百年品质,值得信赖 —— 您的产品名称

5 axis Montion Controller System

NCH02

Manual

M

Manual of NCH02

请在这里输入您的公司名称或产品名称

Manual of NV8727T4V4

Chapter 1. Introduction .................................................................................................................................. - 1 -

1.1 Product Introduction .............................................................................................................................. - 1 -

1.2 Products specification ............................................................................................................................ - 1 -

1.3 Products Appearance and size ................................................................................................................ - 2 -

1.4 substantival explanation ......................................................................................................................... - 4 -

1.5 Noting and Waring ................................................................................................................................. - 5 -

Chapter 2. Connection ................................................................................................................................... - 6 -

2.1 Device Power supply Solution ............................................................................................................... - 6 -

2.2 Hand control NCH02 KEYBOARD's Definition .................................................................................. - 7 -

2.3 Port Definition and connection .............................................................................................................. - 9 -

Chapter 3. Software & Config ..................................................................................................................... - 18 -

3.1 Main Page ............................................................................................................................................ - 18 -

3.2 FILE Page ............................................................................................................................................ - 23 -

3.3 CONFIG Page ...................................................................................................................................... - 24 -

3.4 Test and diagnosis page ........................................................................................................................ - 33 -

Chapter 4. Operation and Application ......................................................................................................... - 36 -

4.1 Establish machine coordinate system .................................................................................................. - 36 -

4.2 Probe .................................................................................................................................................... - 39 -

4.3 Workpiece zero point ........................................................................................................................... - 44 -

4.4 Load and run G code ............................................................................................................................ - 45 -

Chapter 5. G & M instructions supported .................................................................................................... - 47 -

5.1 G instruction Supported ....................................................................................................................... - 47 -

5.2 M instruction Supported ...................................................................................................................... - 48 -

Chapter 6. Question & Answer .................................................................................................................... - 50 -

6.1 Q&A for Hardware .............................................................................................................................. - 50 -

6.2 Q&A for Software ................................................................................................................................ - 50 -

Chapter 7. Contract us ................................................................................................................................. - 51 -

Contects

Chapter1 Introduction

Manual of NCH02

Chapter 1. Introduction

1.1 Product Introduction

Novusun CNC has engaged in the Numerical control industry for 7 years, specialized in

the research, development and production of various CNC controller systems with high quality

and high reliability. We produce the Brushless DC motor, Stepper motor driver, and also 1 to 6

axis CNC motion controllers.。

NCH02 is the 5 axis motion controller we spend 2 years to design.

NCH02 is a CNC system without computer. Only need a U-disk within G-CODE file,

NCH02 can read the G file and run the G file.

This manual introduces operation, connection and usage schedule of our professional

motion controller for engraving machine. Through a lot of the drawing the users can learn

quickly how to use this motion controller.

1.2 Products specification

Read G-CODE from U-DISK;

Operation without computer;

8 ports photoelectric isolated input interface;

5 ports photoelectric isolated output interface;

1 port 0-10V spindle speed analog output interface(can change to PWM output);

can support 5 axis stepper systems,125KHz pulse output for every axis;

ARM motion control chip;

main device is 24VDC power supply input, current should higher than 1A;

- 1 -

Chapter1 Introduction

Manual of NCH02

Support standard MPG and NVMPG;

3.5'' TFT screen;

19 user key;

1.3 Products Appearance and size

The Hand control system NCH02 appearance as the Figure 1-1 show: The host system

NCD02 appearance as the Figure1-2.

The Hand control system NCH02 overall size is 168mm*108mm*30mm;

The host system NCD02 overall size is 100mm*70mm*23.5mm

Figure1-1. NCH02 front appearance and size

- 2 -

Chapter1 Introduction

Manual of NCH02

Figure1-2. The host system NCD02 appearance and size

Figure1-3. NCH02 with NCD02

- 3 -

Chapter1 Introduction

Manual of NCH02

1.4 substantival explanation

When operate the NCH02, where will be a lot of English abbreviation, now we list all of

them for your kindly references:

FRO: Feeding adjust: During the operating process, the F value already set, and need to

adjust the current feeding speed, then we can adjust FRO value to realize it.

SRO: Spindle speed adjust: During the operating process, the S value already set, and need

to adjust the current spindle speed, then we can adjust SRO value to realize it :

Current Speed S#=setting S*SRO.

SRJ: speed adjust manually

During the operating process,as the manual speed already set,and we need to adjust the

current speed,and impossible to fix the value during it is working,then we can revise the SRJ

value to realize it.

Current manual speed FS#=Setting manual speed*SRJ.

F:Feedingspeed,the unit is mm/min.For example F=200,means every minute feeding

2000mm.

S: Spindle Speed. Unit is rad/min.For example S=20000,means 20000 revolution/Minute.

X axis Coordinate

Y axis Coordinate

Z axis Coordinate

A axis Coordinate

B axis Coordinate

C axis Coordinate

Ready:ReadyMode.In the mode we can do any operation,include processing or values

- 4 -

Chapter1 Introduction

Manual of NCH02

modification or starting 2nd mode.

Reset: Reset mode.In this mode,it should stop every operation.

“Step”:Manual Step Mode. Every axis candonduct the manual step operation at this mode.

MPG: MPG mode.Every axis can conduct the MPG operation at this mode.

1.5 Noting and Waring

Free from exposure to the electronics without waterproof

function.Please environment as dry as possible. This is the icon.

Wiring warning, the IO input term inal of this equipment support the

equipment with source switch (such as Inductive proximity switch.)When using

such kind of switch, attention please: avoid the +terminal and –terminal of

power supply to connect with GND.This equipment’s analogy quantity

output terminal of spindlecontrolalos have a certain load capacity. Please avoid

this terminal connect with GND.in case that the interior components and parts be

brokendown.

Operation warning, Please do the security measures well when

connecting with the machine tools.The ESTOP , limit and other things must be

perfected.When comes across the emergancy, please press the ESTOP key at once

or cut off the power directly, thus avoiding the equipment damage and casualty.

High voltage danger, the primary device is 18-32VDC power

supply.Voltage equipment.Pls pay attention to the electricity, safety when conducting

the operation

- 5 -

Chapter2 Connection

Manual of NCH02

Chapter 2. Connection

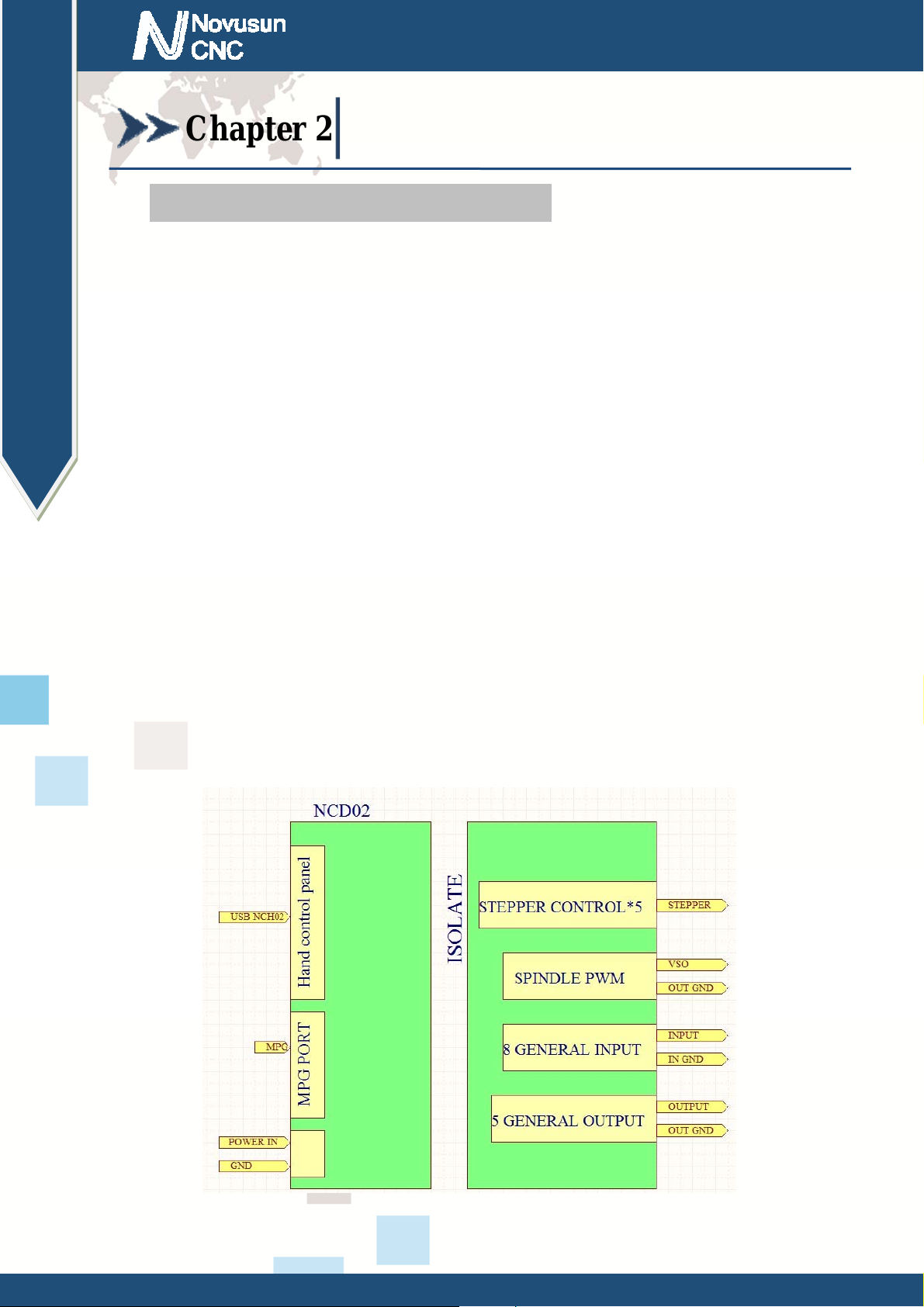

2.1 Device Power supply Solution

The power supply solution in the field of the Industrial automation is always very

complicated, there is a lot of the GND, now we descript the structure of the power supply as

below:

The power supply structure as the Figure 2-1,main power supply input and MPG module and

stepper control output module are common GND, Limited and Estop input module and Spindle

speed adjust module are common GND, between main power supply and output module there are

photoelectric isolation. The inputs of limited switch and Estop and so on are Common cathode,

inside of the device, there is GND as common-, no need to connect external power supply. Based

on the reference of output GND interface, output a 0-10V adjustable voltage to adjust the spindle

speed. The chassis is built with 220V to 48V DC supply to the DC brushless spindle and 4 step

motor driver.

Figure2-1. Power supply structure of NCD02

- 6 -

Chapter2 Connection

Manual of NCH02

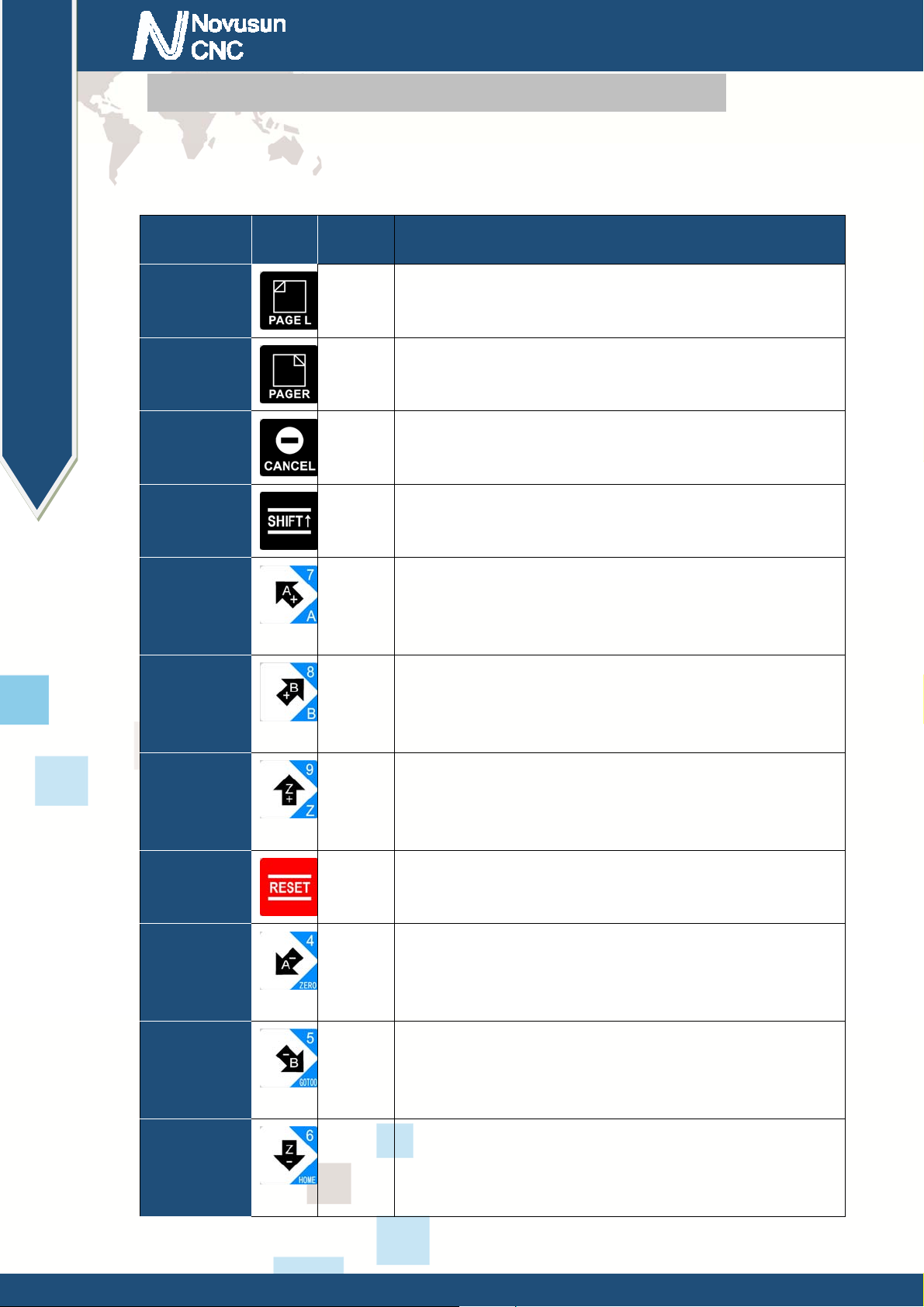

2.2 Hand control NCH02 KEYBOARD's Definition

2.2.1 KEYBOARD's Definition

KEYBOARD's Definition see as Table 2-1

Location Icon Name Function

R 1 C 1 PAGE L 1:Page left

R 1 C 2

R 1 C 3 CANCEL 1:Cancel;2:Sign out

PAGE R 1:Page right

R 2 C 1

R 2 C 2 A+ 1:A axis manual forward;2:Select A axis;3:Number

R 2 C 3 B+ 1:B axis manual forward;2:Select B axis;3:Number

R 2 C 4 Z+ 1:Z axis manual forward;2:Select Z axis;3:Number

R 3 C 1 RESET 1:Reset state switch

R 3 C 2 A- 1:A axis manual reverse; 2:ZERO in Workpiece

SHIFT 1:Shift,Call second functions

7

8

9

coordinates;3:Number 4

R 3 C 3 B- 1:B axis manual reverse;2:Go to zero in workpiece

coordinates;3:Number 5

R 3 C 4 Z- 1:Z axis manual reverse;2:Find zero point Mechanical

coordinates;3:Number 6

- 7 -

Chapter2 Connection

Manual of NCH02

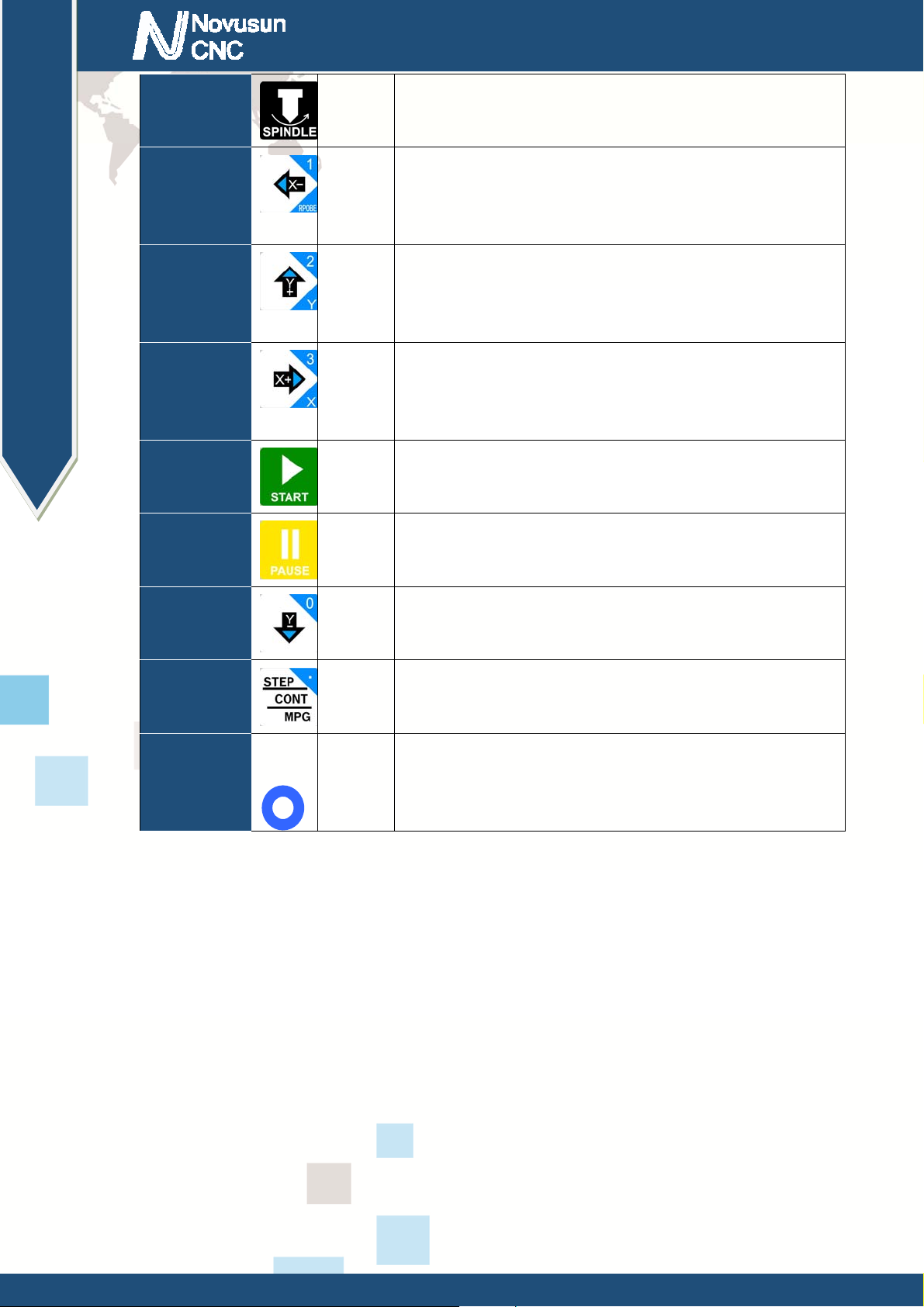

R 4 C 1

R 4 C 2

R 4 C 3 Y+ 1:Y axis manual forward;2:Select Y axis;3:Number

R 4 C 4 X+ 1:X axis manual forward;2:Select X axis;3:Number

R 5 C 1 START 1:Start the G code

SPINDLE

A- 1:A axis manual reverse;2:Probe;3:Number 1;4:

1:Start and Stop Spindle

Move left

2;4:Move up

3;4:Move left

R 5 C 2 PAUSE 1:Pause the G code

R 5 C 3

R 5 C 4 STEP 1:Switch step/ continuous/MPG ;2:Number “.”

R 1 C 4 PUSH

Y- 1:Y axis manual reverse;2:Number 0;3:Move down

PUSH 1:Increase the number clockwise;2:Decrease the

number Counter-clockwise;3:Confirm when push

Table 2-1. Keyboard definition

- 8 -

Chapter2 Connection

Manual of NCH02

2.3Port Definition and connection

Figure2-2. Port of NCD02

As shown in Figure 2-2, the main controller indicates 1-7 are USB port, main power port,

general input port, general output port, MPG port, spindle port and stepper motor control port.

The detailed description of these functional modules and interfaces is described below.

2.3.1 USB port

As Figure 2-2 showed,No.1 terminal block is USB port, you can connect with NCH02

through this interface.

2.3.2 Main power supply port

As the Figure 2-2 show, The marked No. 2 port is power supply port. The access voltage

range is 24VDC, and the power is not less than 20W. The positive and negative connection of the

power supply see as the silk printing, See as Figure 2-2, left is GND, and right is "+".

2.3.3 Limit/Home input port

- 9 -

Chapter2 Connection

Manual of NCH02

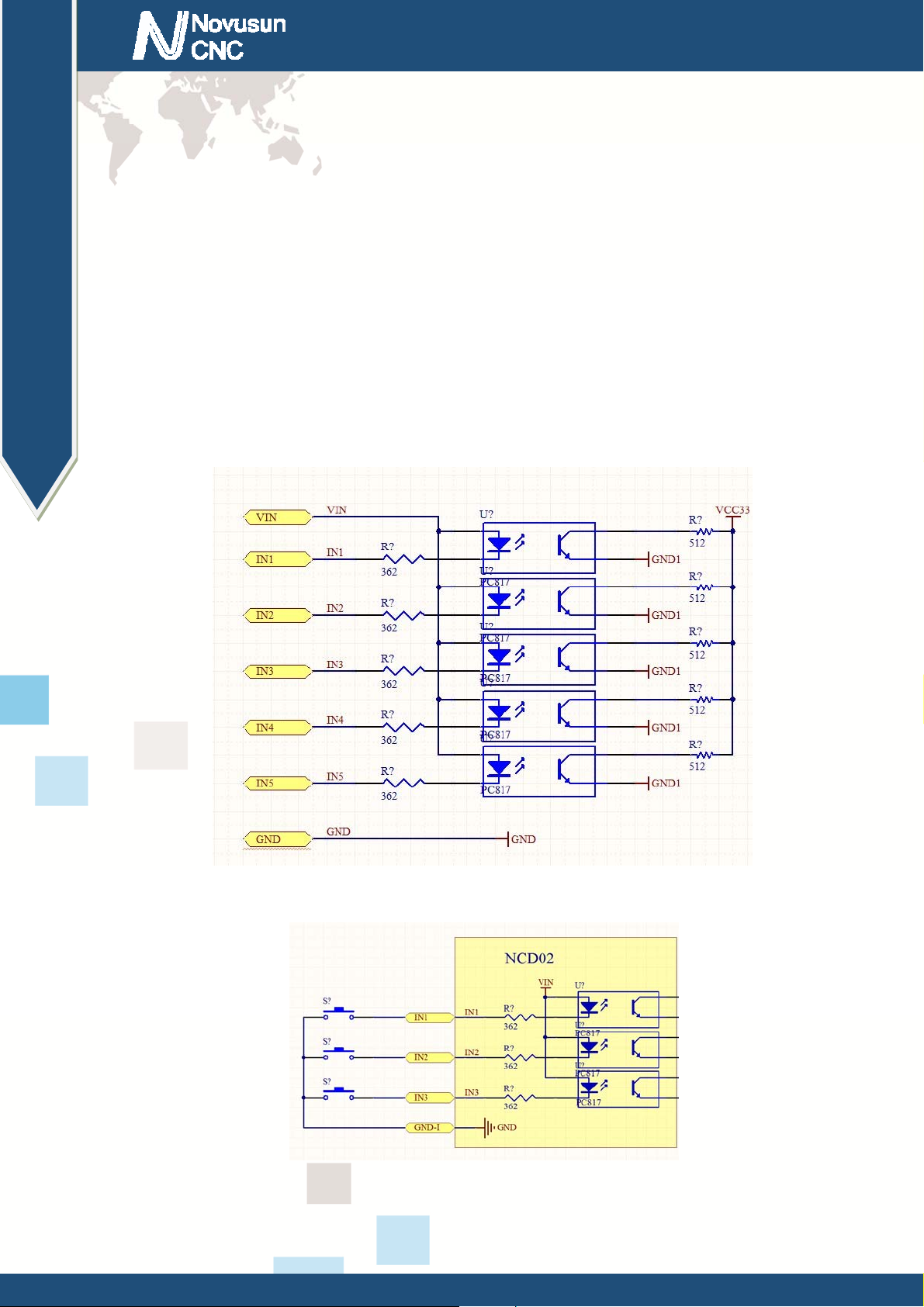

As the Figure 2-2 showed, Marked No. 3 position is the limited /home input port. they are

the optical isolated Input interface. The input interface is a 11P 3.81 direct insertion terminal

interface, as shown in Figure 2-2 shell silk print, and definition is

GND/INP1/INP2/GND/INP3/INP4/INP5/INP6/INP7/INP8/12V from left to right. Internal

structure reference figure 2-3. The interface is a common negative interface, which can be

connected with a micro switch, a 2 line proximity switch or a NPN type 3 line proximity switch.

The interface is isolated by the optocoupler, and the internal structure diagram is referred to

figure 2-4. Estop, micro switch, 2 line proximity switch connection method reference figure 2-5.

Figure2-3. Internal structure diagram of the input port

Figure2-4. Probe/Estop/ ordinary fretting switch input connection

- 10 -

Chapter2 Connection

Manual of NCH02

Figure2-5. input interface serial number IN3 and 2 line proximity switch / common switch limit input

wiring diagram

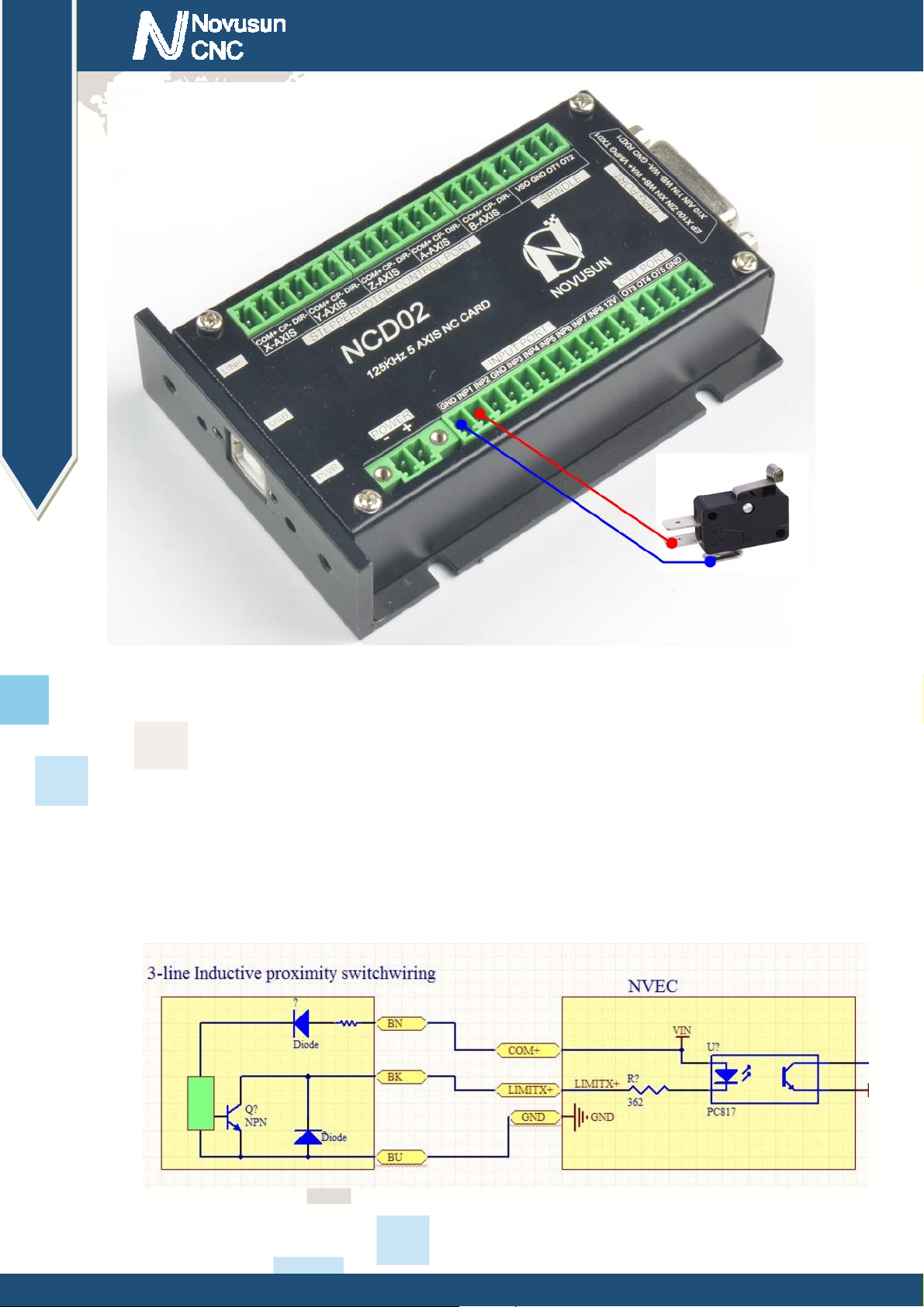

3 lines Proximity Switch connection Figure 2-13,brown cable for Proximity switch connect

with 12V,Black cable connect channel, blue cable connect with GND1.

Only support NPN 3lines proximity switch.

Figure2-6. NPN 3 lines Proximity Switch connection drawing

- 11 -

Chapter2 Connection

Manual of NCH02

Figure2-7. NPN 3 line Proximity switch wiring

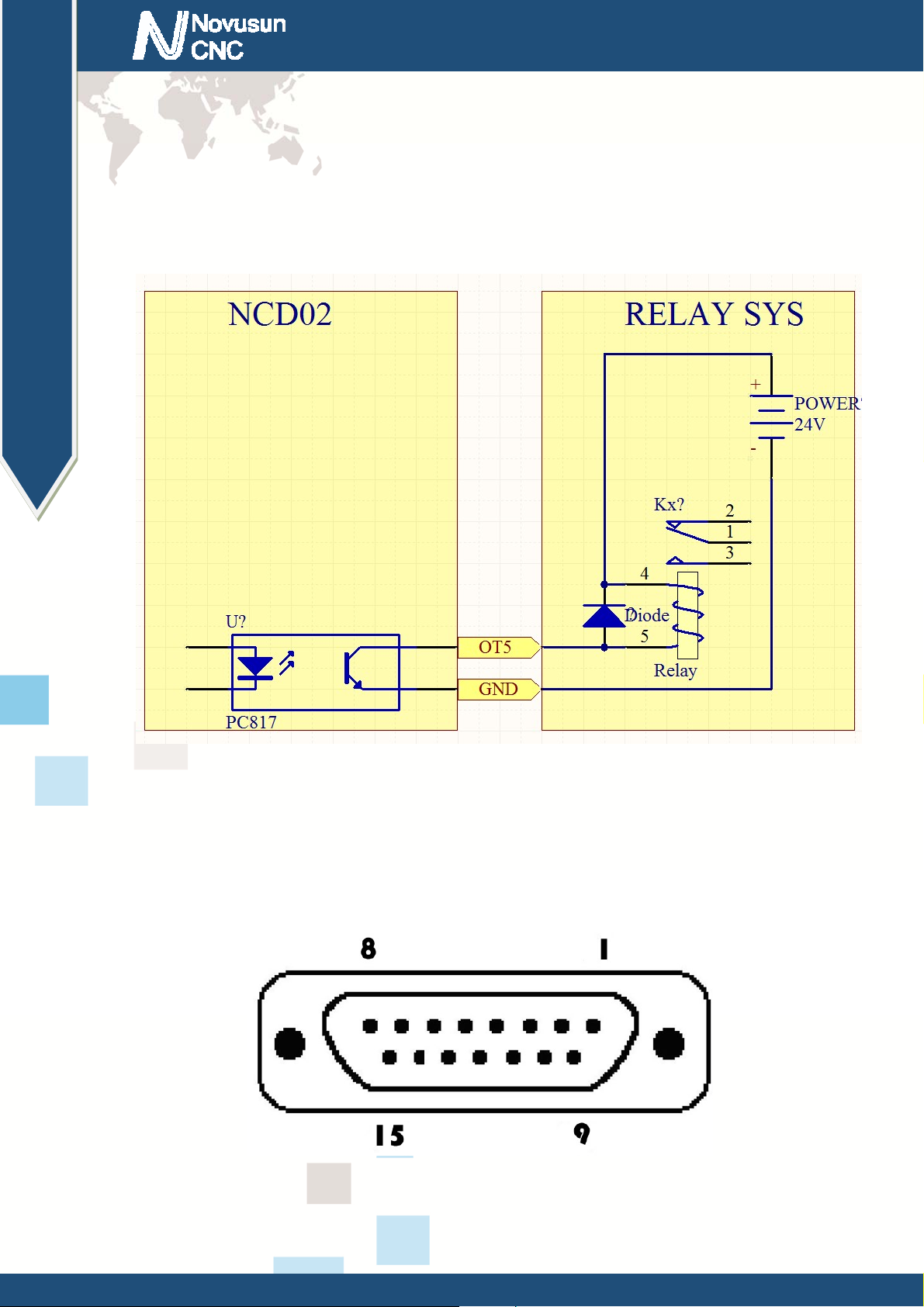

2.3.4 Output port

As Figure 2-2 showed,No.4 switch is Output port, The interface is an open-ground

interface. The internal structure refers to figure 2-8, which can be absorbed not more than 50mA

current.

- 12 -

Chapter2 Connection

Manual of NCH02

Figure2-8. the internal structure of the general output interface

The relay with a absorption current of no more than 50mA can be driven directly. If it's

more than 50mA, and it is recommended to use a current amplification current, such as the use of

a ULN2803 chip. Reference figure 2-9 for external power relay method.

Figure2-9. general output interface connect with a small power relay

2.3.5 MPG port

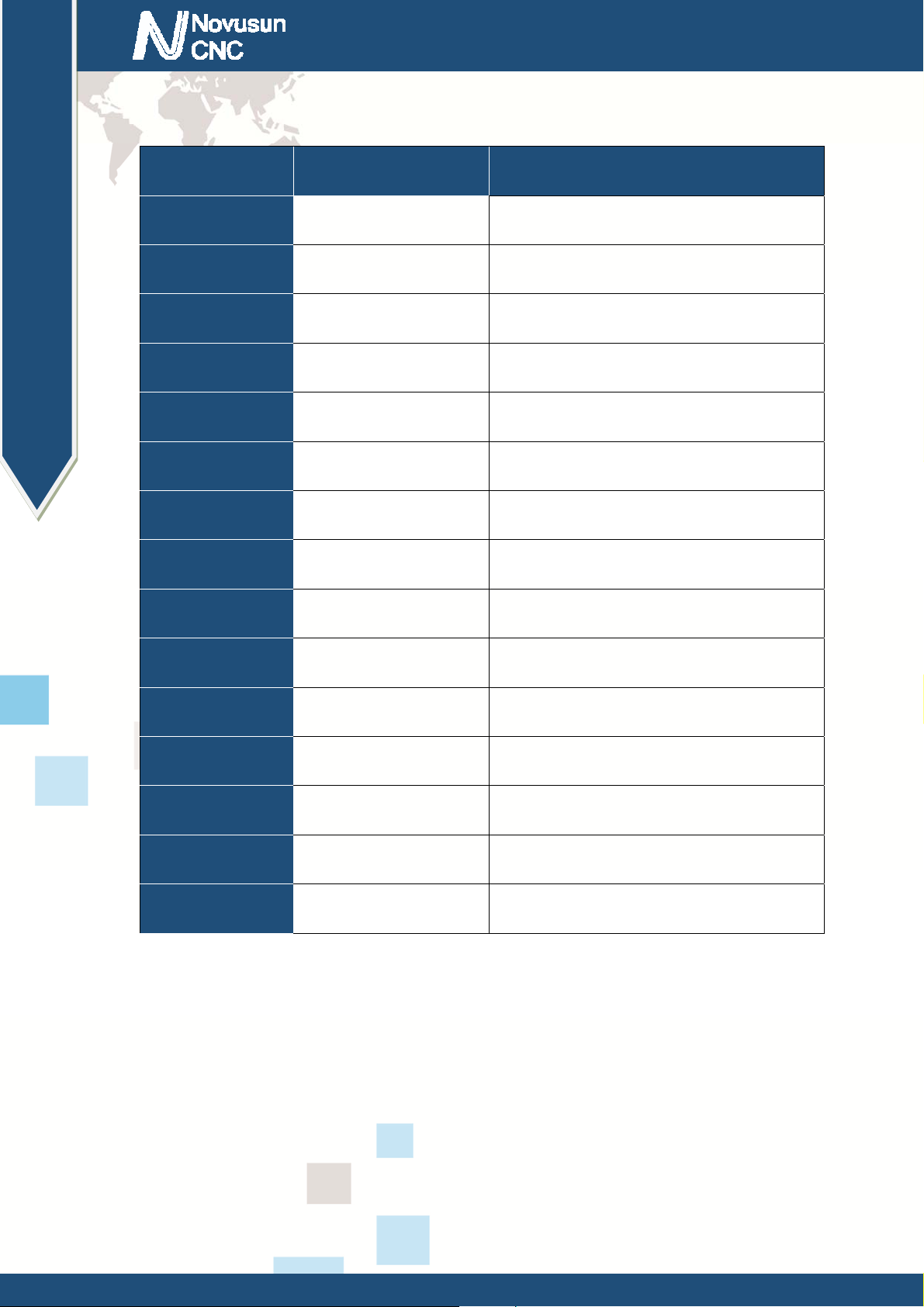

As the Figure 2-2 showed, the marked No.5 position interface is MPG port . The pin order

see as Figure 2-10.

Figure2-10. MPG Port Pin order

- 13 -

Chapter2 Connection

Manual of NCH02

This card connect with MPG by this port. The port definition see as table 2-2

No. Mark Definition

1 T1OUT TXD of Serial port

2 VMPG Power supply + for MPG(5V)

3 WHA+ A phase positive of the encoder

4 WHB+ B phase negative of the encoder

5 XIN X axis select input

6 ZIN Z axis select input

7 X100IN 100 rate select input

8 EP Estop port

9 R1IN RXD of Serial port

10 GND Ground and common end

11 WHA- A phase positive of the encoder

12 WHB- B phase negative of the encoder

13 YIN Y axis select input

14 AIN A axis select input

15 X10IN 10 rate select input

Table 2-2. MPG port definition

2.3.6 Spindle port

As Figure 2-2 showed,No.6 port is Spindle port. The interface definition is

VSO/GND/OT1/OT2 from left to right. Where VSO is the 0-10V analog output, OT1/OT2

digital drive signal output, spindle control output interface and spindle inverter connection

diagram figure 2-11. VSO/GND/OT1/OT2 are respectively connected with the inverter

AIN1/COM/X1/X2, where AIN1 is the input speed signal, COM converter X1 and X2 are the

- 14 -

Chapter2 Connection

Manual of NCH02

common end configured to forward and reverse.

Figure2-11. spindle port definition and connection

2.3.7 Stepper motor port

As Figure 2-2 showed,No.7 port is stepper motor port, which is define as X/Y/Z/A/B. Each

axis is define as COM+/CP-/DIR-. They are Common/Pulse-/Direction-. The connection method

with the stepper motor driver see as Figure 2-12.

- 15 -

Chapter2 Connection

Manual of NCH02

Figure2-12. NCD02 Connect with stepper motor driver

The above detailed description of the NCD02 module definition and connection mode,

NCD02's integrated wiring diagram reference figure 2-13.

- 16 -

Chapter2 Connection

Manual of NCH02

Figure2-13.

NCD02 and NCH02 integrated wiring diagram

- 17 -

Chapter3 Software & config

Chapter 3. Software & Config

The NCH02 software interface is divided into 4 pages, including main page, file

management page, configuration page, test and diagnosis page. Now, the interface elements and

basic operations on 4 pages are described below.

3.1 Main Page

The main page is divided into 20 regions, such as Figure 3-1, and the following 20 regions

Manual of NCH02

are described in detail.

Figure3-1. Main Page of NCH02

1. Manual mode bar

The status bar mainly displays the manual mode. There are three manual modes. They are

manual continuous mode (shown as CONT), step mode (shown as STEP) andMPG mode (shown

- 18 -

Chapter3 Software & config

as MPG). Under the ready state of system, push 3 modes can be switched.

2. Running status bar

The status bar mainly displays the working state of the system. There are four systems in it.

They are reset state (shown as RESET), ready state (shown as READY), manual control state

(shown as JOG) and running state (shown as RUN). In reset state, all operations are invalid, it's

the system protection state; the ready state is ready for work. Any operation can be performed in

Manual of NCH02

the state of preparation; By pressing

state (READY) and the reset state (RESET). In the ready state, when the G code is ready, the G

code can be started by pressing , or the start line of the G code can be specified by

pressing + . In the process of running G code, the running status bar displays the

RUN, indicating that the G code is running. During the operation of hand control operation, the

running status bar shows JOG, indicating that hand control is working.

3. File status bar

The status bar displays the file loading G code or U disk information, It displays "No file

loaded" in the file without loading condition; it displays "U-Disk Detected" when the U disk

, the system can be switched between the ready

insert and correct recognition; "U-Disk Removed" display in the U disk pulled out; it display G

code file name when loaded the correct G code;

4, time display bar

The time display bar mainly displays the current G code running time.

- 19 -

Chapter3 Software & config

The adjustable parameters are described below, and all the adjustable

parameters can be selected by the knob Clockwise rotation or a reversal.

Under normal conditions, the adjustable parameters are white background black

words.

When turning the knob, you can see the valid position is changed with the knob,

a parameter change to blue background and white word when it become a valid

parameter.

When a parameter - we need to modify the value when it is selected. we need to

Manual of NCH02

click the PUSH (button of the knob), then the parameters become black background

and white word, meaning it's in editing, we can modify the parameters according to

the number keys.

After the modification, then press the PUSH, then it exit the edit state and enter

the unselected state, then the parameter displays the adjusted value.

5, FRO parameter setting

FRO is a feed rate adjustment that can be adjusted through the knob, adjusting the range

from 0~200%, and the actual feed speed #F=FRO*F (F is feed speed set value).

6, SRO parameter setting

SRO is the spindle rate adjustment, can be adjusted through the knob, the adjustment range

from 0~200%, the actual spindle speed #S=SRO*S (S is the spindle speed set value).

7, SJR parameter setting

SJR is a manual speed rate adjustment that can be adjusted through the knob, adjusting the

range from 0~100%, the actual manual speed #HF=SJR*HF (HF is the manual speed set value).

8,Step manual mode single step parameter setting

- 20 -

Chapter3 Software & config

The single step parameters can be set into 3 gears, which are 1mm, 0.1mm and 0.01mm,

which can be adjusted by the knob.

9, F parameter setting

This parameter defaults to the minimum speed of each axis in the parameter configuration

item, and can be adjusted by the knob. If there is no F instruction in the G code, the G code is

running in this speed. If there is F instruction in the G code, the feed speed is updated according

to the F instruction.

10, F real-time display

Manual of NCH02

F real-time display values show the real-time speed of F during the running of G code.

Real time feed speed #F=FRO*F (set feed speed).

11, S parameter setting

This parameter defaults to the default spindle speed in the parameter configuration item,

which can be adjusted by the knob. If there is no S instruction in the G code, the G code is

running at this speed. If there is S instruction in the G code, then the spindle speed value is

updated according to the S instruction.

12, S real-time display

S real-time display values show the real-time speed of S during the running of G code.

Real time spindle speed #S=SRO*S (set the spindle speed).

13, M10/M11 state display

The state value of the M10/M11 switch is displayed, which can be manually modified by

the knob or automatically modified according to the M10/M11 instruction in the running G file.

14, M8/M9 state display

The state value of the M8/M9 switch is displayed, which can be manually modified by the

knob or automatically modified according to the M8/M9 instruction in the running G file.

- 21 -

Chapter3 Software & config

15, M3/M4/M5 state display

The state value of the M3/M4/M5 switch is displayed, which can be manually modified by

the knob or automatically modified according to the M3/M4/M5 instruction in the running G file.

16, G coordinate system display

The current coordinate system is displayed, with a modified range of G54~G59, which can

be manually modified by the knob or automatically modified according to the G54~G59

instruction in the running G file.

17. System status bar

Manual of NCH02

The status bar of the system is mainly prompted by the common system state, and the list

of States is as follows

NO. Display Definition

1 SYSTEM REDAY

2 SYSTEM RESET

3 SYSTEM IS RUNNING

4 X++ LIMITED

5 X-- LIMITED

The system is ready to execute the G code

System reset state, no operation can be done

G code is running

Positive limit of X axis is triggered. Same as

other axis

Negative limit of X axis is triggered. Same as

other axis

6 X++ SOFT LIMITED

7 X-- SOFT LIMITED

Table 3-1. system status prompt information and definition

Positive soft limit of X axis is triggered. Same

as other axis

Negative soft limit of X axis is triggered. Same

as other axis

- 22 -

Chapter3 Software & config

18. The running G code display bar

In the process of running the G code, the current line number and the current line G code

are displayed.

19. Coordinate values of each axis

The coordinate value of the workpiece is displayed here.

20. The mechanical coordinates of each axis

The mechanical coordinates of each axis are displayed here, and the mechanical

coordinates of each axis are displayed behind the coordinate values of the workpiece, and the

Manual of NCH02

font is smaller than the coordinate value of the workpiece.

3.2 FILE Page

The file management page can be entered by pressing under the main control page.

The file management page is shown in Figure 3-2.

Figure3-2. File management page

- 23 -

Chapter3 Software & config

The file management page displays all the files in the U disk and can display the file name,

the size of the file, and the last modification date.

In the file management page, you can select the G code file you want to run by the knob.

When selected, press the knob confirmation key (PUSH) to load the G code file. After the load is

finished, the system automatically switches to the main page.

3.3 CONFIG Page

In the file management page, press to enter the parameter configuration page.

Manual of NCH02

Press to switch the sub page of the configuration page. The parameter configuration

page contains 4 sub pages, respectively is the motor parameter configuration (MOTOR), input

configuration (INPUT), and the output spindle configuration (Spindle/OUT) and other(OTHER).

3.3.1 motor parameter configuration (MOTOR)

The motor parameter configuration page is shown in Figure 3-3. This page list specific

parameters by row, and list number axis by column. The parameters of the axis can be adjusted

by the knob.

- 24 -

Chapter3 Software & config

Manual of NCH02

Figure3-3. motor parameter configuration page

The parameter item specifically defines show in table 3-2.

No. Mark Definition Range

1 Stepsper

2 Velocity

3 Accel

the number of pulses required for every

forward 1mm

Speed: the manual or the axis G code runs

maximum speed. The unit is mm/min

Acceleration: the manual or the axis G code

runs the maximum acceleration. The unit is

100-20000

50-20000

10-5000

mm/min2

4 Reserved

5 Step level

System reserved, undefined

The pulse level, 0 indicates that the output

level is 0V when no pulse, and the 1 indicates

- 25 -

1/0

Chapter3 Software & config

Manual of NCH02

that the output level is maximum when no

pulse.

6 Dir Level

7 BL Enable

8 BL Length

3.3.2 Input parameter configuration (INPUT)

The direction level is 0. When the axis goes to

the coordinate + movement, the direction

signal output level 0V, 1 indicates that the

direction signal output level is the maximum

when the axis moves towards the coordinate +

movement.

Backlash Enable, 1: enable; 0: disable

Backlash Length, The unit is mm

Table 3-2. motor parameter configuration

1/0

1/0

0-10

The input parameter configuration page is shown in Figure 3-4. This page list specific

parameters by row, and list number axis by column. The parameters of the axis can be adjusted

by the knob.

- 26 -

Chapter3 Software & config

Manual of NCH02

Figure3-4. Input configuration page (INPUT)

The parameter specifically defines see as table 3-3

No. Mark Definition Range

1 Limit++

2 L++ Level

The forward hard limit input level definition,

1 is the input high level effective; 0 is the

The forward hard limit pin setting, 0

indicates close the limit, and 1-8 indicates

that the limit pin is configured on the

IN1-IN8 specific input port interface.

0-8

1/0

input low level effective.

3 Limit--

The backward hard limit pin setting, 0

indicates close the limit, and 1-8 indicates that

the limit pin is configured on the IN1-IN8

- 27 -

0-8

Chapter3 Software & config

Manual of NCH02

specific input port interface.

4 L-- Level

5 Home

6 Home Level

The backward hard limit input level

definition, 1 is the input high level effective; 0

is the input low level effective.

The home pin setting, 0 indicates close the

home, and 1-8 indicates that the limit pin is

configured on the IN1-IN8 specific input port

interface.

The home input level definition, 1 is the input

high level effective; 0 is the input low level

effective.

1/0

0-8

1/0

7 Home Dir

8 HKB length

3.3.3 Spindle / output parameter configuration (Spindle/OUT)

The spindle / output parameter configuration page is shown in Figure 3-5. This page for a

list of specific parameters to the parameter list, the list number axis. The parameters of the axis

can be adjusted by the knob.

The home's direction , 1 indicates home's

direction is +, and 0 indicates the home's

direction is -.

The return distance after the home operation

is completed.

Table 3-3. input parameter configuration

1/0

0-100

- 28 -

Chapter3 Software & config

Manual of NCH02

Figure3-5. Spindle / output parameter configuration (Spindle/OUT)

Spindle parameters specific definition reference table 3-4.

No. Mark Definition Range

1 Max Speed

2 Default Speed

3 M3/4 Delay

Table 3-4. Spindle parameter configuration

NCD02's spindle speed regulation output is 0-10V voltage, output voltage and maximum

spindle speed and default spindle speed (current speed) are related, the specific formula is:

The max spindle speed

The default spindle speed

Delay time of M3/4 instruction

100-40000

0-40000

0-8

output voltage (VSO) =10*default spindle speed (current speed F) / maximum spindle speed (F

max). For example, the current speed is F=20000, the maximum spindle speed F max=40000,

at this time, the spindle output voltage is VSO=10*20000/40000=5V.

The M3/4 delay time is the time between running the G code in the M3/4 time to the

actual execution of the IO output.

- 29 -

Chapter3 Software & config

The output item parameters reference table 3-4

No. Mark PIN Active Level

Definition Range Definition Range

Manual of NCH02

4 Spindle CW(M3)

5 Spindle CCW(M4)

6 Mist cool(M8)

7 Flood cool(M10)

8 EXT M60

9 EXT M61

10 EXT M62

11 EXT M63

12 EXT M64

Table 3-5. OUT parameter configuration

M3 pin number 0-5 M3 effective level 1/0

M4 pin number 0-5 M4 effective level 1/0

M8 pin number 0-5 M8 effective level 1/0

M10 pin number 0-5 M10 effective level 1/0

M60 pin number 0-5 M60 effective level 1/0

M61 pin number 0-5 M61 effective level 1/0

M62 pin number 0-5 M62 effective level 1/0

M63 pin number 0-5 M63 effective level 1/0

M64 pin number 0-5 M64 effective level 1/0

Note: the output pin number is 0 indicates to close the current output, and the

output pin number 1-5 indicates the corresponding OUT1-OUT5.

Output power level setting 1: execution of current M instruction to indicate output

disconnecting with GND.

Output effective level setting 0: execution of current M instruction to indicate

output connecting with GND.

3.3.4 other parameter configuration (OTHER)

The other parameter configuration pages are shown in Figure 3-6. The parameter page

mainly includes the parameters of the soft limit of each axis, the language, the speed of HOME,

the speed of BACKLASH, the speed of the probe and the coordinates of the position of the

- 30 -

Chapter3 Software & config

tools sensor. The parameters of the axis can be adjusted by the knob. Page reference figure 3-6,

page soft limit parameters specify reference table 3-6. Probe related item parameters reference

table 3-7. other miscellaneous parameters reference 3-8.

Manual of NCH02

Figure3-6. other parameter configuration (OTHER)

No. Mark Definition Range

1 Limit++_Ena

2 Limit++_Value

3 Limit--_Ena

4 Limit--_Value

Enable of positive soft limit,1:enable,0:disable

Positive soft limit position limit value, in

mechanical coordinate system as reference

Enable of negative soft limit,1:enable,0:disable

Negative soft limit position limit value, in

mechanical coordinate system as reference

1/0

0-10000

1/0

0-10000

Table 3-6. Configuration of soft limit

Note the soft limit configuration item XYZAB 5 axis can be set independently.

- 31 -

Chapter3 Software & config

No. Mark Definition Range

Manual of NCH02

5 PROBE-PIN

6 PROBE-LEVEL

7 PROBE-MOD

8 P-X

9 P-Y

The pin of Probe, 0 for closing, and 1-8 for the

corresponding input pin IN1-IN8

Effective level of Probe, 1: high efficiency, 0: low

efficiency

Probe mode, 0:fixed-position probe,

1:floating-position probe

X axis coordinate of Tool sensor in fixed-position

mode

Y axis coordinate of Tool sensor in fixed-position

mode

0-8

1/0

1/0

±10000

±10000

10 P-Z

11 PROBE SPD

No. Mark Definition Range

12 Language

13 Home Spd

14 BL Speed

Z axis coordinate of Tool sensor in fixed-position

mode

Probe speed ratio according to G0

Table 3-7. Configuration of Probe

Language settings (temporary support for

English only)

Home speed ratio according to G0

Backlash speed ratio according to G0

±10000

0-100%

0

0-100%

0-100%

15 Buzzer

Button buzzer switch, 0: close, 1: open

- 32 -

1/0

Chapter3 Software & config

Manual of NCH02

16 ESTOP PIN

17 ESTOP LEVEL

18 P-B-Z

The pin of Estop, 0 for closing, and 1-8 for the

corresponding input pin IN1-IN8

Effective level of Estop, 1: high efficiency, 0:

low efficiency

Back distance of Z axis after Probe in

floating-position mode

Table 3-8. Other parameter setting

3.4 Test and diagnosis page

0-8

1/0

0-100

The test and diagnosis page can be entered by pressing under the parameter

configuration page. The page mainly displays the basic function test information of the system,

including key monitoring, input and output monitoring, spindle monitoring and so on. Page

reference diagram 3-7. detailed description of reference table 3-9.

- 33 -

Chapter3 Software & config

Manual of NCH02

Figure3-7. Test and diagnosis page (TEST)

No. Mark Definition

1 Axis TEST1

2 Axis TEST2

3 SPINDLE TEST

X/Y/Z 3 axis test, adjust the knob to select the function, after the

confirmation (PUSH) to start the test, the X/Y/Z axis is run

according to the design path.

A/B 2 axis test, adjust the knob to select the function, after the

confirmation (PUSH) to start the test, the A/B axis is run

according to the design path.

Spindle test, adjust the knob to select the function. According to

the confirmation (PUSH), after starting the test, the spindle

output is changed according to the design voltage, Voltage is the

output voltage display, and Speed is the spindle speed display.

4 INPUT TEST

The input IO value is displayed in real time. One IO corresponds

- 34 -

Chapter3 Software & config

Manual of NCH02

to a color block, the valid color block becomes red, and the

invalid color is blackened.

5 OUTPUT TEST

6 TEST ALL

7 KEYBOARD

Table 3-9. Description of test and diagnosis page

The output IO value is displayed in real time. One IO

corresponds to a color block, the output block becomes red, and

the invalid color is blackened.

The function is selected by the adjustment knob. After the test is

started (PUSH), all modules are running or changing according

to the design.

Button monitoring can monitor the press position in real time.

- 35 -

Chapter4

Chapter 4. Operation and Application

Operation and Application

The basic operation is introduced in the front part of the keystroke. Here is not going to be

exhausted. Here we introduce the use of this product from the perspective of an initial user. The

first time we start the product, we first configure all the configuration items according to our actual

needs. Here we introduce the usage method, no longer describe the configuration items, and all the

configuration items are configured according to the customers' needs.

First of all, the system is started, our first step is to establish the m achine coordinate system ;

Manual of NCH02

the second step is probe, accurate zero; third step up the workpiece, the tip will move to zero

workpiece, and the workpiece coordinate reset; the fourth step is to load the G file; the above work

is finished, press START to start G code execution. The following sections describe these steps in

detail.

4.1 Establish machine coordinate system

As shown in Figure 4-1, the engraving machine schematic diagram is installed. Each axis is

equipped with a proximity switch. The limit and home share this switch. The X axis switch is

installed in the X-- position. The Y axis switch is installed in the Y++ position; the Z axis switch is

installed in the Z++ position. (here we test the prototype as a reference for installation, the actual

application of the customer can be selected according to the needs of the installation).

- 36 -

Chapter4

Operation and Application

Manual of NCH02

Figure4-1.

For the first time to use the system, we need to establish machine tool coordinate system,

that is, HOME.

After starting the system, we switch to the parameter settings page, "INPUT" sub-page, and

HOME configuration, according to our actual engraving machine configuration, as shown in

Figure 4-2. XYZ's HOME PIN is set to 3,4,5, LEVEL is set to 0, DIR X axis is set to 0, YZ

axis are set to 1. HBlength are all set to 10.

The switch position diagram of the test engraving machine

- 37 -

Chapter4

Operation and Application

Manual of NCH02

Figure4-2.

Switch to the parameter settings page "OTHER" subpage, find "Home Spd", and modify

the HOME speed to the appropriate value, as shown in Figure 4-3.

INPUT settings page

Figure4-3. Home speed settings

Single axis home operation: after setting, switch to the main page of "MAIN", we take X

as an example for single axis home, pressed + + , this is the X axis of

- 38 -

Chapter4

single axis home operation, the axis will run toward X-, stop until the trigger X axis HOME

switch, then switch back until the HOME switch change to the off state, the X axis machine

Operation and Application

coordinate is automatically cleared, said here is the X axis mechanical zero point; then continue

to run 10mm X+ to stop (we set HOME back distance is 10 in the configuration), so X HOME

operation is complete.

The all axis mechanical zero operation: NCH02 supports all axis HOME operation on

the main page, press

this, to ensure to all axis HOME open in INPUT setting, if one axis HOME is close, jump to

Manual of NCH02

+ + to trigger all axis HOME operation, before

the next axis operation. The order of HOME operation in full axis is X, Y, A and Z.

4.2 Probe

The Probe can be configured as a fixed-point probe or a floating-point probe. Below we

describe 2 kinds of probe operation in detail.

4.2.1 Fixed-point probe

Fixed point probe is to fix the tool sensor in a fixed position of the engraving machine, and

every time the probe is processed, the spindle tip automatically moves to this fixed position for

tool setting. The installation position of the tool sensor is shown in reference Figure 4-4.

- 39 -

Chapter4

Operation and Application

Manual of NCH02

Figure4-4. Tool sensor installation position in fixed-point probe mode

Figure4-5. Move to the installation position of the tool sensor

First, we manually move the tool tip to the center of the plane on the tool block, and r ead

- 40 -

Chapter4

the XYZ axis mechanical coordinates. As shown in Figure 4-5, the plane center coordinates (X, Y,

Z) on the tool block are (30,30, -110).

Operation and Application

Secondly, we enter the OTHER sub page under CONFIG. As shown in Figure 4-6, we find

fixed-point tool block location configuration item, and configure related parameters of cutter

block as shown in table 4-1.

No. Mark Value Definition

1 PROBE-PIN 2

2 PROBE-LEVEL 0

Manual of NCH02

Take IN2 Port as probe input port

The input port IN2 is low effective (effective when

the input short with GND)

3 PROBE-MOD 0

4 PROBE-P-X 30

5 PROBE-P-Y 30

6 PROBE-P-Z -110

Table 4-1 Probe configuration item in fixed point probe mode

Probe configuration item screenshot see as figure 4-6.

Set to fixed-point probe mode

The X coordinate value of the position of the tool

sensor is 30

The Y coordinate value of the position of the tool

sensor is 30

The Z coordinate value of the position of the tool

sensor is -110

- 41 -

Chapter4

Operation and Application

Manual of NCH02

Figure4-6.

After the configuration is completed, we enter the main page and move the spindle to any

position. (we suggest that the Z axis of the tool tip is higher than the plane of the tool sensor). Press

+ , the system starts automatic probe. At this m oment, the system will automatically

move to the location of the set of tool sensor to automatically probe. After the probe is finished, the

system will automatically return to the just start position of the probe.

4.2.2 Floating-point probe

The floating probe means that the location of the tool sensor is not fixed at a certain

location, but is placed in any desired location. In this mode, we usually place the tool sensor on

Probe configuration

in fixed-point probe mode

the workpiece surface for floating-point probe. The position of the tool sensor is placed in

reference figure 4-8.

In the floating tool mode, there is no need to configure the position of the tool sensor. We

enter the OTHER subpage under CONFIG and set the probe related settings as shown in Ta ble

4-2. Floating-point probe configuration item screenshot reference figure 4-7.

- 42 -

Chapter4

No. Mark Value Definition

1 PROBE-PIN 2

Operation and Application

2 PROBE-LEVEL 0

3 PROBE-MOD 1

4 PROBE-B-Z 10

Manual of NCH02

Table4-2 Probe configuration item in fixed point probe mode

Take IN2 Port as probe input port

The input port IN2 is low effective (effective when

the input short with GND)

Set to floating-point probe mode

Back distance after probe

Figure4-7. Probe configuration in fixed-point probe mode

- 43 -

Chapter4

Operation and Application

Manual of NCH02

Figure4-8. Tool sensor installation position in floating-point probe mode

After completing the configuration we return to the main page, the tool sensor on the surface

of the workpiece, we only need to manually (MPG) move the spindle nose just above the tool

sensor, and then press + , the system will automatically start probe, after the

probe completion of the Z axis will be automatically lift off the tool sensor plane 10mm.

4.3 Workpiece zero point

After the probe is completed , the next step is confirm wor kpiece zero point, we want to

carve a product, first get the G code, to ensure the workpiece zero position of the G code file .

Some G code file set the workpiece center as the workpiece zero, some set a workpiece the

corner as the workpiece zero. Here is an example of a positive center on the surface of the

- 44 -

Chapter4

workpiece. Under the main page, use manual (MPG) to move the tip of the spindle to the center of

the workpiece surface and then presses + + to set axis coordinates to zero.

Operation and Application

Then move the Z axis out of the workpiece surface to the safety height. At this point, the workpiece

zero is confirmed.

4.4 Load and run G code

Under the main page, press to switch to file management page, adjust the knob to

select the files that need to be processed. As sh own in Figure 4-9, we selected the TEST2.TAP file.

Manual of NCH02

Figure4-9.

After selecting a the file, press the confirmation key to automatically load the G code and

automatically return it to the MAIN page. As shown in Figure 4-10, the title bar file display section

has already appeared TEST2.TAP, indicating that the G code file is loaded successfully.

select TEST2.TAP file in management page

- 45 -

Chapter4

Operation and Application

Manual of NCH02

Figure4-10. Estop and Probe dialog

When the G code is loaded, press. Start the process.

- 46 -

Chapter5 G & M instructions supported

Manual of NCH02

Chapter 5. G & M instructions supported

5.1 G instruction Supported

No. Instruction Definition

1 G0

2 G1

Quick positioning

Straightaway cut

3 G2

4 G3

5 G17

Cut along the circle

Cut inversing the circle

XY plane select

6 G18 ZX

7 G19

8 G28

9 G31

10 G54

11 G55

12 G56

YZ plane select

Home

Probe

G54 coordinate system

G55 coordinate system

G56 coordinate system

plane select

13 G57

14 G58

15 G59

16 G81

17 G82

G57 coordinate system

G58 coordinate system

G59 coordinate system

Drill hole code

Drill hole code

- 47 -

Chapter5 G & M instructions supported

18 G83

19 G90

20 G91

21 G98

22 G99

Manual of NCH02

Circulation Drill hole code

Absolute size mode

Increment size mode

Back to R point

Fixed circulation

Table 5-1 G instruction supported

5.2 M instruction Supported

No. Instruction Definition

1 M3

2 M4

3 M5

4 M8

5 M9

6 M10

7 M11

8 M30

9 M60

Spindle rotates forward

Spindle rotates backward

Spindle stop

Start of water -cooling

Stop of water- cooling

Start of Mist

Stop of Mist

End of G code

Open switch 1

10 M61

11 M62

12 M63

13 M64

14 M80

Open switch 2

Open switch 3

Open switch 4

Open switch 5

Close switch 1

- 48 -

Chapter5 G & M instructions supported

15 M81

16 M82

17 M83

18 M84

Manual of NCH02

Close switch 2

Close switch 3

Close switch 4

Close switch 5

Table 5-2 M instruction supported

- 49 -

Loading...

Loading...