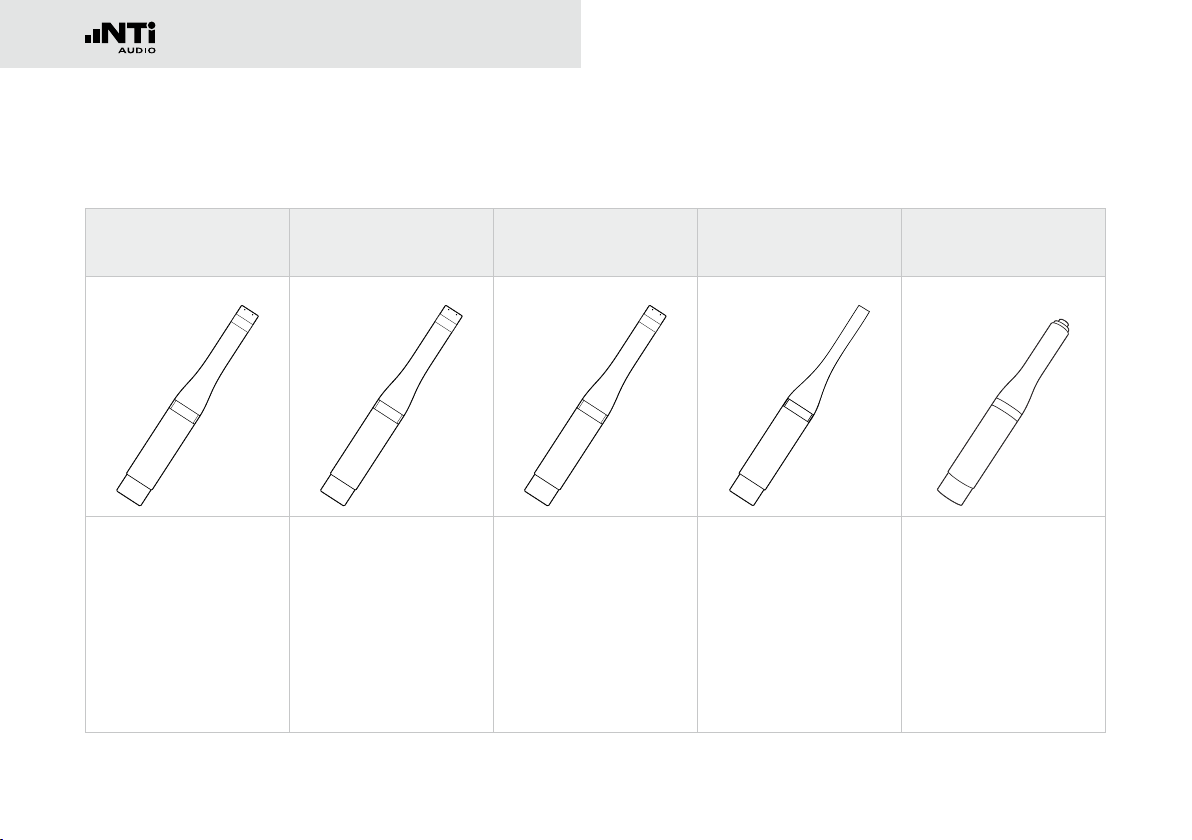

Measurement Microphones

M2230 M2211 M2215 M4261 MA220

Overview

PreAmplifier

Certified Class 1

measurement

microphone

in accordance with

IEC 61672,

metal diaphragm

4

General purpose

measurement

microphone

class 1 frequency

response,

metal diaphragm

Measurement

microphone

for high sound levels

(up to 153 dB),

class 1 frequency

response,

metal diaphragm

Cost-effective class

2 measurement mi-

crophone for general

sound level testing,

commissioning and

service of audio-

acoustic installations

Microphone

preamplifier

compatible with

1/2” pre-polarized

capsules

Page 5

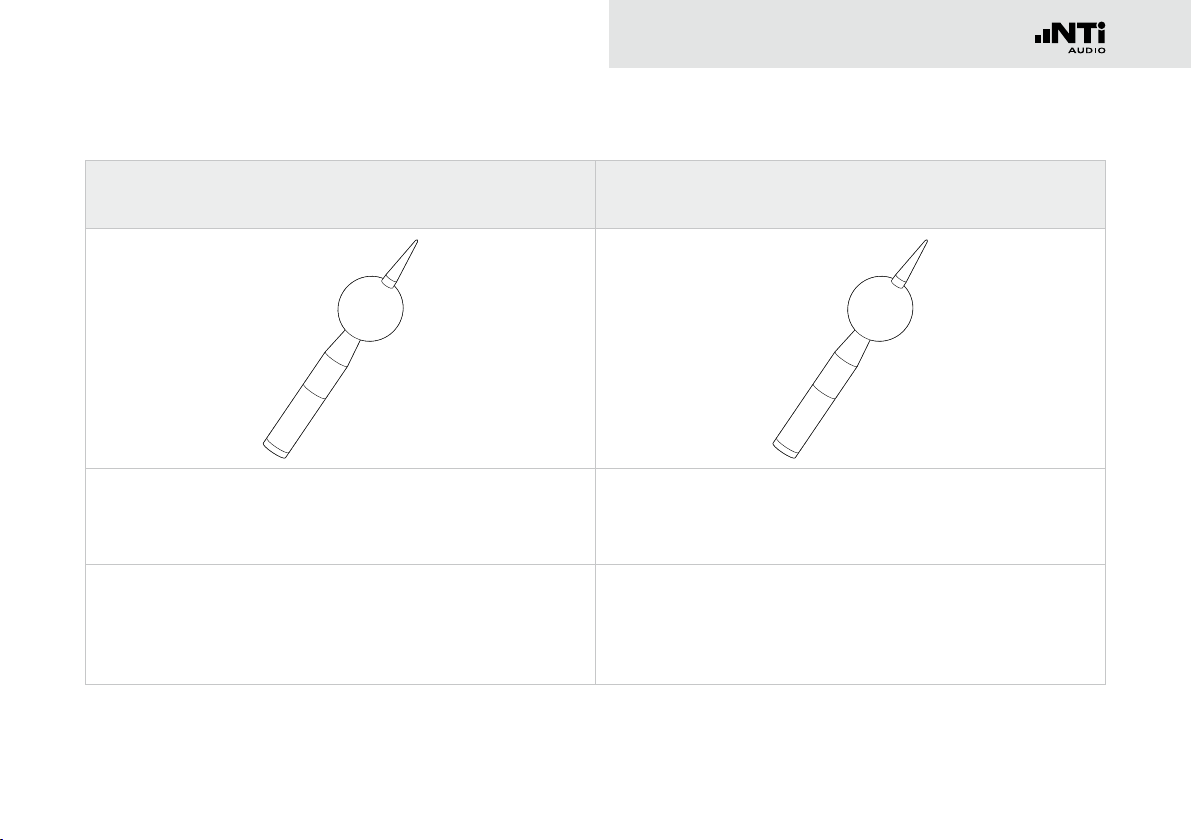

Outdoor Measurement Microphones

Overview

M2230-WP

Outdoor Microphone

Outdoor measurement microphone,

class 1 in accordance with IEC 61672

consists of

M2230 Measurement Microphone

+ WP30 Weather Protection

M4261-WP

Outdoor Microphone

Outdoor measurement microphone,

class 2 in accordance with IEC 61672

consists of

M4261 Measurement Microphone

+ WP61 Weather Protection

5

Page 6

Scope of Delivery

M2230 • Measurement Microphone

consisting of

- MA220 Microphone PreAmplifier

- Microphone Capsule MC230 or MC230A

• Dust Cap

• 50 mm Windscreen

• Microphone-holder MH01

with Adapter 5/8“ - 3/8“

• Operating Manual

• Individual Frequency Response Chart

M2211 • Measurement Microphone

consisting of

- Microphone PreAmplifier MA220

- Microphone Capsule 7052

• Dust Cap

• 33 mm Windscreen

• Microphone-holder

with Adapter 5/8“ - 3/8“

• Operating Manual

Overview

M2215 • M2215 Measurement Microphone

consisting of

- Microphone PreAmplifier MA220

- Microphone Capsule 7056

• Dust Cap

• 33 mm Windscreen

• Microphone-holder

with Adapter 5/8“ - 3/8“

• Operating Manual

M4261 • Measurement Microphone

• 33 mm Windscreen

• Microphone-holder

with Adapter 5/8“ - 3/8“

• Operating Manual

MA220 • PreAmplifier

• Dust Cap

• Microphone-holder

with Adapter 5/8“ - 3/8“

• Operating Manual

6

Page 7

WP30 • WP30 Weather Protection for M2230

- Bird spike

- 90mm Wind screen

- Protection cage

- Upper body tube with allen key mount

- Lower body tube

- Footer plate with tripod mounting thread

(incl. 3 allen screws)

- Allen key

WP61 • WP61 Weather Protection for M4261

- Bird spike

- 90mm Wind screen

- Protection cage

- Upper body tube with allen key mount

- Lower body tube

- Footer plate with tripod mounting thread

(incl. 3 allen screws)

- Allen key

Overview

7

Page 8

Microphone Description

Description

The plug-on measurement microphones combined with the

XL2 Analyzer form a comprehensive sound level meter and

acoustic analyzer. The microphones are 48 VDC phantom-powered and include an electronic data sheet.

Integrated Preamplifier

The microphone bodies contain a preamplifier and require

48 VDC phantom power supply for operation. They combine

high dynamic range and wide frequency range with low noise.

The measurement microphones can also be connected with

an ASD Cable to the XL2 Audio and Acoustic Analyzer for measurements at remote locations or for reduction of acoustic reflections.

Electronic Data Sheet

The microphones include an electronic data sheet. The Automated Sensor Detection (ASD) of the XL2 Analyzer automatically reads this data, i.e. the microphone model and calibration

data. This promotes faster setup and ensures accurate measurements.

Screen connection used for

ASD technology

XLR M

Pin 2 +

Pin 3 Pin 1 Shield

2

2

3

3

1

1

Connection diagram of measurement microphones

with electronic data sheet

Microphone

2

3

1

ASD

Microphone

Capsule

8

Page 9

Microphone Description

Connecting to XL2

Microphone plugs directly into the XL2

The XL2 automatically reads the electronic data sheet of the

connected microphone as follows:

• Connect the measurement microphone to the XL2.

• Switch on the XL2.

The XL2 reads the electronic data sheet of the connected

microphone during a brief initialization process prior to the

first measurement.

Microphone Connection via the ASD Cable

The NTi Audio measurement microphones can be connected

with an ASD Cable to the XL2 Analyzer for measurements at

remote locations or for reducing acoustic reflections. The electronic data sheet is transmitted via the XLR connector’s housing. Do not touch this during the brief initialization period to

ensure the complete data sheet is recognized by the XL2. The

automated sensor detection does not disturb any measurements. You may join 5- or 10-meter ASD Cables together in

series. The ASD technology supports accurate data communication up to a combined cable length of 20 meters (= 65 feet).

Microphone Connection via a professional Audio Cable

For distances longer than 20 meter (= 65 feet) use a high quality, low capacitance standard professional audio cable. The microphone sensitivity has to be entered manually into the XL2

Analyzer.

Alternatively connect the microphone first directly to the Analyzer. The XL2 reads the sensitivity and remembers this value.

Afterwards connect the audio cable.

9

Page 10

Microphone Description

Capsule Replacement Instruction

The microphones for the XL2 Analyzer include an electronic

data sheet. The Automated Sensor Detection (ASD) of the XL2

Analyzer automatically reads this data, i.e. the microphone

model and calibration data. This promotes faster setup and ensures accurate measurements. In case of a capsule replacement, the electronic data sheet needs to be updated with the

data of the new capsule.

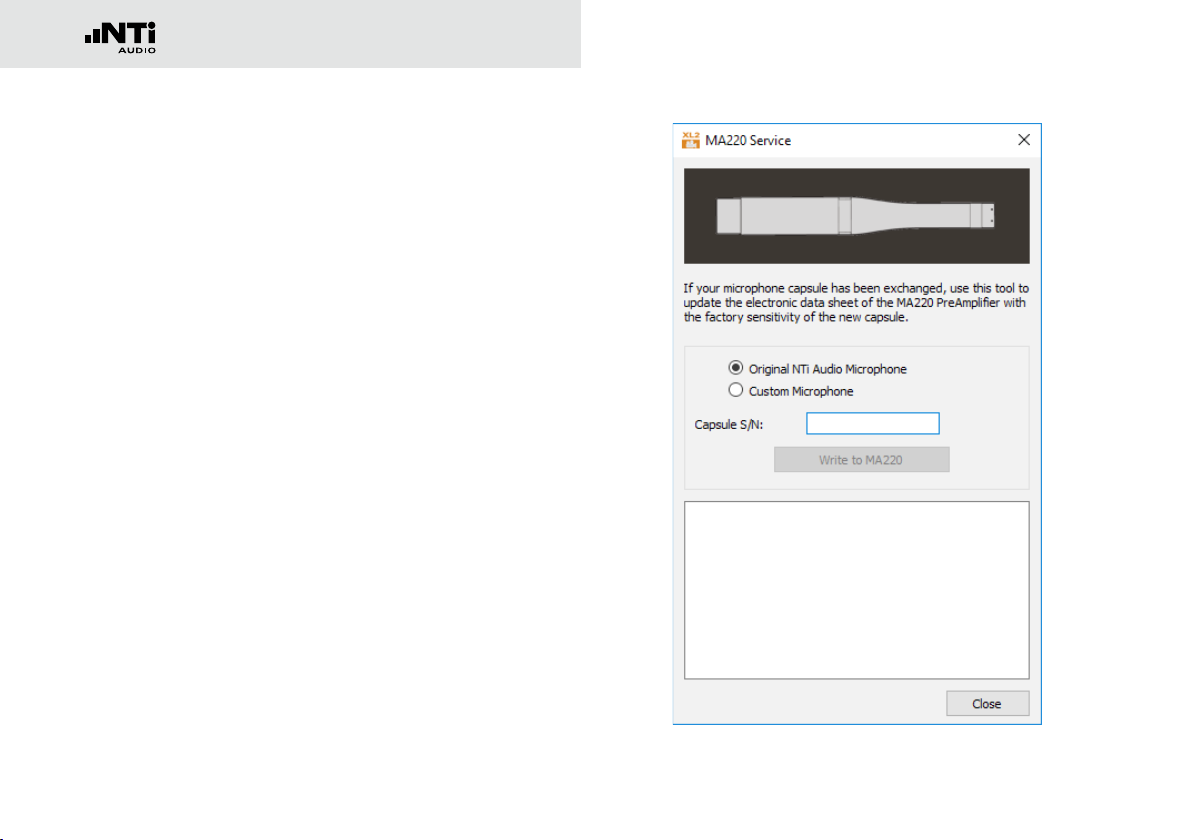

Step-by-Step-Instruction

• Install the new capsule on the microphone preamplifier.

• Plug the measurement microphone directly into the XL2.

• Install the latest firmware in the XL2, available at

https://my.nti-audio.com/support/xl2.

• Start the XL2 Projector PRO Software. The computer requires online connection to the web.

• Connect the XL2 with the USB cable to the Projector PRO

software, thus you see the XL2 display live on the computer

monitor. (if prompted select COM-Port on the XL2)

• Press the computer keyboard keys “Ctrl + Shift + F5” at the

same time (alternatively “Ctrl + Alt + F5”)

10

Page 11

• Select Original NTi Audio Microphone or Custom micro-

phone.

• Case: Original NTi Audio Microphone

- Enter the serial number of the new capsule

- Confirm by clicking Write to MA220.

- Now XL2 reads the factory sensitivity of the new capsule

from the NTi Audio server and stores the new data into

the electronic data sheet of the preamplifier. You will be

prompted if all is in good order.

• Case: Custom microphone

- Enter the microphone sensitivity

- Confirm by clicking Write to MA220.

- Now XL2 stores the microphone sensitivity as factory sensitivity in the electronic data sheet of the MA220 PreAmplifier.

• Verify the setting in the “CALIBRATE” screen of the XL2 and

perform a user calibration to verify if the new capsule works

in good order.

Microphone Description

11

Page 12

Outdoor Microphone

Outdoor Microphones

The Outdoor Microphones M2230-WP and M4261-WP offer a

weather-protected measurement solution for the XL2 Sound

Level Meter allowing acquisition of environmental noise data

in outdoor applications. The corrosion-free polymer housing,

wind screen, water-repellent membrane and bird spike provide

excellent protection from rain, wind, dust and perching birds.

• M2230-WP: M2230 Microphone + WP30 Weather Protection

• M4261-WP: M4261 Microphone + WP61 Weather Protection

• Do not install the Outdoor Microphones

M2230-WP and M4261-WP in horizontal direction. Raindrops may damage the measurement microphone.

• The snap mechanism works only at temperatures above -15°C / 5°F (as the O-Ring stiffens). In colder conditions we suggest you

warm up the housing first, e.g. with your

hands.

Inside:

Protection

Cage with

water-repellent

membrane

Inside:

Measurement

Microphone

Bird Spike

90 mm

Wind Screen

Upper Body

Tube

Lower Body

Tube

Footer Plate with

tripod mounting

thread

12

Page 13

Outdoor Microphone

The Outdoor Measurement Microphone M2230-WP fulfills the

Class 1 requirements according to IEC61672 and ANSI S1.4 for

vertical sound incidence. For compliance with horizontal sound

incidence a spectral correction is employed in the associated

XL2 Sound Level Meter.

The M2230-WP consists of the M2230 Microphone and the

WP30 Weather Protection. An existing M2230 microphone can

thus be converted to an M2230-WP by enclosing the microphone in the WP30 Weather Protection.

• Always activate the frequency correction

filter in the XL2 when measuring a horizontal sound incidence (sound source from the

side) with the M2230-WP. The filter ensures

that the measurements accuracy meets the

class 1 requirements of IEC 61672 and

ANSI S1.4.

• Deactivate the filter only if you are measuring a vertical sound incidence (sound source

from above e.g. airplane noise).

Alternatively, the Measurement Microphone M2211 or M2215

can be fitted into the Weather Protection WP30. These microphones have to be pushed further into the upper body by 3

mm. The top part of the capsule has to be 13 mm above the

upper body housing of the WP30. This is required because the

M2211 and M2215 capsule is 3 mm shorter than the default

M2230 microphone capsule.

The Outdoor Measurement Microphone M4261-WP fulfills the

Class 2 requirements according to IEC61672 and ANSI S1.4.

It consists of an M4261 Microphone and the WP61 Weather

Protection. For compliance with horizontal sound incidence a

spectral correction is employed in the associated XL2 Sound

Level Meter.

13

Page 14

Outdoor Microphone

Assembling

This chapter describes how to install the Measurement Microphone into the weather protection kit:

Install ASD Cable

• Feed the female XLR of the ASD Cable through the bottom

of the lower body tube.

• Attach the footer plate to the lower body tube using the three

allen screws, feeding the cable through the side slot of the

footer plate.

Insert Measurement Microphone

• Connect the measurement microphone to the female XLR

of the ASD Cable.

• Insert the measurement microphone into the upper body

tube so that the bottom end of the microphone is in line

with the bottom end of the upper body tube. Align the fixing

screw hole of the upper body tube with the lower screw of

the measurement microphone (remove the fixing screw to

see the lower screw head through the fixing screw hole).

Fixing Screw Hole

Lower screw of

measurement

microphone

14

Page 15

Outdoor Microphone

Attach the Microphone to the Upper Body Tube

Attaching the fixing screw of the upper body tube onto the

lower screw of the measurement microphone ensures that the

microphone housing is not scratched.

• Insert and gently tighten the fixing screw while jiggling the

microphone. You will feel the fixing screw center in the head

of the lower screw of the microphone. Do not over tighten

the fixing screw.

• Again verify that the bottom end of the inserted M2230 microphone is in line with the bottom end of the upper body

tube.

In Line

Assemble the Weather Protection Body

Retract the ASD cable through the lower body tube and screw

the lower body tube to the upper tube, ensuring that the cable

does not twist during this operation.

15

Page 16

Outdoor Microphone

Mount the Top Section

The top section of the weather protection kit consists of the

wind screen, the enclosed protection cage with water-repellent membrane and the bird spike. Gently slide the top section

over the microphone tip and on to the upper body tube. You will

feel a slight increase in resistance approximately 3 mm before

the top section’s final position. Slightly increase the pressure

until the top section snaps into the final position with an audible click.

You have successfully assembled the Outdoor Measure-

ment Microphone.

Calibration

The design of the Outdoor Measurement Microphone supports easy calibration of the microphone. To calibrate, follow

the procedure below:

• The top section of the Outdoor Microphone is snapped

on to the body tube. Remove the top section of the Outdoor Microphone by gently pulling the bird spike upwards.

At the same time gently push up on the cage inside the

wind screen with two fingers of your other hand. You will

feel when the snap mechanism is released.

Gently remove the top section.

Pull

Push

16

Page 17

• Calibrate the microphone as described in the XL2 user manual using the NTi Audio Precision Calibrator.

Outdoor Microphone

• The outdoor windscreen is recommended

to be replaced annually. The “WP30/WP61

Windscreen Replacement” includes two

spare windscreens, NTi Audio # 600 040 061.

• The water-repellent membrane in the top section is mounted with two O-Rings. Inspect

these O-Rings (13x1 mm) and the membrane

annually for proper seating and good condition. Do not touch the water-repellent membrane.

• Snap the top section back into position on the body tube.

You have successfully calibrated the Outdoor Measure-

ment Microphone.

17

Page 18

Outdoor Microphone

Disassembling the Top Section

• The top section is snapped on to the body tube. Remove

the top section by gently pulling the bird spike upwards. At

the same time gently push up on the cage inside the wind

screen with two fingers of your other hand. You will feel

when the snap mechanism is released.

• Gently remove the top section and turn the top section upside down and hold it by the bird spike.

• Gently unscrew the cage from the hole of the wind screen.

Do not touch the water-repellent membrane!

• Assemble in reverse order.

18

Page 19

Accessories

Accessories

WP30 Weather Protection for M2230

Protect your M2230 microphone from

rain, wind, dust and perching birds with

this professional outdoor weather protection kit. Ideal for precise acquisition of

environmental noise data in outdoor applications.

Features

• Class 1 compliant with IEC 61672 and

• Protection from rain and dust (IP54),

• Built from corrosion-free materials

• Removable top section for easy micro-

• Standard 3/8” tripod mount

• Weight: 270 g (9.5 oz.)

• Optional sturdy outdoor carrying case

ANSI S1.4 for vertical and horizontal

sound incidence

wind and perching birds

phone calibration

available

WP61 Weather Protection for M4261

Protect your M4261 microphone from

rain, wind, dust and perching birds with

this professional outdoor weather protection kit.

Features

• Class 2 compliant with IEC 61672 and

ANSI S1.4 for vertical and horizontal

sound incidence

• Protection from rain and dust (IP54),

wind and perching birds

• Built from corrosion-free materials

• Removable top section for easy microphone calibration

• Standard 3/8” tripod mount

• Weight: 270 g (9.5 oz.)

• Optional sturdy outdoor carrying case

available

NTi Audio # 600 040 080

NTi Audio # 600 040 060

19

Page 20

Accessories

Class 1 Sound Calibrator

The battery-operated Class 1 Sound

Calibrator is classified for the calibration

of class 1 measurement microphones,

sound level meters and other acoustic

measurement equipment. This precision

microphone calibrator delivers 94 or 114

dB at a frequency of 1 kHz.

NTi Audio #: 600 000 388

The optional 1/4” adapter ADP-1/4-P is

required to fit 1/4” measurement microphones.

NTi Audio #: 600 000 391

Class 2 Sound Calibrator

The battery-operated Class 2 Sound

Calibrator is classified for the calibration

of class 2 measurement microphones,

sound level meters and other acoustic

measurement equipment. This microphone calibrator delivers 114 dB at a frequency of 1 kHz.

NTi Audio #: 600 000 394

Calibration

Certificate

Manufacturer Calibration Certificate

The calibration certificate lists the individual product data with serial number. The

calibration and adjustment procedures

follow the documentation and traceability

requirements of the EN ISO / IEC 17025

standard. Annual re-calibration of the instrument is recommended ensuring accurate measurements.

NTi Audio # 600 000 018

Lightweight Tripod

Retractable, lightweight tripod with 1/4”

ball head and 3/8” mounting thread. The

flexible ball head mounts the XL2 Analyzer at any angle. The tripod is suitable

for all measurement microphones, the

outdoor microphone M2230-WP and the

TalkBox.

NTi Audio #: 600 000 397

1/2” Windscreen 90mm

for M2211, M2215 and M2230 measurement microphone

NTi Audio #: 600 040 109

20

Page 21

Accessories

WP30 Windscreen Replacement

The replacement package contains two

spare windscreens for the outdoor measurement microphone M2230-WP or

WP30. The outdoor windscreen is recommended to be replaced annually.

NTi Audio #: 600 040 061

ASD Cable

The ASD Cable allows for extended connections of the NTi Audio measurement

microphones. It supports the transfer of

the electronic data sheet from the microphone to the XL2 Analyzer.

NTi Audio #:

• 5 meter (16 feet): 600 000 336

• 10 meter (32 feet): 600 000 364

• 20 meter (64 feet): 600 000 365

The ASD technology for the electronic

data sheet transfer is applicable for cable

length until 20 meter (64 feet).

STARQUAD cable

with low capacitive load

1 1

2 2

3 3

ASD

Housing Housing

Capacity between ASD line and shield total < 2.7nF

do not connect

21

Page 22

Further Information

Further Information

My NTi Audio

Register your instruments at My NTi Audio and benefit from

the following possibilities:

• Free updates for your instruments

• Activation of optional product functions

• Premium access to downloads

• Receive application and product news

• Faster worldwide support

• Tracing support in case of loss or theft

• Calibration support

22

How to Register

• Open the web page “https://my.nti-audio.com”.

• You are prompted to login or create your My NTi Audio

account.

• The web page “My NTi Audio Products” opens.

• Select the product type and enter the serial number.

• Confirm with “Register”.

• Now your product is listed in the table “My Products“.

Congratulations, your NTi Audio product is registered

Page 23

Further Information

Notes

• Use the microphone for the intended

purpose only.

• Protect the microphone from contamination

by always using the supplied windscreen.

• Never use the microphone in a damp or wet

environment.

• Do not jar or drop the microphone.

• Do not remove the microphone protective grid.

• Do not touch the microphone membrane.

• Remove the black dust cap of the 1/2”

measurement microphones prior to use.

Calibration Certificate

The NTi Audio measurement microphones have been carefully

tested during production and corresponds to the specifications

listed in “Technical Data”. Calibration certificates for new products are optional.

NTi Audio recommends annual calibration of the products after the purchase. The calibration provides documented and

traceable measurement accuracy and confirms that your

NTi Audio product meets or exceeds the published specifications. The calibration and adjustment procedures follow the

documentation and traceability requirements of the standard

EN ISO / IEC 17025.

For calibrations kindly follow the service guidelines at

www.nti-audio.com/service.

Service and Repairs

If your product is not functioning correctly or is damaged,

please contact the local NTi Audio partner for assistance. If

the product needs to be returned for service, kindly follow the

service guidelines at www.nti-audio.com/service.

23

Page 24

Further Information

Warranty Conditions

International warranty

NTi Audio guarantees the function of its products and the individual components for a period of one year from the date

of sale. During this period, defective products will either be

repaired free of charge or replaced.

Limitations

These guarantee provisions do not cover damage caused by accidents, transportation, incorrect use, carelessness, non-original accessories, the loss of parts, operation with non-specified

input voltages, adapter types or incorrectly inserted batteries.

NTi Audio accepts no responsibility for subsequent damage of

any kind. The warranty will be voided by carrying out repairs

or services by third parties who are not part of an approved

NTi Audio Service Centre.

Statutory Rights

Consumers may have legal (statutory) rights under applicable

national laws relating to the sale of consumer products. This

warranty does not affect your statutory rights. You may assert

any legal rights you have at your sole discretion.

Declaration of Conformity

CE / FCC Compliance Statement

We, the manufacturer NTi Audio AG, Im alten Riet 102, 9494

Schaan, Liechtenstein, do hereby declare that the measurement microphones M2230, M2211, M2215, M4261, the preamplifier MA220 and accessories, comply with the following

standards or other standard documents:

• EMC: 2014/30/EU

• Harmonized standards: EN 61326-1

• Explosive atmospheres (ATEX): 2014/34/EU

• Directive 2011/65/EC on the restriction of the use of certain

hazardous substances in electrical and electronic equipment

(RoHS).

• Directive 2012/34/EU on waste electrical and electronic

equipment (WEEE).

This declaration will become invalid if modifications to the

instrument are carried out without the written approval of

NTi Audio.

Date: 31. July 2019

Position: COO

24

Page 25

Information for Disposal and Recycling

Dispose of the instrument in accordance with

the legal environmental regulations in the

Regulations for the EU and other European countries

with corresponding laws

The instrument must not be disposed of in the household garbage. At the end of its service life, bring the instrument to a

collecting point for electrical recycling in accordance with the

local legal regulations.

Other countries outside the EU

Contact the respective authorities for the valid environmental

regulations in the country.

country.

Further Information

25

Page 26

Specifications

Technical Data Measurement Microphones

M2230 M2211 M2215

Classification with XL2 according to IEC 61672, ANSI S1.4

Consisting of PreAmplfier MA220 +

Microphone Type Omnidirectional, pre-polarized condenser,

Capsule / Transducer 1/2” detachable with 60UNS2 thread,

PreAmplifier Type MA220 -

Flatness tolerance bands

typical

Actual Frequency Response freely available as Excel-data, register microphone at My NTi Audio and contact info@nti-audio.com

Frequency Range 5 Hz - 20 kHz

Residual Noise Floor typical 16 dB(A) 21 dB(A) 25 dB(A) 27 dB(A)

Maximum SPL

@ THD 3%, 1 kHz, S_typical

Sensitivity typical @ 1 kHz -27.5 dBV/Pa ±2 dB

Class 1

Certified

MC230 or MC230A

Capsule

137 dBSPL 144 dBSPL 153 dBSPL 142 dBSPL

(42 mV/Pa)

PreAmplfier MA220 +

Capsule 7052

type WS2F according IEC 61094-4

±1 dB @ 5 Hz - 20 Hz

±1 dB @ >20 Hz - 4 kHz

±1.5 dB @ >4 kHz - 10 kHz

±2 dB @ >10 kHz - 16 kHz

±3 dB @ >16 kHz - 20 kHz

-34 dBV/Pa ±3 dB

Frequency Response

Class 1

free field microphone

(20 mV/Pa)

High SPL

PreAmplfier MA220 +

Capsule 7056

-42 dBV/Pa ±3 dB

(8 mV/Pa)

M4261 microphone with per-

1/4” permanently installed

+1/-4.5 dB @ 5 Hz - 20 Hz

±1.5 dB @ >20 Hz - 4 kHz

±3 dB @ >4 kHz - 10 kHz

±4.5 dB @ >10 kHz - 16 kHz

±5 dB @ >16 kHz - 20 kHz

M4261

Class 2

manently installed

capsule

-36 dBV/Pa ±3 dB

(16 mV/Pa)

26

Page 27

Specifications

M2230 M2211 M2215

Temperature Coefficient < -0.01 dB / °C < ±0.015 dB / °C < ±0.02 dB / °C

Temperature Range -10°C to +50°C

Pressure Coefficient -0.005 dB / kPa -0.02 dB / kPa -0.04 dB / kPa

Influence of Humidity

(non-condensing)

Humidity 5% to 90% RH, non-condensing

Long-term Stability > 250 years / dB -

Power Supply 48 VDC phantom power

Current Consumption 2.3 mA typical 1.7 mA typical

Electronic Data Sheet NTi Audio ASD in accordance with IEEE P1451.4 V1.0, Class 2, Template 27

Output Impedance 100 Ohm balanced

Connector Balanced 3-pole XLR

Diameter Dimensions 20.5 mm (0.8”) 20.5 mm (0.8”)

Length Dimensions 154 mm (6.1”) 150 mm (5.9”)

Weight 100 g, 3.53 oz 100 g, 3.53 oz 83 g, 2.93 oz

Environmental Protection IP51 IP51

NTi Audio # 600 040 050 600 040 022 600 040 045 600 040 070

(14°F to 122°F)

< ±0.05 dB < ±0.4 dB

High SPL

M4261

0°C to +40°C

(32°F to 104°F)

27

Page 28

Specifications

Outdoor Measurement Microphones

M2230-WP

(M2230+WP30)

Classification with XL2 according to IEC 61672, ANSI S1.4

Consisting of PreAmplfier MA220

+ MC230 or MC230A Capsule

+ WP30 Weather Protection

Diameter Dimensions 36 mm (1.4”) 36 mm (1.4”)

Length Dimensions 378 mm (14.9”) 378 mm (14.9”)

Weight 430 g, 15.17 oz 413 g, 14.57 oz

Environmental Protection IP54 in vertical position IP54 in vertical position

NTi Audio # 600 040 050 + 600 040 060 600 040 070 + 600 040 080

28

Class 1

Certified

with permanently installed capsule

M4261-WP

(M4261+WP61)

Class 2

M4261 Microphone

+ WP61 Weather Protection

Page 29

Specifications

Typical Frequency Response of Measurement Microphones

8

Tolerance

6

4

2

0

-2

Sensitivity relative [dB]

-4

-6

Class 1, IEC61672-1

Tolerance

Class 2, IEC61672-1

M4261

M2230, M2211,

M2210, M2215

-8

5 10 20 100 1000 10000 20000

log frequency [Hz]

(free field conditions @ reference direction 0°)

29

Page 30

Specifications

Free Field - Pressure Correction Factors

If a measurement microphone is held in a free-field environment, then the measurement microphone acts at high frequencies like a reflector. The sound pressure increases in front

of the microphone capsule membrane. M2230, M2211 and

M2215 are free-field equalized measurement microphones,

they compensate for the increased pressure internally.

The calibrator offers no longer free-field conditions. Therefore,

the free-field equalization of the microphone must be compensated. This needs to be considered prior the calibration. The

correction value needs to be added to the pressure response

of the microphone.

Example:

• During the calibration, the XL2 measures the sound level in

the calibrator. If the B&K4226 calibrator is used and it is set

to 16 kHz, then the XL2+M2230 reads just 86.7 dBA.

• The free-field sound level is calculated by summing the XL2

measurement value and the correction value (= 86.7 dB +

7.3 dB = 94.0 dB).

The following corrections apply with the B&K4226 calibrator:

Nominal

Fre-

quency

[Hz]

31.5

63

125

250

500

1000

2000

4000

8000

12500

16000

M2230

Measurement

Microphone

[dB]

0.0

0.0

0.0

0.0

0.0

0.0

0.3

0.7

2.6

6.0

7. 3

M2211

Measurement

Microphone

[dB]

0.0

0.0

0.0

0.0

0.1

0.1

0.6

1. 7

4.2

7. 3

9.2

M2215

Measurement

Microphone

[dB]

0.0

0.0

0.0

0.0

0.0

0.0

0.2

1. 2

3.9

6.7

9.0

Measurement

Uncertainty U

[dB]

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.4

0.7

0.8

Correction values for other calibrators for M2230:

Type

NTi Audio CAL200 -0.1 1 kHz 114 dB

B&K 4231 -0.2 1 kHz 114 dB

Norsonic Nor-1251 -0.2 1 kHz 114 dB

Correction

Value

Calibration

Frequency

Calibration

Level

30

Page 31

Specifications

Diffuse Field Correction Factors

A diffuse sound field is characterized by the sound arriving at

the receiver from all directions with more or less equal probability. The M2230, M2211, M2215 and M4261 are free-field

equalized measurement microphones. The default frequency

response refers to a 0° sound incidence. The diffuse-field frequency response is calculated by averaging the directional characteristics; this results in a reduction at the high frequencies.

The individual third-octave band correction values for diffusefield conditions are documented in the following table. The directional response of the M2230 is described in the appendix.

Example:

• The sound pressure level in a diffuse sound field shall be

determined. The display of the XL2 with the M2230 reads

80.0 dBA for the 20 kHz third-octave band.

• The diffuse sound level is now calculated from the sum

of the XL2 measurement value and the correction value

(80.0 dB + 8.7 dB = 88.7 dB).

This correction is not necessary using a diffuse

field equalized measurement microphone.

Nominal

Frequency

[Hz]

<63

63

80

100

125

160

200

250

315

400

500

630

800

1000

1250

160 0

2000

2500

3150

4000

5000

6300

8000

10000

12500

16000

20000

1/2”

Microphone

M2230, M2211, M2215

[dB]

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.1

0.1

0.1

0.1

0.1

0.2

0.2

0.3

0.4

0.5

0.6

0.8

1. 1

1. 4

1. 9

2.5

3.4

4.6

6.4

8.7

1/4”

Microphone

M4261

[dB]

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.2

0.2

0.3

0.5

0.7

1. 0

1. 4

1. 9

2.5

3.2

31

Page 32

‐10

‐9

‐8

‐7

‐6

‐5

‐4

‐3

‐2

‐1

0

1

Specifications

M2230 Frequency Response for Free Field, Diffuse Field and Pressure

Idealized

Free Field

1

0

-1

-2

-3

-4

-5

-6

sensitivity relative [dB]

-7

-8

-9

-10

10 20 100 1000 10000 20000

log frequency [Hz]

32

Diffuse Field

Pressure

Page 33

Specifications

Spectral Correction for horizontal Sound Incidents using the Outdoor Microphone

The outdoor microphone M2230-WP fulfills Class 1 requirements of IEC 61672 and ANSI S1.4 for vertical sound incidence.

For compliance with horizontal sound incidence a spectral correction is employed in the associated XL2 Sound Level Meter.

Nominal

Frequency

[Hz]

<800 0.0 0.0

800

1000

1250

160 0

2000

2500

3150

4000

5000

6300

8000

10000

12500

16000

20000

Spectral Correction for

horizontal Sound Incidents with

Firmware V4.20 or higher

[dB]

1/3 Octave 1/1 Octave

0.0

0.0

0.1

0.1

0.3

0.7

1. 3

2.0

2.6

2.7

3.2

3.7

4.3

6.1

6.4

0.0

0.4

2.1

3.3

5.9

33

Page 34

Specifications

Technical Data PreAmplifier

MA220 PreAmplifier

Microphone PreAmplifier Compatible with 1/2” microphone capsules type WS2F in accordance with IEC61094-4

Frequency Range 4 Hz - 100 kHz

Residual Noise Floor typical

Frequency Response Flatness ±0.2 dB

Phase Linearity < 1° @ 20 Hz - 20 kHz

Maximum Output Voltage

Electronic Data Sheet • Containing user calibration data

Impedance Input: 20 GOhm // 0.26 pF, Output: 100 Ohm balanced

Power Supply 48 VDC phantom power, 2.3 mA typical

Attenuation < 0.17 dB (Rphantom 2x 6.8 kOhm)

Connector Balanced 3-pole XLR

Thread for Capsule 60 UNS2

Weight 90 g, 3.17 oz

Dimensions Length 142.5 mm (5.6”), diameter 20.5 mm (0.8”)

Temperature Range -10°C to +50°C (14°F to 122°F)

Humidity 5% to 90% RH, non-condensing

NTi Audio # 600 040 040

1.6 mV(A) at C_in 18pF ≙ 12 dBA @ 20 mV/Pa

21 Vpp ≙ 7.4 Vrms ≙ 145 dBSPL @ 20 mV/Pa, THD 3%, 1 kHz

• Default factory sensitivity = 4.9 V/Pa

• Read/write by XL2 Audio and Acoustic Analyzer

• NTi Audio ASD in accordance with IEEE P1451.4 V1.0, Class 2, Template 27

The product specifications may vary based on the mounted microphone capsule type.

34

Page 35

Page 36

dth 1000 - 04.21

Loading...

Loading...