NTE NTE1834 Datasheet

NTE1834

Integrated Circuit

Dual Reversible Motor Driver

Description:

The NTE1834 is a monolithic IC in a 10–Lead SIP type package designed for use as a dual reversible

motor driver. This device contains two independent circuits designed for driving brush–type DC motors. The control logic inputs are compatible with CMOS devices. The motor torque can be controlled

by varying the motor voltage with the control input (Pin8). With few external components required

and dual circuit configuration, the NTE1834 offers great benefits in terms of reduced components and

reduced circuit board space.

Features:

D Dual Reversible M otor D rivers I mplemented o n a S ingle C hip ( Simultaneous D ual C ircuit O peration

is Not Possible)

D Minimum External Components Required

D Control Inputs Directly Compatible with CMOS Logic (Protection Resistors are Required if CMOS

Output Voltage Exceeds 5V)

D Internal Motor Driving Power Transistors

D Internal Surge Suppressors

D Internal Thermal Shut–Down Circuit

Applications:

D VCRs

D Tape Decks

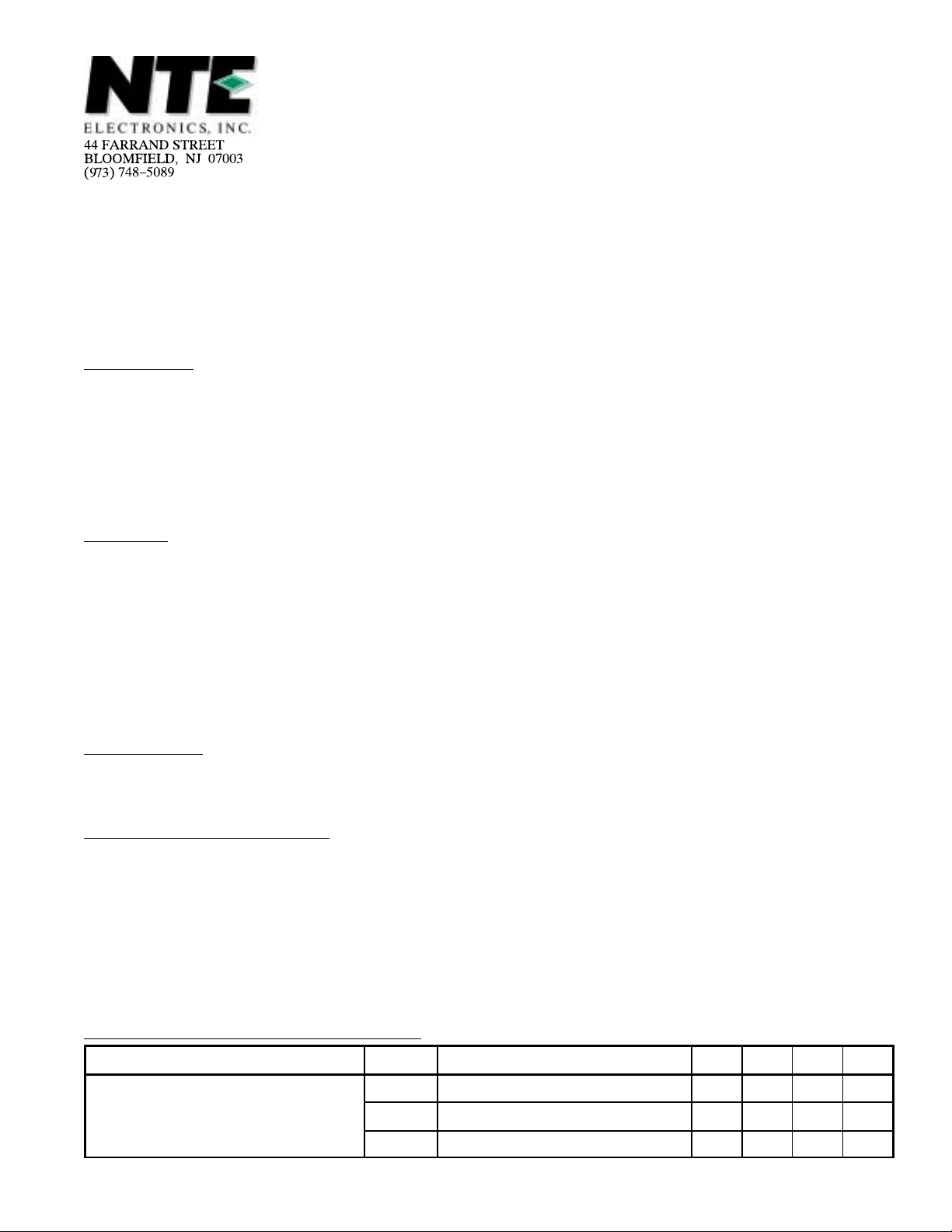

Absolute Maximum Ratings

Supply Voltage, V

Input Voltage Range, V

CC

i

Output Current (Note 1), I

Power Dissipation, P

D

Operating Temperature Range, T

Storage Temperature Range, T

: (TA = +25°C unless otherwise specified)

OUT

opr

stg

–0.3V to +5V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2200mW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–25° to +75°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–55° to +125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Note 1. Pulse Width = 200µs, Duty Cycle = 1%

Recommended Operating Conditions:

Parameter Symbol Test Conditions Min Typ Max Unit

Supply Voltage VCC1 8 – 18 V

(TA = +25°C unless otherwise specified)

VCC2 8 – 18 V

V

R

0 – 18 V

20V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Characteristics: (TA = +25°C, VCC = 12V unless otherwise specified)

Parameter Symbol Test Conditions Min Typ Max Unit

Supply Current I

Input Low Level Voltage

(Pin4, Pin5, and Pin6)

Input High Level Voltage

(Pin4, Pin5, and Pin6)

Output Low Level Voltage

(Pin4, Pin5, and Pin10)

Output High Level Voltage

(Pin4, Pin5, and Pin10)

Output Leakage Current I

Voltage Stability

(Pin2)

(Pin3) ∆V

(Pin10) ∆V

Drain Current

(Pin2)

(Pin3) I

(Pin10) I

Backlash Current I

Thermal Shut–Down Operate

Temperature

V

I

8 (10)

T

CC

V

V

V

OL

OH

OL

∆V

8 (2)

8 (3)

ON

RL = ∞, Pin4, Pin5, and Pin6 = “L” Level – 12 24 mA

IL

IH

Pin8 = Open, IO = 500mA – 0.8 1.5 V

Pin8 = Open, IO = 500mA 10 10.5 – V

RL = ∞, Pin4, Pin5, and Pin6 = “L” Level,

Current flowing to Pin9

VR = 6V with respect

2

to Pin8

3

10

VR = 6V, I

VR = 6V, I

VR = 6V, I

Sink current at Pin9 when Pin4, Pin5, and Pin6

B

are low and one output pin is at –1V

= 500mA, Pin2 = “H” Level –0.5 – 0.5 V

O(2)

= 500mA, Pin3 = “H” Level

O(3)

= 500mA, Pin10 = “H” Level

O(10)

I

= 500mA –0.5 – 0.5 V

O(2)

I

= 500mA

O(3)

I

= 500mA

O(10)

– – 1.0 V

4.0 – – V

– – 1 mA

–0.5 – 0.5 V

–0.5 – 0.5 V

–0.5 – 0.5 V

–0.5 – 0.5 V

– – 0.3 A

– 150 – °C

Thermal Shut–Down Release

Temperature

T

OFF

– 100 – °C

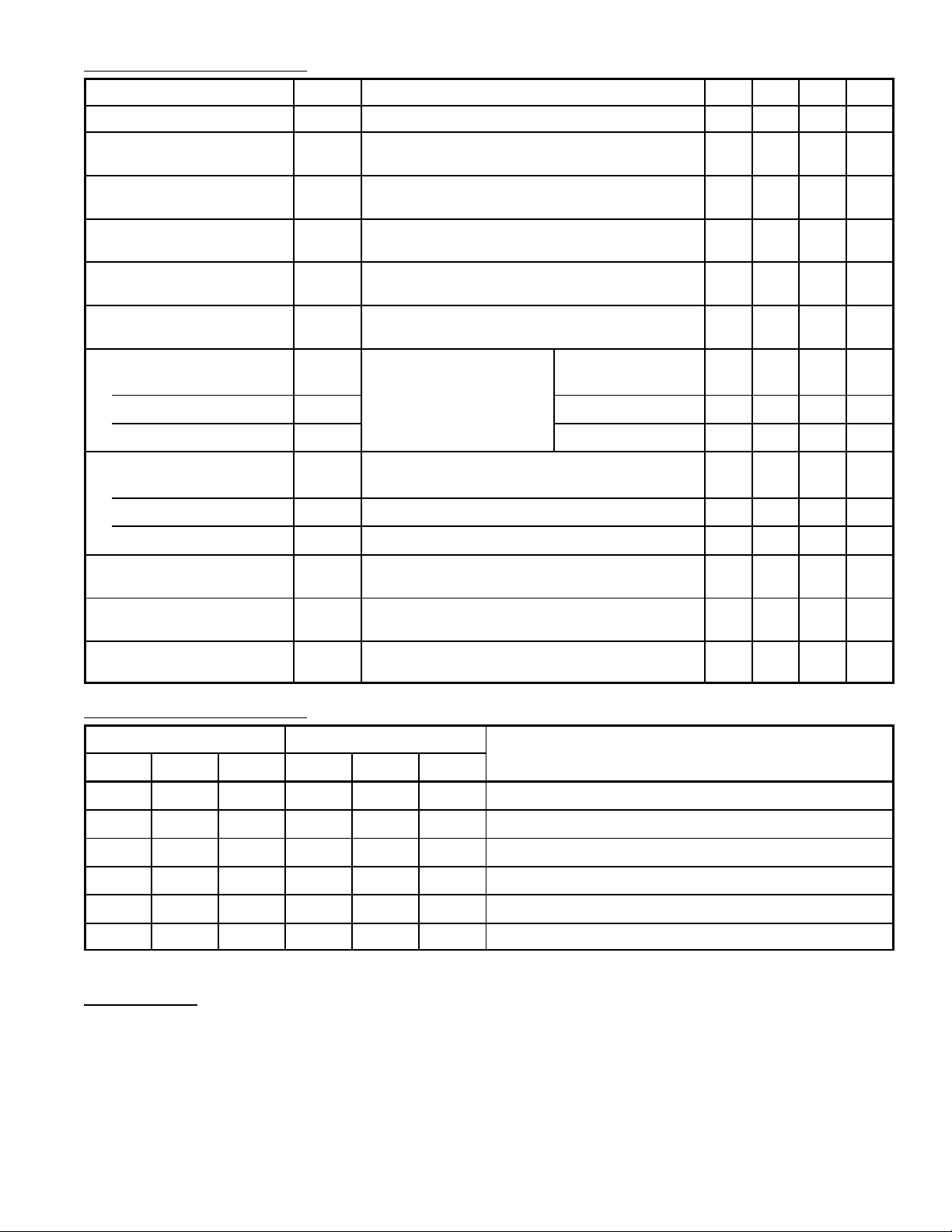

Input/Output Truth Table:

Input Output

Pin4 Pin5 Pin6 Pin10 Pin2 Pin3

L L X L L L Brake

H L L H L OPEN Current flows from Pin10 to Pin2

H L H L H OPEN Current flows from Pin2 to Pin10

L H L H OPEN L Current flows from Pin10 to Pin3

L H H L OPEN H Current flows from Pin3 to Pin10

H H X L L L Brake

Function

X = Don’t Care

Precautions:

1. While the control input pins of the NTE1834 can be directly connected to MOS logic outputs, it is

recommended that you insert a series protection resistor in the range 1kΩ to 10kΩ between the

devices.

2. To improve reliability, be sure to temporarily put the device in brake mode before reversing the

direction of rotation of the motor. A brake mode duration of more than 10µs is recommended.

3. The recommended power on sequence is one in which V

1 (Pin7) is the first turned on and the

CC

last turned off.

Loading...

Loading...