NSC LM1819N Datasheet

LM1819 Air-Core Meter Driver

LM1819 Air-Core Meter Driver

February 1995

General Description

The LM1819 is a function generator/driver for air-core

(moving-magnet) meter movements. A Norton amplifier and

an NPN transistor are included on chip for signal conditioning as required. Driver outputs are self-centering and devel-

g

op

4.5V swing at 20 mA. Better than 2% linearity is guar-

anteed over a full 305-degree operating range.

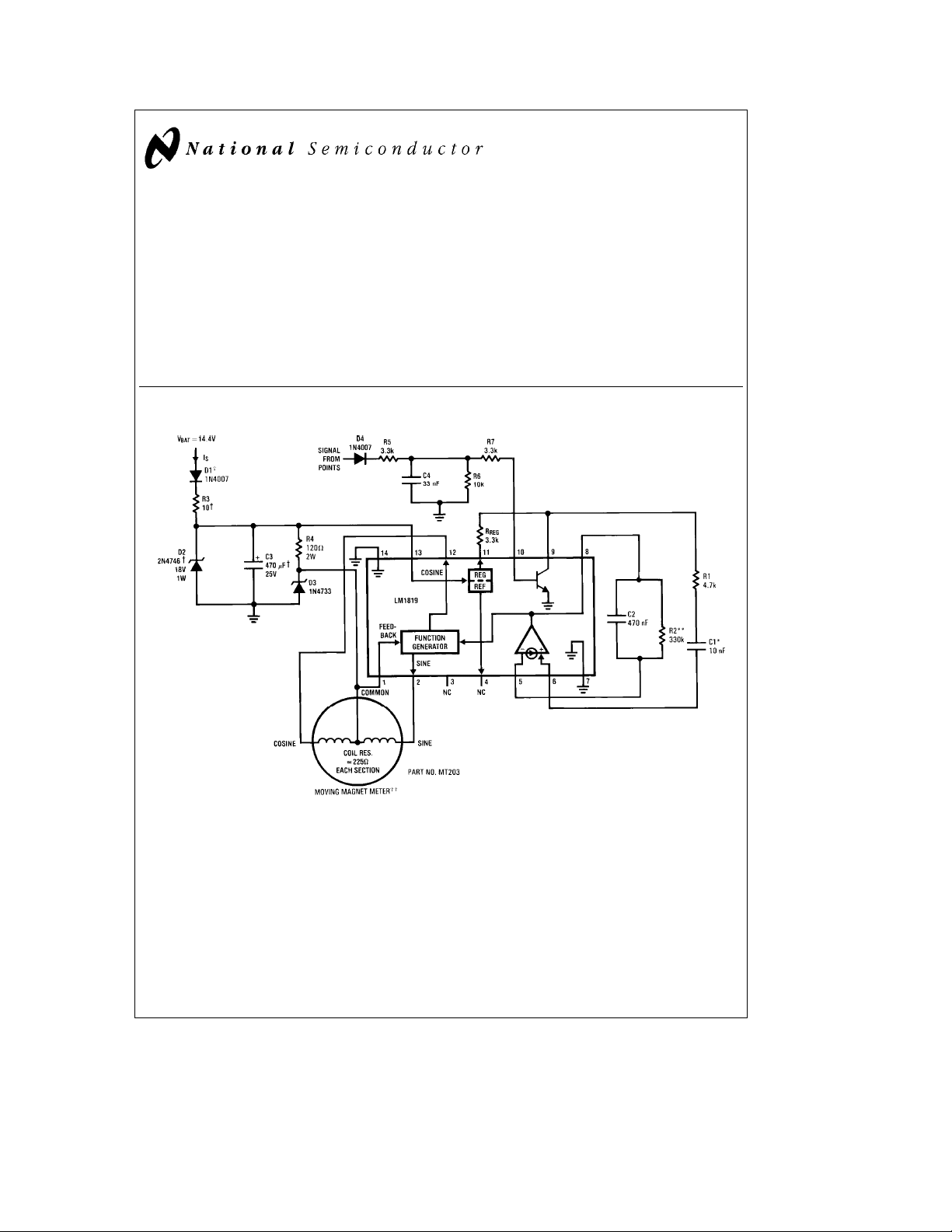

Typical Application

Features

Y

Self-centering 20 mA outputs

Y

12V operation

Y

Norton amplifier

Y

Function generator

Applications

Y

Air-core meter driver

Y

Tachometers

Y

Ruggedized instruments

TL/H/5263– 1

FIGURE 1. Automotive Tachometer Application. Circuit shown operates

with 4 cylinder engine and deflects meter pointer (270

) at 6000 RPM.

§

Order Number LM1819M or LM1819N

See NS Package Number M14A or N14A

*TRW Type X463UW Polycarbonate Capacitor

**RN60D Low TC Resistor (

²

Components Required for Automotive Load Dump Protection

²²

Available from FARIA Co.

C

1995 National Semiconductor Corporation RRD-B30M115/Printed in U. S. A.

g

100 ppm)

P O Box 983, Uncasville, CT 06382

Tel. 203-848-9271

TL/H/5263

Absolute Maximum Ratings

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Supply Voltage, V

Power Dissipation (note 1) 1300 mW

a

(pin 13) 20V

Operating Temperature

Storage Temperature

b

40§Ctoa85§C

b

65§Ctob150§C

Lead Temp. (Soldering, 10 seconds) 260§C

BV

CEO

20V

MIN

Electrical Characteristics V

S

e

13.1V T

e

25§C unless otherwise specified

A

Symbol Parameter Pin(s) Conditions Min Typ Max Units

I

S

V

REG

V

REF

h

FE

k Function Generator Gain Meter Deflection/DV

Note 1: For operation above 25§C, the LM1819 must be derated based upon a 125§C maximum junction temperature and a thermal resistance of 76§C/W which

applies for the device soldered in a printed circuit board and operating in a still-air ambient.

Supply Current 13 Zero Input Frequency

(See

Figure 1

)

Regulator Voltage 11 I

Regulator Output Resistance 11 I

Reference Voltage 4 I

Reference Output Resistance 4 I

Norton Amplifier Mirror Gain 5, 6 I

e

0 mA 8.1 8.5 8.9 V

REG

e

0 mA to 3 mA 13.5 X

REG

e

0 mA 1.9 2.1 2.3 V

REF

e

0 mAto50mA 5.3 kX

REF

j

20 mA 0.9 1.0 1.1

BIAS

NPN Transistor DC Gain 9, 10 125

Function Generator Feedback 1 V

Bias Current

Drive Voltage Extremes, 2, 12 I

Sine and Cosine

Sine Output Voltage 2 V

with Zero Input

Function Generator Linearity FSDe305

e

1

LOAD

e

8

5.1V

e

V

REF

20 mA

§

g

b

50.75 53.75 56.75

8

g

4

350 0

1.0 mA

65 mA

4.5 V

a

350 mV

g

1.7 %FSD

/V

§

Application Hints

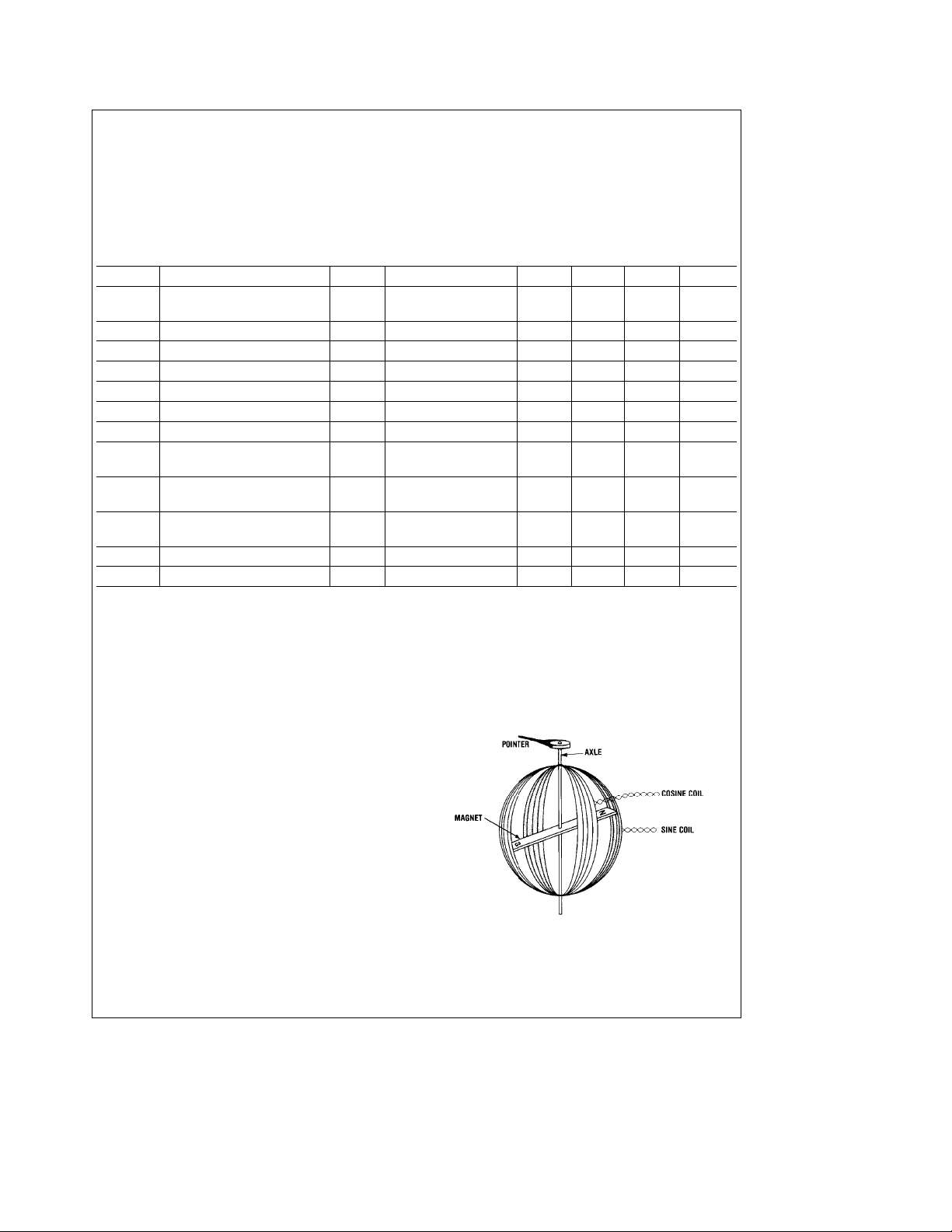

AIR-CORE METER MOVEMENTS

Air-core meters are often favored over other movements as

a result of their mechanical ruggedness and their independence of calibration with age. A simplified diagram of an aircore meter is shown in

Figure 2

. There are three basic

pieces: a magnet and pointer attached to a freely rotating

axle, and two coils, each oriented at a right angle with respect to the other. The only moving part in this meter is the

axle assembly. The magnet will tend to align itself with the

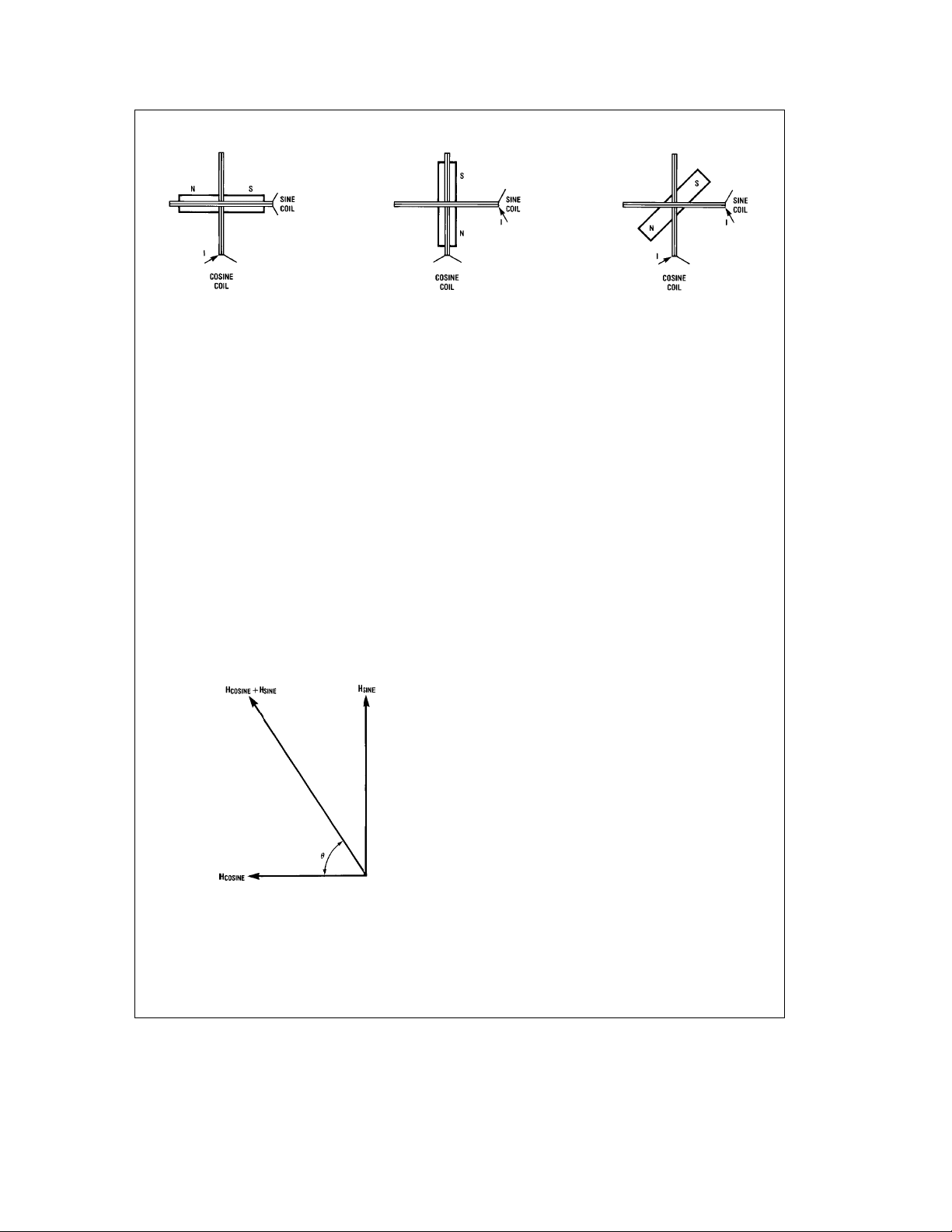

vector sum of H fields of each coil, where H is the magnetic

field strength vector. If, for instance, a current passes

through the cosine coil (the reason for this nomenclature

will become apparent later) as shown in

Figure 3(a)

, the

magnet will align its magnetic axis with the coil’s H field.

Similarly, a current in the sine coil (

Figure 3(b)

) causes the

magnet to align itself with the sine H field. If currents are

applied simultaneously to both sine and cosine coils, the

magnet will turn to the direction of the vector sum of the two

H fields

(Figure 3(c)).

H is proportional to the voltage applied

to a coil. Therefore, by varying both the polarity and magnitude of the coil voltages the axle assembly can be made to

rotate a full 360

ter through a minimum of 305

. The LM1819 is designed to drive the me-

§

.

§

FIGURE 2. Simplified Diagram of an Air Core Meter.

2

TL/H/5263– 2

Application Hints (Continued)

FIGURE 3. Magnet and pointer position are controlled by the H field generated by the two drive coils.

In an air-core meter the axle assembly is supported by two

nylon bushings. The torque exerted on the pointer is much

greater than that found in a typical d’Arsonval movement. In

contrast to a d’Arsonval movement, where calibration is a

function of spring and magnet characteristics, air-core meter calibration is only affected by the mechanical alignment

of the drive coils. Mechanical calibration, once set at manufacture, can not change.

Making pointer position a linear function of some input is a

matter of properly ratioing the drive to each coil. The H field

contributed by each coil is a function of the applied current,

and the current is a function of the coil voltage. Our desired

result is to have i (pointer deflection, measured in degrees)

proportional to an input voltage:

e

i

kV

IN

[1]

where k is a constant of proportionality, with units of degrees/volt. The vector sum of each coils’ H field must follow

the deflection angle i. We know that the axle assembly

always points in the direction of the vector sum of H

and H

formula:

. This direction (see

COSINE

e

(i)

arctan

Figure 4

) is found from the

À

H

l

SINE

l/l

H

COSINE

Ó

l

SINE

[2]

Recalling some basic trigonometry,

e

(i)

arctan(sin (i) / cos(i ))

FIGURE 4. The vector sum of H

in a direction i measured in a clockwise direction from

H

.

COSINE

COSINE

and H

[3]

TL/H/5263– 4

points

SINE

(c)(b)(a)

TL/H/5263– 3

Comparing[3]to[2]we see that if H

of i, and H

ate a net H field whose direction is the same as i. And since

varies as the cosine of i, we will gener-

COSINE

varies as the sine

SINE

the axle assembly aligns itself with the net H field, the pointer will always point in the direction of i.

THE LM1819

Included in the LM1819 is a function generator whose two

outputs are designed to vary approximately as the sine and

cosine of an input. A minimum drive of

g

20 mA atg4V is

available at pins 2 (sine) and 12 (cosine). The common side

of each coil is returned to a 5.1V zener diode reference and

fed back to pin 1.

For the function generator, kj54

input (pin 8) is internally connected to the Norton amplifier’s

output. V

ference of the voltages at pins 8 (Norton output/function

as considered in equation[1]is actually the dif-

IN

/V (in equation 1). The

§

generator input) and 4. Typically the reference voltage at pin

4 is 2.1V. Therefore,

e

b

i

k(V

V

)e54 (V

8

REF

b

2.1)

8

As V8varies from 2.1V to 7.75V, the function generator will

drive the meter through the chip’s rated 305

range.

§

Air-core meters are mechanically zeroed during manufacture such that when only the cosine coil is driven, the pointer indicates zero degrees deflection. However, in some applications a slight trim or offset may be required. This is

accomplished by sourcing or sinking a DC current of a few

microamperes at pin 4.

A Norton amplifier is available for conditioning various input

signals and driving the function generator. A Norton amplifier was chosen since it makes a simple frequency to voltage

converter. While the non-inverting input (pin 6) bias is at one

diode drop above ground, the inverting input (5) is at 2.1V,

equal to the pin 4 reference. Mirror gain remains essentially

flat to I

designed to source current into its load. To bypass the Nor-

MIRROR

e

5 mA. The Norton amplifier’s output (8) is

ton amplifier simply ground the non-inverting input, tie the

inverting input to the reference, and drive pin 8 (Norton output/function generator input) directly.

An NPN transistor is included on chip for buffering and

squaring input signals. Its usefulness is exemplified in

ures 1

&6where an ignition pulse is converted to a rectan-

Fig-

gular waveform by an RC network and the transistor. The

emitter is internally connected to ground. It is important not

to allow the base to drop below

b

5Vdc, as damage may

occur. The 2.1V reference previously described is derived

from an 8.5V regulator at pin 11. Pin 11 is used as a stable

supply for collector loads, and currents of up to 5 mA are

easily accommodated.

[4]

3

Loading...

Loading...