ADC1175-50

8-Bit, 50 MSPS, 125 mW A/D Converter

ADC1175-50 8-Bit, 50 MSPS, 125 mW A/D Converter

January 2000

General Description

The ADC1175-50 is a low power, 50 MSPS analog-to-digital

converter that digitizes signals to 8 bits while consuming just

125 mW (typ). The ADC1175-50 uses a unique architecture

that achieves 6.8 Effective Bits and 25 MHz input and

50 MHz clock frequency. Output formatting is straight binary

coding.

The excellent DC and AC characteristics of this device, together with itslowpowerconsumptionand +5V single supply

operation, make it ideally suited for many video and imaging

applications, including use in portable equipment. Furthermore, the ADC1175-50 is resistant to latch-up and the outputs are short-circuit proof. The top and bottom of the

ADC1175-50’sreference ladder is available for connections,

enabling a wide range of input possibilities. The low input capacitance (7 pF, typical) makes this device easier to drive

than conventional flash converters and the power down

mode reduces power consumption to less than 5 mW.

The ADC1175-50 is offered in SOIC (EIAJ) and TSSOP. It is

designed to operate over the commercial temperature range

of −20˚C to +75˚C.

Features

n Internal Track-and-Hold function

n Single +5V operation

n Internal reference bias resistors

n Industry standard pinout

<

n Power-down mode (

5 mW)

Key Specifications

n Resolution 8 Bits

n Maximum Sampling Frequency 50 MSPS (min)

n THD 54 dB (typ)

n DNL 0.7 LSB (typ)

n ENOB

n Guaranteed No Missing Codes

n Differential Phase 0.5˚ (typ)

n Differential Gain 1.0%(typ)

n Power Consumption 125 mW (typ), 190 mW (max)

@

fIN= 25 MHz 6.8 Bits (typ)

(Excluding Reference Current)

Applications

n Digital Still Cameras

n CCD Imaging

n Electro-Optics

n Medical Imaging

n Communications

n Video Digitization

n Digital Television

n Multimedia

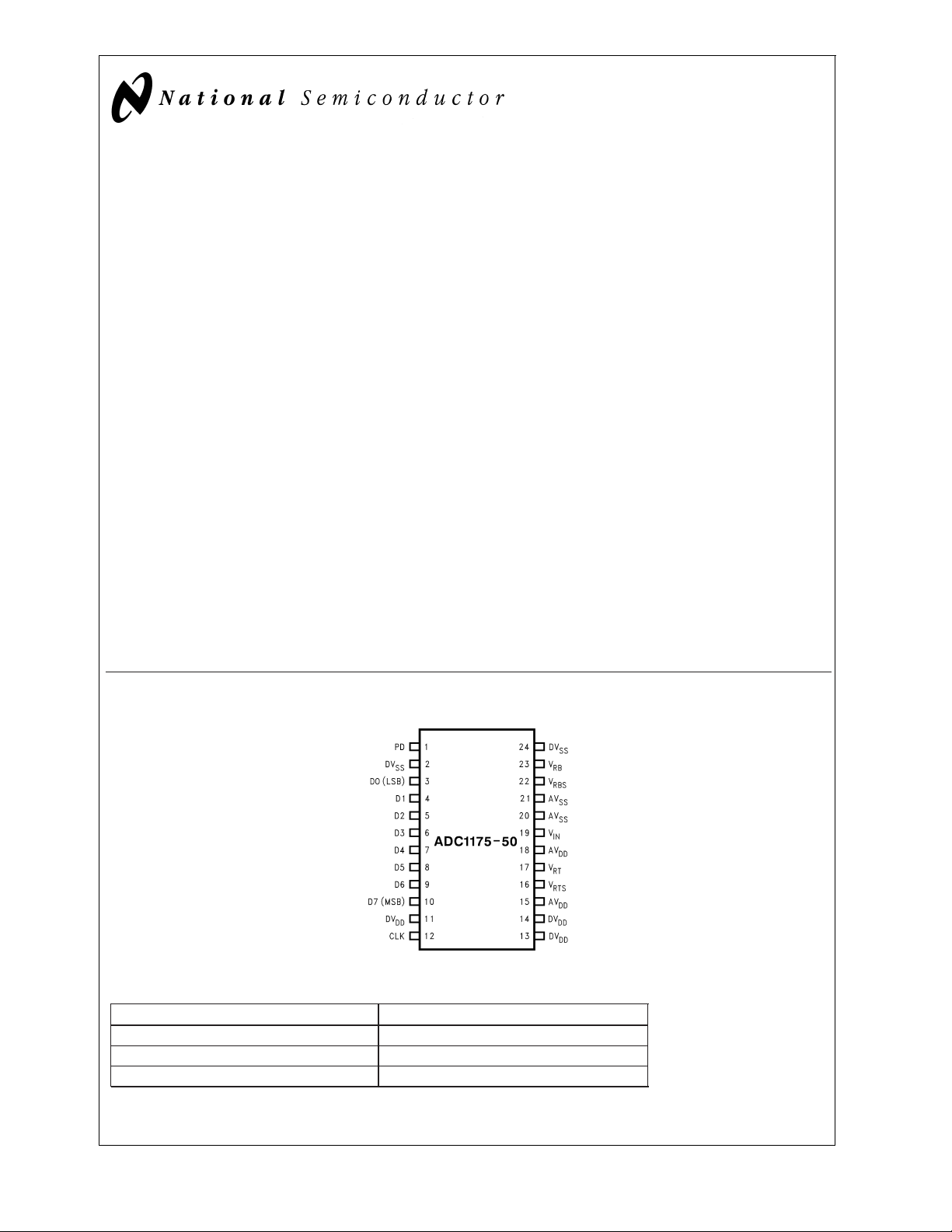

Connection Diagram

DS100896-1

Ordering Information

ADC1175-50CIJM SOIC (EIAJ)

ADC1175-50CIJMX SOIC (EIAJ) (tape and reel)

ADC1175-50CIMT TSSOP

ADC1175-50CIMTX TSSOP (tape and reel)

TRI-STATE®is a registered trademark of National Semiconductor Corporation.

© 2000 National Semiconductor Corporation DS100896 www.national.com

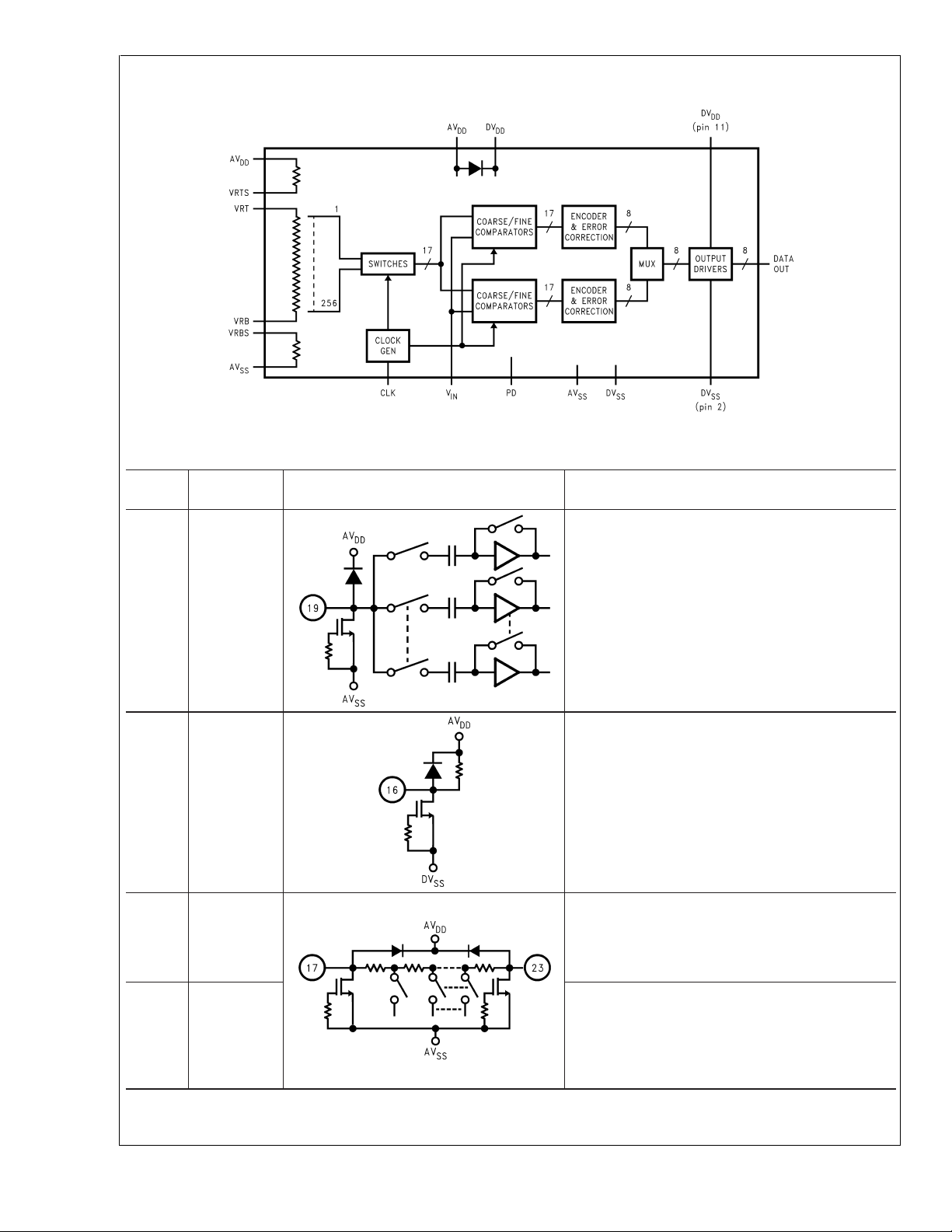

Block Diagram

ADC1175-50

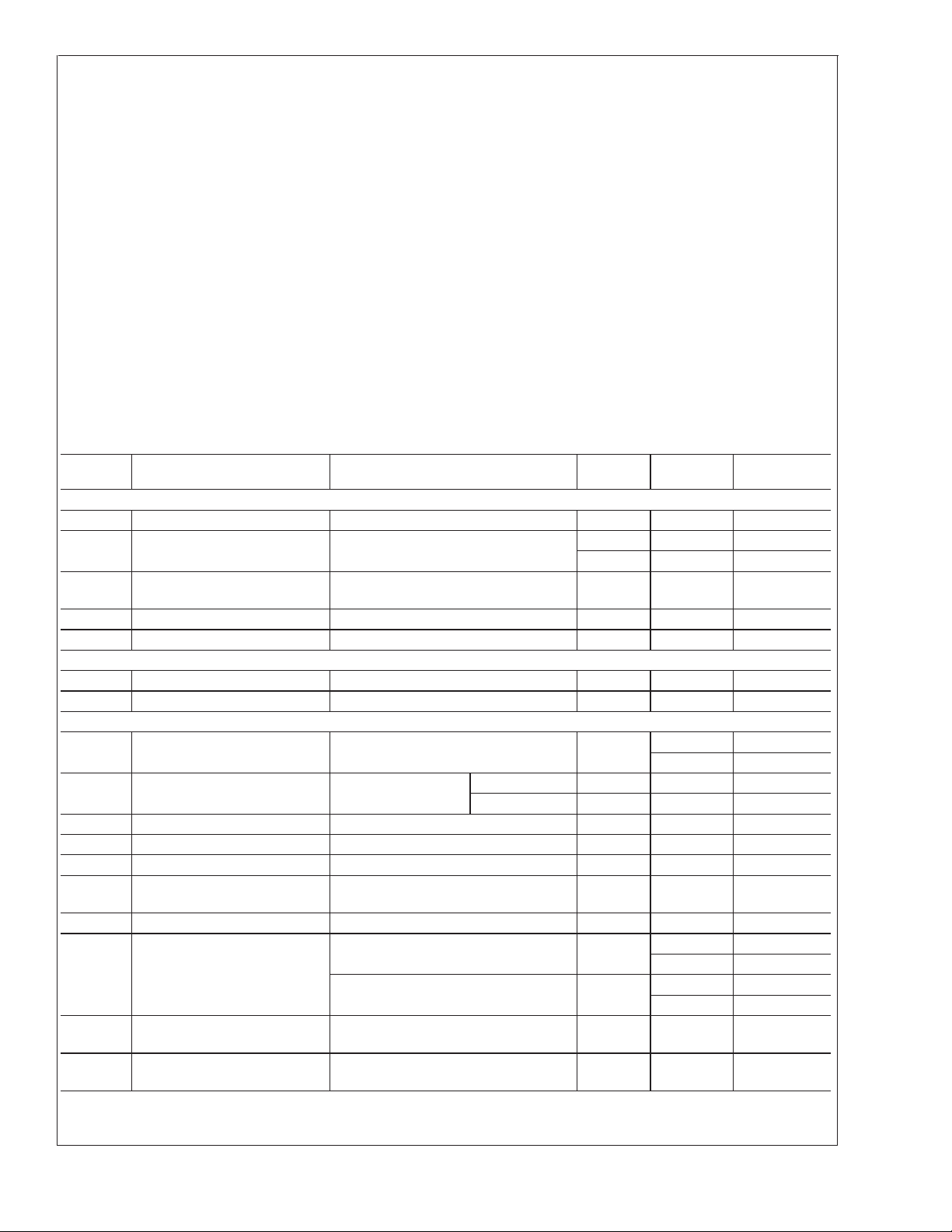

Pin Descriptions and Equivalent Circuits

DS100896-2

Pin

No.

Symbol Equivalent Circuit Description

19 V

16 V

17 V

23 V

RTS

RT

RB

IN

Analog signal input. Conversion range is VRTto

.

V

RB

Reference Top Bias with internal pull up resistor.

Short this pin to V

to self-bias the reference

RT

ladder.

Analog input that is the high (top) side of the

reference ladder of the ADC. Nominal range is 1.0V

to AV

, optimized value of 2.6V. Voltages on V

DD

RT

and VRBinputs define the VINconversion range.

Bypass well. See Section 2.0 for more information.

Analog input that is the low (bottom) side of the

reference ladder of the ADC. Nominal range is 0.0V

to 4.0V, with optimized value of 0.6V. Voltage on

and VRBinputs define the VINconversion

V

RT

range. Bypass well. See Section 2.0 for more

information.

www.national.com 2

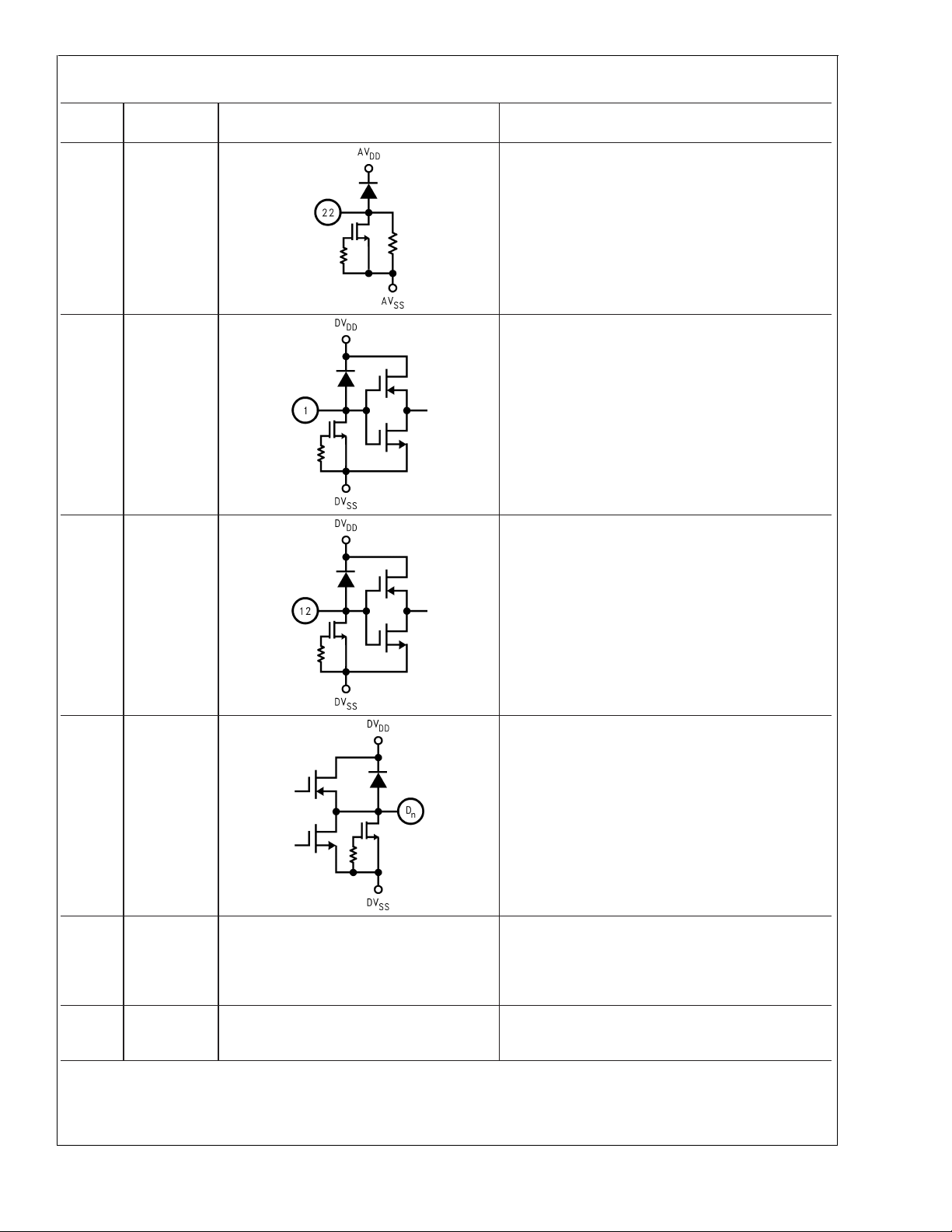

Pin Descriptions and Equivalent Circuits (Continued)

ADC1175-50

Pin

No.

22 V

Symbol Equivalent Circuit Description

RBS

1PD

Reference Bottom Bias with internal pull down

resistor. Short to V

to self-bias the reference

RB

ladder. Bypass well if not grounded. See Section

2.0 for more information.

CMOS/TTL compatible Digital input that, when high,

puts the ADC1175-50 into a power-down mode

where total power consumption is typically less than

5 mW. With this pin low, the device is in the normal

operating mode.

12 CLK

3 thru

10

D0–D7

11,

13, 14

2, 24 DV

DV

CMOS/TTL compatible digital clock input. VINis

sampled on the falling edge of CLK input.

Conversion data digital Output pins. D0 is the LSB,

D7 is the MSB. Valid data is output just after the

rising edge of the CLK input. These pins are in a

high impedance mode when the PD pin is low.

Positive digital supply pin. Connect to a clean, quiet

voltage source of +5V. AV

DD

a common source and be separately bypassed with

and DVDDshould have

DD

a 10 µF capacitor and a 0.1 µF ceramic chip

capacitor. See Section 4.0 for more information.

The ground return for the digital supply. AVSSand

should be connected together close to the

SS

DV

SS

ADC1175-50.

www.national.com3

Pin Descriptions and Equivalent Circuits (Continued)

Pin

No.

ADC1175-50

15, 18 AV

20, 21 AV

Symbol Equivalent Circuit Description

Positive analog supply pin. Connect to a clean,

quiet voltage source of +5V. AV

DD

have a common source and be separately bypassed

with a 10 µF capacitor and a 0.1 µF ceramic chip

capacitor. See Section 4.0 for more information.

The ground return for the analog supply. AVSSand

should be connected together close to the

SS

DV

SS

ADC1175-50 package.

and DVDDshould

DD

www.national.com 4

ADC1175-50

Absolute Maximum Ratings (Notes 1, 2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage (AV

Voltage on Any Input or Output Pin −0.3V to +6.5V

Reference Voltage (V

CLK, PD Voltage Range −0.5 to (AVDD+0.5V)

Digital Output Voltage (V

Input Current at Any Pin (Note 3)

Package Input Current (Note 3)

Power Dissipation at T

,DVDD) 6.5V

DD

)AV

RT,VRB

OH,VOL

)V

DD

DD

±

±

=

25˚C See (Note 4)

A

to V

SS

to V

SS

25 mA

50 mA

ESD Susceptibility (Note 5)

Human Body Model 2000V

Machine Model 250V

Soldering Temperature, Infrared,

(10 sec.) (Note 6) 300˚C

Storage Temperature −65˚C to +150˚C

Short Circuit Duration

(Single High Output to Ground) 1 Second

Operating Ratings (Notes 1, 2)

Operating Temperature Range −20˚C ≤ T

Supply Voltage (AV

−DV

AV

DD

DD

Ground Difference |DV

Upper Reference Voltage (V

,DVDD) +4.75V to +5.25V

DD

–AVSS| 0V to 100 mV

SS

) 1.0V to V

RT

≤ +75˚C

A

Lower Reference Voltage (VRB) 0V to 4.0V

Voltage Range VRBto V

V

IN

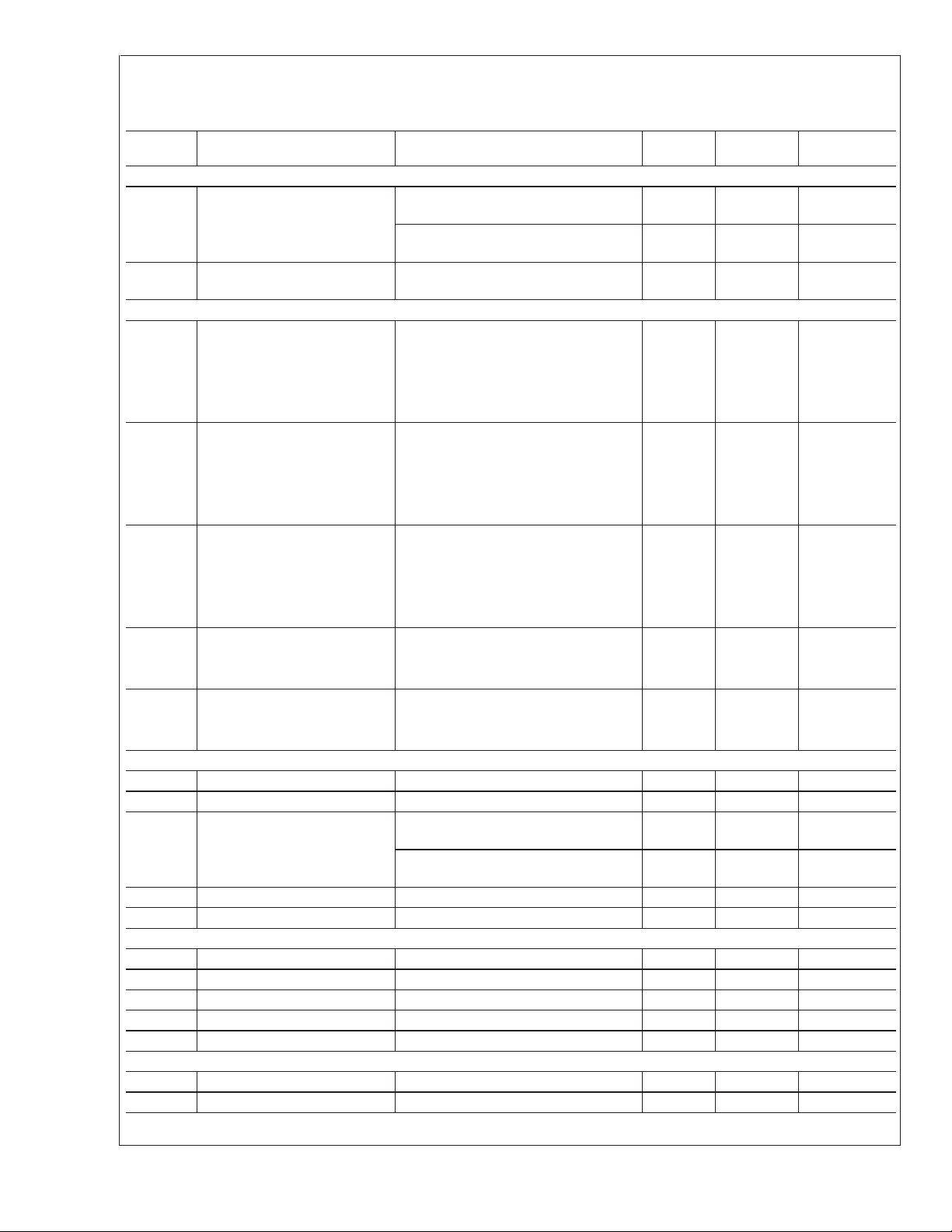

Converter Electrical Characteristics

The following specifications apply for AV

50 MHz at 50%duty cycle. Boldface limits apply for T

=

DD

Symbol Parameter Conditions

DC ACCURACY

INL Integral Non Linearity Error V

DNL Differential Non-Linearity

Resolution for No Missing

Codes

E

OT

E

OB

Top Offset Voltage −12 mV

Bottom Offset Voltage +10 mV

VIDEO ACCURACY

DP Differential Phase Error f

DG Differential Gain Error f

ANALOG INPUT AND REFERENCE CHARACTERISTICS

V

IN

C

IN

R

IN

Input Range 2.0

VINInput Capacitance

RINInput Resistance

BW Full Power Bandwidth 120 MHz

R

R

R

I

V

V

RT

REF

RB

REF

RT

RB

Top Reference Resistor 320 Ω

Reference Ladder Resistance VRTto V

Bottom Reference Resistor 80 Ω

Reference Ladder Current

Reference Top Self Bias

Voltage

Reference Bottom Self Bias

Voltage

=

DV

V

+5.0 V

DD

=

0.6V to 2.6V

IN

=

0.6V to 2.6V +0.7 +1.75 LSB (max)

IN

=

A

,PD=0V, V

DC

to T

T

MIN

MAX

=

+2.6V, V

RT

; all other limits T

Typical

(Note 9)

=

0.6V, C

RB

=

25˚C (Notes 7, 8).

A

(Note 9)

±

0.8

=

20 pF, f

L

Limits

±

1.95 LSB (max)

−0.7 −1.0 LSB (min)

8 Bits

= 4.43 MHz Modulated Ramp 0.5 deg

IN

= 4.43 MHz Modulated Ramp 1.0

IN

V

RB

V

RT

V

= 1.5V

IN

+0.7 Vrms

RB

V

RT=VRTS,VRB=VRBS

V

RT=VRTS,VRB

VRTConnected to V

Connected to V

RBS

VRTConnected to V

Connected to V

RBS

(CLK LOW) 4 pF

(CLK HIGH) 7 pF

>

1MΩ

200

350

5.4 mA (min)

10.8 mA (max)

6.1 mA (min)

12.3 mA (max)

0.55

0.70

=AV

RTS,VRB

RTS,VRB

270

7

SS

8

2.6

0.6

CLK

Units

(Limits)

V (min)

V (max)

Ω (min)

Ω (max)

V (min)

V (max)

V (min)

V (max)

=

%

<

0.5V

DD

RT

www.national.com5

Converter Electrical Characteristics (Continued)

The following specifications apply for AV

50 MHz at 50%duty cycle. Boldface limits apply for T

ADC1175-50

Symbol Parameter Conditions

=

DD

ANALOG INPUT AND REFERENCE CHARACTERISTICS

V

RTS–VRBS

V

RT–VRB

Self Bias Voltage Delta

Reference Voltage Differential 2

CONVERTER DYNAMIC CHARACTERISTICS

ENOB Effective Number of Bits

SINAD Signal-to-Noise & Distortion

SNR Signal-to-Noise Ratio

SFDR Spurious Free Dynamic Range

THD Total Harmonic Distortion

POWER SUPPLY CHARACTERISTICS

IA

ID

IA

ID

DD

DD

DD

DD

Analog Supply Current DVDD=AVDD= 5.25V 13 mA

Digital Supply Current DVDD=AVDD= 5.25V 11 mA

+

Total Operating Current

Power Consumption PD pin low 125 190 mW (max)

Power Consumption PD pin high

CLK, PD DIGITAL INPUT CHARACTERISTICS

V

IH

V

IL

I

IH

I

IL

C

IN

Logical High Input Voltage 2.0 V (min)

Logical Low Input Voltage 0.8 V (max)

Logical High Input Current V

Logical Low Input Current V

Digital Input Capacitance 4 pF

DIGITAL OUTPUT CHARACTERISTICS

I

OH

I

OL

Output Current, Logic HIGH DVDD= 4.75V, VOH= 4.0V −1.1 mA (min)

Output Current, Logic LOW DVDD= 4.75V, VOL= 0.4V 1.8 mA (min)

=

DV

V

+5.0 V

DD

A

Connected to V

RT

=

Connected to V

V

Connected to V

RT

Connected to V

=

f

4.4 MHz, f

IN

=

f

19.9 MHz, f

IN

=

f

1.3 MHz, f

IN

=

f

4.4 MHz, f

IN

=

f

24.9 MHz, f

IN

=

f

4.4 MHz, f

IN

=

f

19.9 MHz, f

IN

=

f

1.3 MHz, f

IN

=

f

4.4 MHz, f

IN

=

f

24.9 MHz, f

IN

=

f

4.4 MHz, f

IN

=

f

19.9 MHz, f

IN

=

f

1.3 MHz, f

IN

=

f

4.4 MHz, f

IN

=

f

24.9 MHz, f

IN

=

1.3 MHz 57 dB

f

IN

=

f

4.4 MHz 56 dB

IN

=

f

24.9 MHz 51 dB

IN

=

1.3 MHz −55 dB

f

IN

=

f

4.4 MHz −54 dB

IN

=

f

24.9 MHz −51 dB

IN

=AVDD= 5.25V,

DV

DD

=50MHz

f

CLK

DV

=AVDD= 5.25V,

DD

CLK Inactive (low)

=

IH

=

IL

DV

DD

0V, DV

=

DD

,PD=0V, V

DC

to T

T

MIN

RTS,VRB

RBS

RTS,VRB

RBS

=

RT

; all other limits T

MAX

+2.6V, V

=

0.6V, C

RB

=

25˚C (Notes 7, 8).

A

Typical

(Note 9)

2

=

20 pF, f

L

Limits

(Note 9)

1.89

2.20

2.3 V

1.0

2.8

=

40 MHz 7.2 6.7 Bits (min)

CLK

=

40 MHz 7.0 6.4 Bits (min)

CLK

=

50 MHz 7.3 Bits

CLK

=

50 MHz 7.2 Bits

CLK

=

50 MHz 6.8 6.1 Bits (min)

CLK

=

40 MHz 45 42 dB (min)

CLK

=

40 MHz 44 40 dB (min)

CLK

=

50 MHz 46 dB

CLK

=

50 MHz 45 dB

CLK

=

50 MHz 43 38.4 dB (min)

CLK

=

40 MHz 46 42.5 dB (min)

CLK

=

40 MHz 44 41 dB (min)

CLK

=

50 MHz 48 dB

CLK

=

50 MHz 45 dB

CLK

=

50 MHz 44 40 dB (min)

CLK

25 36 mA (max)

14 mA

<

5mW mW

AV

=

+5.25V

DD

=

AV

=

+5.25V

DD

±

5 µA (max)

±

5 µA (max)

CLK

Units

(Limits)

(V (min)

V (max)

V (min)

V (max)

=

www.national.com 6

Converter Electrical Characteristics (Continued)

The following specifications apply for AV

50 MHz at 50%duty cycle. Boldface limits apply for T

=

DD

Symbol Parameter Conditions

DIGITAL OUTPUT CHARACTERISTICS

I

OZH,IOZL

TRI-STATE®Output Current

AC ELECTRICAL CHARACTERISTICS

f

C1

f

C2

t

OD

Maximum Conversion Rate 55 50 MHz (min)

Minimum Conversion Rate 1 MHz

Output Delay CLK high to data valid 14

Pipeline Delay (Latency) 2.5 Clock Cycles

t

DS

t

AJ

t

OH

t

EN

Note 1: “Absolute Maximum Ratings” indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics. The guaranteed

specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed test conditions.

Note 2: All voltages are measured with respect to GND=AV

Note 3: When the input voltage at any pin exceeds the power supplies (that is, less thanAV

be limited to 25 mA. The 50 mA maximum package input current rating limits the number of pins that can safely exceed the power supplies with an input current of

25 mA to two.

Note 4: The absolute maximum junction temperature (T

junction-to-ambient thermal resistance (θ

TSSOP, θ

this part is 98˚C/W for the EIAJ SOIC.) Note that the power dissipation of this device under normal operation will typically be about 258 mW (210 mW quiescent power

+38 mW reference ladder power +10 mW due to 1 TTL load on each digital output. The values for maximum power dissipation listed above will be reached only when

the ADC1175-50 is operated in a severe fault condition (e.g., when input or output pins are driven beyond the power supply voltages, or the power supply polarity

is reversed). Obviously, such conditions should always be avoided.

Note 5: Human body model is 100 pF capacitor discharged through a 1.5 kΩ resistor. Machine model is 220 pF discharged through 0Ω.

Note 6: See AN-450, “Surface Mounting Methods and Their Effect on Product Reliability”, or the section entitled “Surface Mount” found in any post 1986 National

Semiconductor Linear Data Book for other methods of soldering surface mount devices.

Note 7: The analog inputs are protected as shown below. Input voltage magnitudes up to 6.5V or 500 mV below GND will not damage this device. However, errors

in the A/D conversion can occur if the input goes above V

be ≤4.80 V

Sampline (Aperture) Delay CLK low to acquisition of data 3 ns

Aperture Jitter 10 ps rms

Output Hold Time CLK high to data invalid 10 ns

PD Low to Data Valid Loaded as in

) and the ambient temperature (TA), and can be calculated using the formula PDmax=(TJmax–TA)/θJA. In the 24-pin

is 92˚C/W, so PDmax=1,358 mW at 25˚C and 815 mW at the maximum operating ambient temperature of 75˚C. (Typical thermal resistance, θJA,of

JA

to ensure accurate conversions.

DC

JA

=

DV

DV

V

+5.0 V

DD

DD

=DVDD,orVOL=0V

OL

=

T

A

= 5.25V, PD = DVDD,

,PD=0V, V

DC

to T

MIN

MAX

=

+2.6V, V

RT

; all other limits T

Typical

(Note 9)

=

0.6V, C

RB

=

25˚C (Notes 7, 8).

A

L

=

20 pF, f

CLK

Limits

(Note 9)

±

20 µA

=

Units

(Limits)

5 ns (min)

20 ns (max)

Figure 2

=

=

DV

SS

max) for this device is 150˚C. The maximum allowable power dissipation is dictated by TJmax, the

J

or below GND by more than 50 mV.As an example, ifAVDDis 4.75 VDC, the full-scale input voltage must

DD

0V, unless otherwise specified.

SS

SS

or DVSS, or greater than AVDDor DVDD), the current at that pin should

140 ns

ADC1175-50

Note 8: To guarantee accuracy, it is required that AV

Note 9: Typical figures are at T

Level).

=

25˚C, and represent most likely parametric norms. Test limits are guaranteed to National’s AOQL (Average Outgoing Quality

J

DS100896-10

and DVDDbe well bypassed. Each VDDpin must be decoupled with separate bypass capacitors.

DD

www.national.com7

Typical Performance Characteristics AV

=

DD

DV

=

5V, f

DD

=

50 MHz, unless otherwise stated.

CLK

INL Plot

ADC1175-50

DNL vs Temperature

DS100896-11

DS100896-14

DNL Plot

SNR vs Temp & f

INL vs Temperature

DS100896-12

IN

DS100896-15

THD vs Temp & f

IN

DS100896-13

DS100896-16

SINAD & ENOB vs Temp & f

tODvs Temperature

IN

DS100896-17

SINAD & ENOB vs Clock

Duty Cycle

Power Supply Current vs f

DS100896-18

CLK

SFDR vs Temp & f

Spectral Response

IN

DS100896-19

DS100896-20

www.national.com 8

DS100896-21

DS100896-22

Specification Definitions

ANALOG INPUT BANDWIDTH is a measure of the fre-

quency at which the reconstructed output fundamental drops

3 dB below its low frequency value for a full scale input. The

test is performed with f

tiples of f

. The input frequency at which the output is

CLK

−3 dB relative to the low frequency input signal is the full

power bandwidth.

APERTURE JITTER is the time uncertainty of the sampling

point (t

), or the range of variation in the sampling delay.

DS

BOTTOM OFFSET is the difference between the input voltage that just causes the output code to transition to the first

code and the negative reference voltage. Bottom Offset is

defined as E

=

OB

sition input voltage. Note that this is different from the normal

Zero Scale Error.

DIFFERENTIAL GAIN ERROR is the percentage difference

between the output amplitudes of a high frequency reconstructed sine wave at two different dc levels.

DIFFERENTIAL NON-LINEARITY (DNL) is the measure of

the maximum deviation from the ideal step size of 1 LSB.

DNL is measured at the rated clock frequency with a ramp

input.

DIFFERENTIAL PHASE ERROR is the difference in the output phase of a reconstructed small signal sine wave at two

different dc levels.

EFFECTIVE NUMBER OF BITS (ENOB, or EFFECTIVE

BITS) is another method of specifying Signal-to-Noise and

Distortion Ratio, or SINAD. ENOB is defined as (SINAD −

1.76)/6.02 and says that the converter is equivalent to a perfect ADC of this (ENOB) number of bits.

INTEGRAL NON-LINEARITY (INL) is a measure of the deviation of each individual codes from a line drawn from zero

scale (1/2 LSB below the first code transition) through positive full scale (1/2 LSB above the last code transition). The

deviation of any given code from this straight line is measured from the center of that code value. The end point test

method is used. INL is measured at rated clock frequency

with a ramp input.

OUTPUT DELAY is the time delay after the rising edge of

the input clock before the data update is present at the output pins.

equal to 100 kHz plus integer mul-

IN

V

ZT−VRB

, where VZTis the first code tran-

OUTPUT HOLD TIME is the length of time that the output

data is valid after the rise of the input clock.

PIPELINE DELAY (LATENCY)is the number of clock cycles

between initiation of conversion and when that data is presented to the output stage. Data for any given sample is

available the Pipeline Delay plus the Output Delay after that

sample is taken. New data is available at every clock cycle,

but the data lags the conversion by the pipeline delay.

SAMPLING (APERTURE) DELAY, or t

, is the time re-

DS

quired after the falling edge of the clock for the sampling

switch to open (in other words, for the Sample/Hold circuit to

go from the “sample” mode into the “hold” mode). The

Sample/Hold circuit effectively stops capturing the input signal and goes into the “hold” mode t

after the clock goes

DS

low.

SIGNAL TO NOISE RATIO (SNR) is the ratio of the rms

value of the input signal to the rms value of the other spectral

components below one-half the sampling frequency, not including harmonics or dc.

SIGNAL TO NOISE PLUS DISTORTION (S/(N+D) or

SINAD) is the ratio of the rms value of the input signal to the

rms value of all of the other spectral components below half

the clock frequency, including harmonics but excluding dc.

SPURIOUS FREE DYNAMIC RANGE (SFDR) is the difference, expressed in dB, between the rms values of the input

signal and the peak spurious signal, where a spurious signal

is any signal present in the output spectrum that is not

present at the input.

TOP OFFSET is the difference between the positive reference voltage and the input voltage that just causes the output code to transition to full scale and is defined as E

V

FT−VRT

. Where VFTis the full scale transition input volt-

OT

age. Note that this is different from the normal Full Scale Error.

TOTAL HARMONIC DISTORTION (THD) is the ratio of the

rms total of the first six harmonic components to the rms

value of the input signal.

ADC1175-50

=

www.national.com9

Timing Diagram

ADC1175-50

DS100896-23

FIGURE 1. ADC1175-50 Timing Diagram

FIGURE 2. tEN,t

Functional Description

The ADC1175-50 maintains superior dynamic performance

with input frequencies up to 1/2 the clock frequency, achieving 6.8 effective bits with a 50 MHz sampling rate and

25 MHz input frequency.

The analog signal at V

by V

and VRBare digitized to eight bits at up to 55 MSPS.

RT

Input voltages below V

sist of all zeroes. Input voltages above V

output word to consist of all ones. While the ADC1175-50 is

optimized for top and bottom reference voltages (V

V

) or 2.6V and 0.6V, respectively, and will give best perfor-

RB

mance at these values, V

log supply voltage, AV

4.0V. V

V

RB

should always be at least 1.0V more positive than

RT

. With VRTvoltages above 2.8V, it is necessary to reduce

the clock frequency to maintain SINAD performance.

If V

RT

and V

are connected together and VRBand V

RTS

are connected together, the nominal values of VRTand V

www.national.com 10

that is within the voltage range set

IN

will cause the output word to con-

RB

has a range of 1.0V to the ana-

RT

, while VRBhas a range of 0V to

DD

will cause the

RT

and

RT

RBS

RB

DS100896-24

Test Circuit

DIS

are 2.6V and 0.6V, respectively. If VRTand V

nected together and V

V

is 2.3V.

RT

is grounded, the nominal value of

RB

RTS

Data is acquired at the falling edge of the clock and the digital equivalent of that data is available at the digital outputs

2.5 clock cycles plus t

later. The ADC1175-50 will convert

OD

as long as the clock signal is present at pin 12.

The Power Down pin (PD), when high, puts the ADC1175-50

into a power down mode where power consumption is typically less than 5 mW. When the part is powered down, the

digital output pins are in a high impedance TRI-STATE. It

takes about 140 ns for the part to become active upon coming out of the power down mode.

Applications Information

1.0 THE ANALOG INPUT

The analog input of the ADC1175-50 is a switch followed by

an integrator. The capacitance seen at the input changes

with the clock level, appearing as 4 pF when the clock is low,

are con-

Applications Information (Continued)

and 7 pF when the clock is high. Since a dynamic capacitance is more difficult to drive than is a fixed capacitance,

choose an amplifier that can drive this type of load. The

CLC409 has been found to be an excellent device for driving

the ADC1175-50. Do not drive the input beyond the supply

rails.

Figure 3

gives an example of driving circuitry.

ADC1175-50

FIGURE 3. Driving the ADC1175-50. Choose an op-amp that can drive a dynamic capacitance.

2.0 REFERENCE INPUTS

The reference inputs V

(Reference Top) and VRB(Refer-

RT

ence Bottom) are the top and bottom of the reference ladder.

Input signals between these two voltages will be digitized to

8 bits. External voltages applied to the reference input pins

should be within the range specified in the Electrical Characteristics table (1.0V to AV

for V

). Any device used to drive the reference pins should

RB

be able to source sufficient current into the V

sufficient current from the V

The reference ladder can be self-biased by connecting V

to V

and connecting the VRBto V

RTS

for VRTand 0V to (AVDD− 1.0V)

DD

pin and sink

pin.

RB

RT

to provide top and

RBS

RT

bottom reference voltages of approximately 2.6V and 0.6V,

respectively, with V

Figure 3

.IfVRTand V

=

5.0V. This connection is shown in

CC

are tied together, but VRBis tied to

RTS

analog ground, a top reference voltage of approximately

2.3V is generated. The top and bottom of the ladder should

be bypassed with 10 µF tantalum capacitors located close to

the reference pins.

The reference self-bias circuit of

Figure 3

is very simple and

the performance is adequate for many applications. Better

linearity performance can generally be achieved by driving

the reference pins with a low impedance source.

DS100896-25

By forcing a little current into or out of the top and bottom of

the ladder, as shown in

Figure 4

, the top and bottom reference voltages can be trimmed and performance improved

over the self-bias method of

Figure 3

. The resistive divider at

the amplifier inputs can be replaced with potentiometers, if

desired. The LMC662 amplifier shown was chosen for its low

offset voltage and low cost. Note that a negative power supply is needed for these amplifiers as the lower one may be

required to go slightly negative to force the required reference voltage.

If reference voltages are desired that are more than a few

tens of millivolts from the self-bias values, the circuit of

ure 5

will allow forcing the reference voltages to whatever

Fig-

levels are desired. This circuit provides the best performance

because of the low source impedance of the transistors.

Note that the V

RTS

and V

pins are left floating.

RBS

To minimize noise effects and ensure accurate conversions,

the total reference voltage range (V

RT−VRB

) should be a

minimum of 1.0V and a maximum of about 2.8V.

TheADC1175-50 is designed to operate with top and bottom

references of 2.6V and 0.6V, respectively. However, it will

function with reduced performance with a top reference voltage as high as AV

.

DD

www.national.com11

Applications Information (Continued)

ADC1175-50

DS100896-26

FIGURE 4. Better Defining the ADC Reference Voltage. Self bias is still used, but the reference voltages are trimmed

by providing a small trim current with the operational amplifiers.

www.national.com 12

Applications Information (Continued)

ADC1175-50

DS100896-27

FIGURE 5. Driving the Reference to Force Desired Values requires driving with a low impedance source, provided by

the transistors. Note that pins 16 and 22 are not connected.

3.0 OUTPUT DATA TIMING

The Output Delay (t

) of the ADC1175-50can be very close

OD

to one half clock cycle. Because of this, the output data transition occurs very near the falling edge of the ADC clock. To

avoid clocking errors, you should use the

rising

edge of the

ADC clock to latch the output data of the ADC1175-50 and

not

use the falling edge.

As with all high speed converters, the ADC1175-50 should

be assumed to have little a.c. power supply rejection, especially when self biasing is used by connecting V

RT

and V

together.

No pin should ever have a voltage on it that is in excess of

the supply voltage or below ground, not even on a transient

basis. This can be a problem upon application of power to a

circuit. Be sure that the supplies to circuits driving the CLK,

4.0 POWER SUPPLY CONSIDERATIONS

Many A/D converters draw sufficient transient current to corrupt their own power supplies if not adequately bypassed. A

10 µF tantalum or aluminum electrolytic capacitor should be

placed within an inch (2.5 centimeters) of the A/D power

pins, with a 0.1 µF ceramic chip capacitor placed as close as

possible to the converter’s power supply pins. Leadless chip

capacitors are preferred because they have low lead inductance.

PD, analog input and reference pins do not come up any

faster than does the voltage at the ADC1175-50 power pins.

5.0 THE ADC1175-50 CLOCK

Although the ADC1175-50 is tested and its performance is

guaranteed with a 50 MHz clock, it typically will function with

clock frequencies from 1 MHz to 55 MHz.

The clock should be one of low jitter and close to 50%duty

cycle.

While a single voltage source should be used for the analog

and digital supplies of the ADC1175-50, these supply pins

should be isolated from each other to prevent any digital

noise from being coupled to the analog power pins. We recommended a choke be used between the analog and digital

supply lines, with a ceramic capacitor close to the analog

supply pin. If a resistor is used in place of the choke, a maximum of 10Ω should be used.

The converter digital supply should

not

be the supply that is

used for other digital circuitry on the board. It should be the

same supply used for the A/D analog supply.

6.0 LAYOUT AND GROUNDING

Proper grounding and proper routing of all signals is essential to ensure accurate conversion. Separate analog and

digital ground planes that are connected beneath the

ADC1175-50 are required to meet data sheet limits. The

analog and digital grounds may be in the same layer, but

should be separated from each other and should

never

over-

lap each other.

Capacitive coupling between the typically noisy digital

ground plane and the sensitive analog circuitry can lead to

poor performance that may seem impossible to isolate and

RTS

www.national.com13

Applications Information (Continued)

remedy. The solution is to keep the analog circuitry well

separated from the digital circuitry and from the digital

ground plane.

ADC1175-50

Digital circuits create substantial supply and ground current

transients. The logic noise thus generated could have significant impact upon system noise performance. The best logic

family to use in systems with A/D converters is one which

employs non-saturating transistor designs, or has low noise

characteristics, such as the 74HC(T) and 74AC(T)Q families.

The worst noise generators are logic families that draw the

largest supply current transients during clock or signal

edges, like the 74F and the 74AC(T) families. In general,

slower logic families, such as 74LS and 74HC(T) will produce less high frequency noise than do high speed logic

families, such as the 74F and 74AC(T) families.

Since digital switching transients are composed largely of

high frequency components, total ground plane copper

weight will have little effect upon the logic-generated noise.

This is because of the skin effect. Total surface area is more

important than is total ground plane volume.

An effective way to control ground noise is by connecting the

analog and digital ground planes together beneath the ADC

with a copper trace that is very narrow (about 1/16 inch)

compared with the rest of the ground plane. This narrowing

beneath the converter provides a fairly high impedance to

the high frequency components of the digital switching currents, directing them away from the analog pins. The relatively lower frequency analog ground currents do not see a

significant impedance across this narrow ground connection.

Generally,analog and digital lines should cross each other at

90˚ to avoid getting digital noise into the analog path. In high

frequency systems, however, avoid crossing analog and

digital lines altogether. Clock lines should be isolated from

ALL other lines, analog AND digital. Even the generally accepted 90˚ crossing should be avoided as even a little coupling can cause problems at high frequencies. Best performance at high frequencies and at high resolution is obtained

with a straight signal path.

Be especially careful with the layout of inductors. Mutual inductance can change the characteristics of the circuit in

which they are used. Inductors should not be placed side by

side with each other, not even with just a small part of their

bodies beside each other.

The analog input should be isolated from noisy signal traces

to avoid coupling of spurious signals into the input. Any external component (e.g., a filter capacitor) connected between the converter’s input and ground should be connected

to a very clean point in the analog ground plane.

DS100896-28

FIGURE 6. Layout Example Showing Separate Analog

and Digital Ground Planes Connected below the

ADC1175-50

Figure 6

gives an example of a suitable layout.All analog circuitry (input amplifiers, filters, reference components, etc.)

should be placed on or over the analog ground plane. All

digital circuitry and I/O lines should be placed over the digital

ground plane.

7.0 DYNAMIC PERFORMANCE

The ADC1175-50 is ac tested and its dynamic performance

is guaranteed. To meet the published specifications, the

clock source driving the CLK input must be free of jitter. For

best ac performance, isolating the ADC clock from any digital

circuitry should be done with adequate buffers, as with a

clock tree. See

Figure 7

.

www.national.com 14

DS100896-29

FIGURE 7. Isolating the ADC Clock from Digital

Circuitry

It is good practice to keep the ADC clock line as short as

possible and to keep it well away from any other signals.

Other signals can introduce jitter into the clock signal.

8.0 COMMON APPLICATION PITFALLS

Driving the inputs (analog or digital) beyond the power

supply rails. For proper operation, all inputs should not go

more than 50 mV below the ground pins or 50 mV above the

Applications Information (Continued)

supply pins. Exceeding these limits on even a transient basis

may cause faulty or erratic operation. It is not uncommon for

high speed digital circuits (e.g., 74F and 74AC devices) to

exhibit undershoot that goes more than a volt below ground.

A resistor of about 50Ω to 100Ω in series with the offending

digital input will usually eliminate the problem.

Care should be taken not to overdrive the inputs of the

ADC1175-50. Such practice may lead to conversion inaccuracies and even to device damage.

Attempting to drive a high capacitance digital data bus.

The more capacitance the output drivers have to charge for

each conversion, the more instantaneous digital current is

required from DV

rent spikes can couple into the analog section, degrading dynamic performance. Buffering the digital data outputs (with a

74ACQ541, for example) may be necessary if the data bus

to be driven is heavily loaded. Dynamic performance can

also be improved by adding 47Ω series resistors at each

digital output, reducing the energy coupled back into the

converter output pins.

Using an inadequate amplifier to drive the analog input.

As explained in Section 1.0, the capacitance seen at the input alternates between 4 pF and 7 pF with the clock. This dynamic capacitance is more difficult to drive than is a fixed capacitance, and should be considered when choosing a

driving device. The CLC409 has been found to be an excellent device for driving the ADC1175-50.

Driving the V

not source or sink the current required by the ladder.As

mentioned in Section 2.0, care should be taken to see that

any driving devices can source sufficient current into the V

pin and sink sufficient current from the VRBpin. If these pins

and DGND. These large charging cur-

DD

pin or the VRBpin with devices that can

RT

RT

are not driven with devices than can handle the required current, these reference pins will not be stable, resulting in a reduction of dynamic performance.

Using a clock source with excessive jitter, using excessively long clock signal trace, or having other signals

coupled to the clock signal trace. This will cause the sam-

pling interval to vary, causing excessive output noise and a

reduction in SNR performance. Simple gates with RC timing

is generally inadequate as a clock source.

Input test signal contains harmonic distortion that interferes with the measurement of dynamic signal to noise

ratio. Harmonic and other interfering signals can be re-

moved by inserting a filter at the signal input. Suitable filters

are shown in

Figure 8

and

Figure 9

. The circuit of

Figure 8

has a cutoff of about 5.5 MHz and is suitable for input frequencies of 1 MHz to 5 MHz. The circuit of

Figure 9

has a

cutoff of about 11 MHz and is suitable for input frequencies

of 5 MHz to 10 MHz. These filters should be driven by a generator of 75Ω source impedance and terminated with a 75Ω

resistor.

Not considering the effect on a driven CMOS digital circuit(s) when the ADC1175-50 is in the power down

mode. Because the ADC1175 output goes into a high im-

pedance state when in the power down mode, any CMOS

device connected to these outputs will have their inputs floating. Should the inputs float to a level near 2.5V, the CMOS

device could exhibit relative large currents through its input

stage. The solution is to use pull-down resistors. The value

of these resistors is not critical, as long as they do not cause

excessive currents in the outputs of the ADC1175-50. These

currents could result in degraded SNR and SINAD performance of the ADC1175-50. Values between 5 kΩ and

100 kΩ should work well.

ADC1175-50

DS100896-30

FIGURE 8. 5.5 MHz Low Pass filter to eliminate harmonics at the signal input. Use at input frequencies of 1 MHz to 5

MHz.

DS100896-31

FIGURE 9. 11 MHz Low Pass filter to eliminate harmonics at the signal input. Use at input frequencies of 5 MHz to 10

MHz

www.national.com15

Physical Dimensions inches (millimeters) unless otherwise noted

ADC1175-50

24-Lead Package JM

Order Number ADC1175-50CIJM

NS Package Number M24D

www.national.com 16

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

ADC1175-50 8-Bit, 50 MSPS, 125 mW A/D Converter

24-Lead Package TC

Order Number ADC1175-50CIMT

NS Package Number MTC24

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Loading...

Loading...