NOVUS V1.5x A User Manual

INSTRUCTION MANUAL

V1.5x A

INTRODUCTION ................................................................................................................................................................. 3

CONNECTIONS AND INSTALLATION ............................................................................................................................... 4

MECHANICAL INSTALLATION ..................................................................................................................................... 4

ATTACHING AND DETACHING THE FRONT COVER .......................................................................................... 8

ATTACHING AND DETACHING THE HMI .............................................................................................................. 9

ELECTRICAL CONNECTIONS ..................................................................................................................................... 9

SAFETY SUMMARY ..................................................................................................................................................... 9

RECOMMENDATIONS FOR INSTALLATION ....................................................................................................... 10

POWER SUPPLY .................................................................................................................................................. 11

DIGITAL I/O ........................................................................................................................................................... 11

RELAYS ................................................................................................................................................................. 11

RS485 .................................................................................................................................................................... 11

AUXILIARY POWER SUPPLY FOR POWERING TRANSMITTERS .................................................................... 12

ANALOG INPUTS .................................................................................................................................................. 13

CONNECTIVITY RESOURCES .................................................................................................................................. 14

FLAGS (LEDS) .................................................................................................................................................................. 15

INSTALLING THE USB DRIVER ...................................................................................................................................... 16

WINDOWS 7 ............................................................................................................................................................... 16

DEFINITION AND SELECTION OF SERIAL PORT (COM) - WINDOWS ......................................................................... 20

CONFIGURATION AND DATA DOWNLOAD SOFTWARE .............................................................................................. 21

CONFIGURATION ...................................................................................................................................................... 22

GENERAL CONFIGURATIONS ............................................................................................................................ 24

RS485 INTERFACE CONFIGURATION ................................................................................................................ 25

ETHERNET INTERFACE CONFIGURATION ....................................................................................................... 26

ETHERNET INTERFACE CONFIGURATION - TCP/IP ................................................................................... 27

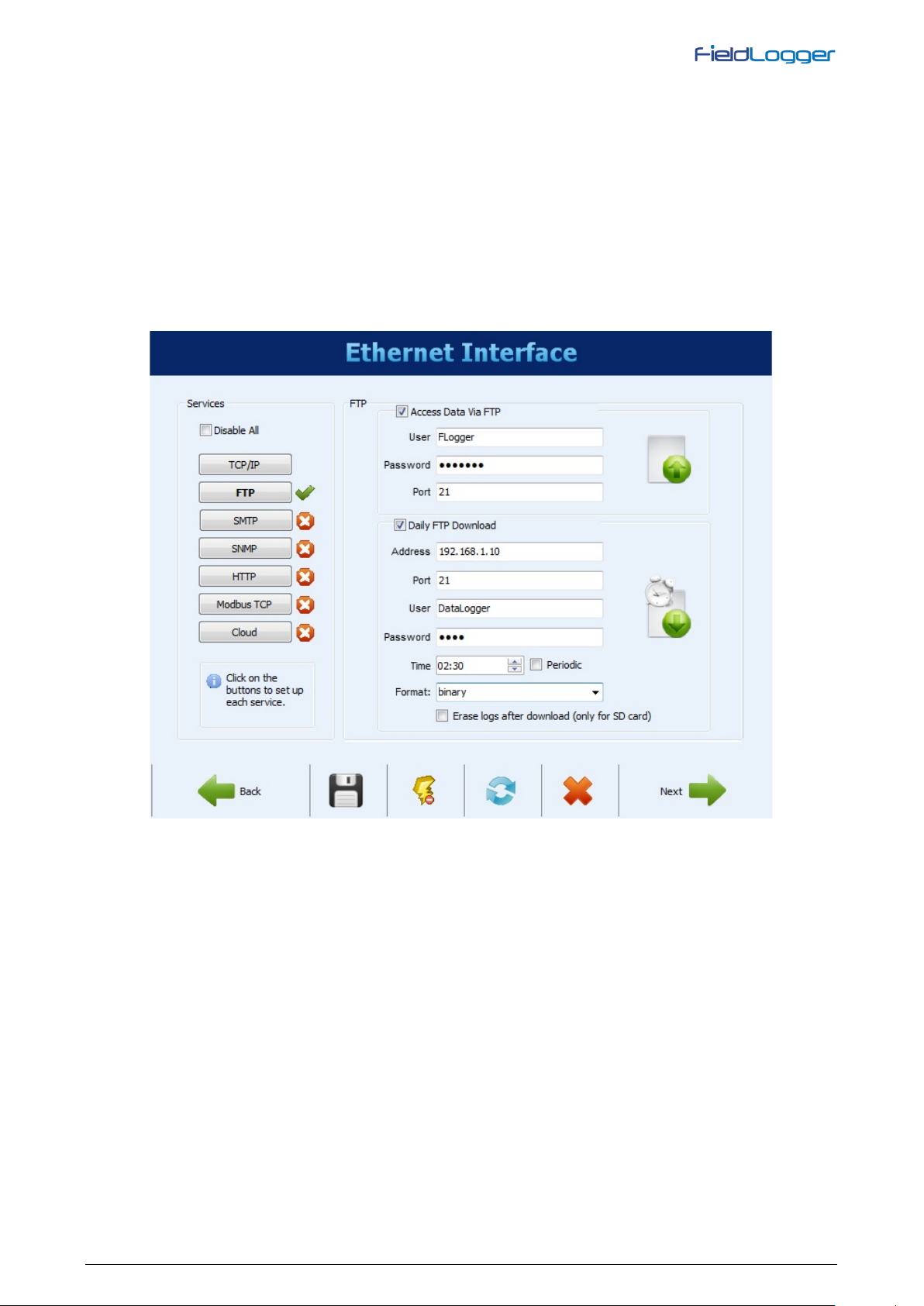

ETHERNET INTERFACE CONFIGURATION – FTP ....................................................................................... 28

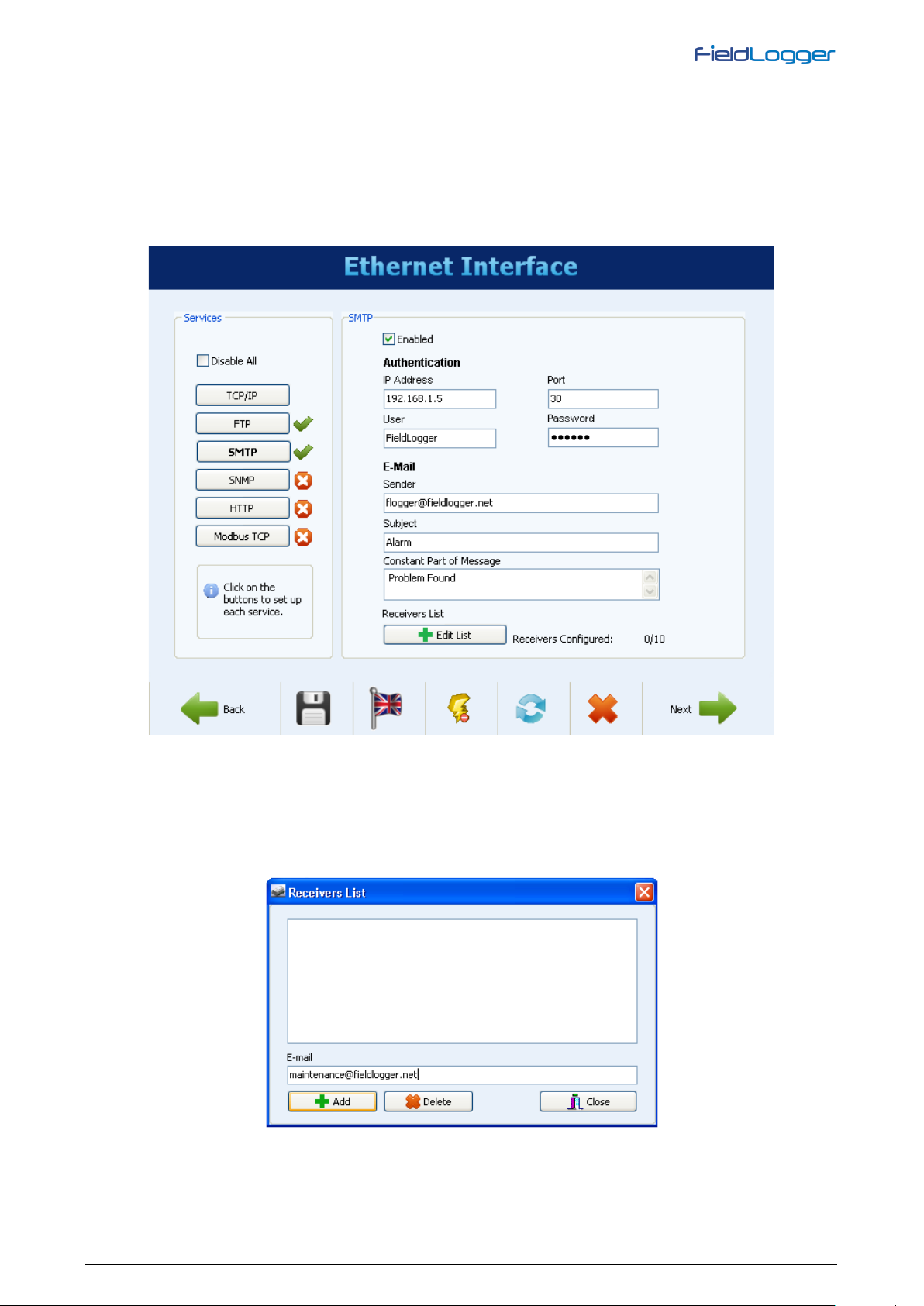

ETHERNET INTERFACE CONFIGURATION - SMTP ..................................................................................... 30

ETHERNET INTERFACE CONFIGURATION - E-MAIL RECEIVERS ............................................................. 30

ETHERNET INTERFACE CONFIGURATION - SNMP .................................................................................... 31

ETHERNET INTERFACE CONFIGURATION – HTTP .................................................................................... 32

ETHERNET INTERFACE CONFIGURATION – MODBUS TCP ...................................................................... 33

ETHERNET INTERFACE CONFIGURATION – CLOUD ................................................................................. 34

ANALOG CHANNELS CONFIGURATION............................................................................................................. 35

ANALOG CHANNELS CONFIGURATION – CUSTOM CALIBRA TION ........................................................... 37

DIGITAL CHANNELS CONFIGURATION.............................................................................................................. 38

REMOTE CHANNELS CONFIGURATION ............................................................................................................ 40

VIRTUAL CHANNELS CONFIGURATION ............................................................................................................ 43

ALARMS CONFIGURATION ................................................................................................................................. 44

LOGS CONFIGURATION ...................................................................................................................................... 48

DIAGNOSTICS ............................................................................................................................................................ 50

DOWNLOAD ............................................................................................................................................................... 53

DOWNLOAD DATA ............................................................................................................................................... 54

DOWNLOAD MANAGER ....................................................................................................................................... 56

USING STEP-BY-STEP (WIZARD) .................................................................................................................. 57

NON STEP-BY-STEP ...................................................................................................................................... 64

PREFERENCES .......................................................................................................................................................... 68

PASSWORD PROTECTION .................................................................................................................................. 68

COMMAND-LINE OPERATION .................................................................................................................................. 69

BATCH FILE .......................................................................................................................................................... 69

ACTION TYPE ................................................................................................................................................. 69

CONNECTION MODE ..................................................................................................................................... 69

NOVUS AUTOMATION www.fieldlogger.net 1/103

ACTION PARAMETERS .................................................................................................................................. 70

EXPORT PARAMETERS ................................................................................................................................. 70

FIELDLOGGER OPERATION ........................................................................................................................................... 71

ANALOG INPUTS ....................................................................................................................................................... 71

DIGITAL INPUTS/OUTPUTS ...................................................................................................................................... 72

COUNTINGS ......................................................................................................................................................... 73

OUTPUT RELAYS ....................................................................................................................................................... 73

RS485 INTERFACE .................................................................................................................................................... 73

AUXILI ARY RS485 ................................................................................................................................................ 73

REMOTE CHANNELS ................................................................................................................................................. 74

VIRTUAL CHANNELS ................................................................................................................................................. 74

USB INTERFACE ........................................................................................................................................................ 76

USB DEVICE ......................................................................................................................................................... 76

USB HOST ............................................................................................................................................................. 76

ETHERNET INTERFACE ............................................................................................................................................ 77

MODBUS-TCP ....................................................................................................................................................... 77

SENDING E-MAILS - SMTP .................................................................................................................................. 77

WEB PAGES - HTTP ............................................................................................................................................. 78

UNCHANGEABLE PAGES .............................................................................................................................. 78

CUSTOM PAGES ............................................................................................................................................ 81

FILE TRANSFER - FTP ......................................................................................................................................... 83

NETWORK MANAGEMENT - SNMP .................................................................................................................... 84

CLOUD .................................................................................................................................................................. 85

OPERATION .................................................................................................................................................... 85

AUTHENTICATION AND OTHER DETAILS .................................................................................................... 85

DATA LOGGING AND DOWNLOAD ........................................................................................................................... 86

ALARMS ...................................................................................................................................................................... 89

DATA COMMUNICATION ................................................................................................................................................. 90

HMI (HUMAN-MACHINE INTERFACE) ............................................................................................................................ 91

“FAVORITES” SCREEN .............................................................................................................................................. 93

“CHART” SCREEN ...................................................................................................................................................... 93

“CHANNEL LIST” SCREEN ......................................................................................................................................... 93

“ALARMS” SCREEN ................................................................................................................................................... 93

“STATUS” SCREEN .................................................................................................................................................... 94

“CONFIGURATION” SCREEN .................................................................................................................................... 94

EQUIPMENT SOFTWARE (FIRMWARE) UPDATE ......................................................................................................... 96

CLOCK BATTERY REPLACEMENT................................................................................................................................. 99

SPECIFICATIONS .......................................................................................................................................................... 101

SAFETY INFORMATION ................................................................................................................................................ 103

SUPPORT AND MAINTENANCE ................................................................................................................................... 103

LIMITED WARRANTY AND LIMITATION OF LIABILITY ................................................................................................ 103

NOVUS AUTOMATION www.fieldlogger.net 2/103

INTRODUCTION

The FieldLogger is a high-resolution and high-speed data acquisition and logging equipment for analog and digital

signals. The result of an advanced technological development, the product is distinguished in diverse aspects, such as

high-performance, high-connectivity and ease of configuration and operation. This technology is presented as the ideal

solution for applications that require flexibility and functionality for diverse communication networks.

Its main features include:

• Analog inputs: 8

• Digital inputs/outputs: 8

• Relay outputs: 2

• 2 MB internal memory

• SD Card interface (up to 16 GB – not availa ble in some mod els)

• RS485 interface

o Main: Modbus RTU master and slave

o Auxiliary (DB9 connector – not available in some models): Modbus RTU slave

• Ethernet services (not available in some models):

o DHCP

o HTTP (web page)

o FTP (client and server)

o SMTP (e-mails sending)

o SNMP

o Modbus TCP

• USB:

o Host

o Device

• HMI (human-machine interface – optional)

There are four input channel types in the FieldLogger: analog, digita l, remote and vi rtual. Analog and digital channels

are those acquired directly by FieldLogger through their respective inputs. The remote channels are those acquired

through Modbus RTU protocol, operating as master on its RS485 interface. Virtual channels are a special type of input

channel where mathematical operations can be carried out, allowing the calculation of complex formulas from the

measured information.

The analog input channels are configurable for reading voltage, current, thermocouples, Pt100 and Pt1000 signals.

These inputs count on the precision of a 24 bit A/D converter with high acquisition speed, which can reach 1000 sam ples

per second. The digital channels can be configured individually as inputs or outputs.

The Ethernet interface allows data download and data access of the inputs and outputs, through services that can be

individually enabled and configured. Through a web browser (HTTP), one can visualize the data of the enabled channel,

diagnostics and general information of the FieldLogger. FTP client can be used for logging data downloads.

FieldLogger can identify up to 32 distinct alarm conditions, allowing the triggering of outputs, sending e-mails or SNMP

traps whenever an alarm condition is detected. All the information relative to the variables, status and diagnostics of the

FieldLogger are available in Modbus registers that can be accessed through the Modbus TCP interface or the Modbus

RTU interface available either through USB interface (device) or RS485 (when operating as slave).

The USB Interface device is used for connection to a computer for configuration, monitoring or download. Whereas th e

USB interface host is used for connection of a USB flash drive, for data downloading from the loggi ng mem ory .

The data logging memory can be transferred by any of the interfaces to the configuration software, which allows the

exportation for the most diverse data formats.

When the indication of the measured data from the process is necessary, an exclusive color graphical display HMI

(Human-Machine Interface) can be attached or installed remotely (optional).

NOVUS AUTOMATION www.fieldlogger.net 3/103

CONNECTIONS AND INSTALLATION

MECHANICAL INSTALLATION

FieldLogger chassis can be installed on a 35 mm DIN rail.

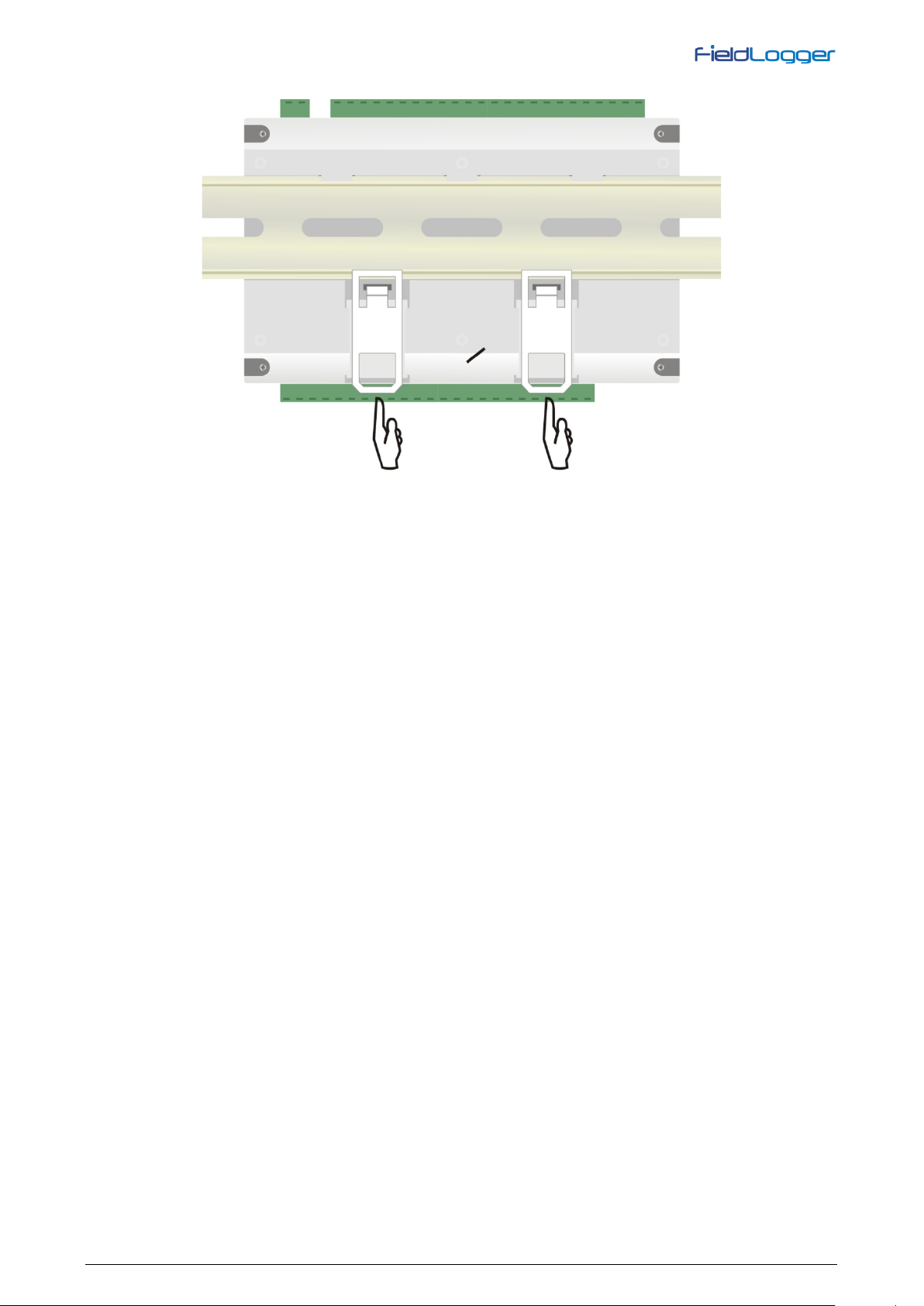

For the installation on the rail, you must pull out the two clamps located right below the connections of the channels,

taking care not to remove them, as per Fig. 01.

Note: If necessary, the connector may be removed for installation of DIN rail.

Fig. 01 - DIN rail installation

Afterwards, fit the FieldLogger to the rail according to Fig. 02.

Fig. 02 - DIN rail installation

NOVUS AUTOMATION www.fieldlogger.net 4/103

And finally, push the two clamps until you hear a double click for the complete installation, as per Fig. 03.

Fig. 03 - DIN rail installation

NOVUS AUTOMATION www.fieldlogger.net 5/103

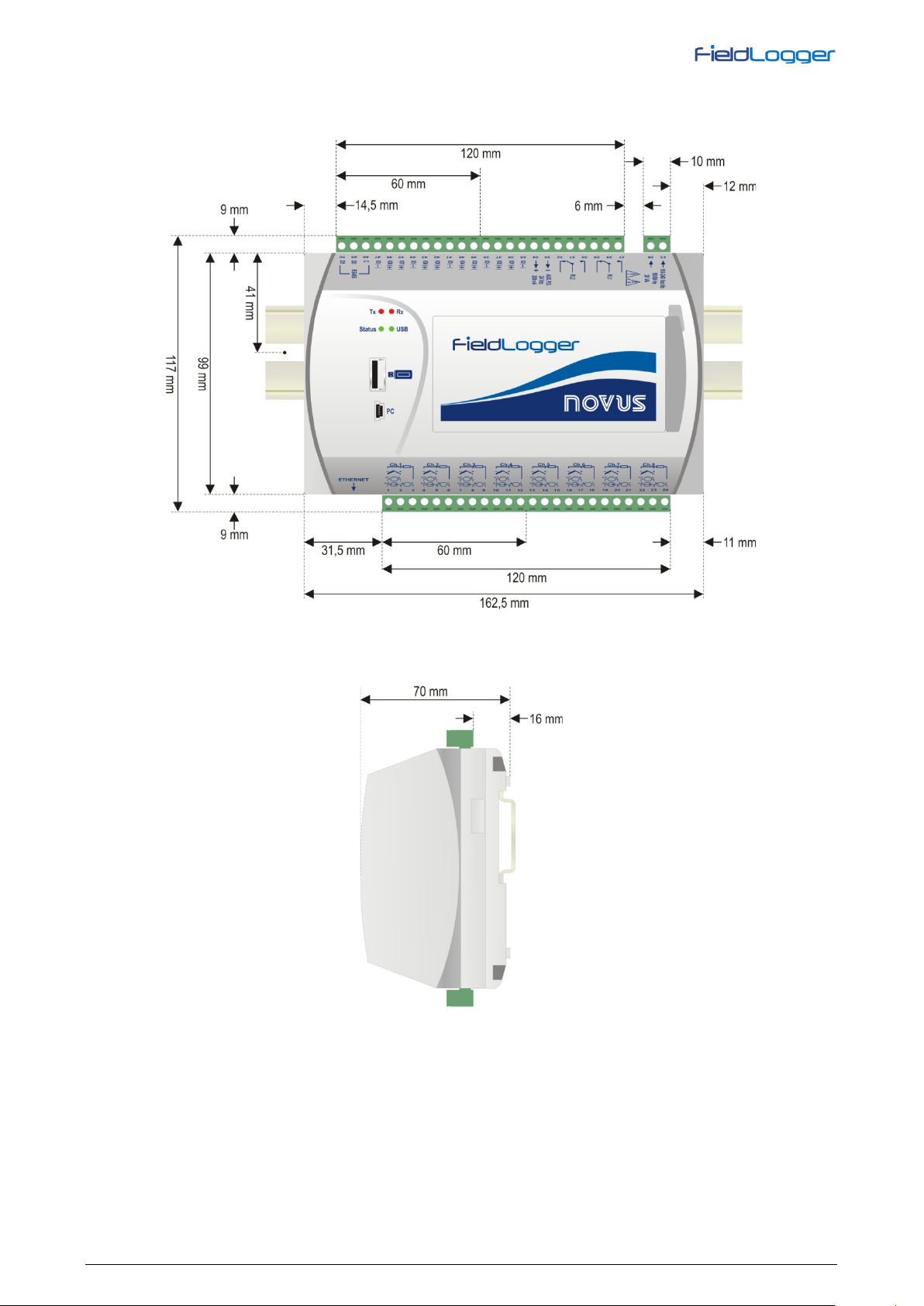

Dimensions:

• Without HMI module:

Fig. 04 – Dimensions of the FieldLogger without HMI module

Fig. 05 – Dimensions of FieldLogger side without HMI module

NOVUS AUTOMATION www.fieldlogger.net 6/103

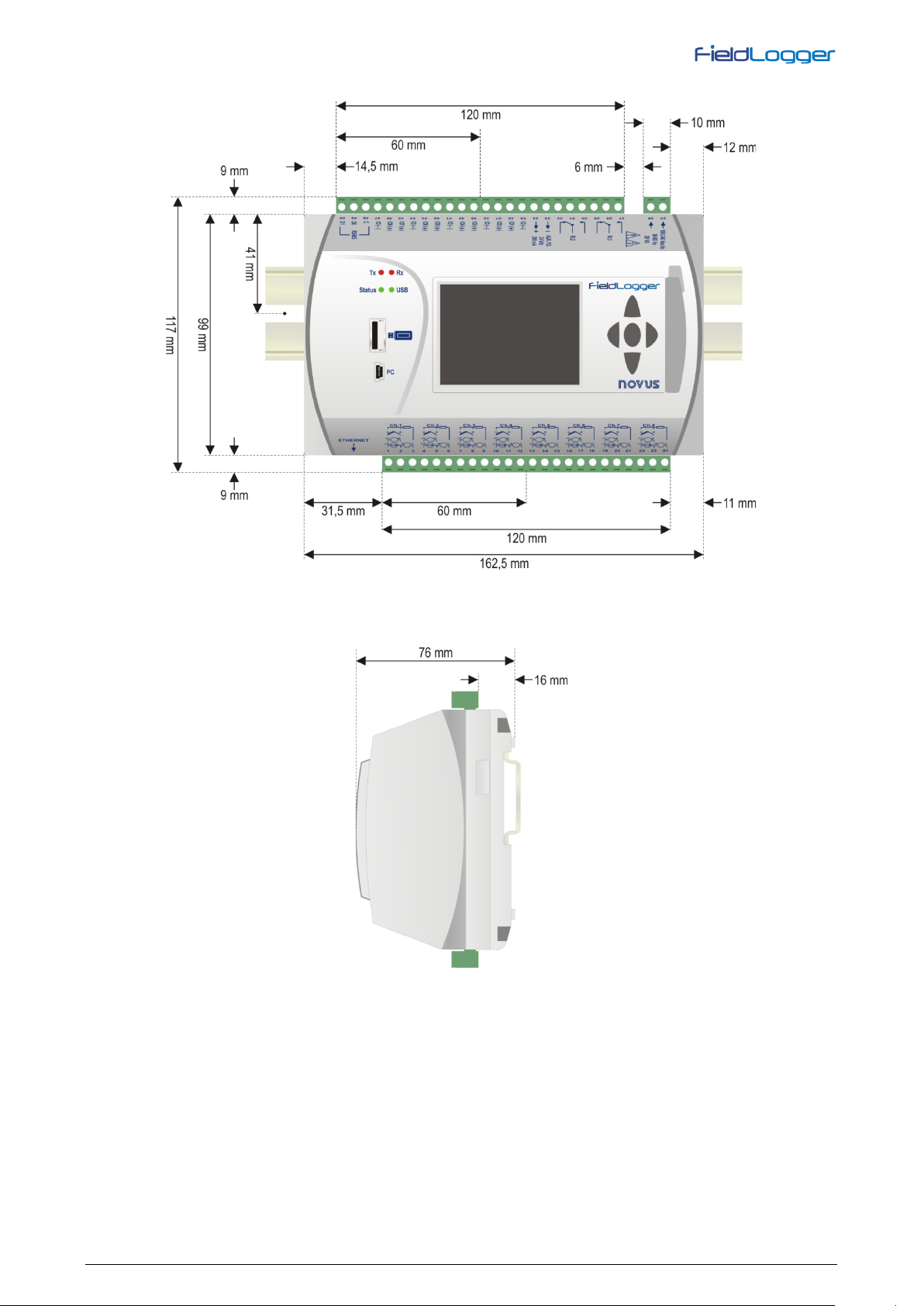

• With HMI module (Optional):

Fig. 06 – Dimensions of the FieldLogger with HMI module

Fig. 07 – Dimensions of FieldLogger side with HMI module

NOVUS AUTOMATION www.fieldlogger.net 7/103

ATTACHING AND DETACHING THE FRONT COVER

When detaching the front cover, pull the lever at the right side of the FieldLogger up to the end.

When attaching it, insert the cover (left side first) and press its right side gently. After that, press the lever back into the

chassis.

Fig. 08 – Attaching and detaching FieldLogger front cover

Fig. 09 – Attaching and detaching FieldLogger front cover (side view)

NOVUS AUTOMATION www.fieldlogger.net 8/103

ATTACHING AND DETACHING THE HMI

When detaching the HMI, pull up the lever at the right side of the FieldLogger u p to the end.

When attaching it, insert the HMI (left side first) and press its right side until DB9 connectors are firmly connected. After

that, press the lever down into the chassis.

Fig. 10 – Attaching and detaching FieldLogger HMI

Fig. 11 – Attaching and detaching FieldLogger HMI (side view)

ELECTRICAL CONNECTIONS

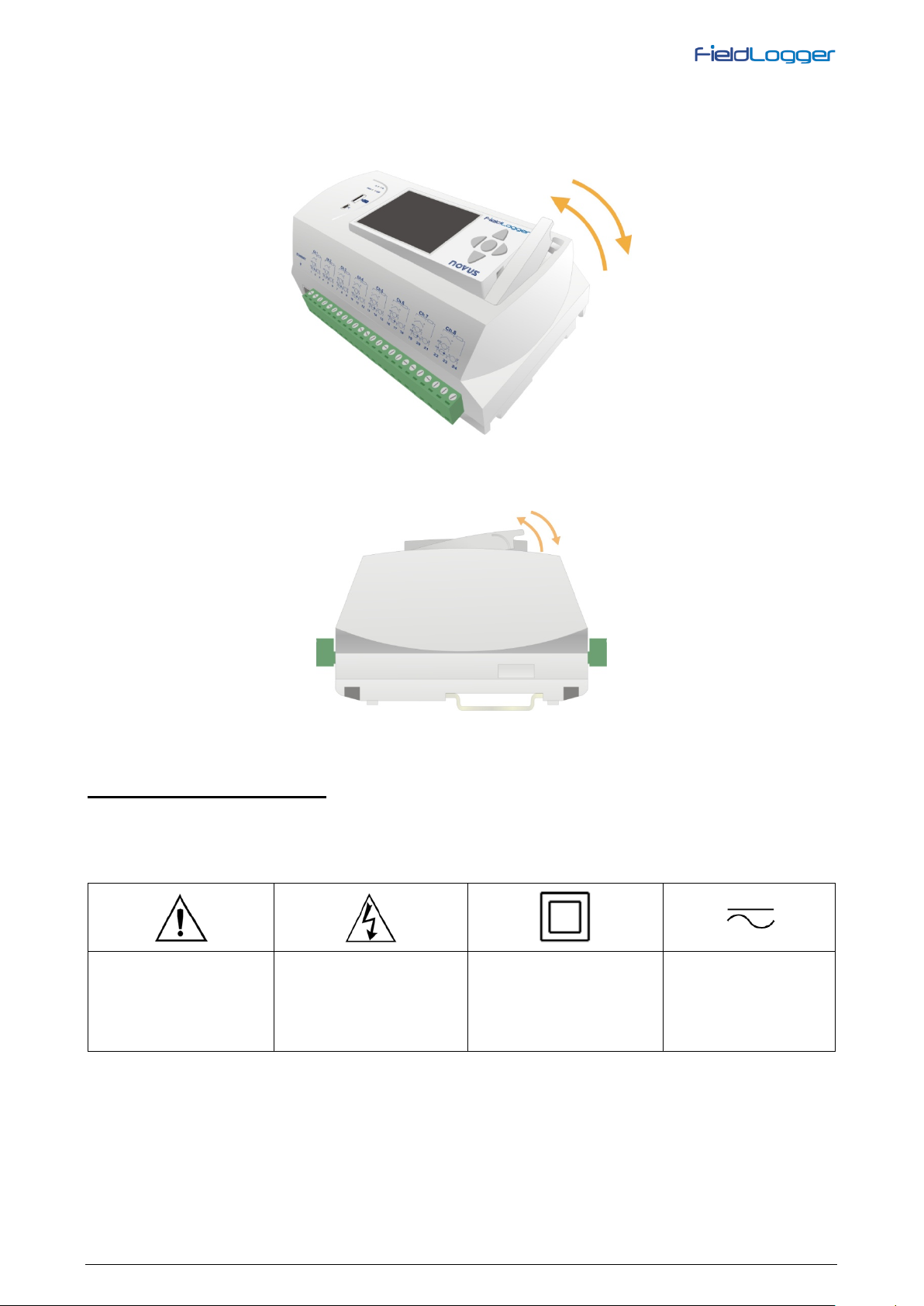

SAFETY SUMMARY

The symbols below are used on the equipment and throughout this document to draw the user’s attention to important

operational and safety information.

CAUTION or WARNING:

Read complete instructions

prior to installation and

operation of the unit.

CAUTION or WARNING:

Electrical Shock Hazard

DOUBLE INSULATION

The FieldLogger power supply

is double insulated, represented

by the above symbol printed on

the equipment’s connection

label.

POWER INPUT

The FieldLogger may be

powered from either AC or

DC power source.

All safety related instructions that appear in the manual must be observed to ensure personal safety and to prevent

damage to either the instrument or the system. If the instrument is used in a manner not specified by the manufacturer,

the protection provided by the equipment may be impaired.

NOVUS AUTOMATION www.fieldlogger.net 9/103

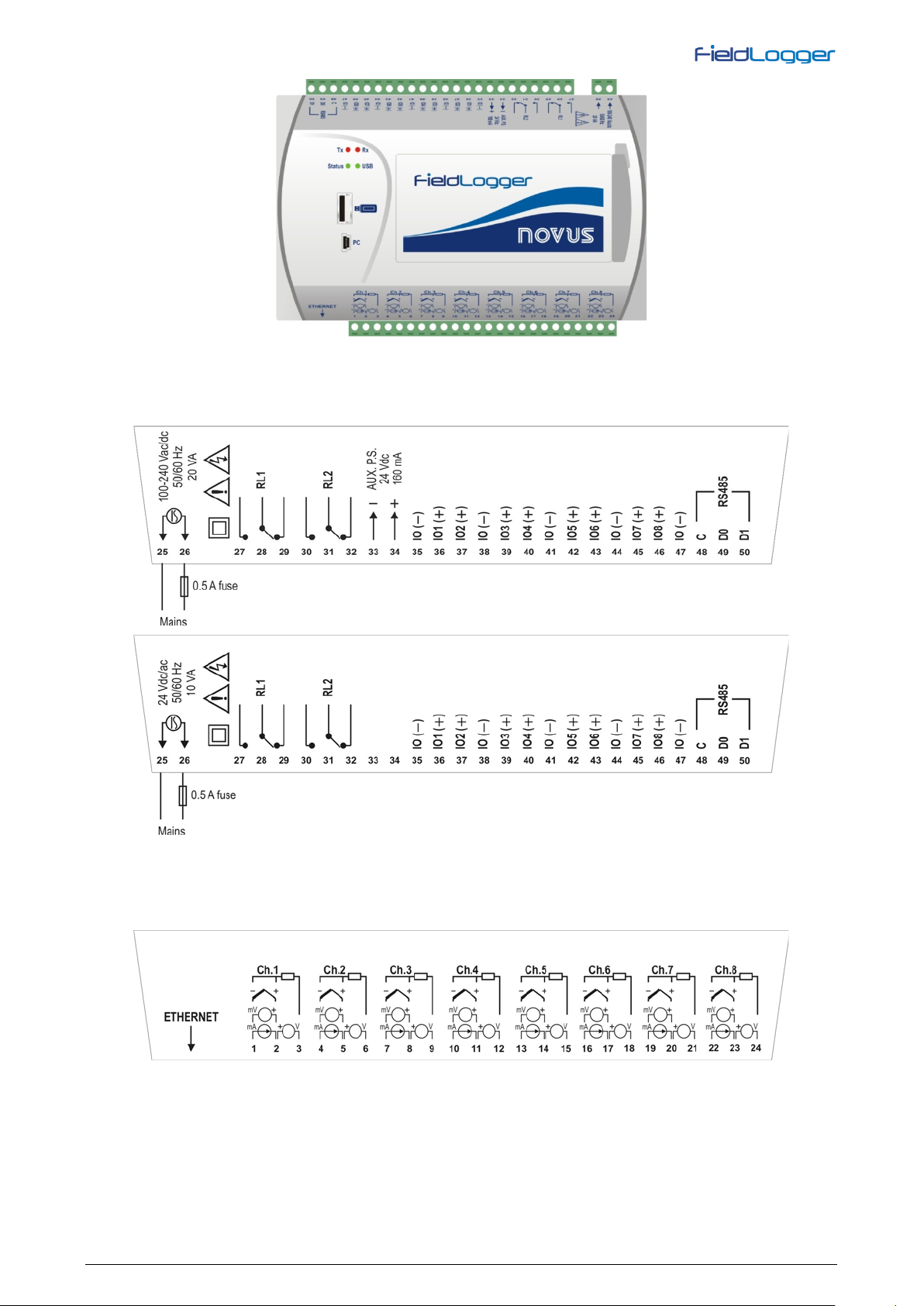

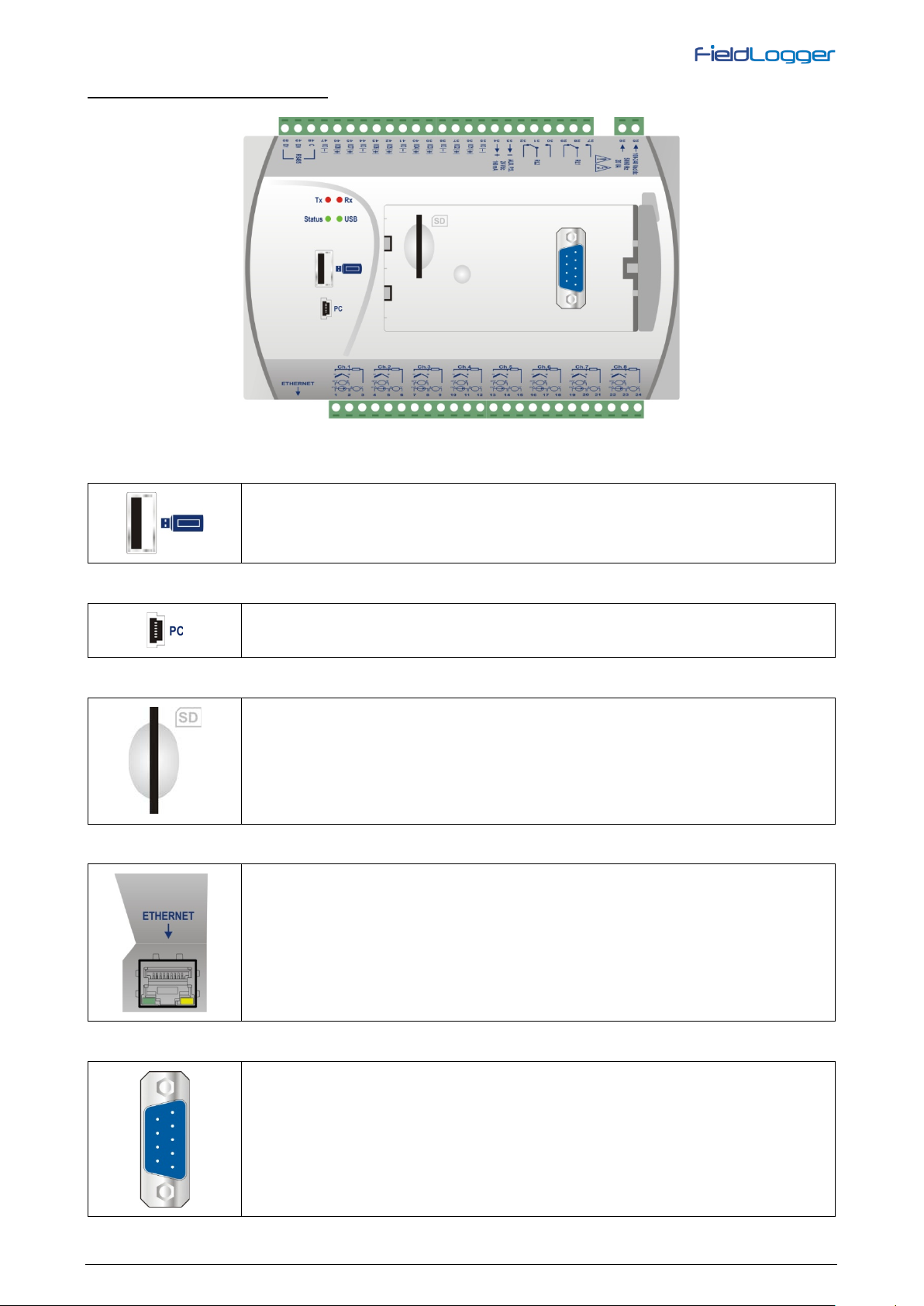

Fig. 12 - FieldLogger front panel

FieldLogger has two rows of terminals for diverse connections; among them are the following items: Ethernet, input

connections, power supply, output relays, auxiliary power supply output, digital inputs and serial communication. This

information is identified in the box of FieldLogger according to Fig. 13 and Fig. 14:

Fig. 13 - Upper side connections for standard and 24 V models

NOTES: 1) An external protection device consisting of a 0.5 A slow blow fuse (UL Listed) must be wired near to the

2) A switc h or circuit-breaker pl aced near to the

FieldLogger shall be used as the disconnecting device.

Fig. 14 - Lower side connections

FieldLogger.

RECOMMENDATIONS FOR INSTALLATION

• Input signal leads must be installed in grounded conduits and away from power or contactor wires.

• Instruments must be powered only by an exclusive power supply.

• Installing RC filters (47 Ω and 100 nF, serial) is strongly recommended at contactor coils or any other inductors.

• System failure should always be taken into account when designing a control panel to avoid irreversible damage to

equipment or injury to people. The RL1 and R L2 output relay s, used as al arms, do not warrant total protection.

• Wires section: minimum gauge 0. 14 mm².

NOVUS AUTOMATION www.fieldlogger.net 10/103

POWER SUPPLY

Fig. 15 - Voltage connection

Fig. 16 - Dry-contact connection

Fig. 17 - NPN Connection

The terminals 25 and 26 indicate the main power supply of FieldLogger.

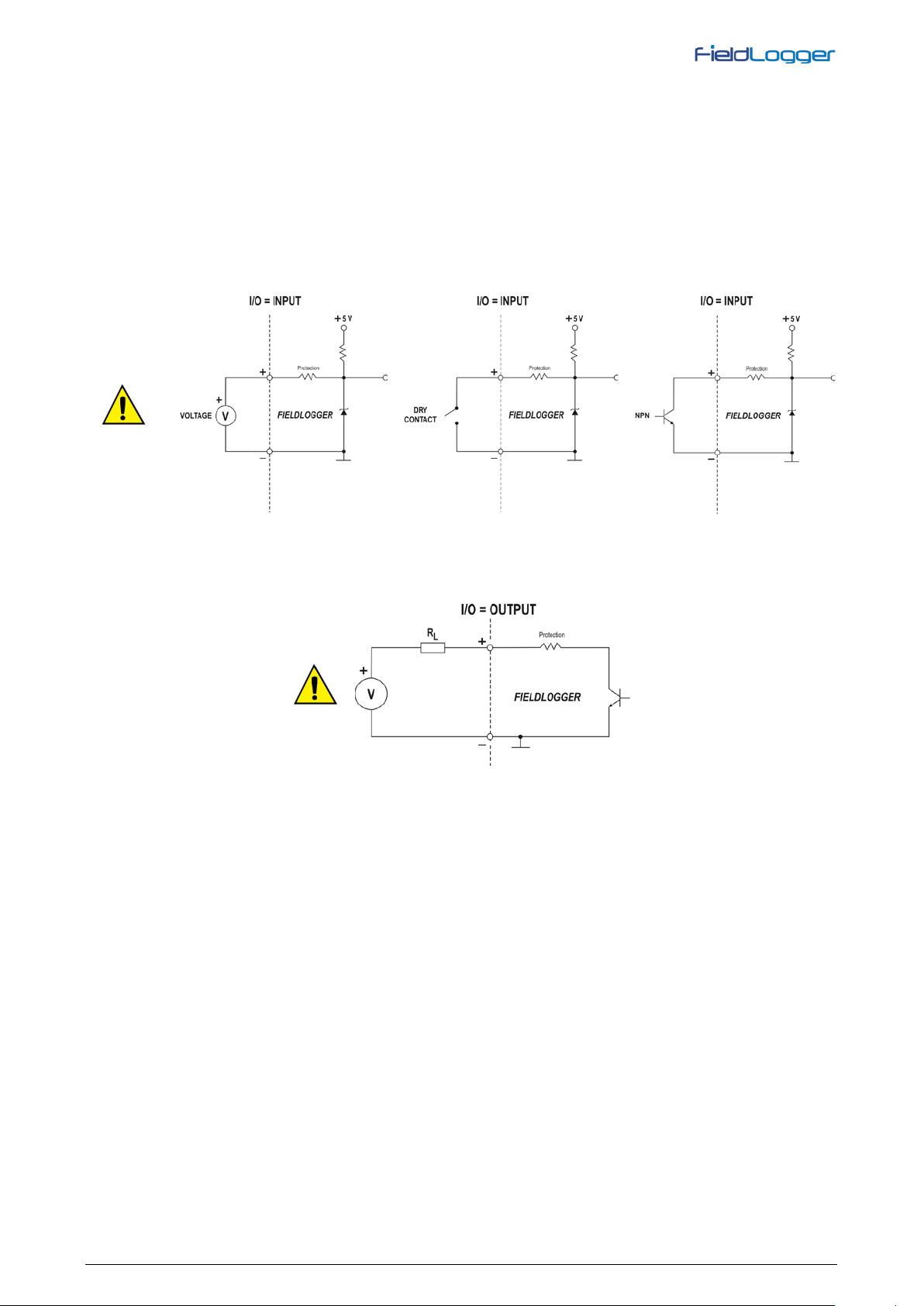

DIGITAL I/O

There are eight I/O t hat can be individually configured as inputs or outputs. There is a terminal for the positive signal of

each I/O, but the negative terminal of all of them is common (there is no isolation among the channels).

• Inputs:

When configured as inputs, they may be connected to voltage outputs (please check the acceptable levels in the

Specifications section), dr y-contact outputs and NPN outputs. Care must be taken when connecting multiple outputs

because of the lack of isolation between the FieldLogger inputs.

• Outputs:

When configured as outputs, they can activate limited power loads (p lea se che ck the Specifications section).

Fig. 18 - Connection of a load RL to a digital output

RELAYS

FieldLogger has 2 relays that can be used in the activation of electrical loads (please check the Specifications section).

For each relay, we have the common terminal, NC (normally closed) terminal and the NO (normally open) terminal.

When deactivated, the relay common is in contact with the NC terminal. When activated, the common is in contact with

the NO terminal.

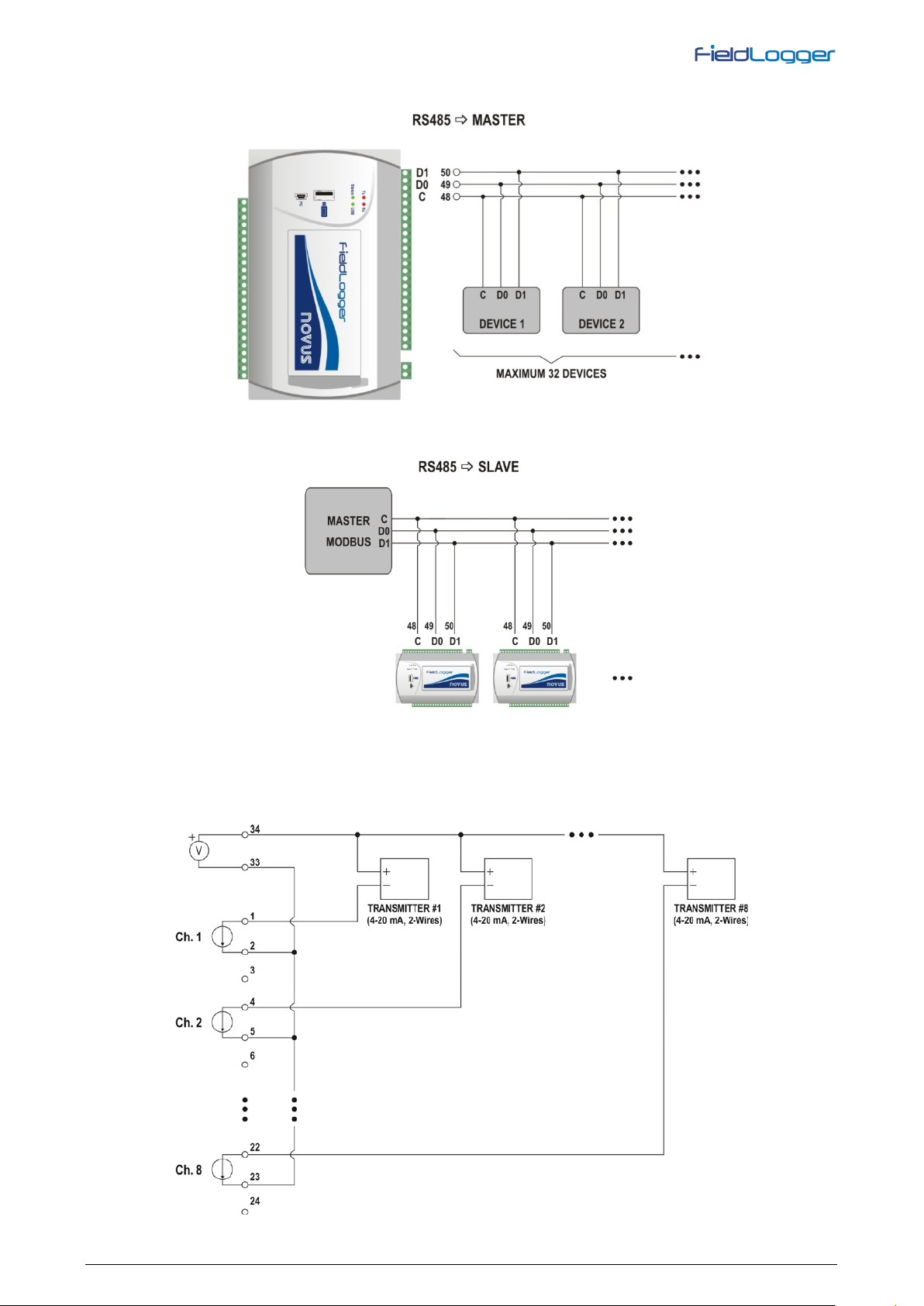

RS485

The RS485 Interface of the FieldLogger has terminals for the 3-wire communication, including the common. The

connection in a Modbus network will depend if the device is configured to operate as a master or a slave.

NOVUS AUTOMATION www.fieldlogger.net 11/103

• Master

• Slave

AUXILIARY POWER SUPPLY FOR POWERING TRANSMITTERS

For non 24 V models, there is a 24 Vdc power supply available in the FieldLogger for powering transmitters in the field.

This auxiliary power supply is electrically isolated from the other FieldLogger terminals.

Below is the correct way to use the auxiliary power supply for powering 4-20 mA transmitters (2-wire).

Fig. 19 – Auxiliary power supply powering 4-20 mA (2-wire) transmitters

NOVUS AUTOMATION www.fieldlogger.net 12/103

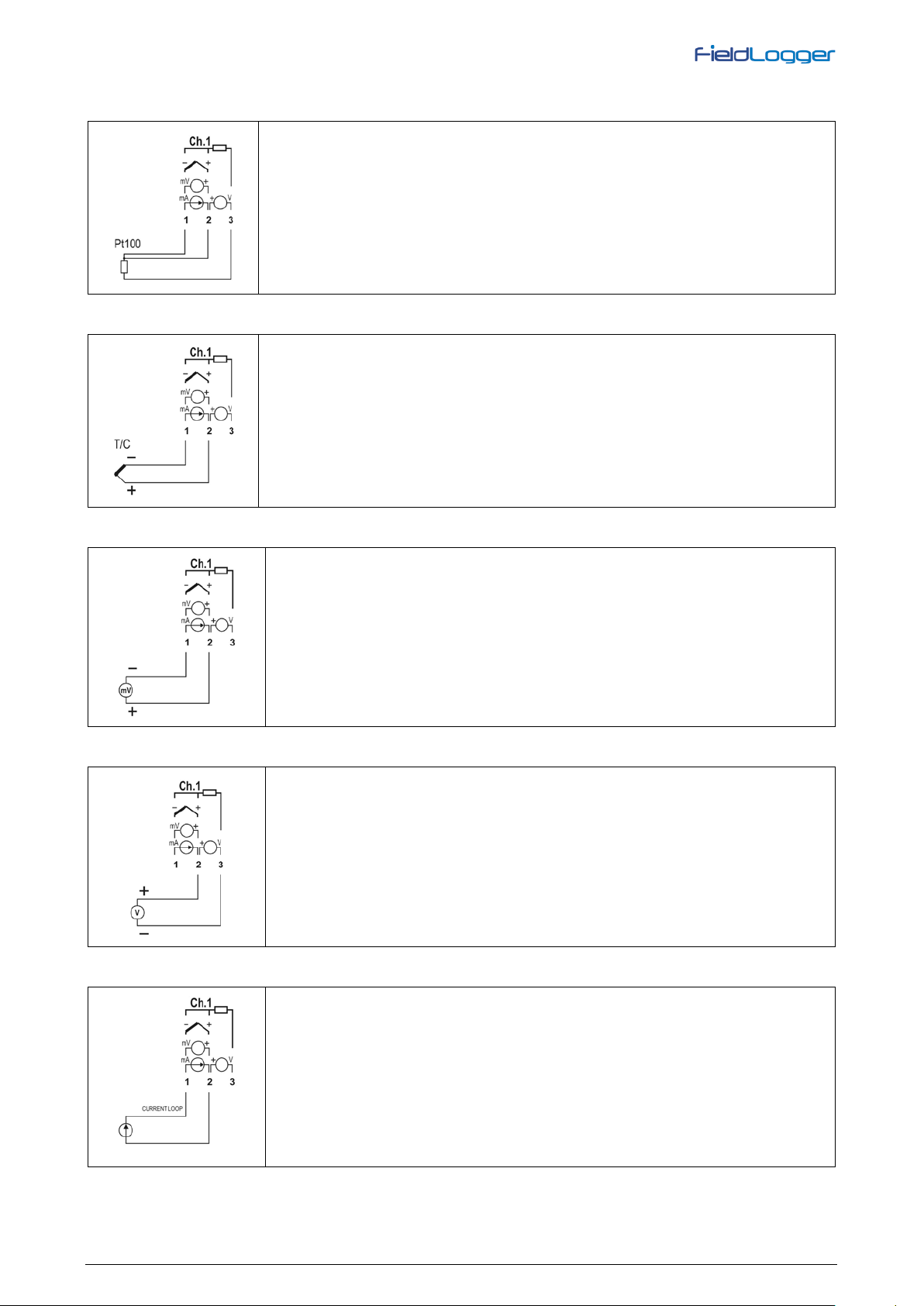

ANALOG INPUTS

correct polarity can cause

The connection for the channels is made in the terminals in accordance with the figure at

Pt100/Pt1000 connection

Thermocouple connection

The connection for the channels is made to the terminals in accordance with the figure at

the left. The 3-wire connection from the Pt100 sensing element to the FieldLogger input

guarantees the cancellation of the error caused by the resistance of the wires. All three

wires must have the same gauge and length.

For the two-wire Pt100, interconnect terminals 1 and 2.

The connection for the channels is made in the terminals in accordance with the figure at

the left. Please observe the correct connection polarity.

Cables used for connecting thermocouples must have the same thermoelectric

characteristics of the used thermocouple (compensation cable or extension cable), and

also must be connected with the correct polarity.

The non-use of compensation cables or the use with the in

significant measurement er ror s.

Voltage (mV) connection

Voltage (V) connection

Current (mA) connection

The connection for the channels is made in the terminals in accordance with the figure at

the left. Please observe the correct polarity of the connection.

the left. Please observe the correct polarity of the connection.

The connection for the channels is made in the terminals in accordance with the figure at

the left. Please observe the correct polarity of the connection.

NOVUS AUTOMATION www.fieldlogger.net 13/103

CONNECTIVITY RESOURCES

USB Connection

Fig. 20 - FieldLogger connectivity resources

PC Connection

SD card connection

Ethernet

Interface used for a USB drive connection, for downloading data from the logging memory.

Interface used for connection to a computer for configuration, monitoring or data download.

Interface used for SD card expansion. The data from the logging memory can be transferred

by any of the interfaces to the configuration software, which allows the exportation for the

most diverse data formats.

Interface used for Ethernet 10/100 communication. It is recommended to use a category 5 (or

better) cable in a RJ45 connector.

The Ethernet connector of the FieldLogger has two LEDS for luminous indication: the green

LED (on the left side) lights indicating the connection to the Ethernet network; the yellow LED

(on the right side) flashes indicating that there is data traffic in the interface.

DB9 connection for HMI (Optional)

Connection for installation of HMI (Human–Machine Interface) of the FieldLogger for

indication of signals measured in the process. From firmware version 1.20 on, it can be used

as a generic RS485/Modbus RTU (slave) port.

NOVUS AUTOMATION www.fieldlogger.net 14/103

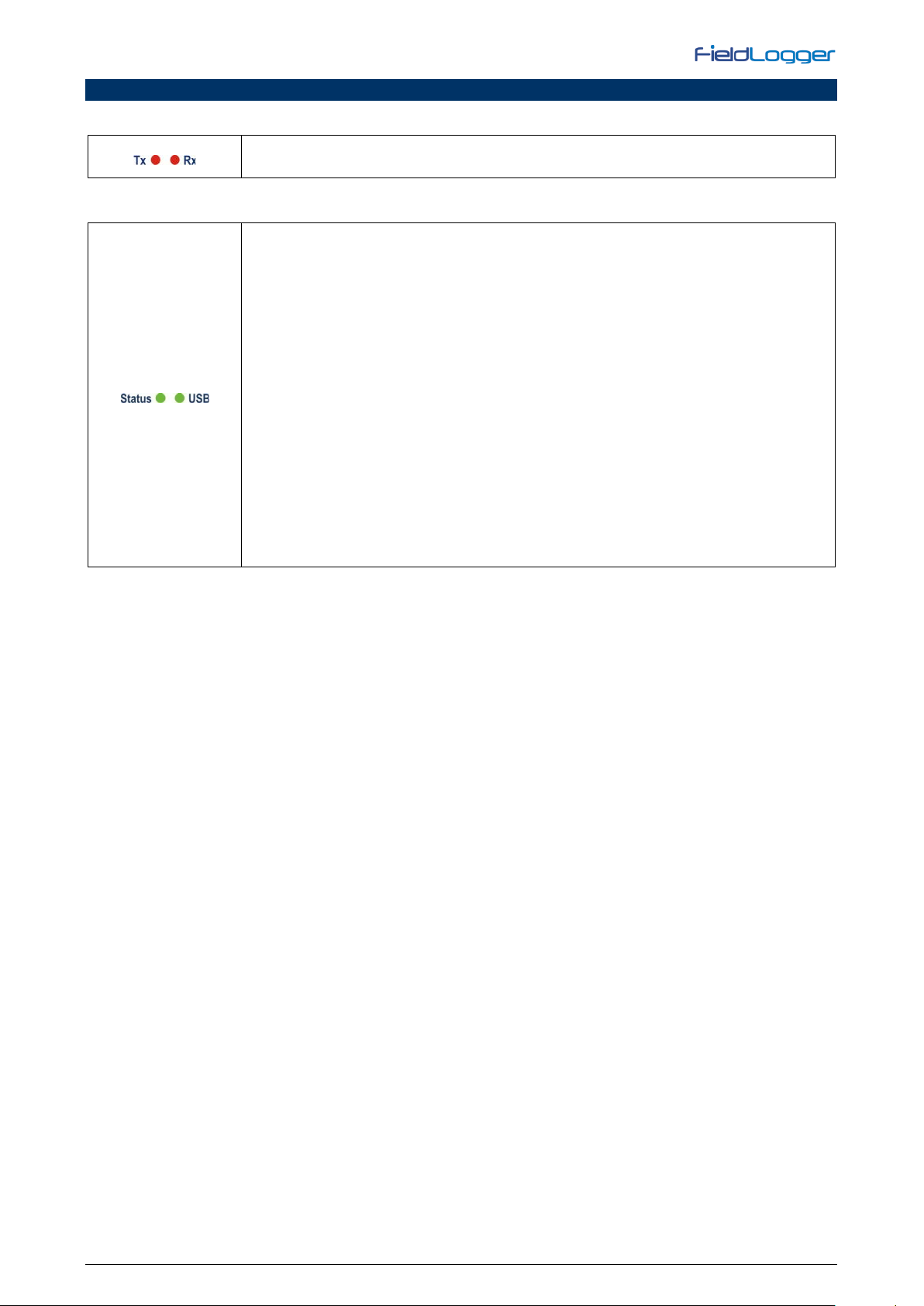

FLAGS (LEDS)

cable is connected in the USB device or while the

drive with insufficient writing space,

drive not compatible

Tx/Rx flags

Status / USB flags

They signal transmission and reception of data by the RS485/Modbus interface, regardless if

it is configured to operate in master or slave mode.

When connecting the equipment, both LEDs flash two times and remain off until all the

initialization has been completed.

The Status flag remains ON in normal condition. When it is logging, flashes 2 times at 3

second intervals. In error cases, this LED will be flashing 3 times at 8 second intervals.

In the error cases, please check if the clock of the FieldLogger has the correct date and

time. If they are wrong, probably the battery of the clock has run low and needs to be

replaced. If it is OK, try rebooting the machine by turning off its power supply and restarting it

after 10 seconds. If the LED continues to indicate an error, there may be something wrong

with your FieldLogger.

The USB flag remains ON only while a

USB flash drive is plugged into the USB host interface. The following exceptions are:

• Download errors via USB flash drive: flash

inability to write in the flash drive (write protected) or flash

(sector different from 512 bytes, for example), the USB LED flashes while the error

conditi on rem ains (t ypica lly, un til t he flash drive has been removed). Check the "USB

Interface" section in the chapter "FieldLogger Operation" for more details.

• At the end of the download, if everything is correct, the USB flag remains ON until the

flash drive has been removed from the equipment.

NOVUS AUTOMATION www.fieldlogger.net 15/103

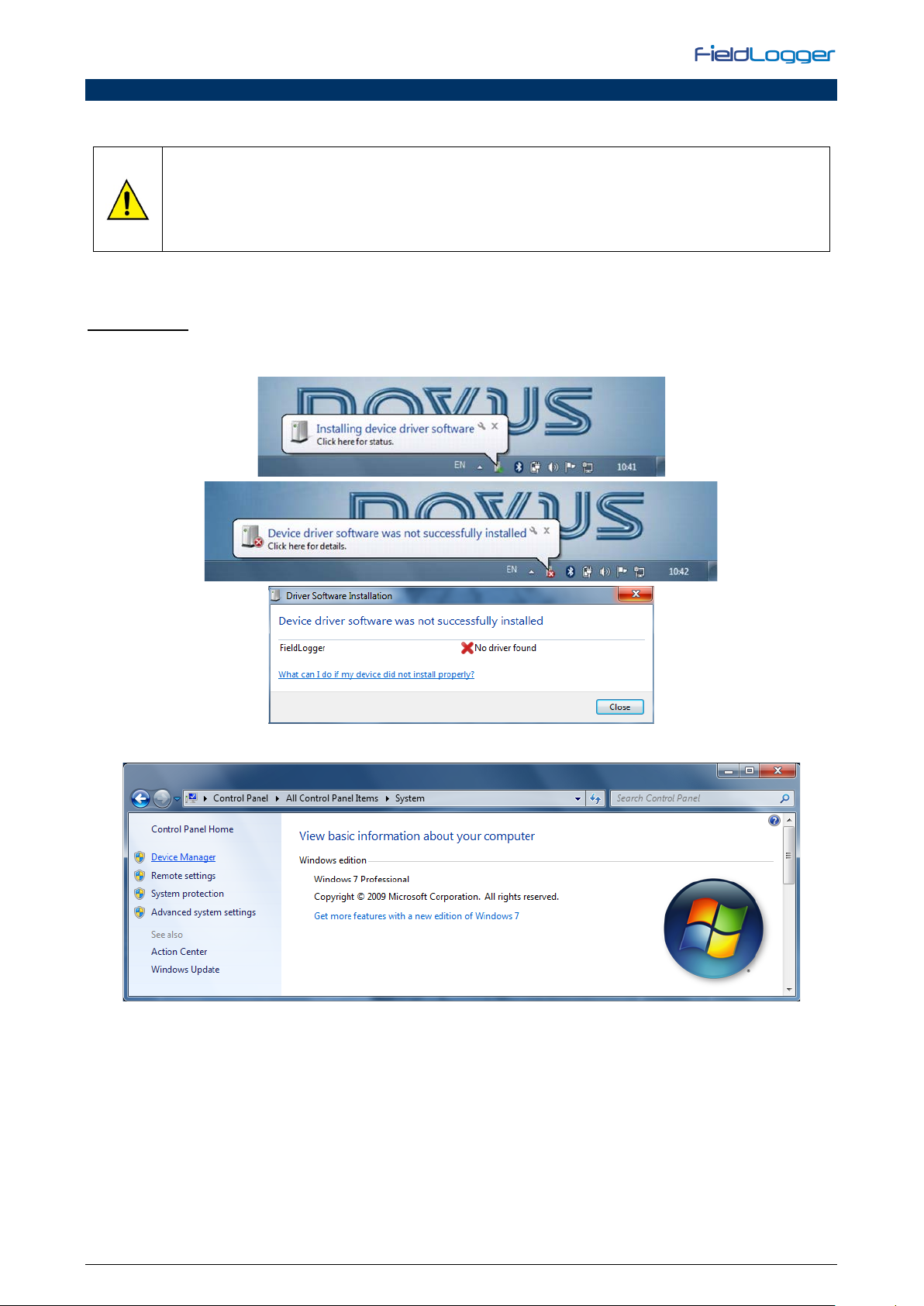

INSTALLING THE USB DRIVER

Windows 8 (64 bits) does not allow the installation of drivers that are not “digitally signed” by Microsoft.

When installing the configuration software, the USB driver is automatically installed. If you need to install the driver

without depending on the software, this can be done by following the procedure described below.

Thus, before installing the USB drivers of the FieldLogger, the following script should be followed:

1. During the boot, you should press the F8 key to enter the Start-up Configurations.

2. Pressing the F7 key, you can disable the Imposition of the Driver Signature.

3. Windows 8 will now allow you to install the USB driver for FieldLogger.

The following installation steps may vary from PC to PC, even for the same operating system version. The steps and

screens that follow below are only for guidance purposes.

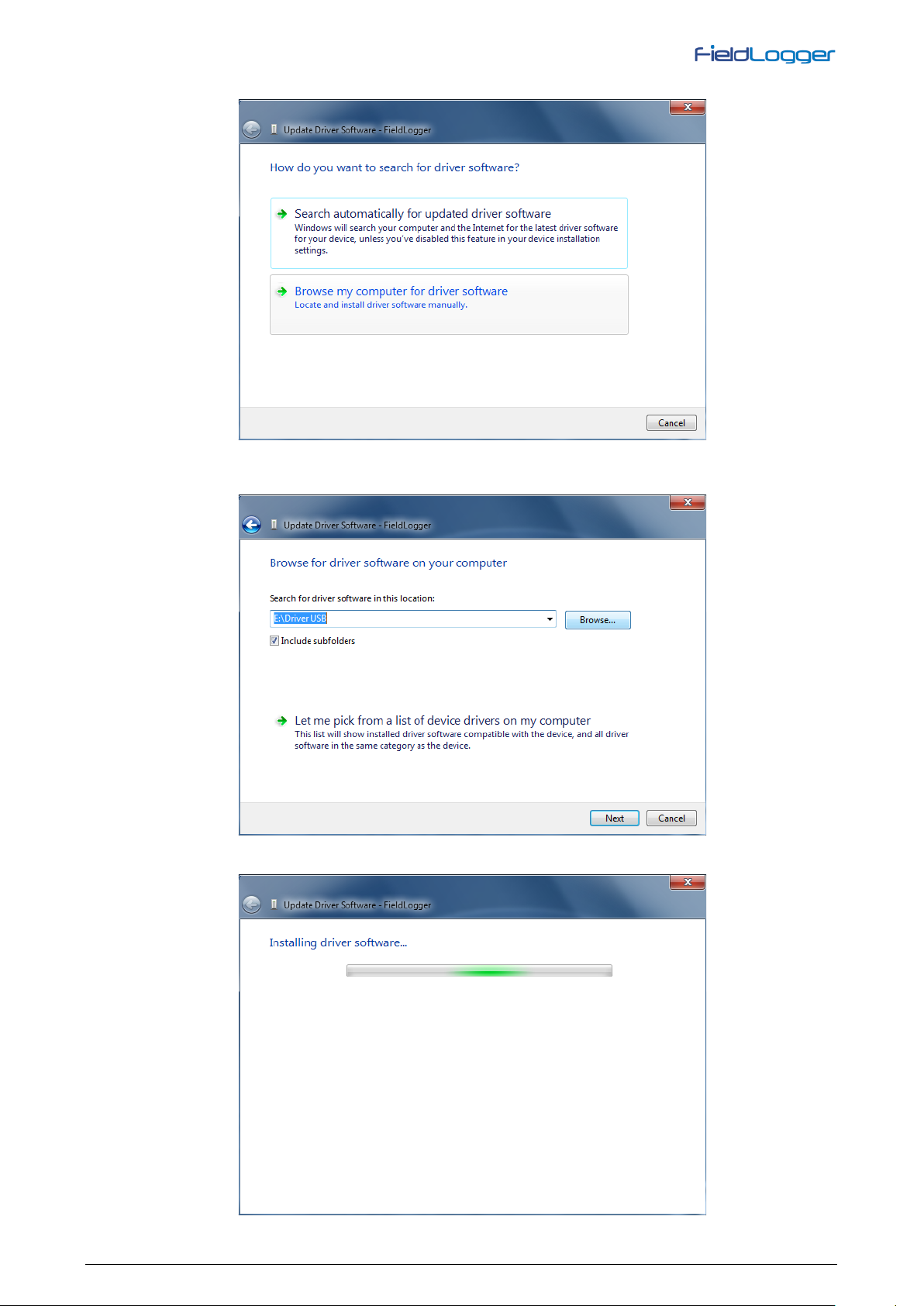

WINDOWS 7

1. Connect FieldLogger in a USB port on your computer. Windows will try to install a driver automatically and will not

succeed, because the necessary driver is not in its standar d librar y .

2. Click on "Start>> Control Panel". Click on "System" and, later on, on the "Device Manager".

NOVUS AUTOMATION www.fieldlogger.net 16/103

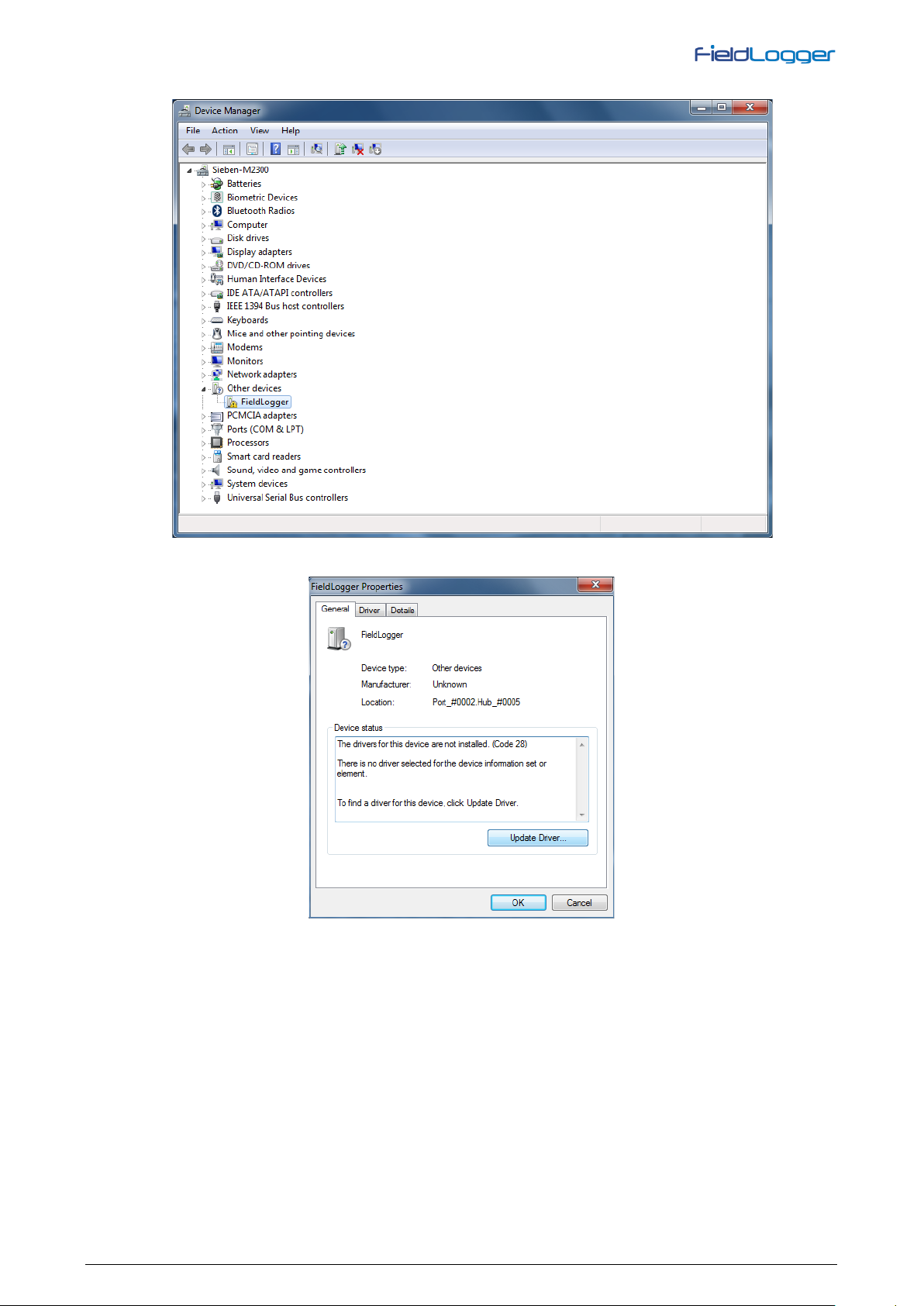

3. Locate the FieldLogger (probably with an icon with an exclamation mark next to it) and double-click on it.

4. Click on the button "Update Driver...".

NOVUS AUTOMATION www.fieldlogger.net 17/103

5. Ask to "Browse my computer for driver software".

6. Enter the path of the folder where the drivers are located (the product CD or folder where you saved them when

downloaded from the site.)

7. Wait for the installation to take start.

NOVUS AUTOMATION www.fieldlogger.net 18/103

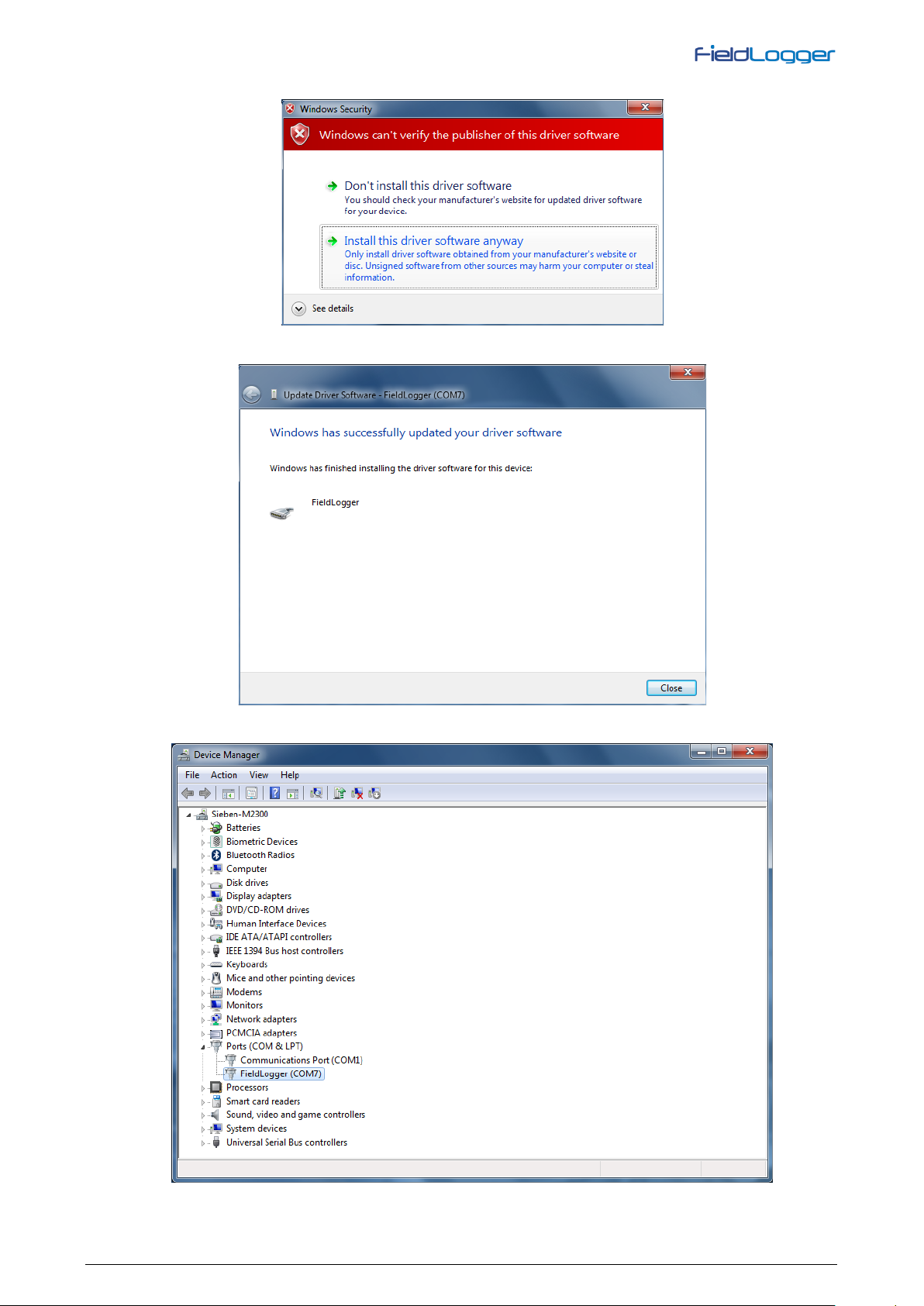

8. Windows will indicate that it cannot verify the editor of this driver. Confirm to install anyw ay!

9. A message indicating successful installation will display.

10. Returning to the Device Manager screen, you can check which virtual serial port is allocated to the FieldLogger.

NOVUS AUTOMATION www.fieldlogger.net 19/103

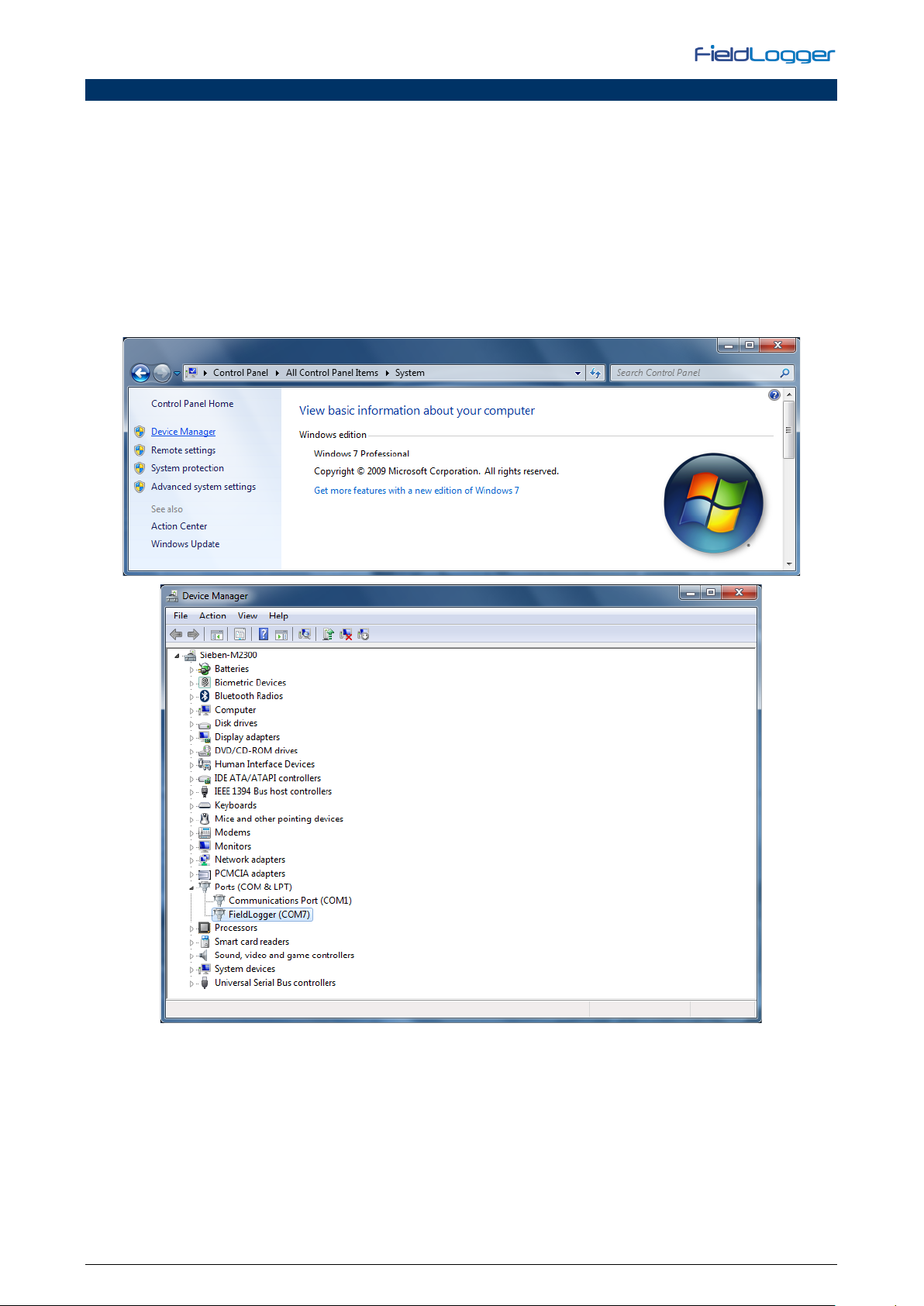

DEFINITION AND SELECTION OF SE RIAL PORT (COM) - WINDOWS

The serial port associated with FieldLogger is automatically defined by the operating system a few moments after

connecting the FieldLogger. The user can easily identify or change the COM port associated with FieldLogger:

Control Panel / System / Hardware / Device Manager / COM & LPT Ports

Select the device "USB Serial Port" corresponding to the FieldLogger and click on "Properties". Select "Port Settings"

guide and click on "Advanced". In the "COM Port Number", select the serial port to be associated with FieldLogger.

Some serial ports can be checked while being used (In Use). Just select one of these ports if you know that it is not

being used by another peripheral device on your computer .

In some cases, the serial ports can be checked as in use even when the associated device is no longer installed on your

computer. In this case it is safe to associate this port to FieldLogger. The following figure presents the view of the device

manager containing a FieldLogger, and the screens showing the property screens where you can reset the associated

COM port.

NOVUS AUTOMATION www.fieldlogger.net 20/103

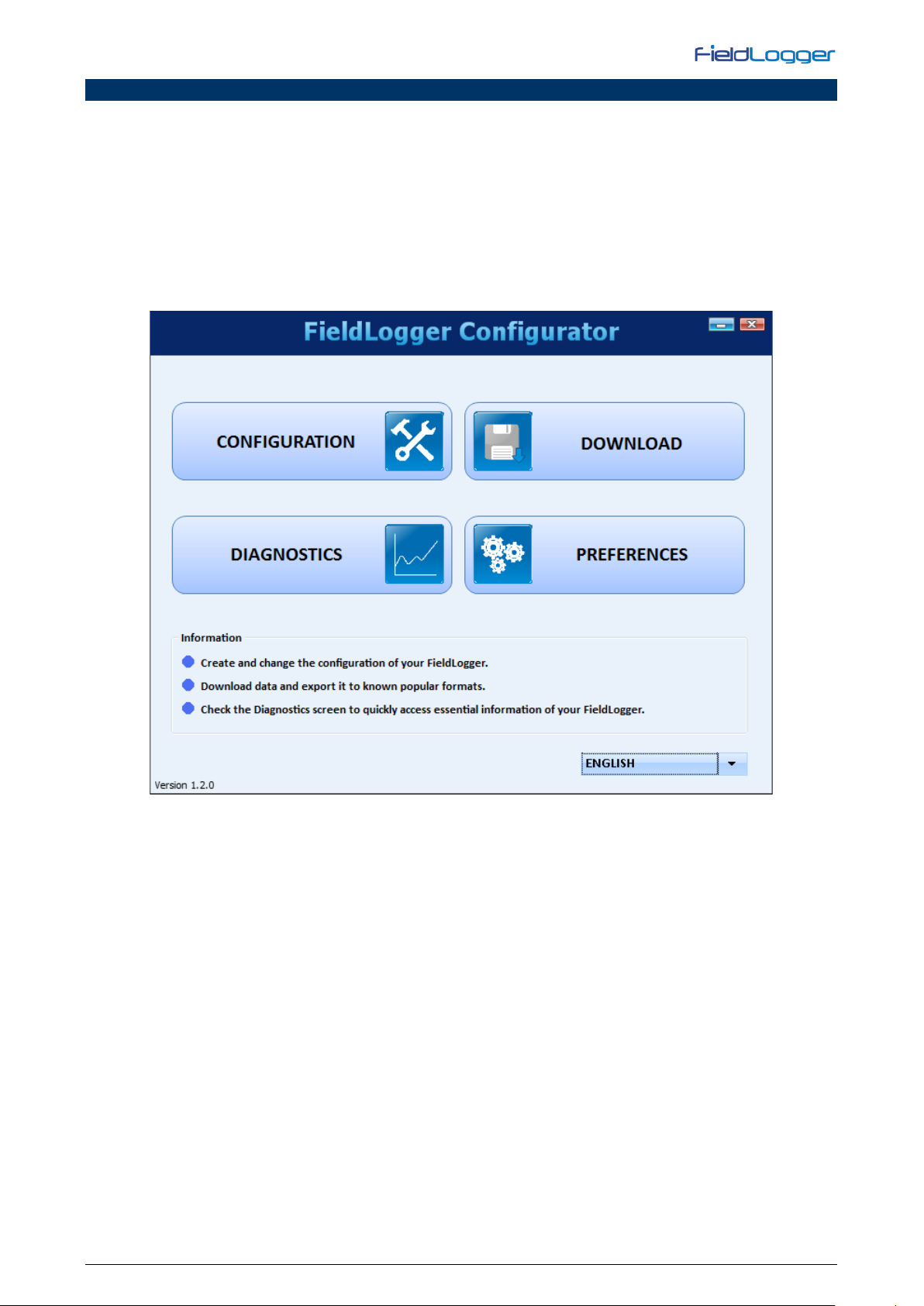

CONFIGURATION AND DATA DOWNLOAD SOFTWARE

The configuration software (Configurator) allows you to configure FieldLogger, download and export logging data and

read input channels and status information. This chapter is intended to show and explain software usage. The use of

FieldLogger with all its features will be detailed in the chapter "FieldLogger Operation”.

On the main screen, you should choose the function that you want to run, as it is shown below:

• Configuration: Allows you to change the FieldLogger configuration.

• Diagnostics: Allows you to read the values of the enabled channels, the status of configured alarms and general

information and device status.

• Download: Allows you to perform data download of FieldLogger logging memory, view and export them in

various formats.

• Preferences: It allows modifying some software options.

NOVUS AUTOMATION www.fieldlogger.net 21/103

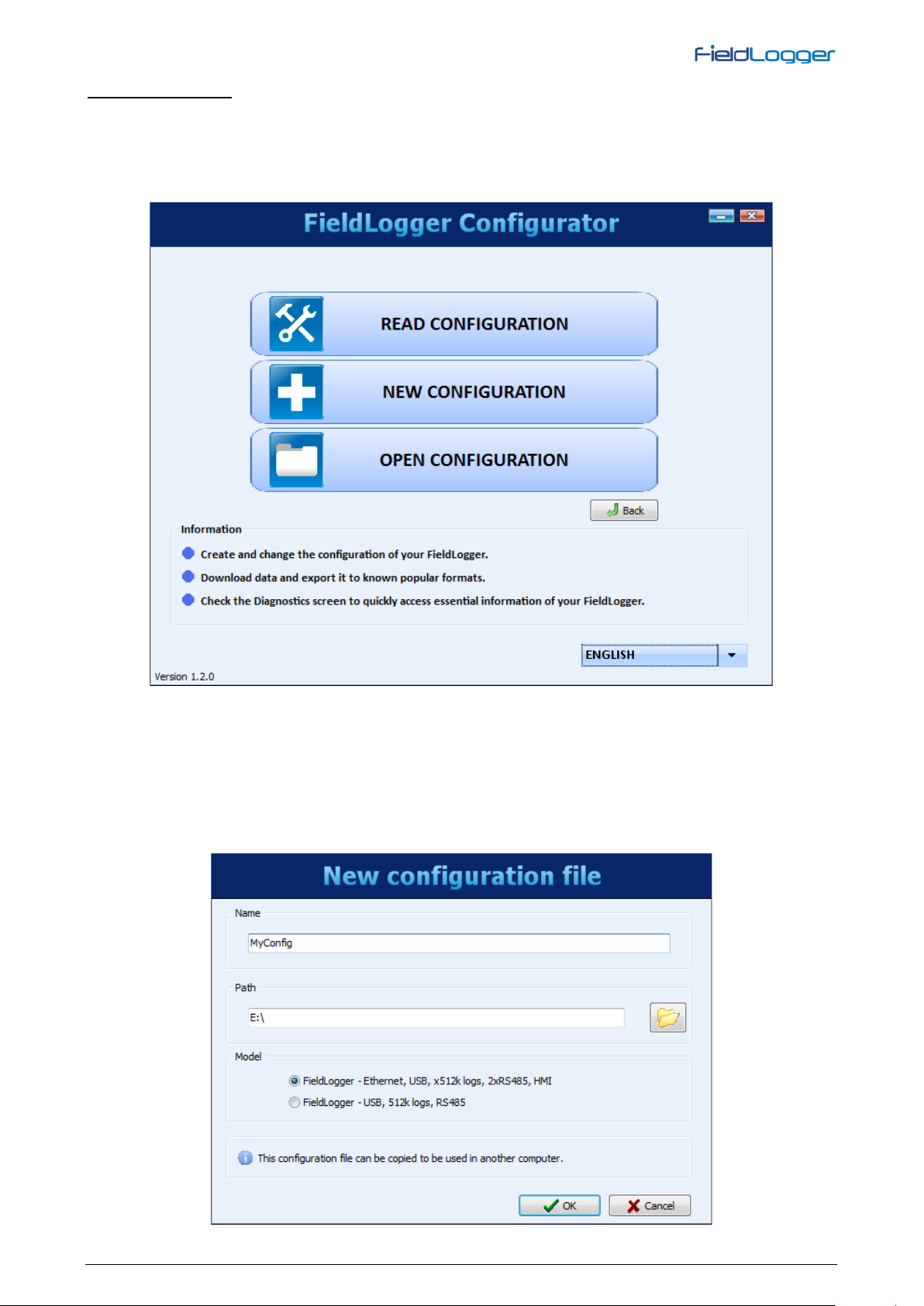

CONFIGURATION

On the configuration screen, you can select one of the following options, as they are described below:

• Read Configuration: Rea ds th e current conf iguration of a FieldLogger.

• New Configuration: Creates a configuration from the scratch.

• Open Configuration: Loads the previously configuration saved to a file.

If the chosen option was to create a new configuration, you must specify a file where this configuration will be saved.

Besides that, from software version 1.40 on, you must select which FieldLogger model you are about to configure (power

– normal or 24 V – does not care on this case):

• Complete model, with Ethernet, USB, expansible memory using an SD Card and a second RS485 interface

ready to accept an optional HMI.

• Model with USB but no Ethernet, non-expansible memory (internal flash only – no SD Card) and only one

RS485 interface.

NOVUS AUTOMATION www.fieldlogger.net 22/103

Once the configuration has been loaded into the software (originated from a device, a file, or simply created from the

scratch, according to the selected option), then one should make the desired configuration. For this, there is a sequence

of screens with various parameters arranged by functionality.

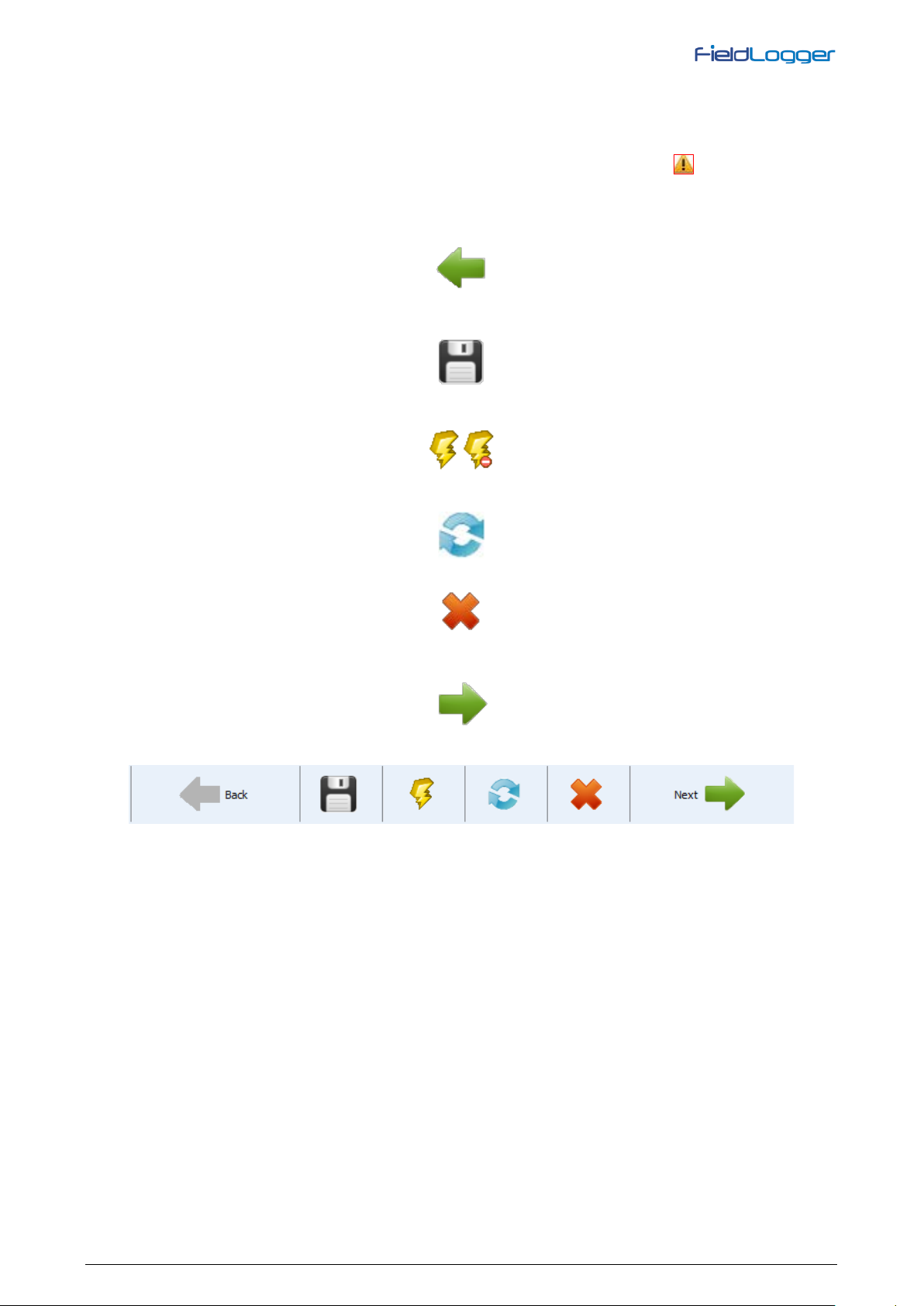

Each time you try to move onto the next screen (via the "Next" button), a check of the configured parameters is done. In

case there is any problem with any parameter, an error window is displayed and the symbol " ” shows up next to the

field that may not be consistent with other previous settings.

The icon bar at the bottom of the window has icons for the following functions, as they are described below:

• Back: It allows coming back to the previous configuration screen.

• Save: Saves the current configuration to a file. If a file has not yet been associated with this configuration, it

opens a dialog screen for the user to choose the name and location of the file.

• Connection: Allows the connection to the equipment (opens a window for the interface selection) when it is

disconnected and the disconnection when it is connected.

• Load Screen Initial Configuration: Undo the changes introduced by the user, returning to the initial configuration

of the current screen.

• Cancel: Closes the current configuration.

• Next: Performs the settings check of the current configuration screen and, if everything is OK, goes to the next

screen.

Icon toolbar

NOVUS AUTOMATION www.fieldlogger.net 23/103

GENERAL CONFIGURATIONS

The first screen shows some general parameters of configuration for the FieldLogger:

• Tag (name) to be given to the equipment (maximum of 16 characters).

• When using a HMI with the FieldLogger, please indicate the level of access that the operator will get through the

HMI:

o No HMI access: Prevents the use of the HMI, because no parameter can be viewed by it in this

FieldLogger.

o Parameters reading: HMI can be used only to view the channels and status of the FieldLogger, not

allowing any type of configuration.

o HMI configuration and overall reading: HMI can have its own parameters configured, besides viewing

the channels and status of the FieldLogger.

o Overall configuration and reading: HMI can be used to configure parameters (its own and some of

FieldLogger), in addition to viewing the channels and status of the FieldLogger.

• Enabling data download by using a USB flash drive: it enables or disables the data download by using a USB

flash drive. When enabled, it also indicates the priority in case of a USB flash drive without enough space to

download all demanded data: more recent data or older data. In addition, you can configure the number of days

(from the day of download, if the priority is the latest, or from the oldest data, if the priority is the oldest) that you

want to download. Becau se of the fact that we do not make a copy of all data from the equipment’s memory

(which, in the case of SD cards, can be a lot of data), this can accelerate download time significantly.

General Configurations

NOVUS AUTOMATION www.fieldlogger.net 24/103

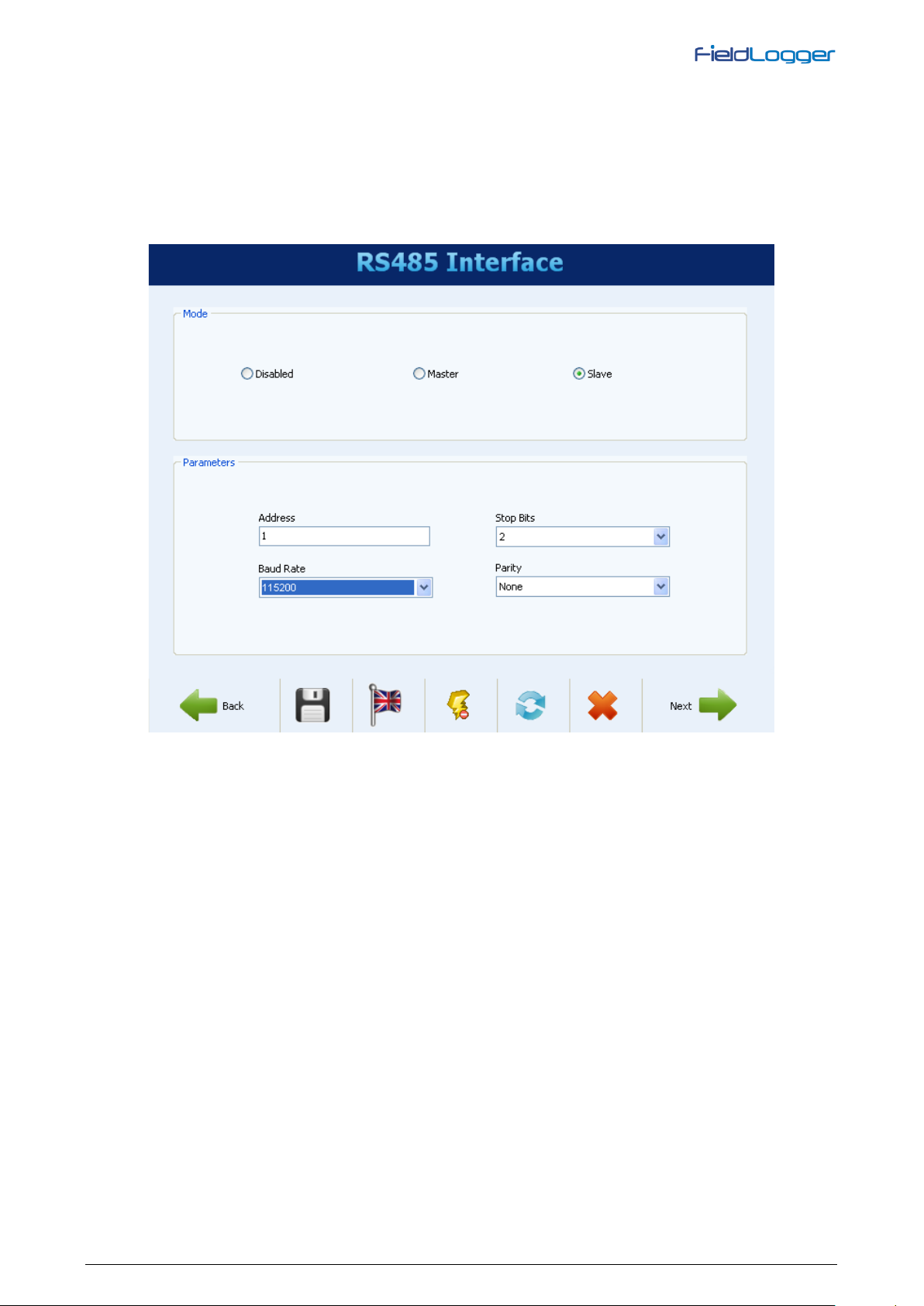

RS485 INTERFACE CONFIGURATION

Next configuration screen is the RS485 Interface screen. On this screen, you should choose the type of behavior of this

interface: whether it will be a Modbus RTU slave, a Modbus RTU master or it shall not be used at all. It is recommended

to disable the interface if it is not used.

When it is used as a slave, you must configure your Modbus address, the baud rate, parity and number of stop bits.

When it is used as a master, it is not necessary to configure the Modbus address (only valid for the slaves). Moreover, in

this case, the configuration of Modbus network, where it says which registers are read from what slaves, will be carried

through later on, on the Remote Channels screen.

Interface RS485

NOVUS AUTOMATION www.fieldlogger.net 25/103

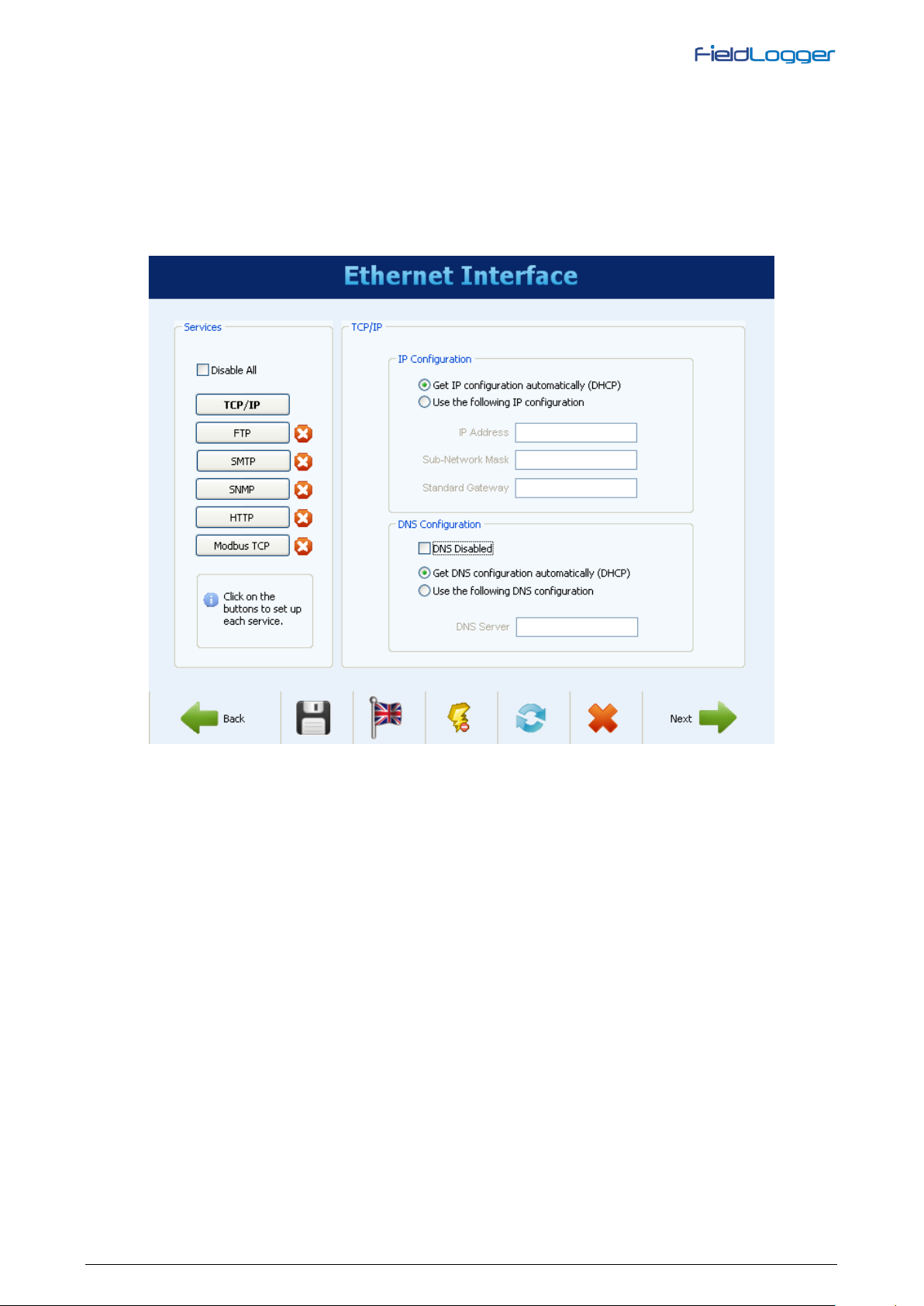

ETHERNET INTERFACE CONFIGURATION

The configuration of the Ethernet interface should be carried through on the next screen. If it is desired not to use this

interface, it is recommended to disable it, as shown in the following figure.

Disabled Ethernet Interface

NOVUS AUTOMATION www.fieldlogger.net 26/103

ETHERNET INTERFACE CONFIGURATION - TCP/IP

Once the interface is enabled, the buttons on the left allow you to enable and configure each of the services offered by

this interface. The icon on the right of each button shows whether the related service is enabled or not.

The first configuration to be made is the selection of using fixed IP or DHCP and, in the case of fixed IP, to choose the

parameters relating to it, such as FieldLogger IP, the subnet mask and default gateway.

Moreover, we must choose whether or not to use DNS, which can be used to connect to the e-mail server or FTP server

(when FieldLogger is the FTP client for the daily download of data through this service). If so, you must configure the

DNS server's IP number or, if the DHCP option has been selected, you can choose to search for the DNS server’s IP

from the DHCP server.

Ethernet Interface - TCP/IP Configuration

NOVUS AUTOMATION www.fieldlogger.net 27/103

ETHERNET INTERFACE CONFIGURATION – FTP

The FTP button allows you to configure the options related to the FTP services. There are two types of FTP related

functionality to choose from in the FieldLogger: client and server.

As a server, FieldLogger allows for an external client to connect to it in order to download logged data, both from the SD

card as well as from the internal memory. For this, you must configure the connection and access data, like user name

(maximum of 10 characters), password (maximum of 10 characters) a nd port for the con ne c tion.

As a client, it can automatically connect to an FTP server to send data from its logging memory (internal or SD card).

This can either be done once a day at a set time, or many times a day (from firmware version 1.50 on) in a configurable

time interval. This way, you must configure the access parameters so FieldLogger will be able to access the server, like

user (maximum of 50 characters) and password (maximum of 10 characters), in addition to the IP address or server

name (in case you enabled the DNS – name being up to 50 characters) and the server’s port. Besides that, since

firmware version 1.40, you can configure the format of the file created by the download: binary (standard) or CSV

(comma separated value) and also select the option that deletes the logging files after the download (valid only when

logging into an SD card).

Ethernet Interface - FTP Configuration – Example 1

NOVUS AUTOMATION www.fieldlogger.net 28/103

Ethernet Interface - FTP Configuration – Example 2

NOVUS AUTOMATION www.fieldlogger.net 29/103

ETHERNET INTERFACE CONFIGURATION - SMTP

The SMTP button opens the parameters related to sending e-mails. The FieldLogger allows, in situations of alarm or

event, e-mails to be sent to multiple receivers. On this screen, the parameters related to the access to the e-mail server

must be configured, such as its IP address or server name (in case you enabled the DNS – name being up to 50

characters), in addition to the user ( max imum of 50 characters) and password (maximum of 12 characters).

Finally, you must configure the parameters of the e-mail to be sent in case of an alarm event. Th is e-mail has a subject

(maximum of 32 characters) and has a part of the message body that is user defined (up to 64 characters) and that is the

same for all alarms or events. The e-mail of the sender (maximum of 50 characters) and the e-mails of the receivers

(maximum of 50 characters for each one) must als o be configured.

Ethernet Interface - SMTP Configuration

ETHERNET INTERFACE CONFIGURATION - E-MAIL RECEIVERS

For the insertion of the of e-mail receivers, you should click on the button "Edit Lis t". A new window will open, allowing for

the inclusion and removal of e-mails from the receivers list. All potential receivers of alarm or event e-mails must be

included in this window. The decision of which alarms or events will be sent to which receivers will be made later, on

alarms configuration screen!

Ethernet Interface - Configuration of E-mail Receivers

NOVUS AUTOMATION www.fieldlogger.net 30/103

Loading...

Loading...