OPERATION MANUAL

CHARGER 2717 DB & CHARGER 2022 DB

Original Instructions

Instructions D'origine

Instrucciones Originales

OPERATION MANUAL

CHARGER 2717 DB & CHARGER 2022 DB

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Failure to observe these instructions can cause

personal injury to machine operator or bystanders.

WARNING: Fire or explosion hazard.

NEVER operate this machine in an

explosive atmosphere (grain dust,

flammable liquids or fumes, etc.).

WARNING: This product contains a chemical known to the state of California to cause

cancer and birth defects or other reproductive harm.

WARNING: Fire or explosion hazard.

NEVER use flammable liquids (gas,

kerosene, solvents, or thinners) to

clean or burnish floor.

INTENDED USE

NSS Burnishers are intended for commercial use,

buffing and burnishing floors in an indoor environment.

It is not intended for spray burnishing.

NSS Burnishers are Twister Approved.

NSS does not recommend using these machines for

any other purpose.

FOR SAFETY

ALWAYS read and understand all instructions before

operating or servicing machine.

ALWAYS use this machine ONLY as described in

this manual.

NEVER attempt to operate this machine unless you

have been trained in its operation.

NEVER allow an untrained person to operate this

machine.

ALWAYS operate this machine from the rear control

panel, not from the side.

ALWAYS turn off master switch when attaching or

changing pads.

NEVER attempt to operate this machine if it is not

working properly or has been damaged in any

manner.

NEVER disconnect or modify any switches or safety

devices (circuit breaker).

NEVER drop or insert any object into any machine

opening.

NEVER operate this machine with any air opening

blocked. Keep all air openings free of dust, lint, hair,

etc.

NEVER pick up anything that is burning or smoking,

such as cigarettes, matches or hot ashes.

NEVER allow this machine to be used as a toy. Close

attention is necessary when used by or near children.

ALWAYS wear clean tennis shoes or “non-slip” shoes.

Leather soled shoes will be extremely slippery.

ALWAYS keep face, fingers, hair or any other body

part or loose clothing away from any machine opening

or moving part (revolving pad driver).

ALWAYS be sure that the ramp is secured to the

vehicle before attempting to load / unload.

ALWAYS use extreme caution when operating the

machine on a ramp or loading / unloading this machine

into or out of a truck / trailer. Use extreme caution if

the ramp is wet, oily, or covered with cleaning

chemicals.

NEVER stop or turn the machine on a ramp or incline.

NEVER attempt to climb a grade or operate this

machine on a ramp or incline of more than 20 degrees.

ALWAYS store this machine indoors in a dry, cool

area.

NEVER park or store the machine near a dock, on

ramps, near a furnace, boiler, open flame, or other

high heat source.

NEVER spray this machine with water or any liquids.

NEVER allow the battery charging plug to get wet or a

short may occur.

NEVER operate this machine when the battery

charger is plugged in.

NEVER operate the machine outdoors or allow

machine to freeze.

NEVER expose the machine to rain, snow, or extreme

temperatures.

NEVER store any items on the machine.

ALL REPAIR SERVICE MUST BE PERFORMED BY AN NSS AUTHORIZED DISTRIBUTOR /

SERVICE STATION USING ONLY NSS ORIGINAL EQUIPMENT PARTS.

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

BATTERY POWERED EQUIPMENT WITH ON BOARD CHARGERS

WARNING: Failure to observe these instructions can cause personal

injury to machine operator or bystanders.

Read and understand all

instructions before installing

or charging batteries.

WARNING: Batteries emit hydrogen, which can cause fire or explosion.

NEVER smoke, light a match, or cause a spark during operation or charging.

ALWAYS charge in a well-ventilated area away from open flame.

No smoking, open

flames, or sparks while

working with batteries.

GENERAL

ALWAYS read and understand all instructions before

installing or charging batteries.

NEVER attempt to install or charge batteries unless

you have been trained to do so.

NEVER allow an untrained person to install or charge

batteries.

ALWAYS remove all jewelry when working on or

near the batteries.

ALWAYS turn off all switches during installation and

service.

ALWAYS disconnect the battery leads before

performing any service or repair.

ALWAYS wear eye protection, rubber gloves and

protective clothing to avoid contact with battery acid.

NEVER lay anything on top of batteries as arcing

may occur.

IF CONTACT WITH BATTERY ACID OCCURS,

follow these instructions:

SKIN – rinse area with water.

EYES – Flush with water for 15 minutes.

INTERNAL – Drink water or milk. Follow with Milk

of Magnesia, beaten egg or vegetable oil. Call a

physician immediately.

BATTERY INSTALLATION

ALWAYS use two people to install, as batteries are

heavy.

ALWAYS turn off all machine switches.

ALWAYS position batteries as shown on the

machine installation decal to maintain machine

balance.

ALWAYS connect batteries as shown on the

machine installation decal to avoid shorting out the

batteries and the electrical system.

ALL REPAIR SERVICE MUST BE PERFORMED BY AN NSS AUTHORIZED DISTRIBUTOR/

SERVICE STATION USING ONLY NSS ORIGINAL EQUIPMENT PARTS

Contains acid.

Avoid contact

BATTERY CHARGING

ALWAYS read instructions on charger carefully.

ALWAYS use the NSS supplied charger with proper

voltage rating.

For lead acid batteries only, (does not apply to gel

cell or maintenance free batteries).

ALWAYS check to ensure the battery water level

covers the battery plates before charging.

ALWAYS check water level after charging and add

distilled water if necessary to bring level to the bottom

of the fill hole.

NEVER

battery

result.

ALWAYS wipe any acid from the top of batteries

using a soap solution.

ALWAYS reattach caps to batteries. Do not charge

with caps loose or removed.

ADD only distilled water.

For All Types of Batteries

ALWAYS study battery manufacturers’ specific

precautions such as recommended rates of charge.

NEVER charge a frozen battery.

ALWAYS plug the charger into an earthed socket-

outlet.

NEVER touch uninsulated portion of output connector

or uninsulated battery terminal.

ALWAYS disconnect the AC supply before making or

breaking the connections to the battery while

charging.

NEVER open or disassemble charger.

NEVER operate charger if the AC supply cord is

damaged or if the charger has received a sharp blow,

been dropped, or otherwise damaged in any way.

Poison. Causes

severe burns. Avoid

contact.

overfill batteries as

and machine damage may

(

(

NOISE AND VIBRATION

Lower Brush/Pad to Operating Position

NOISE

Sound pressure level at Operator

position

VIBRATION

Weighted RMS acceleration value

ISO 5349)

ISO 11201)

68 dB(A)

.269 m/s

2

MACHINE INSPECTION

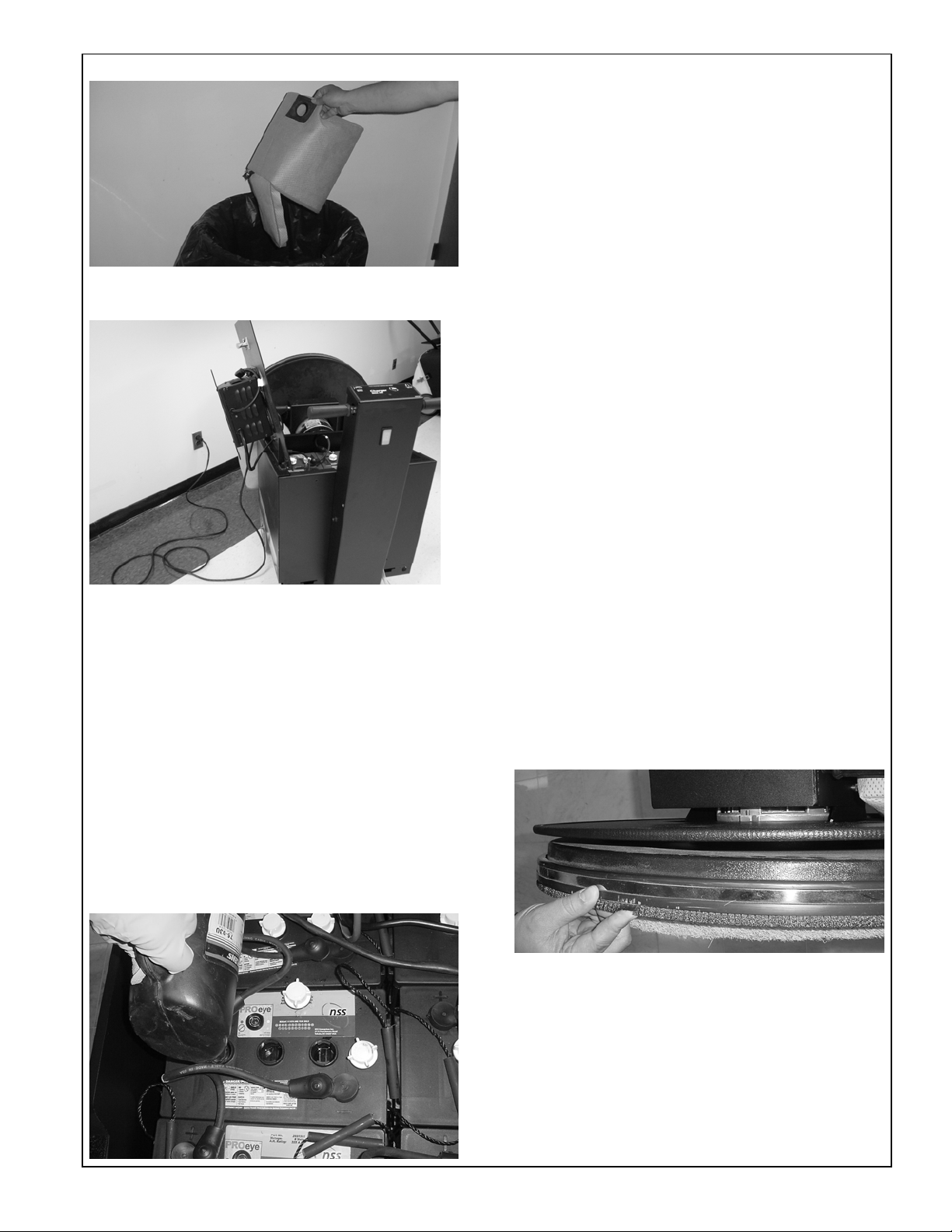

Now that the machine is unpacked remember to

recycle all packing materials.

Inspect the machine for damage or missing

components. If damage is found, contact the

freight company to file a freight claim.

MACHINE OPERATION

General Information

This machine works best with dry polishing or

burnishing. Use mop on restorers rather than spray

buff systems to restore the shine.

Spray buffing is time consuming and uses more pads

because they become loaded with floor finish, which

can cause overloading of the machine’s control

system.

Quick Start

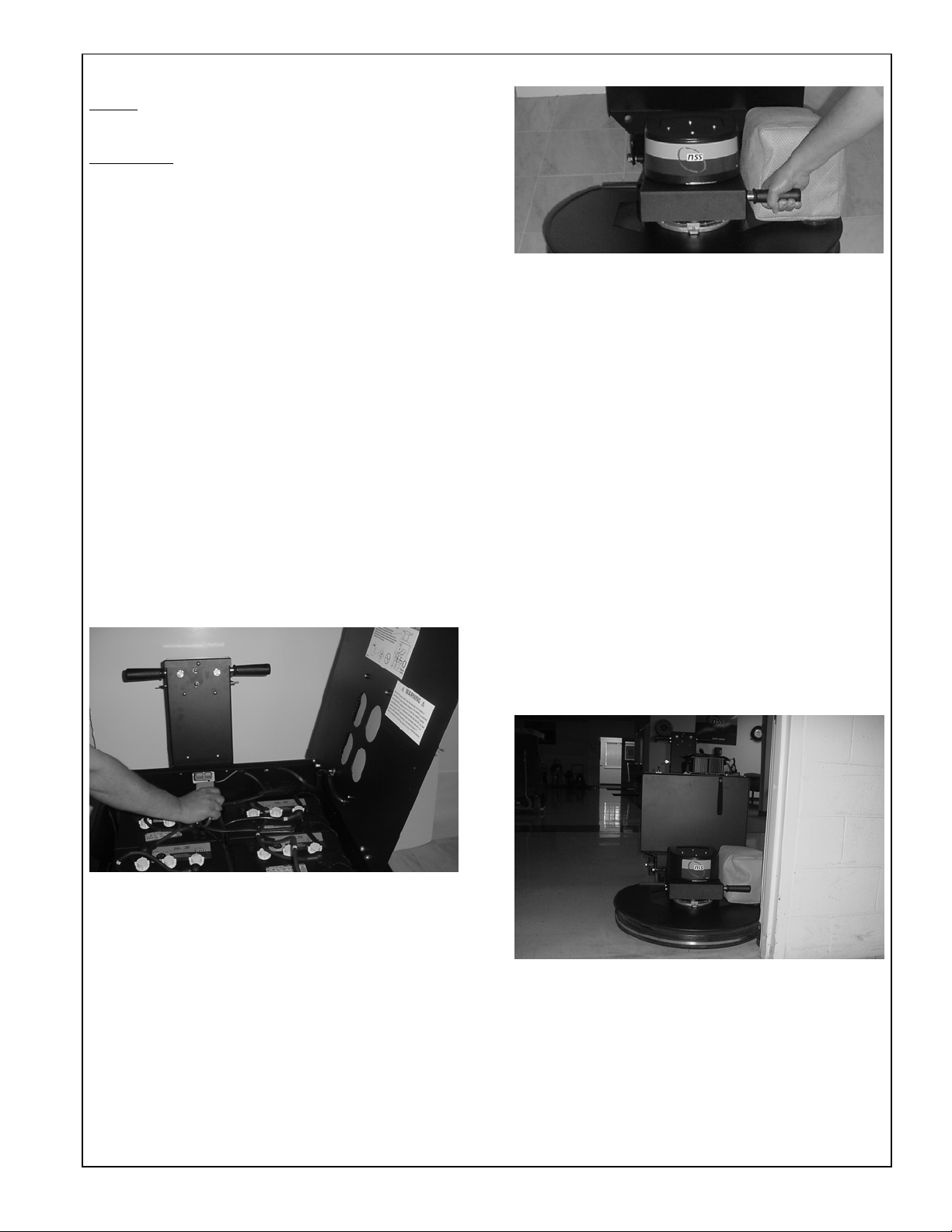

Connecting Battery Pack to Machine

Move the front of the machine from/to pad

changing position or operating position by grasping

the handle and moving it to the desired position.

Turn on master switch (and key switch if so

equipped). Wait until you hear a click, the machine

is now on. See Machine Components for more

information.

Check that the battery meter is reading in the high

or green range. The machine should be put on

charge if not in the high range. See Charging

Instructions later in this manual.

Turn on brush switch. See Machine Components

for more information.

Twist the handle grips forward (away from you) to

activate the Pad and Drive Motors. To move

backward twist the handle grips backward (toward

you). See Machine Components for more

information.

CAUTION: This Machine must be moving at all

times when the pad is rotating or the floor may be

damaged.

Transporting the Machine to Work Site

When the machine is shipped with batteries, the

machine will arrive with the battery pack

disconnected from the machine.

Lift up on the handle on the top cover to expose the

battery pack.

Connect the cable with the Anderson connector

into the Anderson connector mounted to the

machine at the rear of the battery compartment in

front of the control column.

For machines shipped without batteries

See Battery Installation in the Maintenance Section

later in this manual.

NSS recommends transporting the machine to the

work site with the front of the machine in the

operating position and the brush switch in the off

position. This will reduce the potential of damage to

the Flexiwall Shield and Pad Driver when moving

through stock/storage rooms and double swinging

doors.

For questions and all information pertaining to

this machine read the rest of this manual.

MACHINE COMPONENTS

Operator Control Column

The operator control column is located at the rear of

the machine. This column has components that

control various machine functions.

Drive System Control

At the top on both sides of the control column are

two (2) rubber twist grips. These grips rotate

forward and backward to control the direction and

speed of the machine.

They also activate the Brush Motor so it is only on

when the machine is moving. The farther the grips

are rotated, the faster the machine will move.

These twist grips have a safety feature that returns

the machine to the neutral position when the

handles are released.

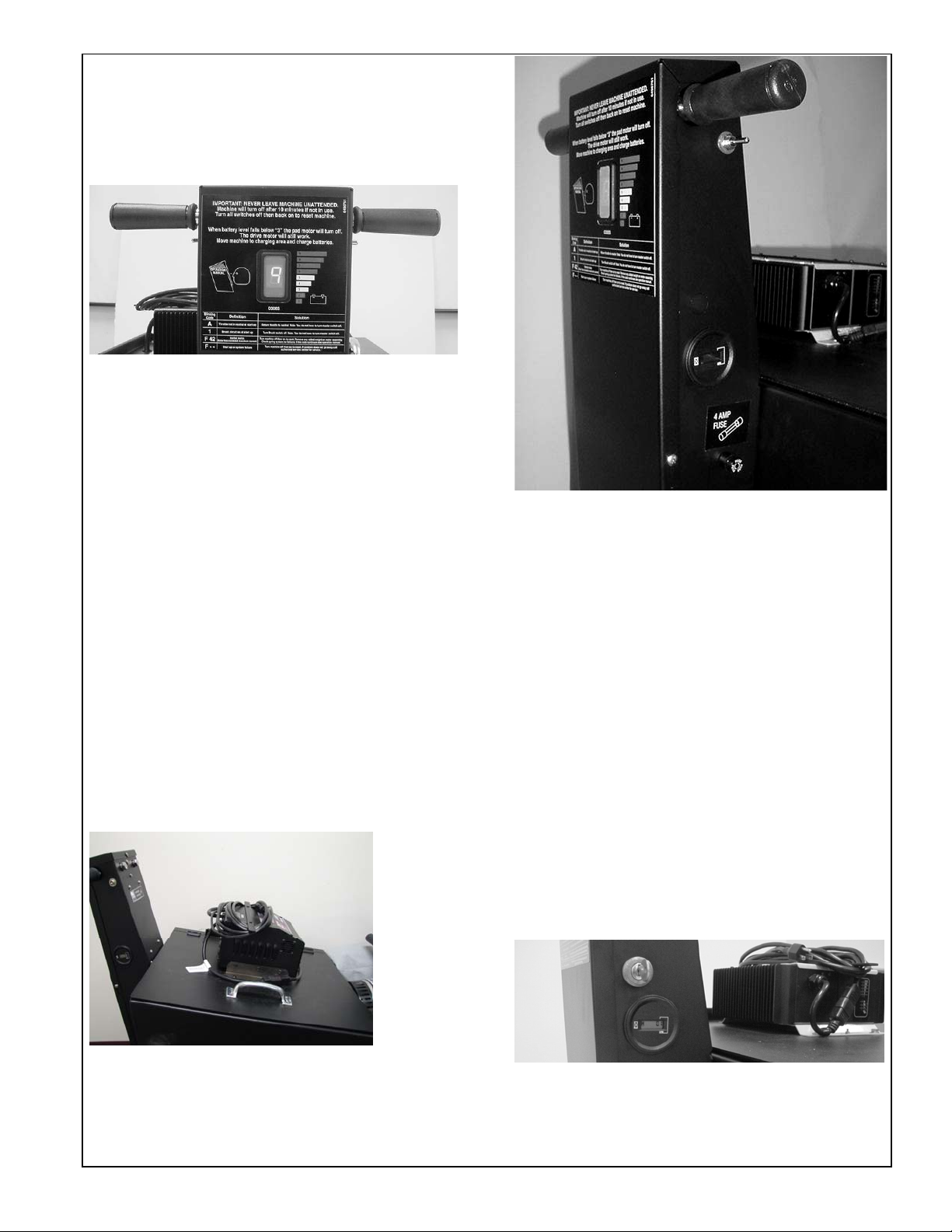

Battery Meter

The battery meter is located in the back of the control

column cover and has two uses. It shows the state of

charge of batteries during operation and flashes fault

codes when there is a problem with the machine.

The rate of charge is indicated by numbers. The

higher the number the greater the charge in the

battery pack.

When there is a fault with the machine, the Battery

Meter will flash an “F” followed by a number.

See Trouble Shooting Chart for more

information.

Battery Charger

Master Switch

The master switch is located on the top right side

of the control column and it turns the machine on

and off.

If the brush switch is on and the brush head is

down or the twist grips are not in the neutral

position the machine will not turn on. A flashing

fault code will appear on the battery meter. See the

bottom of the decal on control column cover and

correct the problem.

The control system will automatically turn the

machine off if it sets idle for 10 minutes. Turned off

the master and brush switch and then turn the

master switch back on to restart.

Hour Meter

The hour meter is located under the Master Switch

and counts the hours the brush motor is on. The

hour meter is used for indicating maintenance

intervals. The hour meter cannot be reset.

See maintenance section for maintenance

intervals.

Fuse Holder

The fuse holder is located under the Hour Meter. It

houses a 2 AMP fuse.

The battery charger is located on top of the battery

box cover.

This high efficiency battery charger is designed for

onboard operation.

Key Switch

A Key Switch is Optional and will be located above

the hour meter when installed. The key switch and

master switch will both need to be used to turn the

machine on and off.

MAINTENANCE

ALWAYS turn OFF all machine switches

before performing any maintenance or

repairs to any equipment.

Check the tension of the Drive Chain after the

first 100 hrs of use and then every 90 days or 300

hours as needed. For the chain tightening

instructions see the maintenance section called

90 Day Maintenance (300 Hours).

Daily Maintenance

Never leave the machine sit with a used pad

installed. This can cause the pad driver to warp.

Pad Installation / Changing

Brush Switch

The brush switch is located on the left side of the

control column and it turns the brush on and off.

There is also a tilt switch in this circuit located

under the brush head that only allows the brush to

be turned on when the brush head is in the

operating position.

Circuit Breaker

There is one master circuit breaker located below

the brush switch on the control column.

Brush Head

The brush motor, Filter Bag and Flexiwall shield

are located at the front of the machine.

The bag connects directly to the Flexiwall shield

and has a snap that retains the rear of the bag.

There is a wide range of pads available for many

different burnishing applications. Consult your local

NSS authorized distributor for application

recommendations.

Lift the front of the machine up to the 90-degree

position to view the pad driver and pad.

Make sure that the correct pad (7/8" to 1" [22mm to

25.4mm]) X 27" [68.6 cm] is being installed.

Place the pad flat on the floor, and remove the

center hole of the pad, step on the center of the

pad to compress the edges around the center hole.

This allows for easier installation of the pad

centering cup.

With the machine in the pad changing position,

carefully center the pad on the driver.

Caution: Pads must be installed concentric (evenly

aligned) with the outside edge of the pad driver.

Failure to follow these precautions will cause

excessive machine vibration, a reduction in pad life

and produce unsatisfactory burnishing results.

Place the pad grabber in the center hole of the

pad.

Holding the pad driver and pad, push on the pad

grabber until the spring clip has clicked twice.

Caution: Failure to install the pad grabber tightly

may allow the pad to be thrown from the driver.

Daily Maintenance (continued)

Empty the filter bag daily or when it is

approximately one-half (1/2) full.

Charging Batteries

Recharge the batteries when indicated by the

Battery Meter.

Never let the batteries sit overnight after the

machine has been run for 1hr or more since last

recharge.

NEVER let the electrolyte level fall below the tops

of the plates. This will damage the batteries

immediately, and void the warranty.

Check charger cord for exposed wires and

damaged plugs before using.

To recharge the batteries plug the charger cord into

the charger located on top of the machine and then

into an electrical outlet.

When the cord is plugged into an outlet the

machine will automatically become disabled.

Charge the batteries with the cover open when

possible to reduce heat build up in the batteries.

See charging instructions for more details.

ALWAYS wear eye protection, rubber gloves and

protective clothing to avoid contact with battery

acid when working around batteries.

After charging batteries check the water level of

each battery cell and add distilled water as

required to level specified by battery manufacturer.

Check and verify that all battery connections are

clean and tight.

Wipe machine down with a damp cloth.

NEVER spray this machine with water or any

liquids.

ALWAYS Check the tilt switch for proper

operation. With the master switch turned off, put

the brush head into the pad change position. Turn

the brush switch on then the master switch on, the

machine should turn on.

If the machine does not turn on and the battery

meter is flashing a one, the tilt switch has failed.

DO NOT use the machine until the tilt switch has

been replaced.

Opportunity Charging

Opportunity charging is charging the batteries when

an opportunity presents itself, such as during breaks,

and is done in addition to a full charge cycle.

Opportunity charging is recommended, as this extra

charging time will help raise the operating voltage of

the batteries, and will help ensure maximum runtime

and cycle life.

See Monthly Maintenance and Operating Battery

Charger Instructions for equalizing your batteries

especially if you have been opportunity charging

your machine.

Weekly Maintenance (Every 25 Hrs)

Verify all daily maintenance has been performed.

Inspect the Flexiwall Shield for dents around the

outside edge and cracks in the plastic.

Check that the Brush and Retaining Band are

properly installed.

Remove dirt build up on the brush along the

bottom of the Flexiwall Shield.

A damaged Flexiwall Shield Assembly will greatly

reduce dust control capabilities of the machine.

Monthly Maintenance

(Every 100 Hrs)

Verify that all daily and weekly maintenance has

been performed.

Equalize your batteries (Flooded only).

The batteries should be equalized once every 30

days for maximum battery runtime and life.

To equalize the batteries:

Plug in the charger, and fully charge the batteries

(until the green 100% LED is on continuously).

Unplug the charger from the wall outlet, then plug it

back in.

The charger will run for 2hrs, holding the batteries

at a constant voltage, and equalizing each cell.

THIS STEP IS ESPECIALLY IMPORTANT IF YOU

PRACTICE OPPORTUNITY CHARGING.

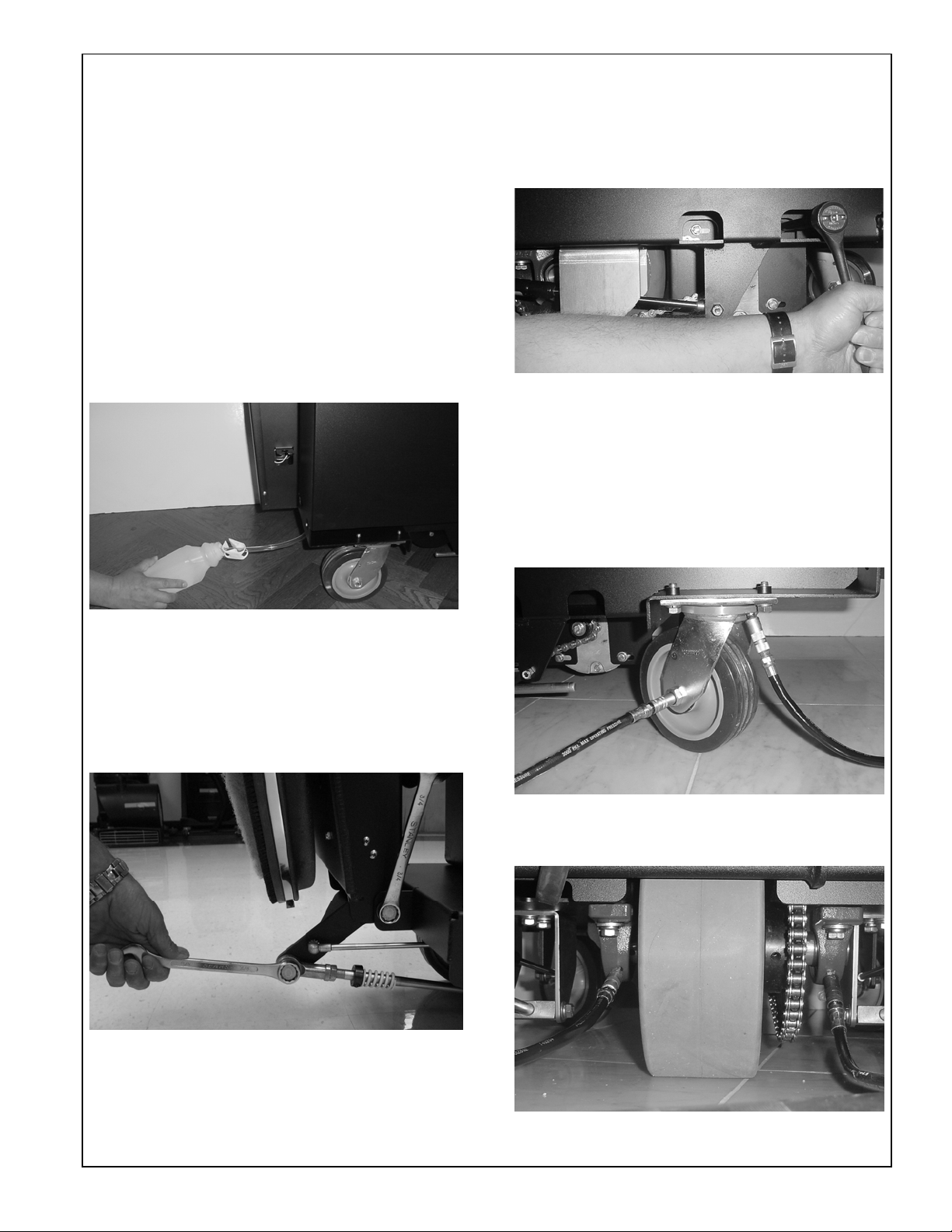

90 Day Maintenance

(Every 300 Hrs)

Verify that all daily, weekly and monthly

maintenance has been performed.

Tighten Chain

Check the tension on the drive motor chain. If the

chain has more than ½” [12.7mm] deflection,

tighten as needed.

Access to the bolts for the drive motor are on the

left side of the machine. There are two bolts on top

which are accessed through the holes as shown in

the picture above. There are also two bolts located

below the frame. A total of four bolts.

Lubrication

Check the Battery Tray Drain Hose for liquid level

on a monthly basis.

Spilled liquids from the battery compartment area

are collected in a tray under the batteries. The tray

can be drained using the hose at the right rear of

the machine as shown above.

IMPORTANT: Drain all liquids into an approved

container and dispose of according to your local

and federal regulations.

Inspect the machine components for wear, loose

fasteners, or damage. Pay special attention to all

pivot points and moving parts.

Call an authorized NSS service center for repairs.

Lubricate the casters with an industrial grade

bearing grease. Failure to lubricate casters will

cause the machine to maneuver with difficulty and

premature failure of the caster will result.

Lubricate the drive wheel bearings with an

industrial grade bearing grease. The zerk fittings

y

on the bearings can be accessed from the front of

the machine.

Failure to lubricate drive wheel bearings will cause

the machine to maneuver with difficulty and

premature failure of the bearings will result.

Every 6 Months (Every 600 Hours)

Call your Authorized NSS Distributor / Service

Station to have the following services performed.

Verify that all daily, weekly, monthly and quarterly

maintenance has been performed.

Inspect Brush Motor carbon brushes for wear.

Lube the drive motor chain with a small amount of

grease using a brush. A chain spray can also be

used.

NEVER use your fingers to put the lube on the

chain. Serious injury may occur.

Lubricate all moving parts as required with a small

amount of grease.

DO NOT lubricate the Gas Spring shaft, it does not

require lubrication as it is self lubricating.

Using compressed air, blow the accumulated

carbon brush dust out of the motor.

Replace carbon brush when they measure ½”

[12.7mm] or less in length.

Failure to replace carbon brushes will cause poor

machine performance and possible motor damage.

Check the condition of the batteries.

A battery may be checked using a Hydrometer to

check the specific gravity (strength) of the acid in

each cell. Variations in readings occur due to the

chemical reaction taking place during use.

Always check the specific gravity when the battery

is fully charged.

Replace batteries as needed.

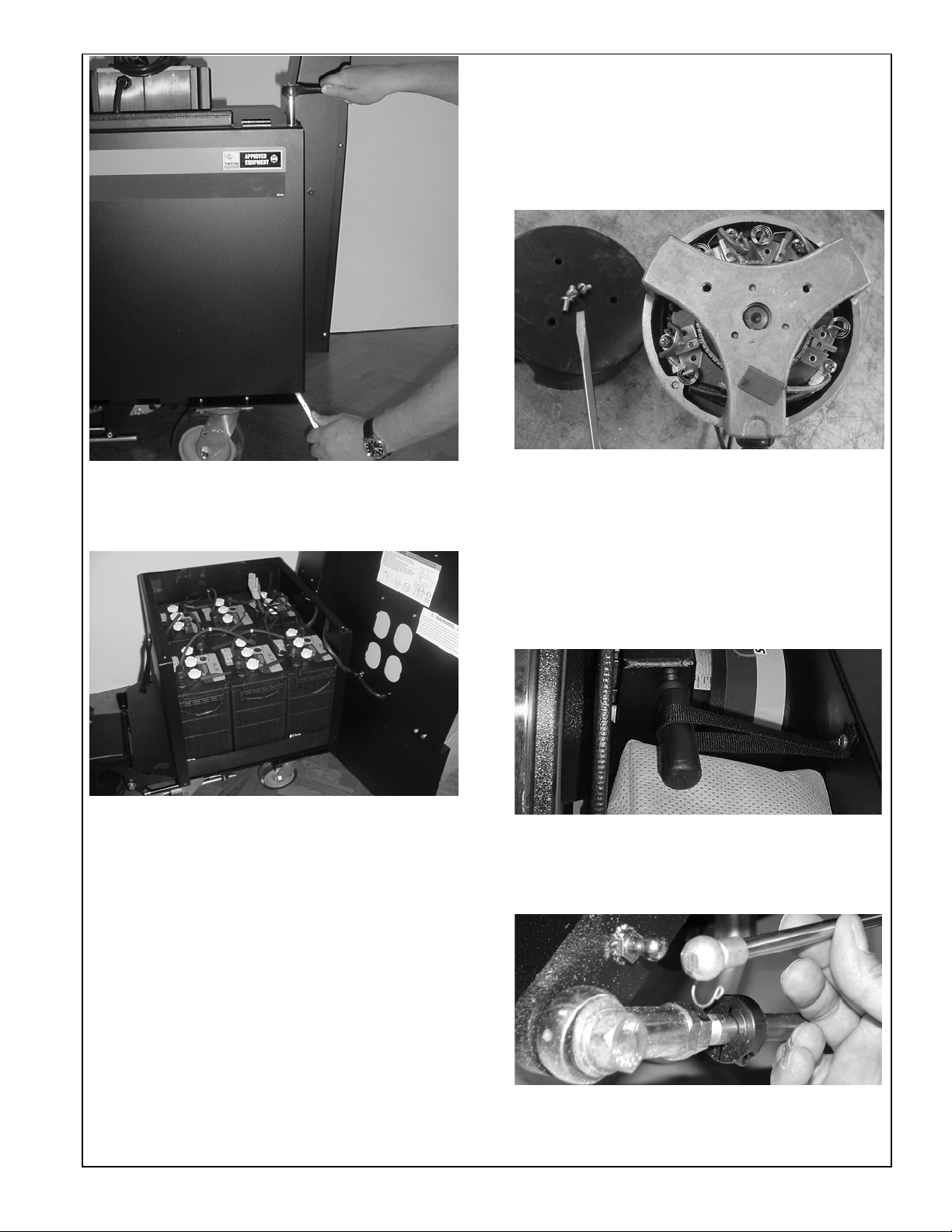

Battery Installation:

Turn off all switches. Disconnect battery pack from

the machine.

ALWAYS wear eye protection, rubber gloves and

protective clothing to avoid contact with battery

acid when installing batteries. See Battery

Warnings on page 3.

Repairs performed by an unauthorized company will void the machine warranty.

If

ou require assistance finding an authorized service center, contact NSS Enterprises.

Every 12 Months

(Every 1200 Hours)

Call your Authorized NSS distributor / Service

Station to have the following services performed.

Verify that all daily, weekly, monthly and quarterly

maintenance has been performed.

Inspect Drive Motor carbon brushes for wear.

Remove the side panel and top cover. There are

two bolts (one in each corner) on top of the side

panel and two nuts (one in each corner) at the

bottom of the cover. Note that the nuts at the

bottom are not visible from the side.

The cover will still be attached to the side panel.

Move them out of the way to install the Batteries.

Batteries are heavy – ALWAYS use two people to

install batteries into machine.

Refer to wiring diagram located on the under side

of the cover. Align batteries in compartment the

same as the old batteries or as shown on diagram.

Install battery cables the same as they were on the

old batteries or as shown on wiring diagram

located on the under side of the cover.

NSS recommends replacing the battery cables

when replacing batteries.

Tighten bolts and hex nuts with a wrench.

Install terminal boots over terminals to complete

installation.

CAUTION: Do not short across two terminals with a

wrench.

CAUTION: Loose or improper battery connections

will cause battery or machine damage and possible

personal injury.

This will require removing the drive motor from the

machine and should only be done by an authorized

NSS Service Station.

Using compressed air, blow the accumulated

carbon brush dust out of the motor.

Replace carbon brush when they measure ½”

[12.7mm] or less in length.

Failure to replace carbon brushes will cause poor

machine performance and possible motor damage.

Gas Spring Service

ALWAYS secure Brush Head in the pad change

position using the strap provided before

attempting any maintenance or repairs to the gas

spring or coil spring assemblies.

Remove the spring clip that secures the gas spring

to the machine. Then pull the gas spring off of the

ball stud. There is a clip and ball stud at each end.

Place one end of the gas spring against a hard

surface and push on it. If you can compress it, it

must be replaced. If you can not compress it, it is

most likely OK.

Pad Pressure Adjustment

The NSS Charger 2717 DB and Charger 2022 DB

is preset at the factory for medium duty

applications. It can be tuned to your specific

application for optimum performance.

ONLY an authorized NSS Service Station should

perform this adjustment.

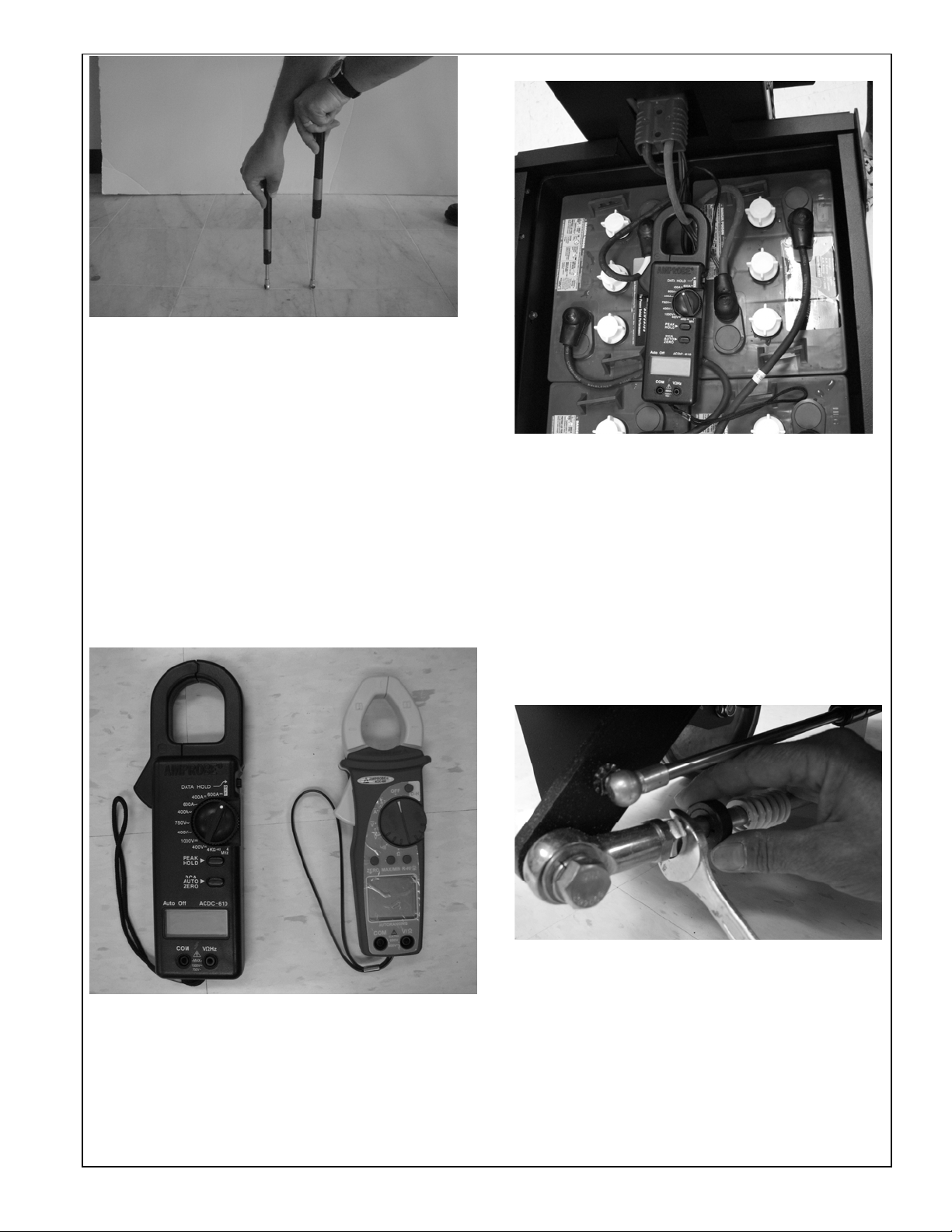

Tools required for Pad pressure adjustment

1) ¾ open end wrench

2) Clamp on Amp Meter

Checking the Pad Motor Amperage

First install a new pad on the pad driver. Caution:

Checking the Amps with a used pad will cause the

machine to have high amps when a new pad is

installed.

Lower the Pad Motor into the operating position

and open the cover over the battery compartment.

Put the clamp on AMP Meter around the red

(positive) wire coming from the battery pack to the

machine as shown.

While running the machine read the amp meter.

The amp meter should be reading between 70-80

amps for the Charger 2717 DB & 50-70 amps for

the Charger 2022 DB.

Pad Pressure Adjustment

It is necessary to use a clamp on AMP Meter when

adjusting the pad pressure.

There are many different manufactures and

models of AMP Meters to choose from. Two AMP

Meters are shown above. The one on the left is

AMPROBE Model ACDC-610 and the one on the

left is AMPROBE Model ACDC-400.

If adjustment is required, follow these

instructions.

It will be easier to access the lock nut and spring

guide rod assembly with the machine in the pad

change position.

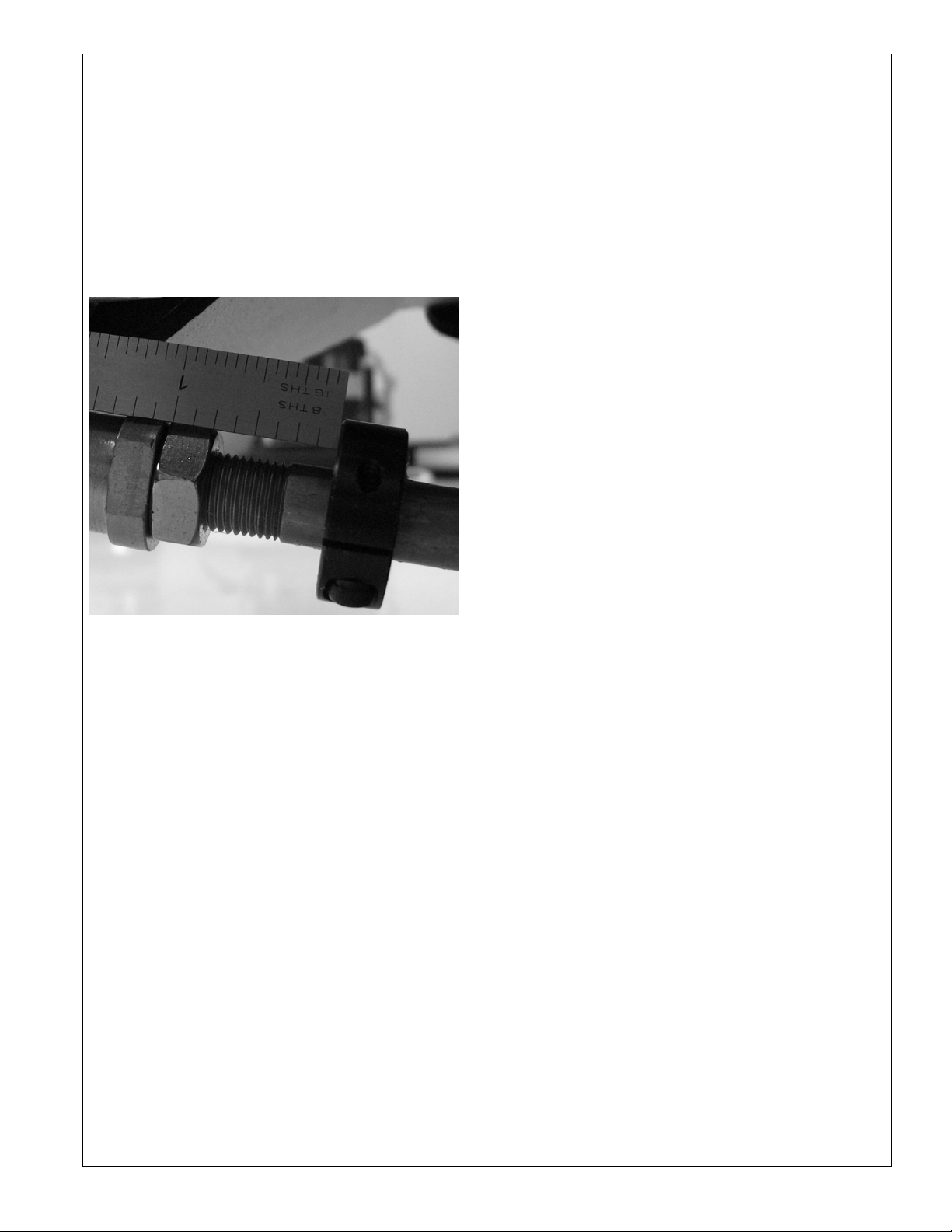

First loosen the lock nut on the spring guide. With

the lock nut loose, the spring guide rod assembly

will be easily turned by grasping the set collar on

the spring guide rod.

Turn the spring rod guide assembly ½ to 1 turn at a

time. A little adjustment goes a long way.

Thread the spring guide rod assembly out of the

ball joint to decrease the pad pressure. Thread the

spring guide rod assembly into the ball joint to

increase the pad pressure.

Every time an adjustment is made check the amps.

This may require a few tries to get it were it should

be.

After the adjustment is made tighten the lock nut

and redo the amp test. If it has not changed the

process is complete.

Fall back setting

If your machine has come totally out of adjustment, or

you need to replace the Spring Rod Guide Assembly

you may need to start from the beginning.

The factory starting setting for the pad pressure on

the Charger 2717 DB is 3/4 of an inch [19mm] from

the set collar to the lock nut.

The factory starting setting for the pad pressure on

the Charger 2022 DB is 1/2 of an inch [12.7mm]

from the set collar to the lock nut.

From this setting, proceed with the Pad Pressure

Adjusted.

Battery Replacement Notes

Entire Pack.

oIt is always recommended to replace all batteries

in the pack at the same time.

One or more batteries out of the pack. This is not

recommended. Replacing just one or two batteries

out of the pack can lead to the following:

Overcharging the new, or the remaining

original, batteries.

Undercharging the new, or remaining

original, batteries.

Over discharging either the new or the

remaining original batteries.

o If you wish to only replace some of the batteries

in the pack, follow these steps for best results:

Replacement batteries must always be of the

same battery manufacturer, model and amphour rating, as the remaining batteries in the

pack.

Never mix batteries from different

manufacturers in the same pack.

Fully charge both the new battery, and the

remaining original batteries. (specific gravity

= 1.265 minimum, use a hydrometer)

Use a replacement battery that is close to the

same age as the remaining original ones.

Do not run the machine as long for about 20

cycles. For example, if you used to get 4 hrs

runtime, only run it for 2.5 hrs, and then

charge the batteries completely.

Opportunity charge whenever possible.

Equalize after 30 days (Flooded only).

The above steps will provide the best

opportunity for the new battery(s) to join the

pack.

Battery Do’s and Don’ts:

a. You do not have to fully discharge the batteries

before charging. They do not have a “memory”.

b. Plug the charger in anytime the machine is not in

use.

c. NEVER let the electrolyte level fall below the tops

of the plates (flooded cell batteries). This will

damage your batteries almost immediately, and

void the battery warranty. They can tell if this

happened.

d. NEVER refill the batteries with well or tap water

(flooded cell batteries).

e. NEVER overfill the batteries (flooded cell

batteries).

f. NEVER let the batteries sit discharged overnight

(or between shifts).

g. ALWAYS check the electrolyte level about every 3

or 4 charge/discharge cycles BEFORE

CHARGING.

h. ALWAYS refill the batteries with distilled water (if

needed) AFTER CHARGING.

i. ALWAYS fully recharge the batteries after use

(until the green LED comes on).

j. ALWAYS equalize the batteries (Flooded only)

every 30 days.

k. NEVER OVER DISCHARGE!

l. NEVER charge GEL batteries with the charger set

to FLOODED/AGM.

m. NEVER charge FLOODED/AGM batteries with the

charger set to GEL. EXCEPTION-CROWN AND

TROJAN AGM’S TO BE CHARGED WITH GEL

SETTING.

Battery charger

The onboard battery charger supplied with this

machine is capable of charging lead acid batteries

from 185 to 350ah capacity. There is no need to

change algorithms or settings based on battery

manufacturer, or battery size.

The charger can also be set to charge flooded (wet)

cell, AGM, or Gel batteries. LED’s on the charger

indicate which type of battery the charger is set to

charge. One setting is for Flooded and (most) AGM

batteries, the other setting is only for Crown and

Trojan AGM and GEL batteries.

Depending on the battery charger model, the charger

can operate on 100/115/230 VAC 1ph 50/60 HZ

power, and will automatically detect these input

voltages. Before connecting the battery charger to

power, check the label on the battery charger to

verify proper input power.

Determining Your Battery Type

CAUTION: DIFFERENT BATTERY TYPES HAVE

DIFFERENT CHARGING REQUIREMENTS.

FAILURE TO PROPERLY IDENTIFY YOUR

BATTERY TYPE, AND SET THE CHARGER

ACCORDINGLY WILL RESULT IN BATTERY

DAMAGE, AND VOID THE WARRANTY.

Your machine may have been ordered with batteries

installed at the NSS factory. The standard battery

type, normally supplied by NSS, is the Flooded (wet)

cell lead acid battery. Gel and AGM sealed batteries

may also be available at customer request.

Flooded (wet) batteries can be easily identified by the

removable cell caps. Removing the caps allows

inspection of the liquid electrolyte (sulfuric acid) level

in each cell.

AGM (Absorbed Glass Mat) batteries are sealed,

maintenance free batteries. They do not have cell

caps intended for removal. Look for “AGM” printed

on the tops or sides of the batteries.

Gel (gelled electrolyte) batteries are also sealed,

maintenance free batteries. They do not have cell

caps intended for removal. Look for “GEL” printed

on the tops or sides of the batteries.

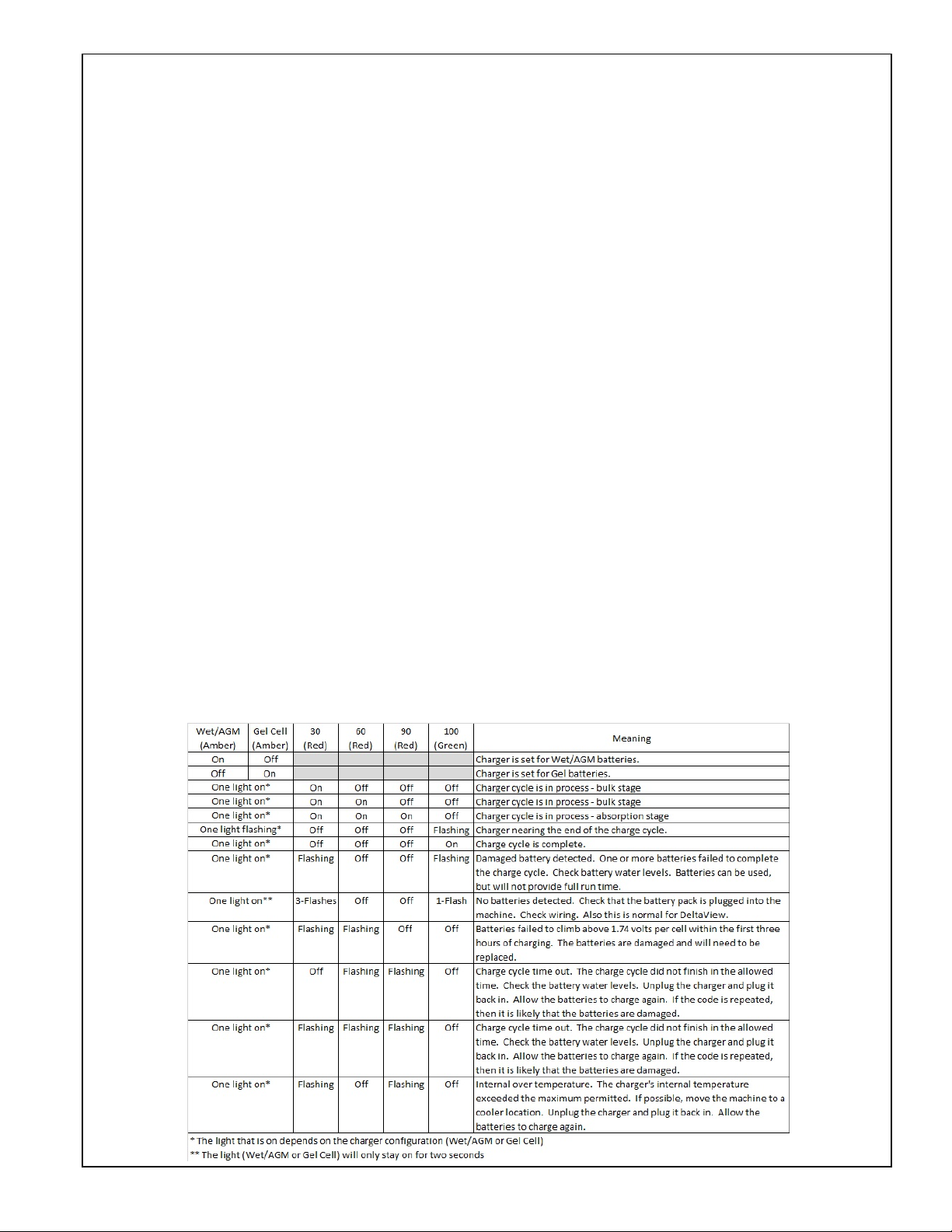

Battery Charger Indicator LED’s

Your battery charger is equipped with LEDs that

indicate the following:

Battery Type Setting. Either of these two LEDs will

be illuminated, anytime the charger is plugged in,

to signal which type(s) of batteries the charger is

configured to charge. The two options available

are:

oWet / AGM: When this LED is illuminated, the

charger is configured to charge either flooded

(wet), or AGM batteries.

oGel Cell. When this LED is illuminated, the

charger is configured to charge Gel batteries

ONLY. EXCEPTION: Crown and Trojan

AGMs are to be charged with the Gel

setting.

State of Charge Indicators. Four additional LEDs

provide information about the charge level of the

batteries during charging.

o30%, 60%, 90% and 100%.

Fault Indications. During charging, the charger

provides feedback about the charge process and

any problems detected. It will provide feedback

and signal the type of problem by flashing LEDs as

described below:

Changing the Battery Type Setting

The standard setting for the onboard battery charger

is Flooded/AGM. EXCEPTION: If your machine was

ordered from NSS equipped with Crown AGM or Gel

batteries, then the charger was configured for Gel

batteries at the factory.

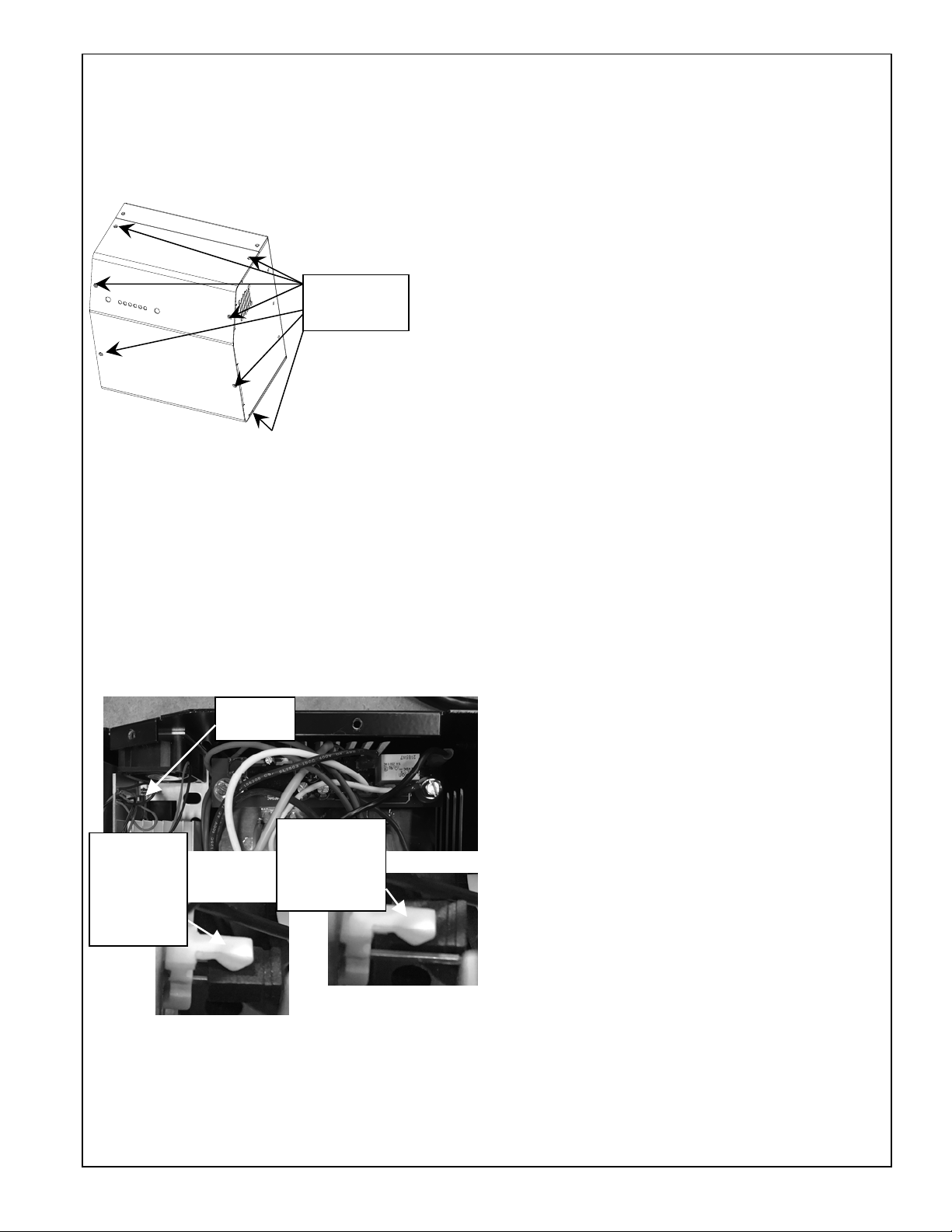

Configuring the Charger for Gel batteries:

Top cover

screws

1. Remove the top cover.

2. Pull the jumper off the 2-pin connector (position 1),

and then move the jumper to position 2 on only

one pin of the 2-pin connector. See photo below.

3. Reinstall the top cover.

1. The green wire outputs a battery voltage when

the charger is not plugged in to AC to provide an

Interlock function.

2. Securely fasten the black ring terminal from the

charger to the negative terminal ("-", "NEG",

NEGATIVE") of the battery pack.

3. Select Charge Algorithm if battery type is other

than factory default.

Jumper

Location

Position 1

For Wet

Cell

(Default)

(Jumper on

both pins)

Position 2

For Gel Cell

(Jumper on 1

Pin of 2-Pin

Connector)

Configure the Charger for Flooded/AGM batteries

1. Remove the top cover

2. Pull the jumper from the 2-pin connector, and

install the jumper at position 1 (on both pins of 2pin connector).

3. Reinstall the top cover.

Operating the Battery Charger

CAUTION: DIFFERENT BATTERY TYPES HAVE

DIFFERENT CHARGING REQUIREMENTS.

FAILURE TO PROPERLY IDENTIFY YOUR

BATTERY TYPE AND SET THE CHARGER

ACCORDINGLY WILL RESULT IN BATTERY

DAMAGE, AND VOID THE WARRANTY.

The battery charger is fully automatic. Simply plug

the charger into a suitable wall outlet, and the

charger will charge the batteries. The green 100%

LED will be continuously illuminated when the charge

cycle is complete.

A bubbling, or boiling sound coming from the

batteries during the last few hours of the charge is

normal. The batteries may be warm, but not too hot

to touch.

The charger will maintain the proper battery voltage

as long as it is plugged in (maintenance mode).

Equalizing the batteries (Flooded only)

The batteries should be equalized once every 30

days for maximum battery runtime and life.

To equalize the batteries:

Plug in the charger, and fully charge the batteries

(until the green 100% LED is on continuously).

Unplug the charger from the wall outlet, then plug it

back in.

The charger will run for 2hrs, holding the batteries at

a constant voltage, and equalizing each cell.

Opportunity Charging

Opportunity charging is charging the batteries when

an opportunity presents itself, such as during breaks,

and is done in addition to a full charge cycle.

Opportunity charging is recommended, as this extra

charging time will help raise the operating voltage of

the batteries, and will help ensure maximum runtime

and cycle life.

See Operating Battery Charger Instructions or

Monthly Maintenance for equalizing your

batteries especially if you have been opportunity

charging your machine.

Notes on LED indications per DoE compliance:

When first connected to DC (AC not connected), the

LEDs will display one or more of the following:

The LEDs will flash the charger’s ID code (this is for

PCS internal use only). Once the LEDs flash the ID,

they will only display one yellow LED. This

configuration will remain until AC is detected and a

charge cycle is in progress.

There is also a possibility the LEDs will not flash

their ID code and only show a yellow LED.

Lastly, the LEDs may not flash their ID code and

may not show any LEDs until AC is detected.

If the AC line and neutral wires are reversed, the unit

will wait 2 minutes before starting a charge. NOTE:

The 2-minute wait period will also be a factor if the

charger is being powered by anything other than

normal grid AC such as a conventional generator,

inverter, etc.

If the AC plug is disconnected during charge, the unit

will turn off as expected. The user may hear some

clicking noise, but should not be alarmed. This is the

Powered by Battery/DOE functionality checking for

AC connection.

How to read charging data from a battery charger

equipped with DeltaView® Link

DeltaView Link

DeltaView Link is a system that allows you to read

data from your battery charger using an app on your

smartphone. The battery charger transmits data to

your phone’s Bluetooth receiver.

These instructions apply to Dual Pro battery chargers

manufactured after 11/29/16. The manufacturing

date is located on the barcode tag attached to the

pigtail cord coming out of the charger. This battery

charger is found on Champ Rider Scrubbers,

Wrangler 3330, Wrangler 2730, Wrangler 2625,

some Wrangler 2016 models, and Charger battery

burnishers.

Instructions

Step 1. Download the Pro Charging Systems “DeltaView

Link” app

For Apple iPhones: Go to the app store and search for

“DeltaView Link” by Pro Charging Systems, LLC.

For Android Phones: Go to the play store and search for

“DeltaView Link” by Pro Charging Systems, LLC.

Step 2. Turn on your phone’s Bluetooth function. If your

Bluetooth is off, the app will turn it on for you when it

starts. Answer “yes” when prompted to turn on

Bluetooth.

Step 3. Locate the “DeltaView Link” icon on your phone

and press it to start the app.

Step 4. A list of all battery chargers that are connected to

AC power within range of your phone will appear. Tap on

a battery charger to select it.

Step 5. Follow the app prompts to read through the data

on your charger. You will find detailed information about

the last 100 charge cycles.

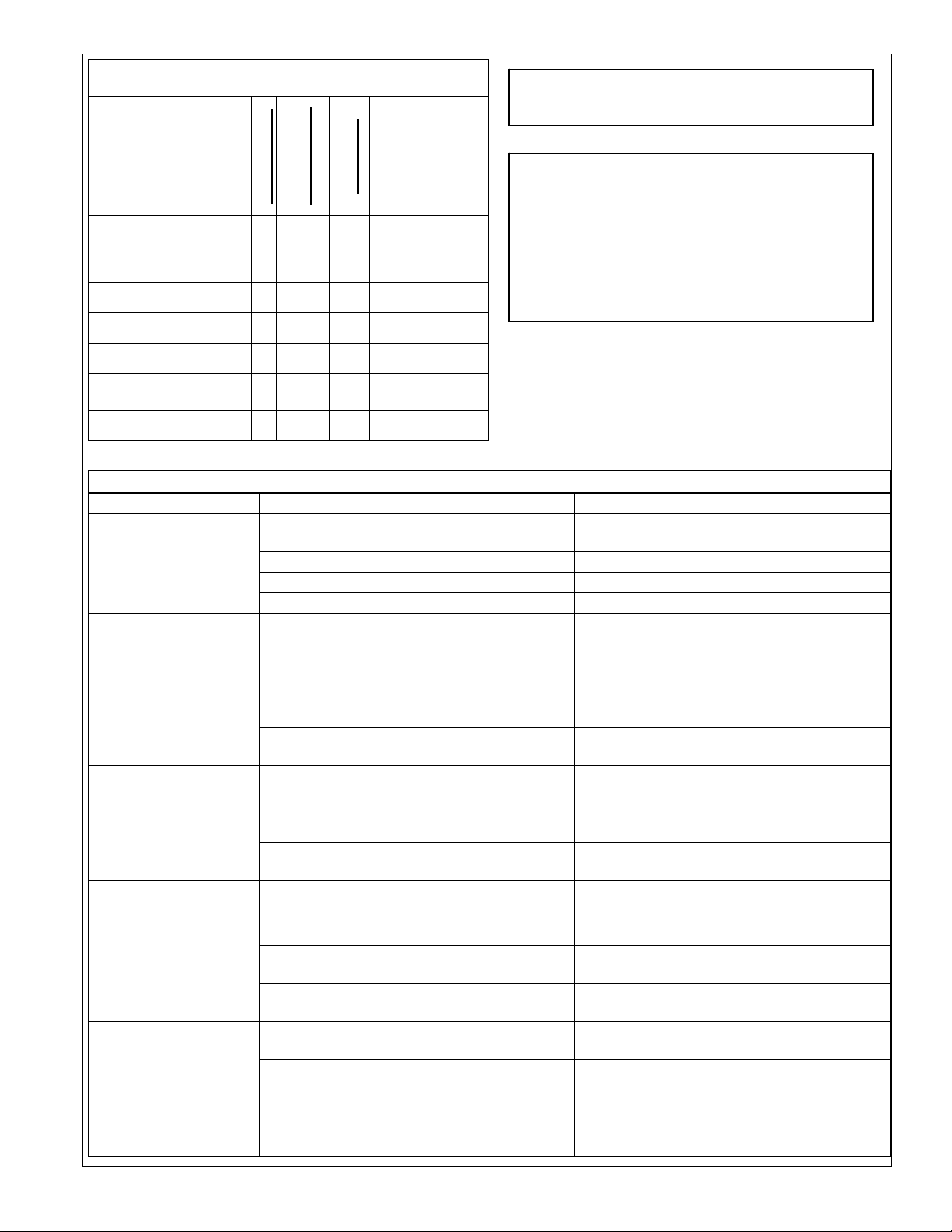

TABLE 1

BATTERY TYPES

NSS Part

Number

Crown

Part

Number

Battery Volts

System Volts

Battery Type

Setting

Amp Hour

4491061 1-1470 12 36 215 Flooded/AGM

3390361 1-1435 6

24 &

235 Flooded/AGM

36

2392111 1-1427 12 24 115 SPE CURVE 0

6393651 1-1428 12 24 130 SPE CURVE 0

2392731 1-12145 12 24 100 SPE CURVE 1

6491931 1-1437 6

24 &

36

200 GEL

2691501 1-1450 6 36 350 Flooded/AGM

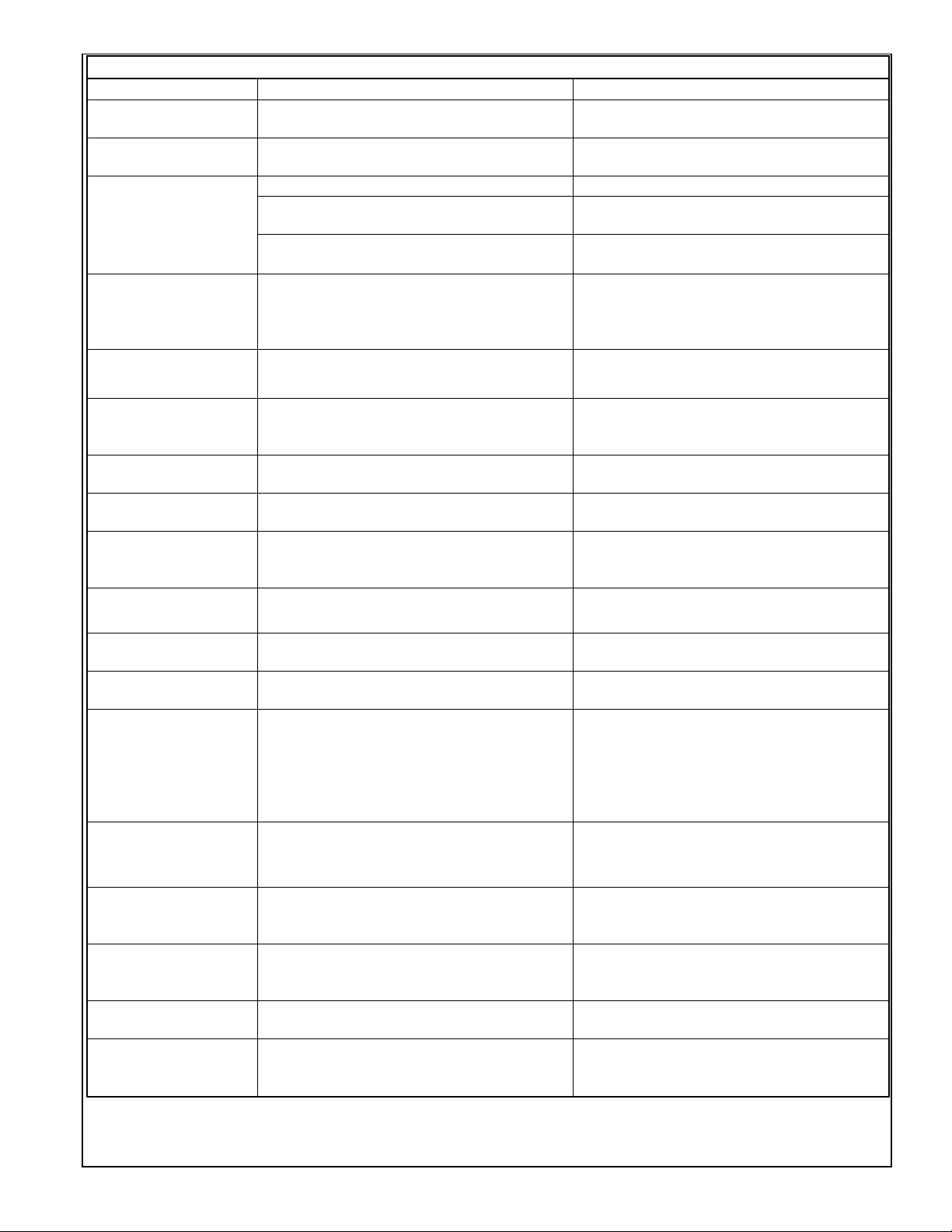

TROUBLE SHOOTING CHART

Problem Cause Solution

Battery pack is not plugged into machine.

Machine will not turn on.

Brush motor will not run

or stopped running.

Brush motor will not turn

off when handles are in

neutral position.

Machine vibrates.

Run time is less than

when new.

Battery charger will not

turn on.

Battery charger is plugged into AC outlet. Unplug the battery charger.

The 2-amp fuse is missing or blown. Replace 2-amp fuse.

Circuit breaker is tripped. Reset circuit breaker.

Current over load of brush motor has exceeded

set parameters in control system.

Tilt switch failure.

Carbon Brushes worn or not making contact.

The potentiometer is set on the threshold of

neutral or potentiometer has failed.

Pad not centered or torn. Center pad. Change torn and worn pad.

Pad driver damaged and/or out of balance.

Damaged or defective battery or battery pack.

Batteries are not fully charged

Incorrect Battery Type Setting on the charger

Battery charger cord damaged.

Connection not made between battery charger

and battery pack.

The battery charger is damaged.

NOTE: Crown and Trojan AGM batteries should

be charged with the GEL setting.

The charger has been tested on batteries from

the following manufacturers:

Trojan flooded cell

US Battery flooded cell

Deka flooded cell

Crown gel

Concord gel

Discover AGM

Open the battery cover and plug the battery

pack into the machine.

Turn off all switches and then turn on the

master switch to reset the control system. If the

problem continues check battery meter for fault

code F42.

Check tilt switch operation. Replace tilt switch if

test failed.

Have an authorized NSS Service Station check

carbon brushes and replace if necessary.

Have an authorized NSS Service Station reset

the potentiometer to neutral or replace.

Check pad driver for damage and replace if

necessary.

Check for fault codes on the battery charger

during battery charging. Have an authorized

NSS Service Station check the batteries and

replace as necessary.

Charge batteries until the green LED indicates

the charge cycle is complete.

Ensure the charger is set according to the type

of batteries installed.

Check for cord damage and replace if

necessary. DO NOT try to repair it.

Check connections at battery pack for corrosion

and loose or broken wires.

Have an authorized NSS Service Station check

and replace if necessary. DO NOT try to repair

it.

y

Problem Cause Solution

Pad will not stay in the

pad change position.

Pad will turn on in the

pad changing position.

Circuit breaker trips.

Front of machine does

not move down to the

floor when turned on.

Flashing number 1

appears in battery

meter.

Flashing letter A

appears in battery

meter.

Fault code F12 appears

in battery meter.

Fault code F23 appears

in battery meter.

Fault code F26 appears

in battery meter.

TROUBLE SHOOTING CHART CONTINUED

Weak or missing gas spring(s). Check and replace if necessary.

Tilt switch failure.

Spray Buffing. DO NOT spray buff.

Pad pressure to heavy.

Pad pressure collars out of adjustment.

Spring guides sticking in slides.

Brush motor circuit closed when machine is

turned on.

Twist grip not in neutral when master switch is

turned on. Potentiometer not set properly in

neutral position.

Internal programmable parameter data is

corrupt.

Internal temperature of controller has exceeded

the set parameters.

Precharge failure when controller is turned on or

the control system has been miswired causing

an internal controller failure.

See daily maintenance for proper checking

procedure. Replace tilt switch as necessary.

Check gas springs for failure and replace as

necessary.

Readjust pad pressure collars as required by

your burnishing conditions.

Check spring guides for proper operation.

Replace if bent. Lubricate if necessary. Loosen

bolts in spring guide mounting bracket, it will

self-align, retighten bolts.

Turn off brush switch. Check tilt switch for

proper operation.

Let go of twist grip. Have an authorized NSS

Service Station reset the potentiometer to

neutral or replace.

Turn machine off and then on. If problem

continues call for service.

Turn machine off and let control system cool off.

If problem continues call for service.

Turn machine off and then on. If problem

continues call for service.

Fault code F29 appears

in battery meter.

Fault code F32 appears

in battery meter.

Fault code F37 appears

in battery meter.

Fault code F42 appears

in battery meter.

Fault code

F44/F4C/F45/F59/F60

appears in battery

meter.

Fault code F4D/F46/F61

appears in battery

meter.

Fault code F58 appears

in battery meter.

Fault code F62 appears

in battery meter.

Fault code F63 appears

in battery meter.

Wired incorrectly. Internal control system failure.

Wired incorrectly. Internal control system failure.

Potentiometer wired incorrectly. Internal control

system failure.

The brush motor is exceeding the current limit

set in the controller.

Caused by wiring short circuit in drive wiring or

shorted drive motor.

Caused by wiring short circuit in brush wiring or

shorted brush motor.

The deceleration of the brush motor or drive

motor exceeded set parameters. Example:

Tried to slow down or stop on too steep a hill.

Wired incorrectly. Internal control system failure.

Caused by wiring short circuit in contactor

wiring or contactor coil.

Check wiring. Turn machine off and then on. If

problem continues call for service.

Check wiring. Turn machine off and then on. If

problem continues call for service.

Check wiring. Turn machine off and then on. If

problem continues call for service.

Check the gas springs for wear. Check the

brush pressure set collars for proper

adjustment. Check pad driver and Flexiwall

shield for proper installation and problems. Turn

machine off and then on. If problem continues

call for service.

Check wiring and drive motor for short circuit.

Correct problem if found. If problem continues

call authorized NSS Service Station for service.

Check wiring and brush motor for short circuit.

Correct problem if found. If problem continues

call for service.

Turn machine off and then on. If problem

continues call authorized NSS Service Station

for service.

Check wiring. Turn machine off and then on. If

problem continues call for service.

Check wiring and contactor for short circuit.

Correct problem if found. If problem continues

call for service.

Repairs performed by an unauthorized company will void the machine warranty.

If

ou require assistance finding an authorized service center, contact NSS Enterprises.

MANUEL D'UTILISATION

CHARGER 2717 DB & CHARGER 2022 DB

Translation from Original Instructions

Une Traduction Des Instructions Originales

Traducción de las Instrucciones Originales

MANUEL D'UTILISATION

CHARGER 2717 DB & CHARGER 2022 DB

CONSIGNES DE SÉCURITÉ IMPORTANTES

AVERTISSEMENT: Le non-respect de ces instructions peut causer des

blessures à l'opérateur de la machine ou des passants.

AVERTISSEMENT: Danger

d'incendie ou d'explosion. JAMAIS

utiliser cet appareil dans une

atmosphère explosive (poussière

de grain, liquides ou vapeurs

AVERTISSEMENT: Danger d'incendie ou

d'explosion.

NE JAMAIS utiliser de liquides

inflammables (gaz, kérosène, de solvants

ou diluants) pour nettoyer ou polir étage.

inflammables, etc.).

AVERTISSEMENT: Ce produit contient un produit chimique connu dans l'état de Californie pour

causer le cancer et des malformations congénitales ou autres problèmes de reproduction.

UTILISATION

NSS Polisseuses sont destinés à un usage commercial,

le polissage et le polissage étages dans un

environnement intérieur. Il n'est pas destiné à pulvériser

le brunissage.

NSS Polisseuses sont Twister approuvé.

NSS ne recommande pas l'utilisation de ces machines

à d'autres fins.

POUR LA SÉCURITÉ

TOUJOURS lire et comprendre toutes les instructions

avant d'utiliser ou d'entretenir la machine.

TOUJOURS utiliser cette machine uniquement

comme décrit dans ce manuel.

NE JAMAIS tenter de faire fonctionner cette machine,

sauf si vous avez été formé dans son fonctionnement.

NE JAMAIS laisser une personne non formée à

fonctionner cette machine.

TOUJOURS cette machine à partir du panneau de

commande arrière, pas de côté.

TOUJOURS éteindre l'interrupteur principal lors de la

fixation ou du changement des plaquettes.

NE JAMAIS tenter de faire fonctionner cette machine

si elle ne fonctionne pas correctement ou s'il a été

endommagé de quelque manière.

NE JAMAIS déconnecter ou modifier des

interrupteurs ou des dispositifs de sécurité

(disjoncteur).

NE JAMAIS laisser tomber ou insérer un objet dans

les ouvertures de la machine.

NE JAMAIS utiliser cette machine avec une

ouverture d'air bloqué. Gardez toutes les ouvertures

d'air libres de poussière, les peluches, les cheveux,

etc.

NE JAMAIS ramasser tout ce qui brûle ou qui fume,

comme des cigarettes, des allumettes ou des cendres

chaudes.

NE JAMAIS laissez cette machine pour être utilisé

comme un jouet. Une attention particulière est

TOUT SERVICE de réparation doit être effectuée par un centre DISTRIBUTEUR / SERVICE AUTORISÉ NSS

utilisant uniquement des pièces ÉQUIPEMENT ORIGINAL NSS

nécessaire lorsqu'il est utilisé par ou près des enfants.

TOUJOURS portez des chaussures de tennis propres

ou chaussures "anti-dérapant". Cuir à semelles des

chaussures deviennent extrêmement glissantes.

TOUJOURS garder le visage, les doigts, les cheveux

ou toute autre partie du corps ou des vêtements

amples loin de toute ouverture de la machine ou la

partie mobile (renouvelable pilote de la tablette).

TOUJOURS s'assurer que la rampe est fixée au

véhicule avant de charger / décharger.

TOUJOURS utiliser une extrême prudence lors de

l'utilisation de la machine sur une rampe ou de

chargement / déchargement de cette machine dans ou

hors d'un camion / remorque. Soyez extrêmement

prudent si la rampe est humide, grasse, ou recouverts

de produits chimiques de nettoyage.

NE JAMAIS arrêter ou faire tourner la machine sur

une rampe ou pente.

NE JAMAIS tenter de monter un grade ou d'utiliser

cette machine sur une rampe ou pente de plus de 20

degrés.

TOUJOURS rangez cet appareil à l'intérieur dans un

endroit frais et sec.

NE JAMAIS stationner ou remiser la machine près

d'un quai, sur des rampes, à proximité d'un four, de la

chaudière, de la flamme nue, ou de toute autre source

de chaleur élevée.

NE JAMAIS vaporisez cette machine avec de liquides.

NE JAMAIS laissez la prise de charge de la batterie à

l'humidité ou un court peut se produire.

NE JAMAIS utiliser cette machine lorsque le chargeur

est branché.

NE JAMAIS utiliser la machine à l'extérieur ou laisser

la machine à geler.

NE JAMAIS pas exposer la machine à la pluie, la

neige ou des températures extrêmes.

NE JAMAIS entreposer tous les articles sur la

machine.

CONSERVER CES INSTRUCTIONS

g

CONSIGNES DE SÉCURITÉ IMPORTANTES

ÉQUIPEMENT DE PILES avec à son bord CHARGEURS

AVERTISSEMENT: Le non-respect de ces instructions peut causer des blessures à

l'opérateur de la machine ou les spectateurs.

Lire et comprendre toutes les

instructions avant d'installer ou

de charger les batteries.

AVERTISSEMENT:

NE JAMAIS fumer, allumer une allumette ou provoquer une étincelle pendant le fonctionnement ou le chargement.

TOUJOURS char

GENERAL

TOUJOURS lire et comprendre toutes les

instructions avant d'installer ou de charger les

batteries.

NE JAMAIS tenter d'installer ou de charger les

batteries, sauf si vous avez été formé pour le faire.

NE JAMAIS laisser une personne non formée à

installer ou de charger les batteries.

TOUJOURS retirer tous les bijoux lorsque vous

travaillez sur ou près des batteries.

TOUJOURS éteindre tous les commutateurs lors de

l'installation et le service.

TOUJOURS débrancher les câbles de batterie avant

d'effectuer une réparation ou.

TOUJOURS porter des lunettes de protection, des

gants en caoutchouc et des vêtements de protection

pour éviter tout contact avec de l'acide de la batterie.

NE JAMAIS rien poser sur le dessus de piles arc

électrique peut survenir.

SI CONTACT AVEC L'ACIDE piles, suivez ces

instructions:

o PEAU - zone avec de l'eau de rinçage.

o YEUX - Rincer à l'eau pendant 15 minutes.

o INTERNE - Buvez de l'eau ou du lait. Suivez avec

du lait de magnésie, un œuf battu ou de l'huile

végétale. Appeler immédiatement un médecin.

INSTALLATION DES PILES

TOUJOURS utiliser deux personnes pour installer,

que les batteries sont lourdes.

TOUJOURS éteindre tous les interrupteurs de la

machine.

TOUJOURS batteries de position, comme indiqué sur

l'autocollant de l'installation de la machine pour

maintenir l'équilibre de la machine.

TOUJOURS raccorder piles comme indiqué sur un

autocollant à l'installation de la machine pour éviter

de court-circuiter les piles et le système électrique.

CHARGE DE LA BATTERIE

TOUJOURS lire les instructions sur le chargeur

soigneusement.

Pas de fumée, les flammes,

les étincelles ou en travaillant

avec des piles.

Les batteries dégagent de l'hydrogène, ce qui peut provoquer un incendie ou une explosion.

er dans un endroit bien ventilé à l'écart de toute flamme.

Contient de

l'acide, éviter tout

contact.

TOUJOURS utiliser le NSS fourni chargeur avec la

tension nominale correcte.

Pour les batteries au plomb-acide seulement (ne

s'applique pas à la cellule de gel ou batteries sans

entretien).

TOUJOURS vérifier pour assurer le niveau de l'eau

de la batterie couvre les plaques de la batterie avant

de la charger.

TOUJOURS vérifier le niveau d'eau après la charge

et ajouter de l'eau distillée si nécessaire pour amener

le niveau vers le bas de l'orifice

de remplissage.

NE JAMAIS trop remplir les

batteries que la batterie et la

machine peut causer des dommages.

TOUJOURS essuyer un acide à partir du haut des

piles en utilisant une solution de savon.

Poison. Provoque des

brûlures graves. éviter

tout contact.

TOUJOURS rattacher des bouchons de batteries. Ne

chargez pas de bouchons en vrac ou supprimé.

Ajouter que de l'eau distillée.

Pour tous les Types de Batteries

TOUJOURS étudier précautions spécifiques des

fabricants de batteries de tels que les taux

recommandés de la charge.

JAMAIS charger une batterie gelée.

TOUJOURS brancher le chargeur sur une prise de

courant mise à la terre.

NE JAMAIS toucher les parties non isolées du

connecteur de sortie ou les bornes de la batterie non

isolée.

TOUJOURS débrancher l'alimentation secteur avant

de faire ou défaire les connexions à la batterie

pendant la charge.

NE JAMAIS ouvrir ou démonter le chargeur.

NE JAMAIS utiliser le chargeur si le cordon

d'alimentation est endommagé ou si le chargeur a

eçu un coup, s'il est tombé ou endommagé de

quelque manière que.

TOUT SERVICE de réparation doit être effectuée par un centre DISTRIBUTEUR /

SERVICE AUTORISÉ NSS utilisant uniquement des pièces ÉQUIPEMENT ORIGINAL NSS

(

(

BRUIT ET DES VIBRATIONS

Basse Brosse/Pad de la Position de Fonctionnement

BRUIT

Niveau de pression acoustique à la

position de l'opérateur

VIBRATION

Valeur d'accélération moyenne

pondérée du carré

ISO 11201)

ISO 5349)

68 dB(A)

.269 m/s

2

INSPECTION DE LA MACHINE

Maintenant que la machine est déballé n'oubliez

pas de recycler tous les matériaux d'emballage.

Inspecter la machine pour les dommages ou les

composants absents. S'il est endommagé,

contacter la compagnie de transport de déposer

une demande de fret.

FONCTIONNEMENT DE LA MACHINE

Informations Générales

Cette machine fonctionne mieux avec polissage à

sec ou polissage. Utilisez vadrouille sur restaurateurs

plutôt que des systèmes de compression de

pulvérisation à restaurer l'éclat.

Pulvérisation polissage prend du temps et utilise plus

de tampons parce qu'ils se chargent de revêtement

de sol, ce qui peut provoquer une surcharge du

système de contrôle de la machine.

Démarrage Rapide

Raccordement Batterie de la Machine

Déplacer l'avant de la machine à partir de / à

tampon de changement de position ou position de

fonctionnement en saisissant la poignée et en le

déplaçant vers la position désirée.

Allumez l'interrupteur principal (et interrupteur à clé

le cas échéant). Attendez jusqu'à ce que vous

entendiez un clic, la machine est maintenant sur.

Voir Composants Machines pour plus

d'informations.

Vérifiez que l'indicateur de batterie est en train de

lire dans la gamme haute ou vert. La machine doit

être mise en charge si elle n'est pas dans le haut

de gamme. Voir Instructions de remplissage plus

loin dans ce manuel.

Allumez l'interrupteur de la brosse. Voir

Composants Machines pour plus d'informations.

Tournez les poignées avant (loin de vous) pour

activer le tapis et Moteurs d'entraînement. Pour

revenir en arrière tordre les poignées arrière (vers

vous). Voir Composants Machines pour plus

d'informations.

PRUDENCE: Cette machine doit se déplacer à tout

moment lorsque le tampon est en rotation ou le

plancher peut être endommagée.

Transport de l'appareil au travail du site

Lorsque la machine est livrée avec des piles, la

machine va arriver avec la batterie débranchée de la

machine.

Soulevez la poignée du capot supérieur pour

exposer la batterie.

Branchez le câble avec le connecteur Anderson

dans le connecteur Anderson monté sur la machine

à l'arrière du compartiment de la batterie en face

de la colonne de commande.

Pour les machines livrées sans piles

Installation de la batterie Voir dans la section

Maintenance loin dans ce manuel.

NSS recommande de transporter la machine sur le

site de travail à l'avant de la machine dans la position

de fonctionnement et l'interrupteur de la brosse dans

la position d'arrêt. Cela permettra de réduire le

potentiel de dommages à l'Flexiwall Shield et tapis

conducteur lorsqu'il se déplace dans chambres

actions / d'entreposage et doubles portes battantes.

Pour les questions et toutes les informations

relatives à cette machine de lire le reste de ce

manuel.

Composants de la Machine

Colonne de contrôle de l'opérateur

La colonne de commande de l'opérateur se trouve à

l'arrière de la machine. Cette colonne a des

composantes qui contrôlent diverses fonctions de la

machine.

Système de Contrôle D'entraînement

Au sommet des deux côtés de la colonne de

contrôle sont deux (2) poignées tournantes en

caoutchouc. Ces poignées pivotent vers l'avant et

vers l'arrière pour commander la direction et la

vitesse de la machine.

Ils activent également le moteur de la brosse si ce

n'est que lorsque la machine est en mouvement.

Le plus loin les poignées sont tournées, plus la

machine se déplace.

Ces poignées tournantes ont une fonction de

sécurité qui renvoie la machine à la position neutre

lorsque les poignées sont libérés.

Jauge de Batterie

L'indicateur de charge est situé à l'arrière de la gaine

de colonne de commande et a deux usages. Il

indique l'état de charge des batteries pendant le

fonctionnement et les codes d'erreur clignote quand il

ya un problème avec la machine.

Le taux de charge est indiquée par des chiffres.

Plus le nombre le plus élevé de la charge de la

batterie.

Quand il ya un défaut de la machine, la jauge de

batterie clignote un «F» suivi d'un numéro.

Voir Tableau de dépannage pour plus

d'informations.

Chargeur de Batterie

Interrupteur Principal

L'interrupteur principal est situé sur le côté en haut

à droite de la colonne de commande et il fait

tourner la machine sous et hors tension.

Si l'interrupteur de la brosse est en marche et la

tête de brosse est en panne ou les poignées

tournantes ne sont pas dans la position neutre de

la machine ne s'allume pas. Un code d'erreur

clignotant apparaît sur le compteur de la batterie.

Voir le bas de la décalcomanie sur le couvercle de

la colonne de commande et corriger le problème.

Le système de commande sera automatiquement

éteindre la machine si elle met au ralenti pendant

10 minutes. Désactivé l'interrupteur principal et le

pinceau, puis tournez le commutateur principal de

retour à redémarrer.

Compteur Horaire

Le compteur horaire est située sous l'interrupteur

principal et compte les heures du moteur de la

brosse est sur. Le compteur d'heures est utilisé

pour indiquer les intervalles de maintenance. Le

compteur d'heures ne peut pas être remis à zéro.

Voir la section d'entretien pour les intervalles

d'entretien.

Porte-fusible

Le porte-fusible est situé sous le compteur horaire.

Il abrite un fusible de 2 ampères.

Le chargeur de batterie est situé sur le dessus du

couvercle de la boîte de la batterie.

Ce chargeur de batterie à haute efficacité est

conçu pour fonctionner à bord.

Interrupteur à Clé

Un interrupteur à clé est facultatif et sera situé au-

dessus du compteur d'heures lorsqu'il est installé.

L'interrupteur et la clé principale sera à la fois

besoin d'être utilisé pour mettre la machine sous et

hors tension.

ENTRETIEN

Toujours éteindre tous les interrupteurs

de la machine avant d'effectuer tout

entretien ou réparation de tout matériel.

Vérifiez la tension de la chaîne de transmission

après les 100 premières heures d'utilisation, puis

tous les 90 jours ou 300 heures, au besoin. Pour

les instructions chaîne de serrage, voir la section

de maintenance appelé 90 jours d'entretien (300

heures).

Entretien Quotidien

Ne jamais laissez la machine s'asseoir avec un

tampon utilisé installé. Cela peut entraîner le pilote

de la tablette se déformer

Tapis Installation / Changement

.

Brosse Commutateur

Le passage de la brosse est située sur le côté

gauche de la colonne de commande et il fait

tourner la brosse sur et en dehors.

Il est également un interrupteur à bascule dans ce

circuit situé sous la tête de brosse qui ne permet

que la brosse à être allumé lorsque la tête de la

brosse est en position de fonctionnement.

Disjoncteur

Il existe un coupe-circuit principal situé au-dessous

de l'interrupteur de la brosse sur le manche de

commande.

Tête de Brosse

Le moteur de la brosse, sac de filtre et Flexiwall

bouclier sont situés à l'avant de la machine.

Le sac se connecte directement à l'écran Flexiwall

et a une pression qui retient l'arrière du sac.

Il existe une large gamme de tampons disponibles

pour de nombreuses applications différentes de

brunissage. Consultez votre distributeur local NSS

autorisé pour les recommandations d'application.

Soulevez l'avant de la machine jusqu'à la position

90 degrés pour voir le pilote de la tablette et le

pad.

Assurez-vous que le tampon correct (7/8 "à 1"

[22mm à 25.4mm]) X 27" [68.6 cm] est en cours

d'installation.

Placez le coussin plat sur le sol, et de supprimer le

trou central de la plaquette, monter sur le centre du

pavé de comprimer les bords autour du trou

central. Cela permet de faciliter l'installation de la

coupe gland de centrage.

Avec la machine dans la position de changement

de tampon, centrer soigneusement le tampon sur

le pilote.

PRUDENCE: Tapis doivent être installés

concentrique (alignés de manière) avec le bord

extérieur de la pilote de la tablette. Le non-respect de

ces précautions provoque des vibrations de la

machine excessive, une réduction de la durée des

plaquettes et des résultats de brunissage

insatisfaisants.

Placez la pince de tampon dans le trou central du

pad.

Tenir le pilote de la tablette et le pad, appuyez sur

la touche jusqu'à ce que grabber la pince à ressort

a cliqué deux fois.

PRUDENCE: Ne pas installer la carte d'acquisition

pad bien peut permettre au tampon d'être jeté dans

le pilote.

Entretien Quotidien (suite)

Vider le sac filtrant quotidienne ou quand il est à

peu près la moitié (1/2) pleine.

Charge des Batteries

Recharger les batteries lorsque cela est indiqué

par la jauge de batterie.

Ne laissez jamais les piles reposer toute la nuit

après que la machine a été exécuté pendant 1

heure ou plus depuis la dernière recharge.

NE JAMAIS laisser le niveau d'électrolyte chute

au-dessous des sommets des plaques. Cela

pourrait endommager les piles immédiatement, et

nullité de sa garantie.

Vérifiez le cordon du chargeur pour les fils exposés

et fiches endommagés avant d'utiliser.

Pour recharger les batteries branchez le cordon du

chargeur dans le chargeur situé sur le dessus de la

machine, puis sur une prise électrique.

Si le cordon est branché dans une prise de la

machine sera automatiquement désactivée.

Charger les batteries avec le couvercle ouvert

lorsque cela est possible afin de réduire

l'accumulation de chaleur dans les batteries.

Voir les instructions de charge pour plus de détails.

TOUJOURS porter des lunettes de protection, des

gants en caoutchouc et des vêtements de

protection pour éviter tout contact avec de l'acide

de la batterie lorsque vous travaillez à proximité

des batteries.

Après la charge des batteries, vérifier le niveau de

chaque cellule de la batterie de l'eau et ajouter de

l'eau distillée que nécessaire jusqu'au niveau

spécifié par le fabricant de la batterie.

Vérifiez et assurez-vous que toutes les connexions

de la batterie sont propres et bien serrés.

Essuyez la machine avec un chiffon humide.

Ne vaporisez jamais cette machine avec de l'eau

ou de liquides.

Vérifiez TOUJOURS l'interrupteur d'inclinaison

pour un fonctionnement correct. Avec l'interrupteur

principal hors tension, mettre la tête de brosse

dans la position de changement de garniture.

Tournez le commutateur de brosse sur alors

l'interrupteur principal, la machine devrait tourner

sur.

Si l'appareil ne s'allume pas et le compteur de la

batterie clignote un, l'interrupteur d'inclinaison a

échoué. NE PAS utiliser la machine jusqu'à ce que

l'interrupteur d'inclinaison a été remplacé.

Possibilité de Charge

Charge d'opportunité est en charge des piles lorsque

l'occasion se présente, comme pendant les pauses,

et se fait en plus d'un cycle de charge complet.

Charge d'opportunité est recommandée, car ce

temps de charge supplémentaire aidera à augmenter

la tension de fonctionnement des batteries, et

permettra d'assurer une autonomie maximale et cycle

de vie.

Voir les instructions d'entretien mensuel et

chargeur de batterie d'exploitation pour égaliser

vos batteries, surtout si vous avez été l'occasion

de charger votre appareil.

Entretien hebdomadaire (chaque 25 heures)

Vérifiez tout l'entretien quotidien a été effectué.

Inspectez le Bouclier Flexiwall les bosses sur le

pourtour et les fissures dans le plastique.

Vérifier que la brosse et de la bande de retenue

sont correctement installés.

Enlever la saleté accumulée sur la brosse le long

du bas du bouclier Flexiwall.

Une Assemblée Bouclier Flexiwall endommagé

permettra de réduire considérablement les

capacités de contrôle de la poussière de la

machine.

Entretien mensuel (chaque 100 heures)

Vérifiez que tout l'entretien quotidien et

hebdomadaire a été réalisée.

Egaliser vos batteries (Inondé seulement).

Les piles doivent être égalisées une fois tous les 30

jours pour l'exécution maximale de la batterie et de la

vie.

Pour égaliser les batteries:

Branchez le chargeur et recharger complètement

les batteries (jusqu'à ce que la LED verte de 100%

est allumé en permanence).

Débranchez le chargeur de la prise murale, puis

rebranchez-le.

Le chargeur de fonctionner pendant 2 heures, en

maintenant les batteries à une tension constante,

et égalisation de chaque cellule.

Cette étape est particulièrement importante si vous

pratiquez OCCASION DE CHARGE.

Entretien de 90 jours (Chaque 300 heures)

Vérifiez que tout l'entretien quotidien,

hebdomadaire et mensuel a été effectué.

Serrer la Chaîne

Vérifier la tension sur la chaîne du moteur

d'entraînement. Si la chaîne dispose de plus de ½"

[12.7mm] déviation, serrer au besoin.

Accès aussi, les boulons pour le moteur

d'entraînement sont sur le côté gauche de la

machine. Il ya deux boulons sur le dessus qui sont

accessibles à travers les trous comme indiqué

dans l'image ci-dessus. Il existe également deux

boulons situés en dessous du châssis. Un total de

quatre boulons.

Lubrification

Vérifier le tuyau de vidange du bac de batterie

pour niveau de liquide sur une base mensuelle.

Les liquides renversés de la zone du compartiment

des piles sont collectées dans un bac sous les

piles. Le plateau peut être évacuée à l'aide du

tuyau à l'arrière droit de l'appareil comme indiqué

ci-dessus.

IMPORTANT: Purger tous les liquides dans un

récipient homologué et éliminer selon les

réglementations locales et fédérales.

Inspecter les composants de la machine pour

l'usure, vis desserrées, ou des dommages. Portez

une attention particulière à tous les points de pivot

et les pièces mobiles.

Appeler un centre de service autorisé pour la

réparation NSS.

Graisser les roulettes avec une graisse industrielle

de roulement de qualité. Manque de graisser

roulettes entraînera la machine à manœuvrer avec

difficulté et une défaillance prématurée de la

roulette se traduira.

Graisser les roulements de roues d'entraînement

avec une graisse de qualité industrielle de palier.

Les embouts de graissage des paliers peuvent

être accessibles à partir de l'avant de la machine.

Ne pas lubrifier les roulements de roues

d'entraînement causera la machine à manœuvrer

avec difficulté et une défaillance prématurée des

roulements entraînera.

Lubrifiant de la chaîne de moteur d'entraînement

avec une petite quantité de graisse à l'aide d'un

pinceau. Une pulvérisation de chaîne peut

également être utilisé.

NE JAMAIS utiliser vos doigts pour mettre le

lubrifiant sur la chaîne. De graves blessures

peuvent se produire.

Tous les 6 mois (Tous les 600 heures)

Appelez votre distributeur autorisé / stationservice NSS pour avoir les services suivants

effectués.

Vérifiez que tout l'entretien quotidien,

hebdomadaire, mensuel et trimestriel a été

effectué.

Inspecter moteur de la brosse balais de charbon

pour l'usure.

Utilisation de l'air comprimé, souffler la poussière

de balai de charbon accumulée sur le moteur.

Remplacer la brosse de carbone quand ils

mesurent ½" [12.7mm] ou moins en longueur.

Ne pas remplacer les balais de charbon entraînera

performances de la machine pauvres et des

dommages moteur.

Vérifier l'état des piles.

Une batterie peut être vérifiée à l'aide d'un

densimètre pour vérifier la gravité spécifique (force)

de l'acide dans chaque cellule. Variations dans les

lectures se produisent en raison de la réaction

chimique qui se produit lors de l'utilisation.

Toujours vérifier la densité lorsque la batterie est

complètement chargée.

Remplacez les piles au besoin.

Installation des Piles:

Éteignez tous les interrupteurs. Débranchez le bloc

batterie de la machine.

TOUJOURS porter des lunettes de protection, des

gants en caoutchouc et des vêtements de

protection pour éviter tout contact avec de l'acide

de la batterie lors de l'installation des piles. Voir

Avertissements batterie à la page 3.

Graisser toutes les pièces mobiles comme l'exige

avec une petite quantité de graisse.

NE PAS lubrifier l'arbre de printemps de gaz, il ne

nécessite pas de lubrification car il est autolubrifiant.

Réparations effectuées par une société non autorisée annulera la garantie de la machine.

Si vous avez besoin d'aide pour trouver un centre de service agréé, contactez NSS entreprises.

Retirez le panneau latéral et le couvercle

supérieur. Il existe deux boulons (une dans chaque

coin) sur le dessus du panneau latéral et deux

écrous (une dans chaque coin) à la partie

inférieure du couvercle. On notera que les écrous

à la base ne sont pas visibles depuis le côté.

Tous les 12 mois (Tous les 1200 heures)

Appelez votre distributeur agréé / station-service

NSS pour avoir les services suivants effectués.

Vérifiez que tout l'entretien quotidien,

hebdomadaire, mensuel et trimestriel a été

effectué.

Inspecter les balais de charbon Moteur

d'entraînement pour l'usure.

Il faudra enlever le moteur d'entraînement de la

machine et ne doit être effectuée par un centre de

service autorisé NSS.

Utilisation de l'air comprimé, souffler la poussière

de balai de charbon accumulée sur le moteur.

Remplacer la brosse de carbone quand ils

mesurent ½" [12.7mm] ou moins en longueur.

Ne pas remplacer les balais de charbon entraînera

performances de la machine pauvres et des

dommages moteur.

Service Ressort à Gaz

La couverture sera toujours fixée au panneau

latéral. Déplacez-les sur la façon d'installer les

batteries.

Les batteries sont lourdes - TOUJOURS utiliser

deux personnes pour installer les piles dans la

machine.

Reportez-vous au schéma de câblage situé sur la

face inférieure du couvercle. Alignez les piles dans

le compartiment le même que les vieilles piles ou

comme indiqué sur le schéma.

Installez les câbles de batterie de la même car ils

étaient sur les piles usagées ou comme indiqué

sur le schéma de câblage situé sur la face

inférieure du couvercle.

NSS recommande de remplacer les câbles de la

batterie lors du remplacement des piles.

Serrer les boulons et les écrous hexagonaux avec

une clé.

Installez les capuchons de borne sur les bornes

pour terminer l'installation.

PRUDENCE: Ne court entre deux bornes avec une clé.

PRUDENCE: Connexions de batterie desserrées ou

incorrectes entraînera la batterie ou d'endommager

l'appareil et provoquer des blessures.

TOUJOURS fixer la tête de brosse dans la

position de changement de patin à l'aide de la

sangle fournie avant de tenter toute opération de

maintenance ou de réparation sur le ressort à gaz