Page 1

User Manual

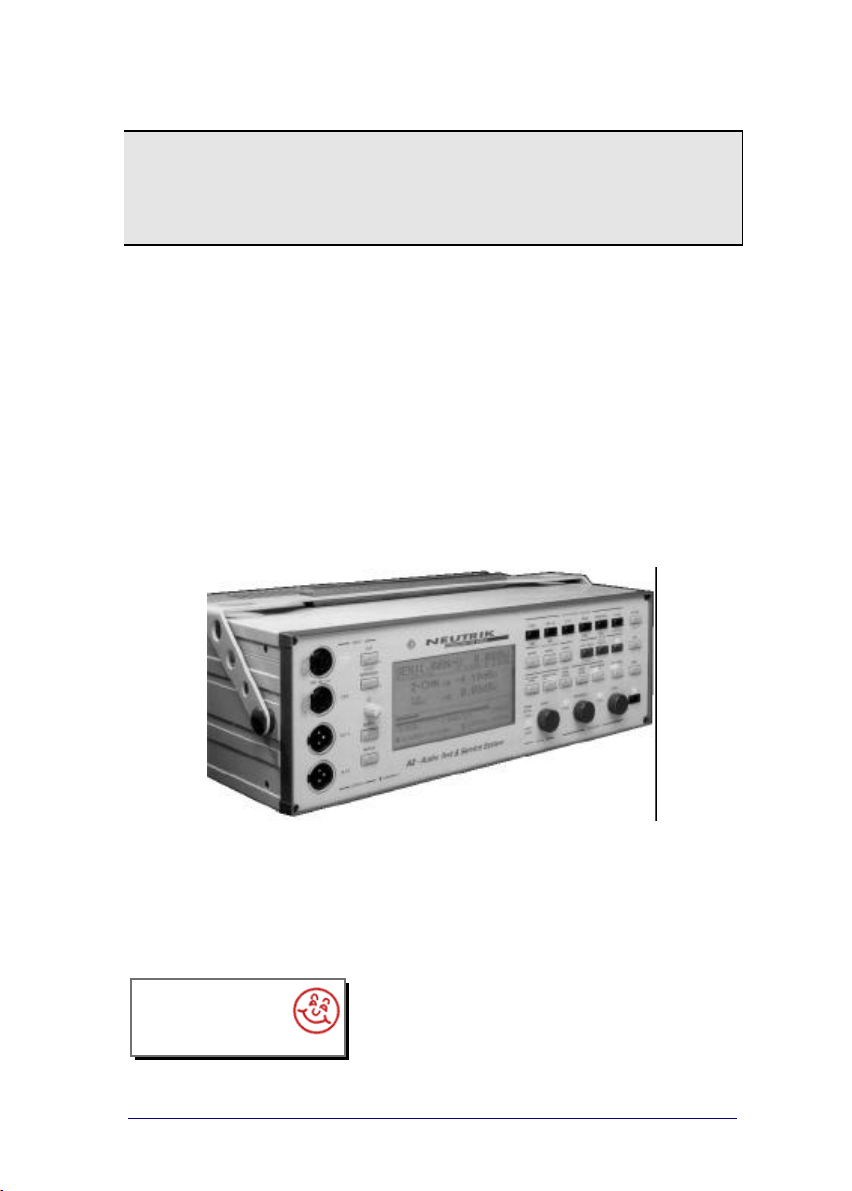

A2

Audio Test & Measurement System

interstage

Phistersvej 31, 2900 Hellerup, Danmark

Telefon 3946 0000, fax 3946 0040

www.interstage.dk

- pro audio with a smile

V

3.1 / July '01 / Ben

N:\A2Proj\#Manuals\User Manual\English\a2um_31e_nti.doc

Test & Measurement System

Version 3.1E

A2 firmware V2.0 or higher

Page 2

User Manual A2 Audio Test & Measurement System

2 / 104 V3.1

Page 3

A2 Audio Test & Measurement System User Manual

CE DECLARATION OF CONFORMITY

We, the manufacturer

hereby declare that the product

Product Name Audio Test & Service System

Model Number A2

Year of Construction 1995

conforms to the following standards or other normative documents

EC-Rules 89/392, 91/368, 93/44, 93/68, 73/23, 89/336, 92/31

Harmonized Standards IEC 65, IEC 68-2-31, IEC 348

EN50081-1, EN50082-1, EN50140, EN 61010-1

This declaration becomes void in case of any changes on the product without written

authorization by NTI.

Date Schaan, 28. 02. 1995

Signature

Position of Signatory Product Manager Test Instruments

Principality of Liechtenstein, Europe

Samples of this instrument have been tested and found to

conform with the statutory protective requirements. Instruments of

this type thus meet all requirements to be given the CE mark.

NTI AG

Im alten Riet 102

FL - 9494 Schaan

V3.1 3 / 104

Page 4

User Manual A2 Audio Test & Measurement System

4 / 104 V3.1

Page 5

A2 Audio Test & Measurement System User Manual

INTERNATIONAL WARRANTY

Limited Warranty

NTI guarantees the A2/A2 -D Audio Test & Service System and its components against

defects in material or workmanship for a period of one year from the date of original

purchase, and agrees to repair or to replace any defective unit at no cost for either parts or

labour during this period.

Restrictions

This warranty does not cover damages that have resulted of accidents, misuse, lack of care,

the attachment or installation of any components that were not provided with the product,

loss of parts or connecting the instrument to any other power supply, input signal voltage or

connector type than specified. In particular, no responsibility is granted for special, incidental,

or consequential damages.

This warranty becomes void if servicing or repairs of the product are performed by any other

party than an authorized service center.

No other warranty, written or oral, is authorized by NTI. Except as otherwise stated in this

warranty, NTI makes no representation or warranty of any kind, expressed or implied in law

or in fact, including, without limitation, merchasing or fitting for any particular purpose and

assumes no liability, either in tort, strict liability, contract or warranty for products.

Note

In case of malfunction, take - or ship prepaid - your NTI A2/A2 -D Audio Test & Service

System, packed in the original packing, to your nearest authorized service center. Be sure to

include a copy of your sales invoice as proof of purchase date. Transit damages are not

covered by this warranty.

Principality of Liechtenstein, Europe

Tel. +423 – 239 6060

Fax +423 – 239 6089

E-mail info@nt-instruments.com

NTI AG

Neutrik Test Instruments

Im alten Riet 102

FL - 9494 Schaan

V3.1 5 / 104

Page 6

User Manual A2 Audio Test & Measurement System

TABLE OF CONTENTS

1. INTRODUCTION ...........................................................................................10

Safety Information ............................................................................................................... 10

Overview.............................................................................................................................. 10

How to use this Manual....................................................................................................... 12

2. INSTALLATION.............................................................................................13

Unpacking............................................................................................................................ 13

Options and Accessories..................................................................................................... 13

Environmental Conditions ................................................................................................... 13

Mains Power Supply....................................................................................................... 13

Printer Connection.......................................................................................................... 14

Interface to PC................................................................................................................ 14

3. GETTING STARTED .....................................................................................15

Measurement Functions ...................................................................................................... 15

Menu Operation...................................................................................................................15

Generator Settings .............................................................................................................. 16

The Display Modes..............................................................................................................16

Sweep Operation............................................................................................................17

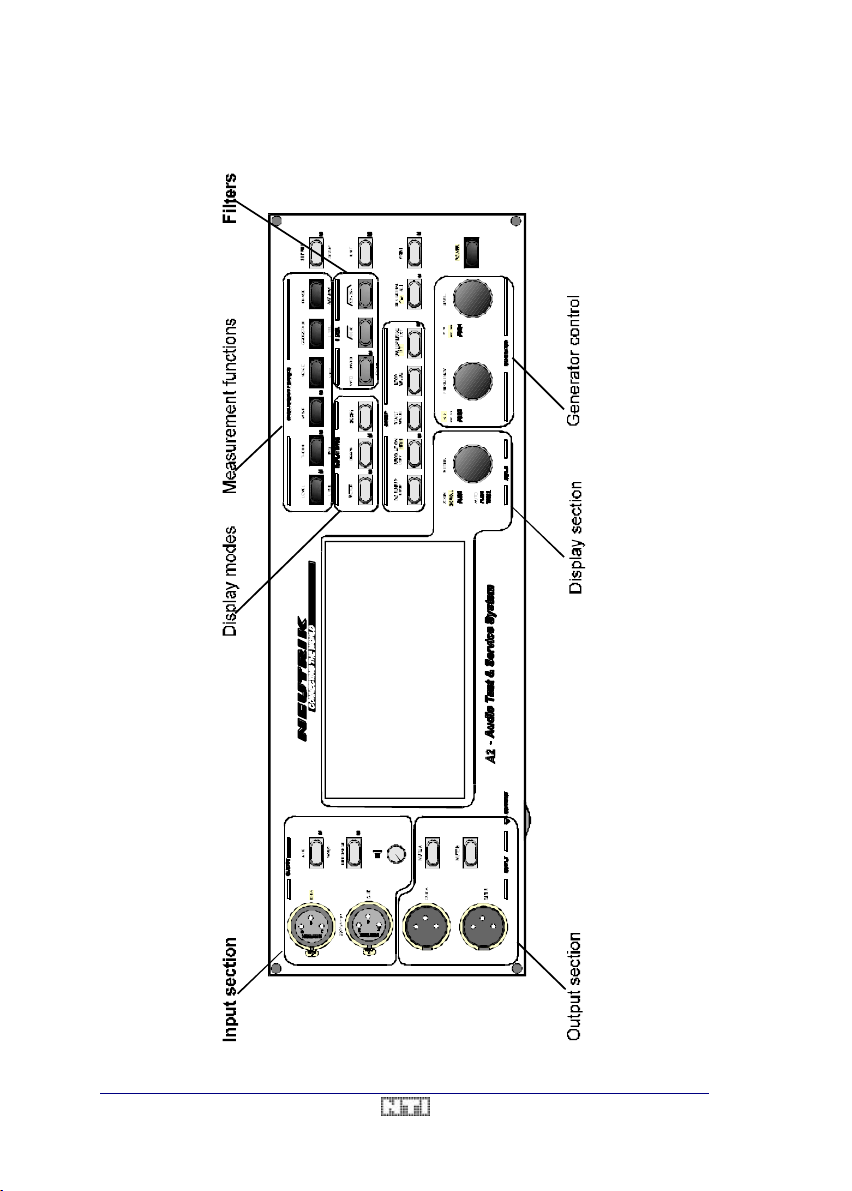

The A2/A2-D User Interface................................................................................................18

A2/A2-D Menu Overview.....................................................................................................19

4. A2/A2-D OPERATION .................................................................................21

Input Section........................................................................................................................21

Input Block Diagram........................................................................................................ 22

Input Wiring & Impedances.............................................................................................22

Input / Output Impedance Selection.................................................................................23

Auto / Fixed Range........................................................................................................24

Connection of a Balanced Output to the A2/A2-D.............................................................25

Connection of an Unbalanced Output to the A2/A2-D.......................................................25

Monitor Outputs............................................................................................................... 26

Monitor Loudspeaker......................................................................................................26

Overview.........................................................................................................................26

Output Section..................................................................................................................... 27

Output Circuit.................................................................................................................. 27

Balanced Operation .......................................................................................................28

Unbalanced Operation...................................................................................................28

Optional Transformer Output Stage.................................................................................28

Output Settings ............................................................................................................... 29

Output Parameters.........................................................................................................29

Signal Waveform...........................................................................................................29

Square Signal (Sym. / Asym.).........................................................................................30

IMD TestSig ..................................................................................................................30

Noise............................................................................................................................31

Warbled Sine.................................................................................................................31

Frequency.......................................................................................................................31

Level................................................................................................................................31

Readback........................................................................................................................32

Output Muting.................................................................................................................. 33

Overview.........................................................................................................................33

Display Modes.....................................................................................................................34

METER Display Mode..................................................................................................... 34

6 / 104 V3.1

Page 7

A2 Audio Test & Measurement System User Manual

Generator Settings.........................................................................................................35

Generator Readback......................................................................................................35

Measurement Results ....................................................................................................35

Units.............................................................................................................................35

The Bar-graph ...............................................................................................................36

Zooming the Bar-graph Scale.........................................................................................36

Scrolling the Bar-graph...................................................................................................36

Input Display..................................................................................................................37

Printouts........................................................................................................................37

GRAPH Display Mode....................................................................................................38

Cursor Function.............................................................................................................39

Y-Scaling.......................................................................................................................39

ZOOM...........................................................................................................................39

SCROLL.......................................................................................................................40

X-Scaling.......................................................................................................................40

GRAPH Printouts...........................................................................................................41

Store & Recall Graphs ....................................................................................................41

SCOPE Display Mode..................................................................................................... 42

Printouts........................................................................................................................43

Overview.........................................................................................................................43

5. MEASUREMENT FUNCTIONS .......................................................................44

Level Function ..................................................................................................................... 44

Mono / Stereo Measurements........................................................................................44

Units ................................................................................................................................ 44

Filters............................................................................................................................... 45

Applications..................................................................................................................... 46

Overview.........................................................................................................................46

Level Relative Function....................................................................................................... 47

Filters............................................................................................................................... 47

Units ................................................................................................................................ 48

Application Example.......................................................................................................48

Signal-to-Noise Measurement........................................................................................48

THD+N Function..................................................................................................................49

Notch Filter...................................................................................................................... 50

Additional Filters.............................................................................................................. 50

Units ................................................................................................................................ 50

SINAD Measurement......................................................................................................51

IMD Function.......................................................................................................................52

Standards ........................................................................................................................ 53

Unit.................................................................................................................................. 54

Filters............................................................................................................................... 54

Applications..................................................................................................................... 54

Noise Function.....................................................................................................................55

Units ................................................................................................................................ 55

Filters............................................................................................................................... 55

Applications..................................................................................................................... 56

Noise Relative Function ...................................................................................................... 57

Units ................................................................................................................................ 57

Filters............................................................................................................................... 57

Crosstalk Function...............................................................................................................59

Units ................................................................................................................................ 59

Filters............................................................................................................................... 59

External Source.............................................................................................................60

Level Selective Function..................................................................................................... 61

Filters............................................................................................................................... 61

V3.1 7 / 104

Page 8

User Manual A2 Audio Test & Measurement System

External Source.............................................................................................................62

Units ................................................................................................................................ 62

Applications..................................................................................................................... 62

Wow & Flutter Function....................................................................................................... 63

Standards ........................................................................................................................ 64

W&F Measurements (Replay only).................................................................................64

W & F Measurements (Record to Replay) ..................................................................... 64

W&F Signal Analysis....................................................................................................... 65

Phase Function.................................................................................................................... 66

Applications..................................................................................................................... 66

Filter Overview.....................................................................................................................67

ADDITIONAL Function........................................................................................................67

6. SWEEPS .....................................................................................................68

Preparing a Sweep.............................................................................................................. 68

Selecting the Sweep Mode............................................................................................. 68

Setting the Sweep Limits & Resolution.......................................................................... 69

Performing a Sweep............................................................................................................ 70

Synchronization (Internal / External).............................................................................. 70

Sweep Recording................................................................................................................ 71

Keep a Recorded Trace.................................................................................................. 71

Store & Recall Sweeps...................................................................................................71

Sweep Modes...................................................................................................................... 73

Frequency Sweep........................................................................................................... 73

Y-Axis Units and Scaling................................................................................................73

Re-Scaling of the Frequency Axis ...................................................................................73

Frequency Sweeps in Different Measurement Modes .......................................................74

Graphics Cursor.............................................................................................................74

Tape Sweep.................................................................................................................... 75

Recording a Tape Sweep...............................................................................................75

External Sweep............................................................................................................... 77

Preparing an External Sweep.........................................................................................77

List of Reference CD Tracks ...........................................................................................78

Stepped Sweeps............................................................................................................78

Gliding Sweeps..............................................................................................................78

Amplitude Sweep............................................................................................................ 79

Units of X- / Y-axis.........................................................................................................79

Time Sweep .................................................................................................................... 80

Table Sweep................................................................................................................... 81

Sweep Data Upload to a PC............................................................................................... 81

7. PRINTOUTS.................................................................................................82

Printer Driver Selection........................................................................................................ 82

Printer Settings....................................................................................................................83

EPSON FX-80, IBM Proprinter .......................................................................................83

EPSON LQ-550 / LQ-1050............................................................................................. 83

hp Laserjet, Deskjet........................................................................................................ 83

Printer Error......................................................................................................................... 83

8. INSTRUMENT SETUP ...................................................................................85

Store & Recall Setups ......................................................................................................... 85

Calibration............................................................................................................................ 85

Connector Pin Assignment.................................................................................................. 87

Centronics Connector..................................................................................................... 87

8 / 104 V3.1

Page 9

A2 Audio Test & Measurement System User Manual

Timing Diagram .............................................................................................................87

RS232 Connector...........................................................................................................87

Cable............................................................................................................................88

9. OPTIONS & ACCESSORIES..........................................................................89

Options Overview................................................................................................................ 89

RS232 Serial Interface (AO1 / AO16).............................................................................90

Baudrate Selection.........................................................................................................90

Filter Options................................................................................................................... 91

A-Weighting Filter (AO4).................................................................................................91

User Filter (AO5)............................................................................................................92

C-Message Filter (AO13)................................................................................................93

80kHz Lowpass Filter (AO14) .........................................................................................94

Transformer Option (AO7).............................................................................................. 95

Phantom Power (AO8)....................................................................................................95

Accessories Overview.........................................................................................................95

10. TECHNICAL SPECIFICATIONS ......................................................................96

Analog Generator................................................................................................................ 96

Digital Generator ................................................................................................................. 96

Sweep Function...................................................................................................................96

Analog Analyzer................................................................................................................... 96

Digital Analyzer.................................................................................................................... 97

Level Function ..................................................................................................................... 97

Total Harmonic Distortion (THD + N)..................................................................................97

Phase................................................................................................................................... 97

IMD ...................................................................................................................................... 97

Crosstalk / Level Selective .................................................................................................. 98

Noise.................................................................................................................................... 98

Wow & Flutter Function....................................................................................................... 98

Drift ...................................................................................................................................... 98

Frequency Function............................................................................................................. 98

Scope Function.................................................................................................................... 98

Filters ................................................................................................................................... 99

Display (of A2/A2-D)............................................................................................................ 99

Interfaces.............................................................................................................................99

General Data ....................................................................................................................... 99

11. INDEX........................................................................................................100

V3.1 9 / 104

Page 10

User Manual A2 Audio Test & Measurement System

1. INTRODUCTION

Safety Information

Please read this safety information thoroughly before starting to operate the A2.

• The NTI A2/A2-D Audio Test & Measurement System was designed to be connected to a

specified mains power source with safety grounding through an approved three -wire

mains power cable.

NEVER operate the instrument with missing or compromised

• To avoid fire hazard, the mains power fuse of the A2/A2-D must be replaced in case of

failure by a fuse with the correct rating (see chapter 2. Installation).

• For safety reasons never apply voltages higher than 200V

measurement inputs of the A2. Voltages higher than that may permanently destroy the

internal electronics.

• There are no parts inside the instrument that may be repaired or replaced by the user.

Therefore, never open the unit for any reason.

Do not try to service the instrument unless properly qualified.

safety ground connection.

or 300Vp to the

RMS

Overview

The NTI A2 is a comprehensive, high performance two -channel audio test set. It includes a

flexible generator, based on a Digital Signal Processor (DSP) and a high performance

analyzer providing a wide variety of measurement functions, as there are

• Level absolute (two-channel) in µV, mV, V, dBV and dBu or dBm

• Level relative in *1, % and dBr

• Level selective in µV, mV, V, dBV and dBu / dBm

• Total harmonic distortion & noise (THD+N) in % and dB

• IMD (Intermodulation distortion) in % and dB

• Wow & Flutter in %

• Noise (absolute), weighted and unweighted, in µVq, mVq, Vq and dBq

• Noise (relative), weighted and unweighted, in *1, % and dBr

• Crosstalk (frequency selective) in *1, % and dBr

• Frequency (two channels simultaneously)

• Phase (interchannel) in the range of ±180°.

In the METER display mode, all measurement results are displayed in numerical form as

large digits and in analog form through a bar-graph. Additional parameters like the I/Ofrequencies and impedances, the input levels and the generator settings are permantly

shown.

10 / 104 V3.1

Page 11

A2 Audio Test & Measurement System User Manual

The standard sweep capabilities of the A2/A2-D allow to perform

• Frequency sweeps

• Amplitude Sweeps

• Time Sweeps

• Table sweeps with freely definable pairs of frequency and level (with Option AO1)

Sweeps can be controlled by the built-in generator or by an external source (e.g. test tapes,

test CDs or other NTI A-series instruments) at a remote location. Several traces can be

recorded and displayed in the GRAPH mode, while up to four complete graphs may be

stored in the internal non-volatile memory of the A2/A2-D. This allows for instance to record

swept measurements in a studio and to print out the results in the office later.

Another powerful diagnostic aid of the A2 is the SCOPE function. In this mode, the waveform

of both input channels is shown on the LC-display just like on a dual trace oscilloscope. If set

to the THD+N function, the A2/A2-D shows both the original signal and the distortion

residual. In other measurement functions, the main input signal is shown as a single trace.

All measurements of level - except noise - are true RMS rectified. Noise is measured as

quasi-peak value according to the CCIR 468-3 standard. Both a 400Hz high -pass and a

22Hz-22kHz band-pass filter are available as a standard.

The two inputs of the A2/A2-D are DC -isolated up to ±300Vp, and equipped with selectable

input impedances to optimally match the output impedance of the device under test (DUT).

As an option, both inputs may also be Phantom-powered.

The normalized input signals are available at the BNC connectors at the rear panel of the

instrument. A small, built-in loudspeaker allows acoustical monitoring of the measured signal.

The versatile generator of the A2/A2-D, based on a Digital Signal Processor, is capable of

generating a large number of different test signals over the full level & frequency range.

• Low distortion pure sine signal

• Low distortion warbled sine

• Dual-tone IMD signal, covering all standards

• Symmetric square wave (50:50 duty cycle)

• Asymmetric square wave (40:60 duty cycle for phase reverse check)

• White noise

• Pink noise

The output impedance (<15Ω up to 600Ω) can be adjusted in a wide range as well in order to

match the input impedance of the device to be tested.

As an option, a RS-232 serial or IEEE-488 parallel interface may be installed into the

instrument to remote control all A2/A2-D features from a PC.

Regardless of the type of interface, AS04, a comprehensive Windows based software

package is included, supporting all operation modes, offering the possibility to store all

results, and allowing to write program sequences in the easy-to-learn Audio Measurement

Sequence Language (AMSL) for fully automatic measurements.

V3.1 11 / 104

Page 12

User Manual A2 Audio Test & Measurement System

How to use this Manual

This User Manual has been written to serve as a complete reference document for using the

A2/A2-D as a solution for your measurement requirements. Maintenance procedures, such

as installation of the instrument, are placed at the beginning while not so frequently required

tasks such as re-calibration are filed at the end of the manual.

The best way to familiarize with the instrument is to place the A2/A2-D in front of you and to

read through the chapters 2. Installation and 3. Getting Started. This way, it won't take long to

feel at ease with the instrument and its many features.

Do not operate the instrument without reading through the chapter

2. Installation. Important information about mains voltage selection and fuse

rating is given therein.

12 / 104 V3.1

Page 13

A2 Audio Test & Measurement System User Manual

1

0

2. INSTALLATION

Unpacking

Your new A2/A2-D comes along together with some accessories. Please check whether all

of the following items are enclosed.

• A2/A2D Audio Test & Service System

• Mains power cable

• Spare fuse for 110VAC

• A pair of rack-mount wings

• This User Manual.

It is strongly recommended to save the original cardboard box for the case that it ever

becomes necessary to ship the A2/A2-D. Never ship the instrument in a box not properly

protecting the unit against mechanical shock, since the NTI warranty does not cover

damages caused by improper packing.

Options and Accessories

Besides the wide range of already built-in features of the A2/A2-D, there are some optional

items available for the A2/A2-D as listed in chapter 8. Instrument Setup. Please ask your local

NTI agency for further details.

Environmental Conditions

The A2/A2D test system will operate in accordance with its specifi cations as long as the environmental conditions are kept within the following ranges.

Temperature 5°-45° Celsius

Humidity 10 -90% non condensing

Mains Power Supply

After having unpacked the unit, it is first necessary to connect the system to the AC mains

power of your country. For this purpose, the enclosed mains power cable has an unconnected end with three colored leads, corresponding to

Brown = Live

Blue = Ground

Green/Yellow = Earth

Attach a mains plug to this end of the cable, fitting to the receptacles of your area. Next,

make sure that the mains power voltage matches the power selection that is shown on the

mains power connector/fuse holder assembly on the rear panel of the A2/A2-D. If this selection is incompatible with the available power source, go through the following paragraph to

adjust the mains power requirements.

The A2/A2-D2 can operate from 100VAC, 120VAC, 230VAC or 240VAC. To configure the

input line voltage of the A2/A2-D, remove the mains cable and open the flap of the

connector/fuse holder assembly at the rear panle of the A2/A2-D by pressing a small

screwdriver into the slot on the top or ruin your fingernails.

V3.1 13 / 104

Page 14

User Manual A2 Audio Test & Measurement System

1

0

Take out the drum and insert it in the new, required position.

The label pointing towards the operator indicates the selected

line voltage.

At the same time, insert a new fuse with the proper current

rating must. For 100VAC and120VAC, a 2A fuse has to be

used, while for 230VAC and 240VAC a 1A fuse is required.

After having set the required line voltage and installation of the

proper fuse, close the flap and insert the power cable.

The A2/A2-D is designed to be connected to protective ground (earth) through the ground

wire in the power cable. This connection is essential for safe operation.

NEVER operate the instrument if the safety ground connection is not available or

has been compromised.

Printer Connection

The CENTRONICS printer connector is located at the rear panel of the A2/A2 -D. It is a 25pin female D-type connector - the same as installed in a standard PC.

To select the required printer driver, please refer to the chapter 7. Printouts. The appendix

describes in detail the pin assignment and the timing of the CENTRONICS port.

Interface to PC

Connection The RS232C serial or IEEE-488 parallel interface is available as an option

together with the software package AS04 to control the A2/A2-D as a remote unit. As long as

this interface is not installed, the hole for the connector is covered with a blanking plate.

Both interface types can be upgraded at a later time by inserting a sub circuit. Please refer to

the chapter 8. Instrument Setup for more detailed information.

RS 232 / IEEE (optional)

0 1 2 3 4 5 6 7

Centronics Printer Port

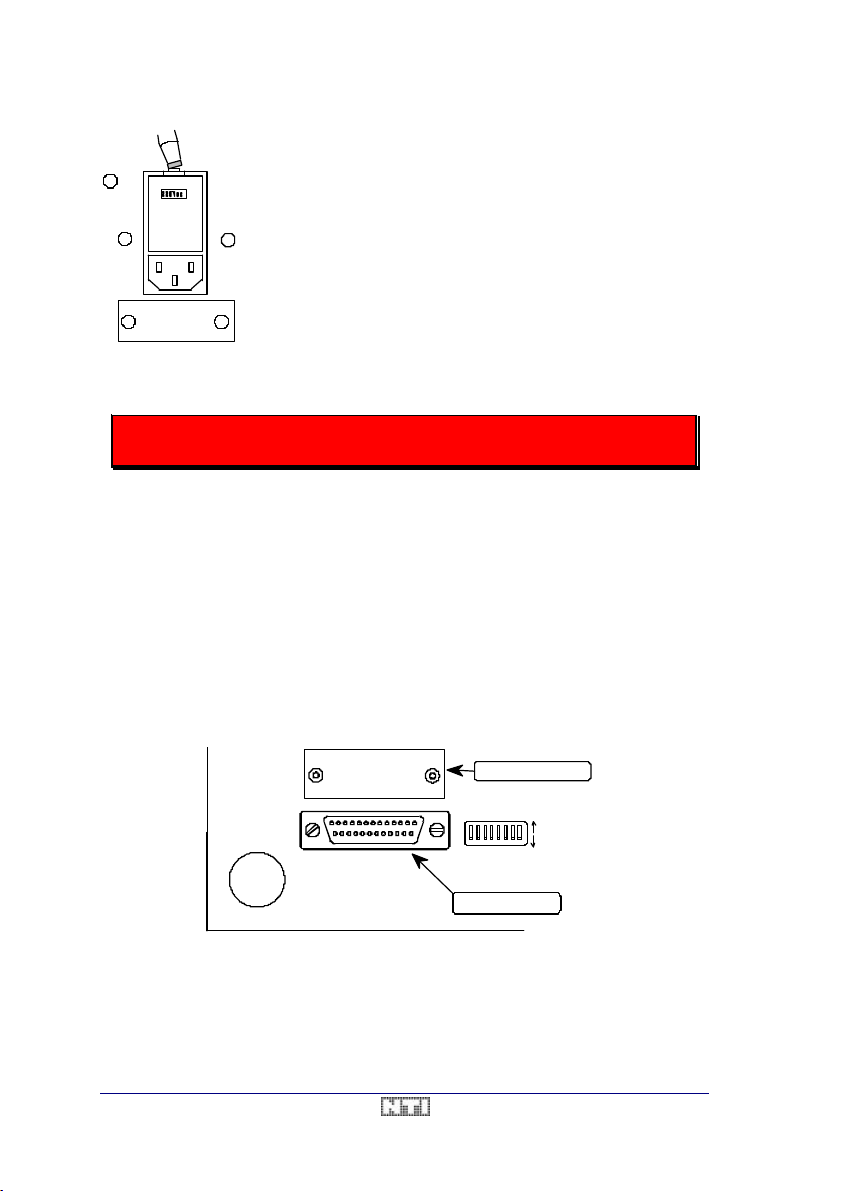

Fig. 1 Rear Panel Interface Connectors

14 / 104 V3.1

Page 15

A2 Audio Test & Measurement System User Manual

. To confirm the chosen entry,

(« »)

3. GETTING STARTED

Read this chapter carefully to become familiar with the operation of the A2/A2-D.

Further details are filed in the following chapters.

The NTI A2/A2-D system is very easy to operate, despite its large number of functions and

the variety of options & settings. Since the user interface is arranged in logical blocks and

every key correlated to a certain function, operation of the unit is virtually self-explaining.

Nevertheless, regardless of the keys that are pressed, the internal logic of the system takes

care that every measurement is done according to the specified standards.

Measurement Functions

The measurement-related keys are arranged on the top row of the right hand side of the

A2/A2-D keyboard. Any measurement function may be selected at any time by pressing the

respective key.

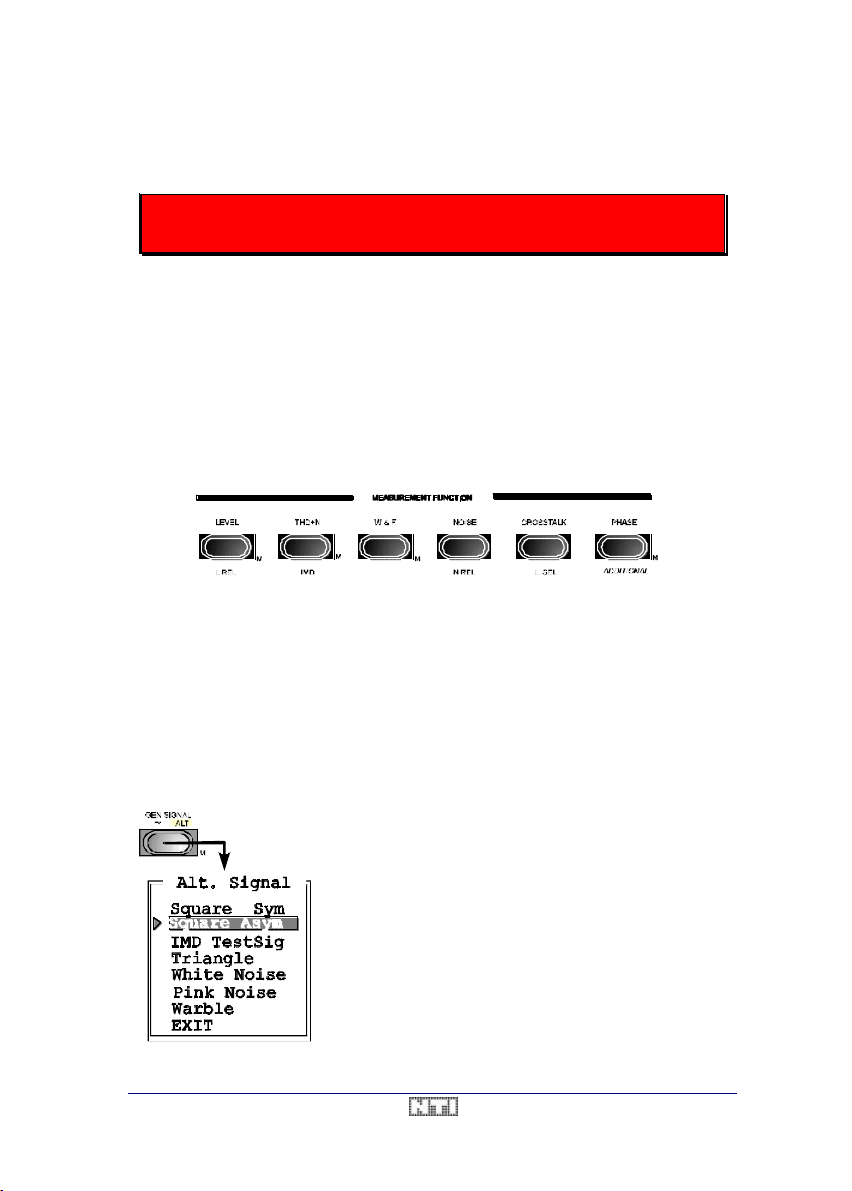

Fig. 2 Measurement Function Keys

Some of the keys provide two selections, thus allowing to select another related

measurement (e.g. <THD+N> and <IMD>). To activate the second function, simply press the

key once more and the measurement mode will toggle. The actually selected function is

permanently displayed.

Menu Operation

To allow the user to activate a special option or setup, several menus may be opened by

double-clicking any of the keys marked with a capital "M" in the bottom right (see p. 19).

As soon as the menu is open, a list of selections appears,

with the currently active selection being displayed in inverted

characters.

In this example, by double-clicking the <GEN SIGNAL> key,

the Alt. Signal menu appears.

To change the actual setting, the small triangle arrow on the

left hand side may be moved to any entry of the menu by

turning the <SCALE> wheel

press the <SCALE> wheel once.

If a new selection has been confirmed, the menu will be

closed. Alternatively, leave the menu through the EXIT entry

or by prressing any key.

V3.1 15 / 104

Page 16

User Manual A2 Audio Test & Measurement System

(« »)

NOTE While a menu is open, any other keypress than to the <SCALE> wheel

will close the menu and execute the new command.

Generator Settings

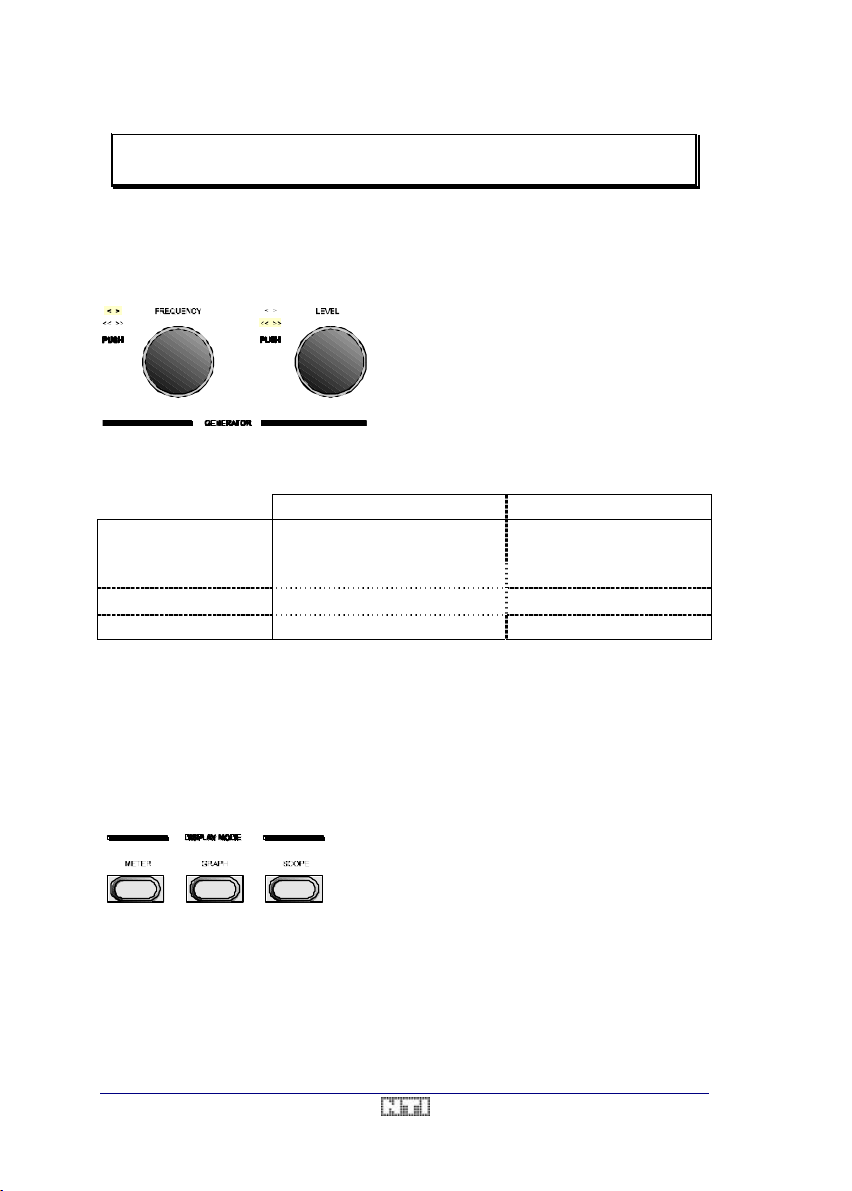

The generator output frequency & level can be selected by the two softwheels labeled with

<FREQUENCY> and <LEVEL>.

By turning the <FREQUENCY> or <LEVEL> wheels slowly or quickly, the width of the step

up/down to the next value may be small or large as listed in Table 1.

<FREQUENCY> <LEVEL>

Coarse mode, quick turn 10Hz - 20Hz - 100Hz - 1kHz -

10kHz - 40kHz - 100kHz

Coarse mode, slow turn ± 12.5% ± 2dB / ± 25.9%

Fine mode, quick turn 3rd-octave steps ± 2dB / ∼ factor 2

Fine mode, slow turn ± 0.5% ± 0.04dB / ± 0.5%

Furthermore, the two generator outputs A and B can be muted by pressing the respective

<MUTE> keys. Otherwise, i.e. if they are muted, both outputs are permanently active.

Neither frequency nor level can be changed

continuously - as with a poti-controlled analog

generator - but in discrete steps only.

By pushing the softwheel once, the stepwidth

toggles between fine (< >) and coarse

mode. The actual selection is indicated by a lit

LED behind the corresponding sign.

Table 1 Softwheel Steps

± 20dB (logarithmic units)

or factor 10 (linear units)

The Display Modes

With the three DISPLAY MODE keys, the user may select one of the available modes, regardless of the actual measurement function.

All these modes can be selected at any time without affecting the actual measurement (e.g.

also during a running sweep).

To increase the lifetime of the backlight of the LC-display, it is automatically switched Off if

no key or wheel on the instrument is used for several minutes. However, any keypress immediately re-lights the illumination.

• The METER mode displays the single results together with all additional measurement parameters.

• Sweeps may be displayed in the GRAPH mode.

• The SCOPE mode shows the waveform of the

input signal in the time domain.

16 / 104 V3.1

Page 17

A2 Audio Test & Measurement System User Manual

Sweep Operation

Sweeps are best performed in the display mode GRAPH, that continuously displays the

setup parameters and the recorded curve(s) on the LCD.

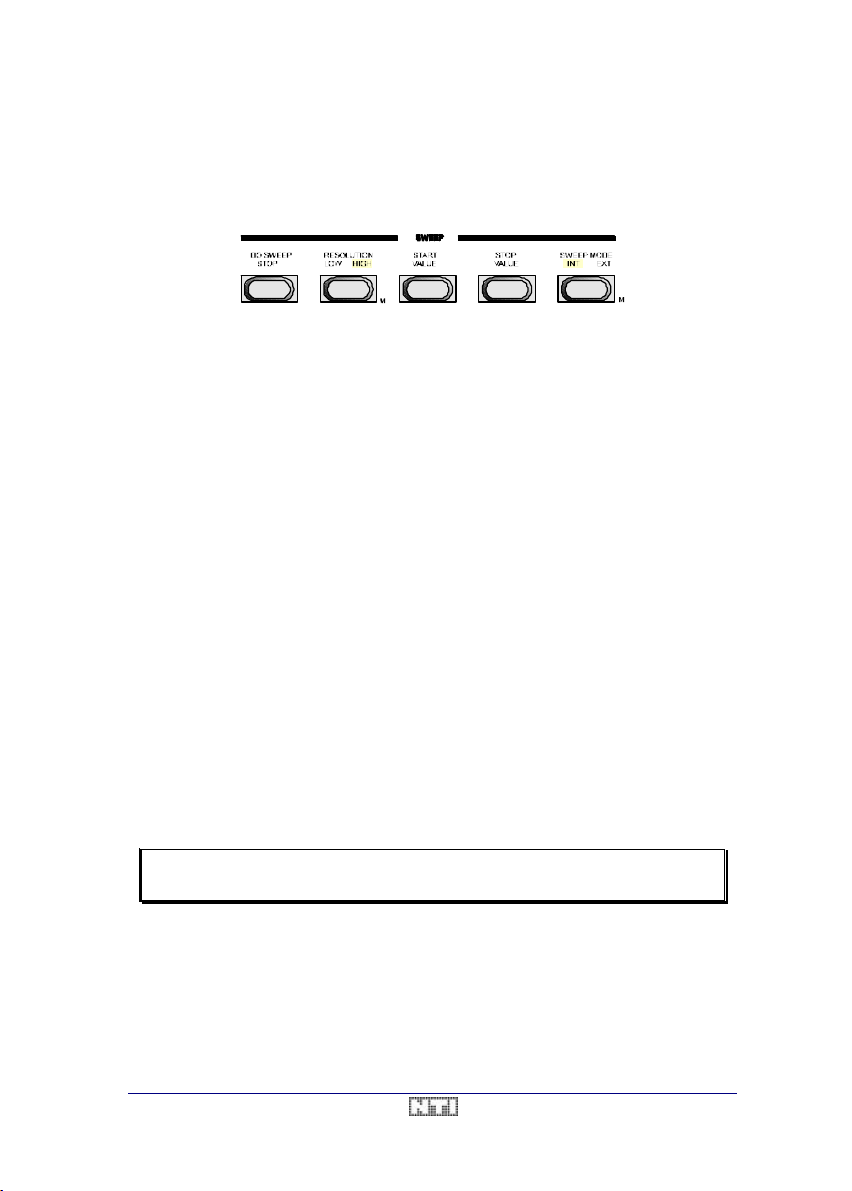

The specific sweep setup may be selected through the keys of the SWEEP block.

Fig. 3 SWEEP Block

Basically, there are 5 sweep modes available, that can be called through the menu behind

the key <SWEEP MODE>.

• Frequency sweeps measure the actually selected function vs. a changing frequency

• Tape sweeps allow to record a defined frequency pattern on a tape

• Amplitude sweeps measure the actually selected function vs. a changing amplitude

• Time sweeps measure the actually selected function vs. time

• Table sweeps allow to measure the actually selected function vs. a previously defined

frequency / amplitude table (requires RS232 or IEEE-488 option)

Furthermore, the <SWEEP MODE> key allows to toggle between internally and externally

generated sweeps.

To define the start / stop value of the X-axis (e.g. 20Hz / 20kHz for a frequency sweep), set

the generator to the desired value and press the <START> / <STOP> key respectively.

Choose the resolution of your sweep, i.e. the number of samples to be recorded, through the

<RESOLUTION> key. Both modes (LOW / HIGH) allow to set the required number of measurements by entering the sweep resolution menu.

The recording of a new sweep is started by pressing the <DO SWEEP / STOP> key, while a

running sweep may be stopped through the same action.

Several sweeps may be permanently stored by entering the menu behind the <GRAPH>

button, and selecting one of the four avilable memory locations (M1-M3). By this way, up to

four complete graphs with a max. of 6 curves per graph may be stored in the non-volatile

memory of thze A2/A2-D for a later printout or upload to a PC.

NOTE This is only a very brief description of the sweep capabilities of the A2.

Please refer also to the chapter 6. Sweeps to see all the possibilities.

V3.1 17 / 104

Page 18

User Manual A2 Audio Test & Measurement System

The A2/A2-D User Interface

18 / 104 V3.1

Page 19

_nti.docTest & Measurement System User Manual

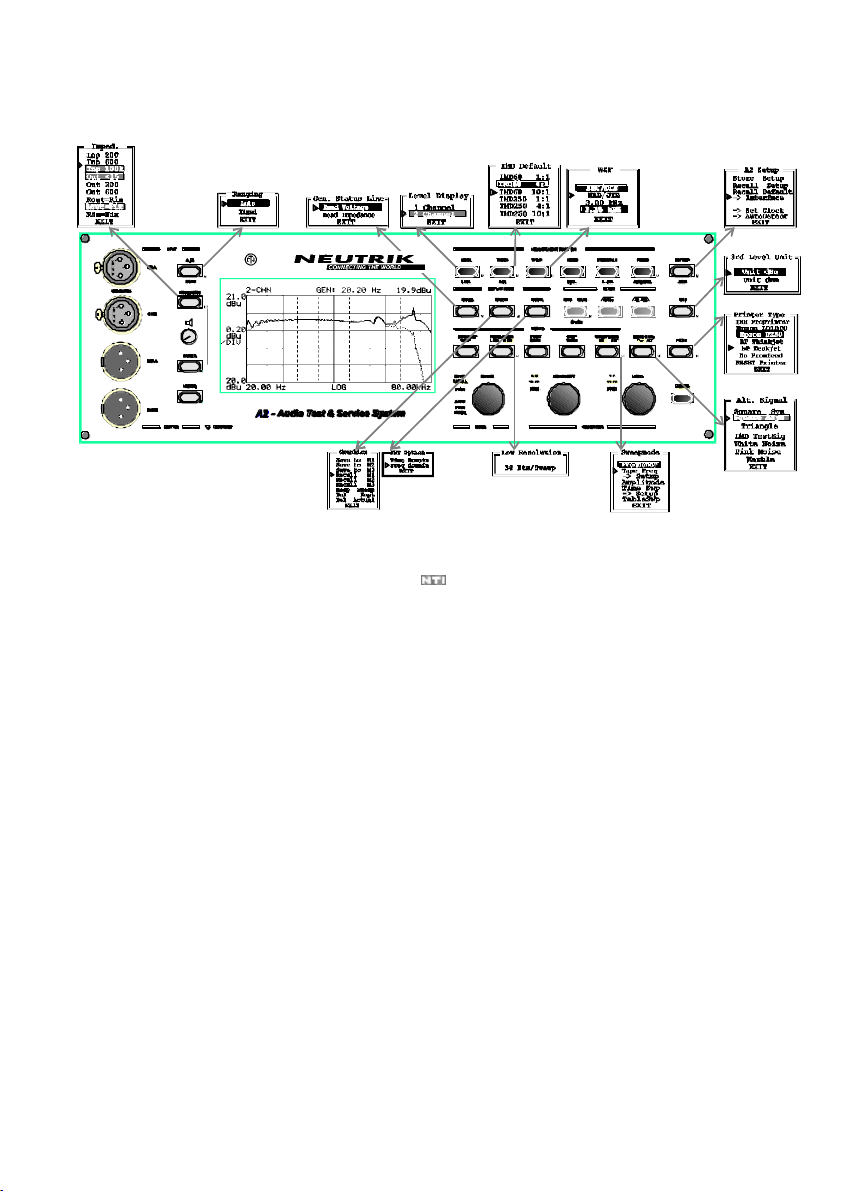

A2/A2- D Menu Overview

V3.1 19 / 104

Page 20

_nti.docTest & Measurement System

V3.1

Page 21

A2 Audio Test & Measurement System User Manual

4. A2/A2-D OPERATION

NOTE Before switching On your A2/A2 -D, make sure that the selected mains

power voltage matches the one of your area. If not, please refer to chapter 2. Installation to set it correctly.

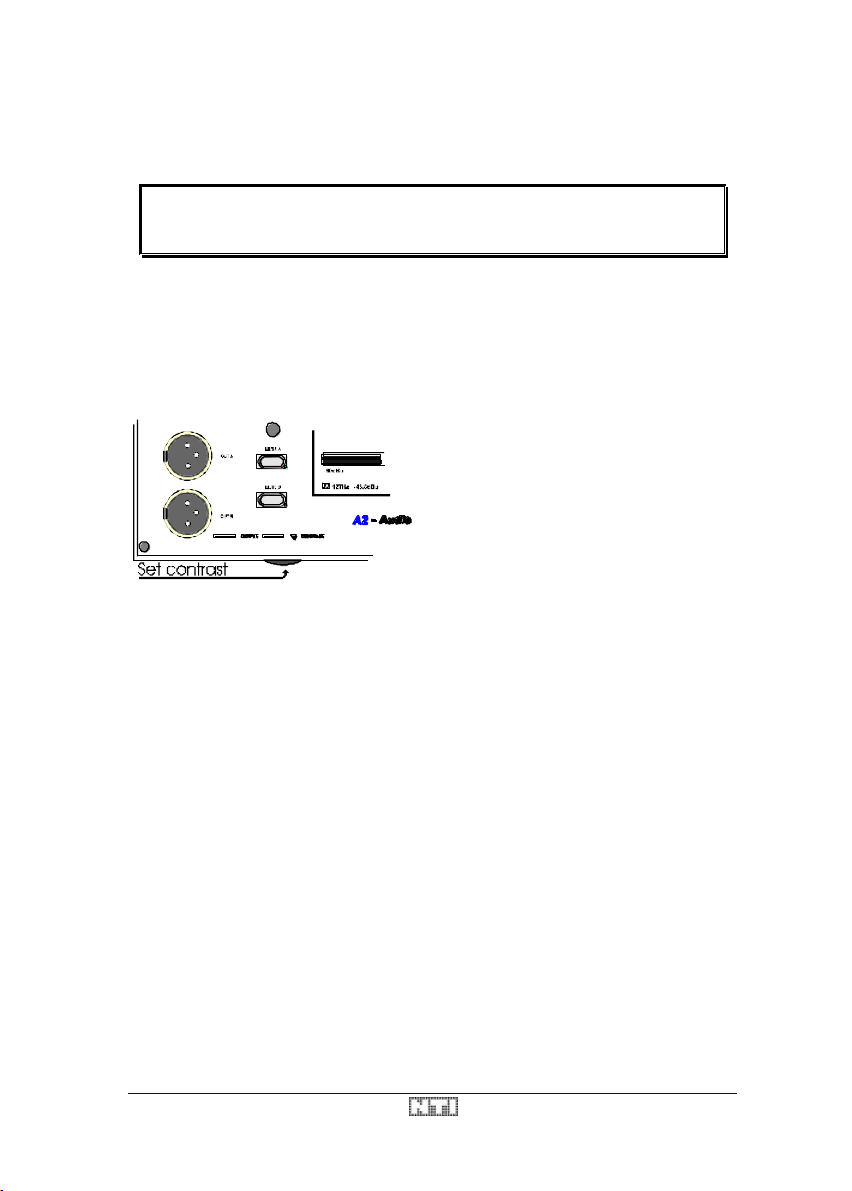

Each time the A2/A2-D is switched On, it perform s a short self-test, during which the A2 logo

will be displayed together with the software version, the current time setting of the internal

clock and the serial number of the unit.

After this test, the A2/A2-D will present itself in the last active setup, i.e. show the same settings and selections as when it was switched off. Nevertheless, it is also possible to define

and recall a user setup (see chapter Store & Recall Setups).

The A2/A2 -D is equipped with a screen saver function to extend the life time of the LCD

backlight. The backlight darkens after ~10 minutes without any operator activity. To turn it On

again, simply press any key or softwheel.

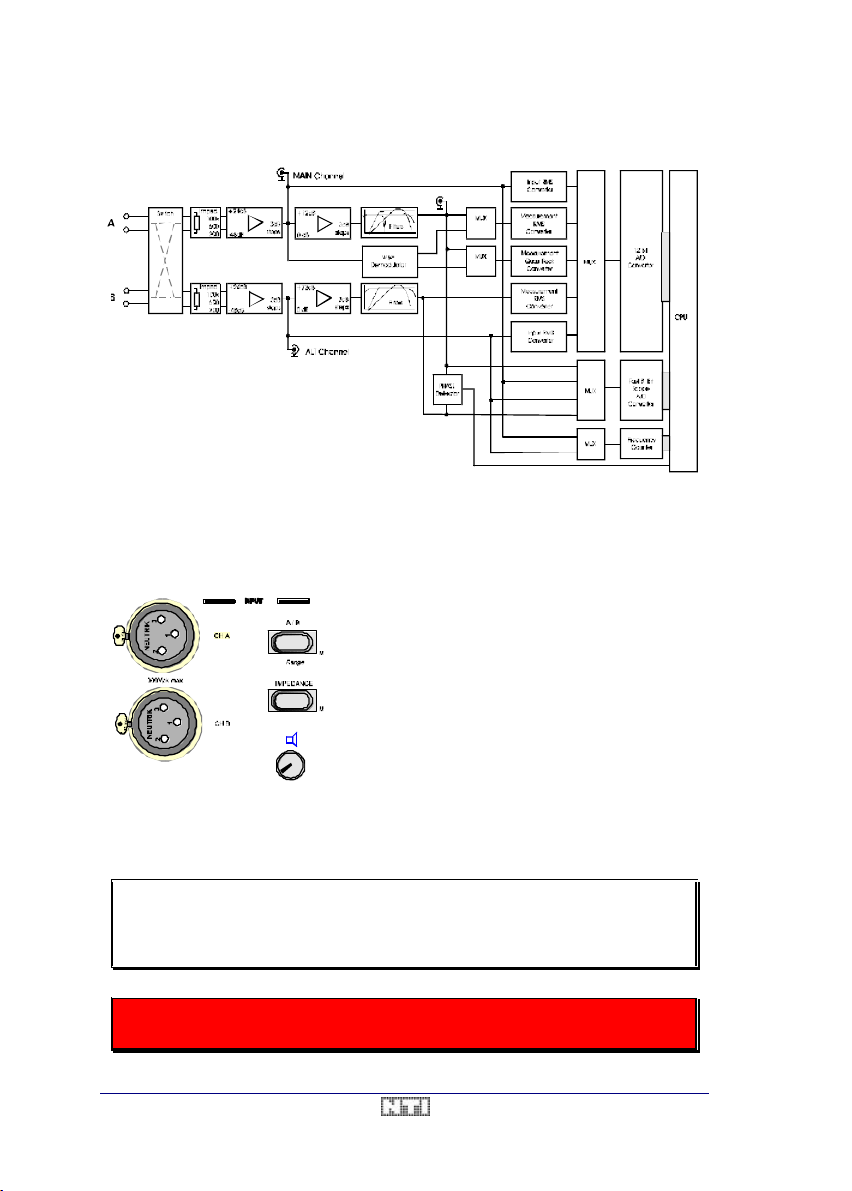

Input Section

The A2/A2-D is a two-channel measurement system, providing two fully independent measurement channels, named MAIN and ALTERNATE. Both channels are equipped with an in-

put impedance circuitry, input attenuators/amplifiers and a filter bank. This allows e.g. to

measure weighted or unweighted levels of both channels simultaneously.

Additionally, the main channel analyzer is equipped with a special filter section for Harmonic

Distortion, Intermodulation and Noise measurements, and also provides the demodulator and

filtering for W&F measurements.

The <A / B> key allows to select which of the input connectors shall be the main channel of

the instrument. In other terms, the input signal of the illuminated (i.e. active) channel is always fed to the main channel, while the other input signal is fed to the alternate channel.

If necessary, one may tilt the instrument

slightly either by turning the carrying handle

below the underside or use the reversible

footings in order to optimze the view on the

LCD.

Furthermore, you may adjust the contrast of

the LC-display to your demands by turning

the potentiometer wheel on the left hand side.

V3.1 21 / 104

Page 22

User Manual A2 Audio Test & Measurement System

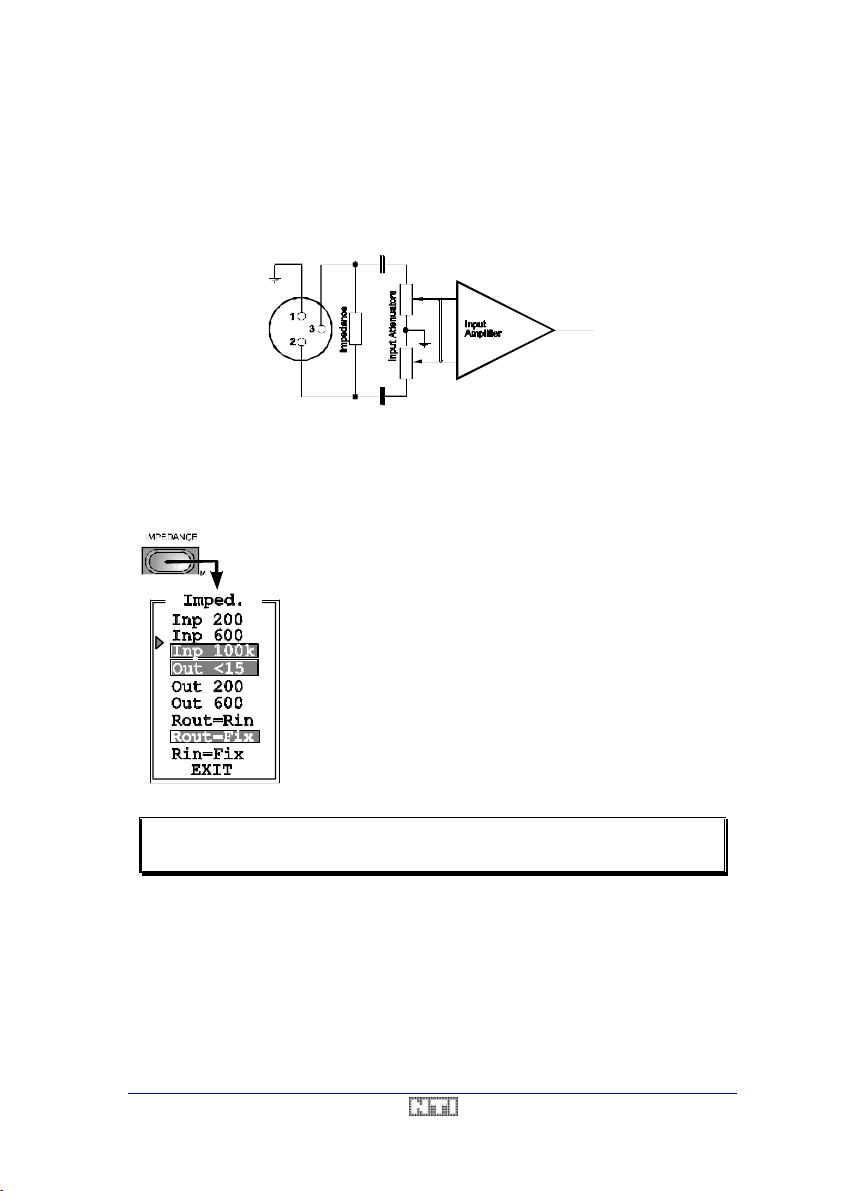

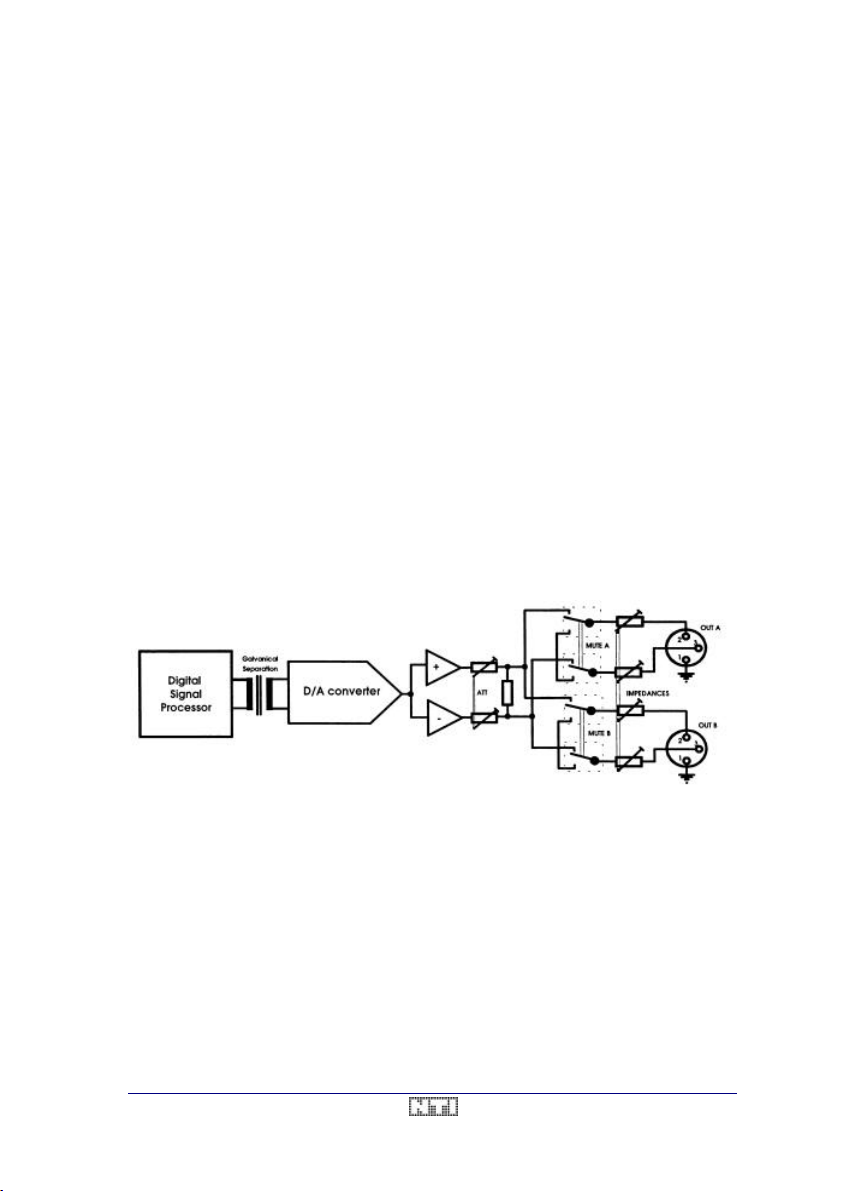

Input Block Diagram

Fig. 4 Block Diagram Analyzer

Input Wiring & Impedances

Both input channels are fully balanced and terminated with defined impedances right behind

the input connectors Three settings are available.

• The highest possible impedance terminates the

inputs with 100kΩ, corresponding a voltage

matching by means of a minimum load to the

output of the device under test.

• The second value, 600Ω, is intended for all instruments with this output impedance.

• The low input impedance can be set to 150Ω or

200Ω.

Choose one of these three settings by pressing the <IMPEDANCE> button. Each keypress

will toggle to the next impedance. The actually selected impedance is displayed on the left

hand side on top of the METER panel.

NOTE As soon as a level of more than 20V is applied to one of the inputs, the

LOW and MEDIUM impedance selections will be disabled automatically

to protect the inputs from being destroyed. An alert message will inform

you accordingly in this case.

If the LOW impedance is activated, NEVER apply an input voltage > 60V, since

higher voltages can permanently destroy the electronics!

22 / 104 V3.1

Page 23

A2 Audio Test & Measurement System User Manual

impedance, or to let the operator fix one impedance while having

the other one switchable. To select your preference, move the

ur selection by

pushing the <SCALE> wheel once. Always leave the menu

capacitor type microphone. Please notice, that the Phantom

d input impedance

The figure below shows the simplified input wiring and the connector pin assignment of one

channel. The circuit is a true instrument-grade differential input. Both input pins (2 and 3) are

loaded with ~100kOhm to ground. Additionally, the input impedances are applied between

the two pins. The inputs are fed to the microprocessor-controlled input attenuator/amplifier,

that adjusts the level of the input signal in order to achieve a high dynamic range at very a

very low distortion.

Input / Output Impedance Selection

In addition to the input impedance selection, a menu is available to choose all available configurations of the input and output impedances. To enter this menu, double -click on the

<IMPEDANCE> key.

The Imped. menu allows either to couple the input to the output

arrow with the <SCALE> wheel and confirm yo

through the EXIT entry.

Optionally, the input connectors of the A2/A2-D can be equipped

with a +15VDC or +48VDC Phantom power to directly connect a

power option replaces the LOW input impedance. Please refer to

chapter Phantom Power (AO8) for more details.

Depending on the configuration, the displaye

on the second line on the METER display, reads Inp 200, Inp 150

or Phantom .

NOTE If the Phantom power option is installed, the 200 Ω (150Ω) input imped-

ance is not available.

V3.1 23 / 104

Page 24

User Manual A2 Audio Test & Measurement System

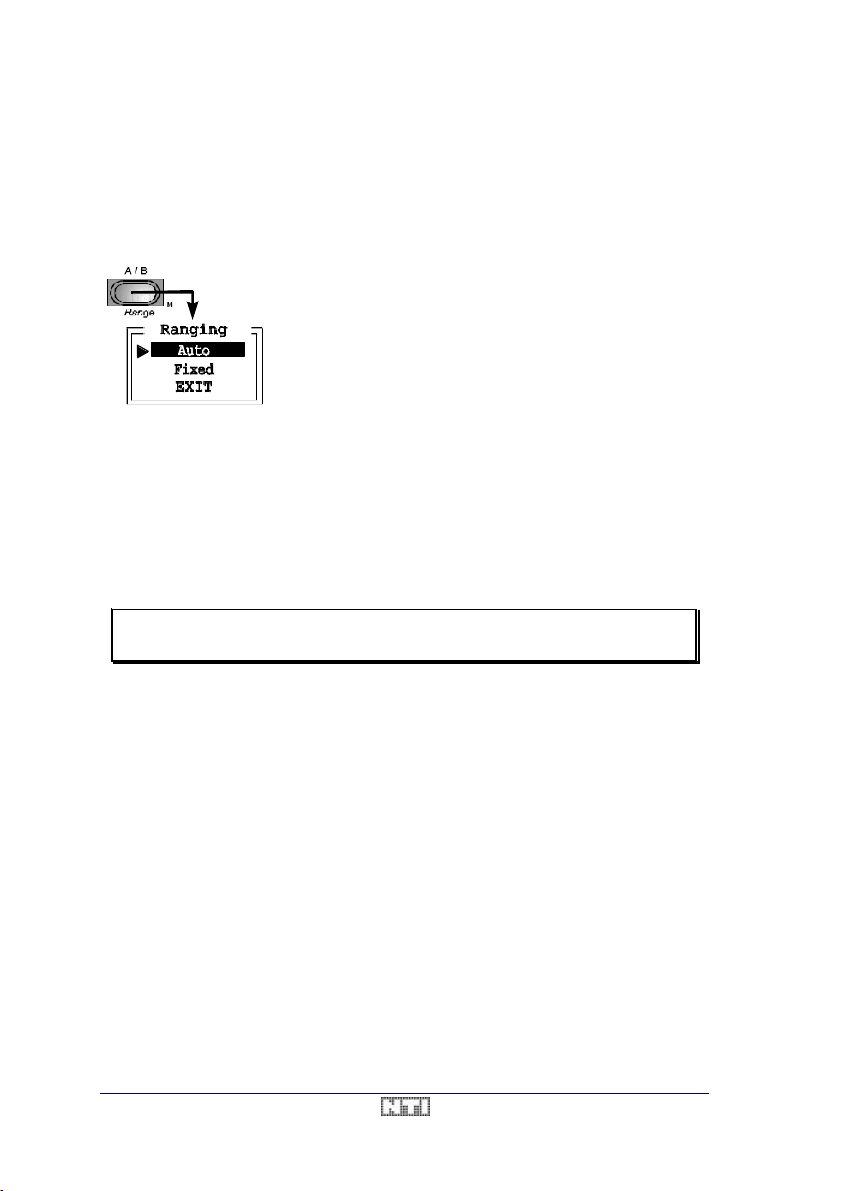

Auto / Fixed Range

The menu behind the <A / B> key allows you to choose between the Auto and Fixed range

setting. In the Auto range mode, i.e. the normal mode, the operator never has to wo rry about

the settings of the input amplifiers.

However, for some applications like testing short bursts, it might be helpful to lock the amplifiers in a certain state.

To lock the input attenuators/amplifiers to a fixed range, proceed as follows.

• Apply the input signal, to which you want to adjust the ranging.

• Call the Ranging menu by double-clicking to the <A / B> button.

• Select the entry Fixed by positioning the arrow through the <SCALE> wheel. Push the

wheel once to activate the setting (the menu closes automatically). The input stages are

now fixed, and all measurements will be performed in this mode.

• To switch back to automatic ranging (normal mode), enter the menu again and select

Auto.

NOTE The input attenuators/amplifiers of the analyzer remain fixed in their

range as long as the Fixed range mode is active.

The Fixed range selection locks the input attenuators/amplifiers

in their actual state as soon as it is chosen by a push on the

<SCALE> softwheel.

If the input signal level is under or over the actual Fixed range,

then the messages TOO LOW or TOO HIGH will appear on the

LCD instead of a measurement result.

24 / 104 V3.1

Page 25

A2 Audio Test & Measurement System User Manual

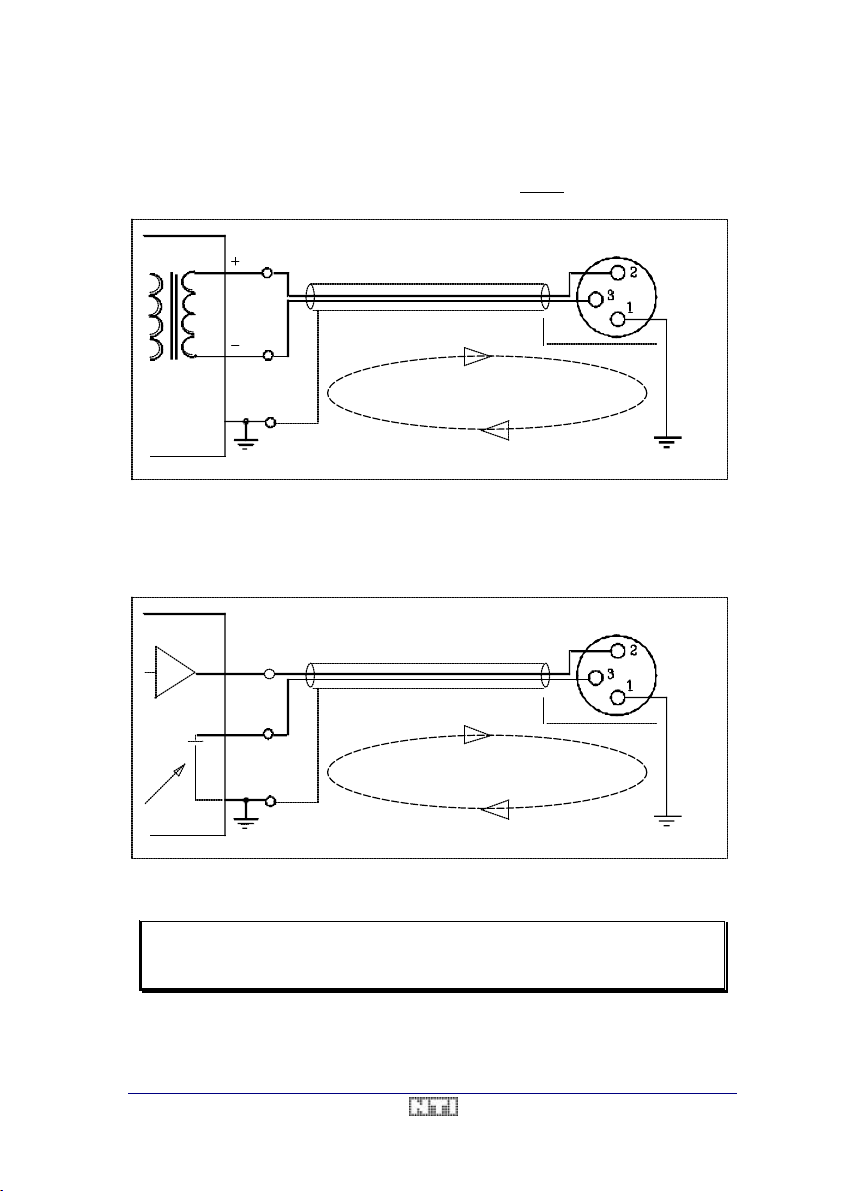

Connection of a Balanced Output to the A2/A2-D

The device under test (DUT) is connected between pin 2 (IN +) and pin 3 (IN -) of the XLR

input connector. The shield may be connected to pin 1, but do not ground the shield on both

ends of the connection, in order to avoid ground loops.

D.U.T.

Balanced

output

Fig. 5 Balanced Connection to the A2/A2-D

ATTENTION ! !

Shielded cable

Avoid ground loop

Input A2

Ground shield

only one side

Connection of an Unbalanced Output to the A2/A2-D

The device under test (DUT) is connected between pin 2 (Signal +) and pin 3 (GND) of the

XLR input connector.

D.U.T.

+

-

ATTENTION ! !

Shielded cable

Input A2

Ground shield

only one side

Avoid ground loop

Be sure not to have

internal connection!

Fig. 6 Unbalanced Connection to the A2/A2-D

NOTE Never c onnect pin 1 and pin 3 together as long as you are not absolutely

sure, that the GND output of the DUT is galvanically isolated from earth.

If in doubt, leave pin 1 of the A2/A2-D unconnected to avoid earth loops.

V3.1 25 / 104

Page 26

User Manual A2 Audio Test & Measurement System

Monitor Outputs

There are three BNC connectors and one headphone jack in the MONITOR section on the

rear panel, providing monitor signals for further processing. Output impedance through the

headphone connector is ~68Ω, while the BNC connectors have an impedance of 600Ω.

MONITOR

MAIN

ALT

CHANNEL

READING

HEADPHONE

CHANNEL

The two connectors MAIN CHANNEL and ALT CHANNEL offer

the signals of each input channel right behind the input amplifiers. The level of these signals are always around 1V (0dBV).

The third BNC output offers the READING signal, which is the analogue signal of the MAIN

channel after all the filtering and weighting, but before its rectification (see Input Block

Diagram).

Please notice, that the signal provided at the READING output is not necessarily the same

as at the two other connectors. Depending on the actual measurement function, the character of the READING signal will be totally different from the two other outputs (e.g. with meas-

urement function THD + N or IMD). More detailed information about this topic are given in the

respective chapters describing the measurement functions.

NOTE The MONITOR outputs are not calibrated and shall not be used for

measurements.

Monitor Loudspeaker

The READING signal is also fed to the internal loudspeaker. The volume can be changed

through the potentiometer on the front panel, marked with the loudspeaker sign.

Overview

• The input impedances may be selected through the <IMPEDANCE> key.

• The unit may be operated in the balanced or unbalanced mode, by setting the <FLOAT

GND> switch on the rear panel accordingly.

• Double-clicking to the <A / B> key opens a menu to select either Auto or Fixed ranging.

• The monitor speaker reflects input signal after the input stage and filtering. Its volume can

be controlled through the potentiometer on the front panel.

• The READING output monitors the input signal after the input and filter stage.

• The MAIN CHANNEL and ALT CHANNEL connectors provide the normalized, but

unweighted input signals.

26 / 104 V3.1

Page 27

A2 Audio Test & Measurement System User Manual

Output Section

The A2/A2-D is equipped with a versatile digital generator, providing optimum performance

with maximum flexibility to supply the device under test with purest signals.

The most important features of the generator are

• Output level -100dBV to +27.6dBV (10µV-24.5V

• Frequency range 10Hz-100kHz

• Selectable output impedances <15Ω to 600Ω

• Seven different signal waveforms

Very pure sine signal with typical THD+N < -91dB (<0.001%)

Warbled sine signal

IMD signal according to SMPTE and DIN

Squarewave (duty cycle 50/50 or 40/60)

W&F signal according to IEC and NAB

White noise

Pink noise

• Fast parameter setup through function keys and softwheels

• Individual mute function for each channel

• Sweep capability over the entire frequency & level range

Output Circuit

The diagram below shows the simplified diagram of the A2 output stage.

RMS

)

Fig. 7 Generator Block Diagram

All output signals are generated by the internal Digital Signal Processor of the A2/A2-D. In

order to isolate the generator from the analyzer circuitry, optocouplers were inserted between

the DSP output and the D/A converter. The analog signal is filtered and fed into the balanced

output amplifier. Behind this stage, an attenuator selects the level range of the output signal.

The signal is then split to the two output channels and fed through the mute relays. The output impedances are wired behind these mute relays.

V3.1 27 / 104

Page 28

User Manual A2 Audio Test & Measurement System

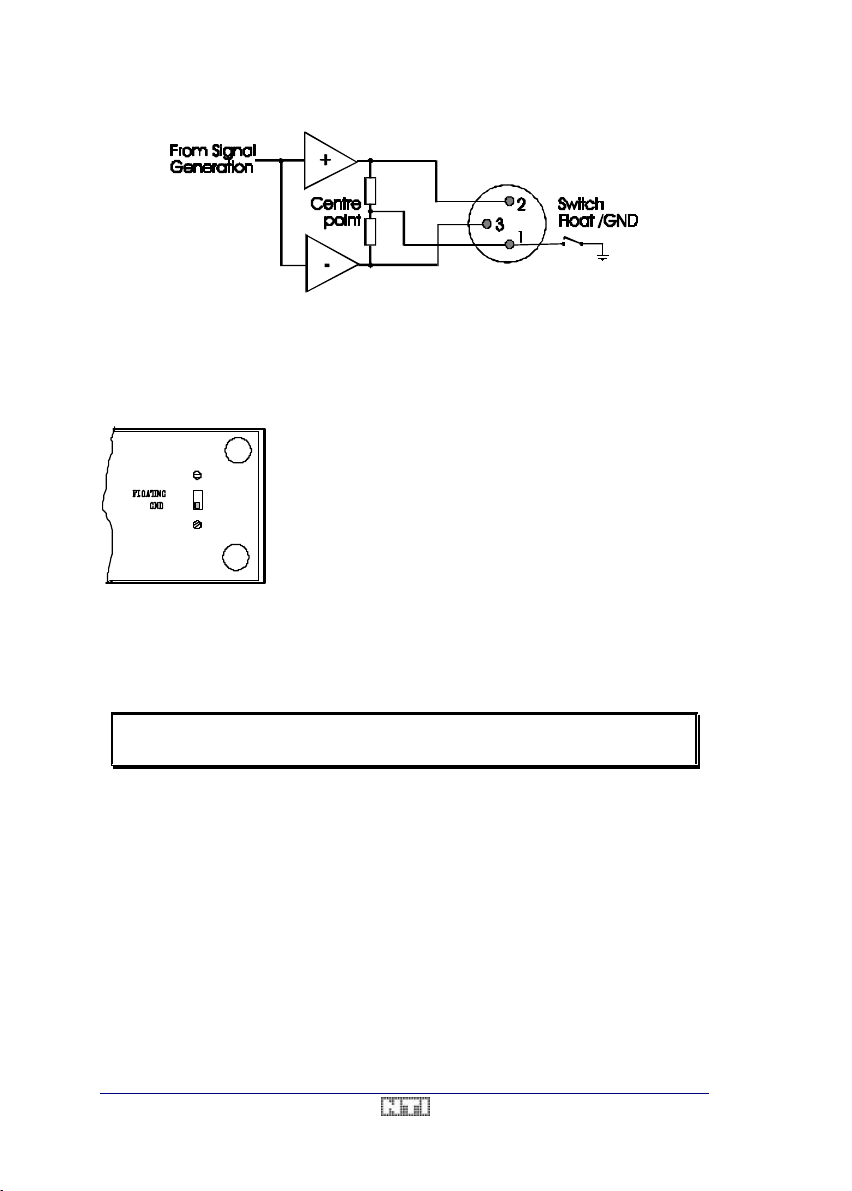

Fig. 8 Output Wiring

Pin 1 of each XLR output connector represents the center potential between pin 2 (+signal)

and pin 3 (-signal). It can either be kept floating or be connected to the chassis ground . In

general, it is recommended to operate the A2/A2-D in the FLOATING mode in order to avoid

ground loops.

The <FLOATING / GND> switch is located on the rear panel of

the A2/A2-D.

• FLOATING disconnects pin 1 from chassis ground, i.e. the

reference potential of the output amplifiers is floating.

• GND links the reference potential of the output amplifiers

to chassis ground.

Balanced Operation

Normally, the A2/A2-D is operated in the balanced (symmetric) mode. In this case, the device

under test (DUT) is connected to the two hot pins 2 (+signal) and 3 (-signal) of the generator

output stage.

NOTE If working with a balanced load, it is recommended to operate the unit in

the FLOATING mode.

Unbalanced Operation

When driving an unbalanced device, it is recommended to connect pin 2 (+signal) of the output stage to the hot input connector of the DUT, and to link pin 3 (-signal) of the output stage

with the ground of the DUT. In this case, operate the A2/A2-D in the FLOATING mode. By

this way only, the loss of half of the output level can be avoided.

On the other hand, unbalanced loads may also be connected between pin 2 (or pin 3) and

pin 1 of the A2/A2-D output stage (half side connection). In this mode, it is recommended to

set the switch on the rear panel to GND in order to get an invariant reference potential.

Optional Transformer Output Stage

Some applications require a complete galvanic separation between the generator output

connectors and the device under test. For this purpose, a transformer option is available (article code AO7), that adds a high quality Audio transformer behind the power amplifier of the

A2/A2-D.

28 / 104 V3.1

Page 29

A2 Audio Test & Measurement System User Manual

The A2/A2-D generator specifications as well as the output impedance circuitry are the same

with and without the transformer option. Please refer to chapter 8. Instrument Setup for further

details.

Output Settings

The METER display mode provides the best overview on the generator settings and measurement results. Therefore, it is recommended to enter this mode when reading through this

chapter.

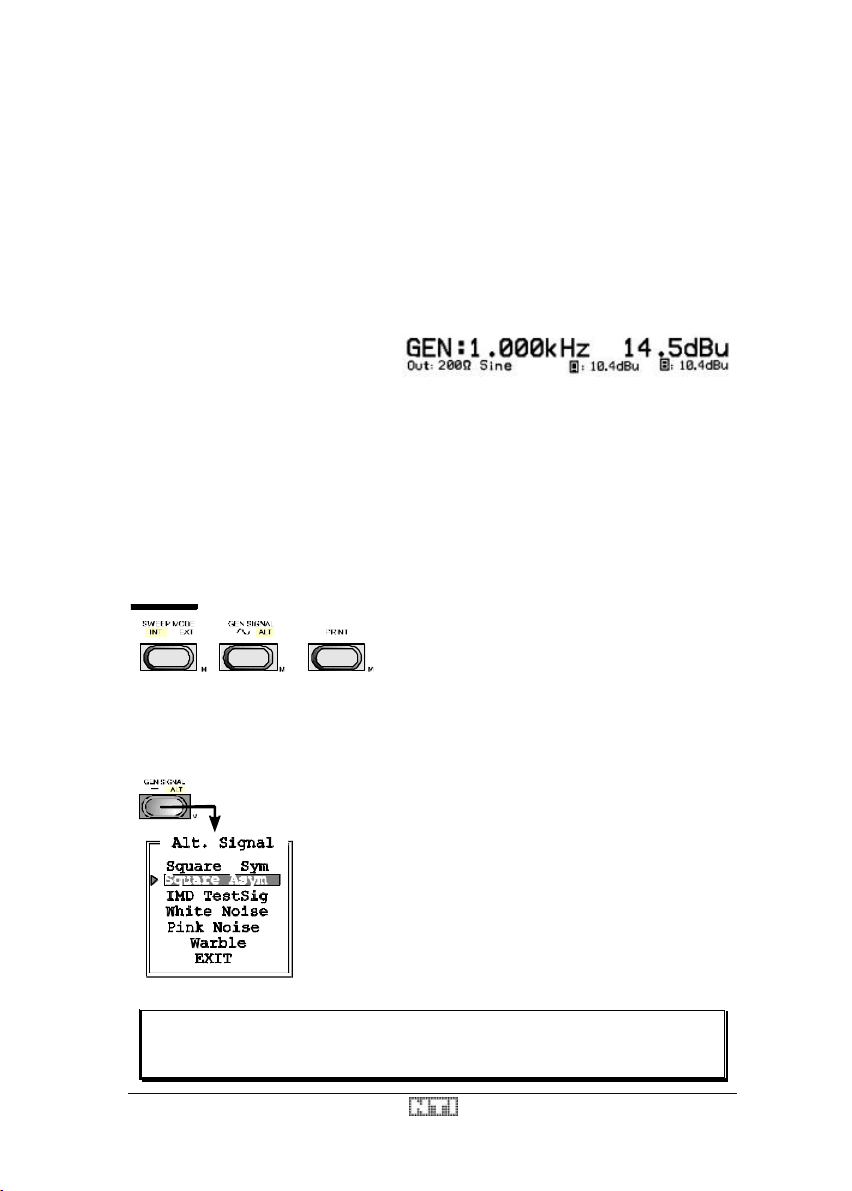

Output Parameters

The generator frequency, output level,

waveform and output impedance are

continuously displayed on the upper

two lines of the LC display.

The top line shows in large characters the set generator frequency and level. In the second

line, the selected output impedance and waveform are indicated, as well the actual output

voltage (readback value) or the input impedance of the device under test (please refer to

chapter Readback for more detailed information).

Signal Waveform

The <GEN SIGNAL> key allows to select the signal waveform to be generated. It will have

either the ~ (sine) or the ALT symbol illuminated from behind by a green LED. To toggle the

setting, simply push the button once.

• In the ~ mode, the generator output will be a

pure sine signal.

• In the ALT mode, the actually selected alter-

nate signal is active.

The A2/A2-D digital generator offers a wide range of alternate signals. To make one of them

the active signal, double-click on the <GEN SIGNAL> key. This opens the Alt Signal menu,

showing the list of available alternate signals.

The active signal is displayed inverted (white characters on a

black background). To change the selection, move the arrow

on the left-hand side through the <SCALE> softwheel to the

alternate signal you wish to select and press the <SCALE>

wheel once.

Consequently, the actual selection of the alternate signal will

change accordingly, i.e. the new signal will become active, and

the menu will close automatically.

Alternatively, selection of the EXIT entry or any keypress to the

A2/A2-D keyboard will leave the menu without a change of the

actual setting.

NOTE In some measurement functions like IMD and W&F, a predefined wave-

form - depending on the selected standard - is activated as alternate signal.

V3.1 29 / 104

Page 30

User Manual A2 Audio Test & Measurement System

Therefore, activation of the "Alt. Signal" menu will show this setting. Al-

though it is possible in this state to alter the signal in the menu, it will be

re-set automatically to the predefined waveform as soon as the menu is

closed.

Square Signal (Sym. / Asym.)

The Square Sym. and Square Asym. are squarewave signals with either a duty cycle of

50/50 (sym) or 40/60 (asym). Regardless of the duty cycle, the squarewave signal has the

actually selected frequency and level, calibrated in true V

A typical application for the 40/60 signal may be for quickly checking the polarity of lines.

RMS

.

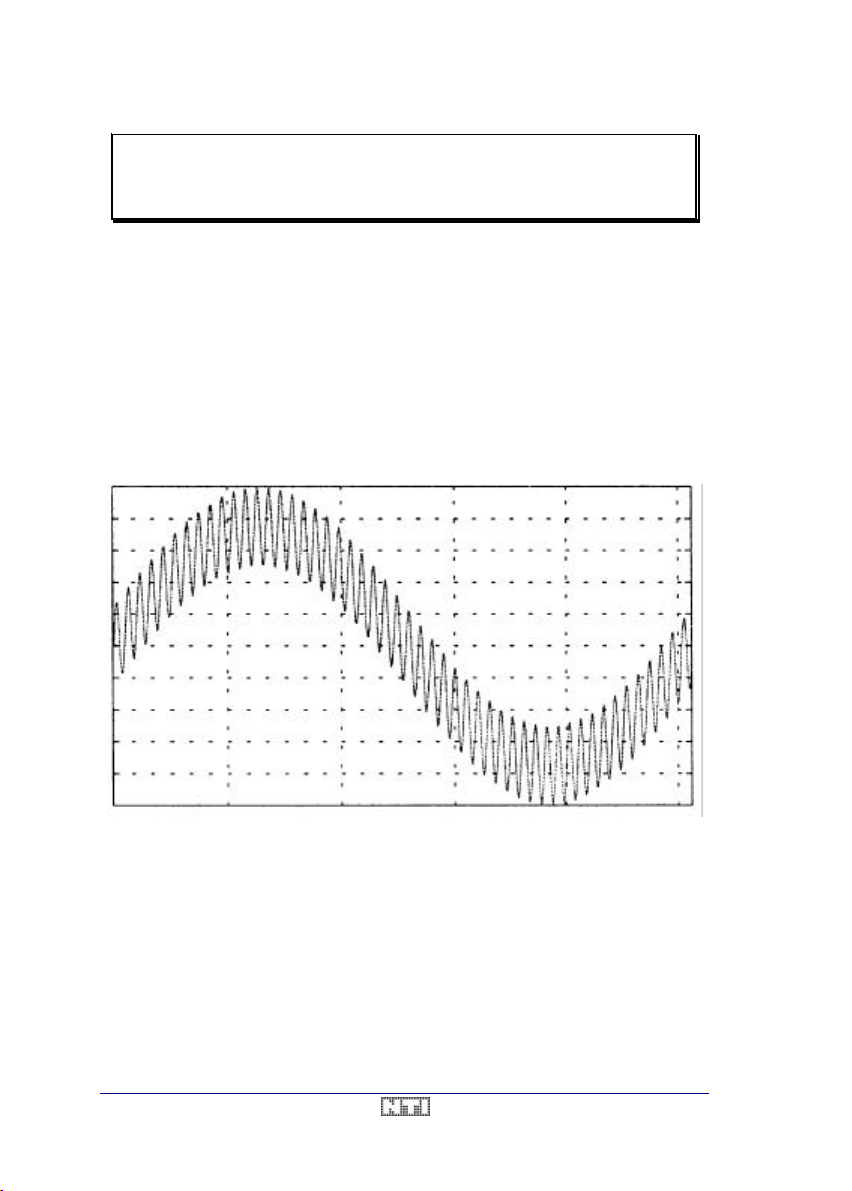

IMD TestSig

The IMD test signal consists of two signals components,

• a sinewave with a fixed frequency of 60Hz or 250Hz, and

• a second sinewave with a frequency of at least 4kHz, that may be set through the

<FREQUENCY> softwheel.

Fig. 9 IMD Testsignal

The level ratio between the low- and the high-frequency component is either 1:1, 4:1 or 10:1

(refer to chapter 5. Measurement Functions). Consequently, there are six different IMD test

signals available (according to the SMPTE and DIN standards). To define one of them as

default signal, the IMD Default menu must be opened by a double-click on the <IMD> key.

In normal operation, the IMD TestSig will be activated automatically as soon as the IMD

measurement function has been entered. Alternatively, it may also be activated manually

through the Alt. Signal menu.

30 / 104 V3.1

Page 31

A2 Audio Test & Measurement System User Manual

limits of +30dBu (27.7dBV / 24.49V)

Noise

The generator of the A2/A2-D offers White and Pink Noise , both with a bandwidth being limited to 20kHz, in order to maximize the energy falling into the Audio band.

• The characteristic of White Noise is a constant energy density for all frequency bands

with identical width (e.g. width = 100Hz). Consequently, the noise spectrum will show a

constant amplitude (energy) if analyzed vs. the linear frequency axis, or a linear rise of

10dB/decade if plotted vs. the logarithmic frequency axis.

• On the other hand, the amplitude of Pink Noise shows a linear decay of 10dB/decade if

analyzed vs. the linear frequency axis, or a constant amplitude if plotted vs. the logarithmic frequency axis.

NOTE Pink Noise has a very high Crest factor , i.e. a high Vp / V

Therefore, it is typical for Pink Noise that its amplitude, measured QuasiPeak or RMS, is never stable.

Warbled Sine

The Warble signal is a sinusoidal signal with oscillating frequency. The active generator fre-

quency defines the center frequency, while the modulating signal has a triangular shape with

4Hz. The Warble signal is best described in the frequency range, showing a fixed amplitude

that oscillates with about 4Hz and a 3rd-octave bandwidth around the center frequency, set

with the <FREQUENCY> softwheel.

level ratio.

RMS

Frequency

The generator ou tput frequency is set through the <FREQUENCY> softwheel. This wheel

has no end stops. Turning it counter-clockwise reduces the frequency or clockwise to increase the frequency. The limits of 10Hz and 100kHz cannot be exceeded.

NOTE In some measurement functions the frequency range is reduced to a

smaller bandwidth. Refer to the corresponding measurement function to

see the exact limits.

• A slow (i.e. stepwise) turn of the softwheel change the output frequency by 1/6 -octave

steps in the coarse mode, or 0.5% steps in the fine mode

• A fast turn in the coarse mode changes generator frequency to 20Hz, 100Hz, 1kHz,

10kHz, 40kHz, 100kHz , while in the fine mode, each fast turn causes the generator to

jump in 3rd- octave steps.

The frequency is not controlled in a continuous fashion - like with an

analog generator controlled by a potentiometer - but in discrete

steps. Pushing the wheel exchanges the step size between coarse

(« ») and fine (< >). The selected step size is indicated by an active

LED behind the respective sign.

Level

The generator level is controlled through the <LEVEL> softwheel.

V3.1 31 / 104

Page 32

User Manual A2 Audio Test & Measurement System

limits of +30dBu (27.7dBV / 24.49V)

Like the output frequency, also the generator level is controlled in discrete steps of 2dB (coarse) or 0.05dB (fine).

Please notice, that the absolute

and -97.7dBu (-100dBV / 10µV) cannot be exceeded.

• A fast turn of the <LEVEL> wheel in the coarse mode causes the generator to jump by

20dB to even values ([dBu] or [dBV] selected), or to the next decade ([V] selected).

• A fast turn in the fine mode forces the generator to jump jump by 2dB to even values, or

with an increment of 1V.

Readback

In case that the input impedance of the device under test is relatively low, a major output

voltage drop on the A2/A2 -D may occur. Actually, th e output voltage UO may be calculated

according to following formula.

U U

=+*

0

G

R

R R

i s

i

→

U R

*

s

0

R

=

i

U U

−

G

0

Obviously, it may happen that the generator voltage UG (set by the <LEVEL> wheel) differs

from the actual output voltage UO at XLR connectors.

In order to detect such cases, the A2/A2-D is equipped with the Readback function, that

measures the true voltage UO between pin 2 and pin 3 of both output channels, independently from the active analyzer function.

The readback measurement reuslts are displayed on right hand side of the status line in the

METER display mode. Alternatively, it is possible to show the load impedance Ri of the device under test with an accuracy of 5% + 1Ω.

To select whether the readback voltage or the load imped-

M

ance of the DUT shall be displayed, open the Gen. Status

Line menu by double-clicking on the <METER> button.

Next, make your selection by turning the <SCALE> softwheel to the respoective position and pushing the wheel

once.

NOTE The reading of the load impedance is most accurate if the selected

source impedance is closest to the displayed load impedance.

32 / 104 V3.1

Page 33

A2 Audio Test & Measurement System User Manual

DUT, that is not stimulated with any signal, by

Fig. 10 METER Mode

Consequently, the displayed values of the second line in the METER panel can be summarized as follows.

1. The selected output impedance

2. The actual waveform

3. The true output level / input impedance of the DUT of both channels.

Output Muting

On the right hand side of the output connectors

are the <MUTE> buttons, that allow to switch Off

the generator signal.

If activated, the mute function internally discon nects the generator from the output connector

and inserts a short circuit behind the impedances (see also Fig. 7). Muted outputs result in a

very quiet output, being properly terminated with

the selected impedance.

This feature simplifies output measurements of a

making the physical disconnection of the gen erator obsolete.

Overview

• The generator outputs may be operated either balanced or unbalanced.

• The selectable output signal parameters are the waveform, frequency and level.

• To set the output impedance, use the <IMPEDANCE> menu / key.

• In the METER mode, the output voltage or impedance may be displayed.

• The generator outputs may be mutes by pressing the respective <MUTE> keys.

V3.1 33 / 104

Page 34

User Manual A2 Audio Test & Measurement System

Fig. 10 METER Mode

Display Modes

Depending on the type of information you need, the A2/A2 -D offers three different display

modes.

• The METER panel for single measurements

• the GRAPH mode for sweep recordings and

• the SCOPE mode to watch the time signal.

NOTE Regardless of the active measurement (including sweeps), it is always

possible to switch to any other display mode without compromising the

accuracy of the measurement.

METER Display Mode

This display mode is entered by pressing the <METER> key once. It provides all the

necessary information and results of the selected measurement task and all related

information which may further help to qualify your measurements. The top line(s) always

contains the generator parameters and the bottom line is reserved for the input parameters.

Fig. 11 GRAPH Mode Fig. 12 SCOPE Mode

Fig. 13 METER Panel

Please notice, that the METER display will automatically change its layout for all 1-channel

measurement, by showing the single measurement result in large letters instead of the two

lines of the 2 -channel Level result.

34 / 104 V3.1

Page 35

A2 Audio Test & Measurement System User Manual

Generator Settings

The selected generator output voltage (nominal value) and frequency are always displayed

on the top of the METER display.

The unit, in which the frequency is expressed, cannot be influenced by the operator, while

the unit of the generator output voltage is the same as selected for the Level measurement

results. Please refer to chapter Output Section / Output Parameters for more details about the

generator settings.

NOTE If the generator signal is set to White or Pink Noise, the frequency of the

generator is still displayed, although a noise signal obviously has no

frequency.

However, the assignment of a generator frequency is necessary to set

the tunable notch-filter of the A2/A2-D to the desired frequency.

Generator Readback

In case of a relatively low input impedance of the device under test (DUT), the true output

voltage of the A2/A2 -D generator may be lower than the selected and displayed nominal

level.

Therefore, an additional readback reading of the true output voltage, or, alternatively, of the

input impedance of the DUT is permanently displayed. Please refer to chapter Output Section

/ Readback for further details.

Open the Gen. Status Line menu by double-clicking to the

<METER> key. Therein, one may toggle the display between the readback voltage and the load impedance of the

DUT by using the <SCALE> softwheel.

Please note that in measurement function IMD the readback feature is disabled.

Measurement Results

The results of the selected measurement function are displayed in both numerical and analog form through large digits and a bar-graph below. In the 2-channel Level measurement

mode, two lines of both display forms are placed on top of each other.

All measurements results - except of noise - are true RMS values. Noise is measured quasipeak according to the CCIR-468-3 standard.

NOTE The input and the readback voltage are always RMS values, independent

of the selected measurement function.

Units

The unit, in which the result shall be expressed, can be selected by pressing the <UNIT>

button on the right hand side of the front panel.

V3.1 35 / 104

Page 36

User Manual A2 Audio Test & Measurement System

Each keypress steps to the next available unit.

If there are no alternative units (e.g.

with measurement function W&F), presing the unit button has no effect.

NOTE The <UNIT> button influences the unit of the measurement result only,

i.e. not the generator level unit, except of measurement functions LEVEL

and 2-Channel, where the units are coupled together.

The Bar-graph

The bar-graph displays the measurement result in an analog way. This makes the bar-graph

very helpful to identify trends and tendencies of changin g / unstable signals, or when doing

adjustments to minimize / maximize a signal.

Normally, in the AUTO mode, the bar-graph is scaling automatically, but its scale can be

zoomed and scrolled to any point in the measuring scale manually.

Zooming the Bar-graph Scale

The <SCALE> softwheel provides the possibility to adjust the bar-graph scale exactly to your

needs. To enter the ZOOM mode, push the <SCALE> wheel once. Each further push to the

<SCALE> wheel will toggle between ZOOM and SCROLL mode. To return to the AUTO

mode, double-click on the wheel.

• In the ZOOM mode, every CW incremental step of the <SCALE> wheel increases the

sensitivity (units/division) of the bar-graph.

• A CCW increment decreases the sensitivity, i.e. it enlarges the displayed range.

• A fast turn of the <SCALE> wheel in the CW / CCW direction sets the scale of the bar-

graph to the highest / lowest sensitivity respectively.

If the bar-graph is zoomed, the center value is kept constant if possible (symmetric zooming).

However, in case that the value 0 (zero) would fall into the scale, it is shifted to the left border

value of the new scale.

Scrolling the Bar-graph

The SCROLL mode may be entered by pushing the <SCALE> softwheel once from the

ZOOM mode, or twice (slowly, no double-click!) from the AUTO mode. It allows to scroll the

visible range of the bar-graph scale through the availbale range.

• Every incremental step of the <SCALE> wheel in CW direction moves the visible part of

the bar-graph to the right by one division.

• On the other hand, a CCW increment moves the visible part of the bargraph to the left.

To quickly locate the range, where the signal is located in the bar-graph, make a fast turn of

the <SCALE> wheel in CW or CCW direction. This acts like a beam finder. Turn CCW if the

signal is 'larger' than the displayed scale, or CW if no signal is visible at all.

To set the scaling function back to AUTO mode, push the <SCALE> wheel twice quickly. The

actually selected mode (AUTO, ZOOM or SCROLL) is always indicated by a LED behind the

respective label.

36 / 104 V3.1

Page 37

A2 Audio Test & Measurement System User Manual

Input Display

On the bottom end of the METER display, additional information about the input signals are

available. The displayed values show the input voltage and frequency, measured right behind the input connectors. If the 2 -channel Level function is used, frequency and level of both

input channels are shown, while the parameters of the active channel, together with the input

impedance of the analyzer, are shown with all single channel functions.

This Input display is very helpful for all non-Level measurement functions (e.g. THD+N, IMD,

Noise etc.), that do not display the input signal level. For instance, in the IMD measurement

mode, it is important to know the frequency and level of the input signal to allow the proper

interpretation of the IMD results. Therefore, this information is shown on the Input display.

In case that the incoming signal is too small or too noisy to be measured, no frequency / level

values are displayed.

NOTE The input level results are always RMS values, regardless of the selected

measurement function. The measuring bandwidth is 500kHz, without any

weighting filter being involved.

Printouts

The METER Display display can be printed out to a printer by pressing the <PRINT> button.

The printout contains all relevant information to document the measurement result.