NSC LM2595S-ADJ, LM2595S-5.0, LM2595S-3.3, LM2595S-12 Datasheet

LM2595

SIMPLE SWITCHER

®

Power Converter 150 kHz

1A Step-Down Voltage Regulator

General Description

The LM2595 series of regulators are monolithic integrated

circuits that provide all the active functions for a step-down

(buck) switching regulator, capable of driving a 1A load with

excellent line and load regulation. These devices are available in fixed output voltages of 3.3V, 5V, 12V, and an adjustable output version.

Requiring aminimumnumber of external components, these

regulators are simple to use and include internal frequency

compensation

†

, and a fixed-frequency oscillator.

The LM2595 series operates at a switching frequency of

150 kHz thus allowing smaller sized filter components than

what would be needed with lower frequency switching regulators. Available in a standard 5-lead TO-220 package with

several different lead bend options, and a 5-lead TO-263

surface mount package. Typically, for output voltages less

than 12V, and ambient temperatures less than 50˚C, no heat

sink is required.

A standard series of inductors are available from several different manufacturers optimized for use with the LM2595 series. This feature greatly simplifies the design of

switch-mode power supplies.

Other features include a guaranteed

±

4%tolerance on output voltage under specified input voltage and output load

conditions, and

±

15%on the oscillator frequency. External

shutdown is included, featuring typically 85 µAstand-by current. Self protection features include a two stage frequency

reducing current limit for the output switch and an over temperature shutdown for complete protection under fault conditions.

Features

n 3.3V, 5V, 12V, and adjustable output versions

n Adjustable version output voltage range, 1.2V to 37V

±

4%max over line and load conditions

n Available in TO-220 and TO-263 (surface mount)

packages

n Guaranteed 1A output load current

n Input voltage range up to 40V

n Requires only 4 external components

n Excellent line and load regulation specifications

n 150 kHz fixed frequency internal oscillator

n TTL shutdown capability

n Low power standby mode, I

Q

typically 85 µA

n High efficiency

n Uses readily available standard inductors

n Thermal shutdown and current limit protection

Applications

n Simple high-efficiency step-down (buck) regulator

n Efficient pre-regulator for linear regulators

n On-card switching regulators

n Positive to negative converter

Note:†Patent Number 5,382,918.

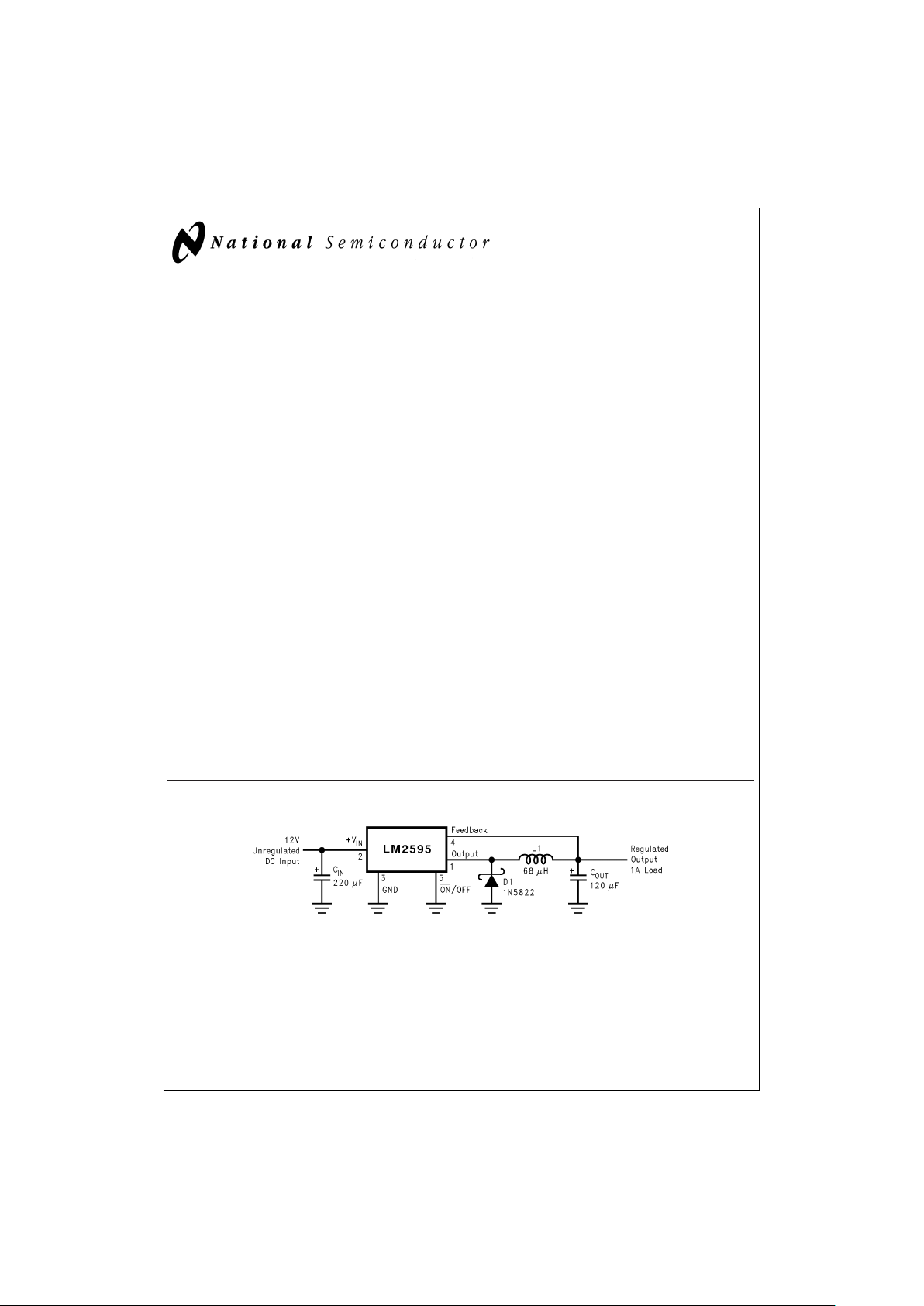

Typical Application (Fixed Output Voltage Versions)

SIMPLE SWITCHER®and

Switchers Made Simple

®

are registered trademarks of National Semiconductor Corporation.

DS012565-1

May 1999

LM2595 SIMPLE SWITCHER Power Converter 150 kHz 1A Step-Down Voltage Regulator

© 1999 National Semiconductor Corporation DS012565 www.national.com

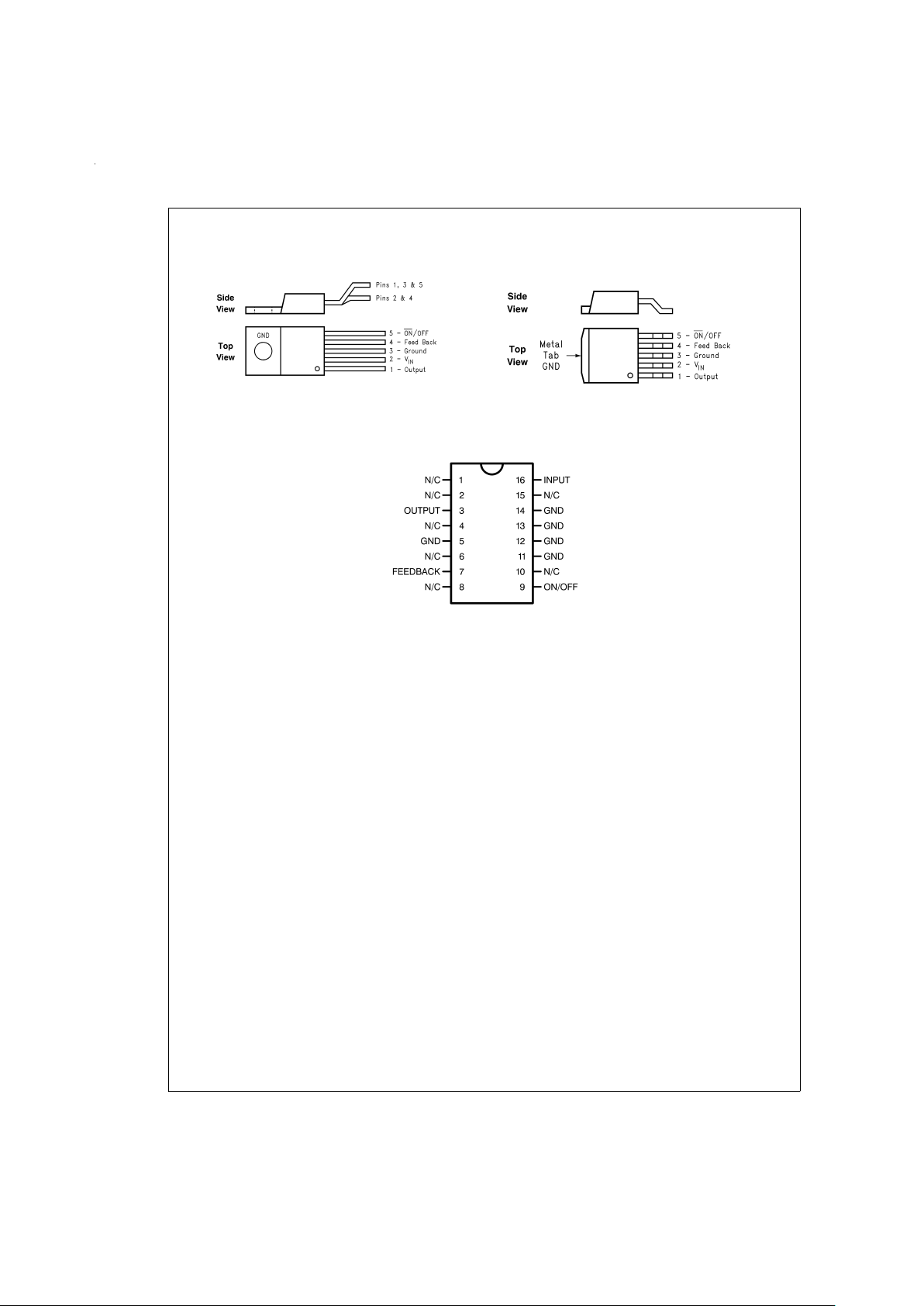

Connection Diagrams and Ordering Information

Bent and Staggered Leads, Through Hole Package

5–Lead TO-220 (T)

DS012565-2

Order Number LM2595T-3.3, LM2595T-5.0,

LM2595T-12 or LM2595T-ADJ

See NS Package Number T05D

Surface Mount Package

5-Lead TO-263 (S)

DS012565-3

Order Number LM2595S-3.3, LM2595S-5.0,

LM2595S-12 or LM2595S-ADJ

See NS Package Number TS5B

16-Lead Ceramic Dual-in-Line Package (J)

DS012565-57

Order Number LM2595J-3.3-QML (5962-9687901QEA),

LM2595J-5.0-QML (5962-9650301QEA),

LM2595J-12-QML (5962-9650201QEA),

or LM2595J-ADJ-QML (5962-9650401QEA)

See NS Package Number J16A

For specifications and information about Military-Aerospace products, please see the Mil-Aero web page at

http://www.national.com/appinfo/milaero/index.html.

www.national.com 2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Maximum Supply Voltage 45V

ON /OFF Pin Input Voltage

−0.3 ≤ V ≤ +25V

Feedback Pin Voltage −0.3 ≤ V ≤ +25V

Output Voltage to Ground

(Steady State) −1V

Power Dissipation Internally limited

Storage Temperature Range −65˚C to +150˚C

ESD Susceptibility

Human Body Model (Note 2) 2 kV

Lead Temperature

S Package

Vapor Phase (60 sec.) +215˚C

Infrared (10 sec.) +245˚C

T Package (Soldering, 10 sec.) +260˚C

Maximum Junction Temperature +150˚C

Operating Conditions

Temperature Range −40˚C ≤ TJ≤ +125˚C

Supply Voltage 4.5V to 40V

LM2595-3.3

Electrical Characteristics

Specifications with standard type face are for T

J

=

25˚C, and those with boldface type apply over full Operating Tempera-

ture Range.

Symbol Parameter Conditions LM2595-3.3 Units

(Limits)

Typ Limit

(Note 3) (Note 4)

SYSTEM PARAMETERS (Note 5) Test Circuit

Figure 1

V

OUT

Output Voltage 4.75V ≤ VIN≤ 40V, 0.1A ≤ I

LOAD

≤ 1A 3.3 V

3.168/3.135 V(min)

3.432/3.465 V(max)

η Efficiency V

IN

=

12V, I

LOAD

=

1A 78

%

LM2595-5.0

Electrical Characteristics

Specifications with standard type face are for T

J

=

25˚C, and those with boldface type apply over full Operating Tempera-

ture Range.

Symbol Parameter Conditions LM2595-5.0 Units

(Limits)

Typ Limit

(Note 3) (Note 4)

SYSTEM PARAMETERS (Note 5) Test Circuit

Figure 1

V

OUT

Output Voltage 7V ≤ VIN≤ 40V, 0.1A ≤ I

LOAD

≤ 1A 5.0 V

4.800/4.750 V(min)

5.200/5.250 V(max)

η Efficiency V

IN

=

12V, I

LOAD

=

1A 82

%

LM2595-12

Electrical Characteristics

Specifications with standard type face are for T

J

=

25˚C, and those with boldface type apply over full Operating Tempera-

ture Range.

Symbol Parameter Conditions LM2595-12 Units

(Limits)

Typ Limit

(Note 3) (Note 4)

SYSTEM PARAMETERS (Note 5) Test Circuit

Figure 1

V

OUT

Output Voltage 15V ≤ VIN≤ 40V, 0.1A ≤ I

LOAD

≤ 1A 12.0 V

11.52/11.40 V(min)

12.48/12.60 V(max)

η Efficiency V

IN

=

25V, I

LOAD

=

1A 90

%

www.national.com3

LM2595-ADJ

Electrical Characteristics

Specifications with standard type face are for T

J

=

25˚C, and those with boldface type apply over full Operating Tempera-

ture Range.

Symbol Parameter Conditions LM2595-ADJ Units

(Limits)

Typ Limit

(Note 3) (Note 4)

SYSTEM PARAMETERS (Note 5) Test Circuit

Figure 1

V

FB

Feedback Voltage 4.5V ≤ VIN≤ 40V, 0.1A ≤ I

LOAD

≤ 1A 1.230 V

V

OUT

programmed for 3V. Circuit of

Figure 1

1.193/1.180 V(min)

1.267/1.280 V(max)

η Efficiency V

IN

=

12V, V

OUT

=

3V, I

LOAD

=

1A 78

%

All Output Voltage Versions

Electrical Characteristics

Specifications with standard type face are for T

J

=

25˚C, and those with boldface type apply over full Operating Tempera-

ture Range. Unless otherwise specified, V

IN

=

12V for the 3.3V, 5V, and Adjustable version and V

IN

=

24V for the 12V ver-

sion. I

LOAD

=

200 mA.

Symbol Parameter Conditions LM2595-XX Units

(Limits)

Typ Limit

(Note 3) (Note 4)

DEVICE PARAMETERS

I

b

Feedback Bias Current Adjustable Version Only,V

FB

=

1.3V 10 nA

50/100 nA (max)

f

O

Oscillator Frequency (Note 6) 150 kHz

127/110 kHz(min)

173/173 kHz(max)

V

SAT

Saturation Voltage I

OUT

=

1A (Notes 7, 8) 1 V

1.2/1.3 V(max)

DC Max Duty Cycle (ON) (Note 8) 100

%

Min Duty Cycle (OFF) (Note 9) 0

I

CL

Current Limit Peak Current (Notes 7, 8) 1.5 A

1.2/1.15 A(min)

2.4/2.6 A(max)

I

L

Output Leakage Current Output=0V (Notes 7, 9) and (Note 10) 50 µA(max)

Output=−1V 2 mA

15 mA(max)

I

Q

Quiescent Current (Note 9) 5 mA

10 mA(max)

I

STBY

Standby Quiescent ON/OFF pin=5V (OFF) (Note 10) 85 µA

Current 200/250 µA(max)

θ

JC

Thermal Resistance TO-220 or TO-263 Package, Junction to Case 2 ˚C/W

θ

JA

TO-220 Package, Junction to Ambient (Note 11) 50 ˚C/W

θ

JA

TO-263 Package, Junction to Ambient (Note 12) 50 ˚C/W

θ

JA

TO-263 Package, Junction to Ambient (Note 13) 30 ˚C/W

θ

JA

TO-263 Package, Junction to Ambient (Note 14) 20 ˚C/W

ON/OFF CONTROL Test Circuit

Figure 1

ON /OFF Pin Logic Input 1.3 V

V

IH

Threshold Voltage Low (Regulator ON) 0.6 V(max)

V

IL

High (Regulator OFF) 2.0 V(min)

www.national.com 4

All Output Voltage Versions

Electrical Characteristics

(Continued)

Specifications with standard type face are for T

J

=

25˚C, and those with boldface type apply over full Operating Tempera-

ture Range. Unless otherwise specified, V

IN

=

12V for the 3.3V, 5V, and Adjustable version and V

IN

=

24V for the 12V ver-

sion. I

LOAD

=

200 mA.

Symbol Parameter Conditions LM2595-XX Units

(Limits)

Typ Limit

(Note 3) (Note 4)

ON/OFF CONTROL Test Circuit

Figure 1

I

H

ON/OFF Pin

Input Current

V

LOGIC

=

2.5V (Regulator OFF) 5 µA

15 µA(max)

I

L

V

LOGIC

=

0.5V (Regulator ON) 0.02 µA

5 µA(max)

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur.Operating Ratings indicate conditions for which the device is intended to be functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: The human body model is a 100 pF capacitor discharged through a 1.5k resistor into each pin.

Note 3: Typical numbers are at 25˚C and represent the most likely norm.

Note 4: All limits guaranteed at room temperature (standard type face) and at temperature extremes (bold type face). All room temperature limits are 100%produc-

tion tested. All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods. All limits are used to calculate

Average Outgoing Quality Level (AOQL).

Note 5: External components such as the catch diode, inductor, input and output capacitors, and voltage programming resistors can affect switching regulator system performance. When the LM2595 is used as shown in the

Figure 1

test circuit, system performance will be as shown in system parameters section of Electrical

Characteristics.

Note 6: The switching frequency is reduced when the second stage current limit is activated. The amount of reduction is determined by the severity of current over-

load.

Note 7: No diode, inductor or capacitor connected to output pin.

Note 8: Feedback pin removed from output and connected to 0V to force the output transistor switch ON.

Note 9: Feedback pin removed from output and connected to 12V for the 3.3V, 5V, and the ADJ. version, and 15V for the 12V version, to force the output transistor

switch OFF.

Note 10: V

IN

=

40V.

Note 11: Junction to ambient thermal resistance (no external heat sink) for the TO-220 package mounted vertically, with the leads soldered to a printed circuit board

with (1 oz.) copper area of approximately 1 in

2

.

Note 12: Junction to ambient thermal resistance with the TO-263 package tab soldered to a single printed circuit board with 0.5 in

2

of (1 oz.) copper area.

Note 13: Junction to ambient thermal resistance with the TO-263 package tab soldered to a single sided printed circuit board with 2.5 in

2

of (1 oz.) copper area.

Note 14: Junction to ambient thermal resistance with the TO-263 package tab soldered to a double sided printed circuit board with 3 in

2

of (1 oz.) copper area on

the LM2595S side of the board, and approximately 16 in

2

of copper on the other side of the p-c board. SeeApplication Information in this data sheet and the thermal

model in

Switchers Made Simple

®

version 4.3 software.

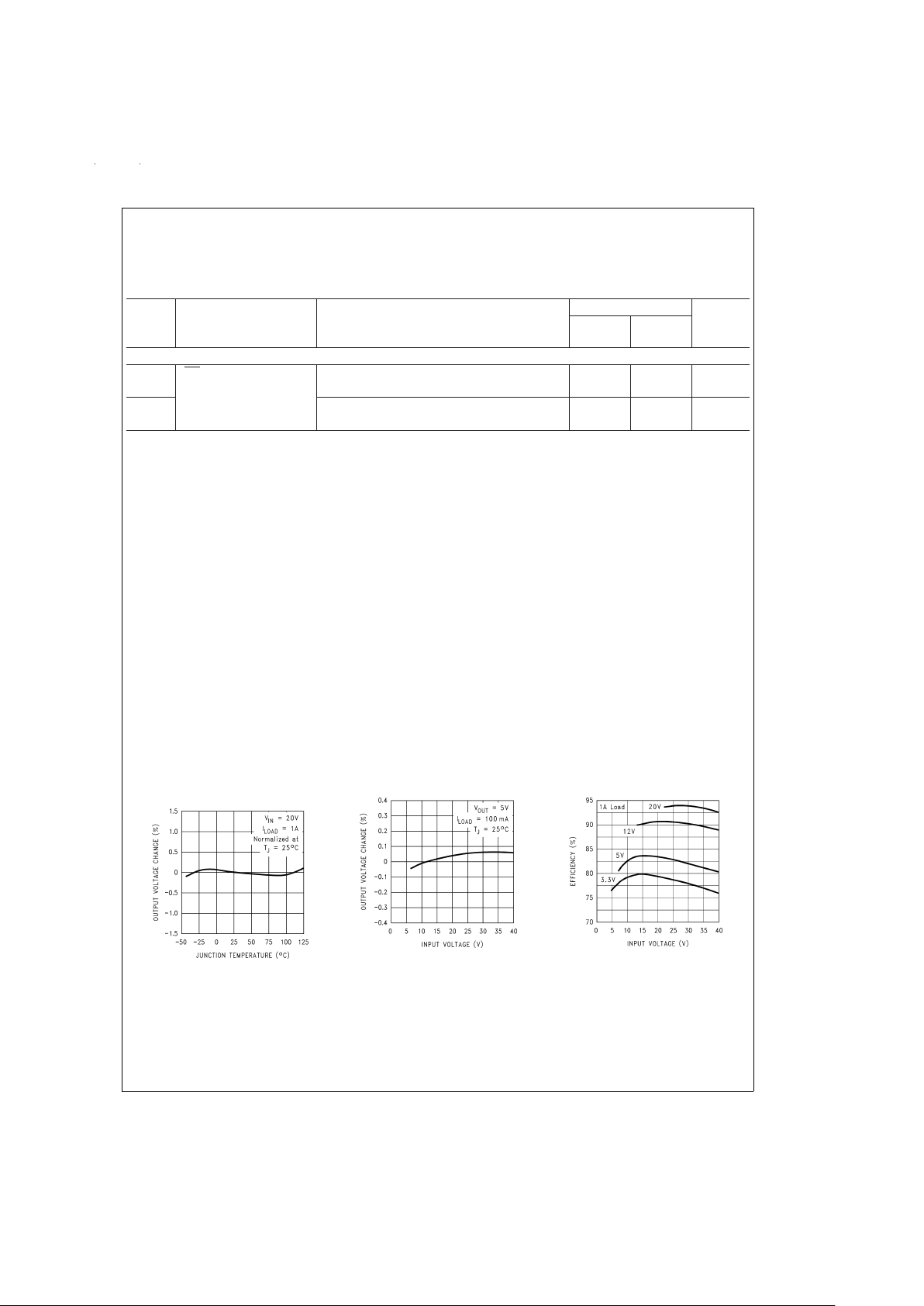

Typical Performance Characteristics (Circuit of

Figure 1

)

Normalized

Output Voltage

DS012565-11

Line Regulation

DS012565-12

Efficiency

DS012565-13

www.national.com5

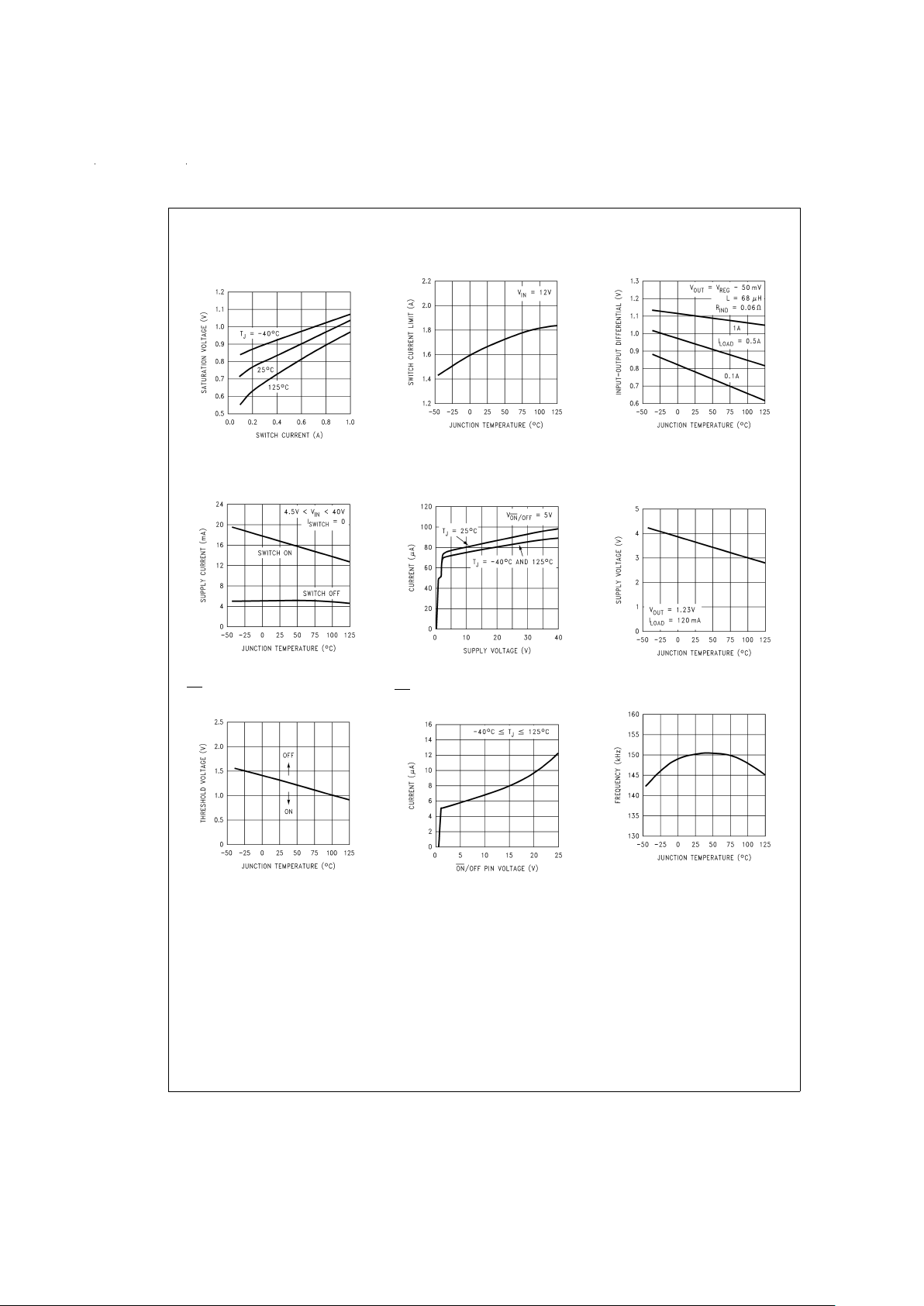

Typical Performance Characteristics (Circuit of

Figure 1

) (Continued)

Switch Saturation

Voltage

DS012565-14

Switch Current Limit

DS012565-15

Dropout Voltage

DS012565-16

Operating

Quiescent Current

DS012565-4

Shutdown

Quiescent Current

DS012565-5

Minimum Operating

Supply Voltage

DS012565-6

ON /OFF Threshold

Voltage

DS012565-7

ON /OFF Pin

Current (Sinking)

DS012565-8

Switching Frequency

DS012565-9

www.national.com 6

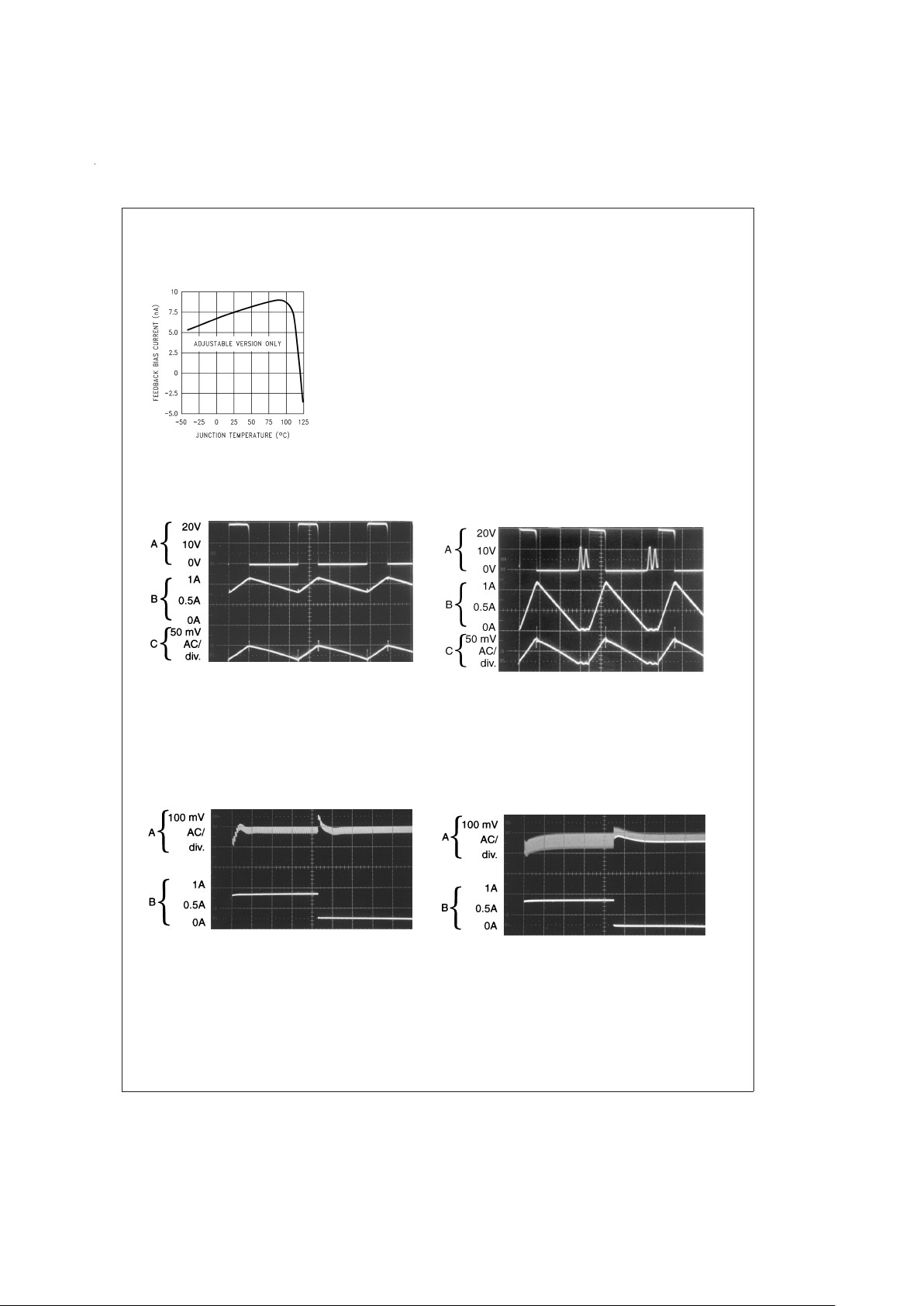

Typical Performance Characteristics (Circuit of

Figure 1

) (Continued)

Feedback Pin

Bias Current

DS012565-10

Continuous Mode Switching Waveforms

V

IN

=

20V, V

OUT

=

5V, I

LOAD

=

1A

L=68 µH, C

OUT

=

120 µF, C

OUT

ESR=100 mΩ

DS012565-17

A: Output Pin Voltage, 10V/div.

B: Inductor Current 0.5A/div.

C: Output Ripple Voltage, 50 mV/div.

Horizontal Time Base: 2 µs/div.

Discontinuous Mode Switching Waveforms

V

IN

=

20V, V

OUT

=

5V, I

LOAD

=

600 mA

L=22 µH, C

OUT

=

220 µF, C

OUT

ESR=50 mΩ

DS012565-18

A: Output Pin Voltage, 10V/div.

B: Inductor Current 0.5A/div.

C: Output Ripple Voltage, 50 mV/div.

Horizontal Time Base: 2 µs/div.

Load Transient Response for Continuous Mode

V

IN

=

20V, V

OUT

=

5V, I

LOAD

=

250 mA to 750 mA

L=68 µH, C

OUT

=

120 µF, C

OUT

ESR=100 mΩ

DS012565-19

A: Output Voltage, 100 mV/div. (AC)

B: 250 mA to 750 mA Load Pulse

Horizontal Time Base: 100 µs/div.

Load Transient Response for Discontinuous Mode

V

IN

=

20V, V

OUT

=

5V, I

LOAD

=

250 mA to 750 mA

L=22 µH, C

OUT

=

220 µF, C

OUT

ESR=50 mΩ

DS012565-20

A: Output Voltage, 100 mV/div. (AC)

B: 250 mA to 750 mA Load Pulse

Horizontal Time Base: 200 µs/div.

www.national.com7

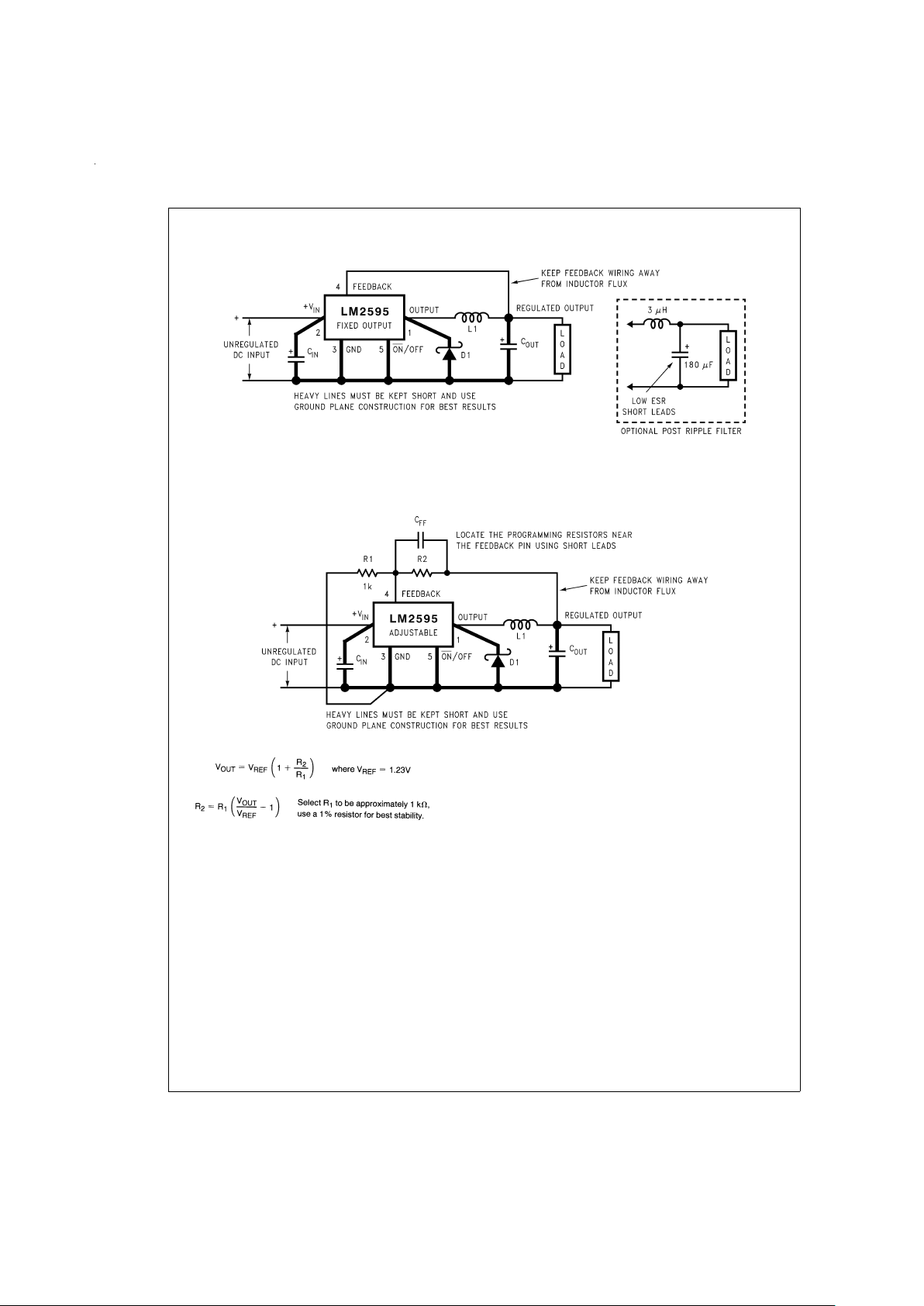

Test Circuit and Layout Guidelines

As in any switching regulator, layout is very important. Rapidly switching currents associated with wiring inductance can

generate voltage transients which can cause problems. For

minimal inductance and ground loops, the wires indicated by

heavy lines should be wide printed circuit traces and

should be kept as short as possible. For best results, ex-

ternal components should be located as close to the

switcher lC as possible using ground plane construction or

single point grounding.

If open core inductors are used, special care must be

taken as to the location and positioning of this type of inductor.Allowing the inductor flux to intersect sensitive feedback,

lC groundpath and C

OUT

wiring can cause problems.

When using the adjustable version, special care must be

taken as to the location of the feedback resistors and the associated wiring. Physically locate both resistors near the IC,

and route the wiring away from the inductor, especially an

open core type of inductor. (See application section for more

information.)

Fixed Output Voltage Versions

DS012565-22

CIN— 120 µF, 50V,Aluminum Electrolytic Nichicon “PL Series”

C

OUT

— 120 µF, 25V Aluminum Electrolytic, Nichicon “PL Series”

D1— 3A, 40V Schottky Rectifier, 1N5822

L1— 100 µH, L29

Adjustable Output Voltage Versions

DS012565-23

CIN— 120 µF, 50V,Aluminum Electrolytic Nichicon “PL Series”

C

OUT

— 120 µF, 25V Aluminum Electrolytic, Nichicon “PL Series”

D1— 3A, 40V Schottky Rectifier, 1N5822

L1— 100 µH, L29

R

1

—1kΩ,1

%

C

FF

— See Application Information Section

FIGURE 1. Standard Test Circuits and Layout Guides

www.national.com 8

LM2595 Series Buck Regulator Design Procedure (Fixed Output)

PROCEDURE (Fixed Output Voltage Version) EXAMPLE (Fixed Output Voltage Version)

Given:

V

OUT

=

Regulated Output Voltage (3.3V, 5V or 12V)

V

IN

(max)=Maximum DC Input Voltage

I

LOAD

(max)=Maximum Load Current

Given:

V

OUT

=

5V

V

IN

(max)=12V

I

LOAD

(max)=1A

1. Inductor Selection (L1)

A. Select the correct inductor value selection guide from

Fig-

ure 4

,

Figure 5

,or

Figure 6

. (Output voltages of 3.3V,5V, or

12V respectively.) For all other voltages, see the design procedure for the adjustable version.

B. From the inductor value selection guide, identify the inductance region intersected by the Maximum Input Voltage line

and the Maximum Load Current line. Each region isidentified

by an inductance value and an inductor code (LXX).

C. Select an appropriate inductor from the four manufacturer’s part numbers listed in

Figure 8

.

1. Inductor Selection (L1)

A. Use the inductor selection guide for the 5V version shown

in

Figure 5

.

B. From the inductor value selection guide shownin

Figure 5

,

the inductance region intersected by the 12V horizontal line

and the 1A vertical line is 68 µH, and the inductor code is

L30.

C. The inductance value required is 68 µH. From the table in

Figure 8

, go to the L30 line and choose an inductor part number from any of the four manufacturers shown. (In most instance, both through hole and surface mount inductors are

available.)

2. Output Capacitor Selection (C

OUT

)

A. In the majority of applications, low ESR (Equivalent Series

Resistance) electrolytic capacitors between 47 µF and 330

µF and low ESR solid tantalum capacitors between 56 µF

and 270 µF provide the best results.This capacitor should be

located close to the IC using short capacitor leads and short

copper traces. Do not use capacitors larger than 330 µF.

For additional information, see section on output capacitors in application information section.

B. To simplify the capacitor selection procedure, refer to the

quick design component selection table shown in

Figure 2

.

This table contains different input voltages, output voltages,

and load currents, and lists various inductors and output capacitors that will provide the best design solutions.

C. The capacitor voltage rating for electrolytic capacitors

should be at least 1.5 times greater than the output voltage,

and often much higher voltage ratings are needed to satisfy

the low ESR requirements for low output ripple voltage.

D. For computer aided design software, see

Switchers

Made Simple

®

version 4.2 or later.

2. Output Capacitor Selection (C

OUT

)

A. See section on output capacitors in application information section.

B. From the quick design component selection table shown

in

Figure 2

, locate the 5V output voltage section. In the load

current column, choose the load current line that is closest to

the current needed in your application, for this example, use

the 1A line. In the maximum input voltage column, select the

line that covers the input voltage needed in your application,

in this example, use the 15V line. Continuing on this line are

recommended inductors and capacitors that will provide the

best overall performance.

The capacitor list contains both through hole electrolytic and

surface mount tantalum capacitors from four different capacitor manufacturers. It is recommended that both the manufacturers and the manufacturer’s series that are listed in the

table be used.

In this example aluminum electrolytic capacitors from several

different manufacturers are available with the range of ESR

numbers needed.

220 µF 25V Panasonic HFQ Series

220 µF 25V Nichicon PL Series

C. For a 5V output, a capacitor voltage rating at least 7.5V or

more is needed. But, in this example, even a low ESR,

switching grade, 220 µF 10V aluminum electrolytic capacitor

would exhibit approximately 225 mΩ of ESR (see the curve

in

Figure 14

for the ESR vs voltage rating). This amount of

ESR would result in relatively high output ripple voltage. To

reduce the ripple to 1%of the output voltage, or less, a capacitor with a higher voltage rating (lower ESR)should be selected. A 16V or 25V capacitor will reduce the ripple voltage

by approximately half.

Procedure continued on next page. Example continued on next page.

www.national.com9

Loading...

Loading...