NOVUS TagTemp User Manual

: A measure error can be fixed using the

Product suitable for applications requiring up to

degree of protection. See item "Special

Proportional to the number of records. 20

Configurator software for Windows ® 8, 7 and

Sets up, reads and displays data on the

TagTemp-USB

TEMPERATURE LOGGER – INSTRUCTIONS V 1.0x A

1 INTRODUCTION

TagTemp-USB is a small portable el ectronic temperature logger. Its

internal sensor measures local environment temperature and logs

such values in an electronic memory. Logged data, or

ACQUISITIONS, can be later viewe d and analyzed on a PC where

they can be opened in tabular and graph forms.

The LogChart II software ena bles to set up the equipment operation

mode. It is also us ed for viewing acquisitions. Othe r parameters suc h

as end of measurements, logging interval, etc., are easily defined

through the LogChart II software.

Acquisitions can also be exported to be analyzed in other

applications, such as spreadsheet programs.

1.1 IDENTIFICATION

The identification label is on the equipment body. Check if the

features described are in accordance with your order.

Fig. 01 – Front view of the device

Status indicator: This visual i ndicator reports the st atus of operation

of equipment through the n umber of fl ashes that occur in an interval

of five seconds. The states of operation are:

• One flash: The device is waiting to start the log in memory

(standby) or completed a series of logs in memory;

• Two flashes: the device is performing logs in memory;

• Three flashes: the device is or has gone through an alarm

condition and is not performing logs in memory;

• Four flashes: the device is or has gone through an alarm

condition and is performing logs in memory.

2 TECHNICAL DATA

Measure Range

Accuracy

Measurement

Resolutions

Memory capacity 32.000 (32 k) logs.

Measurement Interval

Supply 3.0 V lithium battery (CR2032) , built-in

Estimated autonomy

Operating temperat ure From -20 °C to 70 °C

Case PC-ABS

Protection

Dimensions 55 x 37,5 x 15 mm

Equipment -PC data

transfer time

PC Interface Micro-USB cable

LogChart ll software

operation environment

Temperature: –20.0 °C to 70.0 °C.

± 0.1 °C @ 25 ºC.

± 1 °C max. alon g the entire me asured range.

Note

OFFSET paramet er i n the LogC har t II software.

Temperature: 0.1 °C.

5 seconds min.

18 hours max.

• More than 400 days – Sampling rate of 1

minute.

• More than 500 days – Sampling rate of 30

minutes.

IP67

Care".

seconds to 3 2,000 records.

XP.

Menus in Portuguese, English or Spanish.

screen.

3 OPERATION

It is only possible to operate the equipment after the LogChart II

software is installed to a PC, according to the steps described in

LogChart II Software section of this manual. The communication

between equipment and PC is performed with the aid of the microUSB cable.

The equipment operati on mode set up is defined in advance by using

the LogChart II software. Each setting must be defined and the

consequences observed.

The equipment starts and stops logging as defined in settings.

NOVUS AUTOMATION 1/5

4 LOGCHART II SOFTWARE

Icons enabled when the communication port selected is a valid por t

4.1 INSTALLING LOGCHART II

The LogChart II, application is used to configure the parameters for

data transfer. To install the LogChart II, run the file LC_II_Setup.exe

available on our web site.

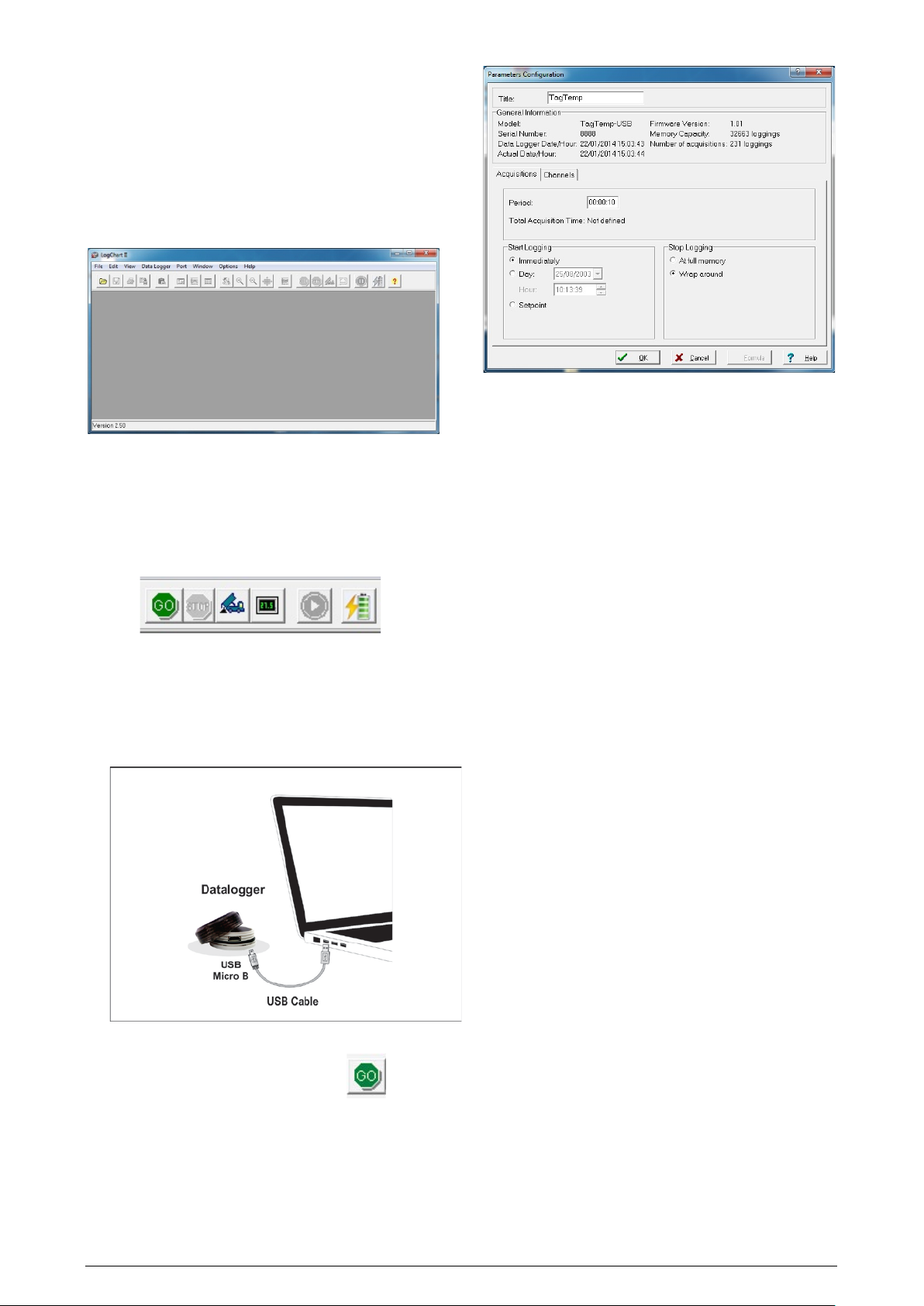

4.2 RUNNING LOGCHART II When you open LogChart II the main window is displayed.

Fig. 02 – LogChart II main window

Next, select the serial port that the communication i nterface will use

in the “Port” menu.

Check which serial is available. Usually COM2 is free, once the

mouse uses COM1. The chosen port wi ll be chosen by default next

times the LogChart II is initiated. When a val id port is selected, the

icons below are displayed.

Fig. 03 –

4.3 CONFIGURING THE EQUIPMENT

For device configuration is necessary that the communication

interface is connected to the computer, using the selected port

described in the previous section. See figure below.

Fig. 04 – Communication via USB cable

After the serial port is selected, click on the button:

The Parameters Con figuration screen is displayed. In this s creen

the user can define the equipment operation mode and also obt ains

general information about the device.

Fig. 05 – Configuration window

Fields are:

1- Title: In this field, the user identif ies the equipment by assigning it

a name.

2- General info rmation: Area with inf ormation about the equipment,

such as Model, Serial Number, equipment Date/Time, PC Date/ Ti me,

firmware version, memory capacity and number of acquisitions

stored in memory.

In this field, time is constantly updated while the communication

between equipment and computer is taking place.

3- Readings: Presents a series of parameters that define the

acquisition process.

Interval: Defines the interval betw een readings: The minimum

interval is (5) seconds and maximum is (18) hours.

Note: When the type of value l ogged is minimum, maximum or

average values, the minimum interval is 50 seconds.

Estimated time: In this parameter, the equipment informs the

user how long it will take to occupy the full memory, in the

conditions set up during configuration.

Start of Readings: Readings can be started in one of three

different modes:

• Immediately: s tart as soon as set up is ready and sent

(OK) to the equipment.

• Date: readings start at predefined date and time.

• Setpoint: acquisitions start when a temperature setpoint

is reached. In this option, t he setpoint v alue is defined i n

the Channels field, where the Alarm parameter is

replaced by setpoint.

Stop loggings: Options for the end of readings are:

• Full Memory: readings can be stored up to the full

memory capacity is reached.

• Don’t stop (Wrap around): readings are continuous,

replacing old records with new ones as the number of

readings overpass the memory capacity.

4- Channels: Displays other parameters related to temperature

measurement:

Unit: Defines the unit of the value measured: ºC or ºF for

channel 1 (temperature).

Value: It defines how the value measured will be registered.

Options are:

• Instantaneous: The val ue logged wi l l be ex actl y the val ue

measured at each interval def ined. Measurement is taken

at the end of the defined interval. The minimum interval

between measurements is 5 seconds.

TagTemp-USB

NOVUS AUTOMATION 2/5

Loading...

Loading...