NSC LM628N-6, LM628N-8 Datasheet

LM628/LM629

Precision Motion Controller

LM628/LM629 Precision Motion Controller

November 1999

General Description

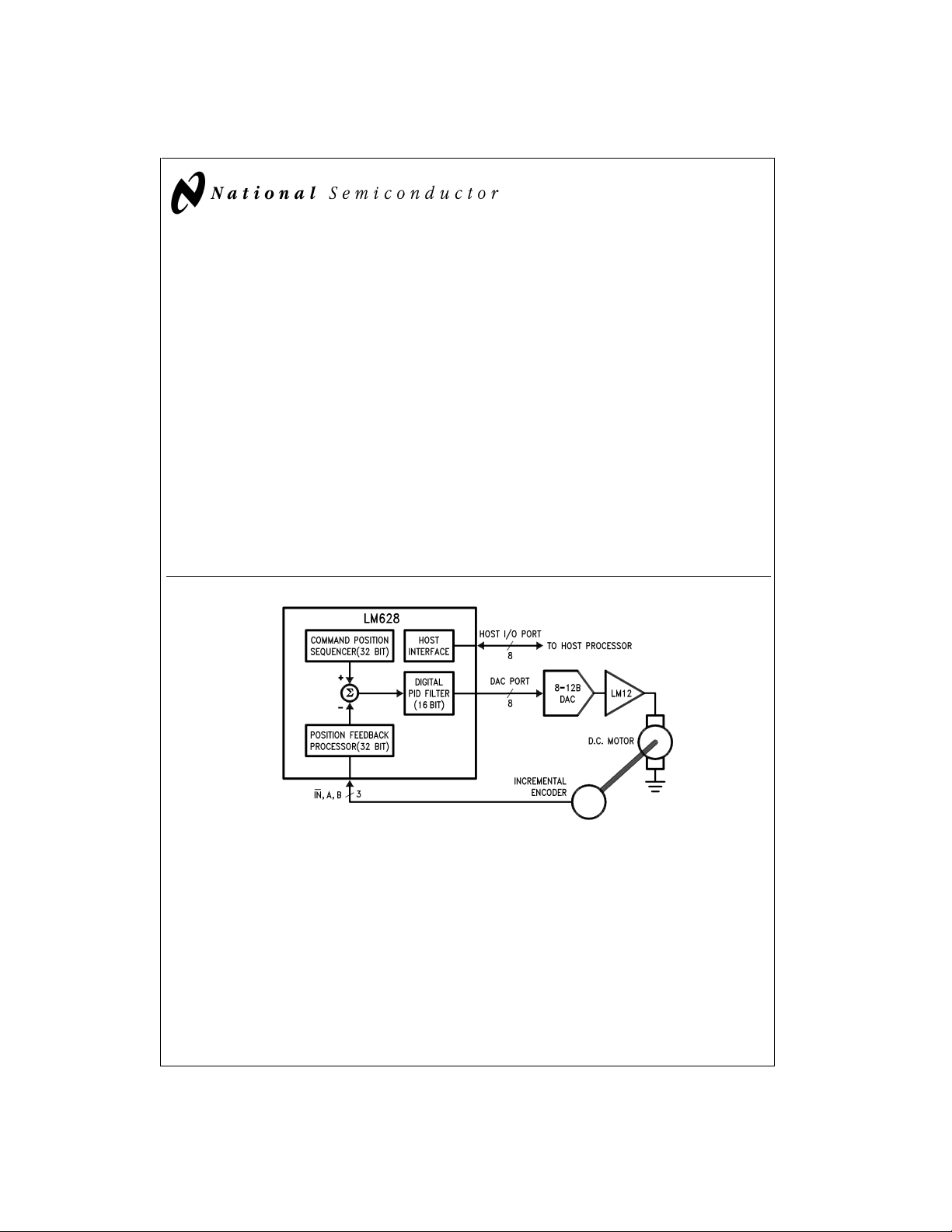

The LM628/LM629 are dedicated motion-control processors

designed for use with a variety of DC and brushless DC

servo motors, and other servomechanisms which provide a

quadrature incremental position feedback signal. The parts

perform theintensive, real-time computational tasks required

for high performance digital motion control. The host control

software interface is facilitated by a high-level command set.

The LM628 has an 8-bit output which can drive either an

8-bit or a 12-bit DAC. The components required to build a

servo system are reduced to the DC motor/actuator, an incremental encoder, a DAC, a power amplifier, and the

LM628. An LM629-based system is similar, except that it

provides an 8-bit PWM output for directly driving H-switches.

The parts are fabricated in NMOS and packaged in a 28-pin

dual in-line package or a 24-pin surface mount package

(LM629 only). Both 6 MHz and 8 MHz maximum frequency

versions are available with the suffixes -6 and -8, respectively, used to designate the versions. They incorporate an

SDA core processor and cells designed by SDA.

Features

n 32-bit position, velocity, and acceleration registers

n Programmable digital PID filter with 16-bit coefficients

n Programmable derivative sampling interval

n 8- or 12-bit DAC output data (LM628)

n 8-bit sign-magnitude PWM output data (LM629)

n Internal trapezoidal velocity profile generator

n Velocity, target position, and filter parameters may be

changed during motion

n Position and velocity modes of operation

n Real-time programmable host interrupts

n 8-bit parallel asynchronous host interface

n Quadrature incremental encoder interface with index

pulse input

n Available in a 28-pin dual in-line package or a 24-pin

surface mount package (LM629 only)

DS009219-1

FIGURE 1. Block Diagram

TRI-STATE®is a registered trademark of National Semiconductor Corporation.

© 1999 National Semiconductor Corporation DS009219 www.national.com

Connection Diagrams

LM628/LM629

LM628N

DS009219-2

LM629N

DS009219-3

*Do not connect.

Order Number LM629M-6, LM629M-8, LM628N-6, LM628N-8, LM629N-6 or LM629N-8

See NS Package Number M24B or N28B

LM629M

DS009219-21

www.national.com 2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Voltage at Any Pin with

Respect to GND −0.3V to +7.0V

Ambient Storage Temperature −65˚C to +150˚C

Lead Temperature

28-pin Dual In-Line

Package (Soldering, 4 sec.) 260˚C

24-pin Surface Mount

Package (Soldering, 10 sec.) 300˚C

Maximum Power Dissipation

≤ 85˚C, (Note 2) 605 mW

(T

A

ESD Tolerance

=

120 pF, R

(C

ZAP

=

1.5k) 2000V

ZAP

Operating Ratings

Temperature Range −40˚C<T

Clock Frequency:

LM628N-6, LM629N-6,

LM629M-6 1.0 MHz

LM628N-8, LM629N-8,

LM629M-8 1.0 MHz

Range 4.5V<V

V

DD

<

f

CLK

<

f

CLK

<

A

<

6.0 MHz

<

8.0 MHz

DD

+85˚C

<

5.5V

LM628/LM629

DC Electrical Characteristics

(VDDand TAper Operating Ratings; f

Symbol Parameter Conditions Tested Limits Units

I

DD

Supply Current Outputs Open 110 mA

INPUT VOLTAGES

V

IH

V

IL

I

IN

Logic 1 Input Voltage 2.0 V

Logic 0 Input Voltage 0.8 V

Input Currents 0 ≤ VIN≤ V

OUTPUT VOLTAGES

V

OH

V

OL

I

OUT

Logic 1 I

Logic 0 I

TRI-STATE®Output Leakage Current 0 ≤ V

CLK

=

6 MHz)

Min Max

DD

=

−1.6 mA 2.4 V

OH

=

1.6 mA 0.4 V

OL

≤ V

OUT

DD

−10 10 µA

−10 10 µA

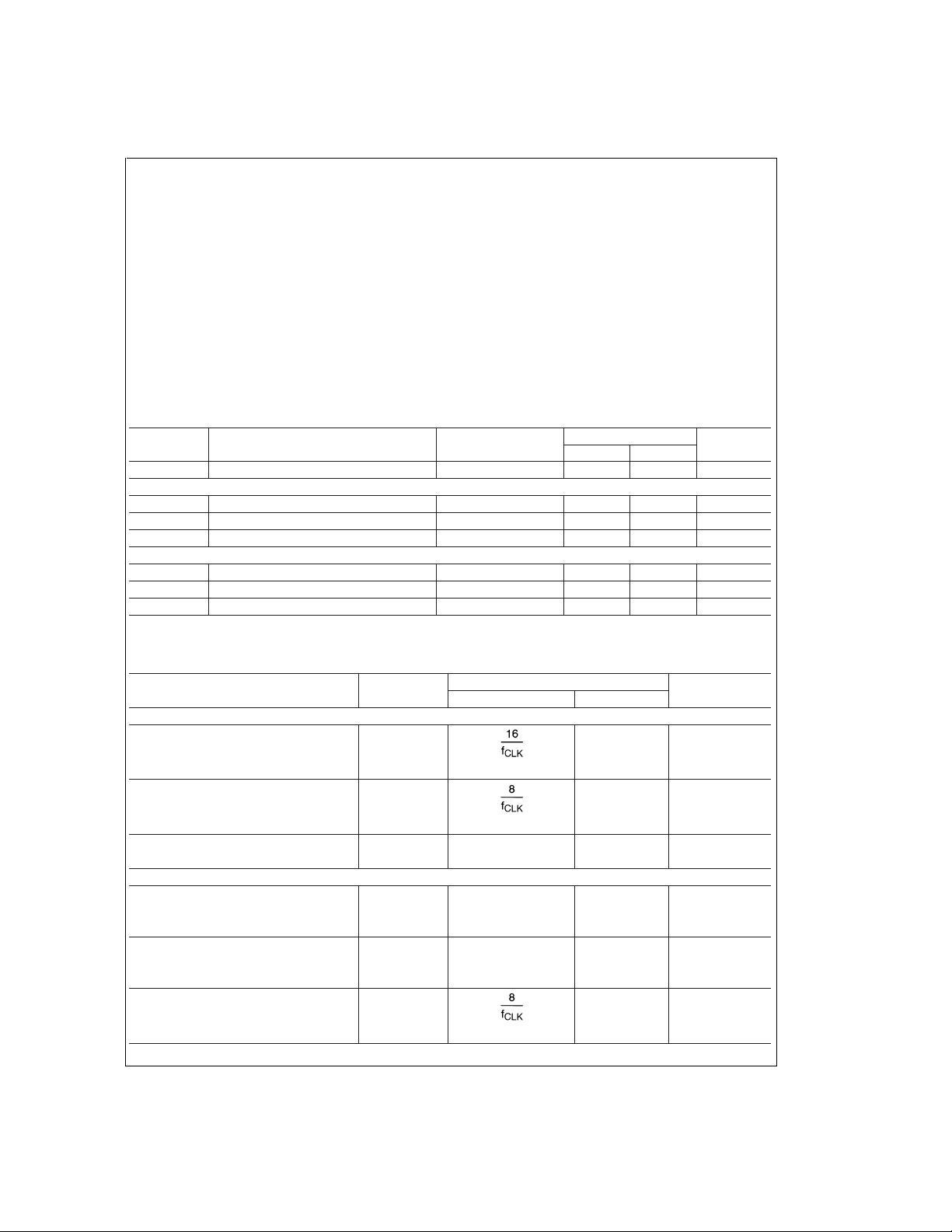

AC Electrical Characteristics

(VDDand TAper Operating Ratings; f

CLK

=

6 MHz; C

Timing Interval T

Figure 2

ENCODER AND INDEX TIMING (See

)

Motor-Phase Pulse Width T1

Dwell-Time per State T2

Index Pulse Setup and Hold T3 0 µs

(Relative to A and B Low)

CLOCK AND RESET TIMING (See

Figure 3

)

Clock Pulse Width

LM628N-6, LM629N-6, LM629M-6 T4 78 ns

LM628N-8, LM629N-8, LM629M-8 T4 57 ns

Clock Period

LM628N-6, LM629N-6, LM629M-6 T5 166 ns

LM628N-8, LM629N-8, LM629M-8 T5 125 ns

Reset Pulse Width T6

=

50 pF; Input Test Signal t

LOAD

#

=

=

t

10 ns)

r

f

Tested Limits Units

Min Max

µs

µs

µs

www.national.com3

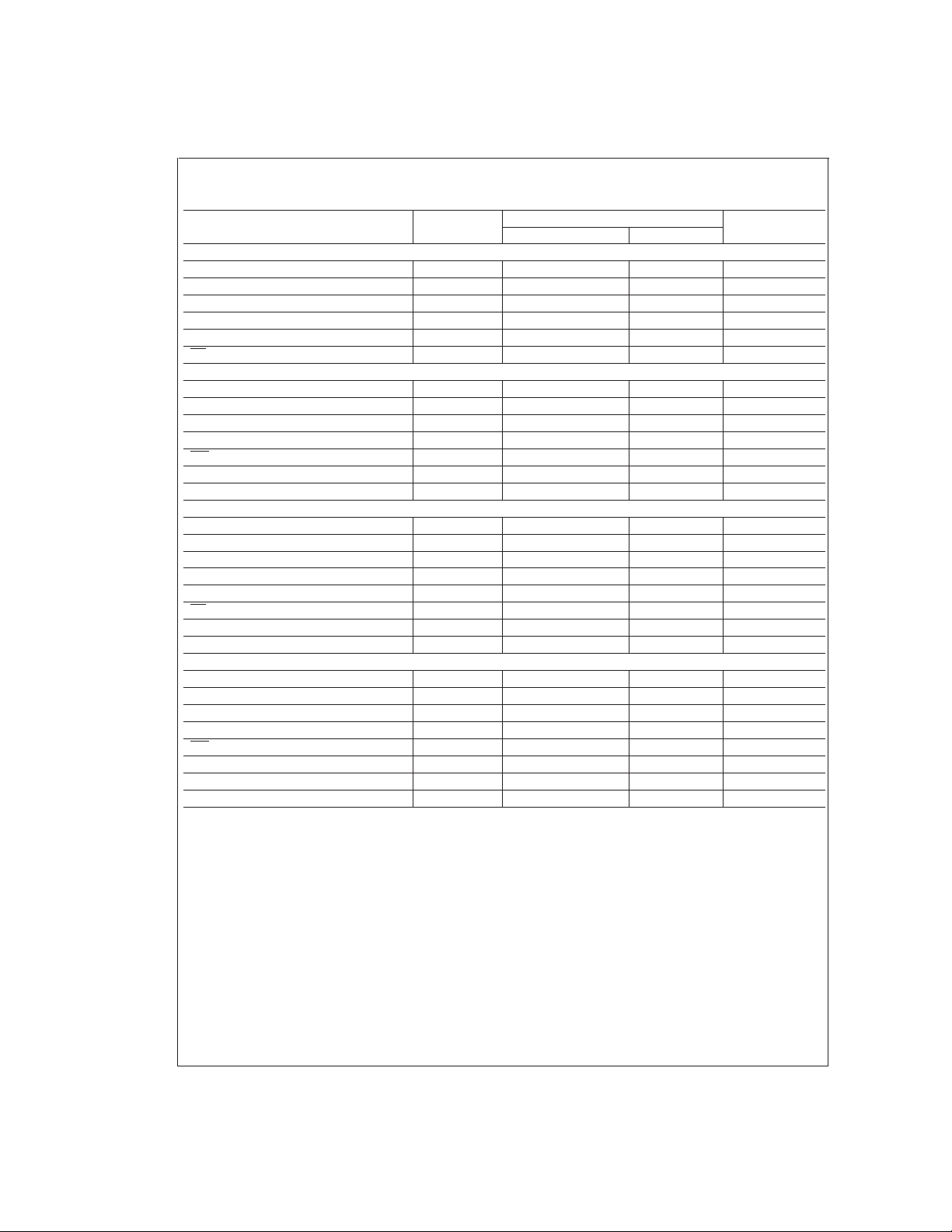

AC Electrical Characteristics (Continued)

(VDDand TAper Operating Ratings; f

CLK

=

6 MHz; C

Timing Interval T

LM628/LM629

Figure 4

Figure 5

Figure 7

)

)

)

)

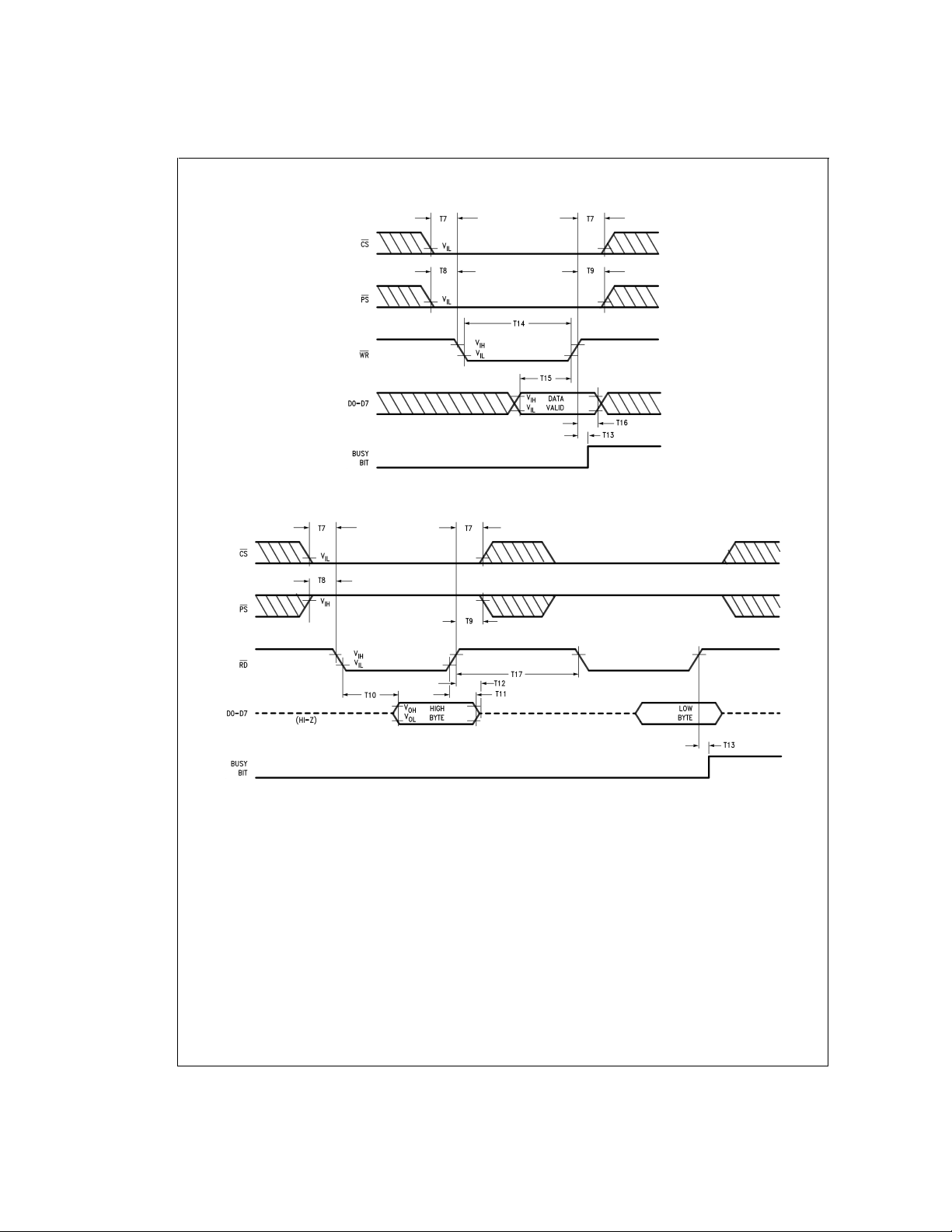

STATUS BYTE READ TIMING (See

Chip-Select Setup/Hold Time T7 0 ns

Port-Select Setup Time T8 30 ns

Port-Select Hold Time T9 30 ns

Read Data Access Time T10 180 ns

Read Data Hold Time T11 0 ns

RD High to Hi-Z Time

COMMAND BYTE WRITE TIMING (See

Chip-Select Setup/Hold Time T7 0 ns

Port-Select Setup Time T8 30 ns

Port-Select Hold Time T9 30 ns

Busy Bit Delay T13 (Note 3) ns

WR Pulse Width

Write Data Setup Time T15 50 ns

Write Data Hold Time T16 120 ns

DATA WORD READ TIMING (See

Figure 6

Chip-Select Setup/Hold Time T7 0 ns

Port-Select Setup Time T8 30 ns

Port-Select Hold Time T9 30 ns

Read Data Access Time T10 180 ns

Read Data Hold Time T11 0 ns

RD High to Hi-Z Time

Busy Bit Delay T13 (Note 3) ns

Read Recovery Time T17 120 ns

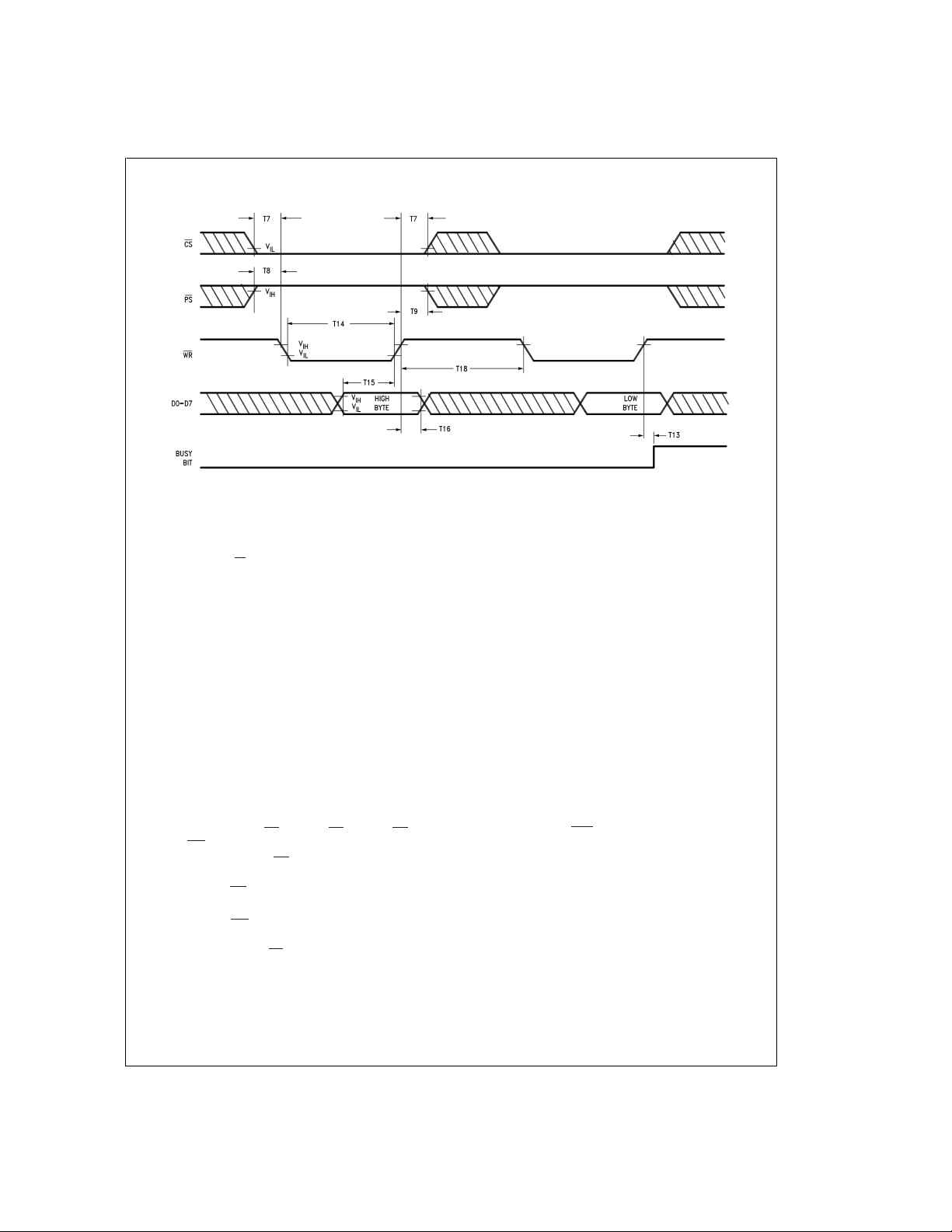

DATA WORD WRITE TIMING (See

Chip-Select Setup/Hold Time T7 0 ns

Port-Select Setup Time T8 30 ns

Port-Select Hold Time T9 30 ns

Busy Bit Delay T13 (Note 3) ns

WR Pulse Width

Write Data Setup Time T15 50 ns

Write Data Hold Time T16 120 ns

Write Recovery Time T18 120 ns

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. DC and AC electrical specifications do not apply when operating

the device beyond the above Operating Ratings.

Note 2: When operating at ambient temperatures above 70˚C, the device must be protected against excessive junction temperatures. Mounting the package on a

printed circuit board having an area greater than three square inches and surrounding the leads and body with wide copper traces and large, uninterrupted areas of

copper, such as a ground plane, suffices. The 28-pin DIP (N) and the 24-pin surface mount package (M) are molded plastic packages with solid copper lead frames.

Most of the heat generated at the die flows from the die, through the copper lead frame, and into copper traces on the printed circuit board. The copper traces act

as a heat sink. Double-sided or multi-layer boards provide heat transfer characteristics superior to those of single-sided boards.

Note 3: In order to read the busy bit, the status byte must first be read. The time required to read the busy bit far exceeds the time the chip requires to set the busy

bit. It is, therefore, impossible to test actual busy bit delay. The busy bit is guaranteed to be valid as soon as the user is able to read it.

=

50 pF; Input Test Signal t

LOAD

#

Tested Limits Units

=

=

t

10 ns)

r

f

Min Max

T12 180 ns

T14 100 ns

T12 180 ns

T14 100 ns

www.national.com 4

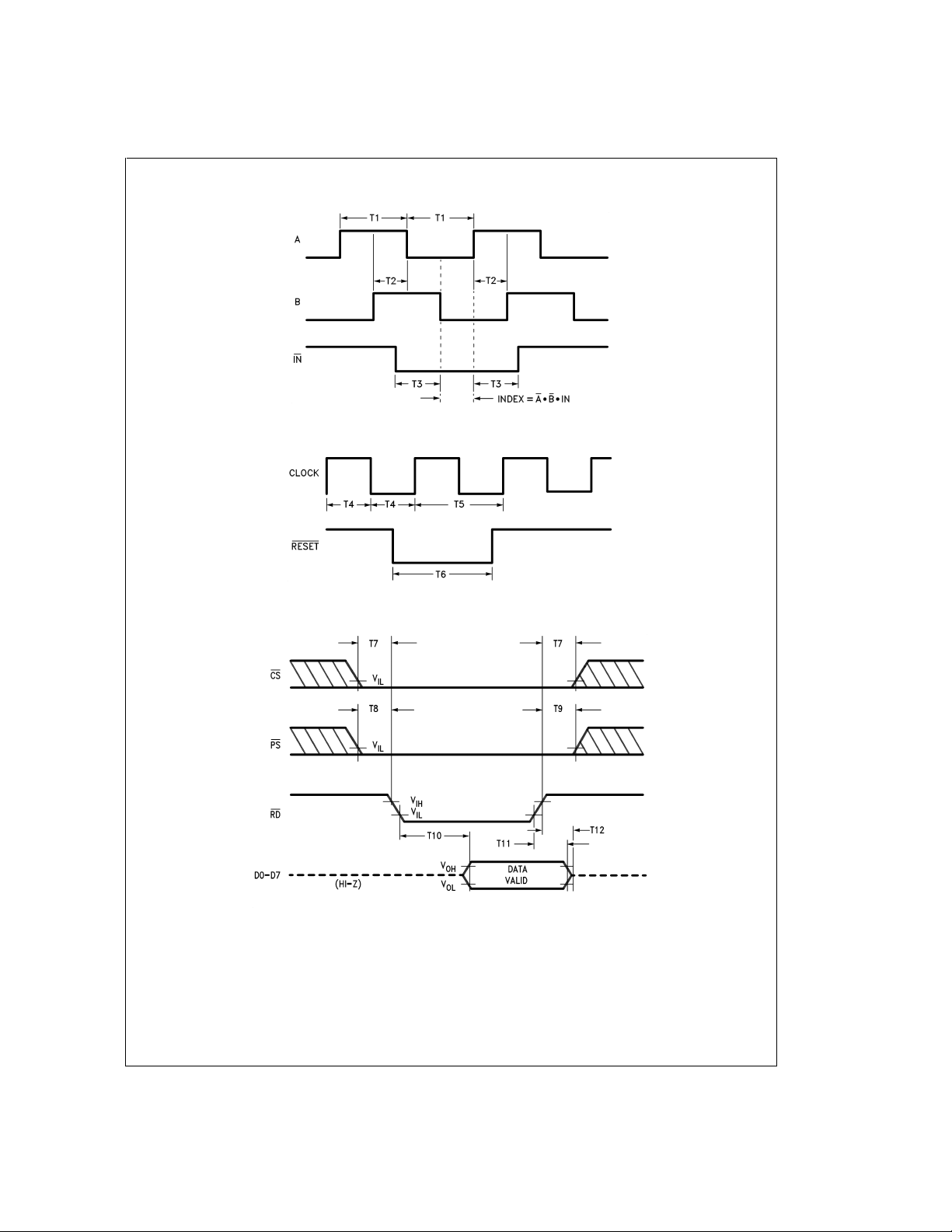

AC Electrical Characteristics (Continued)

FIGURE 2. Quadrature Encoder Input Timing

FIGURE 3. Clock and Reset Timing

LM628/LM629

DS009219-4

DS009219-5

FIGURE 4. Status Byte Read Timing

DS009219-6

www.national.com5

AC Electrical Characteristics (Continued)

LM628/LM629

FIGURE 5. Command Byte Write Timing

DS009219-7

FIGURE 6. Data Word Read Timing

www.national.com 6

DS009219-8

AC Electrical Characteristics (Continued)

FIGURE 7. Data Word Write Timing

Pinout Description

(See Connection Diagrams) Pin numbers for the 24-pin surface mount package are indicated in parentheses.

Pin 1 (17), Index (IN) Input: Receives optional index pulse

from the encoder. Must be tied high if not used. The index

position is read when Pins 1, 2, and 3 are low.

Pins 2 and 3 (18 and 19), Encoder Signal (A, B) Inputs:

Receive the two-phase quadrature signals provided by the

incremental encoder. When the motor is rotating in the positive (“forward”) direction, the signal at Pin 2 leads the signal

at Pin 3 by 90 degrees. Note that the signals at Pins 2 and 3

must remain at each encoder state (See

mum of 8 clock periods in order to be recognized. Because

of a four-to-one resolution advantage gained by the method

of decoding the quadrature encoder signals, this corresponds to a maximum encoder-state capture rate of 1.0 MHz

=

(f

8.0 MHz) or 750 kHz (f

CLK

clock frequencies the encoder signals must also remain at

each state a minimum of 8 clock periods.

Pins 4 to 11 (20 to 24 and 2 to 4), Host I/O Port (D0 to D7):

Bi-directional data port which connects to host computer/

processor. Used for writing commands and data to the

LM628, and for reading the status byte and data from the

LM628, as controlled by CS (Pin 12), PS (Pin 16), RD (Pin

13), and WR (Pin 15).

Pin 12 (5), Chip Select (CS ) Input: Used to select the

LM628 for writing and reading operations.

Pin 13 (6), Read (RD ) Input: Used to read status and data.

Pin 14 (7), Ground (GND): Power-supply return pin.

Pin 15 (8), Write (WR ) Input: Used to write commands and

data.

Pin 16 (9), Port Select (PS ) Input: Used to select com-

mand or data port. Selects command port when low, data

port when high. The following modes are controlled by Pin

16:

1. Commands are written to the command port (Pin 16

low),

2. Status byte is read from command port (Pin 16 low), and

Figure 9

=

6.0 MHz). For other

CLK

) for a mini-

DS009219-9

3. Data is written and read via the data port (Pin 16 high).

Pin 17 (10), Host Interrupt (HI) Output: This active-high

signal alerts the host (via a host interrupt service routine)

that an interrupt condition has occurred.

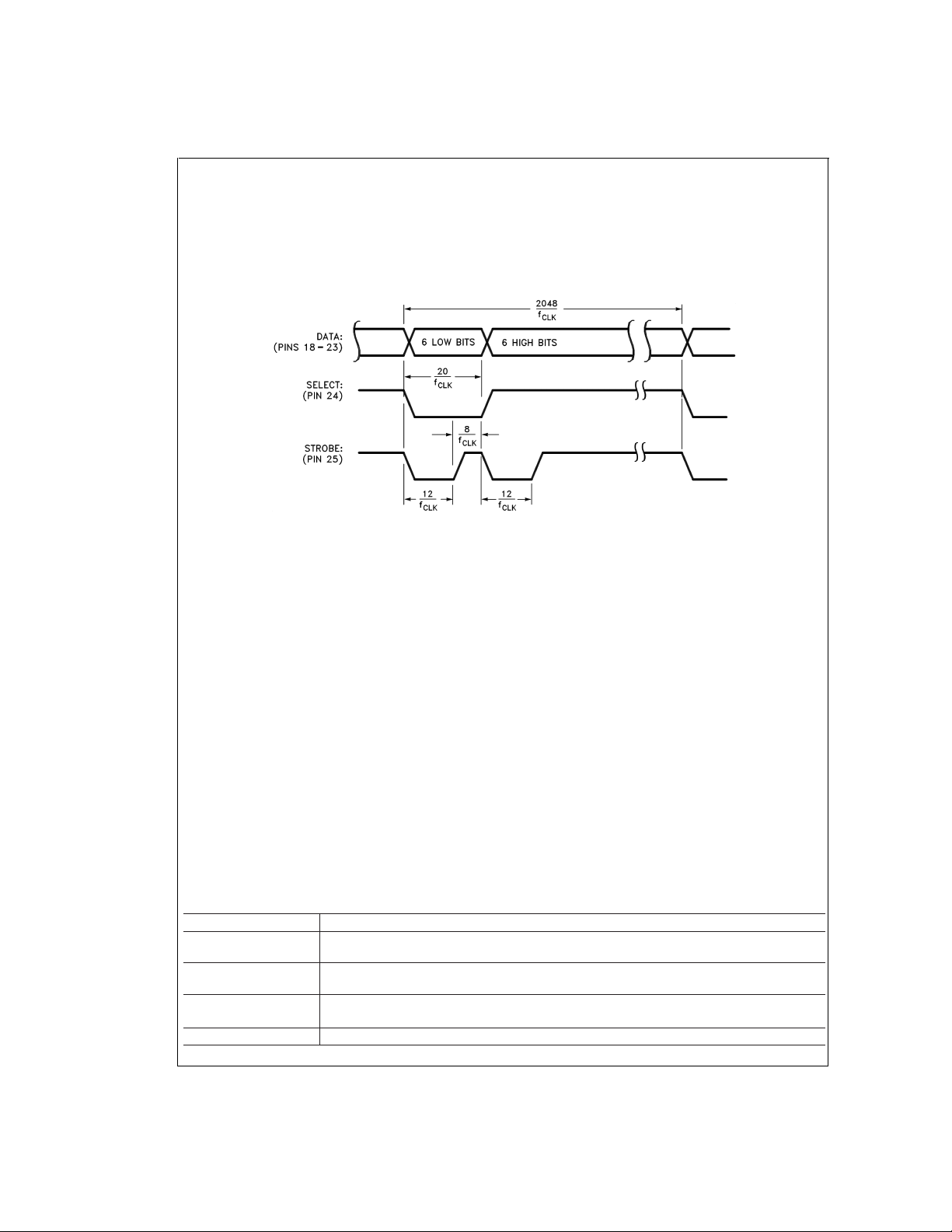

Pins 18 to 25, DAC Port (DAC0 to DAC7): Output port

which is used in three different modes:

1. LM628 (8-bit output mode): Outputs latched data to the

DAC. The MSB is Pin 18 and the LSB is Pin 25.

2. LM628 (12-bit output mode): Outputs two, multiplexed

6-bit words. The less-significant word is output first. The

MSB is on Pin 18 and the LSB is on Pin 23. Pin 24 is

used to demultiplex the words; Pin 24 is low for the

less-significant word. The positive-going edge of the signal on Pin 25 is used to strobe the output data.

Figure 8

shows the timing of the multiplexed signals.

3. LM629 (sign/magnitude outputs): Outputs a PWM sign

signal on Pin 18 (11 for surface mount), and a PWM

magnitude signal on Pin 19 (13 for surface mount). Pins

20 to 25 are not used in the LM629.

Figure 11

shows the

PWM output signal format.

Pin 26 (14), Clock (CLK) Input: Receives system clock.

Pin 27 (15), Reset (RST) Input: Active-low, positive-edge

triggered, resets the LM628 to the internal conditions shown

below. Note that the reset pulse must be logic low for a minimum of 8 clock periods. Reset does the following:

1. Filter coefficient and trajectory parameters are zeroed.

2. Sets position error threshold to maximum value (7FFF

hex), and effectively executes command LPEI.

3. The SBPA/SBPR interrupt is masked (disabled).

4. The five other interrupts are unmasked (enabled).

5. Initializes current position to zero, or “home” position.

6. Sets derivative sampling interval to 2048/f

for an 8.0 MHz clock.

CLK

or 256 µs

7. DAC port outputs 800 hex to “zero” a 12-bit DAC and

then reverts to 80 hex to “zero” an 8-bit DAC.

LM628/LM629

www.national.com7

Pinout Description (Continued)

Immediately after releasing the reset pin from the LM628,

the status port should read “00”. If the reset is successfully

completed, the status word will change to hex “84” or “C4”

LM628/LM629

within 1.5 ms. If the status word has not changed from hex

“00” to “84” or “C4” within 1.5 ms, perform another reset and

repeat the above steps. To be certain that the reset was

FIGURE 8. 12-Bit Multiplexed Output Timing

Theory of Operation

INTRODUCTION

The typical system block diagram (See

servo system built using the LM628. The host processor

communicates with the LM628 through an I/O port to facilitate programming a trapezoidal velocity profile and a digital

compensation filter. The DAC output interfaces to an external digital-to-analog converter to produce the signal that is

power amplified and applied to the motor.An incremental encoder provides feedback for closing the position servo loop.

The trapezoidal velocity profile generator calculates the required trajectory for either position or velocity mode of operation. In operation, the LM628 subtracts the actual position

(feedback position) from the desired position (profile generator position), and the resulting position error is processed by

the digital filter to drive the motor to the desired position.

Table1

provides a brief summary of specifications offered by

the LM628/LM629:

POSITION FEEDBACK INTERFACE

The LM628 interfaces to a motor via an incremental encoder.

Three inputs are provided: two quadrature signal inputs, and

an index pulse input. The quadrature signals are used to

Figure 1

TABLE 1. System Specifications Summary

) illustrates a

properly performed, execute a RSTI command. If the chip

has reset properly, the status byte will change from hex “84”

or “C4” to hex “80” or “C0”. If this does not occur, perform another reset and repeat the above steps.

Pin 28 (16), Supply Voltage (V

(+5V).

): Power supply voltage

DD

DS009219-10

keep track of the absolute position of the motor. Each time a

logic transition occurs at one of the quadrature inputs, the

LM628 internal position register is incremented or decremented accordingly. This provides four times the resolution

over the number of lines provided by the encoder. See

ure 9

. Each of the encoder signal inputs is synchronized with

Fig-

the LM628 clock.

The optional index pulse output provided by some encoders

assumes the logic-low state once per revolution. If the

LM628 is so programmed by the user, it will record the absolute motor position in a dedicated register (the index register)

at the time when all three encoder inputs are logic low.

If the encoder does not provide an index output, the LM628

index input can also be used to record the home position of

the motor. In this case, typically,the motor will close a switch

which is arranged to cause a logic-low level at the index input, and the LM628 will record motor position in the index

register and alert (interrupt) the host processor. Permanently

grounding the index input will cause the LM628 to malfunction.

Position Range −1,073,741,824 to 1,073,741,823 counts

Velocity Range 0 to 1,073,741,823/2

16

counts/sample; ie, 0 to 16,383 counts/sample, with a resolution of 1/2

counts/sample

Acceleration Range 0 to 1,073,741,823/2

resolution of 1/2

16

counts/sample/sample; ie, 0 to 16,383 counts/sample/sample, with a

16

counts/sample/sample

Motor Drive Output LM628: 8-bit parallel output to DAC, or 12-bit multiplexed output to DAC

LM629: 8-bit PWM sign/magnitude signals

Operating Modes Position and Velocity

www.national.com 8

16

Loading...

Loading...