NOVUS TP510 User Manual

510

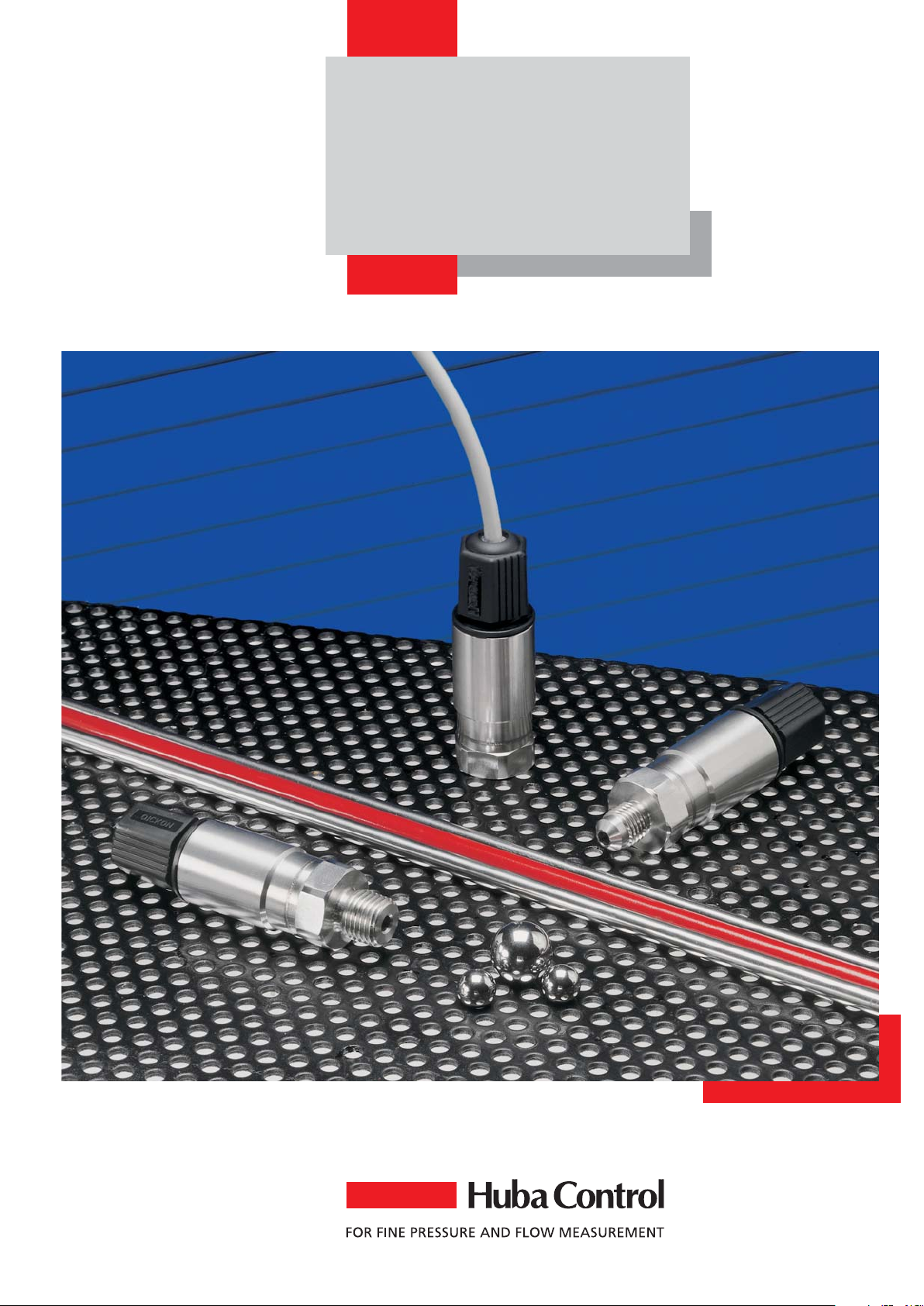

OEM

Pressure transmitter for

refrigeration technology

Relative pressure - 1 to 160 bar

EDITION 07/2004

HUBA-REGISTERED TRADE MARK

EDITION 07/2004

Dynamic response

Suitable for static and dynamic

measurements.

Response time < 2 ms

typ. 1 ms

Pressure connections

See order code selection table

Weight

Version inside thread 88 grams

Version outside thread 98 grams

Technical overview

These compact OEM pressure transmitters type 510 have been developed for applications in the industrial

refrigeration technology.

The special sensor is based on thickfilm technology, developed by Huba

Control, which utilises a special grade of steel welded to the pressure

sensor. This means that the 510 can

be used for all gases and media in

refrigeration, including ammoniac.

Highest requirements concerning

EMC and accuracy for all temperature ranges can be met in combination with the unique integrated

electronic design.

Suitable from small series to high

quantity applications with best price to performance ratio.

The distinct advantages

• Compact, rugged construction for

highest operational reliability

• Protection IP 67 standard

• Welded without sealing parts,

no elastomer-sealings

• Negligible temperature influence

on accuracy

• Excellent EMC-capacity

• Saving time by quick cable mounting

by the customer with Quickon-System

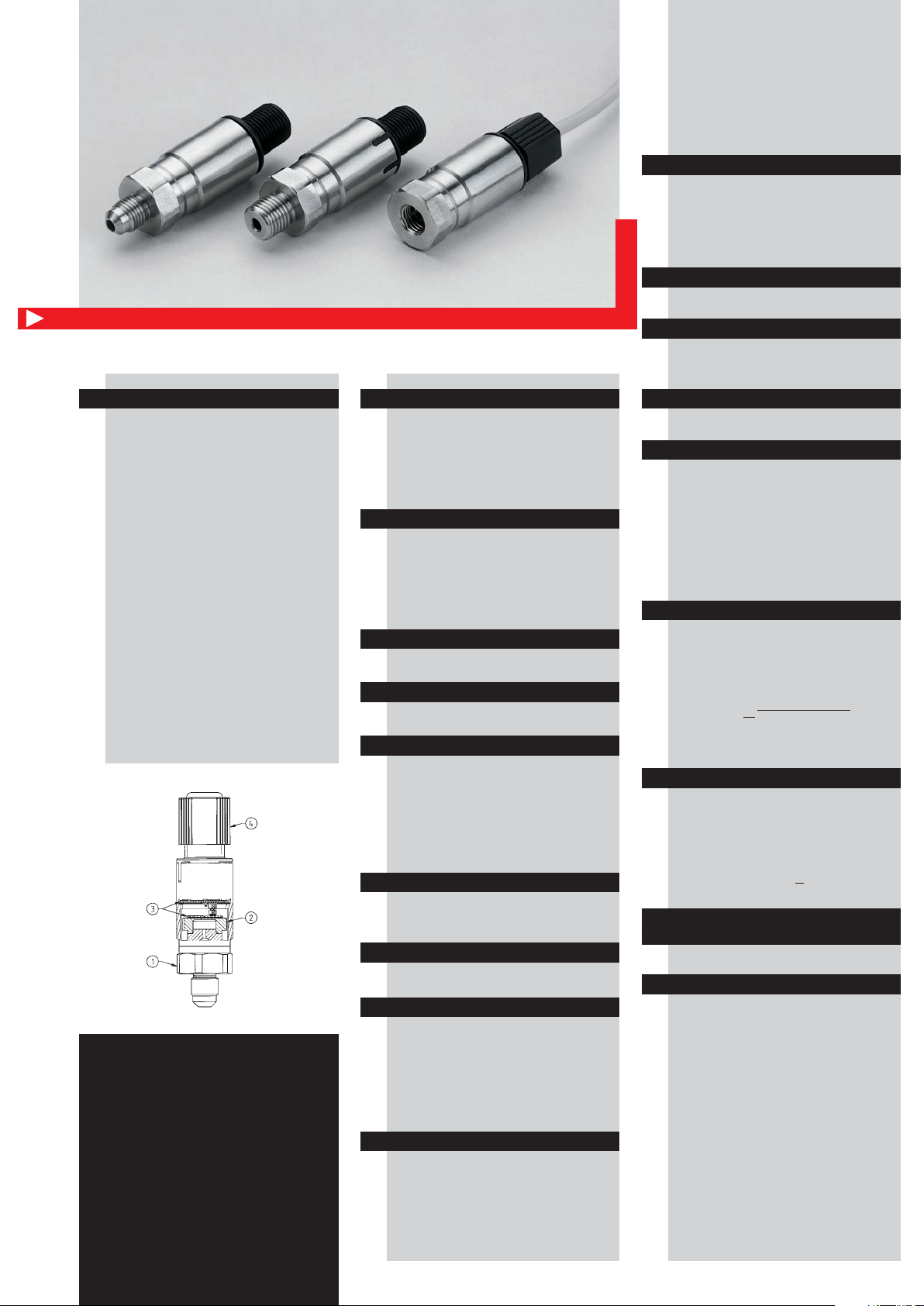

Legend to cross-section drawing

1 Connection fitting

2 Steel cell welded

3 Electronic with EMC-protection

4 Electrical connection (example

Quickon)

Pressure ranges

Relative pressure (Gage)

(differential measurement of pressure relative to ambient pressure).

Ranges see order code selection

table

Overload

3.0x Full scale

Rupture pressure

6.0x Full scale

Accuracy

Total of linearity, hysteresis and

repeatability

< +/- 0.5% fs

Adjustment accuracy zero point and

full scale

< +/- 0.5% fs

Housing material

Casing:

Stainless steel 1.4305 (AISI 303)

Materials in contact with the medium

Sensor: Stainless steel 1.4305

Application temperature

Medium temperature

- 40 … + 150 °C

Ambient temperature with

Cable 1.5 meters max. 85 °C

Quickon max. 85 °C

(temperature – 150 °C on request)

Temperature influences

TC zero point < +/- 0.03% fs/K

TC sensitivity < +/- 0.015% fs/K

temperature range - 40 … + 125 °C

Installation arrangement

Unrestricted

Outputs / Power supply

See order code selection table

• Short circuit-proof and protected

against polarity reversal. Each

connection against other with max.

+/– supply voltage.

Electric strength 500 VDC,

on request 1000 VDC

Load

0 – 5 V > 10 kOhm < 100 nF

1 – 6 V > 10 kOhm < 100 nF

0 – 10 V > 10 kOhm < 100 nF

4 – 20mA <

Supply voltage - 8 V

0.02 A

ratiometric >10 kOhm < 100 nF

Current consumption

With max. signal output:

0 – 5 V < 4 mA

1 – 6 V < 4 mA

0 – 10 V < 4 mA

4–20mA <

20 mA

ratiometric < 4 mA

Electrical connections /

Protection standard

See order code selection table

Tests

Shock acc. IEC 68-2-27

100 G, 11 ms half sine wave, all

6 directions. Free fall from 1 m on

concrete (6x).

Constant shock acc. IEC 68-2-29

40 G for 6 ms, 1000 x all 3 directions.

Vibration acc. IEC 68-2-6

20 G, 9 ... 2000 Hz, 2 ... 9 Hz with

amplitude +/- 15 mm, 1 Octave /

minute all 3 directions, 50 constant load

EMC-behaviour see on the back

UL according to standard 873

[Ohm]

Loading...

Loading...