Page 1

INSTRUCTION MANUAL

LISTED

DIGITAL TIME SWITCH

24 HOUR

DG180A

DG280A

DG280A-24

FOR TECHNICAL SUPPORT:

888.500.4598

A DIVISION OF NSi INDUSTRIES, LLC

USA • 800.321.5847 • www.nsiindustries.com

MLI-199(A)

Page 2

TABLE OF CONTENTS

Section Page

Installation Instructions and

Capabilities ...........................1

1.0 Clock Format . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.0 Clock Set Mode . . . . . . . . . . . . . . . . . . . . . . . . 2

3.0 Date Set Mode .........................2

4.0 Daylight Saving Time.....................3

4.1 To Modify Daylight Savings Dates ............3

5.0 Duty Cycle and Signal ....................4

5.1 To set Duty Cycle and Signal ...............5

6.0 Schedule Set Mode ......................6

6.1 Setting Hours and Minutes .................6

7.0 Skip Day Mode . . . . . . . . . . . . . . . . . . . . . . . . 7

7.1 To set Skip Day Mode . . . . . . . . . . . . . . . . . . . . 8

8.0 Review, Modify, and Delete . . . . . . . . . . . . . . . 10

Override Mode........................10

Wiring Diagram .......................13

Schedule Sheets . . . . . . . . . . . . . . . . . . . . 14 -16

Page 3

TORK MODEL

DG180A/DG280A/DG280A-24

7 DAY DIGITAL TIME SWITCH

READ INSTRUCTIONS CAREFULLY BEFORE

ATTEMPTING TO INSTALL TIME SWITCH. SEE

WARNING ON FRONT PANEL – Failure to comply with

instructions could result in personal injury and/or property

damage.

INSTALLATION:

UNIT IS TO BE INSTALLED BY A LICENSED ELECTRICIAN

1. Remove unit from enclosure by pushing the inside

tab (located near the outside hasp) to the right.

Swing unit to left and remove.

2. Mount the enclosure at eye level using screws

or other suitable fastening device. Bring supply

and load wires in through or side knockouts.

DO NOT USE TOP.

3. Reinstall unit by reversing step #1 above and

connecting wires to units as per suggested

wiring diagrams at back of manual.

4. Unit should be programmed with AC power. Do

not program under super cap back up power.

AT POWER UP;

Connect unit to main power source prior to entering the

settings. When powering up the unit for the first time,

allow 1-2 minutes for super cap to charge and the

display will show 12 HOUR. Press reset button after 2

minutes if screen is blank.

CAPABILITIES

- 24 hour scheduling

- 56 set points

- 2 Duty cycle or signal durations (maximum 24 hours)

- Unique “Skip Day” cycle pattern (repeats for up to 31

day cycles)

1

Page 4

FEATURES

Daylight saving - Automatic (user selectable)

Leap year - Automatic compensation

Power outage - Permanent schedule retention. Super

capacitor provides 7 days of real time back up.

Manual override - Until the next scheduled event

AM/PM or 24 hour format - user selectable

Multi-Voltage Input: 120 – 277VAC

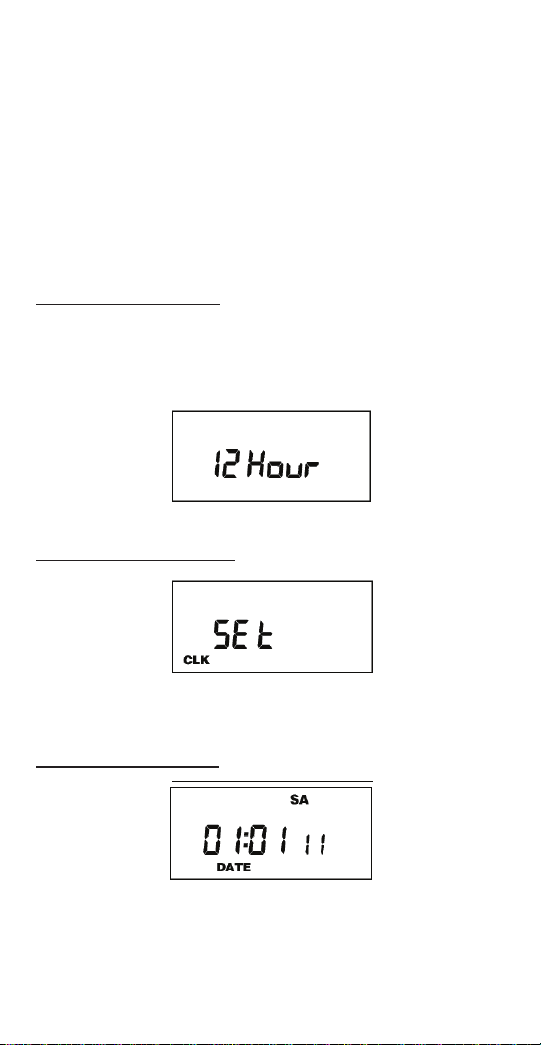

1.0 CLOCK FORMAT

The first time unit is powered up, it will display a

flashing 12 Hour. Use HOUR key to set clock format to

either 12 Hour (AM/PM) or 24 Hour. Press the ENTER

key.

2.0 CLOCK SET MODE

Press HOUR and MIN to advance to the present hour

and minutes. Check AM/PM, and press ENTER.

3.0 DATE SET MODE

2

Page 5

Press MONTH, DATE, and YEAR key to advance to

the desired month, date and year, then press ENTER.

NOTE: The day of the week will automatically set

once the date is entered.

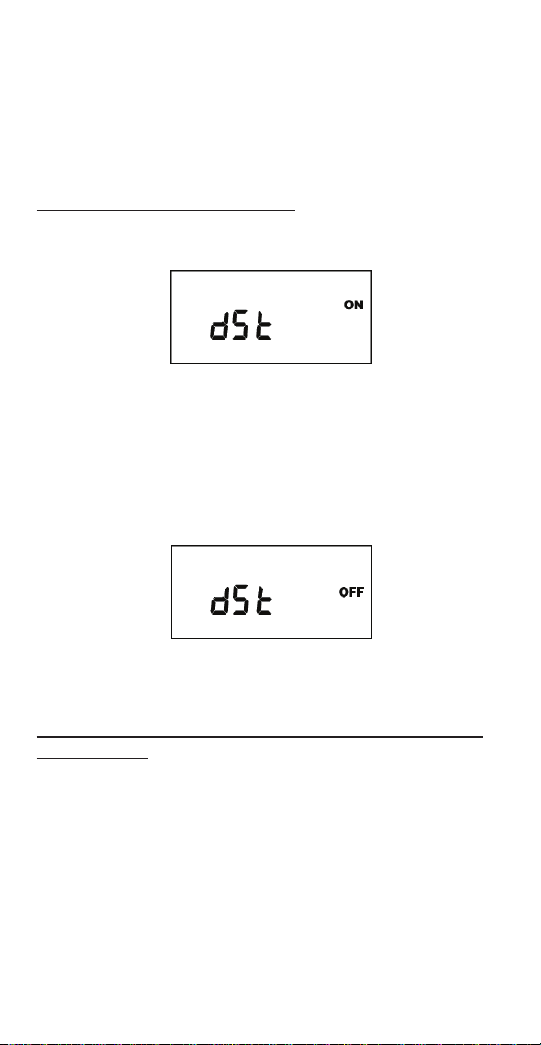

4.0 DAYLIGHT SAVING TIME

After setting or modifying the date, display will show:

a. For standard USA daylight savings (DSt), press

MODE and go to step 5.0.

b. For dates other than standard USA dates, press

MONTH and go to step 4.1.

c. If daylight saving time (DSt) is NOT required, press

DEL display will show:

Press ENTER then go to step 5.0.

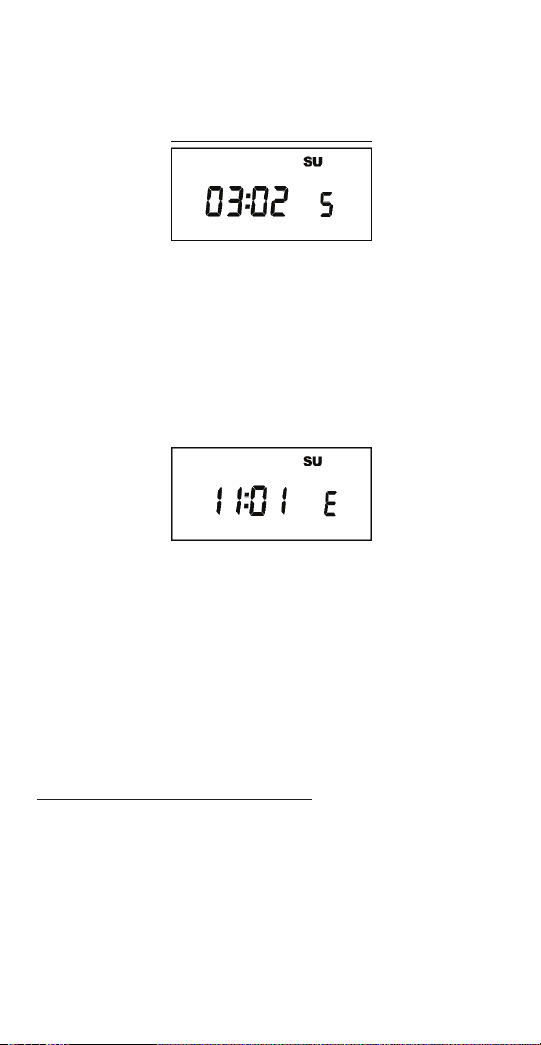

4.1 TO MODIFY STANDARD USA DAYLIGHT SAVINGS DATES

NOTE: The first two digits represent the month and

the second set of digits represent the week in the

month. Choices for week are 01 (1st), 02 (2nd), 03

(3rd) or L (Last) week of the month. The default day

3

Page 6

is Sunday (SU.) Once modified date set, the unit will

automatically calculate the correct start dates in the

future.

Now press MONTH and DATE buttons to modify the

starting DST settings. Pressing D AY changes default

day. EXAMPLE: A screen showing “04:01 SU S” repre

sents April (04), the first week (01), Sunday (SU), and

the Start (S) of daylight savings time.

Press ENTER to save and the display will show:

Now press MONTH and DATE buttons to modify the

ending DST settings. Pressing DAY changes default

day. EXAMPLE: A screen showing “10: L SU E”

represents October (10), the Last week (L), Sunday

(SU), and the End (E) of daylight savings time.

Press ENTER to save and the display will show the

modified DSt starting date.

Press MODE twice to go to step 5.0.

5.0 DUTY CYCLE AND SIGNAL

The Duty Cycle programming mode begins with a

display that shows the ON duration first for Duty Cycle

1 and the OFF duration second. Programming both

ON and OFF will enable the load to repeatedly turn

ON then OFF.

4

Page 7

The Signal Timer operation can be used by setting only

the ON duration of each duty cycle. Skip the OFF

duration entry. The load will turn ON for the duration of

the ON period, and it will not be repeated.

Once you’ve selected a cycle time, you need to

program the schedule in Section 6.0. Schedule the

events whenever you need to start and end the duty

cycle or to execute a signal, such as school bells.

If not needed, press the MODE key

5.1 TO SET DUTY CYCLE AND SIGNAL

Press either HOUR, MIN, or SEC keys to set the

desired ON duration for the cycle (ON C1).

Press the ENTER key.

a) For signal timer application, press the ENTER key.

b) For a cycle program, press the HOUR, MIN, or SEC

keys to set the time to the desired OFF duration for

the cycle (OFF C1). Press the ENTER key.

5

Page 8

Follow the same procedures above to set the second

signal or duty cycle entries.

Press MODE key to advance to next screen.

6.0 SCHEDULE SET MODE

Press MODE key until display shows:

6.1 SETTING HOURS AND MINUTES

Note: A schedule is needed for each event. If a typical

ON/OFF pair is required, use SCH 01 for the ON

event and SCH 02 for the OFF event.

Press the HOUR, and MIN keys to set the desired time.

Press EVENT to set desired event

(ON or OFF, C1, or C2)

Note: C1 or C2 will not be displayed if the duty cycle

durations are not set in Step 5.

Press CH SELECT key to select channel on

DG280A.

6

Page 9

Press ENTER to save.

Follow the same procedures above to set more

schedule entries.

Press MODE when schedules are complete.

7.0 SKIP DAY MODE

The Skip Day programming allows events to be

repeated for a certain number of days, and then

skipped for a number of days. Both active and skip

periods are set by the user from 1 to 31 days. The

timer will follow the programmed 24 hour schedule

during each day of the active period.

Example: A generator may have an active schedule

for 1 day and then skip 29 days to allow operation

once a month for testing purposes. On the one active

day, a 10 minute schedule may be programmed to start

at 4:00am.

The two channels of the DG280A add additional

programming capabilities in the Skip Day mode.

Alternating days of operation may be set for each

channel. This lets one load be active while the second

load is skipped.

Example: Two pumps are used to operate at alternate

times to extend the life of each pump. An active

schedule may be set so Pump A operates 5 days and

skip 2 days. Pump B can be set to be active on

2 days and skip the other 5. Care must be taken in

programming if the two pumps must not operate at the

same time.

If not needed, press the MODE key

7

Page 10

7.1 SETTING SKIP DAY MODE

Review the Skip Day carefully before

using this feature.

Call the Tork Tech Support line if you have

any question on set-up 888-500-4598.

Press MODE until display shows:

Press D/ON button to set the number of days load will

be active. The first number pair will change.

Press D/OFF button to set the number of days load will

skip. The second number pair will change.

Press DAY button to set today’s position within the

D/ON and D/OFF pattern. The third number pair will

change.

8

Page 11

Example 1: The screen below shows a pattern with 3

active days and 2 skip days with today set as the first

day of skip (01 OFF).

Example 2: For the DG280A with opposite

operations, screen below shows channel 2 set for a

cycle with 2 active days and 3 skip days with today

set as the first active day (01 ON) to be opposite the

first example.

Press MODE when Skip Days are complete.

Unit is in the AUTO (automatic) mode.

The word FLASH may appear to indicate a new

program has been written to memory.

Press the EVENT key once (or twice for two circuit

units) to activate current schedule then EVENT key

again to return to AUTO mode.

9

Page 12

8.0 REVIEW, MODIFY AND DELETE

Press MODE to advance to any of the following

MODES:

1. AUTO MODE: In this automatic mode, the unit will

execute the scheduled programs. Time, day, seconds

and load status are displayed. C1or C2 is displayed

when Duty Cycle is programmed and operating.

OVERRIDE IN AUTO MODE: The load status of the

channel can be manually changed by pressing the

OVRD key (or OVR1 and OVR2 key for DG280A).

The unit will stay in this position until the next scheduled

event. A flashing LCD load indication (ON, OFF) shows

the status was changed by the override not a scheduled

event.

Press the OVRD (or OVR1 and OVR2 key for

DG280A) key until ON or OFF stops flashing to return

to programmed setting.

OVERRIDE IN MAN MODE: The load status of the

channel can be manually changed by pressing the

OVRD key (or OVR1 and OVR2 key for DG280A).

The unit will stay in this position until OVRD is pressed

again. A flashing LCD load indication (ON, OFF)

shows the status was changed by the override not a

scheduled event.

3. CLK MODE: To change the current time press

HOUR and MIN to modify existing settings. Press

ENTER to save changes.

4. DATE MODE: Press MONTH, DATE and YEAR to

modify existing settings. Press ENTER to save

changes. DAY is automatically adjusted.

5. DSt MODE: Factory default is set at US standard

daylight savings dates noted by ON. To remove

daylight savings time setting from, press DEL to change

10

Page 13

screen to show OFF. DST may be activated again by

pressing DEL. Press ENTER to save changes. To change

the from the standard DST month/week/day setting

press HOUR and refer to step 4.1.

6. CYCLE MODE: To change duty cycle timing, press

either the HOUR, MIN, or SEC keys. Press ENTER to

save changes.

7. SCH MODE: To change schedule, press ENTER to

advance to desired event. Press HOUR, MIN, EVENT

to modify time settings. Press DEL to delete. Press

ENTER after each modification to save changes.

8. SKIP MODE: Press D/ON, D/OFF and DAY to

modify existing settings. Press ENTER to save

changes.

NOTES:

1. Unit has a look back feature. Press the EVENT key

once (or twice for two circuit units) to activate current

schedule then EVENT key again to return to the

time (run) screen. Unit will automatically pick up the last

schedule.

2. To clear date and time only and provide unit with

a soft reboot, press and release the reset button that is

recessed under the small hole to right side of LCD

screen.

3. To clear all memory, while in the RUN mode, press

ENTER, display will show:

Use the EVENT key to display:

11

Page 14

Now press ENTER briefly and everything in the timer

memory is wiped off including real time, date and

12HOUR will flash.

4. A “PF” on the display indicates a Power Failure and

the unit requires AC power to operate. The time and

date are protected for 7 days by the super cap. The

program is retained in permanent memory.

5. A “Lo” on the display indicates that the super cap

has run low and the unit needs to be powered with AC.

A minimum of 8 hours is required to fully charge the

super cap.

6. All programs and cycles will end at 1200 a.m. on

the start of a skip day.

7. The CH1 symbol (or CH2 symbol on a two channel)

will flash when in skip day/s. No operations will occur

on channel with flashing symbol.

12

Page 15

120/277VAC

120/277VAC

120/277VAC

DG180A

120/277VAC

DG280A

DG280A-24

13

Page 16

141516

Page 17

Page 18

Page 19

Page 20

A DIVISION OF NSi INDUSTRIES, LLC

USA • 800.321.5847 • www.nsiindustries.com

Loading...

Loading...