2000 National Semiconductor Corporation Confidential www.national.com

March 2001

LM9617 Monochrome CMOS Image Sensor VGA 30 FPS

General Description

The LM9617 is a high performance, low power, third inch VGA

CMOS Active Pixel Sensor capable of capturing grey-scale digital still or motion images and converting them to a digital data

stream.

In addition to the active pixel array, an on-chip 12 bit A/D convertor, fixed pattern noise elimination circuits and a video gain is

provided. Furthermore, an integrated programmable smart timing and control circuit allows the user maximum flexibility in

adjusting integration time, active window size, gain and frame

rate. Various control, timing and power modes are also provided.

Features

• Supplied with micro lenses

• Video or snapshot operations

• Progressive scan and interlace read out modes.

• Programmable pixel clock, inter-frame and inter-line delays.

• Programmable partial or full frame integration

• Programmable gain

• Horizontal & vertical sub-sampling (2:1 & 4:2)

• Windowing

• External snapshot trigger & event synchronisation signals

• Auto black level compensation

• Flexible digital video read-out supporting programmable:

- polarity for synchronisation and pixel clock signals

- leading edge adjustment for horizontal synchronization

• Programmable via 2 wire I2C compatible serial interface

• Power on reset & power down mode

Applications

• Security Cameras

• Toys

• Machine Vision

• Biometrics

• Infrared Camera

• Barcode Scanner

Key Specifications

• Array Format

Total: 664H x 504V

Active: 648H x 488V

• Effective Image Area

Total: 4.98mm x 3.78 mm

Active: 4.86 mm x 3.66 mm

• Optical Format 1/3“

• Pixel Size 7.5µm x 7.5µm

• Video Outputs 8,10 & 12 Bit Digital

• Dynamic Range 57dB

• FPN 0.35%

Sensitivity 28.7 Kilo LSBs / lux.s

• Quantum Efficiency 27%

• Fill Factor 47% (no micro lens)

• Package 48 LCC

• Single Supply 3.3 V

• Power Consumption 90 mW

• Operating Temp 0 to 50oC

12bit digital image

lens

I2C compatible

Digital Image

Processor

Storage

snapshot

event trigger

LM9617

System Block Diagram

LM9617 Monochrome CMOS Image Sensor VGA 30 FPS

Confidential 2 www.national.com

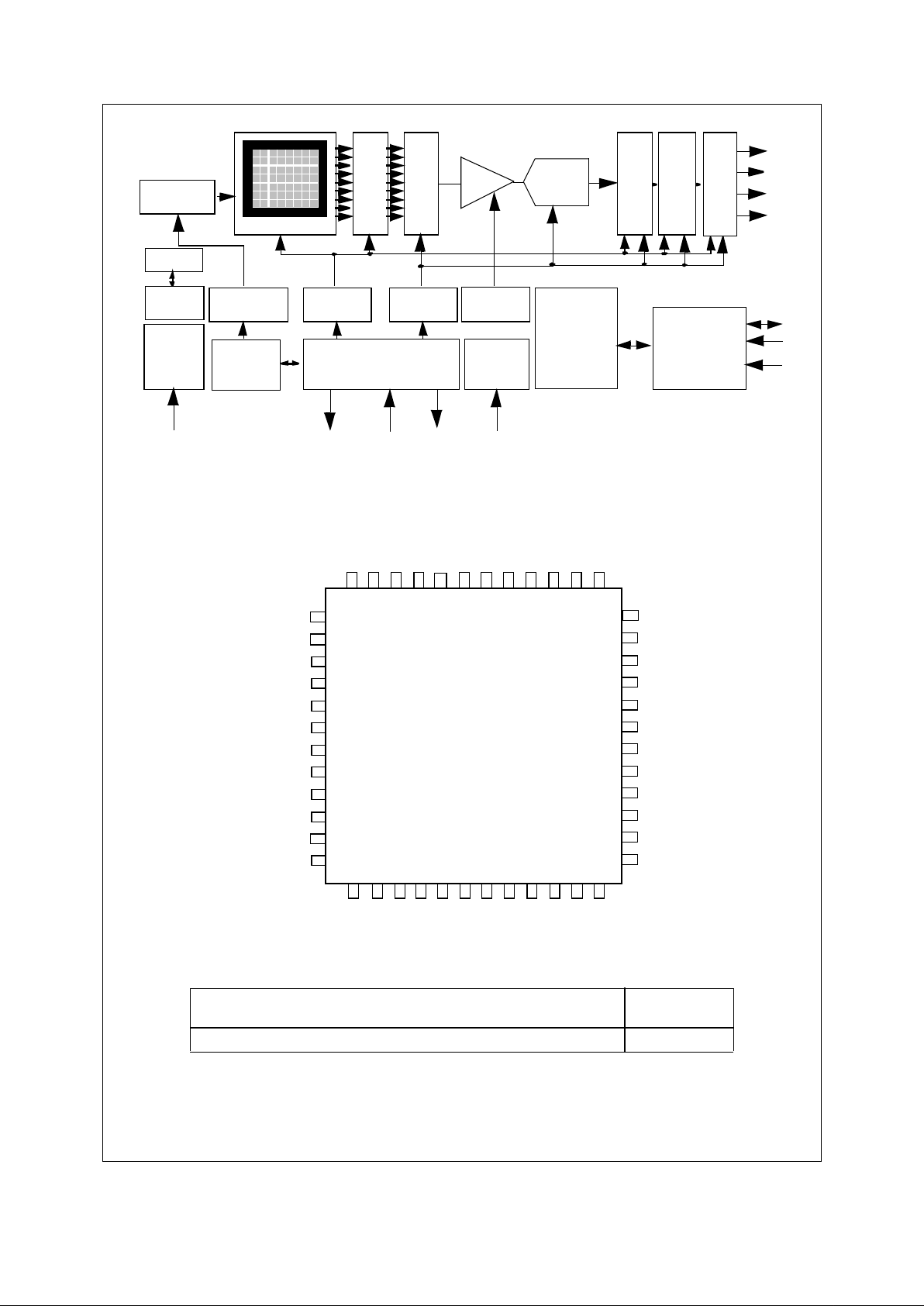

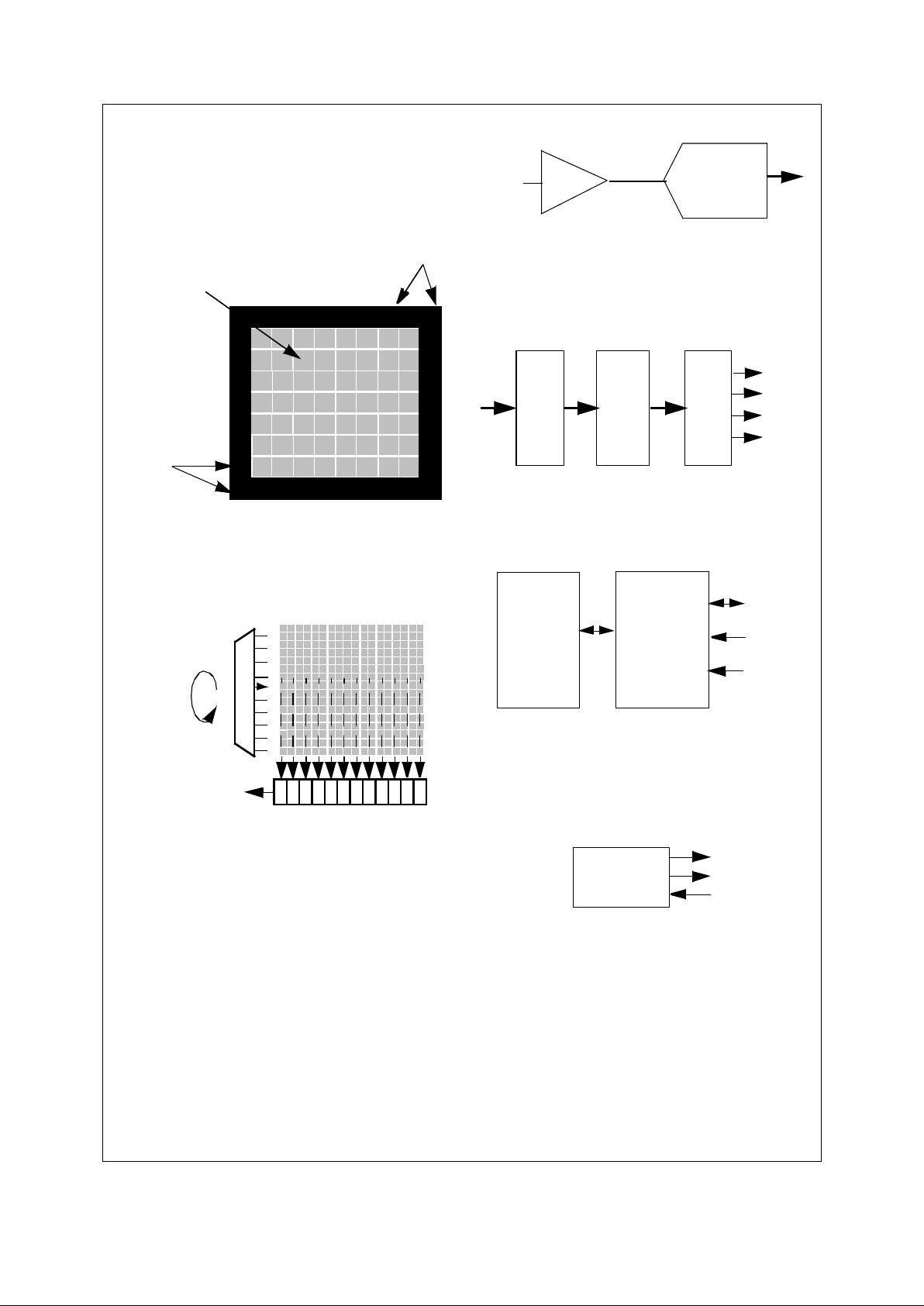

Column CDS

APS Array

Horizontal Shif t

Register

POR

1

2 Bit A/D

AMP

Bad P ixel

Detect & Correct

Digital Video

Frame r

Black Level

Compensation

d[11:0]

pclk

hsync

vsync

Row Address

Decoder

Vertical

Horizontal

Master Timer

Timing

Timing

Row Address

Gen

Clock Gen

I2C Compatible

Register Bank

Reset

Gen

Gain

Control

Serial I/F

sda

sclk

sadr

Power

Control

pdwnsnapshot

extsync

Controller

(sequencer)

irq

mclk

Overall Chip Block Diagram

Figure 1. Chip Block Diagram

7

9

10

11

12

13

14

15

16

18

17

42

40

39

38

37

36

35

34

33

31

32

sclk

resetb

pdwn

vss_dig

vdd_dig

vsync

pclk

mclk

d1

d0

fine_i

vss_od1

vss_od3

gnd

fine_ctrl

offset

vdd_ana1

vdd_ana2

vss_ana2

sda

sadr

irq

vdd_pix

vrl

vsrvdd

extsync

vdd_od 1

6 5 4 3 2

1

48 47 46 45

NC

d4

d5

d6d8d7

d9

vdd_od2

vss_od2

19 20 21 2322 24 25 26 27 28 30

48 PIN LCC

43

d11

d10

8

snapshot

41

NC

44

vref_adc

29

d3

d2

LM9617

hsync

vss_ana1

vdd_o d3

NC

NC

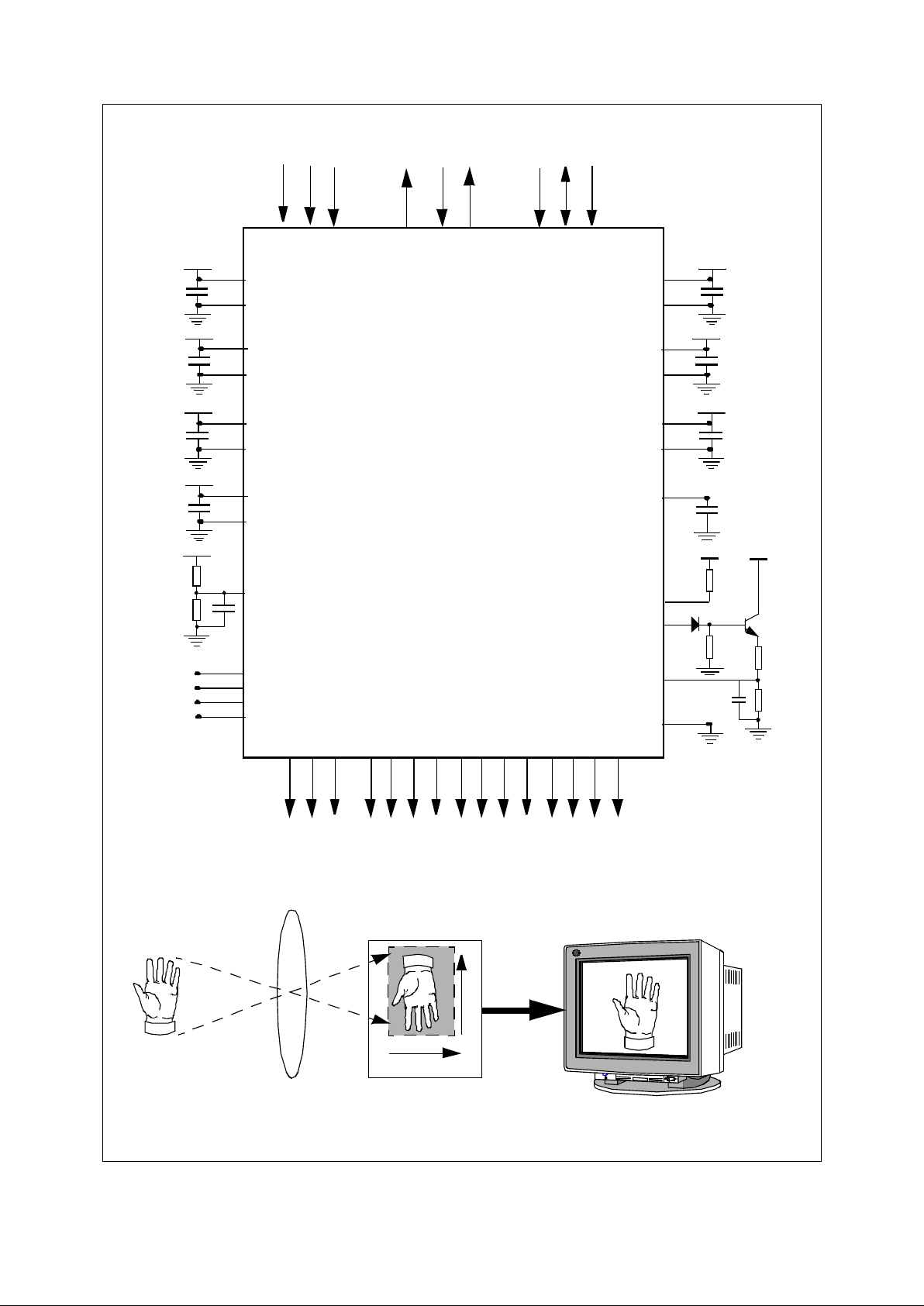

Connection Diagram

Ordering Information

Temperature

(0°C ≤ TA ≤ +50°C)

NS Package

LM9617 CCEA LCC

LM9617

Confidential 3 www.national.com

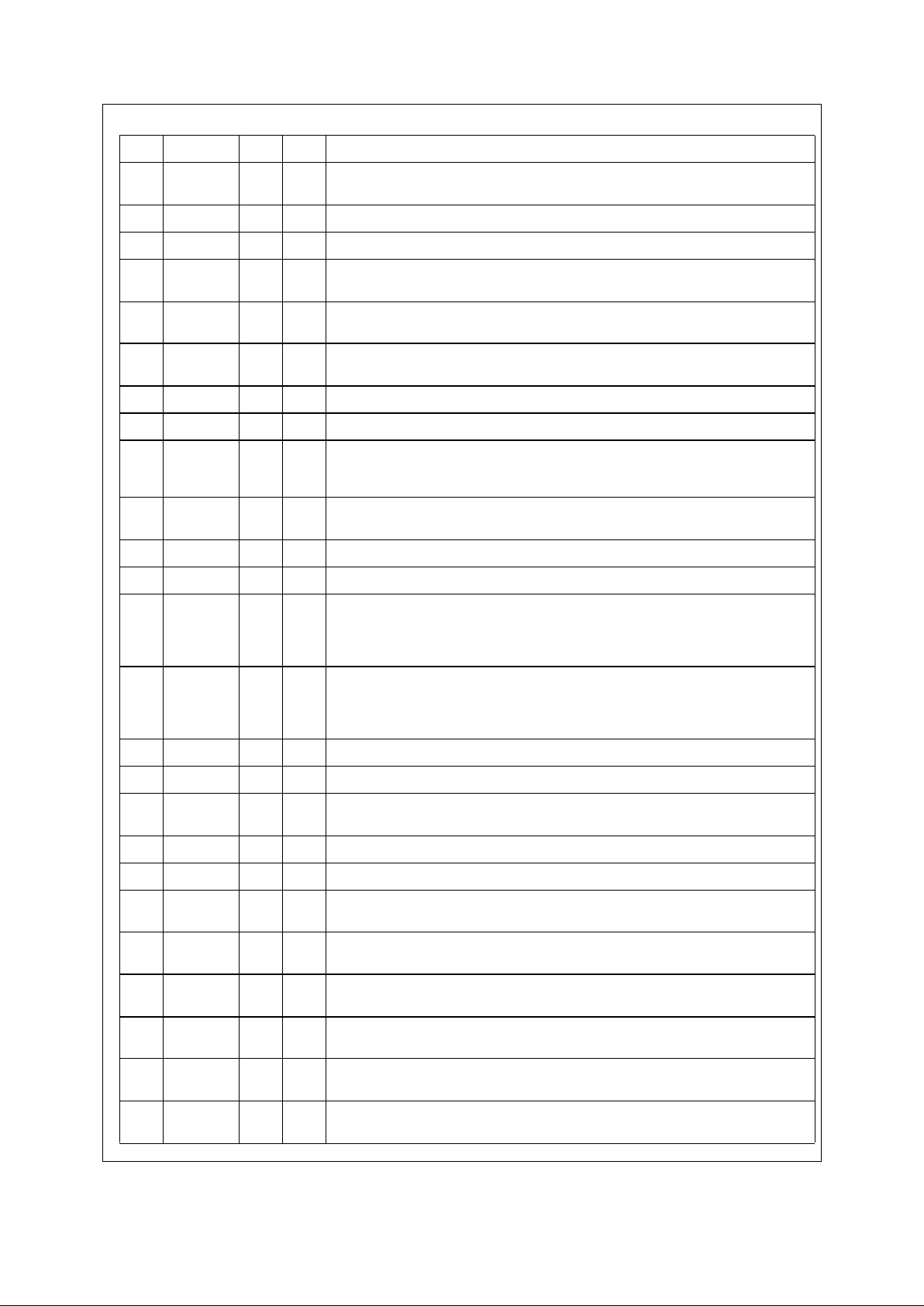

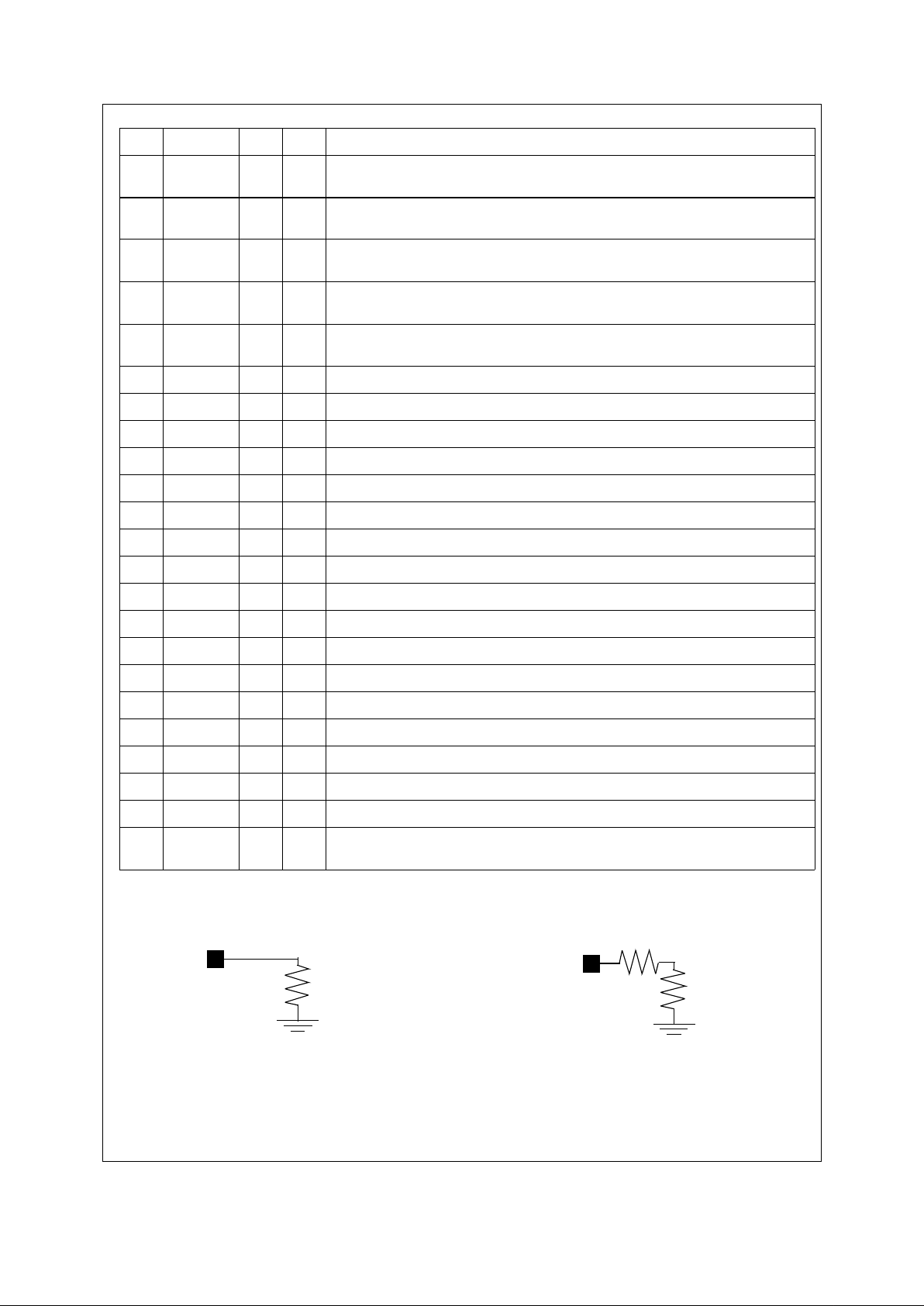

Typical Application Circuit

0.1µF

1.5k

Ω

820

Ω

3.3V analog

0.1µF

3.3V digital

12

9

37

36

35

7 6810

vss_dig

resetb

vdd_ana1

vss_ana1

vref_adc

vdd_od1

vss_od1

sadr

extsyn c

sclk

sda

d9

d8

d7d5d6

d4

d1

d0

snapshot

30 29 28 2627 25 24 23 22 21 17

d2

d3

11

vdd_dig

48 5

20

d10

d11

0.1µF

3.3V analog

31

32

vdd_od2

vss_od2

0.1µF

3.3V digital

0.1µF

3.3V digital

47

46

vdd_pix

vrl

0.1µF

3

2

1

vsrvdd

1.0µF

13 14 15

hsyn c

vsync

pclk

LM9617

pdwn

Serial Control Bus

System Control

Digital Video Bus

Camera Control

irq

4

33

34

vdd_ana2

vss_ana2

0.1µF

3.3V analog

16

mclk

vdd_od3

vss_od3

0.1µF

44

45

fine_i

41

gnd

40

3.3V analog

3.3V digital

offset

fine_ctrl

39

NC

18

NC

19

NC

42

NC

43

10kΩ

1.2kΩ

470Ω

2N3904

1N4148

4.7µF

vdd_ana

22kΩ

vdd_ana

38

1%

1%

1%

1%

Figure 2. Typical Application Diagram

Scan Read Out Direction

Figure 3. Scan directions and position of origin in imaging system

(0,0)

pin 1

CMOS Image Sensor

(0,0)

digital

out

lens

(0,0)

horizontal scan

vertical scan

LM9617

Confidential 4 www.national.com

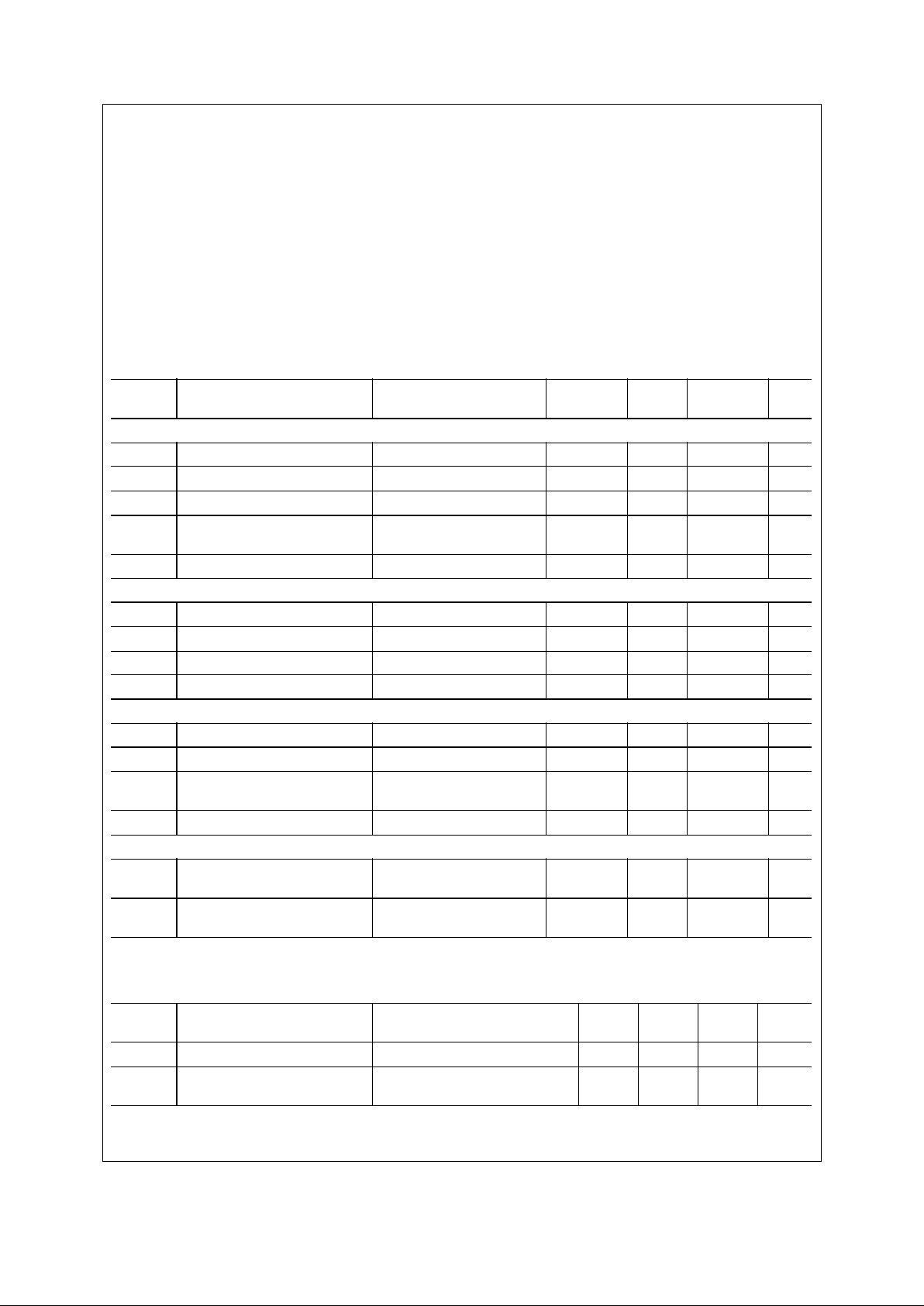

Pin Descriptions

Pin Name I/O Typ Description

1 vsrvdd I0 P

Analog bidirectional, it should be connect to ground via a 1.0µf capacitor. This pin is the

internal charge pump voltage source.

2 vrl I A Anti blooming pin. This pin is normally tied to ground.

3 vdd_pix I P 3.3 volt supply for the pixel array.

4 irq O D

Digital output, the interrupt request pin. This pin generates interrupts during snapshot

mode.

5 sadr I D

Digital input with pull down resistor. This pin is used to program different slave addresses

for the sensor in an I2C compatible system.

6 sda IO D

I2C compatible serial interface data bus. The output stage of this pin has an open drain

driver.

7 sclk I D I2C compatible serial interface clock.

8 snapshot I D Digital input with pull down resistor used to activate (trigger) a snapshot sequence.

9 resetb I D

Digital input with pull up resistor. When forced to a logic 0 the sensor is reset to its default

power up state. The resetb signal is internally synchronized to mclk which must be run-

ning for a reset to occur.

10 pdwn I D

Digital input with pull down resistor. When forced to a logic 1 the sensor is put into power

down mode.

11 vss_dig I P 0 volt power supply for the digital circuits.

12 vdd_dig I P 3.3 volt power supply for the digital circuits.

13 hsync IO D

Digital Bidirectional. This is a dual mode pin. When the sensor’s digital video port is con-

figured to be a master, (the default), this pin is an output and is the horizontal synchroni-

zation pulse. When the sensor’s digital video port is configured to be a slave, this pin is

an input and is the row trigger.

14 vsync IO D

Digital Bidirectional. This is a dual mode pin. When the sensor’s digital video port is con-

figured to be a master, (the default), this pin is an output and is the vertical synchroniza-

tion pulse. When the sensor’s digital video port is configured to be a slave, this pin is an

input and is the frame trigger.

15 pclk O D Digital output. The pixel clock.

16 mclk I D Digital input. The sensor’s master clock input.

17 d0 O D

Digital output. Bit 0 of the digital video output bus. This output can be put into tri-state

mode.

18 NC Pin not used, do not connect.

19 NC Pin not used, do not connect.

20 d1 O D

Digital output. Bit 1 of the digital video output bus. This output can be put into tri-state

mode.

21 d2 O D

Digital output. Bit 2 of the digital video output bus. This output can be put into tri-state

mode.

22 d3 O D

Digital output. Bit 3 of the digital video output bus. This output can be put into tri-state

mode.

23 d4 O D

Digital output. Bit 4 of the digital video output bus. This output can be put into tri-state

mode.

24 d5 O D

Digital output. Bit 5 of the digital video output bus. This output can be put into tri-state

mode.

25 d6 O D

Digital output. Bit 6 of the digital video output bus. This output can be put into tri-state

mode.

LM9617

Confidential 5 www.national.com

Pin Descriptions (Continued)

Legend: (I=Input), (O=Output), (IO=Bi-directional), (P=Power), (D=Digital), (A=Analog).

Figure 4. Equivalent Circuits For adc_ref and offset pins

Pin Name I/O Typ Description

26 d7 O D

Digital output. Bit 7 of the digital video output bus. This output can be put into tri-state

mode.

27 d8 O D

Digital output. Bit 8 of the digital video output bus. This output can be put into tri-state

mode.

28 d9 O D

Digital output. Bit 9 of the digital video output bus. This output can be put into tri-state

mode.

29 d10 O D

Digital output. Bit 10 of the digital video output bus. This output can be put into tri-state

mode.

30 d11 O D

Digital output. Bit 11 of the digital video output bus. This output can be put into tri-state

mode.

31 vdd_od2 I P 3.3 volt supply for the digital IO buffers.

32 vss_od2 I P 0 volt supply for the digital IO buffers

33 vdd_ana2 I P 3.3 volt supply for analog circuits.

34 vss_ana2 I P 0 volt supply for analog circuits.

35 vref_adc I A A/D reference resistor ladder voltage. See figure 4 for equivalent circuit.

36 vss_ana1 I P 0 volt supply for analog circuits.

37 vdd_ana1 I P 3.3 volt supply for analog circuits.

38 offset I A Analog input used to adjust the offset of the sensor. See figure 4 for equivalent circuit.

39 fine_ctrl O A Analog output used to drive the offset pin.

40 gnd This pin must be tied to ground.

41 fine_i I A Bias current for the fine offset adjust.

42 NC Pin not used, do not connect.

43 NC Pin not used, do not connect.

44 vdd_od3 I P 3.3 volt supply for the sensor.

45 vss_od3 I P 0 volt supply for the sensor.

46 vss_od1 I P 0 volt supply for the digital IO buffers

47 vdd_od1 I P 3.3 volt supply for the digital IO buffers.

48 extsync O D

Digital output. The external event synchronization signal is used to synchronize external

events in snapshot mode.

800Ω

adc_vref

1KΩ

200Ω

offset

LM9617

Confidential 6 www.national.com

Absolute Maximum Ratings (Notes 1 & 2)

Any Positive Supply Voltage 6.5V

Voltage On Any Input or Output Pin -0.5V to 6.5V

Input Current at any pin (Note 3) ±25mA

ESD Susceptibility (Note 5)

Human Body Model 2000V

Machine Model 200V

Package Input Current (Note 3) ±50mA

Package Power Dissipation @ TA(Note 4) 2.5W

Soldering Temperature Infrared,

10 seconds (Note 6) 220°C

Storage Temperature -40°C to 125°C

Operating Ratings (Notes 1 & 2)

Operating Temperature Range 0°C≤T≤+50°C

All VDD Supply Voltages +3.15V to +3.6V

Voltage Range on vref_adc pin +0.6V to +1.0V

Voltage Range on offset pin +0.04V to +0.4V

DC and logic level specifications

The following specifications apply for all VDD pins= +3.3V. Boldface limits apply for TA = T

MIN

to T

MAX

: all other limits TA = 25oC

(Note 7)

Power Dissipation Specifications

The following specifications apply for All VDD pins = +3.3V. Boldface limits apply for TA = T

MIN

to T

MAX

: all other limits TA = 25oC.

Symbol Parameter Conditions

Min

note 9

Typical

note 8

Max

note 9

Units

sclk, sda, sadr, Digital Input/Output Characteristics

VIH Logical “1” Input Voltage 0.7*vdd_od vdd_od+0.5 V

VIL Logical “0” Input Voltage -0.5 0.3*vdd_od V

VOL Logical “0” Output Voltage vdd_od = +3.15V, Iout=3.0mA 0.5 V

V

hys

Hysteresis (SCLK pin only) vdd_od = +3.15V

0.05*vdd_o

d

V

I

leak

Input Leakage Current Vin=vss_od -1 mA

mclk, snapshot, pdwn, resetb, hsync, vsync Digital Input Characteristics

VIH Logical “1” Input Voltage vdd_dig = +3.6V 2.0 V

VIL Logical “0” Input Voltage vdd_dig = +3.15V 0.8 V

IIH Logical “1” Input Current VIH = vdd_dig 0.1 mA

IIL Logical “0” Input Current VIL = vss_dig -1 mA

d0 - d11, pclk, hsync, vsync, extsync, irq, Digital Output Characteristics

VOH Logical “1” Output Voltage vdd_od=3.15V, Iout=-1.6mA 2.2 V

VOL Logical “0” Output Voltage vdd_od=3.15V, Iout =-1.6mA 0.5 V

IOZ TRI-STATE Output Current

VOUT = vss_od

VOUT = vdd_od

-0.1

0.1

mA

mA

IOS Output Short Circuit Current +/-17 mA

Power Supply Characteristics

IA Analog Supply Current

Power down mode, no clock.

Operational mode in dark

700

19

mA

mA

ID Digital Supply Current

Power down mode, no clock.

Operational mode in dark

300

7

mA

mA

Symbol Parameter Conditions

Min

note 9

Typical

note 8

Max

note 9

Units

P

dwn

Power Down no clock running 5 mW

PWR Average Power Dissipation

mclk = 48Mhz & sensors default settings in dark.

90 mW

LM9617

Confidential 7 www.national.com

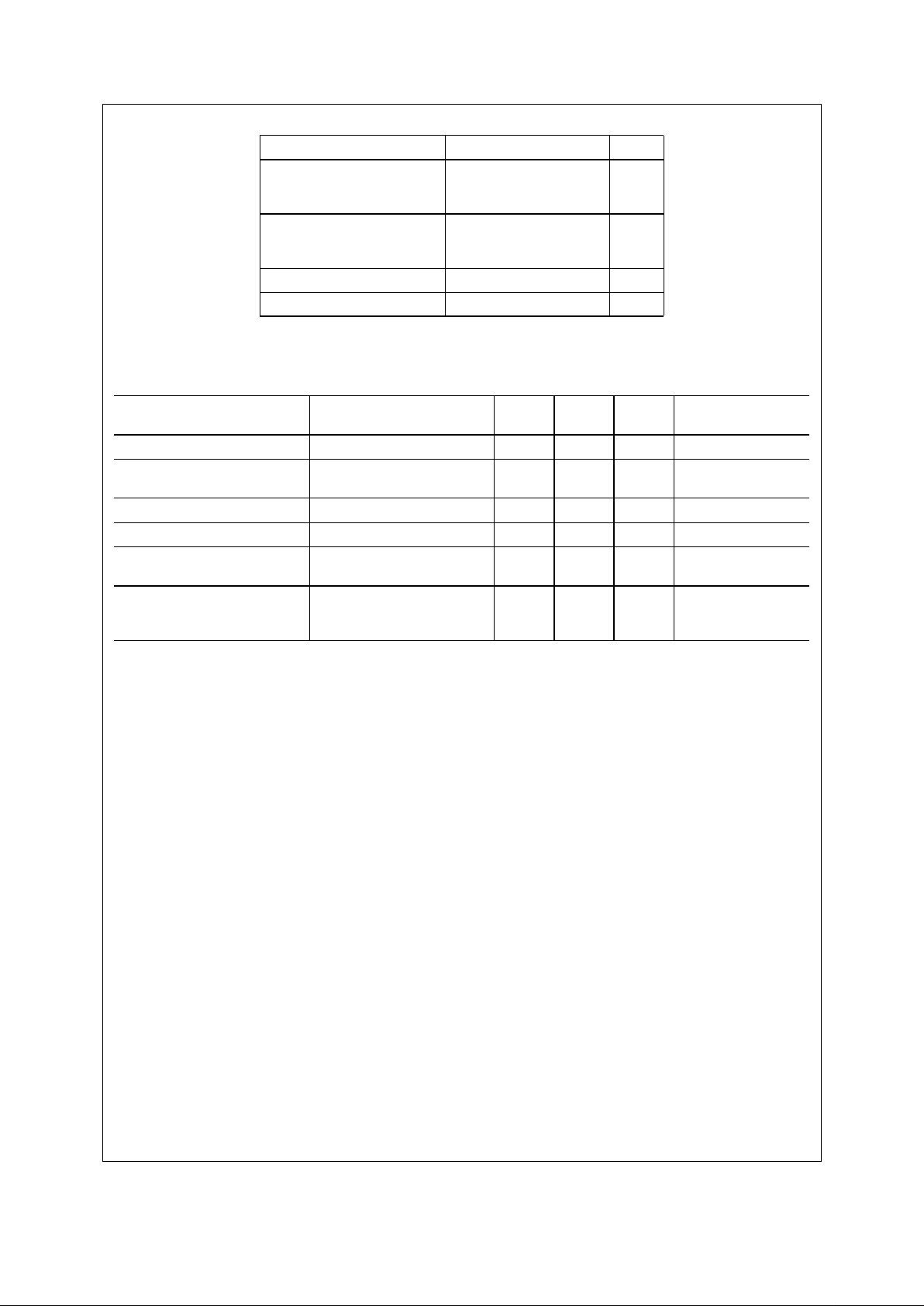

Video Amplifier Specifications

The following specifications apply for all VDD pins= +3.3V. Boldface limits apply for TA = T

MIN

to T

MAX

: all other limits TA = 25oC.

AC Electrical Characteristics

The following specifications apply for All VDD pins = +3.3V. Boldface limits apply for TA = T

MIN

to T

MAX

: all other limits TA = 25oC.

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate con-

ditions for which the device is functional, but do not guarantee specific performance limits. For guaranteed specifications

and test conditions, see the Electrical Characteristics. The guaranteed specifications apply only for the test conditions

listed. Some performance characteristics may degrade when the device is not operated under the listed test conditions.

Note 2: All voltages are measured with respect to VSS = vss_ana = vss_od = vss_dig = 0V, unless otherwise specified.

Note 3: When the voltage at any pin exceeds the power supplies (VIN < VSS or VIN > VDD), the current at that pin should be lim-

ited to 25mA. The 50mA maximum package input current rating limits the number of pins that can safely exceed the power

supplies with an input current of 25mA.

Note 4: The absolute maximum junction temperature (TJmax) for this device is 125oC. The maximum allowable power dissipation

is dictated by TJmax, the junction-to-ambient thermal resistance (ΘJA), and the ambient temperature (TA), and can be cal-

culated using the formula PDMAX = (TJmax - TA)/ΘJA. In the 48-pin LCC, ΘJA is 38.5oC/W, so PDMAX = 2.5W at 25oC

and 1.94W at the maximum operating ambient temperature of 50oC. Note that the power dissipation of this device under

normal operation will be well under the PDMAX of the package.

Note 5: Human body model is 100pF capacitor discharged through a 1.5kΩ resistor. Machine model is 220pF discharged through

ZERO Ohms.

Note 6: See AN450, “Surface Mounting Methods and Their Effect on Product Reliability”, or the section entitled “Surface Mount”

found in any post 1986 National Semiconductor Linear Data Book, for other methods of soldering surface mount devices.

Note 7: The analog inputs are protected as shown below. Input voltage magnitude up to 500mV beyond the supply rails will not

damage this device. However, input errors will be generated If the input goes above AV+ and below AGND.

Note 8: Typical figures are at TJ = 25oC, and represent most likely parametric norms.

Note 9: Test limits are guaranteed to National's AOQL (Average Outgoing Quality Level).

Symbol Parameter Conditions

Min

note 9

Typical

note 8

Max

note 9

Units

Video Amplifier Nominal Gain 64 linear steps 0-15 dB

Symbol Parameter Conditions

Min

note 9

Typical

note 8

Max

note 9

Units

F

mclk

Input Clock Frequency 12 48 MHz

T

ch

Clock High Time @ CLK

max

10 45 ns

T

cl

Clock Low Time @ CLK

max

10 45 ns

Clock Duty Cycle @ CLK

max

45/55 55/45 min/max

Trc, TfcClock Input Rise and Fall Time 3 ns

F

hclk

Internal System Clock Frequency

1.0 14.0 MHz

T

reset

Reset pulse width 1.0 µs

FRM

rate

Frame Rate 1 30 fps

IOP

Pad

VDD

VSS

Internal Circuits

LM9617

Confidential 8 www.national.com

CMOS Active Pixel Array Specifications

Image Sensor Specifications

The following specifications apply for All VDD pins = +3.3V, TA = 25oC, Illumination Color Temperature = 2850oK, IR cutoff filter at

700nm, mclk = 48MHz, frame rate = 30Hz, vref_adc = 0.6 volt, video gain 0dB.

Note 1: Typical figures are at TJ = 25oC, and represent most likely parametric norms.

Parameter Value Units

Number of pixels (column, row)

Total

Active

664 x 504

648 x 488

pixels

pixels

Array size (x,y Dimensions)

Total

Active

4.98 x 3.78

4.86 x 3.66

mm

mm

Pixel Pitch 7.5 µ

Fill Factor (without micro-lens) 47 %

Parameter Conditions

Min Typical

note 1

Max Units

Optical Sensitivity @ A/D output 28.7 kLSBs/(lux.s)

Optical Sensitivity @ A/D input

4.13

volt/(lux.s)

Dynamic Range 57 dB

Read Noise 5.3 LSBs

Offset Fixed Pattern Noise

RMS value of pixel FPN in dark

as a percentage of full scale.

0.35 %

Sensitivity Fixed Pattern Noise

RMS variation of pixel sensitivities as a percentage of the average sensitivity.

1 %

LM9617

Confidential 9 www.national.com

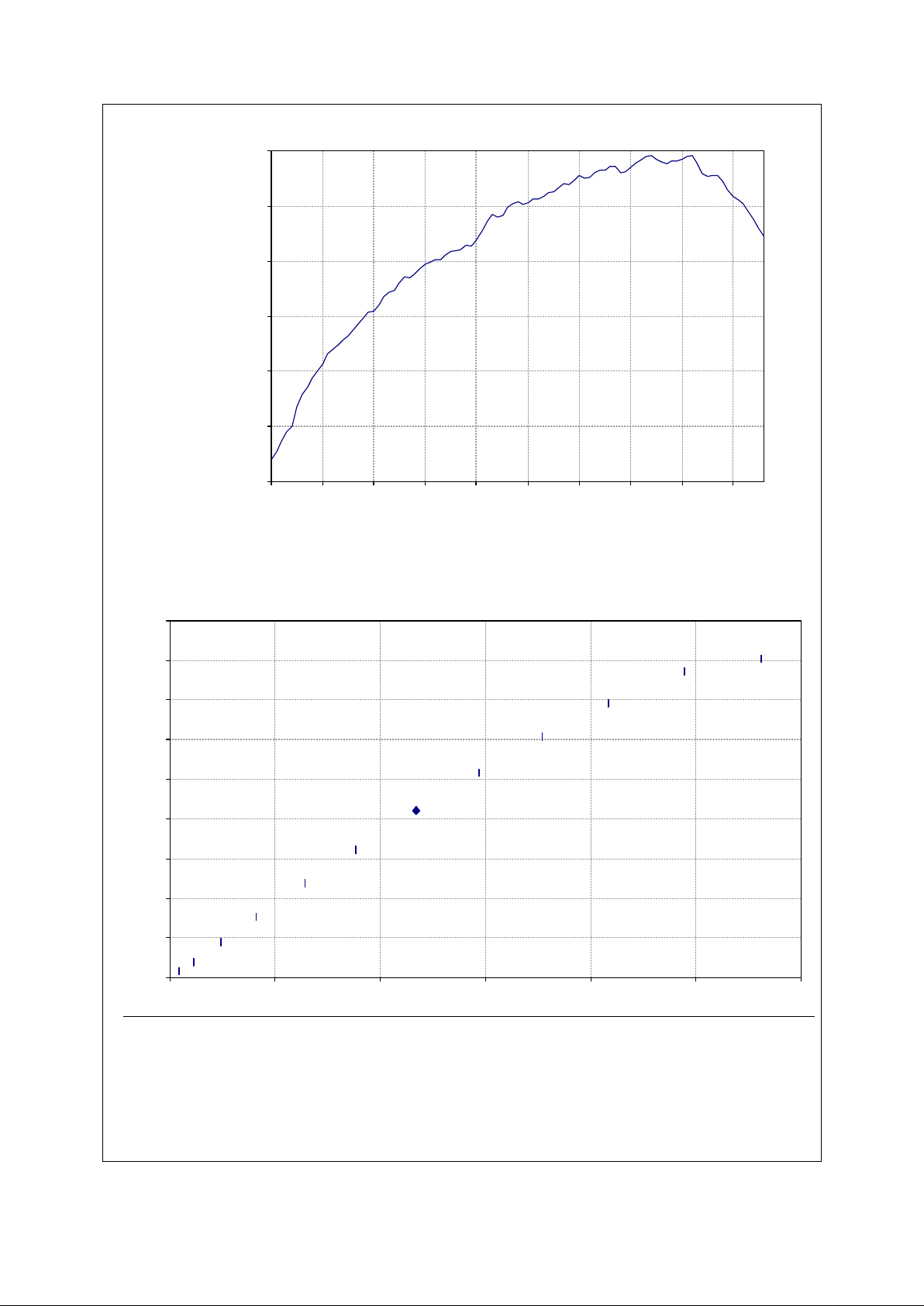

Sensor Response Curves

0.00E+00

2.00E+02

4.00E+02

6.00E+02

8.00E+02

1.00E+03

1.20E+03

370 420 470 520 570 620 670 720 770 820

wavelength [nm]

Spectral sensitivity [V/((W/m^2)*s)]

Figure 5. Spectral Response Curve

0

500

1000

1500

2000

2500

3000

3500

4000

4500

0 0.05 0.1 0.15 0.2 0.25 0.3

Exposure (lux.sec)

A/D output code

Figure 6. Linearity Response Curve

LM9617

Confidential 10 www.national.com

Functional Description

1.0 OVERVIEW

1.1 Light Capture and Conversion

The LM9617 contains a CMOS active pixel array consisting of

648 rows by 488 columns. This active region is surrounded by 8

columns and 8 rows of optically shielded (black) pixels as shown

in Figure.

8 columns, 8 rows

black pixels

8 columns, 8 rows

black pixels

648 columns, 488 rows

mono-chrome active pixels

Figure 7: CMOS APS region of the LM9617

At the beginning of a given integration time the on-board timing

and control circuit will reset every pixel in the array one row at a

time as shown in Figure 8. Note that all pixels in the same row

are simultaneously reset, but not all pixels in the array.

a b c d e f g h i j k l m n o p q r

0

1

2

3

4

5

6

7

8

9

10

11

12

14

13

15

CDS/Shift Register

Line Address

Analog Data Out

Figure 8: CMOS APS Row and Column addressing scheme

At the end of the integration time, the timing and control circuit

will address each row and simultaneously transfer the integrated

value of the pixel to a correlated double sampling circuit and

then to a shift register as shown in Figure 8.

Once the correlated double sampled data has been loaded into

the shift register, the timing and control circuit will shift them out

one pixel at a time starting with column “a”.

The pixel data is then fed into an analog video amplifier, where a

user programmed gain is applied .

After gain adjustment the analog value of each pixel is converted to a 12 bit digital data as shown in Figure 9.

12 Bit A/D

Video

AMP

Analog pixel values Digital pixel data

0-15dB

Figure 9: Analog Signals In, Digital Data Out.

The digital pixel data is further processed to:

• remove defects due to bad pixels,

• compensate black level, before being framed and presented

on the digital output port. (see Figure 10).

Figure 10. Digital Pixel Processing.

1.2 Program and Control Interfaces

The programming, control and status monitoring of the LM9617

is achieved through a two wire I2C compatible serial bus. In

addition, a slave address pin is provided (see Figure 11).

Figure 11. Control Interface to the LM9617.

Additional control and status pins: snapshot and external event

synchronization are provided allowing the latency of the serial

control port to be bypassed during single frame capture. An

interrupt request pin is also available allowing complex snapshot

operations to be controlled via an external micro-processor (see

Figure 12).

Figure 12. Snapshot & External Event Trigger Signals

Bad Pixel

Correction

Digital Video

Framer

Black Level

Compensation

do[11:0]

pclk

hsync

vsync

I2C Compatible

Register Bank

Serial I/F

sda

sclk

sadr

Timing

Generator

irq

snapshot

extsyn

LM9617

Confidential 11 www.national.com

Functional Description (continued)

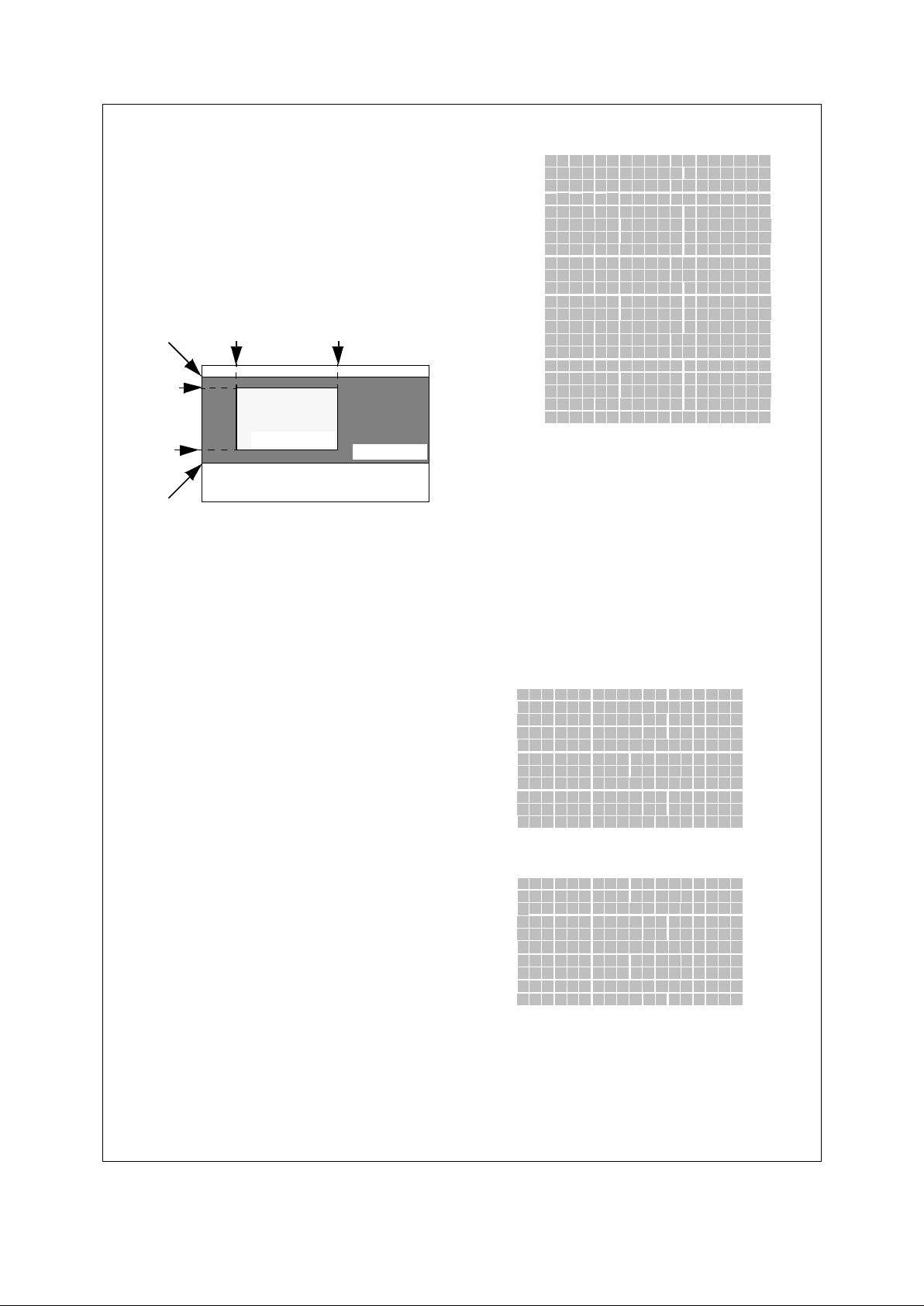

2.0 WINDOWING

The integrated timing and control circuit allows any size window

in any position within the active region of the array to be read out

with a 1x1 pixel resolution. The window read out is called the

“Display Window”.

A “Scan Window” must be defined first, by programing the start

and end row addresses as shown in Figure 13. Four coordinates

(start row address, start column address, end row address &

end column address) are programmed to define the size and

location of the “Display Window” to be read out (see Figure 13).

Figure 13. Windowing

Notes:

• The “Display Window” must always be defined within the

“Scan Window”.

• A “Display Window” can only be read out in the progressive

scan mode.

• By default the “Display Window” is the complete array.

2.1 Programming the scan window

Two registers (SROWS & SROWE) are provided to program the

size of the scan window. The start and end row address of the

scan window is given by:

Where:

SwStartRow

is the contents of the Scan Window start row

register (SROWS)

SwEndROW

is the contents of the Scan Window end row register (SROWE)

SwLsb

is bit 6 of the Display Window LSB register

(DWLSB)

2.2 Programming the display window

Five register (DROWS, DROWE, DCOLS, DCOLE and DWLSB)

are provided to program the display window as described in the

register section of this datasheet.

3.0 READ OUT MODES

3.1 Progressive Scan Readout Mode

In progressive scan readout mode, every pixel in every row in

the display window is consecutively read out, one pixel at a time,

starting with the left most pixel in the top most row. Hence, for

the example shown in Figure 13, the read out order will be

a0,b0,...,r0 then a1,b1,...,r1 and so on until pixel r20 is read out.

a b c d e f g h i j k l mn o p q r

1

2

3

4

5

6

7

8

9

10

11

12

13

15

14

16

17

18

19

20

Row/Vertical

0

Column/Horizontal

Figure 14: Progressive Scan Read Out Mode

3.2 Interlaced Readout Mode

In interlaced readout mode, pixels are read out in two fields, an

Odd Field followed by an Even Field.

The Odd Field, consisting of all even rows contained within the

display window, is read out first. Each pixel in the “Odd Field” is

consecutively read out, one pixel at a time, starting with the left

most pixel in the top most even row.

The Even Field, consisting of all odd rows contained within the

display window, is then read out. Each pixel in the “Even Field”

is consecutively read out, one pixel at a time, starting with the

left most pixel in the top most odd row.

a b c d e f g h i j k l mn o p q r

2

4

6

8

10

12

14

16

18

20

0

Row/Vertical

Column/Horizontal

Odd Field

1

3

5

9

7

11

13

15

17

19

Row/Vertical

Column/Horizontal

Even Field

a b c d e f g h i j k l mn o p q r

Figure 15: Interlace Read Out Mode

Hence, for the example shown in Figure , the display window is

broken up into two fields, as shown in Figure . Pixels a0,b0,...,r0

followed by a2,b2,...,r2 and so on until pixels a20,b20,...r20 in

the even field are read out first. The even field read out is followed by pixels in the odd field, a1,b1,...,r1 then a3,b3,...,r3 until

pixels a19,b19,...,r19.

display row

Active Pixel Array

Display Window

Scan Window

display row

display col

display col

start address

end address

start address

end address

scan row

start address

scan row

end address

scan row start address = (2* SwStartRow) + SwLsb

scan row end address = (2* SwEndRow) + 1 + SwLsb

LM9617

Confidential 12 www.national.com

Functional Description (continued)

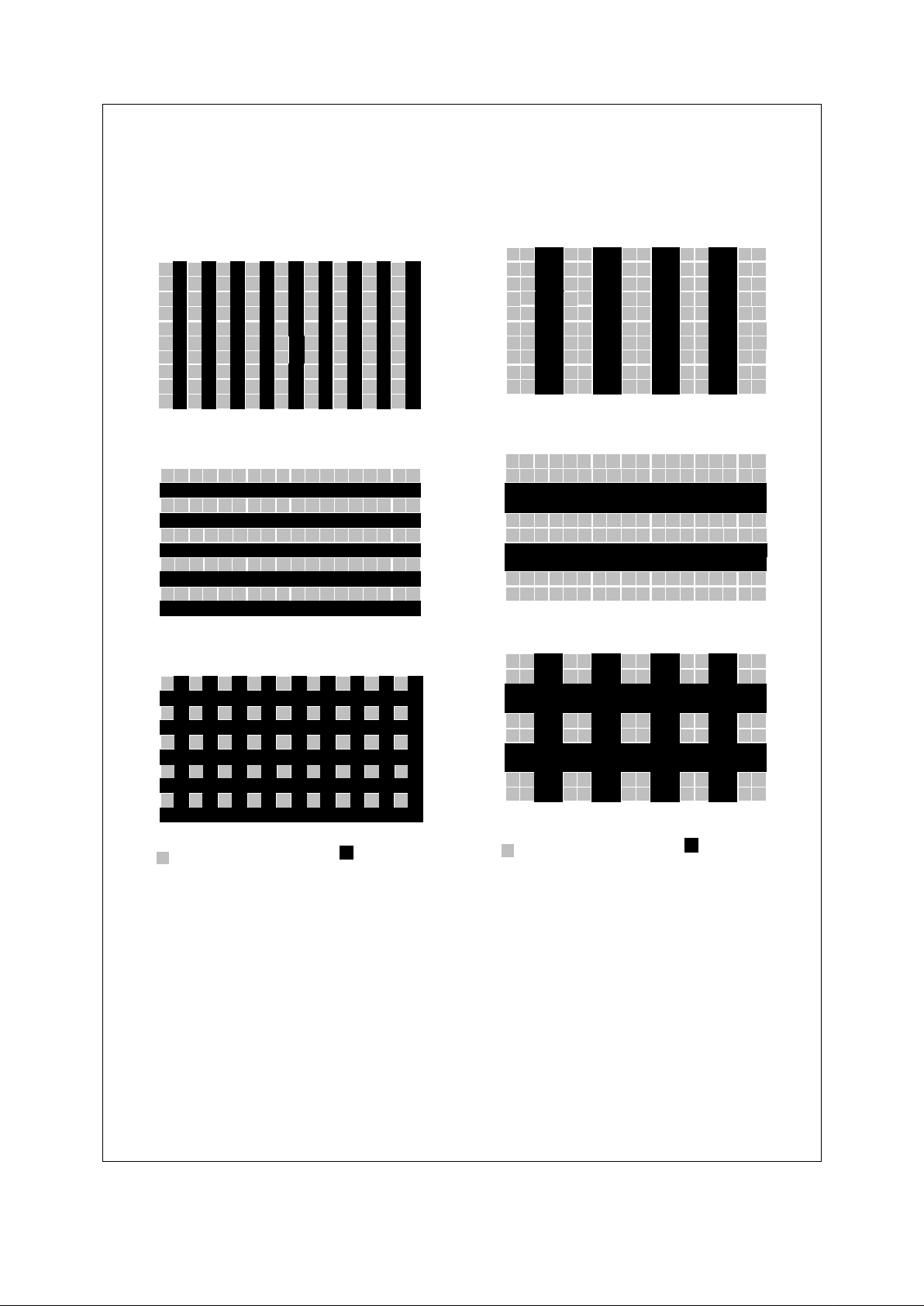

4.0 SUBSAMPLING MODES

4.1 2:1 Sub-Sampling

The timing and control circuit can be programmed to sub-sample pixels in the display window vertically, horizontally or both,

with an aspect ratio of 2:1 as illustrated in Figure16

0

1

2

3

4

5

6

7

8

9

Column/Horizontal

a b c d e f g h i j k l l n o p q r

a b c d e f g h i j k l m n o p

0

1

2

3

4

5

6

7

8

9

b) Vertical Sub-Sampling

Row/Vertical

Column/Horizontal

q

r

a b c d e f g h i j k l m n o p q r

0

1

2

3

4

5

6

7

8

Column/Horizontal

Row/Vertical

9

a) Horizontal Sub-Sampling

c) Horizontal & Vertical Sub-Sampling

Read Out

Not Read Out

Row/Vertical

Figure 16: 2:1 Horizontal and Vertical Sub-Sampling

4.2 4:2 Sub-Sampling

The timing and control circuit can be programmed to sub-sample pixels in the display window vertically, horizontally or both,

with an aspect ratio of 4:2 as illustrated in Figure17.

Column/Horizontal

a) Horizontal Sub-sampling

Read Out

Not Read Out

a b c d e f g h i j k l m n o p q r

0

1

2

3

4

5

6

7

8

9

Row/Vertical

a b c d e f g h i j k l m n o p q r

0

1

2

3

4

5

6

7

8

9

Column/Horizontal

Row/Vertical

a b c d e f g h i j k l m n o p q r

0

1

2

3

4

5

6

7

8

9

Column/Horizontal

Row/ Vertica l

c) Horizontal & Vertical Sub-sampling

b) Vertical Sub-sampling

Figure 17: 4:2 Horizontal and Vertical Sub-Sampling

LM9617

Loading...

Loading...