Page 1

SURGERY SYSTEM

OPERATION MANUAL

OM-E0262E

0197

Page 2

• Keep out from explosive substances and flammable materials. Do not use for patients

anesthetized with nitrous oxide gas especially.

• The system may present a possibility of malfunction when used in the presence of

electromagnetic interference wave. Do not install the system in the vicinity of the device

which emits magnetic waves. Turn off the power switch of the Control Unit of this system

when an ultrasonic oscillation device or an electrode knife located in the vicinity is used.

• Surgic XT is intended for use in dental, oral surgical, and surgical procedures. Do not use

in operating rooms due to potential flammable gas mixtures present in such environment.

• Patient safety is a priority.

• Read this Operation Manual before use, and fully understand the functions of each part

for starting use.

• Inspect the operating status of the equipment before use, and use only after confirming

that no abnormalities exist.

• Test run the product to ensure its correct operation prior to using it.

• If the product should ever malfunction (excessive vibration, noise, heat, etc) please turn it

off immediately and return it to your Authorized Dealer for inspection.

• When the product is very frequently used please consider the maintenance of a small

stock of replaceable parts.

• Use the equipment only after preparing spares for consumable parts. In particular, the

preliminary head SGM easily fails as a result of intrusion of blood or saline solution,

therefore, be sure to prepare spare parts.

• Use an electrical outlet that is grounded.

• To avoid possible injury or product damage, ensure that the Micromotor has completely

stopped before changing burs.

• Severe shock – Eg. Dropping the product – may cause damage.

• Do not bend the Irrigation Tube while the water pump is operating. It could cause tube

breakage.

• Never attempt to disassemble the Control Unit, the Foot Control or the Micromotor.

•

Handpiece Attachments should be cleaned, lubricated and sterilized immediately after use.

• Do not lubricate the Micromotor. Oil could generate excessive heat and cause damage.

• The Control Unit and the Foot Pedal Controller cannot be sterilized by any method.

• The Control Unit may be cleaned with a moist cloth. Disconnect the power supply before

cleaning.

• Do not clean the Control Unit with any solvent solutions.

• Do not disconnect the motor cord from the motor.

• Make sure that the cover is not fitted during calibration.

• Be sure to dispose of the irrigation tube as medical waste after use.

• The system functions normally in the environment where the temperature is at 0-40ºC (32104ºF), humidity at 10-85% RH, atmospheric pressure at 500- 1060hPa, and no moisture

condensation in the Control Unit. Use at outside of these limits may cause malfunction.

S Classification of equipment

• Type of protection against electric shock :

– Class l equipment

• Degree of protection against electric shock :

– Type BF applied part

• Method of sterilization or disinfection recommended by the manufacture :

– See 8. Sterilization

• Degree of protection against ingress of water as detailed in the current edition of IEC 529 :

– Foot Control : IPX8 (Protected against the effects of continuous immersion in water)

• Degree of safety of application in the presence of a flammable anesthetic mixture with air

or with oxygen or nitrousoxide :

– EQUIPMENT not suitable for use in the presence of a flammable anesthetic mixture with

air or with oxygen or nitrousoxide

• Mode of operation :

– Continuous operation

IMPORTANT

For correct operation please read this manual before use.

CONTENTS

1. Safety precautions prior to use

2. Package contents

3. Control unit with an irrigation pump

4. Foot control

5. Installation

6. Operation

7. Care and maintenance

8. Sterilization

9. Optional accessories

10. Specifications

11. Disposing product

SAFETY CAUTIONS

Read these safety cautions thoroughly before use and operate the product properly.

These indicators are to allow you to use the product safely and prevent danger and harm to you

and others. These are classified by degree of danger, damage and seriousness. All indicators

concern safety, be sure to follow them.

Indicators of Hazardous Conditions

1

2

3

5

6

9

11

13

14

14

14

••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••

Safety precautions prior to use

1

q

Classification

WARNING

CAUTION

NOTICE

Degree of Danger or Danger and Seriousness

Explains an instruction where personal injury or physical damage may occur.

Explains an instruction where minor to medium injury or physical damage may occur.

Explains an instruction that should be observed for safety reasons.

WARNING

CAUTION

• Turn off the Power Switch after each use.

• For service requirements and spare parts please contact your dealer.

• The use of NSK genuine pre-sterilized, disposable Irrigation Tube Kit is recommended.

• Store the system in the place where the temperature is at -10-60ºC (14-140ºF), humidity at

10-85%RH, atmospheric pressure at 500-1060 hPa, and the system is not subject to air

with dust, sulfur, or salinity.

NOTICE

Thank you for purchasing the NSK Surgic XT, surgical unit.

The EU directive 93/42/EEC was applied in the design and production of this medical

device.

Page 3

Description of Operation

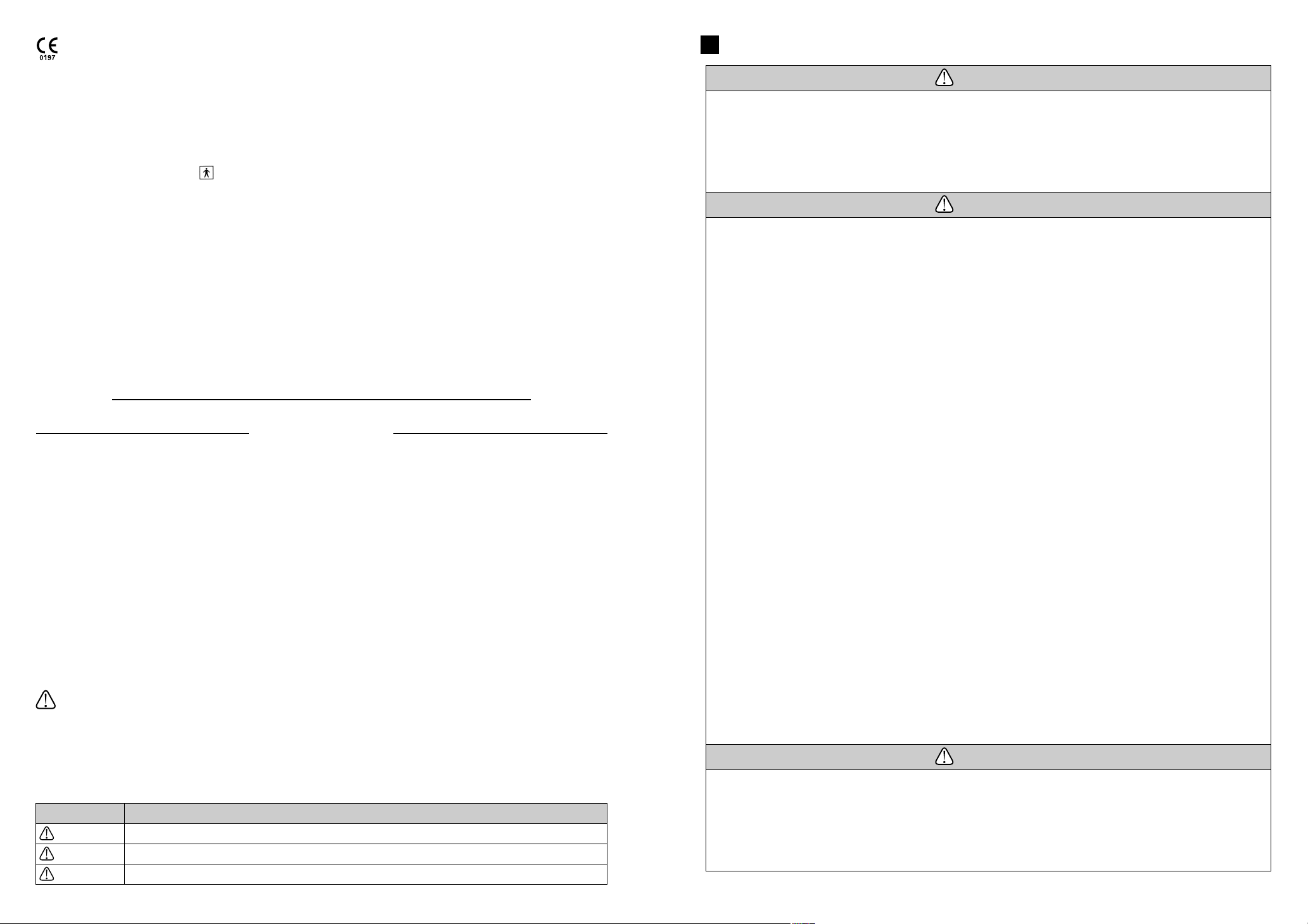

S Keys on the Unit

a Program key

This key is used to select any one of 10 available programs. Press [+] to ascend program

numbers and [-] to descend the numbers. By pressing either [+] or [-] the numbers rotate

continuously through all available programs.

s Speed key

This key is used to set the micromotor speed. Press [+] to increase speed by one step, and [-]

to decrease speed by one step. When [+] is pressed and the speed setting reaches maximum

or [-] is pressed and the speed setting reaches minimum, an audible intermittent beep sounds,

and the speed cannot be changed any further.

d Torque key

This key is used to set the torque. Press [+] to increase torque by one step and [-] to decrease

torque by one step. When [+] is pressed and the torque setting reaches maximum, or [-] is

pressed and the torque setting reaches minimum, an audible intermittent beep sounds, and the

torque cannot be changed any further. The range of torque setting steps vary according to the

gear ratio selected to match the handpiece attachment in use.

f System key

This key is used to calibrate the handpiece attachment before use. To activate the automatic

calibration mode, connect the handpiece attachment to the micromotor and press this key. The

micromotor will automatically operate for a few moments and, when it automatically stops, the

handpiece attachment will be calibrated to the micromotor.

g Gear Ratio key

This key is to select match ratio of the handpiece attachment, before use, to the unit. Press this

key until the LCD display exhibits the correct gear ratio of the handpiece attachment.

h Coolant Flow key

This key is used to select the coolant solution flow volume. 5 flow volume rates are available for

selection, plus the flow can be turned off.

j Forward/Reverse key

This key is used to change the rotational direction of the micromotor. Press this key once to

change the rotational direction.

k Memory key

This key is used to memorize the program parameters set by the operator. Press this key for

approx. 1 second to memorizes parameters. An audible beep confirms that new program

parameters have been memorized.

ew

Gear Ratio key

Coolant Flow key

Forward/Reverse key

System key

Memory key

Speed key

Program key

Torque key

Coolant Solution Hanger Post

AC Electrical Cord Connection Jack

Fuse Holder

Main Power Switch

Micromotor Cord

Jack

Foot Control Cord Jack

Package contents

Irrigation Pump

2

u !0 !3

e !1 y q w

!2 t i r o !4 !5 !6 !7

q

w

e

r

t

y

u

i

o

Quantity

1

1

1

1

1

1

5

1

1

Description

Control Unit with Irrigation Pump

Foot Control

AC Electrical Cord

Autoclavable Micromotor with Cord

Reduction Handpiece Attachment (Opt)

Micromotor Cradle

Irrigation Tube

Internal Spray Nozzle

Irrigation Tube Clamp

Item

No.

!0

!1

!2

!3

!4

!5

!6

!7

Quantity

7

1

1

2

1

1

1

1

Description

Tube Holder

Coolant Solution Hanger Post

Wrench for Handpiece Attachment

Spare Fuse

Y-connector

Nozzle Cleaning Fine Wire

Autoclave Plug for Motor

Spray Lubricant Nozzle

Item

No.

Control Unit with an Irrigation Pump

3

Page 4

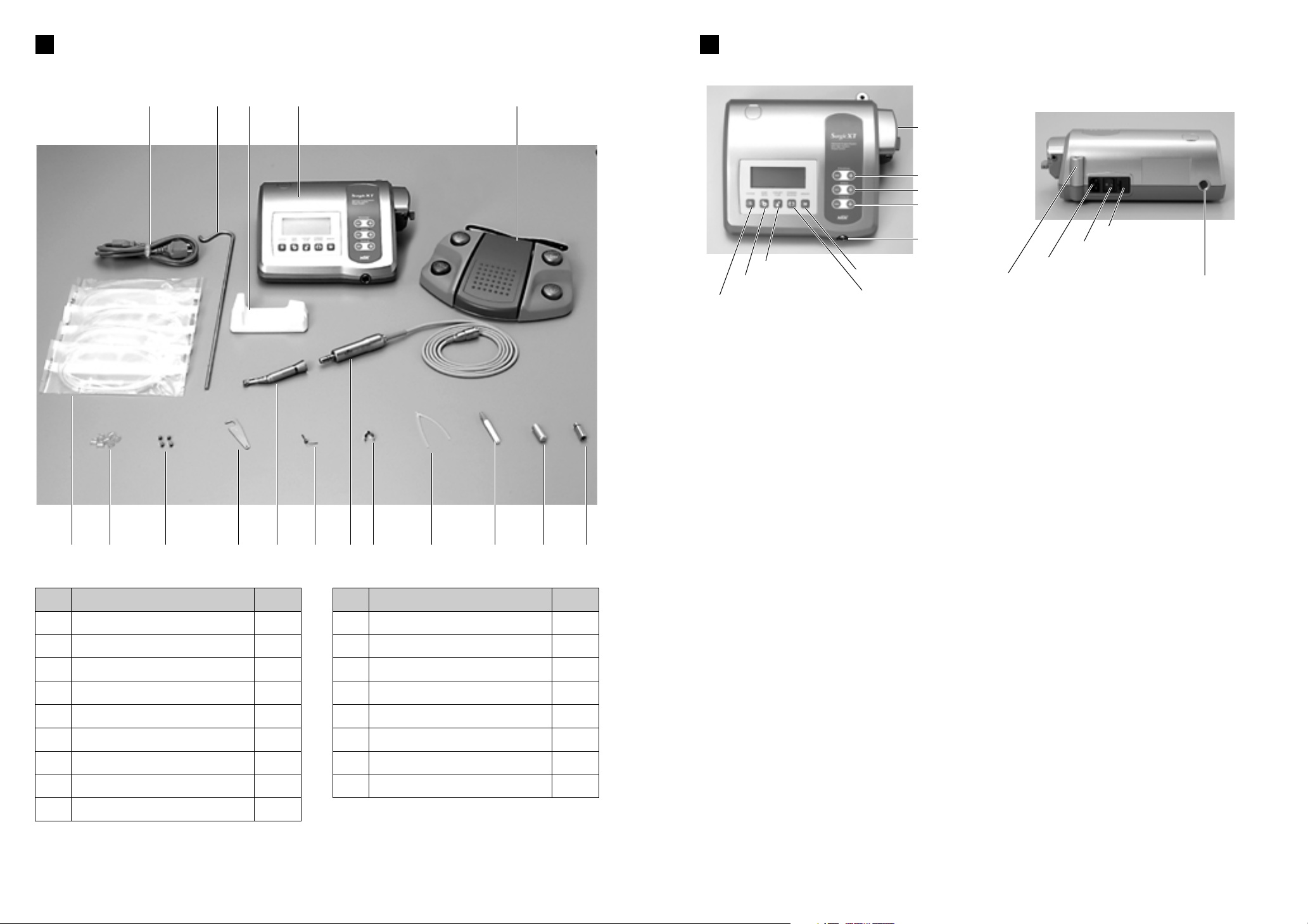

PRG (Program) button

Foot Control

cord and plug

Speed/Torque button

Forward/Reverse

button

Speed Control pedal

Program Number Gear Ratio

Coolant flow level

Speed/Torque Bar Graph

Forward/Reverse

Speed/Torque

Coolant solution flow

volume button

a Coolant Flow

Displays the selected coolant solution flow volume level. The selected flow volume level is

indicated by one of 5 levels of light. No light indicates the coolant solution flow is off.

s Program Number

Displays the selected program number.

d Gear Ratio

Displays the gear ratio of the handpiece.

f Forward/Reverse Indicator

Displays the rotational direction of the micromotor.

g Speed/Torque

Displays the selected speed and torque. Normal speed is shown when the unit is switched on

and also when a program is changed. To display speed, press the [Speed] key on the Control

Unit. To display torque, press the [Torque]. Speed and torque can also be displayed by pressing

the Speed/Torque button on the foot control.

✻ When the gear ratio is a constant speed or when using the Speed Increasing Handpiece,

the torque is not displayed.

h Speed/Torque Bar Graph

During operation displays an approximate percentage indication of the actual operating speed

or torque relevant to the preset maximum speed or torque. When all bars illuminate, the

operating speed or torque is at maximum. When bars are half illuminated then the operating

speed is approximately 50% of the preset speed.

S LCD display on the unit console

r t

CAUTION

The LCD display panel is produced from liquid crystal and should always be

treated with care.

a Coolant Solution Flow Volume button

This button is used to select the volume of coolant solution flow. Five levels are available and

each level may be increased by one step pressing this button once only. The step above level 5

and below level one turns the flow off.

s PRG (Program) button

This button is used to select the desired program number. Program numbers will always ascend

each time this button is pushed and will roll from No. 10 program onto No. 1 program. When the

button is pushed too many times and the wrong program is selected, press the button for 1

second more. It could get back to one program before the selected program.

d Speed Control Pedal

This pedal is used to start and stop the micromotor and to vary the speed during operation.

f Forward/Reverse button

This button is used to change the rotational direction of the micromotor. Push once to change

rotational direction.

g Speed/Torque button

This button is used to change the LCD display from Speed to Torque or vice versa. Push once

only to change the display.

Foot control

4

Page 5

Tube Guide

Position

Position

lrrigation Tube

Needle End

Stopper

Installation

5

5-4 Installing the Irrigation Tube

Mount the irrigation tube in the irrigation pump, with

the irrigation tube needle toward backside of the unit.

Position the stoppers of the tube in the guide

securely. (Fig.6)

5-5 Mounting the coolant solution bottle

Insert the coolant solution bottle hanger post into the

holder on the Control Unit. Place the bottle as shown

in Fig.10.

Only after the tubes are correctly positioned, close

the pump cover by turning the pump cover lever 90

degrees to the left Fig.8.

5-1 Connecting the motor cord

Face the [] mark on the Micromotor Cord plug

upward then insert the plug into the Micromotor

Cord jack on the Control Unit (Fig.1).

A click is heard when the motor cord plug is

correctly inserted into the control unit. To

disconnect the plug, pull back the lock joint, then

disconnect the cord (Fig.2).

5-2 Connecting the foot control

Face the screw on the foot pedal control cord

plug downward then insert the plug into the Foot

Control cord jack on the Control Unit. Secure the

plug by fastening the lock nut. See Figs.3 and 4.

5-3 Connecting the electrical power cord

Align correctly then insert the electrical power

cord into the power cord connection at the back

of the control unit (Fig.5).

uy

Fig.1

Fig.2

Fig.3

Fig.4

Fig.5

Base of micromotor

cord jack

Lock nut

Screw

Lock joint marking

CAUTION

Make sure that the tube is securely set on

the rollers when closing the pump cover.

If the tube is not correctly positioned on

the rollers and the cover is closed, the

tube could be cut or sheared. (Fig.7)

Rollers

Fig.7

Fig.6

Fig.8

Fig.9

Fig.10

Pump cover lever

Pump roller

Page 6

Bottle Cap

lrrigation

Tube Needle

Tube Clamp

Tube Cap

Power Switch

Symbol Mark

Function OFF ON

6-1 Programming the micromotor operation

The control unit can memorize 10 sets of programs. Each program includes the following

functions which will be automatically performed when the appropriate program number is

selected.

Gear ratio of contra angle handpieces

Speed

Direction of rotation

Torque upper limit

Coolant solution flow

a Turn on the power by pushing the main switch toward [-].

Whenever the main power switch is turned ON, program

number 1 is always displayed.

s Select a program number by using either step a) or step b):

O a Press the [Program] key on the unit control panel

until the program number you require is displayed OR

O b Press the [Program] button on the foot control until the program number

you require is displayed.

d Selecting the gear ratio of the handpiece relevant to the program

Press the [Gear Ratio] key the gear ratio of the handpiece to be used is displayed.

f Setting the speed

Set the speed by pressing the [Speed] key.

-Each time this key is pressed the display changes to the next speed level. By pressing this key

for more than 1 second brings the speed quickly to the next level until the speed display

reaches its upper or lower limit.

-When the speed setting reaches the upper or the lower limit, an audible beep is heard and the

speed setting cannot be changed any further.

g Setting the torque upper limit

Set the torque upper limit by pressing the [Torque] key on the unit control panel.

-Each time this key is pressed the display changes to the next torque level. By pressing this key

for more than 1 second brings the torque quickly to the next level until the torque display

reaches its upper or lower limit.

-When the torque setting reaches the upper or the lower limit, an audible beep is heard and the

torque cannot be changed any further.

h Select the rate of coolant solution flow volume

Select the rate of the coolant solution flow volume by pressing the [Coolant Flow] key.

-The rate of coolant solution flow volume has 5 flow rate steps plus "no coolant flow".

j Memorize settings

After completing steps 1-6 press the [Memory] key for more than 1 second until a long

audible beep is heard. The long beep confirms that the programming is completed. If you hear a

short audible beep when the [Memory] key is first pressed please ignore this signal and

keep the [Memory] key depressed until a long beep is heard.

Repeat the above steps 1-7 to program any one of the 10 available programs.

5-6 Insertion of the irrigation tube

a Place the coolant solution bottle on the hanger post

and insert the irrigation tube needle into the bottle

cap. (Fig.11)

s Close the tube clamp, between the irrigation tube

needle and the irrigation pump, as shown in Fig.12

d Open the tube cap to supply air into the bottle.

(Fig.13)

5-7 Mounting the internal spray nozzle

It is possible to connect water to the external

irrigation nozzle (Fig.14) and the internal

irrigation nozzle (Fig.15) simultaneously.

Simply connect the Y connector (Fig.16) onto

the main water supply tube at the rear of the

handpiece then connect the 2 water supply

tubes.

5-8 Attaching the tube holder

Use the tube holder to combine together the

motor cord and the irrigation tube. It is easier

to insert motor cord first and, next, the

irrigation tube.

Operation

6

oi

CAUTION

Do not operate the irrigation pump if the

tube is bent or the tube clamp is in the

closed position. This could cause the tube

to burst or slip out of the bottle.

Fig.11

Fig.12

Fig.13

Fig.14

Fig.15

Fig.16

Fig.17

Motor cord

Tube holder

Irrigation tube

Y-connector

PROGRAM

SPEED

TORQUE

Page 7

7-1 Protection circuit

An electronic circuit breaker automatically functions to protect the micromotor and the control

unit if the micromotor is ever overloaded. Power supply to the micromotor will automatically be

terminated and the Error code will be displayed on the control unit.

S Resetting the protection circuit

To reset the protection circuit, release and then depress the speed control pedal or push the

system key on the control unit.

7-2 Error Code

If an operational problem occurs the display shows the Error code to allow an immediate

problem diagnosis.

6-2 Calibration of the Handpiece to be used

The resistance of a handpiece attachment against the rotation of the micromotor varies slightly

depending on the handpiece model, its age and condition, the degree of wear on the handpiece

gears, and so on. The Surgic XT unit incorporates an automatic function to recognize the level

of the resistance of any handpiece attached to the micromotor, and to calibrate the micromotor

to rotate the handpiece attachment to the specific speed and torque settings required.

a Attach the handpiece to the micromotor and remove the bur.

s Press the [System] key for approx. 3 seconds until a long beep is heard. "CAL" is displayed.

d Press the [Gear Ratio] key and select the gear ratio of the attached handpiece.

f Press the [System] key again. After a moment the micromotor will automatically starts to run.

After a short series of resistance diagnosis is completed, the display returns to normal display

and the micromotor will automatically stop. Calibration of the handpiece is now completed.

6-3 Standard operation

All standard operational functions can be controlled at the foot control.

a Turn on the Main Switch

The Control Unit is ready to perform the program memorized in program number 1.

s Select the desired program number

Step on the foot control PRG [Program] button and the program display ascends to the next

program number. Select the desired program number as displayed on the control unit. The

program numbers ascend to 10 and then continue on to program 1. Pressing the PRG [Program]

Button for one second more could get back to one program before the selected program.

d Verify the details of the program

Verify the details of the program on the display.

The largest numerals displayed exhibit the speed setting. To verify torque, step on the foot

control Speed / Torque button and the speed display changes to the torque setting display.

f Operating the micromotor

Step on the speed control pedal in the middle of the foot control and the micromotor will start to

run. When the coolant solution flow is programmed to operate the pump will also automatically

run. Speed increases as the pedal is depressed. When the pedal is fully depressed the speed

reaches the maximum set value.

g Activation of the torque limiter

During operation of the micromotor, when the drilling load reaches the programmed torque

upper limit the integrated torque limiter automatically activates in to prevent torque application

excessive to the set requirement. When the torque limiter activates, the motor stops over

beeping after 5 seconds. To reactivate the micromotor simply press the [ System ] key.

h Stopping the micromotor

Release the foot control pedal, and the micromotor will automatically stop.

j Reversing the micromotor rotational direction

To reverse direction of the micromotor (and bur) simply step on the foot control Forward /

Reverse button. A warning beep can be heard when the rotational direction is in reverse mode.

Care and maintenance

7

!1!0

CAUTION

• Because the handpiece AUTOMATICALLY starts to run, any bur must be

removed from the handpiece before beginning the calibration process.

Leaving a bur in the handpiece may cause harm to the operator.

Care should be exercised not to ever add any load to a handpiece during

calibration, because an incorrect diagnosis would result in incorrect

torque control.

•

If “FAIL” is displayed on the liquid crystal panel, check the mounting of

each part and operate again. If “FAIL” is still displayed, contact your dealer.

CAUTION

This equipment is optimized to obtain the highest accuracy at a gear ratio of

1/20. When using another gear ratio, please note that the accuracy

decreases with an increase in the ratio relative to 1/20.

Erroneous memory.

Memory failure.

Extended use under heavy load.

Short circuit in the power cord.

Short circuit in the motor cord.

Main power cord failure.

Micromotor sensor failure (Hall IC).

Micromotor cord failure.

Signal line failure.

Overheating by extended use

under heavy load.

Operation of the unit under an

extremely high temperature.

Abnormal voltage generated in the

start / stop switch circuit.

Failure in the start / stop switch

circuit.

Handpiece attachment failure.

Micromotor failure.

When the motor stops for more

than 5 seconds after

reaching the torque upper limit.

Cause of Error

Request repair.

Electrical contact may be

insufficient.

Securely re-connect the motor

cord.

When an error cannot be

eliminated, request repair.

Allow it to cool down before use.

In order that heat is sufficiently

radiated, periphery of the main unit

should be well-ventilated wherever

possible.

When an error cannot be

eliminated, request repair.

When rotation and stop are repeated in short frequencies, a circuit

may be activated which limits acceleration at start. Wait a few seconds and then use.

When an error cannot be eliminated, request repair.

The chuck may be opened, or may

not be sufficiently closed.

Securely close the chuck.

When an error cannot be

eliminated, request repair.

This is not a failure. It stops for

safety reasons.

When the error is reset, this can

be used as it is.

Remedy

System Error

Excessive Current

Detected

Excessive Voltage

Detected

Motor Sensor Error

Unit Interior

Over-heating Error

Braking Error

Motor Rotation

Failure Error

Cause of Error

E 0

E 1

E 2

E 3

E 4

E 5

E 6

Error Code

Display

Page 8

120V

230V

T3.15AL 250V

T1.6AL 250V

The following items are autoclavable.

• Handpiece

• Micromotor with cord

• Motor handpiece cradle

• Internal coolant nozzle

• Irrigation tube clamp

• Tube holder

• Autoclave plug for micromotor

[ Autoclaving ]

a Remove blood and debris from the handpiece.

s Clean inside the handpiece, by using the spray lubricant (refer to "7. Care and Maintenance").

Do not attempt to spray lubricant into the micromotor.

Attach the micromotor autoclave plug to the micromotor.

d Place the handpiece in an autoclave pouch (not included in the package) and seal it.

f Autoclave for 20 min. at 121˚C (250˚F), or 15 min. at 132˚C (270˚F).

7-3 Replacement of the fuse

If the control unit does not function, check the fuses.

To access the fuse box simply squeeze the fuse box

lock located on the side of the control unit (Fig.18). If

the lock is too tight use a

pointed tool to squeeze the

lock.

7-4

Maintenance of the Control Unit and Foot Control

If blood or saline solution is stained on the Control

Unit or Foot Control, remove the power code, wipe

off the Unit or Foot Control with the cloth water

squeezed dry, and wipe off with the alcoholabsorbed cloth.

7-5

Maintenance of the handpiece attachment

After each operation, immerse the head in clean,

warm water and repeat run-stop of the motor four or

five times to rinse out blood or saline solution from

the handpiece head. If the handpiece exterior is

heavily stained, wash off with water, and dry with a

soft cloth. Do not immerse the entire handpiece in

water and prevent water from entering from back

end of the handpiece.

[ Using a Spray Lubricant ]

As shown in Fig.19, insert the spray lubricant can EType nozzle into the back of the handpiece. Spray

the lubricant into the handpiece 2-3 times for 2-3

seconds each time.

If the handpiece head is excessively stained with

blood or debris then remove the head by unscrewing

the nut with the supplied wrench (Fig.20). Attach the

specific head lubrication nozzle onto the spray

lubricant can and spray directly into the head to

wash away blood and debris. (Fig.21)

If the coolant nozzle is clogged use the Nozzle

cleaning fine wire supplied. Push it into the nozzle to

unclog it. (Fig.22)

When debris or dirt accumulates around the coolant

nozzle use the cleaning brush supplied (Fig.23).

Sterilization

8

!3!2

CAUTION

• Hold the handpiece and the spray can

securely or the handpiece may eject

from your hand due to the high pressure

of the spray.

• Shake the spray can a few times to mix

well the lubricant and the propellant.

• Hold the spray can upright for spraying.

Caution for autoclaving

• Clean and lubricate the handpiece before autoclaving. Autoclaving a

handpiece stained with blood or debris could cause damage to the

handpiece.

• Do not lubricate the micromotor.

• Do not use the autoclave drying cycle if the temperature at this cycle could

exceed 135˚C (275˚F).

• The Irrigation Tube is a single use disposable type and cannot be

autoclaved.

Fig.18

Fig.19

Fig.20

Fig.21

Fig.22

Fig.23

Fuse

Fuse box

Fig.24 Fig.25

Autoclave Plug Motor

Page 9

Please consult with dealer from whom you purchased it about waste disposal.

Disposing Product

11

14

Optional Accessories

NSK Surgical Handpieces

Part No. Model No.

Description

Bur Speed

10-1 Control Unit with Irrigation Pump

10-2 Micromotor

Specifications

10

9

RemarksDescriptionPart No.

Used for branching the internal and external coolant irrigation.

(See Fig.16 for installation)

For replacement tube use.

Supplied as standard accessory items.

Supplied as standard accessory items.

Supplied as standard accessory items.

Supplied as standard accessory items.

Y-Connector

Irrigation Tube

Internal Irrigation Tube

Tube Clamp

Tube Holder

Spray lubricant

C823-752

Z263-001

C293-025

C202-750

Y900-083

Z017-100

Type

Power Supply Voltage

Frequency

Power Consumption

Max. Pump Output

Dimensions

Weight

Speed Range

Input Voltage

Dimensions

Weight

200 - 40,000min

-1

(rpm)

DC30V

ø 24 x L120mm

133g (Without the motor cord)

NE111

AC120 / 230V

50/60Hz

48VA

75mL / min. (.02 gal/min.)

W268 x D230 x H103mm

3.1kg

C293

Y200-830

Y200-890

Y200-880

Y200-840

Y200-850

C221

C332

C295

H084

H083

SGM-I

SGM-E16RI

SGM-E20RI

SGM-E32RI

SGM-E64RI

SGM-E256RI

FBG-E

ES-85

ES-95

SGS-E

SGA-E

Min.

–

12.5

10

6.25

3.125

1.56

800

1,000

1,000

200

200

Max.

–

2,500

2,000

1,250

625

156

160,000

200,000

200,000

40,000

40,000

Mini latch head

16:1 speed reduction E-type sheath with mini latch head

20:1 speed reduction E-type sheath with mini latch head

32:1 speed reduction E-type sheath with mini latch head

64:1 speed reduction E-type sheath with mini latch head

256:1 speed reduction E-type sheath with mini latch head

1:4 speed increase E-type sheath with FG head, push-button

1:5 speed increase E-type sheath with mini FG head, push-button

1:5 speed increase E-type sheath with FG head, push-button

1:1 speed E-type straight handpiece

1:1 speed E-type angled handpiece

Loading...

Loading...