LM3911 Temperature Controller

General Description

The LM3911 is a highly accurate temperature measurement

and/or control system for use over a

b

25§Ctoa85§C temperature range. Fabricated on a single monolithic chip, it

includes a temperature sensor, a stable voltage reference

and an operational amplifier.

The output voltage of the LM3911 is directly proportional to

temperature in degrees Kelvin at 10 mV/

nal op amp with external resistors any temperature scale

K. Using the inter-

§

factor is easily obtained. By connecting the op amp as a

comparator, the output will switch as the temperature transverses the set-point making the device useful as an on-off

temperature controller.

An active shunt regulator is connected across the power

leads of the LM3911 to provide a stable 6.8V voltage reference for the sensing system. This allows the use of any

power supply voltage with suitable external resistors.

The input bias current is low and relatively constant with

temperature, ensuring high accuracy when high source impedance is used. Further, the output collector can be returned to a voltage higher than 6.8V allowing the LM3911 to

drive lamps and relays up to a 35V supply.

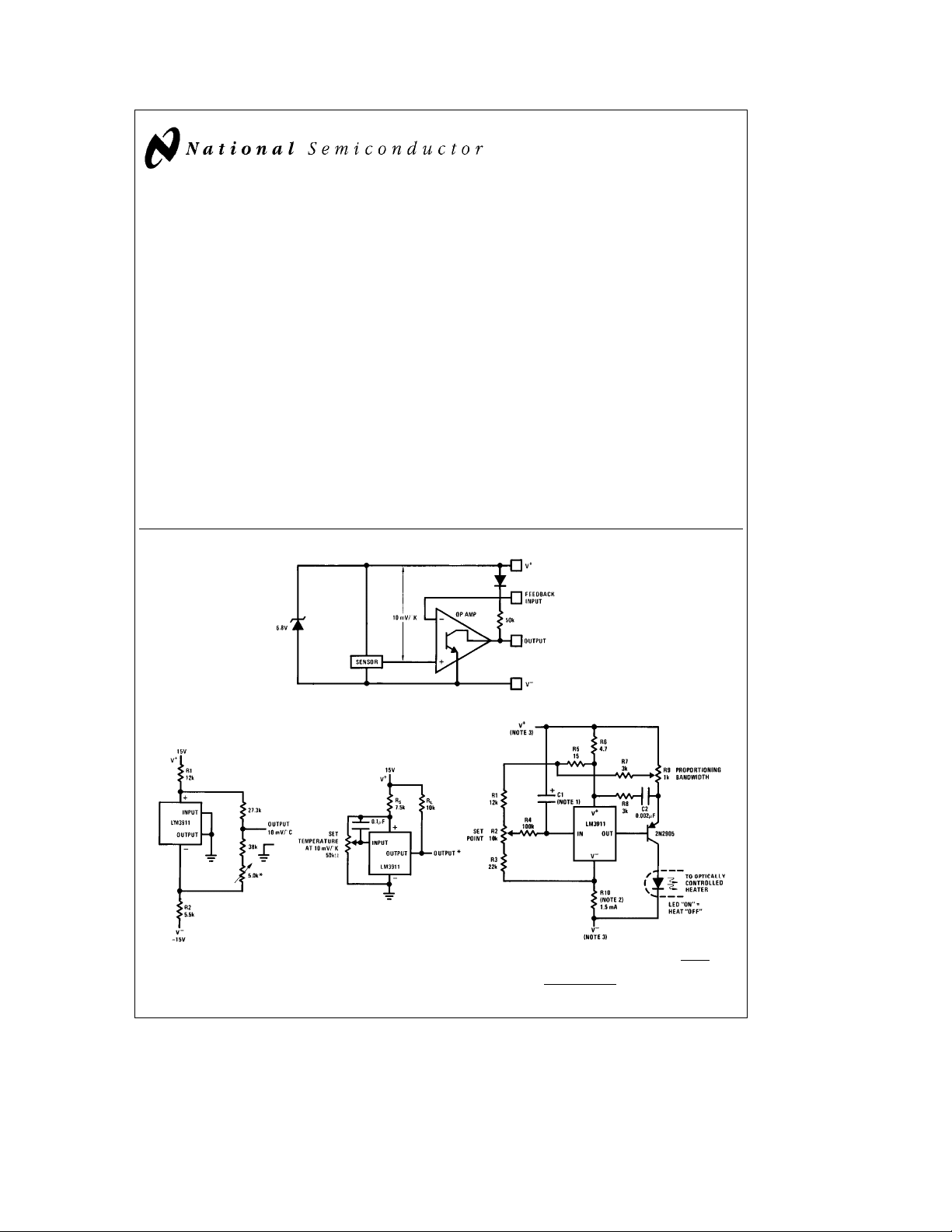

Block Diagram

The LM3911 uses the difference in emitter-base voltage of

transistors operating at different current densities as the basic temperature sensitive element. Since this output depends only on transistor matching the same reliability and

stability as present op amps can be expected.

The LM3911 is available in two package styles, a metal can

TO-46 and an 8-lead epoxy mini-DIP. In the epoxy package

all electrical connections are made on one side of the device allowing the other 4 leads to be used for attaching the

LM3911 to the temperature souce. The LM3911 is rated for

operation over a

Features

Y

Y

Y

Y

Y

Y

Y

b

25§Ctoa85§C temperature range.

Uncalibrated accuracyg10§C

Internal op amp with frequency compensation

Linear output of 10 mV/§K (10 mV/§C)

Can be calibrated in degrees Kelvin, Celsius or

Fahrenheit

Output can drive loads up to 35V

Internal stable voltage reference

Low cost

LM3911 Temperature Controller

June 1994

Typical Applications

Ground Referred

Proportioning Temperature

Controller

Centigrade Thermometer

Basic Temperature Controller

* Output goes negative on

temperature increase

a

e

b

R

(V

6.8V) kX

* Trims out initial zener tolerance.

Set output to read C

C

1995 National Semiconductor Corporation RRD-B30M115/Printed in U. S. A.

S

TL/H/5701

Note 1: C1 determines proportioning frequency f

Note 2: R10

Note 3: Either V

a

b

V

V

l

lal

e

0.0015A

b

or Vacan be ground.

b

7V

l

TL/H/5701– 1

&

2R4 C1

1

Absolute Maximum Ratings

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Supply Current (Externally Set) 10 mA

Output Collector Voltage, V

Feedback Input Voltage Range 0V to

aa

36V

a

7.0V

Output Short Circuit Duration Indefinite

Operating Temperature Range

Storage Temperature Range

b

25§Ctoa85§C

b

65§Ctoa150§C

Lead Temperature (Soldering, 10 seconds) 260§C

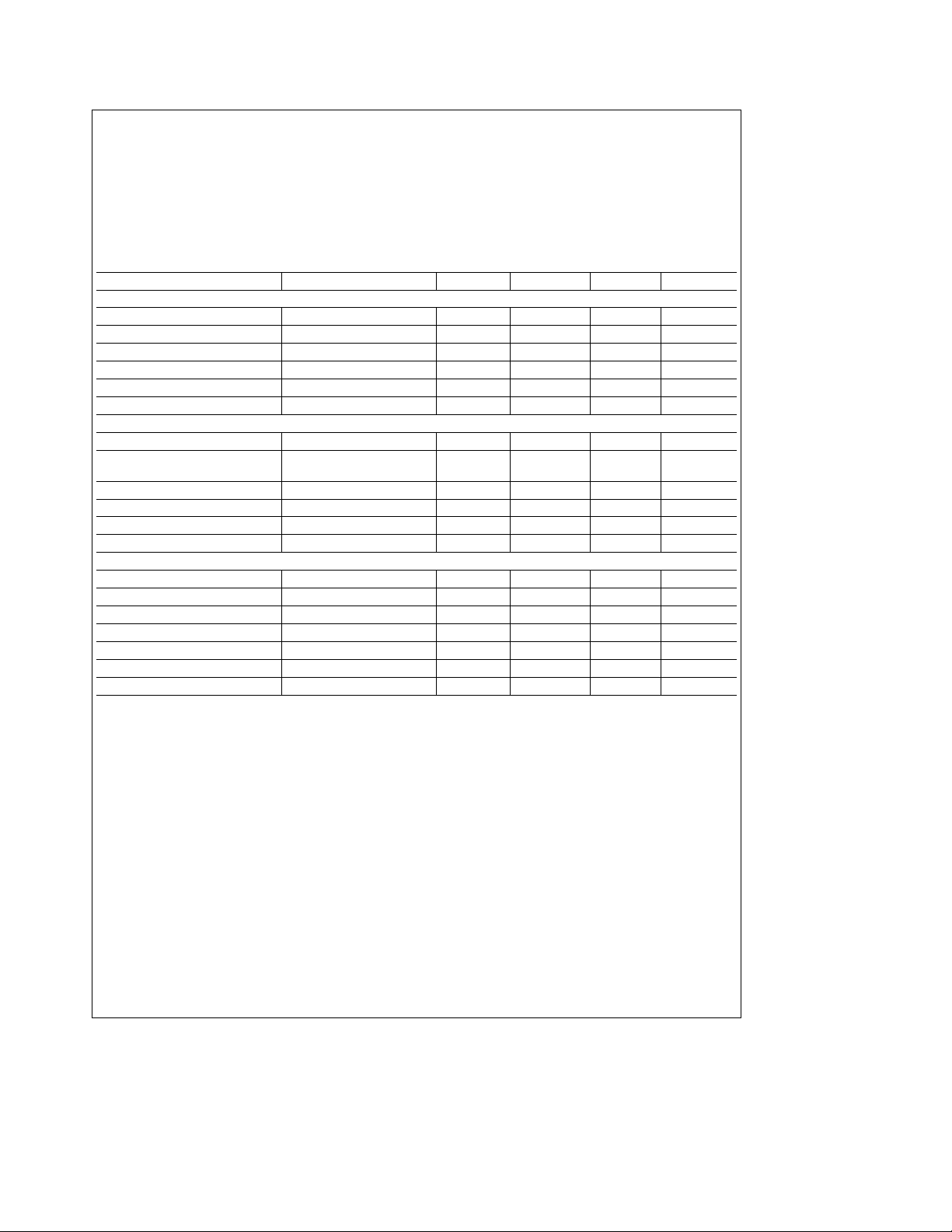

Electrical Characteristics (Note 1)

Parameter Conditions Min Typ Max Units

SENSOR

Output Voltage T

Output Voltage T

Output Voltage T

eb

25§C, (Note 2) 2.36 2.48 2.60 V

A

ea

25§C, (Note 2) 2.88 2.98 3.08 V

A

ea

85§C, (Note 2) 3.46 3.58 3.70 V

A

Linearity DTe100§C 0.5 2 %

Long-Term Stability 0.3 %

Repeatability 0.3 %

VOLTAGE REFERENCE

Reverse Breakdown Voltage 1 mAsI

Reverse Breakdown Voltage 1 mAsI

Change With Current

s

5 mA 6.55 6.85 7.25 V

z

s

5mA 10 35 mV

z

Temperature Stability 20 85 mV

Dynamic Impedance I

e

1 mA 3.0 X

z

RMS Noise Voltage 10 Hzsfs10 kHz 30 mV

Long Term Stability T

ea

85§C 6.0 mV

A

OP AMP

Input Bias Current T

ea

25§C 35 150 nA

A

Input Bias Current 45 250 nA

Voltage Gain R

Output Leakage Current T

e

36k, V

L

e

25§C (Note 3) 0.2 2 mA

A

e

36V 2500 15000 V/V

aa

Output Leakage Current (Note 3) 1.0 8 mA

Output Source Current V

Output Sink Current 1VsV

Note 1: These specifications apply forb25§CsT

Note 2: The output voltage applies to the basic thermometer configuration with the output and input terminals shorted and a load resistance of

the feedback sense voltage and includes errors in both the sensor and op amp. This voltage is specified for the sensor in a rapidly stirred oil bath. The output is

referred to V

Note 3: The output leakage current is specified with

defined as V

a

.

(with output and input shorted)b100 mV. This specification applies for V

OUT

s

3.70 10 mA

OUT

s

36V 2.0 mA

OUT

s

a

85§C and 0.9 mAsI

A

t

100 mV overdrive. Since this voltage changes with temperature, the voltage drive for turn-off changes and is

s

1.1 mA unless otherwise specified; C

SUPPLY

e

36V.

OUT

L

s

50 pF.

t

1.0 M X. This is

Application Hints

Although the LM3911 is designed to be totally trouble-free,

certain precautions should be taken to insure the best possible performance.

As with any temperature sensor, internal power dissipation

will raise the sensor’s temperature above ambient. Nominal

suggested operating current for the shunt regulator is 1.0

mA and causes 7.0 mW of power dissipation. In free, still, air

this raises the package temperature by about 1.2

though the regulator will operate at higher reverse currents

K. Al-

§

and the output will drive loads up to 5.0 mA, these higher

currents will raise the sensor temperature to about 19

above ambient-degrading accuracy. Therefore, the sensor

should be operated at the lowest possible power level.

With moving air, liquid or surface temperature sensing, selfheating is not as great a problem since the measured

§

media will conduct the heat from the sensor. Also, there are

many small heat sinks designed for transistors which will

improve heat transfer to the sensor from the surrounding

medium. A small finned clip-on heat sink is quite effective in

free-air. It should be mentioned that the LM3911 die is on

the base of the package and therefore coupling to the base

is preferable.

The internal reference regulator provides a temperature stable voltage for offsetting the output or setting a comparison

point in temperature controllers. However, since this reference is at the same temperature as the sensor temperature,

K

changes will also cause reference drift. For application

where maximum accuracy is needed an external reference

should be used. Of course, for fixed temperature controllers

the internal reference is adequate.

2

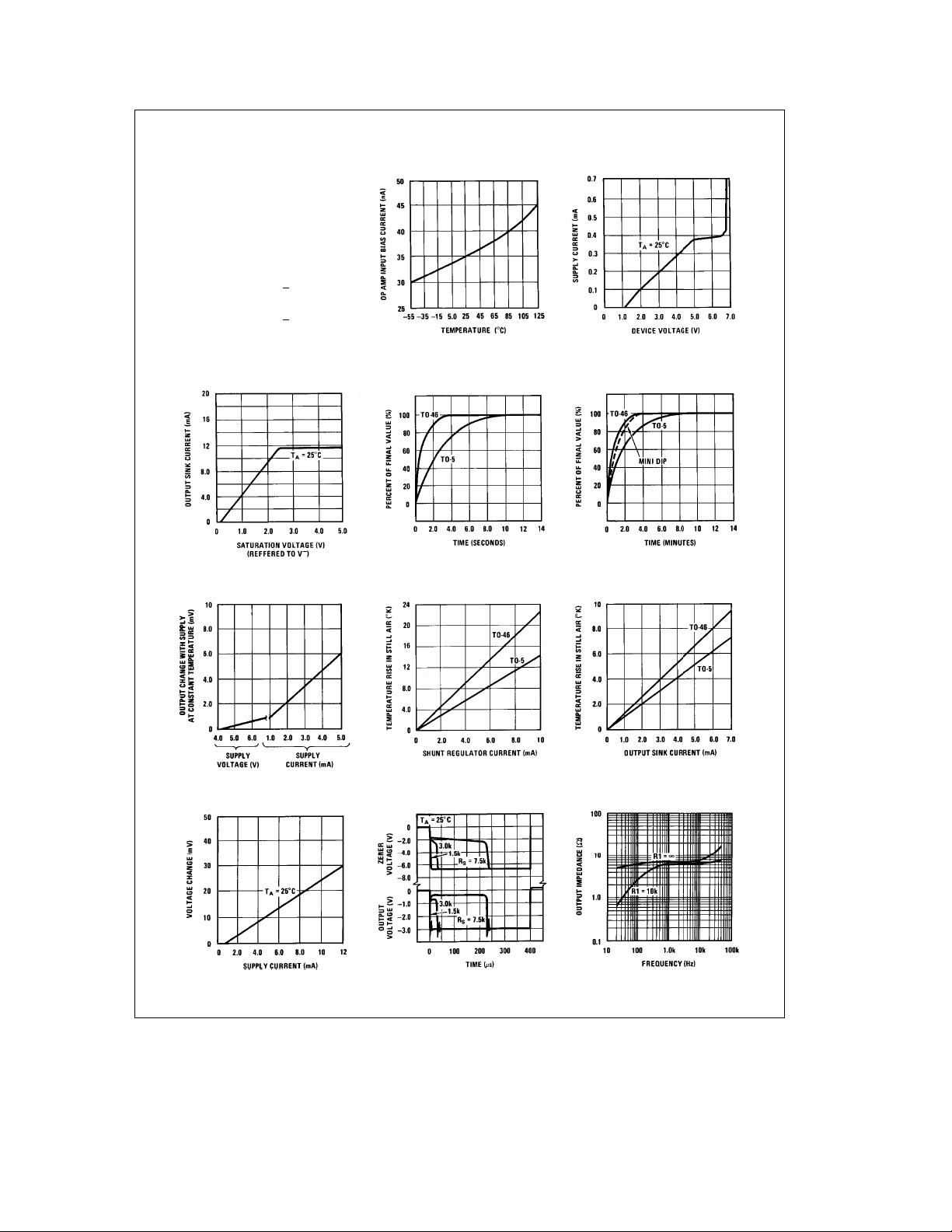

Typical Performance Characteristics

Temperature

Op Amp Input Current Power Supply Current

Conversion

e

T

K

a

T

273.16

C

(40aTF)

(40aTC)

e

T

C

e

T

F

5

b

40

9

9

b

40

5

Thermal Time Constant

in Stirred Oil Bath

Thermal Time Constant in

Still Air

T

CENTIGRADE

T

FAHRENHEIT

T

KELVIN

e

T

K

e

T

C

e

T

F

Output Saturation

Voltage

Supply Sensitivity Device Temperature Rise Device Temperature Rise

Reference Regulation Turn ‘‘ON’’ Response

3

Amplifier Output Impedance

TL/H/5701– 2

Loading...

Loading...