CBO-750 HYBRID-R OVEN | Instructions Manual

ELECTRICAL DIAGRAM IS LOCATED BEHIND FRONT PANEL

THIS OVEN MAY BE OPERATED OUTDOORS.

ELECTRICAL DIAGRAMS ARE LOCATED BEHIND FRONT PANEL.

KEEP THIS MANUAL FOR FUTURE USE.

Chicago Brick Oven, LLC. | 205 E. Butterfield Road, #448 | Elmhurst, IL 60126

Customer Assistance: 630.359.4793

© 2016 Chicago Brick Oven. All rights reserved.

TO INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE CONSUMER.

TO CONSUMER: RETAIN THESE INSTRUCTIONS FOR FUTURE USE.

WARNING!

1. DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE LIQUIDS OR VAPORS IN THE VICINITY

OF THIS OR ANY OTHER APPLIANCE.

2. AN LP CYLINDER NOT CONNECTED FOR USE SHALL NOT BE STORED IN THE VICINITY OF THIS OR

ANY APPLIANCE.

WARNING! DO NOT USE THIS APPLIANCE UNDER EXTENDED AWNINGS.

FAILURE TO COMPLY COULD RESULT IN A FIRE OR PERSONAL INJURY.

DANGER!

IF YOU SMELL GAS:

• SHUT OFF GAS TO THE APPLIANCE.

• EXTINGUISH ANY OPEN FLAME.

• REMOVE DOOR.

• IF ODOR CONTINUES, KEEP AWAY FROM THE APPLIANCE AND IMMEDIATELY CALL YOUR GAS

SUPPLIER OR YOUR FIRE DEPARTMENT.

2

Installation

I. General

• Upon receipt of your oven, thoroughly inspect for

any damage. If damage is observed, contact the

delivery agency immediately.

• Safe and satisfactory operation of your oven

depends to a great extent on its proper

installation. Installation must conform to local

codes or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54,

or the Natural Gas and Propane Installation Code,

CSA B149.1, as applicable.

• Keep any electrical supply cord and the fuel

supply hose away from any heated surface.

• Keep oven area free and clear from combustibles,

gasoline and other flammable vapors or liquids.

• Provide adequate clearances for air opening into

combustion chamber.

• Provide adequate clearance for servicing and

proper operation.

• The area in front of and above the oven must

be clear to avoid any obstruction of flow of

combustion and ventilation air. Means must be

provided for adequate air supply and adequate

clearance for air openings into the combustion

chamber.

• The ambiance burner is equipped with orifices

which are an integral part of the burner

assembly. The heart burner is equipped with an

orifice. Note: It is important to verify that the

orifice is properly aligned with the venturi of the

burner where gas and air enter the burner.

• For counter and freestanding installations the

oven is completely assembled as shipped. Do

not make any modifications to the oven or stand.

Any modifications can cause injury or property

damage and void warranty.

• This outdoor cooking oven shall be used

outdoors only and not to be used in a building,

garage or any other enclosed area. It is not

intended to be installed in or on boats or

recreational vehicles.

II. Clearances to Combustible and

Noncombustible Construction

Sides = 4 inch (10.2 cm) Back = 4 inch (10.2 cm)

Top = 10 inch (25.4 cm)

For use only on noncombustible floors or counters.

III. Gas Piping for Fixed Gas Supply

• Connect oven to gas supply line. Under no

circumstances should the gas supply line be

smaller than the inlet pipe on the oven. Use pipe

sealant on all joints. Sealant must be resistant to

the action of LP gases.

• A 1/8-inch (3.175 mm) pressure tap is provided

on the gas control for checking the gas pressure.

The gas control is equipped with a pressure

regulator. The outlet pressure setting is 4-inch

(101.6 mm) water column on natural gas and 10inch (254 mm) water column on propane gas.

• Level oven and its individual shut-off valve must

be disconnected from the gas supply piping

system during any pressure testing of the system

at test pressures in excess of ½ psig (3.45kPa).

• The oven must be isolated from the gas supply

piping system by closing the individual manual

shut-off valve during any pressure testing of the

gas supply piping system at test pressures equal

to or less than ½ psig (3.45kPa).

To check for leaks, use a soap and water solution.

DO NOT USE OPEN FLAME

3

Installation Continued

IV. Information for Use with a Self Contained LP-Gas Supply System

DO NOT STORE A SPARE LP GAS CYLINDER UNDER OR

NEAR THIS APPLIANCE.

NEVER FILL THE CYLINDER BEYOND 80% FULL. IF

THESE TWO STATEMENTS ARE NOT FOLLOWED

EXACTLY, A FIRE CAUSING DEATH OR SERIOUS

INJURY MAY OCCUR.

• If your oven is factory-built for LP (Propane)

the regulator supplied is set for 11" W.C. and is

for use with LP gas only. The factory-supplied

regulator and hose must be used with a 20 LB LP

cylinder.

• The LP-gas supply cylinder must be constructed

and marked in accordance with the Specifications

for LP-gas Cylinders of the U.S. Department of

Transportation (D.O.T.) or the National Standards

of Canada CAN/CSA-B339, Cylinders, Spheres

and Tubes for the Transportation of Dangerous

Goods, and Commission, as applicable; and

Locate and orient the LP cylinder to provide proper

vapor withdrawal. Connect the regulator to the

LP cylinder. Hand tighten it. Do not use a wrench.

Check for leaks using a soapy water solution.

NEVER USE OPEN FLAME TO CHECK FOR GAS

LEAK.

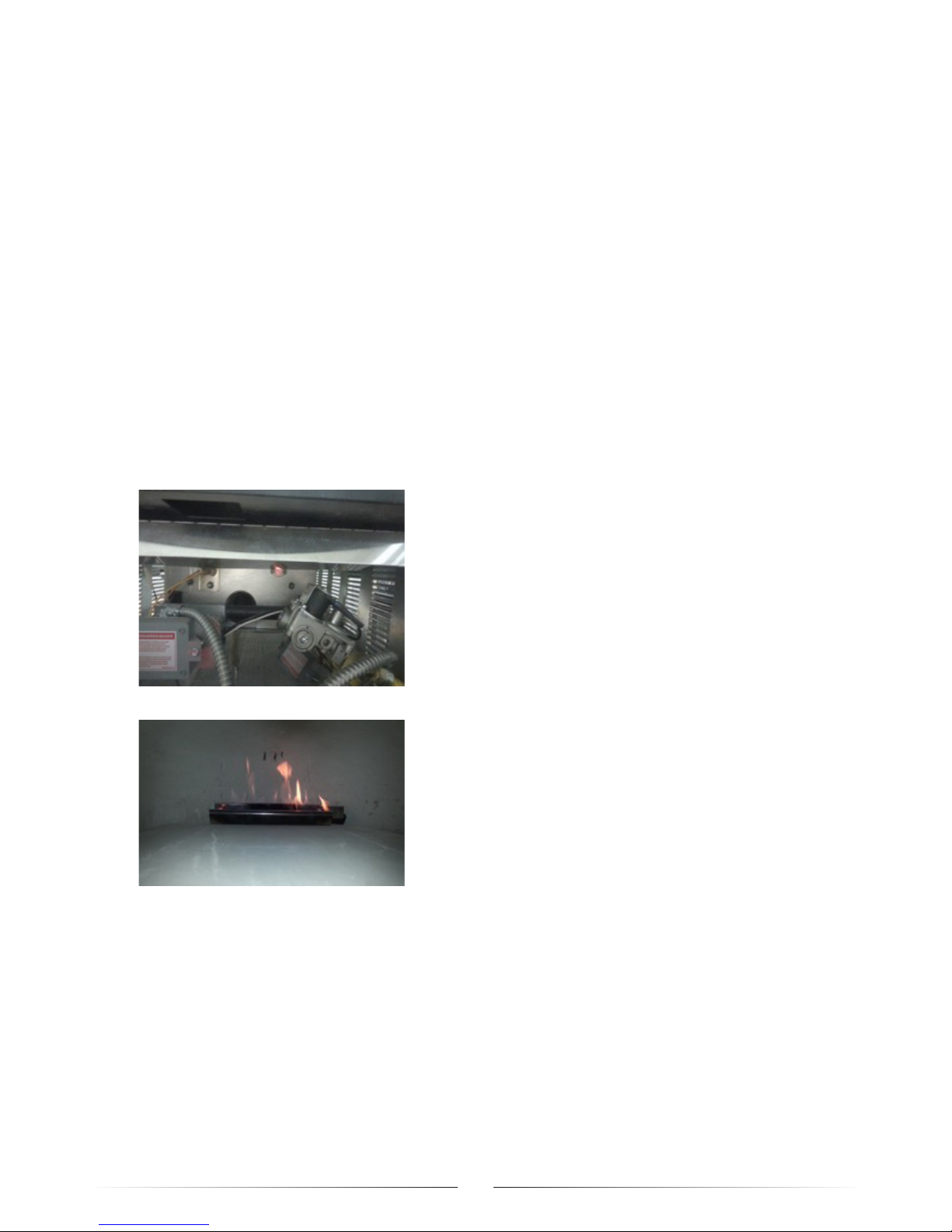

Note: Any 20 LB LPG cylinder can be used provided it

is compatible with the retention means as shown in

photo.

• If the oven is not in use, the gas must be turned

“OFF” at the supply cylinder. The cylinder must be

disconnected from the oven and stored outdoors,

out of the reach of children and must not be stored

in building, garage or any other enclosed area.

• Always inspect the hose before each use of the

oven. If it is evident there is excessive abrasion or

wear, or the hose is cut, it must be replaced prior to

the oven being put in operation. The replacement

hose assembly shall be that specified by the

manufacturer.

1. Provided with a listed overfilling prevention

device

2. Provided with a cylinder connection device

compatible with the connection for outdoor

cooking appliances

3. Marked with a 20 LB LPG capacity

It must be provided with a shut-off valve terminating

in gas tank valve outlet. It must include a collar

to protect the cylinder valve. The cylinder supply

system must be arranged for vapor withdrawal.

• Install the factory-supplied hose and regulator

assembly as shown in illustration. Connect the

3/8" flare end of the hose to the oven piping

outlet coupling using a ¾" open wrench. Do not

apply pipe sealant to the ¾" flare connection.

The pressure regulator and hose assembly supplied

with to the oven must be used. Replacement of

pressure regulator and hose assembly must be those

specified by the oven manufacturer.

4

Installation Continued

VIII. Electrical Connections

When installed, the oven must be electrically

grounded in accordance with local codes or in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70, or the Canadian Electrical Code

Part 1, CSA C22.1.

Electrical Rating

Volts Amps Frequency

120 1.50 60

• To protect against electric shock, do not immerse

cord or plugs in water or other liquid;

• Unplug from the outlet when not in use and before

cleaning. Allow to cool before putting on or taking

off parts;

• Do not operate any outdoor cooking gas appliance

with a damaged cord, plug, or after the appliance

malfunctions or has been damaged in any manner.

Contact the manufacturer for repair;

• Do not let the cord hang over the edge of a table or

touch hot surfaces;

• Do not use an outdoor cooking gas appliance for

purposes other than intended;

• When connecting, first connect plug to the outdoor

cooking gas appliance then plug appliance into

the outlet;

• Use only a Ground Fault Interrupter (GFI) protected

circuit with this outdoor cooking gas appliance;

• Never remove the grounding plug or use with an

adapter of 2 prongs; and

• Use only extension cords with 3-prong grounding

plug, rated for the power of the equipment, and

approved for outdoor use with a W-A marking.

ELECTRICAL DIAGR AM IS LOCATED BEHIND FRONT PANEL

VI. Hearth Burner Lighting Instructions

READ INSTRUCTIONS BEFORE LIGHTING

1. Set main gas supply cock in “OFF” position.

2. Turn main electrical supply “OFF.”

3. Wait at least (5) five minutes.

4. Set temperature control to desired settings

5

Installation Continued

5. Place ambiance burner “ON/OFF” switch in

“OFF” position.

6. Set main gas supply cock in “ON” position.

7. Turn main electrical supply “ON.”

8. Place main “ON/OFF” switch in “ON” position.

9. If burner does not light, repeat steps 1-8.

VII. Ambiance Burner Lighting

Instructions

Note: The hearth burner system must be ON as controlled by the

thermostat.

Place ambiance burner ON/OFF switch in “ON” position.

VIII. Shutting Down Instructions

To shut down the burner control systems for a period

of time, turn “OFF” the main electrical supply and place

the main panel ON/OFF switch and ambiance burner

circuit ON/OFF switch to the “OFF” position.

To shut down the burner control systems for longer than

a week, turn “OFF” and “LOCK OUT” the main electrical

supply to the burner systems and turn “OFF” and “LOCK

OUT” the incoming gas supply gas cock.

6

Operation

IX. CAUTION: In the event of power

failure, do not attempt to operate oven

until power is resumed.

NOTE: Inspect the gas hose (if used) before each use of the oven.

If it is evident there is excessive abrasion or wear, or

the hose is cut, it must be replaced prior to the oven

being put in operation. The replacement hose assembly

shall be that specified by the manufacturer.

Lighting & Shutting down Instructions: Refer to

related section in Installation portion of this manual and

label located on oven front panel.

To cure the oven on first firing and release the moisture

from the oven dome, the thermostat should be set at

approximately 212ºF (100ºC) over a period of 2-3 days.

Curing the oven can be done with only the ambiance

burner turned “ON”. Use one tank of propane or get the

oven to 250ºF (121ºC) for 16 hours in duration. This can

be split into two different 8-hour time periods.

Note: Due to thermal expansion, small cracks may

appear in the dome or hearth during the curing process.

This is normal and the quality of your oven will not be

compromised.

This oven can be operated as a gas oven or as a hybrid

oven:

• For gas operation, follow Lighting & Shutting down

Instructions.

• For hybrid operation, wood can be inserted on the

cooking surface after oven temperature reaches

thermostat setting.

Note: Use only small amounts of wood to enhance the

flavor of foods. NEVER place wood on top of or direct

contact with the ambiance burner at the back of the

oven.

Do not cook with the door closed. All cooking should be

done with the door open.

WARNING

NEVER COVER SLOTS, HOLES, OR PASSAGES IN THE OVEN BOTTOM OR COVER THE ENTIRE DECK WITH MATERIAL

SUCH AS ALUMINUM FOIL.

DOING SO BLOCKS AIR FLOW THROUGH THE OVEN AND MAY CAUSE CARBON MONOXIDE POISONING.

ALUMINUM FOIL LININGS MAY TRAP HEAT CAUSING A FIRE HAZARD.

7

Maintenance

X. CAUTION: Oven must be “OFF” and

cool before any cleaning is done.

Disconnect the power supply to the appliance before

cleaning and servicing the oven.

• Clean the oven cooking surface after each use with

a cleaning brush.

• Periodically check and clean hearth burner venturi

tube for insects and insect nests.

A CLOGGED VENTURI TUBE CAN LEAD TO A FIRE

INSIDE THE OVEN

• For service and repairs, contact factory, factory

representative or local service company.

• All maintenance and/or repair MUST be performed

by someone trained/qualified to work on gas/

electrical equipment. For additional information or

assistance, contact Chicago Brick Oven Customer

Assistance at 630.359.4793

• In dirty/dusty/wet atmospheres, it may be necessary

to examine/perform maintenance at additional times

depending on the burner packages’ usage.

• Visually check burner flames for proper operation.

• Keep outdoor oven area clear and free from

combustible materials, gasoline and other flammable

vapors and liquids.

• Do not obstruct the flow of combustion and

ventilation air.

• Keep the ventilation openings of the cylinder

enclosure free and clear from debris.

8

chicagobrickoven.com

Chicago Brick Oven, LLC. | 205 E. Butterfield Road, #448 | Elmhurst, IL 60126

Customer Assistance: 630.359.4793

© 2016 Chicago Brick Oven. All rights reserved.

Loading...

Loading...