Page 1

INST6210 – 4/09

Installation / Operation / Maintenance

Sentinel Benchtop Ionizing Blower

Model 6210

Overview

The Sentinel Benchtop Ionizer utilizes DC high voltage to

generate balanced ionized airflow to eliminate static charges

on surfaces. The Ionizer can be placed at one end of the

workbench, wall or shelf mounted, and directed at the target

or area to be neutralized. The target’s neutralization time

will be optimal when placed 12” to 48” directly in front of

the Ionizer and will increase as the distance increases.

General Guidelines

• Keep water, oil, contamination and any fluids away

from the Ionizer at all times.

• Keep the Ionizer clean inside and out for optimal performance.

CAUTION: DISCONNECT THE IONIZER FROM

POWER BEFORE PERFORMING ANY MAINTENANCE, INSPECTION OR CLEANING TO AVOID

AN ELECTRICAL SHOCK HAZARD AND TO PREVENT DAMAGE TO THE IONIZER.

Contents

Remove the Ionizer from the carton and inspect for damage.

Included with the Ionizer should be:

• One (1) Sentinel Benchtop Ionizing Blower with Stand

and adjustment knobs installed.

• One (1) Detachable IEC Power cord (US 115V or 230V,

UK or Euro; must be specified at time of order).

• One (1) Round foam air filter with (1) ¾” round hook

fastener dot.

• This Installation, operation, and maintenance instruc-

tions sheet.

Installation

Locate the Ionizer 12” to 48” from the target to be neutralized for optimal performance, making sure that the airflow

will not be restricted. The Ionizer comes with a stand so that

it can be positioned on a flat surface, aimed at the target and

locked via adjustment knobs. It can also be wall or

shelf mounted to keep valuable bench space free for other

purposes and equipment. A working electrical outlet within

reach of the 6’ long detachable cord that is supplied with the

Ionizer will be required. The outlet must be a properly installed and grounded 3-prong outlet with supplied voltage to

match the Ionizer being installed. If one is not present, consider relocating the Ionizer to be within reach of an outlet or

having an electrical outlet installed near the Ionizer. Be sure

the ON/OFF switch, located on the front of the Ionizer, is in

the “OFF” position. Plug the power cord into the back of the

Ionizer and then into the appropriate AC power source.

IMPORTANT NOTE: Before powering up the Ionizer,

verify that the AC outlet is properly grounded and that the

supplied line voltage matches the electrical specification on

the label at the bottom of the Sentinel Benchtop Ionizer.

Plugging the Ionizer into an outlet with the incorrect voltage

may damage the Ionizer and will void any warranty coverage. The Ionizer must have a good ground to maintain

proper balance.

Page 2

INST6210 – 4/09

Installation / Operation / Maintenance

Sentinel Benchtop Ionizing Blower

Model 6210

Operation

Set the fan speed switch on the front of the Ionizer to the

LOW or HIGH position depending on the operator comfort

or desired decay time. Higher airflow will result in faster

static decay rates. Position the Ionizer so that the maximum

airflow is directed at the items or area to be neutralized.

Turn the Ionizer ON.

When the Ionizer is turned on, the “Status” LED will illuminate and remain GREEN, indicating that the Ionizer is

running normally. The audible alarm may chirp and the

“Status” LED may illuminate AMBER momentarily at

startup but it should return to normal/green mode in one second or less. If the Ionizer self test circuitry detects a fault

condition, the LED will illuminate and remain AMBER and

an audible alarm will sound.

Refer to the Troubleshooting section of this manual in the

case of a fault condition. There are no user serviceable parts

in this Ionizer. Routine cleaning is the only maintenance

that the user can perform.

Balance Adjustment

The Ionizer is an auto-balancing unit. However, tuning or

manual adjustment can be accomplished by inserting a small

flat screwdriver or trimmer adjustment tool into the tiny hole

for the balance adjustment potentiometer located at the bottom left corner on the back of the Ionizer. To increase the

output of positive ions, turn the potentiometer in a clockwise

direction. Conversely, to increase the output of negative

ions, turn the potentiometer in a counterclockwise direction.

Ideally the Ionizer will produce equal numbers of positive

and negative ions. Use a calibrated Charge Plate Monitor to

verify balanced operation of the Ionizer. Do not attempt

balance adjustment without a Charge Plate Monitor.

Maintenance / Alarms

Under normal conditions, the Ionizer will attract dirt and dust

(especially on the emitter pin electrodes). To maintain optimum neutralization efficiency and operation, cleaning

should be performed on a regular basis, once a month is recommended. In addition to improving decay time, cleaning

also keeps the Ionizer balanced without the need for adjustment.

NOTE: The AC power cord MUST be disconnected before

the Ionizer can be disassembled for maintenance. First, turn

the Ionizer OFF and unplug the power cord. Remove the

back cover by disengaging the four (4) screws on the back.

The emitter pin electrodes should be cleaned using a Q-Tip

type cotton swab or a soft nylon toothbrush dampened with

isopropyl alcohol. Clean the blades of the fan and the back

of the balance-sensing grill in front of the fan as much as is

accessible from the back of the Ionizer.

Use caution when cleaning inside the Ionizer. The emitter pin electrodes are sharp.

After cleaning the emitter pin electrodes, reattach the back

cover using the four (4) screws. Plug in the power cord and

turn the Ionizer back ON.

A filter has been provided for applications and/or environments outside of the Cleanroom and Medical Industries. It is

strongly recommended that industrial manufacturing type

users install the filter onto the back grill using the ¾” round

hook fastener dot (included with the Ionizer) to keep the

inside of the Ionizer clean. This filter should be changed

every 2 – 4 weeks, or as needed per a visual inspection.

Replacement emitter pin electrodes can be ordered from the

factory. Eight (8) emitter pins are required per Ionizer.

Neutralization (Decay) Times

The comparative efficiency of benchtop ionizers is determined by a standard test published by the ESD Association:

Standard S3.1. Positive and negative decay times (from

1000 volts to 100 volts) are measured in tenths of a second

using this standard. This test was performed with the Ionizer

positioned as shown, with the fan speed on high, and without

a filter. Decay times are as shown.

NOTE: Unauthorized servicing or modifications to your

Ionizer will void the product warranty and may create dangerous conditions. Servicing should be performed only at

the factory, or by a factory approved technician.

Page 3

INST6210 – 4/09

Installation / Operation / Maintenance

Sentinel Benchtop Ionizing Blower

Model 6210

Troubleshooting

The internal state-of-the-art circuitry of the Sentinel Blower

monitors the ion balance of the air exiting the blower, maintaining optimal offset voltage (balance) to protect ESD

sensitive components and products. If the circuit detects an

offset in the ion balance due to dirty emitter pins or other

conditions, it manipulates the output of the internal DC high

voltage power supplies to compensate for the offset and correct the condition. When the Ionizer status light is green, the

system is functioning properly and sensing balanced ionization. When the status light turns amber an audible alarm

sounds warning of a “fault” condition, which can usually be

resolved easily by the end user.

To troubleshoot a fault condition, follow these steps:

• Turn the switch to “OFF”.

• Remove the power cord from the back of the Ionizer.

• Using a small, soft nylon (or similar) bristle brush,

lightly dampened in isopropyl alcohol (not more than

70% solution), clean the eight (8) stainless steel emitter

electrode pins, the fan blades and the internal sensing

grill from the back side of the Ionizer to remove any dirt

or dust. A toothbrush can be used if the back cover is

removed from the Ionizer but power must be disconnected from the Ionizer before opening up the chassis to

prevent an electrical shock hazard. If available, blow

out the Ionizer with compressed air to clean it out and to

dry the alcohol before powering back up.

• Reconnect to power and turn the Ionizer on.

If the alarm condition persists, adjust the balance of the Ionizer using the small potentiometer screw accessed through

the tiny hole at the bottom left corner at the back of the Ionizer. This should only be done by an experienced technician

using proper equipment and procedures as specified in the

EOS/ESD-S3.1-1991 Standard. NRD LLC can calibrate and

certify the Ionizer performance for a nominal fee. If unable

to correct a fault condition, the Ionizer must be returned prepaid to the factory for evaluation, repair and/or calibration.

Contact NRD for a Return Authorization number and shipping address.

IMPORTANT NOTE: In some cases, if the balancesensing grill inside the blower becomes contaminated, the

Ionizer may not be able to detect an out-of-balance condition

and may continue to run in a “green light” status.

The presence of contamination on the backside (the side

nearest the fan) of the balance-sensing grill can cause the

Ionizer to overcompensate due to a false reading of the balance. Keeping the Ionizer clean as recommended in the

Maintenance section of this manual will help insure optimal

performance from your Sentinel Blower. A filter has been

provided for applications and/or environments outside of the

Cleanroom and Medical Industries. It is strongly recommended that industrial manufacturing type users install the

filter onto the back grill using the ¾” round hook fastener

dot (included with the Ionizer) to keep the inside of the Ionizer clean. This filter should be changed every 2 – 4 weeks,

or as needed per visual inspection.

Contact NRD for service, replacement filters, parts information and pricing.

Limited Warranty

NRD expressly warrants that for a period of one (1) year

from the time of purchase, the Ionizer will be free of defects

in material (parts) and workmanship (labor). Within the

warranty period, the Ionizer will be tested, repaired, or replaced at discretion of NRD, free of charge. Any Ionizer

under warranty should be shipped prepaid to the NRD factory. Call Customer Service at (716) 773-7634 for a Return

Authorization number and shipping instructions. Include a

copy of your original packing slip, invoice, or other proof of

purchase date.

If the Ionizer is out of warranty, NRD LLC will quote repair

charges necessary to bring your Ionizer up to factory standards.

Warranty Exclusions

The forgoing express warranty is made in lieu of all other

product warranties, expressed and implied, including merchantability and fitness for a particular purpose that is

specifically disclaimed. The express warranty will not apply

to defects or damage due to accidents, neglect, misuse, alterations, operator error, or failure to properly maintain, clean

or repair products.

Limit of Liability

The user shall determine the suitability of the product

for their intended use, and the user assumes all risk and

liability whatsoever in connection therein.

Page 4

INST6210 – 4/09

Installation / Operation / Maintenance

Sentinel Benchtop Ionizing Blower

Model 6210

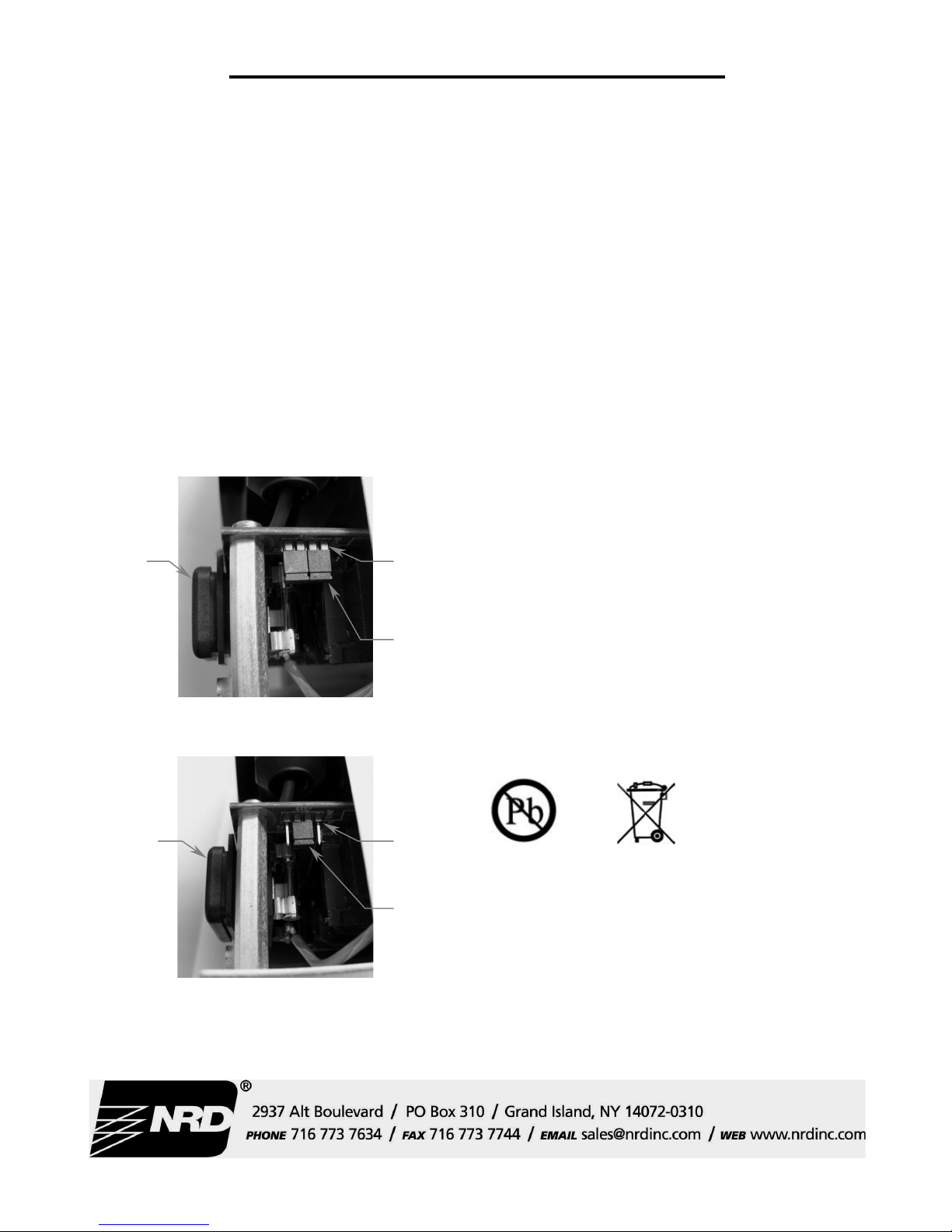

Changing Voltage

The input power voltage should be set to your specification

as ordered and prior to shipping. It is marked on the box

label and the specification label affixed to the bottom of the

Ionizer. The voltage can be reset to a different AC voltage

by removing the back of the case. NOTE: The AC power

cord MUST always be disconnected before the Ionizer is

disassembled. Reconfigure the voltage jumpers as shown in

the diagram(s) below to match your AC line voltage supply.

Input voltage is selected with the two internal jumpers as

shown below:

115 volt Jumper Settings

230 volt Jumper Settings

Specifications

Air Velocity: Two speed fan (250 lfpm with fan on high

speed).

Balance: ± 3 volt typical

(Temperature range: 65°F to 80°F,

Relative humidity: 15% to 65%)

Ion Emission: Steady state DC with sensor feedback.

Emitter Pin Electrodes: .050” diameter 316 stainless steel;

8 required.

High Voltage Power Supply: 5.5 kV DC nominal;

(1) positive HVDC and (1) negative HVDC

Input Power: AC line power, internally selectable for

100/120 VAC, 50/60 Hz, 1 phase or

200/240 VAC, 50/60 Hz, 1 phase

Fuse: 250 mA slow blow; located at AC inlet inside

rear cover; 2 required

Chassis: Powder coated aluminum or steel housing

Weight: 7.0 lbs. With cord; 7.4 lbs. Shipping weight with

Packaging

Dimensions: Width: 6.76” (8.08” with knobs)

Height: 9.82” (with stand)

Deep: 3.77”

Mounting: Bench top tilt adjust frame with locking knobs;

can also be wall or shelf mounted.

Ozone: Less than 0.005 ppm

Power

Jack

Voltage

Selection

Header

Jumpers

Power

Jack

Jumper

Voltage

Selection

Header

Loading...

Loading...