NOVUS 4-20ma User Manual

INSTALLATION

The TxBlock transmitter is intended for in head mounting. Its drawing is presented

in Figure 04.

Figure 04 – TxBlock dimensions

ELECTRICAL CONNECTIONS

Figure 4 and 5 below shows the thermocouple wiring. Terminals 1, 2 and 3 are

used for sensor input. For 2-wire Pt100, terminals 2 and 3 shall be connected

together. The LOAD represents the input shunt of an instrument measuring the 420 mA current loop.

Figure 05 – Transmitter connections – Pt100

Figure 06 – Transmitter connections – Thermocouple

Its is important to follow the recommendations below:

•

Signal wires should be installed in grounded in conduits and away from power or

contactor wires.

•

The instrument should have its own power supply wires, which should not be

shared with electrical motors, coils, contactors, etc.

•

Installing RC filters is strongly recommended at contactor coils or any other

inductors.

•

System failure should always be taken into account when designing a control

panel to avoid irreversible damage to equipment people.

SPECIFICATIONS

Sensor input: User defined. The supported sensors are listed in Table 01, along

Thermocouples: Types J, K, R, S, T, N and E, according to IEC 60584 (ITS-90).

Impedance >> 1 M

Pt100: Excitation: 0.17 mA. 2 or 3-wire connection (for 2-wire

Voltage: 0 to 50 mVdc. Impedance >> 1 MΩ

Sensor Type Range Minimum Measurement Span

Thermocouple K 0 to 1370 °C 100 °C

Thermocouple J 0 to 760 °C 100 °C

Thermocouple R 0 to 1760 °C 400 °C

Thermocouple S 0 to 1760 °C 400 °C

Thermocouple T 0 to 400 °C 100 °C

Thermocouple N 0 to 1300 °C 100 °C

Thermocouple E 0 to 720 °C 100 °C

Total accuracy: better than 0,3 % of the maximum range for thermocouples and

0,2 % for Pt100 and voltage;

Response time: < 100 ms

Output: 2-wire 4-20 mA, linear with respected to the measured temperature.

Resolution: 0,004 mA (12 bits).

Power supply: 12 to 35 Vdc, across the transmitter;

Maximum load (RL): RL (max.) = (Vdc – 12) / 0,02

Operating temperature: -40 to 85 °C

Humidity: 0 to 90 % RH

Electromagnetic compatibility: EN 50081-2, EN 50082-2

No isolation between the sensor and the 4-20 mA loop.

Internal protection against polarity inversion.

Cold junction compensation for thermocouples.

Housing: ABS UL94-HB.

Dimensions: 44 mm (diameter) x 25 mm (height).

with their maximum ranges.

Ω

sensors, tie terminals 2 and 3 together). α= 0.00385,

according to IEC 60751(ITS-90).

Pt100 -200 to 650 °C 40 °C

Voltage 0 to 50 mV 5 mV

Table 01 – Transmitter input sensors

Were: Vdc= Power supply voltage

[Ω]

M I C R O P R O C E S S O R

B A S E D T E M P E R A T U R E T R A N S M I T T E R

T x B l o c k

I N S T A L L A T I O N A N D O P E R A T I N G M A N U A L

Man 5001472

CONFIGURATION

If the transmitter is already configured as required by the application (sensor type,

range, etc), it may be installed and used right away. However, if a distinct

configuration is required, this can be done through the TxConfig software and the

TxConfig Interface.

The TxConfig interface and software can be purchased from the manufacturer or at its

authorized distributors and representatives. Updates for the software are available at

our website. To install the TxConfig software, run the Tx_setup.exe file and follow the

instructions.

Serial port configuration errors may occur when other devices are sharing

the same port (ex.: Palm Hot Sync). Close all serial port applications prior to

using the TxConfig software.

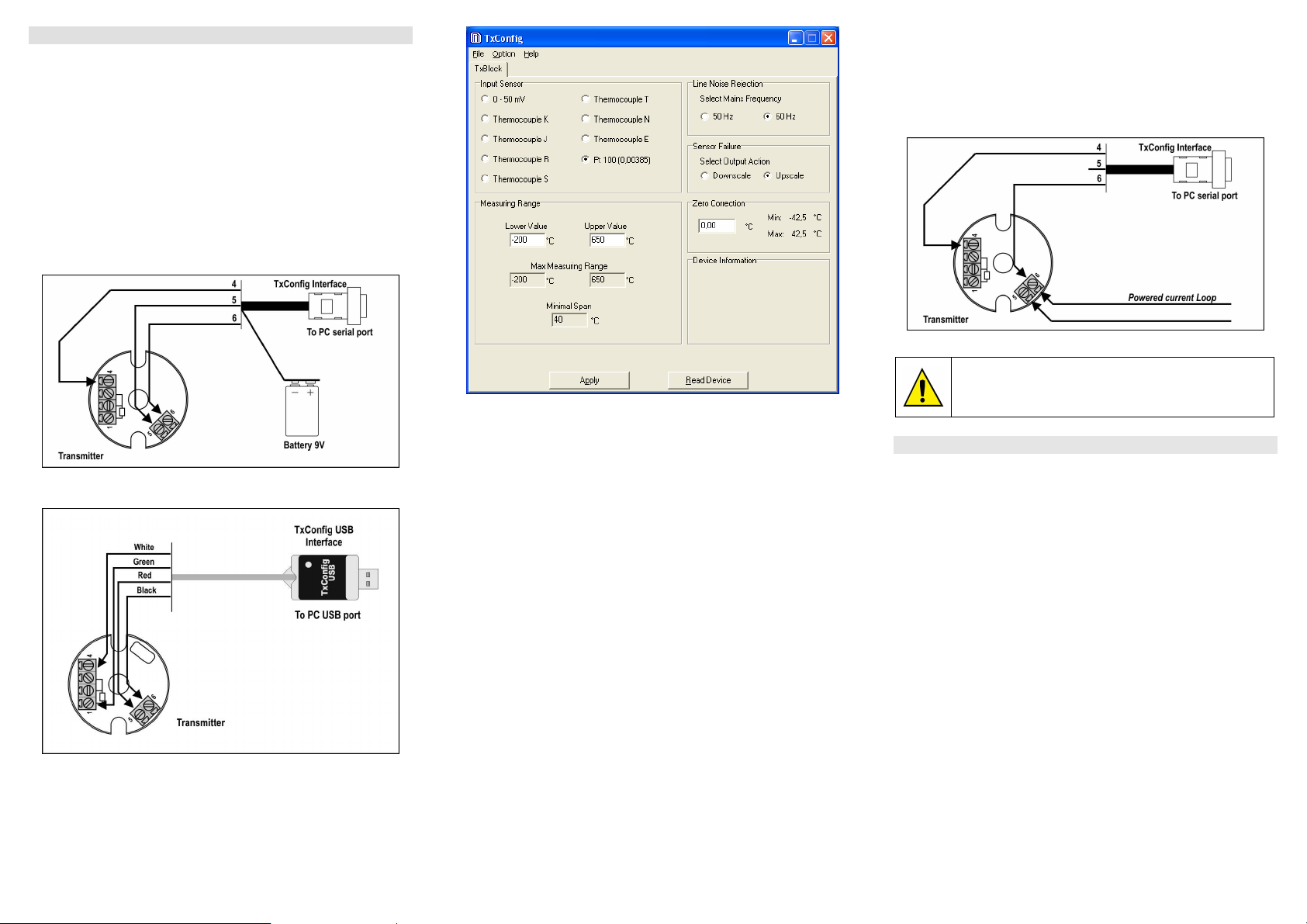

The TxConfig interface connects the transmitter to the PC, as shown in Figures 01

and 02. There are two types of interface: TxConfig-RS232 and TxConfig-USB.

The transmitter must be powered in order to be configured. The TxConfig-USB

interface provides the needed power.

The TxConfig-RS232 interface, however, requires an auxiliary supply for guarantee

reliable communication with the computer. An external 9V battery can be used for this

purpose (Figure 01). An alternative is to configure the transmitter while it is in operation;

this way, the needed energy is supplied by the current loop, as in Figure 04.

Figure 01 – TxConfig Interface connections model RS232

Figure 02 – TxConfig Interface USB connections

Once the connection is accomplished, the software shows the configuration options

of the transmitter model attached. Access the Help for usage instructions.

The TxConfig screen in shown in Figure 3.

Figure 03 – TxConfig main screen

The fields in the screen mean:

1. Input Sensor: Choose the desired temperature sensor among the available

options. See Table 01.

2. Measuring Range: Defines the output scale for the input sensor. Program here

the measurement Lower Range Value and the Upper Range Value.

When the Lower Range Value is configured with a value higher than the Upper

Range Value, the current output will have a decrescent behavior (20~4 mA).

The values chosen for the limits must lay within the sensor span as shown in

this same field. Also, each sensor has a its own minimum span value, as

indicated in the screen. See Table 01.

3. Line Noise Rejection: The transmitter incorporates a digital filter to cancel the

induced noise from the 50 or 60 Hz systems. For better performance, select the

line frequency used in your country.

4. Sensor Failure Detection: establishes the transmitter output behavior (upscale or

down-scale) in the presence of a sensor fail.

5. Zero Correction: Allows for small sensor corrections. See item Operation.

6. Read Configuration: Brings to the screen the current transmitter parameters

configuration.

7. Apply: Sends a new configuration to the transmitter.

8. Device Information: The Device Information box contains relevant data

concerning a particular transmitter. Please pass along this information when

contacting the technical assistance department.

Note: The factory default configuration is (unless otherwise specified or ordered):

Pt100 input, 0 to 100 ºC;

60 Hz filtering and upscale (20 mA) output for sensor fail.

Figure 04 – TxConfig Interface connections – Loop powered

The TxConfig interfaces contain dedicated circuitry for proper

communication between transmitters and computer. Always make use of

the TxConfig interfaces for configuration purposes, otherwise the

transmitters may get damaged, voiding the warranty.

OPERATION

All input types are factory calibrated. Recalibration in the field is not recommended,

but can be accomplished through the TxConfig software. Contact the factory for the

calibration procedures.

When necessary, fine adjustments to the transmitter output current can be

accomplished directly at the transmitter. For this, short circuit transmitter terminals 1

and 4. After 2 seconds, the output current starts to increase gradually until it

reaches 0.8 mA above the initial value. After reaching that value, it drops to 0.8 mA

below the initial value, increasing gradually again. The user must monitor the

current and open the circuit when the current reaches the desired value.

The offset correction can also be accomplished through the TxConfig software. The

TxConfig interface can be connected to the transmitter while it is operating in the

process (Figure 04). See in Figure 03 the Zero Correction field for this purpose.

The user must choose the sensor and configure the sensor span which best suit

the application. The sensor span must not exceed the maximum range supported

by the transmitter for a particular sensor, neither be lower than the minimum span.

It is important to note that the transmitter accuracy is related to the total sensor

span of a sensor, regardless of the output scale (span) configured. Example:

Pt100; maximum input span of –200 to +650 °C, 0.2% accuracy.

Maximum error: 1,7 °C ( 0,2 % of 850 °C )

This error is the same no matter if total span is used (-200 to 650 °C) or a

narrower user-defined span is used, like 0 to 100 °C.

Note: When using a Pt100 simulator, make sure the TxBlock’s Pt100 excitation

current (0.17 mA) is compatible with the simulator specification.

Loading...

Loading...