NTC STAVEBNÍ TECHNIKA spol. s r.o.

Maloskalická 120, 552 03 Česká Skalice

Czech Republic

Tel: +420 491 452 184 ORIGINAL OPERATION MANUAL (2006/42/EC)

Fax: +420 491 401 609

e-mail:

ntc@ntc.cz, sales@ntc.cz

www.ntc.cz (issued 10/2011)

OPERATION MANUAL

Vibratory plate compactors

V

D15P, 18P,

VD20P, 24P

Vibratory plate compactors Operation manu al

page 2

ES PROHLÁŠENÍ O SHODĚ (originál)

EC Declaration of Conformity (překlad/translation)

Prohlašujeme, že zařízení definované níže uvedenými údaji je ve shodě s požadavky níže uvedených NV a směrnic

We declare that the trough below mentioned specifications defined equipment complies with requirements of below cited Directives

Výrobce (manufacturer): NTC STAVEBNÍ TECHNIKA spol. s r.o.

Sídlo firmy (company domicile): V Aleji 654, Nové Město nad Metují 549 01

Sídlo provozovny : Maloskalická 120, Česká Skalice 552 03

(office premises)

IČ (identification number): 63221152

Osoba pověřená sestavením a NTC STAVEBNÍ TECHNIKA spol. s r.o.

uchováváním technické dokumentace:

(Person in charge of assembling

and storing technical documentation)

Název (model):

VIBRAČNÍ DESKA JEDNOSMĚRNÁ / VIBRATORY PLATE

Typ (type):

VD15P, 18P, 20P, 24P

Výrobní číslo (serial number)

Popis (description): Vibrační desky jsou určeny pro zhutňování všech druhů zemin včetně navazujících půdních úseků, pro zhutňování

příkopů a ploch, jakož i pro zhutňování asfaltových povrchů. Při použití s plastovou podložkou je možné vibrační

desku používat rovněž pro zahutnění zámkové dlažby. Pohon vibrační desky je zajištěn čtyřdobým jednoválcovým

motorem HONDA (čistý výkon: 3,6 kW).

The forward vibratory plates are designed for compaction of soils or asphalt layers, when used with an optional

plastic pad it can be used also for c ompaction of asfalt surfaces. The machine is driven with four-stroke sing le-

cylinder engine HONDA (net power 3,6 kW).

Všechna příslušná ustanovení, Strojní zařízení – směrnice 2006/42/ES; NV č.176/2008 Sb.

která výrobek splňuje Machinery Directive 2006/42/EC

(The product meets all relevent provisions) Emise hluku – směrnice 2000/14/ES; NV č.9/2002 Sb.

Noise Emission 2000/14/EC

Elektromagnetická kompatibilita – směrnice 2004/108/ES; NV č.616/2006 Sb.

Electromagnetic Compatibility Directive 2004/108/EC

Harmonizované technické normy a ČSN EN ISO 12100, ČSN EN ISO 14121-1, ČSN EN 500-1+A1, ČSN EN 500-4,

technické normy: ČSN EN 474-1+A1, ČSN EN 602204-1 ed.2, EN ISO 14982:2009

(The harmonized technical standards

and technical standards)

Osoby zúčastněné na posouzení Autorizovaná osoba č. 255 (authorized Body No. 255)

shody Notifikovaná osoba č. 1016 (the European Notified Body No. 1016)

(Persons involved in the conformity Státní zkušebna zemědělských, potravinářských a lesnických strojů, a.s., Třanovského 622/11, 16304 Praha 6-Řepy, ČR

assessment) The Government Testing Laboratory of Agricultural, Food Industry and Forestry Machines,Jjoint-stock company

Použitý p o stup na posouzení shody: Na základě směrnice 2000/14/ES příloha VI; NV č.9/2002 Sb., příloha č.5

(To the conformity assessment Pursuant to the Directive for Noise Emission 2000/14/EC Annex VI

applied procedure) Na základě směrnice 2006/42/ES příloha VIII; NV č.176/2008 Sb., příloha č.8

Pursuant to the Machinery Directive 2006/42/EC Annex VIII

Naměřená hladina akustického výkonu: LWA =

104, 103 dB

(Measured sound power level)

Garant o vaná hladina akustického výkonu: L

WA

=

105, 104 dB

(Guaranteed sound power level)

Poznámka:

Veškeré předpisy byly použity ve znění jejich změn a doplňků platných v době vydání tohoto prohlášení bez jejich citování.

Note: All regulations were applied in wording of later amendments and modifications valid at the time of this declaration issue without any citation of them.

Místo a datum vydání: Osoba zmocněná k podpisu za výrobce:

Place and date of issue: Signed by the person entitled do deal in the name of producer:

Česká Skalice, 01.12.2011

Jméno

(Name): Funkce (Grade) Podpis (signature)

Ing. Petr Ratsam jednatel společnosti (Company Executive)

Vibratory plate compactors Operation manu al

page 3

Congratulations! You have purchased a non-reversible vibratory plate

compactor. You receive high-quality and powerful compaction machine,

intended for professional use under the heaviest conditions.

Read carefully this operation manual before starting the machine and always

keep the instruction - this way you will secure safe operation, high working

output and long durability of the machine.

The manufacturer bears no responsibility for damages arising from not keeping

the operation manual.

The manufacturer of this machine is the company NTC STAVEBNÍ TECHNIKA spol. s r.o.

Address: Maloskalická 120

552 03 Česká Skalice

tel.: +420 491 452 184, fax: +420 491 401 609

E-mail: ntc@ntc.cz

CONTENTS:

1. SAFETY INSTRUCTIONS ........................................................................................................................... 5

1.1. GENERAL SAFETY INSTRUCTIONS FOR WORK WITH SMALL TOOLS AND DEVICE .............................................. 5

1.1.1. Qualification Requiremen ts ..................................................................................................................... 5

1.1.2. Contractor's Obligations ......................................................................................................................... 5

1.1.3. Operator's Obligations ............................................................................................................................ 5

1.1.4. Machine Operation .................................................................................................................................. 6

1.1.5. Inspections, Maintenance & Repairs ....................................................................................................... 6

1.1.6. Loading & Transportation ....................................................................................................................... 7

1.2. PROHIBITED OPERATIONS .................................................................................................................................. 7

1.3. HYGIENIC PRINCIPLES ....................................................................................................................................... 7

1.4. ENVIROMENTAL PRINCIPLES ............................................................................................................................. 8

1.5. DISPOSAL OF THE MACHINE AFTER THE END OF ITS SERVICE LIFE .................................................................... 8

1.6. SAFETY INSTRUCTIONS FOR WORK WITH COMPACTING MACHINES .................................................................. 8

1.7. HYGIENIC DATA................................................................................................................................................. 9

1.8. LIST OF SAFETY SYMBOLS USED ON THE MACHINE ............................................................................................ 9

1.9. DISPOSAL OF THE PACKING MATERIAL ............................................................................................................ 10

2. TECHNICKÝ POPIS ................................................................................................................................... 11

2.1. BASIC TECHNICAL DATA: ................................................................................................................................. 11

2.2. LUBRICANTS ................................................................................................................................................... 12

2.3. MACHINE IDEN TIFICATION ............................................................................................................................... 13

3. PRIOR TO STARTING ............................................................................................................................... 14

3.1. INSPECTION OF ENGINE OIL LEVEL ................................................................................................................... 14

3.2. VISUAL INSPECTION OF THE MACHINE ............................................................................................................. 15

3.3. INSPECTION OF FUEL LEVEL ............................................................................................................................. 15

3.4. INSPECTION O AIR FILTER ................................................................................................................................ 15

4. OPERATING THE MACHINE .................................................................................................................. 16

4.1. STARTING ........................................................................................................................................................ 16

4.2. OPERATING THE MACHINE ............................................................................................................................... 18

4.3. TURNING THE ENGINE OFF.............................................................................................................................. 18

4.4. HANDLING, TRANSPORT, STORAGE .................................................................................................................. 19

4.4.1. Manual handling ................................................................................................................................... 19

4.4.2. Handling by crane ................................................................................................................................. 19

4.4.3. Handling by forklift ............................................................................................................................... 20

4.4.4. Transport ............................................................................................................................................... 20

Vibratory plate compactors Operation manu al

page 4

4.4.5. Storage ................................................................................................................................................... 20

4.5. SPECIAL CONDITIONS OF OPERATION ............................................................................................................... 20

4.5.1. Operation at low ambient temperature .................................................................................................. 20

4.5.2. Operation at high altitudes .................................................................................................................... 20

4.5.3. Operation in Dusty Environment ........................................................................................................... 20

5. MAINTENANCE ......................................................................................................................................... 20

5.1. ENGINE MAINTENANCE .................................................................................................................................... 20

5.2. TENSIONING OF THE DRIVE BELT ..................................................................................................................... 21

5.3. INSPECTION OF VIBRATOR OIL LEVEL ............................................................................................................... 21

5.4. EXCHANGE OF OIL IN THE VIBRATOR ............................................................................................................... 22

5.5. INSPECTION OF BOLTED CONNECTIONS ............................................................................................................ 22

5.6. SETTING THE CENTRIFUGAL C LUTCH ............................................................................................................... 22

5.7. ADJUSTMENT OF ENGINE SPEED ....................................................................................................................... 23

7. MAINTENANCE SCHEDULE ................................................................................................................... 24

8. WARRANTY TERMS ................................................................................................................................ 25

Revision No.

Content

Date

Vibratory plate compactors Operation manu al

page 5

1. SAFETY INSTRUCTIONS

1.1. General Safety Instructions for Work with Small Tools and Device

As a rule, no machine oper ator 's card is requi red for work with small tools and devices. Nevertheless, the

person in charge of operating small tools and devices individually should meet the following conditions:

1.1.1. Qualification Requirements

1. The persons to be charged with working with small tools and devices should:

• be older than 18;

• be physically and mentally fit for this kind of work;

• be properly trained and have shown the employer their capabilities to operate such machines;

• be expected to work duly and properly according to their supervisors' instructions;

2. Before the work is started, the operator should acquaint himself with the Operating Instructions

and to follow them during the work.

3. The operator should acquaint himself with the safety instructions applicable to the respective

machine and follow these instructions for the whole time of work. The acquaintance with the

instructions should be provable, which means that the operator should confirm this fact by his or

her signature.

The contractor is deemed to be a natural or legal entity in charge with performing the construction work

using the given machine. The contractor is responsible for safety of the work with the machine.

1.1.2. Contractor's Obligations

The contractor is especially obliged:

• To designate the machine operator and to train him duly and properly;

• To provide the operator with safe conditions for working with the machine;

• To supervise the observance of the respective safety instructions;

• To supervise whether the operator follows the respective Operating Instructions;

• To provide organizational backup for regular inspections, maintenance a repairs od the machine;

• To provide suitable, safe and secured place for storing the machine if not in use.

Moreover, the contractor is obliged to provide organizational backup for observing other legal

requirements for labour safety and other regulations applicable to the given workplace.

The machine operator should be designated by the contractor providing always that the pr ovisions of Par.

1.1.1 above are met.

1.1.3. Operator's Obligations

The operator is especially obliged:

• To acquaint himself with the Operating Instructions including the applicable labour-safety rules

before the work is started;

• To follow all the provisions of the Operating Instructions;

• To acquaint himself with the workplace itself including the la bour-safety rules applicable for the

given workplace and to follow the rules;

• To pay full attention to the machine operation;

• To provide organizational backup for regular inspections, maintenance a repairs of the machine;

• To require the employer to provide the conditions for following the safety instructions, for

carrying out regular inspections, maintenance and repairs of the machine.

• To prevent the machine from being damaged or stolen and from unauthorized use. To st ore the

machine in a safe and duly secured place after fork.

Vibratory plate compactors Operation manual

Page 6

1.1.4. Machine Operation

1. Check the machine, especially all its protective elements (e.g. covers) and controls. Make sure

that there are no leaks of fuel from the fuel system or oil from the engine. Should a defect is

found, the machine must not be operated until the defect is repaired.

When working with the machine operator must observe the following guidelines:

2. Use personal protective means (such as the respective crash helmet, ear protectors, protective

goggles, gloves, shoes). The protective clothing should be close-fitting, not loose. Loose or

damaged (torn) clothing should not be used. Any chains, watches, rings, etc. should not be worn

as they can be caught by rotating parts of the machine and injure the operator.

3. Before work, check whether the machine can be safely started up without endangering the

operating staff or other persons nearby.

4. Do not start up the engine in closed spaces unless sufficient ventilation is provided.

5. Pay full attention to the machine operation to prevent injury or collision with solid obstacles,

other machines or vehicles.

6. Listen the run of the machine carefully. In case of unusual sounds or if smoke appears, stop the

machine immediately check the machine and get it repaired.

7. Fill the machine with fuel only at standstill. The fuel must not come into contact with hot parts of

the machine. If the fuel is spilled over, wipe up the fuel immediately. Do not fill the tank up to

the neck.

8. See to it that that the fuel tank cap is tight. If not in operation, the fuel valve should be closed. If

the machine is transported for a longer distance the fuel tank should be emptied.

CAUTION – broken or leaking fuel tanks and fuel piping can cause expl osion, it is necessary to

replace them without delay.

9. The machine should not be operated everywhere where there is danger of explosion of

combustible gases or dust.

10. When operating the machine in closed spaces (tunnels, shafts, deep holes, etc.), the operator

should be provided with fresh air supply (see the applicable regulations for constructional work).

11. After the work is finished, stop the engine, put the machine in a safe place, secure it against theft

or unauthorized use. The machine should be stored in such a manner that it cannot fall down or

overturn and that it is not an obstacle to other machines and vehicles.

1.1.5. Inspections, Maintenance & Repairs

2. Machine servicing may only be carried out by a duly qualified person authorized by the

contractor. Machine servicing can also be carried out by the worker of the respective service

organization.

1. Check the technical condition of the machine regularly and focus on perfect functioning of

protective and control elements. If a defect is found, have it repaired without delay.

3. The machine should be serviced in a clean and safe place. If possible, service the machine in a

workshop with the adequate equipment. If it is necessary to service the machine in-situ, the place

should be secured in such a manner that any collision with other machines or vehicles is

eliminated. The machine should not be serviced in otherwise dangerous places (landslides, caveins, operation of other machines and vehicles etc.).

4. Service the machine at standstill with the engine off only. If there is a need for starting up the

engine when servicing the machine, pay full attention to labour safety.

5. When repairing the machine, use the original spare parts only. Only original spare parts (that

have been tested and approved by the manufacturer) can guarantee save operation of the

machine.

6. Any changes and modifications of the machine can only be made with the manufacturer's express

consent.

Vibratory plate compactors Operation manual

Page 7

1.1.6. Loading & Transportation

2. When loading the machine with a crane, all the regulations applicable to work with a crane

should be observed. This should be done by a duly qualified person(s).

1. The machine may only be loaded and transported using a device or a vehicle with the lifting or

loading capacity corresponding to the weight of the machine (see "Basic Specifications").

3. The sling should be placed in the marked place on the machine frame.

4. When handling the machine manually, more persons is necessary in order not to exceed

maximum permissible weight to be lifted by one person.

5. During transportation, the machine should be sufficiently secured against overturning, falling or

shifting. The slings should be fixed on the marked place(s).

6. During transportation, the shaft of the machine should be lifted and duly fixed in position.

It is strictly prohibited:

1.2. Prohibited Operations

• To use the machine for purposes other than those the machine is intended for;

• To control the machine in a different way from that set forth in the Operating Instructions;

• To operate the machine under influence of alcoholic beverages or drugs;

• T o operate the machine in such a manner that safety of persons, buildings, structur es, things or

road traffic and its smoothness is endangered.

• To operate the machine if other persons are within the working radius of the machine;

• To operate the machine with any of its protective elements removed or damaged;

• To operate t he machine in dangerous areas with imminent external danger such as caving-in the

machine, landslides, overturning the machine, release of dangerous substa nces, risk of explosion

or fire, electric shock hazard, etc.)

• T o operate the machine in the areas where buildings, other structures or underground services

could be damaged (e.g. by excessive vibrations).

• To operate the machine within the protective zones of electric lines and transformer stations;

• To cross electric cables with the machine unless they are sufficiently protected against

mechanical damage;

• To operate the machine at poor visibility or at night without sufficient illumination of the whole

workplace;

• To leave the machine while in operation or to leave the machine without having secured it

against unauthorized use;

• To disactivate safety and protective elements or to change their parameters;

• To operate the machine with leaking oil, fuel or other liquids;

• To start up the engine in a manner different from that mentioned in the Operating Instructions;

• To clean the machine or to remove dirt while in operation;

• T o smoke or use open fire when fueling or lubri cating the machine, when checking the fuel level

or the accumulator.

Oil products (fuels, lubricants) ar e substances dangerous to health. Workers who come into contact with

these substances when operating, maintaining or repairing machines should observe general principles of

health protection and follow the hygienic and safety instructions issued by manufacturers of such

substances. They are especially obliged:

1.3. Hygienic Principles

• To protect their skin from coming into contact with such substances;

• To wash their hands thoroughly after work, before eating and to put a suitable regenerating

cream on them.

Vibratory plate compactors Operation manual

Page 8

Oil products as well as other detergents, preservatives and dangerous substances should at all times be

stored in original, properly marked containers. Never allow storing such substances in different

containers, in unlabelled containers or in food containers or bottles in order to prevent confusion. Stor e

such substances out of the reach of children. If such substance come into contact with the skin, eyes or if

inhaled or ingested, apply the first-aid measures and seek medical attention immediately.

1.4. Enviromental Principles

Fuels, lubricants and operating liquids in individual systems of the machine are dangerous for the

environment. After the end of their service life, they become dangerous waste materials. Moreover, the

parts of the machine that come into contact with the above substances are also dangerous (e.g. filters).

Please prevent these substances from their getting into soil or water (including sewerage systems). These

substances should be stored in such a manner that all accidental spil ls can be caught. If such substances

are released when refueling or lubricating the machine, dispose them in a proper and safe manner

(sprinkle them with an absorbent, have them disposed by a specialized firm). Dispose the used liquids

according to the respective regulations.

When disposing the machine after the end of its service life, the user is obliged to comply with all the

applicable legal regulations. When disposing the machine, the oil filling from the engine and the

vibrating mechanism as well as the respective filters should be removed. Pursuant to the Waste Material

Disposal Act, the owner of the disposed machine is obliged:

1.5. Disposal of the Machine after the End of Its Service Life

• T o hand over the metal parts of the machine only to those persons who are duly authorized to

dispose, collect or purchase metal materials;

• T o hand over t he used e ngine and hydrauli c oil only to those persons who ar e duly authori zed to

dispose used oils;

NTC cannot be held responsible for any damages to the user's health or to the environment if the

aforementioned hygienic and environmental principles are not observed.

Compacting machines are vibration plates, vibration (jumping) rammers and vibration rollers. When

working with these machines, the following safety instructions should be followed:

1.6. Safety Instructions for Work with Compacting Machines

1. Before work, evaluate the bearing capacity of the terrain, locate the places of underground spaces

and underground services to prevent caving-in the machine or damaging the underground

structures.

2. When working with the machine close to buildings and structures, bear in mind the possibil ity of

damaging the buildings or structures by vibrations.

3. When operating the machines in excavation pits, secure the wall s of the pit to prevent them from

sliding and causing injury to the operators.

4. When operating the machines on embankments, do not work on the very edge of the embankment

so that it should not slide down causing turning the machine over.

5. It is strictly prohibited to oper ate t he machine on such slope s where t here i s danger of tur ning the

machine over or of loss of adhesion resulting in an uncontrolled skid of the machine.

Vibratory plate compactors Operation manual

Page 9

Noise:

1.7. Hygienic data

Declared level of acoustic pressure A in workplace of the operator

(measured according to ČSN EN ISO 11201 by conditions determined in ČSN EN 500-4+A1, Annex B)

VD15P VD18P VD20P VD24P

L

pA,d

[dB] 91+4 92+4 93+4 91+1

Guaranted level of acoustic power A

(measured according to NV č.9/2002 Sb., Annex č. 3, part B, point 9c) and ČSN EN ISO 3744.

VD15P VD18P VD20P VD24P

L

WA,G

[dB] 105 105 105 104

Vibration:

Declared overall value of vibrations acceleraiton – trasferred to hand – arm of vibratory plate operator

(measured according to ČSN EN ISO 20643 by conditions determined in ČSN EN 500-4+A1, Annex C).

VD15P VD18P VD20P VD24P

a

hvd

[m.s-2] 7,6+3,1 6,0+2,4 9,4+3,8 8,7+3,5

With regard to value of declared level of acoustic pressure in operator´s area and value of vibrations

transferred to operator´s arms, when operating particular type of vibratory plate it is necessary to use, in

accordance to Government regulation no. 148/2006 Sb. in valid version, personal protection equipment

effectual in such level of acoustic pressure or vibrations transferred to arms, whose values for particular

type of vibratory plate are determined by machine operator by workplace categorization.

Manuals for operation of vibratory plate must be modified so, that t here are obvious technological pauses

leading to interruption of operator machine usage.

At the designated types of machinery vibration plate types VD15P, 18P, 20P a 24P to comply with the

Act No. 22/1997 Coll. on technical requirements for products, as amended, located stickers symbols

safety signs, symbols and informative descriptions of the design and implementation determine the

technical norm.

1.8. List of safety symbols used on the machine

The following text shows individual stickers (label s) placed on the machine. Each individual sticker is

provided with the respective explanatory text.

Vibratory plate compactors Operation manual

Page 10

1.

A united sticker comprising safety signs according to ČSN

ISO 3864 (symbols B.2.5, B.3.1 and NB.2.26) and the CE

symbols pursuant to Governmental Order 291/2000 Sb.

including the explanatory text.

Sign B.2.5 orders the operating staff to wear ear protectors

when the machine is in operation.

Sign 7.28 informs the operating st aff that they are obliged to

read the Operating Instructions before work with the machine.

The NB.2.26 sign ord

ers the operating staff (operators) to

wear protective gloves when working with the machine to

protect the hands from vibrations.

Warning sign B.3.1 (exclamation mark) warns the operators

against danger.

Information for the operating staff how to perform repairs,

cleaning and setting the machine.

2.

Sticking label No. 8.1 pursuant to ČSN ISO 6405-1 marks the

location of the engine oil discharging screw.

3.

Sticking label No. 7.25 pursuant to ČSN ISO 6405-1 (the

symbol marks the hoisting point, (i.e. the place in which the

machine can be hoisted).

4.

A sticker informing the operating staff about the fuel to be

used for the engine of the machine.

5.

Sticker with the symbol vibrator and verbal indication of the

type specified oil and its maximum volume

6.

Sticker "RED CIRCLE"

Sticker indicates the closing screw hole for pouring oil into

the vibrator machine.

7.

A sticker showing the noise level measured according to the

conditions set forth in NV 9/2002 Sb.

The company of NTC STAVEBNÍ TECHNIKA spol. s r.o. is registered with the EKO-KOM a.s. company.

This means that there is a contract between EKO-KOM a.s. and NTC STAVEBNÍ TECHNIKA spol. s r.o.

on repurchase of all kinds of packing materials either by NTC or by suppliers of the packing materials.

1.9. Disposal of the Packing Material

Vibratory plate compactors Operation manual

Page 11

Vibratory plates are designed for compaction of all types of soils, including soil related sections for

compaction of trenches and areas - the machine without sprinkling. Machines are also designed for

compacting asphalt surfaces – the machine with sprinkling.

2. TECHNICAL DESCRIPTION

When used with a plastic backing plate vibration can also be used for ground paving.

These vibratory plates have optimized centrifugal force and compaction area and thus reach optimal

compaction effect. The vibratory effect is ensured by non-directed eccentric which creates circular

vibration. The main working part - the base plate - is a structure made of welded steel. The vibrator is

bolted or welded to the base plate. The engine plate is mounted to the base plate through the rubber

mounts.

The vibratory plate is driven by a four-stroke single-cylinder air cooled engine. The engine is connected

with the vibrator by a drive belt, with a centrifugal clutch which disengages the drive at idle speed.

The operator controls the machine using its handle.

Special equipment to transport the chassis vibration plates, plastic mat compaction paving and operating

hours counter.

2.1. Basic technical data:

Vibration plates are characterized by one-way design with a comfortable cushioned handle and folding

ROPS, which protects the engine from damage and ease of handling.

Type VD15P

VD18P

VD20P

VD24P

Weight

[kg]

85

95

105

110

Frequency

[Hz]

100

100

100

100

Centrifugal force

[kN]

15

18

20

24

Max. speed

[m/min]

25

25

25

25

Max. gradability

[%]

30

30

30

30

Width of base plate

[mm]

400

450

500

500

Length of base plate

[mm]

564

564

564

564

Height of base plate

[mm]

980

980

980

980

ENGINE

HONDA

HONDA

HONDA

HONDA

Model GX160

GX160

GX160

GX160

Fuel gasoline

gasoline

gasoline

gasoline

Oil sensor

YES

YES

YES

YES

Net engine power

[kW]

3,6

3,6

3,6

3,6

Rated engine speed

[RPM]

3600

3600

3600

3600

Fuel consumption

[l/hr]

1,4

1,4

1,4

1,4

Capacity of water tank

[l]

12

12

12

12

Actual output of the engine installed in the machine can be different with regard to various factors,

such as operation speed of the engine, operation conditions, maintenance and other factors.

Engine operation speed is not identical with engine rated speed and this is set according to

technical parameters of the machine.

Vibratory plate compactors Operation manual

Page 12

Fig. Basic description of the machine – a variant without sprinkling

1. Plate with vibratory, 3. Frame with handlebars Praktik, 4. Engine, 6. Cover, 7. Cover VD, 10. Signs

Fig. Basic description of the machine – a variant with sprinkling

1. Plate with vibratory, 3. Frame with handlebars Praktik, 4. Engine, 5. Sprinkling, 6. Cover, 10. Signs

For use in both engine and the vibrator use high-quality engine oils of the following specifications:

15W-40 API SJ/CF

2.2. Lubricants

- engine oil HONDA GX160 capacity 0,60 l

- oil in the vibrator capacity 0,07 l ± 5%

1

3

4

7

10

6 3 1 5 6 3 4

10

3

Vibratory plate compactors Operation manual

Page 13

2.3. Machine identification

It is highly important to refer the exact type and serial number of your machine whenever contacting the

manufacturer or the dealer (i.e. for warranty reasons, ordering of spare parts or service, for technical

questions). These data are stated at the type plate.

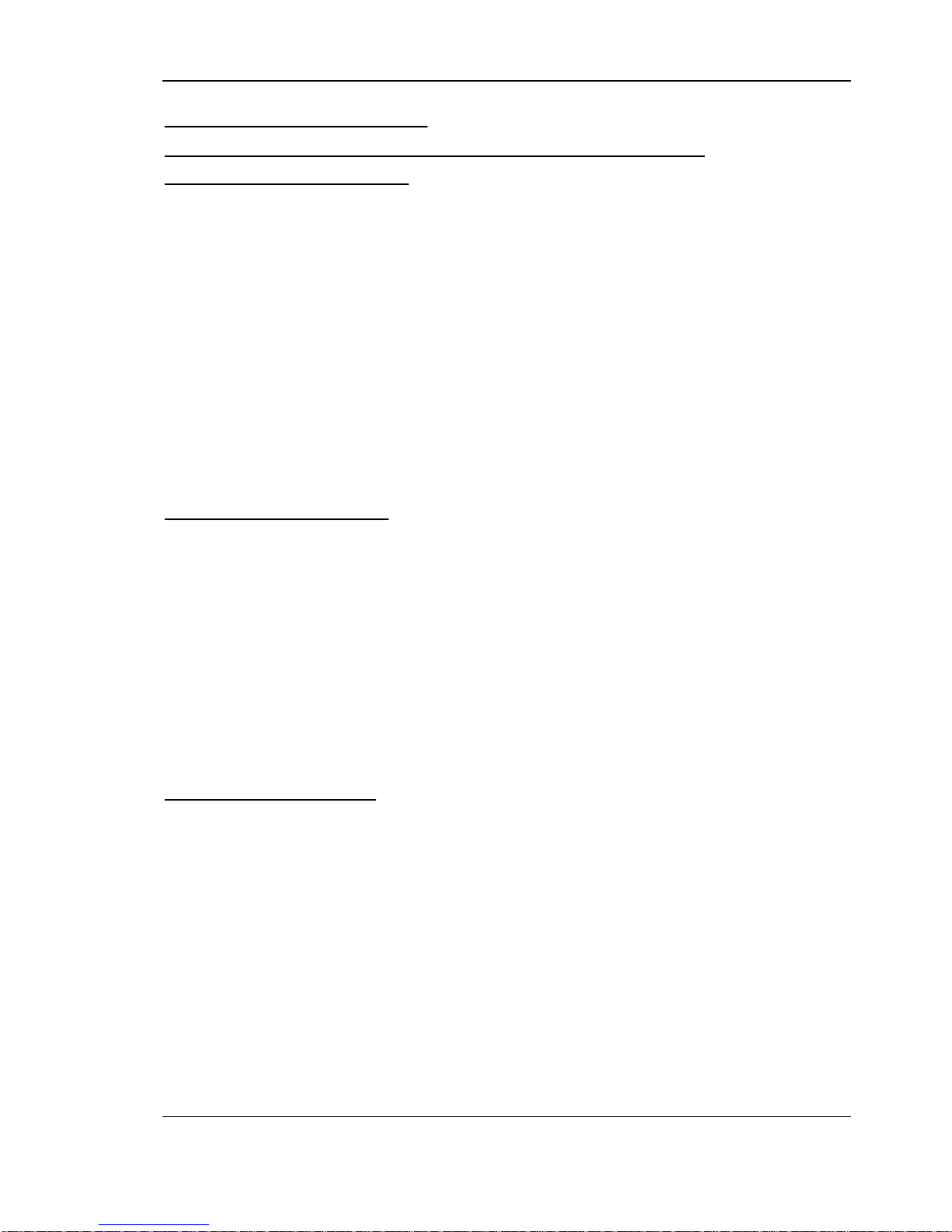

Fig. Location of type plate

Fig. Example of type plate

In the case of engine related problems refer also the engine type and serial number. This number of

stamped at the engine block (for HONDA). In a case of doubts please contact an authorized service or the

manufacturer.

2.4. Identification of the engine

Fig. Location of serial number at the HONDA engine

Vibratory plate compactors Operation manual

Page 14

It is recommended to write down important identification data of your machine into the following table.

You will find it useful when ordering parts or service, in case of a warranty claim or in the event of

reporting stolen equipment:

Model

Serial number

Year of production

Engine type

Engine serial number

- Continually check that the engine leaks or a vibrator oil. In case of failure to contact an authorized

service center or manufacturer.

- Bolted joints are glued to rubber mount. We therefore recommend against any potential activity

associated with the tightening and loosening of joints and contact information to an authorized service or

the manufacturer.

3. PRIOR TO STARTING

Check the oil level every day!

Use only the recommended types of oil. Choose the oil viscosity to match the thermal conditions of space

use.

3.1. Inspection of engine oil level

ATTENTION:

Running the engine with insufficient oil level can result in serious engine damage.

In case of oil leakage from the engine immediately stop the operation of the machine and call service or

contact the manufacturer.

Checking the oil level must be in accordance with the instructions for operating the engine!

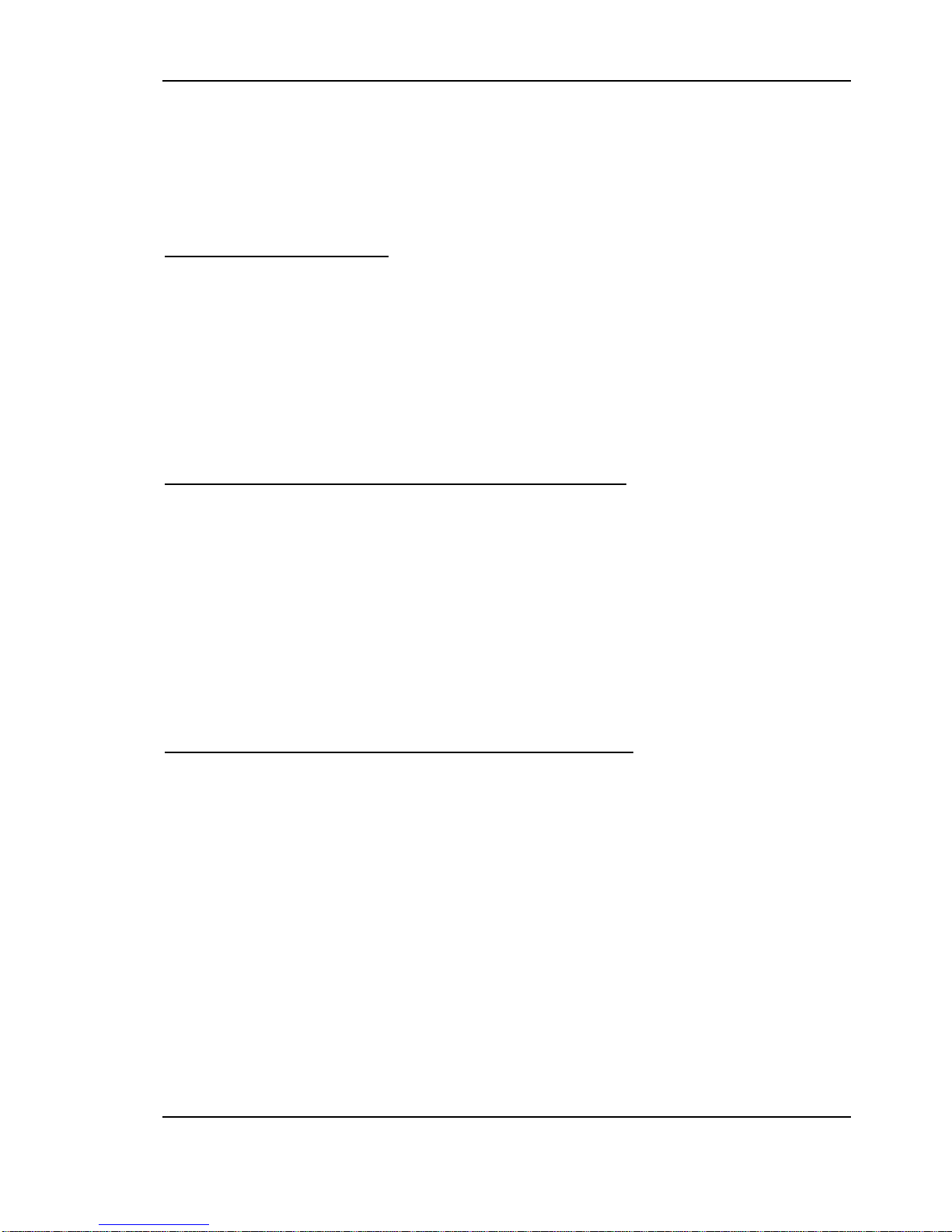

Place the machine int o a horizontal position. Before you unscrew the plug from the control / filler on the

engine, so carefully clean the area to prevent degradation of oil contamination and subseque nt engine

damage. With proper oil level is level with the hole at the same time, oil is leaking slightly.

Fig. Check engine oil level

Vibratory plate compactors Operation manual

Page 15

Inspect the machine regularly, with particular attention to:

3.2. Visual inspection of the machine

• completeness of the machine (missing parts);

• condition of the protective devices (covers) and controls;

• bolter connections;

• fuel or oil leakage;

• intactness of rubber mounts.

For gasoline engines use gasoline for motor vehicles with an octane rating of 90 or more.

3.3. Inspection of fuel level

We recommend that petrol NATURAL 95.

At low levels of fuel is the fuel necessary to fill up the edge of the filtered water.

Never use dirty gasoline or mixture with oil. Prevent dust, dirt or water from entering into the tank.

This activity is performed in accordance with the instructions for operating the engine!

3.4. Inspection o air filter

Place the machine into a horizontal position.

Paper cartridge air filter, check to make sure that it is clean and in good condition.

Paper filter cartridge carefully clean with compressed air from the inside out. In the case of significant

pollution filter paper cartridge change.

Wash the foam cuff Jarov water,

not flammable!

In case of damage replace the foam cuff.

Fig. Inspection of air filter - HONDA engines

Never operate the engine without the filter or with a damaged one. Dirt and dust entering the

engine would cause its rapid damage.

Vibratory plate compactors Operation manual

Page 16

4. OPERATING THE MACHINE

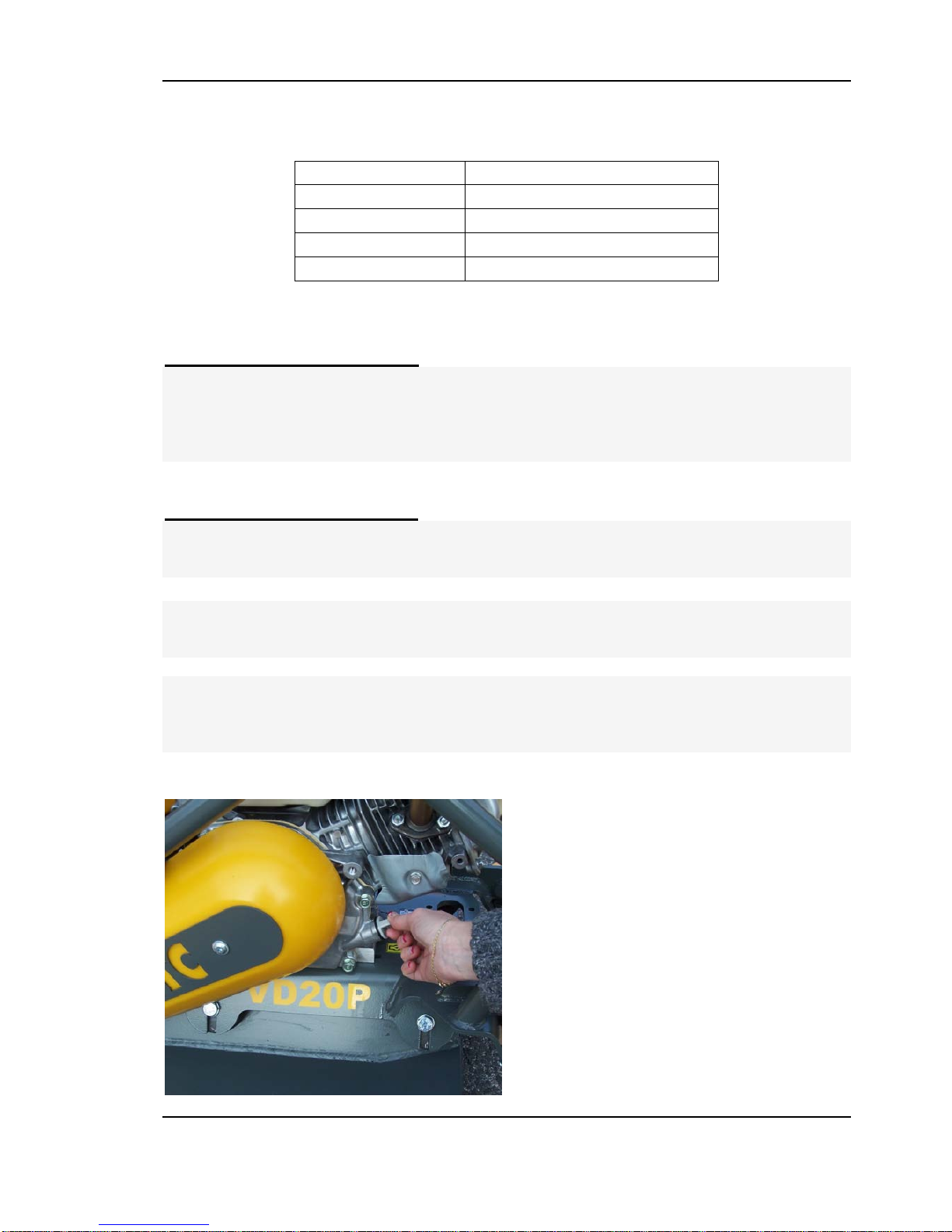

1. Turn the fuel valve to the open position

4.1. Starting

Fig. Open fuel valve engine

2. Turn the switch (ignition switch) the motor position ON (lever switch down)

Fig. Engine ON/OFF switch

3. Engine throttle position to give SLOWLY (slightly open throttle)

Fig. Lever position in gas engine slowly

Vibratory plate compactors Operation manual

Page 17

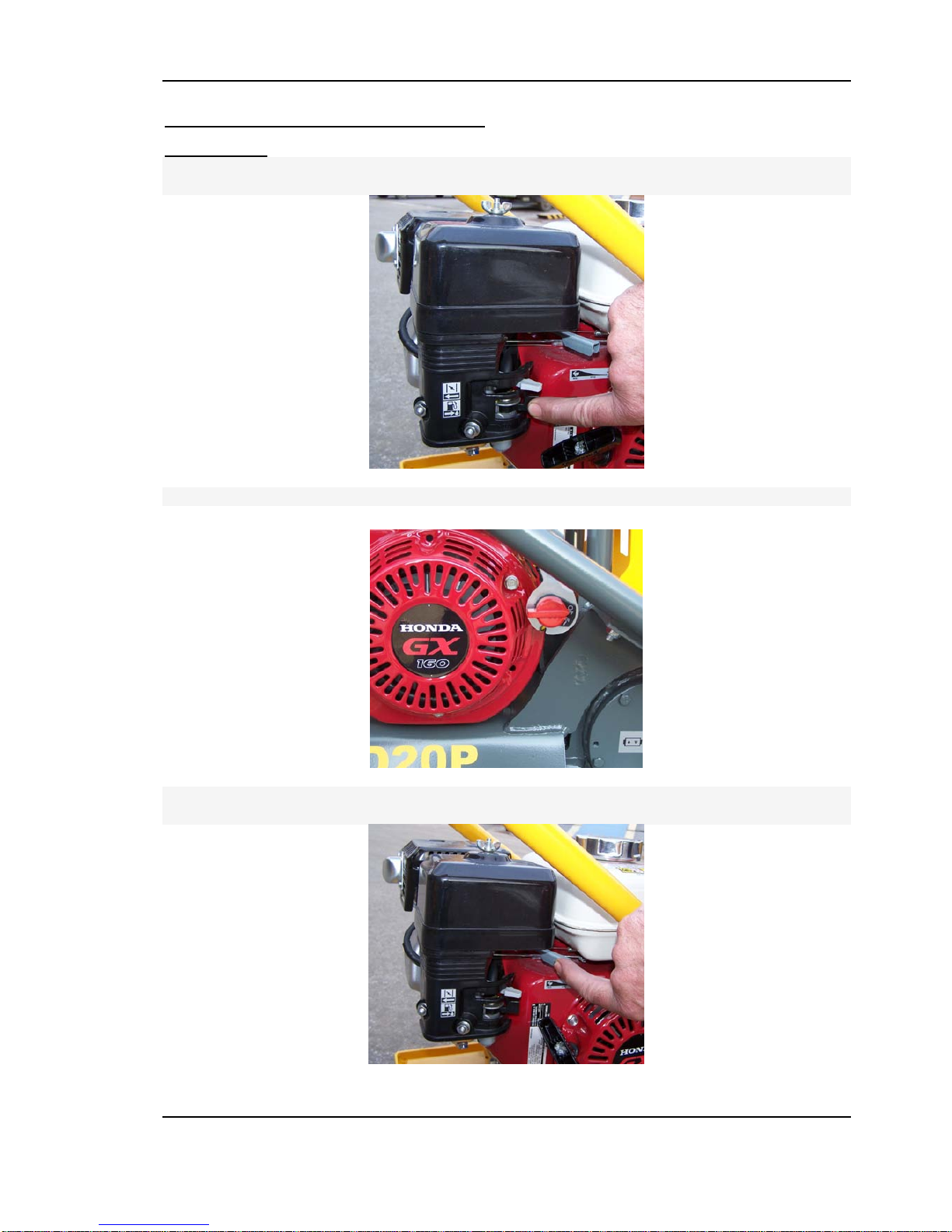

4. Turn the choke to start position.

Do not choke when the engine is warm or if the higher ambient temperature.

Fig. On the motor choke

5. Handle pull the starter cord until you feel resistance, then pull rapidly

Starter cord handle drop sharply back. In retrospect, moving her hands to hold.

Fig. Starter motor pulled out cord

6. After a gradual warm up the engine, move the choke lever to OFF position.

Fig. Choke off the engine

Vibratory plate compactors Operation manual

Page 18

7. Motor full load before running moment leave to heat up.

8. Move the throttle to full throttle position. At about 1700 rev / min centrifugal clutch automatically

switches the machine begins to vibrate.

Fig. The lever position, engine throttle

Starting and stopping the engine is described in detail in the attached instruction manual Honda

engine.

Run the machine across the area to be compacted, keeping slightly overlapping lanes. For good

compaction, it is recommended to do 4 travels in each lane.

4.2. Operating the machine

For soil compaction, the best results will be reached when compacting by layers, each layer not thicker

than 20-30 cm of loose soil, depending on the type of soil.

Approximate compaction effect for compaction to 90% (95%) of Proctor Standard is shown in the

following table. For exact control of the degree of compaction, some method of compaction measurement

must be used.

TAB. Compaction effect

This table is valid for sand and gravel, considering 4

passes. For mixed soils derate by approx. 30%.

4.3. Turning the engine OFF

1. Set up the throttle control leer into the idle position. The centrifugal clutch gets disengaged and

vibration will stop.

Fig. Lever position in gas engine slowly

Vibratory plate compactors Operation manual

Page 19

2. Turn the ignition switch into the "OFF" position (switch lever up).

3. Fig. Engine ON/OFF switch

3. Turn the fuel valve to the closed position.

Fig. Closed fuel valve engine

When handling the machine and its transport strictly follow the safety instructions in this manual, as well

as generally applicable transcripts to work with handling equipment or lifting equipment.

4.4. Handling, transport, storage

4.4.1. Manual handling

When manual handling is usually needed to co-parties in order to comply with the maximum load weight,

which the worker may lift. Lift the machine frame for or. the grips. Do not lift the machine engine!

4.4.2. Handling by crane

The machine is allowed to handle and transport the equipment only with adequate capacity (weight

machines is given in chapter "Technical Specifications").

When loading crane must comply with applicable regulations to work with the crane. This activity may

be performed only by qualified person (s) with valid card.

Binding means fix it in the space frame of the machine.

Vibratory plate compactors Operation manual

Page 20

4.4.3. Handling by forklift

If the machine is often handled with a forklift (for example when sending collection service), we attach a

variety of machine and send it together with a variety. For one machine is suitable for "small" range of

dimensions 0.8 x 0.6 m, two machines for a variety of standard EUR 1.2 x 0.8 m.

4.4.4. Transport

When transporting the machine must be adequately secured against overturning, falling or shifting to the

base.

The machine must be transported in an upright position.

4.4.5. Storage

Store the machine in place secured against theft and misuse. We recommend a dry sheltered place does

not affect the chemical substances and where there is excessive dust.

Before long-term storage engine first clean, repair the damaged areas and preserve the paint (including

the preservation of the motor). Clearly label the machine is conserved.

4.5. Special conditions of operation

Compaction at temperature below freezing is highly dependent on water content in the soil to be

compacted. Under such conditions, soil becomes harder and more difficult to compact. It is possible to

compact dry materials or rapidly compact fresh soil, before it gets frozen.

4.5.1. Operation at low ambient temperature

With increasing altitude, engine power decreases due t o changed oxygen content. Within certain extent,

it is possible to improve the engine power by installing different main nozzle and by adjusting the

carburetor (gasoline engines) or by adjusting the inj ection system (diesel engines). Should the machine

be operated in high altitudes (above 1500 m above sea level), contact the engine manufacturer to carry

out the adjustments.

4.5.2. Operation at high altitudes

In case that you intent to operate the machine in high altitudes in the time of purchase, consult the

manufacturer.

In case that the machine is operated in extremely dusty environment, it is recommended to shorten the

service intervals for cleaning or replacement of the air filter.

4.5.3. Operation in Dusty Environment

Clean the machine from dust regularly.

Basic maintenance as described in this Operation Manual can be carried out by the operator. Repairs and

adjustments beyond the extent of this Manual should be done by an authorized service center.

5. MAINTENANCE

In the warranty period it is strictly prohibited to dismantle the vibrator; such repair can be done

exclusively by an authorized service center. Further, no interventions into engine except of the prescribed

maintenance are allowed in the warranty period.

Bolts of the rubber mounts are secured wit h a glue. Therefore it is highly recommended to contact

authorized service before dismantling or mounting the rubber mounts.

- see enclosed engine operation manual.

5.1. Engine maintenance

Vibratory plate compactors Operation manual

Page 21

Inspect tensioning of the drive belt on a regular basis. Belt deflec ti on should be a bout 10mm under finger

pressure (2 kg).

5.2. Tensioning of the drive belt

When necessary to tighten the belt, proceed as follows:

• Loose two bolt fastening the water tank. Tilt the tank forwards and carefully place aside (not

necessary to disconnect the water hose).

• Loose four bolts that fasten the engine to the base plate and a lock nut of the tensioning screw (located

under the water tank).

• Tension the drive belt by means of the tensioning screw.

• Re-tighten the bolts and the lock nut.

• Replace the water tank.

Bear in mind that the drive belt connects the engine and the vibrator, whic h are in mutual movement

under operation. Be careful not to overtension the belt, so that it is able to allow this movement.

DO NOT OVERTENSION THE BELT!

Fig. Inspection of drive belt tensioning

5.3.

Continually check that oil leaking from the vibrator. Interval control and exchange of oil in the vibrator

(see section 6)

Inspection of vibrator oil level

The vibrator is filled with 0.07 l ± 5% oil 15W-40.

To check the oil level, proceed as follows:

Place the machine on a level area.

Unscrew the inspection plug (marked “oil level”; oil should slightly run out.

In case of oil escape, stop the machine immediately and contact authorized service.

In the warranty period only authorized service may carry out repairs of the vibrator. Any

unauthorized intervention into the vibrator voids warranty.

ATTENTION

Low oil level in the vibrator may cause serious damage to the bearings vibrator

High oil level will increase the temperature of the vibrator, reduces engine power or engine

"chokes".

Vibratory plate compactors Operation manual

Page 22

5.4. Exchange of oil in the vibrator

To carry out oil exchange, proceed as follows:

• warm-up the vibrator to operational temperature

• turn off the engine, unscrew the drain plug (marked with an arrow)

Fig. Filling, inspection and draining plug

• incline the machine to drain off oil completely (c/a 0,07 ltr)

• add oil vibrator (f illing control drain plug on vibrator - marked in red, see section 5.3) so

that the oil level after settling just reached the lower edge of the hole plugs - oil leaking

slightly

5.5. Inspection of bolted connections

Caution - All the important screw connections on the machine are glued and bolts are tight

dotahovacím prescribed torque. We therefore recommend against any potential activity associated

with the tightening and loosening of joints and contact information to an authorized service or the

manufacturer.

We recommend starting the machine before each check screw connections.

The engagement speed of the centr ifugal clutch should not exce ed 1950 RPM, otherwise the clutch may

slip and get damaged.

5.6. Setting the centrifugal clutch

It is recommended to have the clutch checked and adjusted by authorized service.

Fig. Measuring of engine speed

Vibratory plate compactors Operation manual

Page 23

5.7. Adjustment of engine speed

Remove the belt cover and measure revolutions of the vibrator pul ley. The vibrator frequency is 100Hz

(6000 VPM) and the engine speed is 3324 RPM.

In case of repair or replacement of the engine, adjust the engine speed as follows:

Measure the revolutions with a suitable speedometer.

It is recommended to have the engine speed checked and adjusted by authorized service.

NEVER ADJUST HIGHER ENGINE SPEED!

When exceeding the engine speed set by the manufacturer may damage the machine.

The manufacturer does not recognize the claims of defects arising from this cause! DURING THIS

WARRANTY MAY MAKE ADJUSTMENTS AUTHORIZED SERVICE ONLY!

Fig. Speed control shaker

6. NOTES:

Page 24

This maintenance schedule contains only the most important operations. Besides of these operations, carry out maintenance and repairs of the machine as necessary

depending on the respective conditions of operation. Check also the engine operation manual.

7. MAINTENANCE SCHEDULE

WARNING:

Turn off the engine before any maintenance or repair activity.

Use genuine spare parts only. Use of non-original spare parts may lead to damage to the machine. The manufacturer will not honor any warranty claim

arising from such reason.

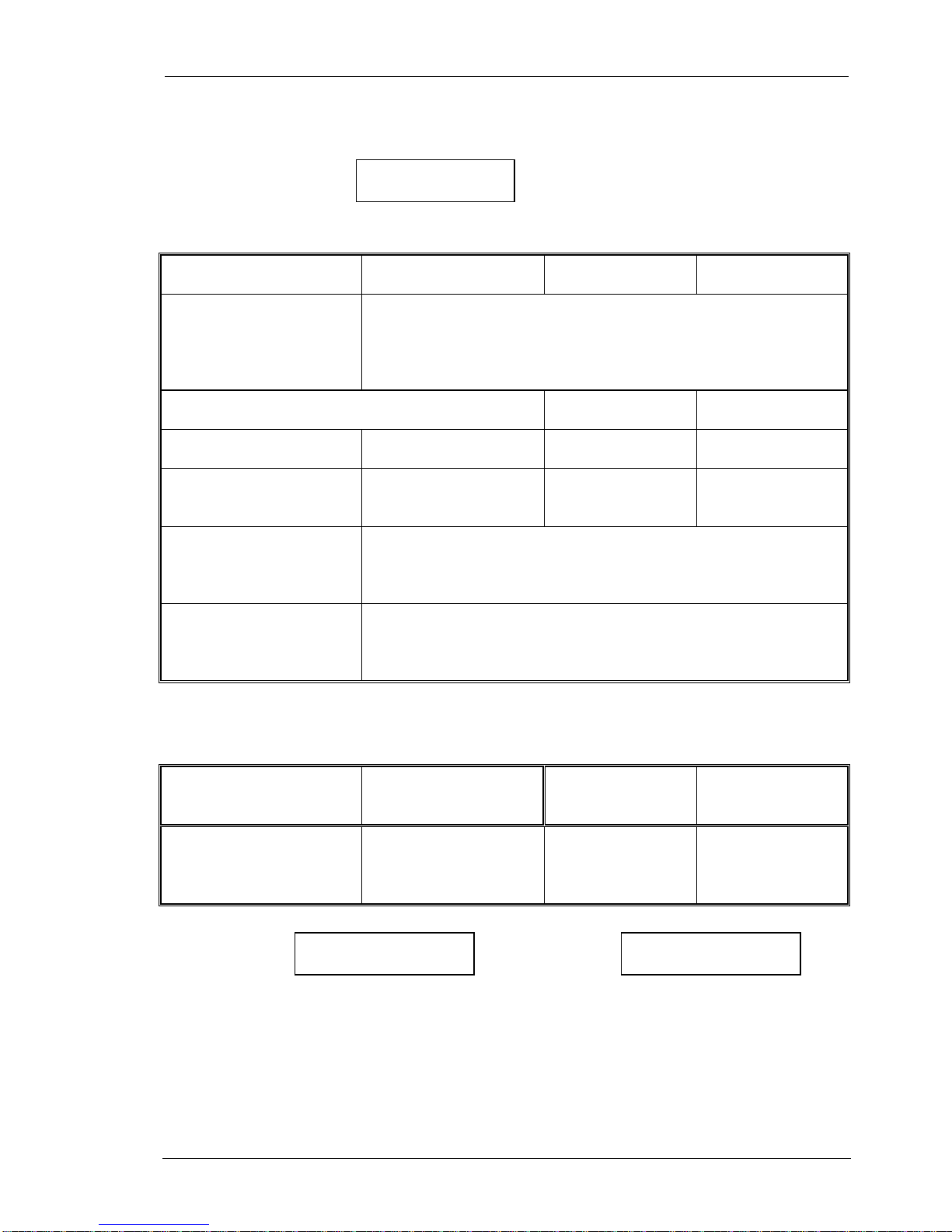

Item Operation Initial inspection

After 1st month or 20

hours

Every 3 months or 50

hours

Every 6 months or

100 hours

Engine oil

Inspection of oil level

DAILY

Exchange

Air filter

Inspection

Cleaning

(1)

Spark plug

Inspection - cleaning

Filter bowl

Cleaning

Fuel hose

Inspection - exchange

Every two years

Valve clearance

Inspection - adjustment

Every 12 months or 250 hours (2)

Fuel tank and sieve

Cleaning

Every 12 months or 300 hours (2)

Vibrator

Inspection of oil level, exchange

Inspection for tightness - daily

Oil replacement

- every 2 years

Drive belt (3)

Tensioning

Rubber mounts

Inspection of the integrity

150 hours

Handle assembly

Lubrication, exchange

1. To be carried more often when operating in dusty environment!

2. It is recommended to be carried out by authorized service.

3. Replacement of drive belt every 300 hours.

Page 25

8. WARRANTY TERMS

The NTC construction machines are designed and manufactured to suit to long-term operation even

under the toughest operating conditions. In accordance with long-term experience we can say that the

machines reliably work not only for the warranty period, but even much longer.

Should the machine still fail to work to your full satisf action, we are ready to be anytime helpful solving

the problem. In a case of a failure, proceed as follows:

1. Check, whether the failure is not caused by a failure to follow the operation manual, or exclude

trivial problems such as empty fuel tank, low oil level or clogged air filter.

2. If you do not succeed to repair the pr oblem this way, contact the manufacturer or any authorized

service (see the warranty certificate).

• company name, your name, phone and fax number

• machine model and serial number

• description of the failure

• in case that the machine is in warranty, inform the service that you are reporting a

warranty claim and state date of purchase

4. In case of a warranty claim, the claim must be consequently submitted in writing, preferably using

the form "Warranty Protocol".

5. Every warranty claim will be immediately considered and the service technician will discuss with

you the method of repairing.

The following warranty conditions are valid for all NTC products:

Unless agreed otherwise, the producer warranty its products and good for a period of 12 months from

date of delivery to the end-user. Should a fail ure cause by improper design, material or workmanship

should occur within the warranty period, the manufacturer will by its sole decision r epair or replace the

faulty part.

The warranty does not cover fast wearing parts, such as the drive belts, rubber mounts, filter elements,

spark plugs or control cables.

The manufacturer bears no responsibility for f ailures a rising from failure t o follow the operati on manual,

by improper maintenance or lack of it, by unprofessional service action, by using the machine for other

than intended purpose, by using unsuitable fuels, lubrica nts, accident or act of God. The manufacturer

further bears no responsibility for damages caused by transportation or storage. The warranty conditions

are also stated at the warranty certificate.

Vibratory plate compactors Operation manual

Page 26

Warranty Protocol

Number: (to be filled in by NTC comm. dept.)

Failure reporting (to be filled in by user of the machine):

Model:

Serial number:

Detailed description of the

failure:

Is the machine in operable condition?

YES*

NO*

Date of the failure

occurrence:

Date of reporting:

Date of purchase:

The machine was

purchased from:

NTC / dealer*

Dealer:

User:

(address, phone, contact

person)

Location of machine usage:

(if different from the user´s

address)

This properly filled in protocol should be sent by fax or registered letter to the above address; that

will help us to resolve your warranty claim quickly.

Confirmation of rightfulness of the warranty claim (to be filled in by NTC commercial department):

Date of sale:

Warranty void:

YES/NO*

Is the machine in warranty

at the moment of

reporting?

YES/NO* Name: Signature:

QC signature: Date:

Loading...

Loading...