NOVUS TxIso Rail User Manual

MECHANICAL INSTALLATION (TXISORAIL-HART)

SENSOR TYPE

MEASUREMENT RANGE

MINIMUM MEASUREMENT

SPAN:

Thermocouple B

0 to 1820 °C

500 °C

Thermocouple E

-270 to 1000 °C

50 °C

Thermocouple J

-210 to 1200 °C

50 °C

Thermocouple K

-270 to 1372 °C

50 °C

Thermocouple N

-270 to 1300 °C

50 °C

Thermocouple R

-50 to 1768 °C

500 °C

Thermocouple S

-50 to 1768 °C

500 °C

Thermocouple T

-270 to 400 °C

50 °C

Pt100

-200 to 850 °C

20 °C

Pt500

-200 to 250 °C

20 °C

Pt1000

-200 to 250 °C

40 °C

Cu50

-50 to 150 °C

40 °C

Cu100

-50 to 150 ºC

40 °C

* Ni100

-60 to 180 °C

50 °C

* Ni500

-60 to 180 °C

20 °C

* Ni1000

-60 to 150 °C

20 °C

Resistance

0 to 400 Ohms

20 Ohms

Resistance

0 to 2000 Ohms

20 Ohms

Voltage

-10 to 75 mV

20 mV

Voltage

-100 to 100 mV

20 mV

Voltage

-100 to 500 mV

20 mV

Voltage

-100 to 2000 mV

20 mV

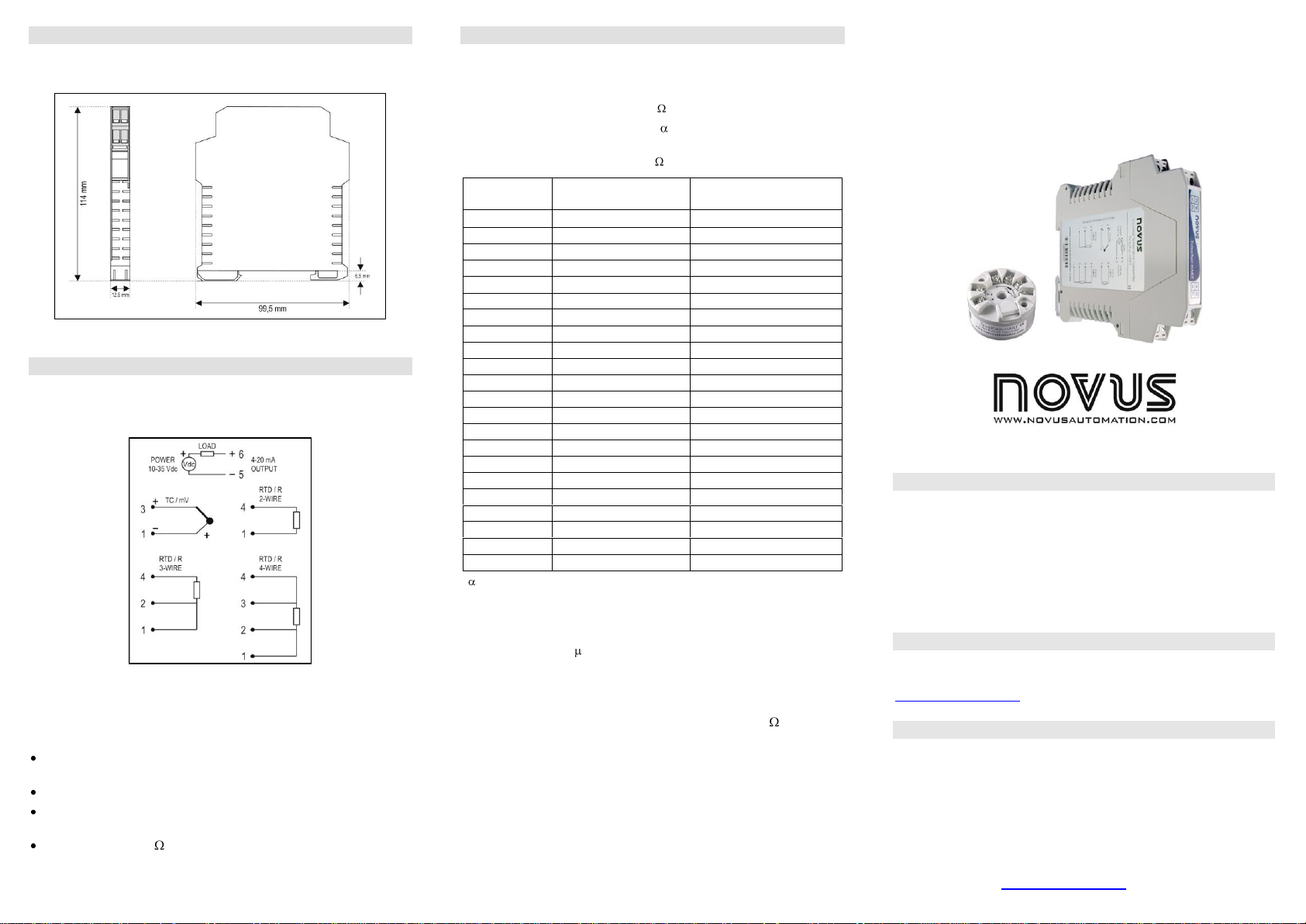

The TxIsoRail-HART is meant for DIN rail mounting. Its dimensions are drawn in

Figure 05 below.

SPECIFICATIONS

Sensor input: Configurable. The supported sensors are listed Table 01, along with

their corresponding ranges.

Thermocouples: Types B, E, J, K, N, R, S and T to IEC 60584

Impedance >> 1 M

Pt100: Excitation 0.35 mA = 0.00385, according to IEC 60751

Voltage: 0 to 50 mVdc

Impedance >> 1M

TxI s o P a c k - HART a n d

TxI s o R a i l - HART

O P E R A T I N G M A N U A L

Figure 05 – Transmitter dimensions TxIsoRail-HART

ELECTRICAL INSTALLATION (TXISORAIL-HART)

The Figure 06 shows the electrical connections required. The TxIsoRail-HART

wiring for thermocouple, RTD, resistance and voltage are done according to the

figure below.

Figure 06 – TxIsoRail-HART transmitter electrical connections

LOAD represents the 4-20 mA current measuring device (indicator, controller,

register, etc.).

Recommendations for Installation

Input signal conductors should run away from power and contactor wires, if

possible, in grounded conduits.

The instruments must be powered by a suitable network for instrumentation.

System failure should always be taken into account when designing a system to

avoid irreversible damage to equipment or people.

Installing RC filters (47 and 100 nF, in series) is strongly recommended at

contactor coils or any other inductors.

Man 5001552

SAFETY INFORMATION

Any control system design should take into account that any part of the system has

the potential to fail. This product is not a protection or safety device and its alarms

are not intended to protect against product failures. Independent safety devices

should be always provided if personnel or property are at risk.

Product performance and specifications may be affected by its environment and

* = 5000 ppm/K or 6180 ppm/K

Table 01 – Transmitter sensor list

Output: 4-20 mA, 2-wire, loop powered;

Output Resolution: 0.3 A (12 bits);

Total Accuracy: Maximum error 0.3 % of the maximum range for thermocouples;

0.2 % of the maximum range for Pt100;

Power Supply: 10.5 to 35 Vdc (voltage across the transmitter);

Maximum Load (RL): RL (max. in Ohms) = (Vdc – 10.5) / 0.022 A [ ];

Where: Vdc= Power supply in Volts;

Operating Temperature: -40 to 85 °C;

Humidity: 20 to 90 % HR;

Electromagnetic Compatibility: EN61000-4-2, EN61000-4-3, EN61000-4-4,

EN61000-4-6;

Internal protection against polarity inversion in the loop voltage.

Cold junction compensation for thermocouples. Galvanic isolation.

Recommended wire gauge: 0.14 a 1.5 mm². Torque: 0.8 Nm.

installation. It’s user’s responsibility to assure proper grounding, shielding, cable

routing and electrical noise filtering, in accordance with local regulations, EMC

standards and good installation practices.

SUPPORT AND MAINTENANCE

This product contains no serviceable parts inside. Contact our local distributor in

case you need authorized service. For troubleshooting, visit our FAQ at

www.novusautomation.com.

LIMITED WARRANTY AND LIMITATION OF LIABILITY

NOVUS warrants to the original purchaser that this product is free from defects in

material and workmanship under normal use and service within one (1) year from

the date of shipment from factory or from its official sales channel to the original

purchaser.

NOVUS liability under this warranty shall not in any case exceed the cost of

correcting defects in the product or of supplying replacement product as herein

provided and upon the expiration of the warranty period all such liability shall

terminate.

For complete information on warranty and liability limitations, check appropriate

section in our web site: www.novusautomation.com.

INTRODUCTION

The temperature transmitters TxIsoPack-HART (head mount) and TxIsoRail-HART

(DIN rail mount) are programmable devices that can be configured to work in a

variety of industrial processes. The input sensor can be configured to accept RTDs,

thermocouples, resistance and mV. They convert the sensor signal into a 4-20 mA

output proportional the measured value.

These transmitters offer digital communication by means of the HART protocol,

through which the transmitter configuration and input monitoring can be accessed.

In this protocol, the digital communication is superimposed to the current loop.

The input and output in the TxIsoPack-HART and the TxIsoRail-HART are

electrically isolated, enhancing their performance and electromagnetic immunity.

CONFIGURATION

If the transmitter is already configured to the application, it can be installed

immediately. However, if a change in the configuration is required, this can be

accomplished with the TxConfig software and then sent to the transmitter via the

TxConfig-HART Interface connected to the PC USB port.

The TxConfig-HART Interface and software TxConfig consists of the Transmitter

Configuration Kit which can be ordered from the manufacturer of its authorized

representatives. The latest release of this software can be downloaded from our

web site. To installing, run the Tx_setup.exe file and follow the instructions.

The interface connects the transmitter to the computer, as shown in Figures 01 and

02:

After the connections are made, the user must run the TxConfig software and, if

necessary, use the Help topic to configure the transmitter.

The fields in this software have the following purposes:

1. Sensor: Sets the sensor to be used. See Table 01.

2. Measure: Sets the transmitter measurement range (minimum and maximum

values).

When the Lower Limit is set with a value higher than the Upper Limit value, the

output current operates between 20 and 4 mA

The values chosen cannot exceed the Sensor Range shown in this same field,

and also may not establish a range with width (span) smaller than the Minimum

Range indicated later in this same field. See Table 1 of this manual.

3. Filtering: Filters the measurements made by the transmitter eliminating

interferences from the electrical system that feeds the process.

4. Failure: Establishes the behavior of the output when problems are present by the

sensor. When Minimum is selected, the output current shifts to < 4 mA (down-

scale), typically used en refrigeration. When Maximum, is selected > 20 mA (upscale), typically used for heating.

5. Zero Correction: Corrects minor errors presented by the transmitter, for

example, when the sensor is changed. See item Operation in this manual.

6. Transmitter Information: In this field, there are data that identify the transmitter.

This information must be informed in any consultation with the manufacturer.

7. Send Configuration: When selected, this allows one to send the configuration to

the transmitter connected.

8. Read Configuration: When selected, this allows one to read the configuration on

the transmitter connected.

Note: If on the purchase order the user does not define a specific configuration, the

following configuration will be set:

Pt100 sensor, range 0 to 100 °C, 0 °C zero correction.

Filter to 2 A and maximum output for sensor failures.

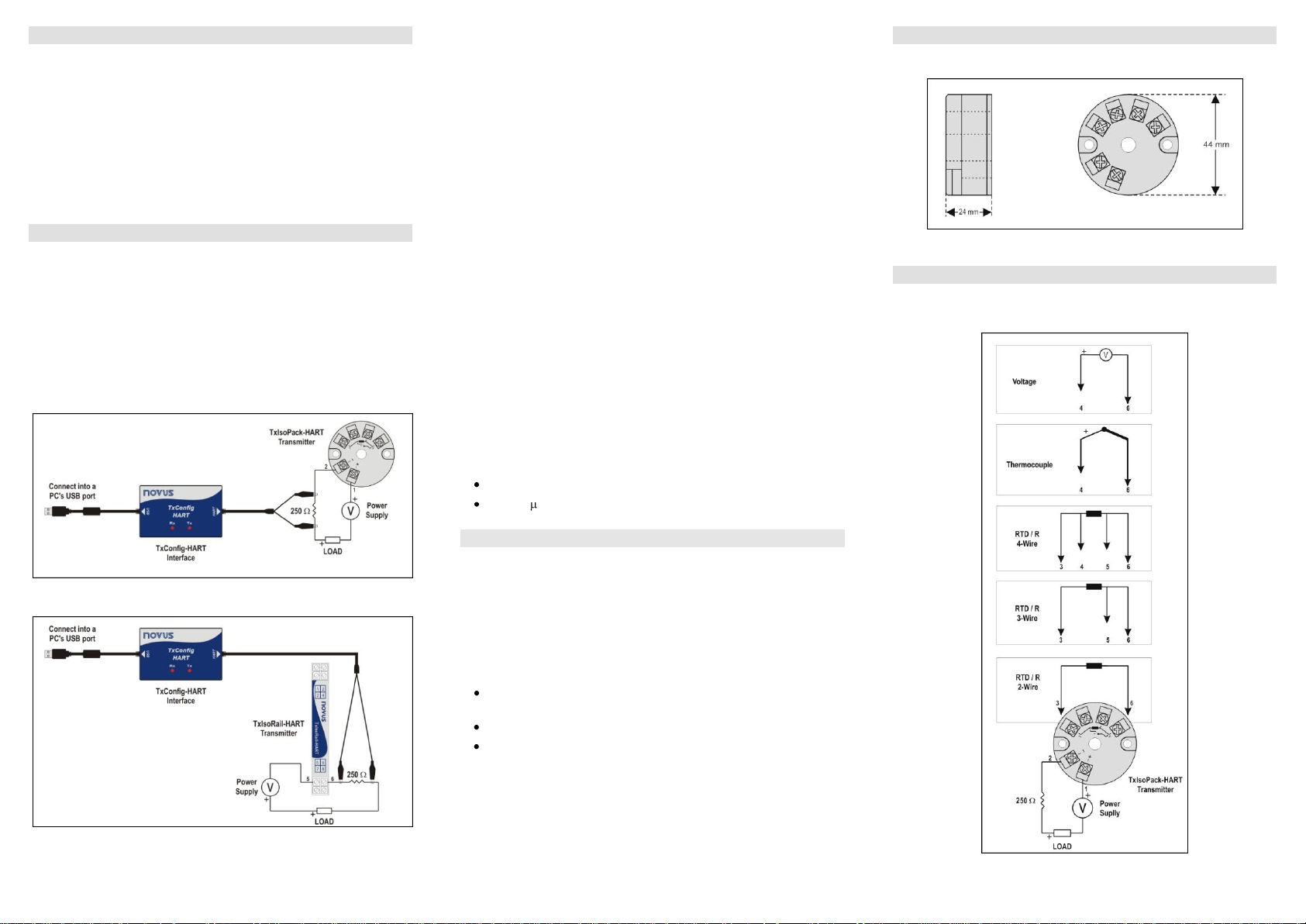

MECHANICAL INSTALLATION (TXISOPACK-HART)

The TxIsoPack-HART is designed for head mounting.

Figure 03 –TxIsoPack-HART dimensions

ELECTRICAL INSTALLATION (TXISOPACK-HART)

Refer to the Figure 04 below for the transmitter required connections (loop

excitation and sensor wiring: thermocouple, RTDs, resistance or mV).

Figure 01 – TxConfig-HART interface connection to the TxIsoPack-HART

Figure 02 - TxConfig-HART interface connection to the TxIsoRail-HART

OPERATION

The transmitter is perfectly factory calibrated with standardized sensors, not

requiring any adjustment by the user.

Fine corrections can be accomplished through the TxConfig software (in units of

temperature).

The user may choose the sensor and the span that best fits its application. The

sensor span must lie within the range specified for the selected sensor.

It is important to note that the accuracy of the transmitter refers to the maximum

range of the sensor used, regardless of the actual span. Example:

The sensor Pt100 has a max. range of –200 to 850 °C and total accuracy de

0.2 %.

Thus, we can have an absolute error up to 1.7 °C (0.2 % of 1050 °C).

This error is the same no matter if total span is used (-200 to 850 °C) or a

narrower user-defined span is used, like 0 to 100 °C

Figure 04 – TxIsoPack-HART transmitter electrical connections

Loading...

Loading...