Page 1

Head Mounting Ring

Marked Screw

Joint Cover

PHATELUS AIR MOTOR

PTL-SDN/PTL-CD/PTL-CR

OM-M0020E

002

CAUTION

• When operating the handpiece, always consider the safety of patient.

• This handpiece is designed only for dental clinic use.

• Check instrument and accessories before use.

• Should the handpiece function abnormally, cease operation immediately and return the handpiece to the dealer for

repair.

• Depressing the push-button while handpiece bur is in rotation will result in OVERHEATING of the handpiece head.

Special caution must be exercised during use to keep cheek tissue AWAY from the push-button of the handpiece.

Contact with cheek tissue may cause the push-button to depress and burn injury to the patient may occur.

• Always use clean burs. Uncleaned burs may cause unwanted amount of pressure on the chuck.

• Do not attempt to disassemble the handpiece nor tamper with the mechanism.

• Do not drop the handpiece.

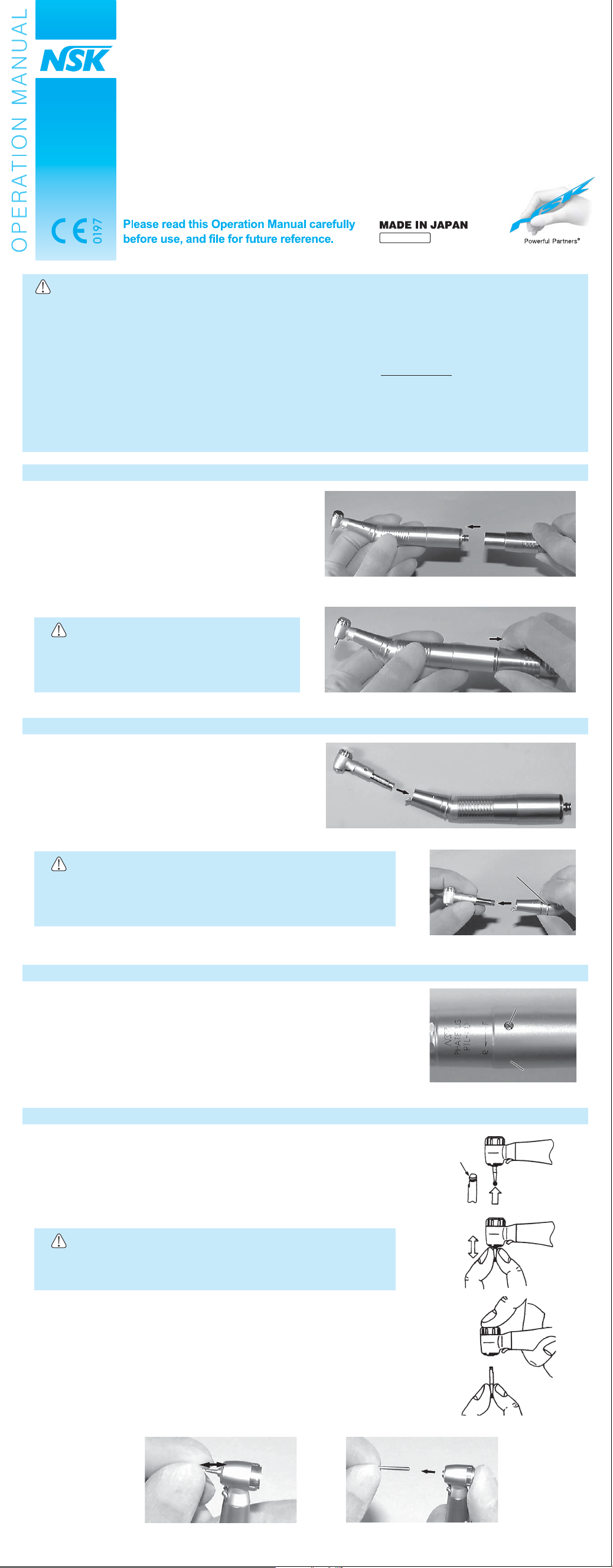

1. Mounting the air motor

If PHATELUS or MACH-LITE handpiece is now in use with

NSK swivel coupling, the air motor will be ready for use

only when the air turbine has been replaced with a

PHATELUS motor at the coupling joint (Fig.1).

The same supply air pressure as for the air turbine can be

used. To remove the air motor from the coupling, pull

back the connector ring toward the hose, in the same

way as for the turbine (Fig.2).

Fig.1

CAUTION

Do not pull back the connector ring when the air

pressure is applied, as the motor will be ejected by

the air pressure.

2. Installation and Removal of the head

To install the head, align the fiber optic pipes with the

corresponding slots of the head and insert the head

straight into the motor (Fig.3).

To remove the head, pull the head mounting ring toward

the hose and pull the head straight out (Fig.4).

CAUTION

When the head is removed, take care not to bend the exposed fiber

optic pipes.

Keep the head installed even when the air motor is not in use.

3. Changing the direction of rotation of the air motor

Head Mounting Ring

Fig.2

Fig.3

Fig.4

The air motor will rotate in the normal direction when the marked screw on

the joint cover is turned to the "F" position, and in the reverse direction when

it is turned to the "R" position.Rotation of the air motor can be stopped by

positioning the screw to the middle position between "F " and "R" (Fig.5).

4. Mounting and removal of the bur

When mounting a bur, be sure to mount the head onto the motor first.

(1) NPB-PTL and NPBG-PTL

Insert a latch bur into the head and gently turn the bur to find a position at

which its "D" shaped section is aligned with its counterpart in the bur tube.

Insert it further into the head (Fig.6).

When the bur is further inserted in that aligned position, it will lock with a

clicking sound.

CAUTION

Before using the handpiece, pull out the bur gently to make sure that

the bur is securely seated and locked (Fig.7).

To remove the bur, first make sure that the motor is to stop completely. Push the push

button to release the bur (Fig.8).

"D" shaped cutout

Marked Screw

Marked Screw

Joint Cover

Joint Cover

Fig.5

Fig.6

Fig.7

(2) NFB-PTL and NFBG-PTL

Insert a FG bur into the head to a depth of 2mm to 3mm, then push the push button

with the tip of your thumb and insert the bur into the chuck. After mounting the bur, be

sure to push and pull the bur to make sure it is completely installed (Fig.9).

Pushing and pulling of the bur increases its grip force.

To remove the bur, push the push button with the tip of your thumb. Remove the bur

(Fig.10).

Fig.9 Fig.10

Fig.8

Page 2

PHATELUS Spray Nozzle

PANA-SPRAY Plus / PANA-SPRAY

(3) ARS-PTL

Mount a rubber cup or the brush by screwing into the head.

To remove the rubber cup or the brush, it may be easily removed by running

the air motor at a very low speed in the reverse direction while holding the

cup or the brush firmly by fingers (Fig.11).

(4) NRS-PTL, TE-PTL, and NM-PTL

To mount the bur, open the latch blade, insert the bur by aligning the

D-section of the bur with its mating hole in the bur tube. Swing back the

latch blade to the original position.

To remove the bur, swing open the latch blade and pull out the bur.

(5) EVA-PTL

This can be mounted only by pushing the EVA-Tip stem into the head plunger.

For removal, push the EVA-Chip out by pressing it with the pin section of the wrench of an accessory from the rear

of the head.

(6) VM-PTL

Push the push button to open the chuck. When the chuck is open, insert

the hand file grip into the chuck as shown and release the push button

(Fig.12).

Before using the endo instrument, lightly pull out to make sure it is securely

held.

The instrument grip that can be fit into the VM-PTL is 3.8mm to 4.1mm in

diameter.

To remove the instrument, push the push button and pull out the

instrument.

Fig.11

Fig.12

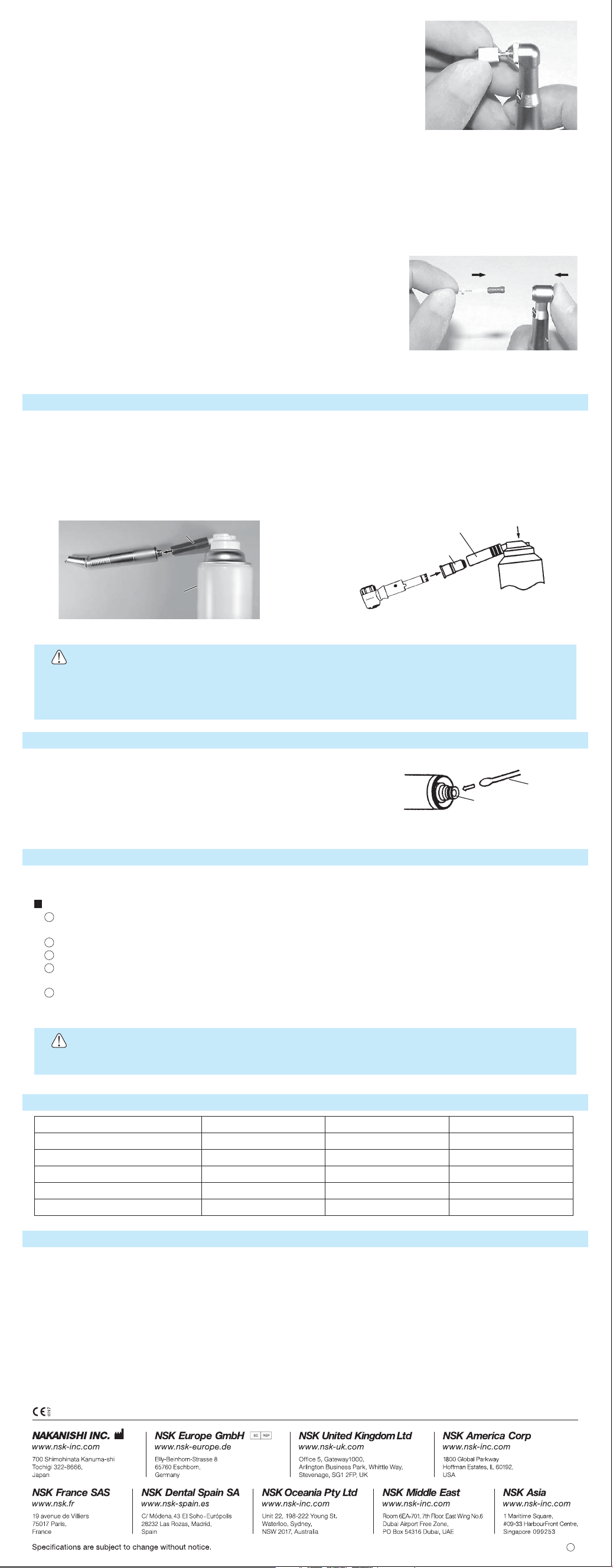

5. Lubrication

Always lubricate the air motor after use, and before autoclaving, with PANA- SPRAY Plus / PANA- SPRAY. Push

PHATELUS Spray nozzle attachment over the PANA SPRAY Plus / PANA- SPRAY nozzle until it firmly seats.

Insert the PHATELUS Spray nozzle into the rear of the air motor and spray for 2 seconds (Fig.13).

Lubrication of Contra Head.

Attach the contra head spray adapter to the end of PHATELUS Spray nozzle.

Insert the contra head drive gear into the spray adapter and spray for 2 seconds. (Fig.14)

PHATELUS Spray Nozzle

PHATELUS Spray Nozzle

PANA-SPRAY Plus / PANA-SPRAY

PANA-SPRAY Plus / PANA-SPRAY

PHATELUS Spray Nozzle

Contra Head

Spray Adapter

Fig.13

CAUTION

• Hold the air motor or contra head firmly when lubricating. Lubricant propellant pressure could eject the air

motor or contra head from the spray nozzle. Cover the head or the air motor front with paper tissue.

• Hold the spray can upright.

6. Cleaning of the fiber optic end (Except PTL-SDN)

Fig.14

In case the light has become dim, clean the fiber optic end with an

alcohol-soaked cotton swab (Fig.15).

Do not use a pointed tool or sharp edges to clean the fiber end. They may

damage the mirror finish and reduce the light transmission efficiency.

Fiber End

If the fiber optic end has become damaged, send the handpiece to your local

distributor for repair.

7. Sterilization

Steam autoclave is recommended.

Sterilization is required first time you use and after each patient as noted below.

Autoclave Procedure :

Scrub dirt and debris from the air motor body, and wipe clean with alcohol- immersed cotton swab or cloth. Do

1

not use a wire brush.

Lubricate with PANA-SPRAY Plus / PANA-SPRAY. Refer to 5 Lubrication.

2

Insert into an autoclave pouch. Seal the pouch.

3

Autoclavable up to max. 135°C.

4

ex.) Autoclave for 20 min. at 121°C, or 15 min. at 132°C.

5

Keep the handpiece in the autoclave pouch to keep it clean until you use it.

* Sterilization at 121°C for more than 15 minutes is recommended by EN13060 or EN ISO17665-1.

CAUTION

Do not wipe with, or clean or immerse in, high acid water or sterilizing solutions.

8. Specification

Cotton Swab

Fig.15

Motor Type

Drive Air Pressure

Air Consumption

Torque

Speed

Weight

MPa

NL/min

min

(kgf/cm2)

gf-cm

-1

(rpm)

g

PTL-SDN

0.25 (2.5)

32

190

25,000

90

PTL-CD

0.25 (2.5)

32

190

25,000

81

9. Repair Service

For genuine NSK service and parts, always return the handpiece to your NSK dealer.

The EU directive 93/42/EEC was applied in the design and production of this medical device.

PTL-CR

0.25 (2.5)

32

540

6,500

89

’11.09.005 S

Loading...

Loading...