NTE NTE5671 Datasheet

NTE5671

TRIAC – 800VRM, 20A

TO220 (Isolated)

Description:

The NTE5671 TRIAC is designed for use in applications requiring high bidirectional transient and

blocking voltage capability. Typical applications include AC power control circuits such as lighting, industrial and domestic heating, motor control and switching systems..

Absolute Maximum Ratings:

Non–Repetitive Peak Off–State Voltage (Either Direction, t ≤ 10ms), V

Repetitive Peak Off–State Voltage (Either Direction, δ ≤ 0.01), V

Crest Working Off–State Voltage (Either Direction), V

DWM

RMS On–State Current (Conduction Angle 360°, TH = +67°C), I

Repetitive Peak On–State Current, I

Non–Repetitive Peak On–State Current, I

TRM

TSM

DRM

T(RMS)

DSM

(TJ = +120°C Prior to Surge, t = 20ms, Full Sine Wave) 140A. . . . . . . . . . . . . . . . . . . . . . . . . .

I2t for Fusing (t = 10ms), I2t 95A2s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rate of Rise of On–State Current After Triggering, dIT/dt

(IG = 200mA to IT = 20A, dIGdt = 0.2A/µs) 30A/µs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Average Power Dissipation (Averaged Over any 20ms Period), P

Peak Power Dissipation, P

GM

RMS Isolation Voltage (From All Three Terminals to External Heatsink[Peak]), V

Isolation Capacitance (From T2 to External Heatsink), C

Full Operating Temperature, T

Storage Temperature Range, T

J

stg

(ISO)

Typical Thermal Resistance, Junction–to–Heatsink (See Mounting Instructions), R

G(AV)

(ISO)

–40° to +125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

thJH

With Heatsink Compound 3.5K/W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Without Heatsink Compound 4.5K/W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermal Resistance, Junction–to–Ambient (Note 1), R

thJA

800V. . . . . . . . . . . . . . . .

800V. . . . . . . . . . . . . . . . . . . . .

400V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16A. . . . . . . . . . . . . . . . . . . .

140A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.5W. . . . . . . . . . . . . . . . . . .

5.0W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1000V. . . . . .

12pF. . . . . . . . . . . . . . . . . . . . . . . . . . . .

+120°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

55K/W. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Note 1. Mounted on a printed circuit board at any lead length. The quoted value of R

used only when no leads of other dissipating components run to the same tie–point.

should be

thJA

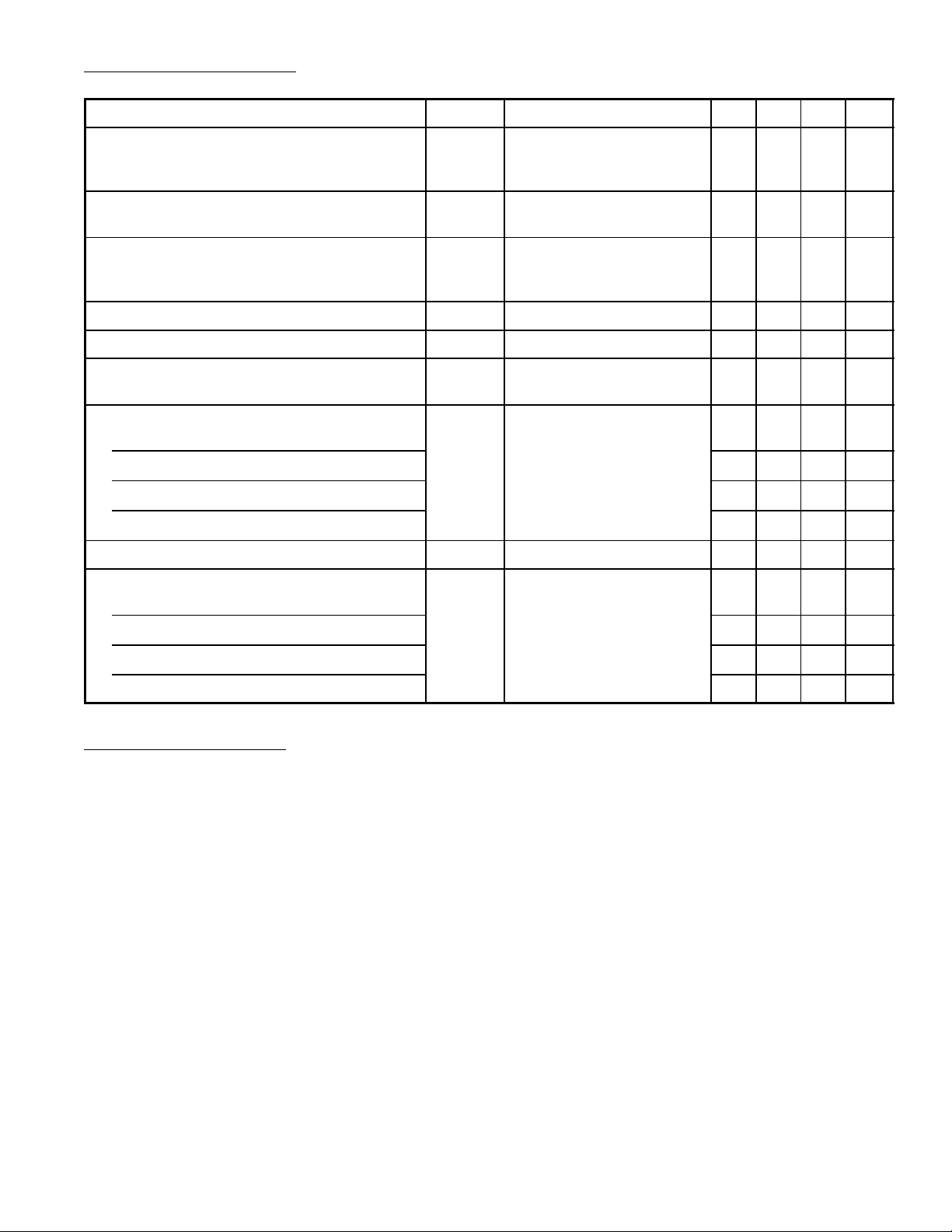

Electrical Characteristics: (TJ = +25°C, unless otherwise specified. Polarities, positive or negative,

are identified with respect to MT1.)

Parameter Symbol Test Conditions Min Typ Max Unit

On–State Voltage (Measured under pulse

V

IT = 20A – – 1.6 V

T

conditions to prevent excessive

dissipation)

Rate of Rise of Off–State Voltage

dVD/dt TJ = +120°C, Gate Open – – 100 V/µs

(That will not trigger any device)

Rate of Change of Commutating Voltage

(That will not trigger any device)

Off–State Current I

Gate Voltage (That will trigger all devices) V

dV

com

D

GT

/dt –dI

I

V

/dt = 7.2A/ms,

com

T(RMS)

= 16A, TH = 70°C,

= 400V, Gate Open

D

– 10 – V/µs

VD = 400V, TJ = +120°C – – 0.5 mA

1.5 – – V

Gate Voltage (That will not trigger any device)

(+), G (+); MT2 (–), G (–) V

MT

2

GD

VD = 400V, TJ = +120°C – – 250 mV

Gate Current (That will trigger all devices)

(+), G (+) I

MT

2

GT

G to MT

1

35 – – Ma

MT2 (+), G (–) 35 – – mA

MT2 (–), G (–) 35 – – mA

MT2 (–), G (+) 70 – – mA

Holding Current I

H

– – 30 mA

Latching Current

(+), G (+) I

MT

2

L

VD = 12V – – 40 Ma

MT2 (+), G (–) – – 60 mA

MT2 (–), G (–) – – 40 mA

MT2 (–), G (+) – – 60 mA

Mounting Instructions:

1. The TRIAC may be soldered directly into the circuit, but the maximum permissible temperature

of t he s oldering i ron o r b ath i s + 275°C; i t m ust n ot b e i n c ontact w ith t he j oint f or m ore t han 5 seconds.

Soldered joints must be at least .185” (4.7mm) from the seal.

2. The leads should n ot be b ent l ess than . 094” (2.4mm ) from t he s eal, a nd s hould b e s upported d uring

bending. The leads c an b e b ent, twisted or strai ghtened b y 90° maximum. The minimum b endi ng

radius is .039” (1mm).

3. Mounting by means of a spring clip (not provided by NTE) is the best mounting method because

if offers good thermal contact under the crystal area and slightly lower R

values than screw

thJH

mounting. However, if a screw is used, it should be an M3 cross–recess pan–head. Care should

be taken to avoid damage to the plastic body.

4. For good thermal contact, heatsink compound should be used between the seating plane and the

heatsink. values of R

given for mounting with heatsink compound refer to the use of a metallic–

thJH

oxide loaded compound. Ordinary silicone grease is not recommended.

5. Rivit mounting is not recommended.

6. The heatsink must have a flatness in the mounting area of .0007 (.02mm) maximum per .393

(10mm). Mounting holes must be deburred.

Loading...

Loading...