Page 1

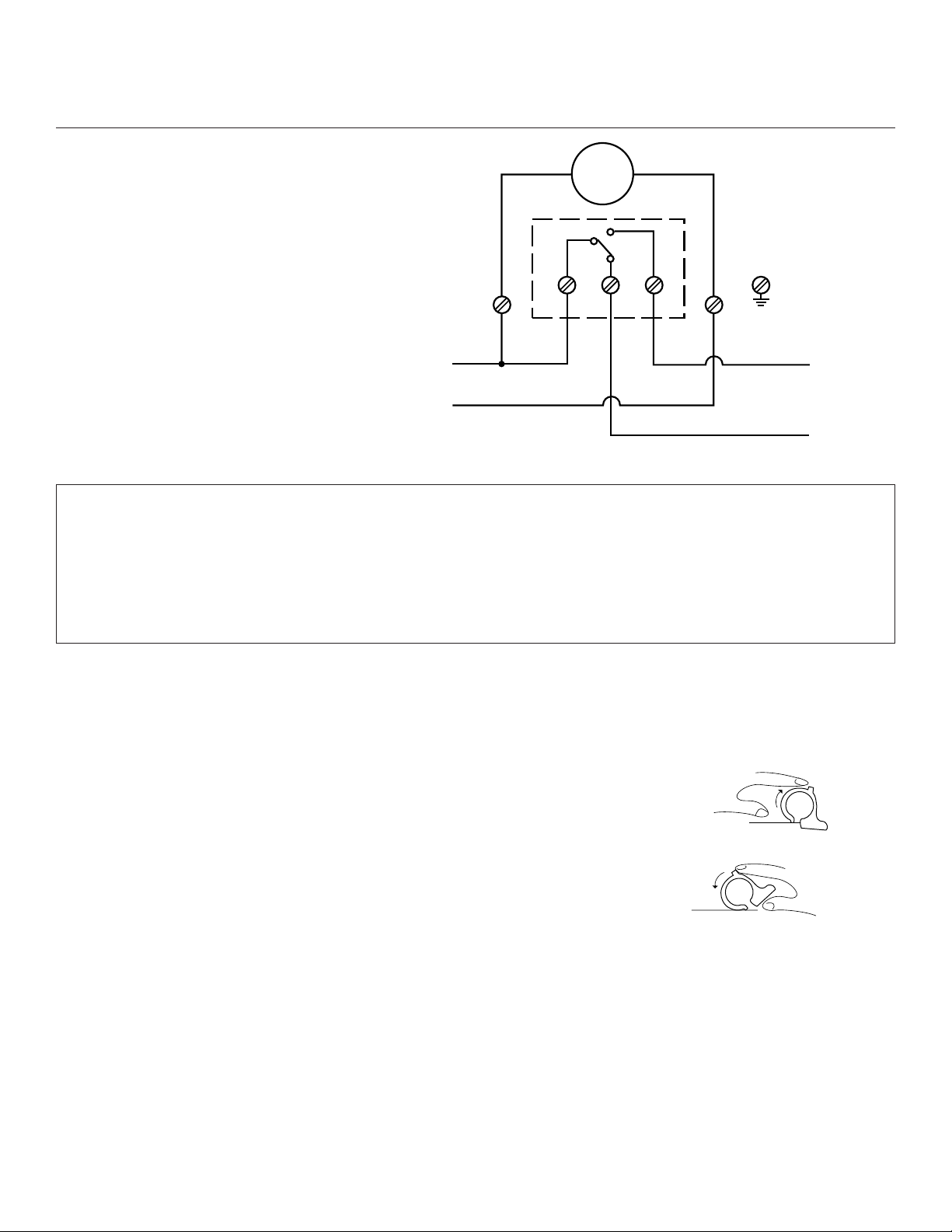

TORK MODEL 8001

DUTY CYCLE TIMER

SWITCH: SPDT

CONTACT RATINGS:

20 AMP 120/240VAC

3/4HP 120VAC;

1-1/2HP 240VAC

TIMING MOTOR:

120VAC 60Hz

POWER CONSUMPTION:

3 WATTS MAX.

INSTALLATION AND OPERATING INSTRUCTIONS

TO SET OPERATING TIMES: Each dial tab represents approximately 15 min-

utes. These tabs can be tilted in and out with the fingers.

FOR OFF OPERATION: Tilt tabs outward as illustrated in

figure 1. Tilt out one tab for each fifteen minute period.

This closes load 2 and opens load 1.

Disconnect power at main panel prior to installing or servicing this

time switch or the equipment connected to it.

Connect in accordance with national and local electrical codes.

Supply Connections: Use gauge specified (AWG # 8-14) suitable for

75 degrees C (167 degrees F)

FOR ON OPERATION: Tilt tabs inward toward center of

dial, as illustrated in figure 2. This closes load 1 and

opens load 2.

TO SET DIAL TO TIME: Turn dial counter-clockwise until correct time is indicated by arrow on nameplate. Be sure to check whether time set is A.M. or P.M.

TO REMOVE MECHANISM FROM CASE: Press lever near case latch to

release mainplate and swing the movement out. To replace, insert mainplate projections in slots opposite latch and swing movement in until it latches.

TORK

®

1 GROVE STREET, MT. VERNON, NY 10550 TEL: 914-664-3542

FAX: 914-664-5052

LI-568(A)

H

120VAC

N

C

L2

NONC

LOAD 2

MOTOR

LOAD 1

CLOSED WITH

TAB INWARD

CLOSED WITH

TAB OUTWARD

Fig. 1

Fig. 2

Page 2

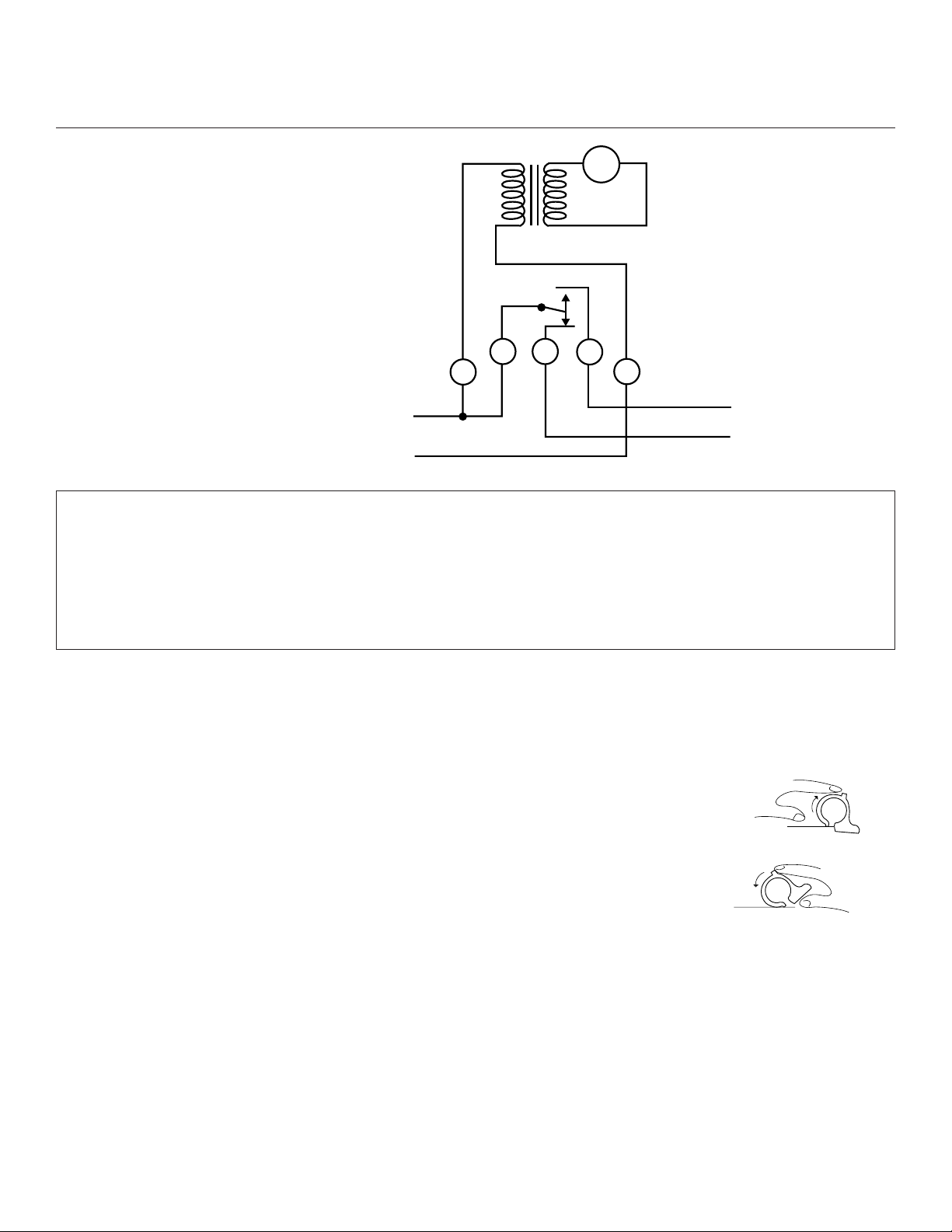

TORK MODEL 8001U

DUTY CYCLE TIMER

SWITCH: SPDT

CONTACT RATINGS:

5 AMP 480VAC

TIMING MOTOR:

120VAC 60Hz

TRANSFORMER:

480VAC/120VAC

POWER CONSUMPTION:

3 WATTS MAX.

INSTALLATION AND OPERATING INSTRUCTIONS

TO SET OPERATING TIMES: Each dial tab represents approximately 15 min-

utes. These tabs can be tilted in and out with the fingers.

FOR OFF OPERATION: Tilt tabs outward as illustrated in figure

1. Tilt out one tab for each fifteen minute period. This closes load

2 and opens load 1.

FOR ON OPERATION: Tilt tabs inward toward center of dial, as

illustrated in figure 2. This closes load 1 and opens load 2.

TO SET DIAL TO TIME: Turn dial counter-clockwise until correct time is indicated by arrow on nameplate. Be sure to check whether time set is A.M. or P.M.

TO REMOVE MECHANISM FROM CASE: Press lever near case latch to

release mainplate and swing the movement out. To replace, insert mainplate projections in slots opposite latch and swing movement in until it latches.

Disconnect power at main panel prior to installing or servicing this

time switch or the equipment connected to it.

Connect in accordance with national and local electrical codes.

Supply Connections: Use gauge specified (AWG # 8-14) suitable for

75 degrees C (167 degrees F)

TORK

®

1 GROVE STREET, MT. VERNON, NY 10550 TEL: 914-664-3542

FAX: 914-664-5052

LI-580(A)

MOTOR

CNC

480V LINE

NO

CLOSED WITH

2L

TAB OUTWARD

CLOSED WITH

TAB INWARD

LOAD 2

LOAD 1

Fig. 1

Fig. 2

Page 3

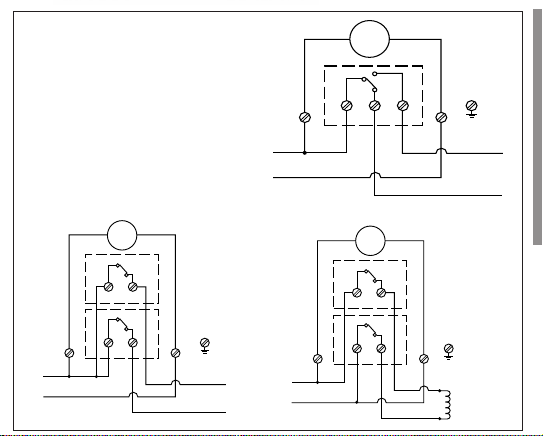

H

N

125VAC

CNC

CNC

MOTOR

LOAD 1

LOAD 2

®

LISTED

U

L

®

ALL SPDT

MODELS

Model

8002N

DPST

MOTOR

C

MOTOR

NONC

Model

L2

H

120VAC

N

8042N

CNC

DPST

LOAD 2

CLOSED WITH

TAB OUTWARD

LOAD 1

CLOSED WITH

TAB INWARD

H

208-250VAC

H

CNC

LOAD

STARTER

COIL

OR MOTOR

Page 4

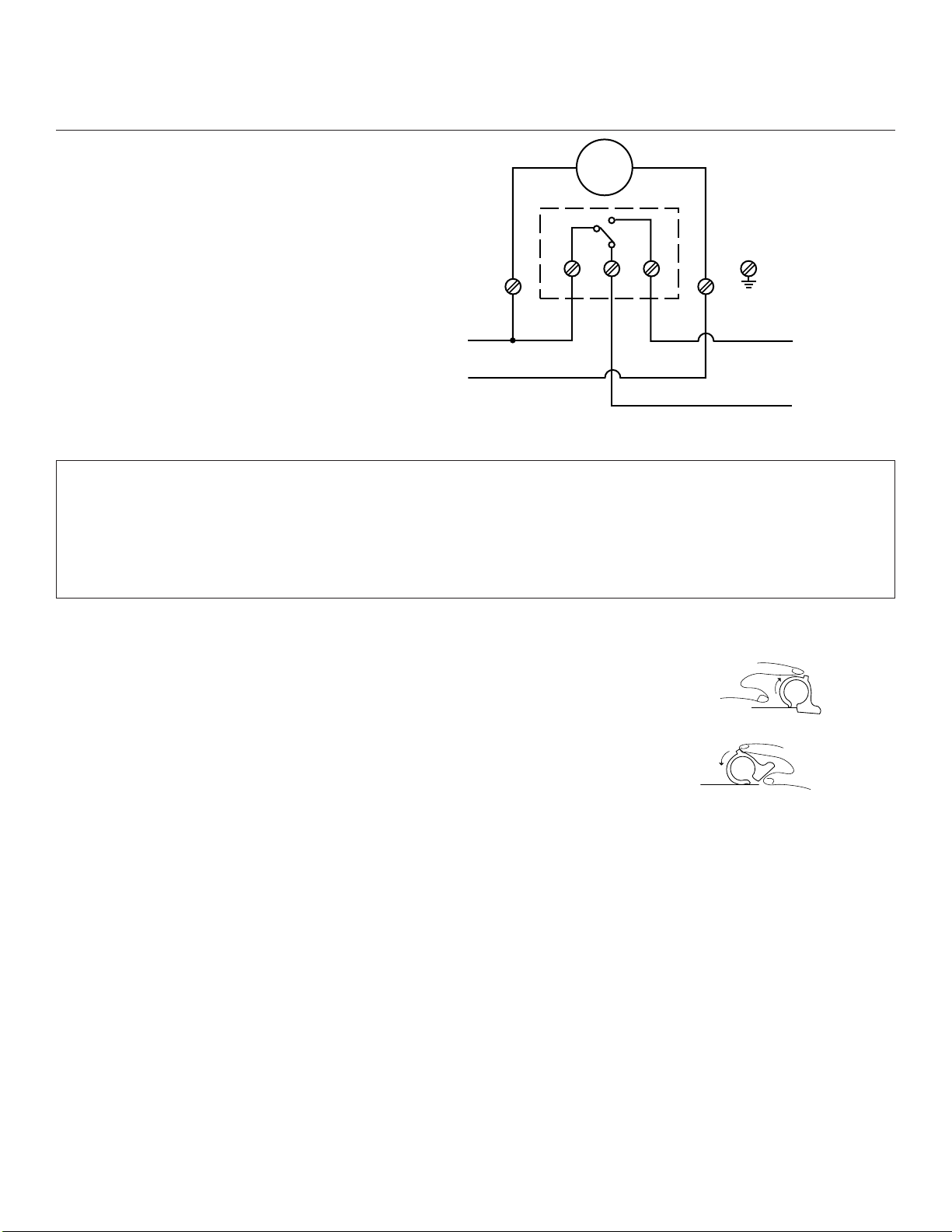

TORK MODEL 8004

DUTY CYCLE TIMER

SWITCH: SPDT

CONTACT RATINGS:

20 AMP 120/240VAC

3/4HP 120VAC;

1-1/2HP 240VAC

TIMING MOTOR:

208-277VAC 60Hz

POWER CONSUMPTION:

3 WATTS MAX.

INSTALLATION AND OPERATING INSTRUCTIONS

TO SET OPERATING TIMES: Each dial tab represents approximately 15 min-

utes. These tabs can be tilted in and out with the fingers.

FOR OFF OPERATION: Tilt tabs outward as illustrated in

figure 1. Tilt out one tab for each fifteen minute period. This

closes load 2 and opens load 1.

FOR ON OPERATION: Tilt tabs inward toward center of dial,

as illustrated in figure 2. This closes load 1 and opens load 2.

TO SET DIAL TO TIME: Turn dial counter-clockwise until correct time is indicated by arrow on nameplate. Be sure to check whether time set is A.M. or P.M.

TO REMOVE MECHANISM FROM CASE: Press lever near case latch to

release mainplate and swing the movement out. To replace, insert mainplate projections in slots opposite latch and swing movement in until it latches.

Disconnect power at main panel prior to installing or servicing this

time switch or the equipment connected to it.

Connect in accordance with national and local electrical codes.

Supply Connections: Use gauge specified (AWG # 8-14) suitable for

75 degrees C (167 degrees F)

TORK

®

1 GROVE STREET, MT. VERNON, NY 10550 TEL: 914-664-3542

FAX: 914-664-5052

LI-574(A)

H

120VAC

N

C

L2

NONC

LOAD 2

MOTOR

LOAD 1

CLOSED WITH

TAB INWARD

CLOSED WITH

TAB OUTWARD

208-277VAC

Fig. 1

Fig. 2

Page 5

TORK MODEL 8007

DUTY CYCLE TIMER WITH OMITTING DEVICE

SWITCH: SPDT

CONTACT RATINGS:

20 AMP 120/240VAC

3/4HP 120VAC;

1-1/2HP 240VAC

TIMING MOTOR:

120VAC 60Hz

POWER CONSUMPTION:

3 WATTS MAX.

INSTALLATION AND OPERATING INSTRUCTIONS

TO SET OPERATING TIMES: Each dial tab represents approximately 15

minutes. These tabs can be tilted in and out with the fingers.

FOR OFF OPERATION: Tilt tabs outward as illustrated in figure 1. Tilt

out one tab for each fifteen minute period. This closes load 2 and opens

load 1.

FOR ON OPERATION: Tilt tabs inward toward center of dial, as illustrated

in figure 2. This closes load 1 and opens load 2.

TO SET DIAL TO TIME: Tur n dial counter-clockwise until correct time is indicated by arrow on nameplate. Be sure to check whether time set is A.M. or P.M.

TO OMIT OPERATIONS: 7 spoke wheel at lower right of 24 hour dial moves ahead once each day at

about 2:00 A.M. Insert brass knurled screw in appropriate spokes on days when load 1 should

remain open (load 2 remains closed). CAUTION: Do not attempt to insert screw in spoke while it is

pointing to the copper colored arrow. If necessary, turn seven spoke wheel, then insert screw.

TO SET OMITTING WHEEL TO CORRECT DAY: If setting is being made later than 2:00 A.M. turn

omitting wheel CLOCKWISE until present day of week is indicated by copper arrow. (Between midnight and 2:00 A.M., setting must be made to day just ended at midnight.)

TO REMOVE MECHANISM FROM CASE: Press lever near case latch to release mainplate and

swing the movement out. To replace, insert mainplate projections in slots opposite latch and swing

movement in until it latches.

Disconnect power at main panel prior to installing or servicing this

time switch or the equipment connected to it.

Connect in accordance with national and local electrical codes.

Supply Connections: Use gauge specified (AWG # 8-14) suitable for

75 degrees C (167 degrees F)

TORK

®

1 GROVE STREET, MT. VERNON, NY 10550 TEL: 914-664-3542

FAX: 914-664-5052

LI-569(A)

H

120VAC

N

C

L2

NONC

LOAD 2

MOTOR

LOAD 1

CLOSED WITH

TAB INWARD

CLOSED WITH

TAB OUTWARD

Fig. 1

Fig. 2

Page 6

TORK MODEL 8007V

DUTY CYCLE TIMER

SWITCH: SPDT

CONTACT RATINGS:

20 AMP 120/240VAC

3/4HP 120VAC;

1-1/2HP 240VAC

TIMING MOTOR:

120VAC 60Hz

POWER CONSUMPTION:

3 WATTS MAX.

TO ALTERNATE CIRCUITS ONCE EACH WEEK, leave all dial tabs in ON

position and turn 7 consecutive omitting screws down and leave the other 7

turned out.

TO SET OPERATING TIMES: Each dial tab represents approximately 15 minutes. These tabs can be tilted in and out with the fingers.

FOR OFF OPERATION: Tilt tabs out-ward as illustrated in figure 1. Tilt out one

tab for each fifteen minute period. This closes load 2 and opens load 1.

FOR ON OPERATION: Tilt tabs inward toward center of dial, as illustrated in figure 2. This closes

load 1 and opens load 2.

TO SET TO TIME OF DAY: Turn dial counter-clockwise until the correct time of day is indicated by

the arrow in center of 24 hour dial. Be sure to check whether time set is A.M. or P.M.

TO SELECT DAY OR DAYS OF THE WEEK FOR OPERATION: 14 spoke calendar wheel at lower

right of dial rotates one revolution per 2 weeks. For day no ON operation is to occur (Load #2 remains

energized), simply turn down the brass knurled screws of the appropriate spokes. CAUTION: Do not

attempt to turn down screw in spoke while it is pointing to the black arrow. If necessary, tur n 14 spoke

wheel, then turn down screw.

TO SET 14 SPOKE WHEEL TO CORRECT DAY:

1.Turn dial counter-clockwise until special tab at 12:00 P.M. advances 14 spoke wheel.

2.Turn 14 spoke wheel by hand until spoke, indicating present day of week is pointing to black arrow

(in operation, present day is always in this position).

3.Reset dial to correct time of day.

Disconnect power at main panel prior to installing or servicing this

time switch or the equipment connected to it.

Connect in accordance with national and local electrical codes.

Supply Connections: Use gauge specified (AWG # 8-14) suitable for

75 degrees C (167 degrees F)

TORK

®

1 GROVE STREET, MT. VERNON, NY 10550 TEL: 914-664-3542

FAX: 914-664-5052

LI-522(B)

H

120VAC

N

C

L2

NONC

LOAD 2

MOTOR

LOAD 1

CLOSED WITH

TAB INWARD

CLOSED WITH

TAB OUTWARD

Fig. 1

Fig. 2

Page 7

TORK MODEL 8008

DUTY CYCLE TIMER WITH OMITTING DEVICE

SWITCH: SPDT

CONTACT RATINGS:

20 AMP 120/240VAC

3/4HP 120VAC;

1-1/2HP 240VAC

TIMING MOTOR:

208-277VAC 60Hz

POWER CONSUMPTION:

3 WATTS MAX.

INSTALLATION AND OPERATING INSTRUCTIONS

TO SET OPERATING TIMES: Each dial tab represents approximately 15

minutes. These tabs can be tilted in and out with the fingers.

FOR OFF OPERATION: Tilt tabs outward as illustrated in figure 1. Tilt out

one tab for each fifteen minute period. This closes load 2 and opens load 1.

FOR ON OPERATION: Tilt tabs inward toward center of dial, as illustrated

in figure 2. This closes load 1 and opens load 2.

TO SET DIAL TO TIME: Tur n dial counter-clockwise until correct time is indicated by arrow on name-

plate. Be sure to check whether time set is A.M. or P.M.

TO OMIT OPERATIONS: 7 spoke wheel at lower right of 24 hour dial moves ahead once each day at

about 2:00 A.M. Insert brass knurled screw in appropriate spokes on days when load 1 should remain

open (load 2 remains closed). CAUTION: Do not attempt to insert screw in spoke while it is pointing

to the copper colored arrow. If necessary, turn seven spoke wheel, then insert screw.

TO SET OMITTING WHEEL TO CORRECT DAY: If setting is being made later than 2:00 A.M. turn

omitting wheel CLOCKWISE until present day of week is indicated by copper arrow. (Between midnight and 2:00 A.M., setting must be made to day just ended at midnight.)

TO REMOVE MECHANISM FROM CASE: Press lever near case latch to release mainplate and

swing the movement out. To replace, insert mainplate projections in slots opposite latch and swing

movement in until it latches.

Disconnect power at main panel prior to installing or servicing this

time switch or the equipment connected to it.

Connect in accordance with national and local electrical codes.

Supply Connections: Use gauge specified (AWG # 8-14) suitable for

75 degrees C (167 degrees F)

TORK

®

1 GROVE STREET, MT. VERNON, NY 10550 TEL: 914-664-3542

FAX: 914-664-5052

LI-573(A)

208-277VAC

MOTOR

L2

H

120VAC

N

C

NONC

LOAD 2

CLOSED WITH

TAB OUTWARD

LOAD 1

CLOSED WITH

TAB INWARD

Fig. 1

Fig. 2

Page 8

TORK MODEL 8011

1 MINUTE REPEATING TIMER

SWITCH: SPDT

CONTACT RATINGS:

20 AMP 120/240VAC

3/4HP 120VAC;

1-1/2HP 240VAC

TIMING MOTOR:

120VAC 60Hz

POWER CONSUMPTION:

3 WATTS MAX.

INSTALLATION AND OPERATING INSTRUCTIONS

TO SET OPERATING TIMES: Each dial tab represents approximately 1 second.

These tabs can be tilted in and out with the fingers.

FOR OFF OPERATION: Tilt tabs outward as illustrated in figure

1. Tilt out one tab for each 1 second period. This closes load 2

and opens load 1.

FOR ON OPERATION: Tilt tabs inward toward center of dial, as

illustrated in figure 2. This closes load 1 and opens load 2.

TO REMOVE MECHANISM FROM CASE: Press lever near case latch to

release mainplate and swing the movement out. To replace, insert mainplate projections in slots opposite latch and swing movement in until it latches.

Disconnect power at main panel prior to installing or servicing this

time switch or the equipment connected to it.

Connect in accordance with national and local electrical codes.

Supply Connections: Use gauge specified (AWG # 8-14) suitable for

75 degrees C (167 degrees F)

TORK

®

1 GROVE STREET, MT. VERNON, NY 10550 TEL: 914-664-3542

FAX: 914-664-5052

LI-579(A)

H

120VAC

N

C

L2

NONC

LOAD 2

MOTOR

LOAD 1

CLOSED WITH

TAB INWARD

CLOSED WITH

TAB OUTWARD

Fig. 1

Fig. 2

Page 9

®

LISTED

U

L

®

MOTOR

C

L2

H

120VAC

N

NONC

LOAD 2

CLOSED WITH

TAB OUTWARD

LOAD 1

CLOSED WITH

TAB INWARD

Page 10

TORK MODEL 8121

12 MINUTE REPEATING TIMER

SWITCH: SPDT

CONTACT RATINGS:

20 AMP 120/240VAC

3/4HP 120VAC;

1-1/2HP 240VAC

TIMING MOTOR:

120VAC 60Hz

POWER CONSUMPTION:

3 WATTS MAX.

INSTALLATION AND OPERATING INSTRUCTIONS

TO SET OPERATING TIMES: Each dial tab represents approximately 12 sec-

onds. These tabs can be tilted in and out with the fingers.

FOR OFF OPERATION: Tilt tabs outward as illustrated in figure

1. Tilt out one tab for each 12 second period. This closes load 2

and opens load 1.

FOR ON OPERATION: Tilt tabs inward toward center of dial, as

illustrated in figure 2. This closes load 1 and opens load 2.

TO REMOVE MECHANISM FROM CASE: Press lever near case latch to

release mainplate and swing the movement out. To replace, insert mainplate projections in slots opposite latch and swing movement in until it latches.

Disconnect power at main panel prior to installing or servicing this

time switch or the equipment connected to it.

Connect in accordance with national and local electrical codes.

Supply Connections: Use gauge specified (AWG # 8-14) suitable for

75 degrees C (167 degrees F)

TORK

®

1 GROVE STREET, MT. VERNON, NY 10550 TEL: 914-664-3542

FAX: 914-664-5052

LI-577(A)

H

120VAC

N

C

L2

NONC

LOAD 2

MOTOR

LOAD 1

CLOSED WITH

TAB INWARD

CLOSED WITH

TAB OUTWARD

Fig. 1

Fig. 2

Page 11

TORK MODEL 8150

SWITCH: SPST

CONTACT RATINGS:

10 AMP 120/240VAC

3/4HP 120VAC

TIMING MOTOR:

120VAC 60Hz

POWER CONSUMPTION:

3 WATTS MAX.

INSTALLATION AND OPERATING INSTRUCTIONS

TO SET OPERATING TIMES: Each dial tab represents approx-

imately 15 minutes. These tabs can be tilted in and out with the

fingers.

FOR ON OPERATION: Tilt tabs out-ward as illustrated in figure

1. Tilt out one tab for each fifteen minute period.

FOR OFF OPERATION: Tilt tabs inward toward center of dial, as illustrated in

figure 2.

TO SET DIAL TO TIME: Tur n dial counter-clockwise until correct time is indicat-

ed by arrow on nameplate. Be sure to check whether time set is A.M. or P.M.

TO SET DELAY: Delay is manually adjustable from 0-8 minutes. Turn “DELAY

CONTROL” clockwise for longer delay, counter-clockwise for shorter delay.

TO REMOVE MECHANISM FROM CASE: Press lever near case latch to

release mainplate and swing the movement out. To replace, insert mainplate projections in slots opposite latch and swing movement in until it latches.

Disconnect power at main panel prior to installing or servicing this

time switch or the equipment connected to it.

Connect in accordance with national and local electrical codes.

Supply Connections: Use gauge specified (AWG # 8-14) suitable for

75 degrees C (167 degrees F)

TORK

®

1 GROVE STREET, MT. VERNON, NY 10550 TEL: 914-664-3542

FAX: 914-664-5052

LI-562(A)

L 2

H

N

120V, 60 Hz

CNC NO

LOAD

DELAY

SWITCH

SUSTAINED

SWITCH

M

Fig. 1

Fig. 2

Page 12

M

DELAY

SWITCH

L 2

H

N (120V)

H (480V)

SUSTAINED

SWITCH

CNC NO

LOAD

8150 Series

Page 13

TORK MODEL 8150U

SWITCH: SPST

CONTACT RATINGS:

5 AMP 480VAC

3/4HP 120VAC

TRANSFORMER:

480/120VAC

TIMING MOTOR:

120VAC 60Hz

POWER CONSUMPTION:

3 WATTS MAX.

INSTALLATION AND OPERATING INSTRUCTIONS

TO SET OPERATING TIMES: Each dial tab represents approx-

imately 15 minutes. These tabs can be tilted in and out with the

fingers.

FOR ON OPERATION: Tilt tabs out-ward as illustrated in figure

1. Tilt out one tab for each fifteen minute period.

FOR OFF OPERATION: Tilt tabs inward toward center of dial, as illustrated in

figure 2.

TO SET DIAL TO TIME: Tur n dial counter-clockwise until correct time is indicat-

ed by arrow on nameplate. Be sure to check whether time set is A.M. or P.M.

TO SET DELAY: Delay is manually adjustable from 0-8 minutes. Turn “DELAY

CONTROL” clockwise for longer delay, counter-clockwise for shorter delay.

TO REMOVE MECHANISM FROM CASE: Press lever near case latch to

release mainplate and swing the movement out. To replace, insert mainplate projections in slots opposite latch and swing movement in until it latches.

Disconnect power at main panel prior to installing or servicing this

time switch or the equipment connected to it.

Connect in accordance with national and local electrical codes.

Supply Connections: Use gauge specified (AWG # 8-14) suitable for

75 degrees C (167 degrees F)

TORK

®

1 GROVE STREET, MT. VERNON, NY 10550 TEL: 914-664-3542

FAX: 914-664-5052

LI-563(A)

480VAC

DELAY

SWITCH

SUSTAINED

SWITCH

C

H

H

NC NO

LOAD

MOTOR

L2

Fig. 1

Fig. 2

Page 14

TORK MODEL 8301

30 MINUTE REPEATING TIMER

SWITCH: SPDT

CONTACT RATINGS:

20 AMP 120/240VAC

3/4HP 120VAC;

1-1/2HP 240VAC

TIMING MOTOR:

120VAC 60Hz

POWER CONSUMPTION:

3 WATTS MAX.

INSTALLATION AND OPERATING INSTRUCTIONS

TO SET OPERATING TIMES: Each dial tab represents approximately 30 sec-

onds. These tabs can be tilted in and out with the fingers.

FOR OFF OPERATION: Tilt tabs outward as illustrated in figure 1.

Tilt out one tab for each 30 second period. This closes load 2

and opens load 1.

FOR ON OPERATION: Tilt tabs inward toward center of dial, as

illustrated in figure 2. This closes load 1 and opens load 2.

TO REMOVE MECHANISM FROM CASE: Press lever near case latch to

release mainplate and swing the movement out. To replace, insert mainplate projections in slots opposite latch and swing movement in until it latches.

Disconnect power at main panel prior to installing or servicing this

time switch or the equipment connected to it.

Connect in accordance with national and local electrical codes.

Supply Connections: Use gauge specified (AWG # 8-14) suitable for

75 degrees C (167 degrees F)

TORK

®

1 GROVE STREET, MT. VERNON, NY 10550 TEL: 914-664-3542

FAX: 914-664-5052

LI-576(A)

H

120VAC

N

C

L2

NONC

LOAD 2

MOTOR

LOAD 1

CLOSED WITH

TAB INWARD

CLOSED WITH

TAB OUTWARD

Fig. 1

Fig. 2

Page 15

TORK MODEL 8061

6 MINUTE REPEATING TIMER

SWITCH: SPDT

CONTACT RATINGS:

20 AMP 120/240VAC

3/4HP 120VAC;

1-1/2HP 240VAC

TIMING MOTOR:

120VAC 60Hz

POWER CONSUMPTION:

3 WATTS MAX.

INSTALLATION AND OPERATING INSTRUCTIONS

TO SET OPERATING TIMES: Each dial tab represents approximately 6 sec-

onds. These tabs can be tilted in and out with the fingers.

FOR OFF OPERATION: Tilt tabs outward as illustrated in

figure 1. Tilt out one tab for each 6 second period. This

closes load 2 and opens load 1.

FOR ON OPERATION: Tilt tabs inward toward center of

dial, as illustrated in figure 2. This closes load 1 and opens

load 2.

TO REMOVE MECHANISM FROM CASE: Press lever near case latch to

release mainplate and swing the movement out. To replace, insert mainplate projections in slots opposite latch and swing movement in until it latches.

Disconnect power at main panel prior to installing or servicing this

time switch or the equipment connected to it.

Connect in accordance with national and local electrical codes.

Supply Connections: Use gauge specified (AWG # 8-14) suitable for

75 degrees C (167 degrees F)

TORK

®

1 GROVE STREET, MT. VERNON, NY 10550 TEL: 914-664-3542

FAX: 914-664-5052

LI-578(A)

H

120VAC

N

C

L2

NONC

LOAD 2

MOTOR

LOAD 1

CLOSED WITH

TAB INWARD

CLOSED WITH

TAB OUTWARD

Fig. 1

Fig. 2

Page 16

TORK MODEL 8602

60 MINUTE REPEATING TIMER

SWITCH: SPDT

CONTACT RATINGS:

20 AMP 120/240VAC

3/4HP 120VAC;

1-1/2HP 240VAC

TIMING MOTOR:

208-277VAC 60Hz

POWER CONSUMPTION:

3 WATTS MAX.

INSTALLATION AND OPERATING INSTRUCTIONS

60 MINUTE DIAL: 1 to 30 ON-OFF operations per hour. 60 tabs permit 1 minute

switching changes. Cycles adjustable from 2, 3, 4, 5, 6, 10, 12, 15, 20, 30, or 60

minutes, with 1 minute minimum ON and/or OFF settings.

TO SET OPERATING TIMES: Each dial tab represents approximately 1 minute.

These tabs can be tilted in and out with the fingers.

FOR OFF OPERATION: Tilt tabs outward as illustrated in

figure 1. Tilt out one tab for each 1 minute period. This closes

load 2 and opens load 1.

FOR ON OPERATION: Tilt tabs inward toward center of dial,

as illustrated in figure 2. This closes load 1 and opens load 2.

TO REMOVE MECHANISM FROM CASE: Press lever near case latch to

release mainplate and swing the movement out. To replace, insert mainplate projections in slots opposite latch and swing movement in until it latches.

Disconnect power at main panel prior to installing or servicing this

time switch or the equipment connected to it.

Connect in accordance with national and local electrical codes.

Supply Connections: Use gauge specified (AWG # 8-14) suitable for

75 degrees C (167 degrees F)

TORK

®

1 GROVE STREET, MT. VERNON, NY 10550 TEL: 914-664-3542

FAX: 914-664-5052

LI-572(A)

H

120VAC

N

C

L2

NONC

LOAD 2

MOTOR

LOAD 1

CLOSED WITH

TAB INWARD

CLOSED WITH

TAB OUTWARD

208-277VAC

Fig. 1

Fig. 2

Loading...

Loading...