Combined Hardness Tester

NOVOTEST T-UD3

Operating Manual

2018

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 2

CONTENT

1 DESCRIPTION AND OPERATION OF THE DEVICE AND ITS COMPONENTS ......................... 5

1.1 The purpose of the device ............................................................................................................... 5

1.2 Technical characteristics of the device ........................................................................................... 5

1.3 Standard delivery set ....................................................................................................................... 7

1.4 Purpose of the probes ...................................................................................................................... 7

1.5 Parts ................................................................................................................................................. 8

1.5.1 Ultrasonic Contact Impedance Probe U1 probe ..................................................................... 10

1.5.2 Leeb probe.............................................................................................................................. 10

1.6 Design and functioning ................................................................................................................. 11

1.6.1 Modes ..................................................................................................................................... 11

1.6.2 Leeb measurement principle (Leeb) ...................................................................................... 12

1.6.3 Ultrasonic Contact Impedance method .................................................................................. 12

1.7 Means of measurement, tools and accessories .............................................................................. 13

1.8 Marking and sealing ...................................................................................................................... 13

1.9 Packing .......................................................................................................................................... 13

2 INTENDED USE ................................................................................................................................. 14

2.1 Operational limitations .................................................................................................................. 14

2.2 Preparing the device for use .......................................................................................................... 14

2.2.1 Visual inspection .................................................................................................................... 14

2.2.2 Installing the batteries ............................................................................................................ 14

2.2.3 Connecting the Probe ............................................................................................................. 15

2.3 Using the device ............................................................................................................................ 15

2.3.1 Preparing the object of testing ............................................................................................... 15

2.3.2 Turning on .............................................................................................................................. 16

2.3.3 Charging the battery ............................................................................................................... 17

2.3.4 Measurements using Ultrasonic Contact Impedance Probe U1 probe ................................... 18

2.3.5 Measurements with the Rebound Leeb Probe ........................................................................ 21

2.3.6 Measurement modes .............................................................................................................. 24

2.3.7 Calibration .............................................................................................................................. 28

2.3.8 Settings ................................................................................................................................... 34

2.3.9 Archive ................................................................................................................................... 35

2.3.10 Memory card ........................................................................................................................ 36

2.3.11 Information........................................................................................................................... 36

2.3.12 Photo fixation of the measurements ..................................................................................... 37

2.3.13 Connecting to PC ................................................................................................................. 39

3 TECHNICAL MAINTENANCE OF THE PRODUCT AND ITS COMPONENTS ......................... 44

3.1 Security measures ......................................................................................................................... 44

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 3

3.2 Verification ................................................................................................................................... 44

3.2.1 Operations and verification means ......................................................................................... 44

3.2.2 Visual inspection .................................................................................................................... 45

3.2.3 Testing .................................................................................................................................... 45

3.2.4 Determination of the basic error of the instrument according to the HRC scale ................... 45

3.2.5 Determination of the basic error of the instrument on the scale HB ...................................... 46

3.2.6 Determination of the basic error of the instrument on the scale НV ..................................... 46

3.3 Warranty........................................................................................................................................ 47

3.3.1 Basic Warranty ....................................................................................................................... 47

3.3.2 Extended warranty ................................................................................................................. 47

3.3.3 Warranty for repaired or replaced parts ................................................................................. 47

All NOVOTEST brand spare parts installed during the warranty repair process are covered by the

NOVOTEST guarantee (until the end of the warranty period). ...................................................... 47

Spare parts replaced during warranty service under warranty are not returned to the owner of the

device. ............................................................................................................................................. 47

3.3.4 Wear parts .............................................................................................................................. 47

3.3.5 Duties of the owner ................................................................................................................ 48

3.3.6 Warranty Limitations ............................................................................................................. 48

3.3.7 Other cases not covered by the warranty ............................................................................... 49

3.3.8 Guarantees and consumer legislation ..................................................................................... 49

3.4 Maintenance of the device ............................................................................................................ 49

4 MAINTENANCE ................................................................................................................................ 52

5 STORAGE ........................................................................................................................................... 52

6 TRANSPORTATION .......................................................................................................................... 52

7 RESYCLING ....................................................................................................................................... 52

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 4

Caution!

Please read this manual carefully before using the NOVOTEST T-UD3 hardness tester.

This operating manual (hereinafter OM) includes general information intended to familiarize the

operating personnel with the operation and operating rules of the NOVOTEST T-UD3 hardness tester

(hereinafter referred to as the device or hardness tester). The document contains technical

characteristics, description of the design and principle of operation, as well as information necessary

for the correct use of the product. Before getting started, it is necessary to familiarize yourself with this

manual, since the operation of the device must be carried out by persons familiar with the principle of

operation and design of the device.

Proper and effective use of the hardness tester requires mandatory availability:

Methods of testing;

Conditions for carrying out the testing, according to the testing procedure;

Trained, and familiar with this OM user.

The enterprise-manufacturer reserves the right to make non-critical changes, without impairing

product specifications. These changes may not be mentioned in the text of this document.

The scope of delivery of the instrument includes the operational documentation including this

operating manual and the instrument passport.

The present OM applies to all modifications of the device: T-UD3, T-U3, T-D3.

Terms used in this manual:

Hardness testers for metals – are used for material hardness testing, without destroying its

structure.

Hardness – property of a material to resist the elastic and plastic deformation, or destruction when

an indenter of another material that is more solid and takes no deformation of its body incorporated

into the surface layer.

Indenter – An element of the device pressed into the material for measuring its hardness. For

manufacturing indenters diamonds, hard alloys, hardened steel are used.

Young's modulus (modulus of longitudinal elasticity) – Physical quantity characterizing the

properties of the material to resist tension, compression under elastic deformation.

Leeb method – To measure the hardness of the material, the elastic rebound method is used (The

ratio of the speed of the impact body before and after the impact is measured).

Ultrasonic Contact Impedance – Consists in measuring the degree of change (damping) of the

vibration frequency of the rod with the indenter at the end when inserted into the surface of the sample.

The softer is the metal the dipper indenter penetrates into it, the bigger the square of the contact and

the less it influences the rod oscillation frequency (ultrasonic).

Kalman filter – An effective recursive filter that estimates the vector of a dynamic system state

using a series of incomplete and noisy measurements.

Median Filter – One type of digital filter, widely used in digital signal processing to reduce noise.

The median filter is non-linear FIR filter. Median filtering is an efficient procedure for processing

signals subject to impulse noise.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 5

1 DESCRIPTION AND OPERATION OF THE DEVICE AND ITS COMPONENTS

1.1 The purpose of the device

The device is designed to measure hardness of:

metals and alloys on the Rockwell (HRC), Brinell (HB) and Vickers (HV), Leeb (HL),

Shore (HS) hardness scales and others.;

surface layer of metal subjected to fusing, spraying, mechanical, thermal and other types of

metal surface treatment;

cast iron, stainless steels and non-ferrous alloys, using the calibration mode on non-

standard hardness test blocks;

measuring of the tensile strength (v) for stretching products from carbonaceous steels of

the pearlite class by automatic recalculation from the Brinell hardness scale (HB).

The Hardness Tester allows instant analysis of the hardness of the product directly at the site of

operation or production of the product in workshop, laboratory and field conditions, for example, in

machine building, metallurgy, power engineering, shipbuilding and railway transport, aerospace and

oil and gas industry, repair and installation and service organizations etc.

The objects of measurement can be: pressure vessels for various purposes (reactors, steam

generators, collectors, boiler drums, gas holders, etc.), rotors of turbines and generators, pipelines,

rolls, crankshafts, gears, parts of various vehicles, industrial semi-finished products (castings,

Forgings, sheets), etc. Also, the hardness tester can be used for:

assessing the stability of technological processes (product processing, welding, etc.);

diagnostics of equipment, in order to evaluate its residual safe resource (control of

hardness of pipelines, boilers, etc.);

assessing the quality of performed repairs;

heat treatment quality evaluation.

1.2 Technical characteristics of the device

The NOVOTEST T-UD3 hardness tester is a portable device made in an impact-resistant housing

(with a special protective silicone bumper-case for complicated operating conditions) inside which a

board with electronic components and accumulators are placed. The main characteristics of the device

are presented in Table. 1.1, Table. 1.2 shows the ranges of measurements, and characteristics of probes

in Table. 1.3.

Table 1.1 - The main characteristics of the device

Overall dimensions, mm

180х80х35

Powered by three NiMH batteries or AA batteries

each 1,2 V

Power supply current, not more than, mA

100

Time of continuous operation, not less than, h

10

Weight of electronic unit with batteries, not more than, g

250

Operating temperature range, ° С

from -20 to + 40

Humidity, not more,%

from 30 to 80

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 6

Table 1.2 - Measurement range and limits of the basic permissible error

Hardness scale

Measurement range

Measurement error

U1

Leeb

Rockwell, HRC

From 20 to 70

±2

±2

Brinell, HB

from 90 to 150

±10

±10

Brinell, HB

from 150 to 650

±15

Vickers, HV

from 240 to 500

±15

±15

Vickers, HV

from 500 to 940

±20

Leeb, HL

from 300 to 800

–

±15

Shore, HS

from 30 to 100

Is determined when markup

Strength limit σv (reference), Мpa

from 370 to 1500

Is determined when markup

Table 1.3 - Characteristics of probes

Probe Type

U1 (98 N)

U1 (50 N)

U1 (10 N)

Leeb

Overall dimensions, mm

Ø30х140

Ø30х140

Ø30х140

Ø20х145

Weight, g, not more than

250

250

250

130

Roughness of the measured surface, Ra

2,5

2,5

2,5

3,2

Radius of curvature of the measured

surface, mm

5 5 5

10

Weight of the controlled product, not less

than, kg

0,1

0,1

0,1

5

Thickness of the controlled product, not

less than, mm

1 1 1

12

Load, kgf

10 5 1

-

The device corresponds to: ASTM A956 “Standard Test Method for Leeb Hardness Testing of

Steel Products”; ASTM A 1038 “Standard Test Method for Portable Hardness Testing by the

Ultrasonic Contact Impedance Method”.

MTBF

Mean time between failures of the device without taking into account the reliability factor of the

probes is not less than 6000 h.

Service time

The total average service life of the device is not less than 10 years.

The criteria of decommissioning of the device - economic inexpediency of restoring the operable state

of the components of the instrument by repairing.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 7

1.3 Standard delivery set

Electronic Unit ........................................................................................................................ 1 pc.

Rebound Leeb Probe ............................................................. Availability - according to the order

Ultrasonic Contact Impedance Probe U1 (98 N) .................. Availability - according to the order

Ultrasonic Contact Impedance Probe U1 (50 N) .................. Availability - according to the order

Ultrasonic Contact Impedance Probe U1 (10 N) .................. Availability - according to the order

Rechargeable battery ............................................................................................................... 3 pc.

Charger .................................................................................................................................... 1 pc.

USB cable for PC .................................................................................................................... 1 pc.

Case ......................................................................................................................................... 1 pc.

Operating manual NOVOTEST.T-UD3.000 OM ................................................................... 1 pc.

Passport NOVOTEST.T-UD3.000 PS ................................................................................... 1 pc.

Additional equipment:

Hardness test blocks (HRC, HB, HV, HLD, etc.) .................................................. If ordered

Cordless grinder ...................................................................................................... If ordered

* At the request of the customer, the delivery kit can be expanded with additional equipment or

parts. The exact information about the delivery set is indicated in the passport of the device.

1.4 Purpose of the probes

The Rebound Leeb Probe (Figure 1.1, Rebound Leeb Probe) – purposed for hardness

measurement by dynamic method. It is intended for measuring hardness of large-sized objects, and

also coarse-grained materials.

The Ultrasonic Contact Impedance Probe U1 (Figure 1.1, Contact Impedance Probe U1) Measurement of hardness by Ultrasonic Contact Impedance method. The use of a diamond indenter

allows the probe to be mounted precisely at any tiny point, and leaves a small-size imprint, making the

measurement of the U1 the least destructive.

The probe is perfectly suited for the following tasks: measuring the hardness of complex shapes,

fine-grained materials, heat-treated materials, thin layers and coatings, surface hardened parts, thinwalled pipes, small parts, etc.

Table 1.4 shows the characteristics of the UCI U1 type probes.

Figure 1.1 - Types of probes

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 8

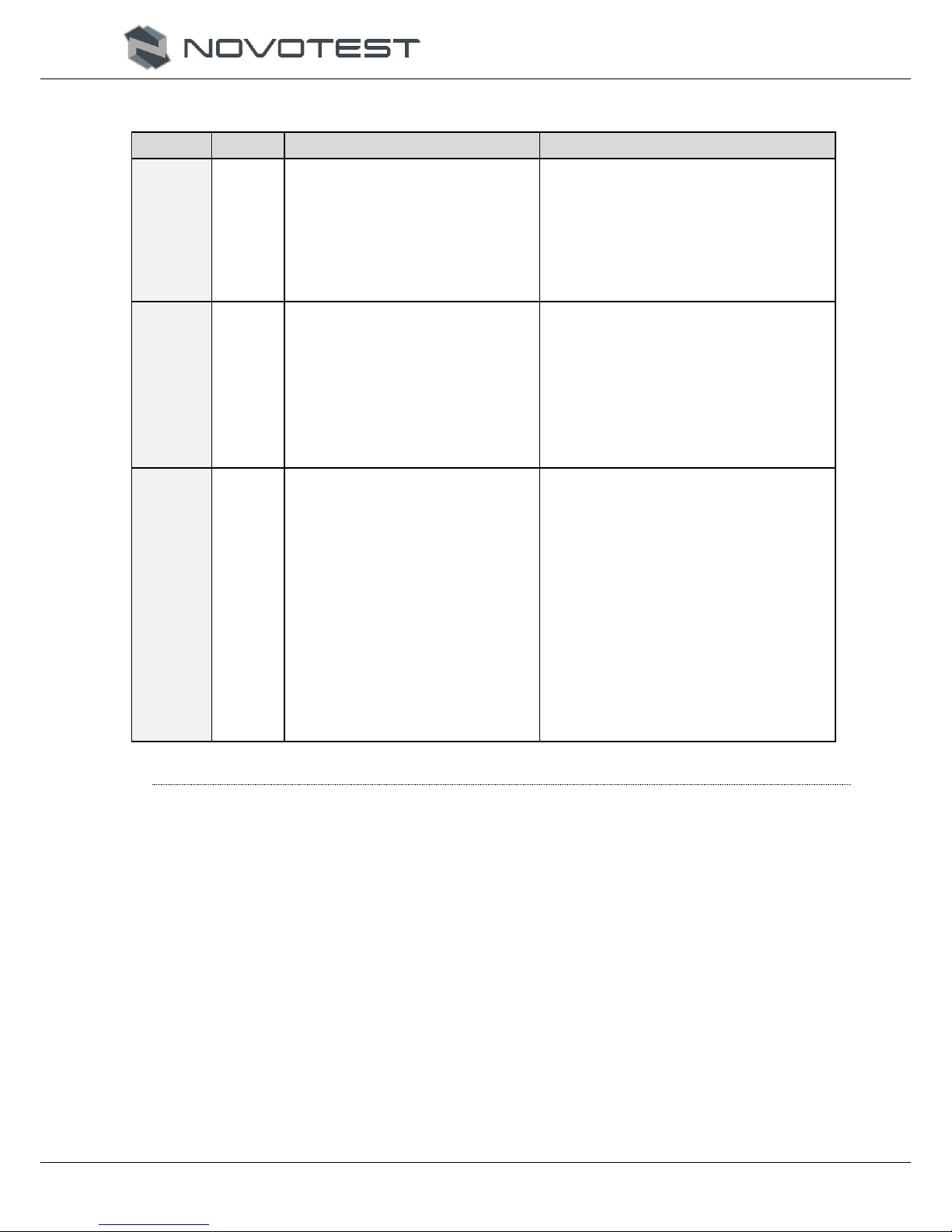

Table 1.4 - Features and applications of UCI U1 probe type

Model

Load

Features

Main applications

UCI U1

(98 N)

98 N

(10 kgf)

The main type of probe for

solving most problems of

hardness measurement. 10 kg

load is to be applied for

measurement (set automatically

by the probe). Low requirements

for surface cleanliness.

Heat-treated and cemented details.

Measuring in grooves, on teeth, on

radius surfaces.

Measurement on the blades, on the

internal surface of the pipes,

openings.

UCI U1

(50 N)

50 N

(5 kgf)

The main probe type for the most

tasks of hardness measurement. 5

kg. load is to be applied for

measurement (automatically

controled by the probe). Average

surface cleannes requirements.

Heat-treated and cemented parts, for

example, shafts, turbines, gears,

teeth, welds, heat affected zones.

Measuring in grooves, on teeth, in

grooves, on radius surfaces.

Measurement on the blades, on the

internal surface of the pipes,

openings.

UCI U1

(10 N)

10 N

(1 kgf)

The reduced load probe is

designed to measure the hardness

of material with increased

requirements to the print size

(polished surfaces), to measure

the hardness of surface hardened

layers. 1 kg. load is to be applied

for measurement (automatically

controled by the probe).

More sensible to the surface

cleanliness, in comparison with

U1 (50 N).

Nitrided and cemented surface

layers of molds, stamps, stamps,

thin-walled parts.

Bearings, lateral surfaces of saws

teeth.

Measurement of hardness of

hardening coatings.

Measurement on the blades, on the

inner surface of the pipes, inside the

holes.

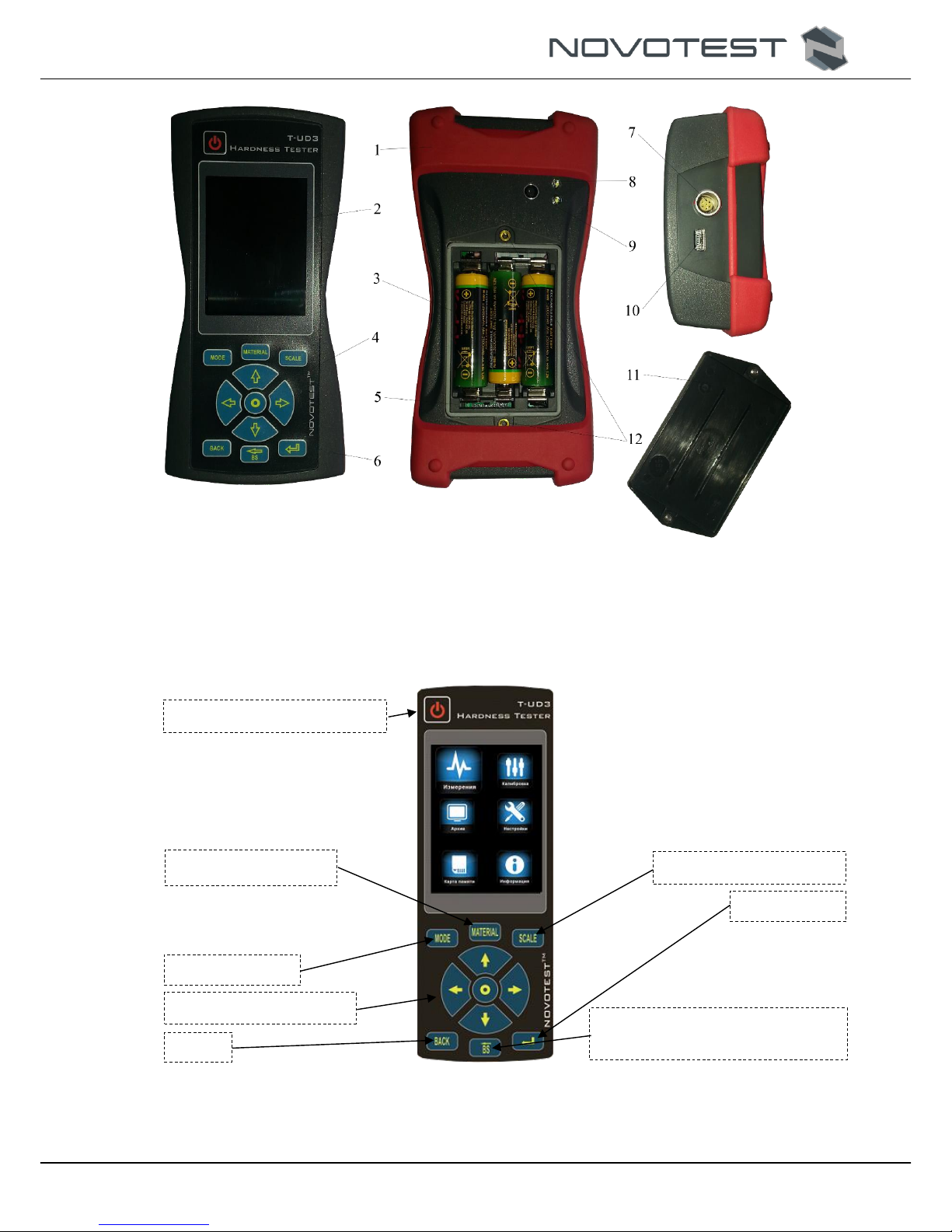

1.5 Parts

The device consists of an electronic unit made of impact-resistant ABS plastic and placed into a

protective silicone bumper, as well as connected probes. The detachable connection is located on the

upper end surface of the housing; there is also a mini USB connector, which is used to connect the

device to PC or to charge the batteries. The control keyboard is located on the front panel, which also

houses a contrasting color LCD / TFT display. In the lower rear part of the device under the cover,

fixed with the threaded connection with the help of two screws, there is a battery compartment in

which the batteries are installed (Figure 1.2.). In Fig. 1.3, it shows the control keyboard of the device.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 9

1– bumper; 2 – LCD/TFT color contrast display; 3 – NiMH battery; 4 – control keyboard; 5 – battery

compartment; 6 – electronic unit; 7 – probe socket; 8 – flash light; 9 – photo camera; 10 – mini USB

socket; 11 – cover; 12 – cover securing with threaded connections.

Figure 1.2 - Hardness meter NOVOTEST T-UD3

Figure 1.3 - Control buttons and their functional purpose

On/Off button

Material selection

Mode selection

Navigation keys

Back

Scale mode selection

Enter

Backspace (back /delete one

position)

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 10

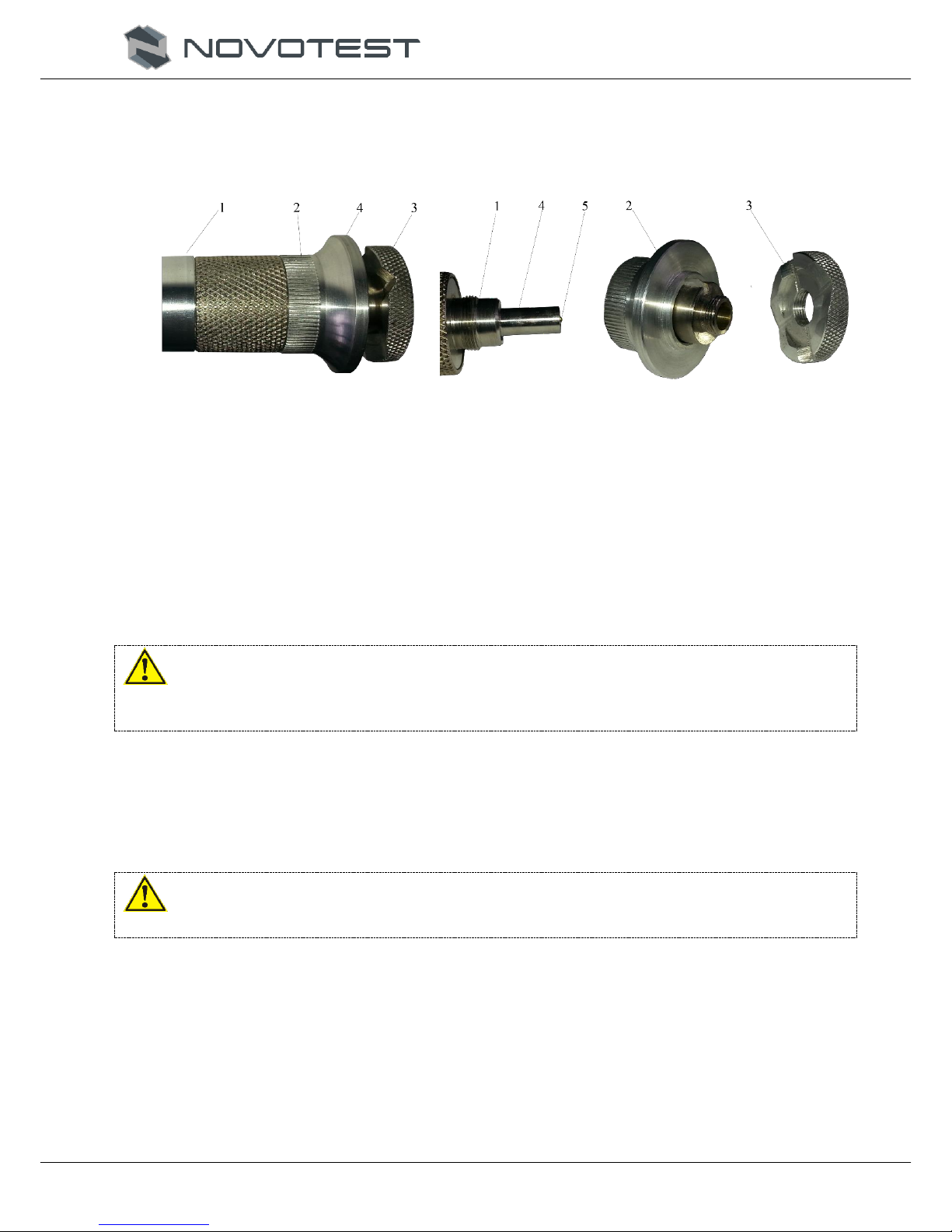

1.5.1 Ultrasonic Contact Impedance Probe U1 probe

The construction of the probe is shown in Fig. 1.4. The probe has a special removable collapsible

head with a double-sided thrust washer. The thrust washer provides the convenience of positioning the

probe onto the product and pressing during the measurement.

1 – housing; 2 – removable collapsible nozzle; 1 – housing; 2 – removable collapsible nozzle;

3 – removable double sided thrust washer; 3 – removable double sided thrust washer;

4 – support platform. 4 – centering pipe; 5 – diamond tip.

Figure 1.4 - Appearance of the Ultrasonic Contact Impedance Probe U1

One side of the washer is flat; the other has prismatic grooves designed for the convenience of

measuring hardness on cylindrical products of different diameters. The probe with the removed washer

is used for carrying out of measurement of hardness in narrow and hardly accessible places.

To measure hardness on flat surfaces, the washer on the probe head should be installed flat to the

surface of the product, and to measure the hardness on the cylindrical surfaces, the washer on the

probe head should be installed with a side with prismatic grooves to the product.

Caution!

To ensure a better smoothness of the collapsible detachable nozzles, they are individually grounded to

each probe. Replacement of probe tips is not allowed.

1.5.2 Leeb probe

The Leeb probe has a built-in mechanism for charging the spring, which is the most ergonomic

and convenient to work with. Spring charging is provided by moving the upper part of the probe

housing downwards, after which the probe can be installed on the controlled object and measurement

can be done.

Caution!

It is forbidden to discharge the trigger of the Leeb probe “in the air”.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 11

Figure 1.5 - The appearance of the Leeb probe

1.6 Design and functioning

The principle of operation of the hardness tester depends on the type of the connected probe.

When using the Leeb probe, the hardness is measured by the dynamic method of Leeb, and when

using the UCI probe - by the ultrasonic contact impedance method.

The dynamic method of measuring hardness is used to control:

hardness of objects weighing more than 5 kg and wall thickness of more than 10 mm;

hardness on solid products, products with coarse-grained structure, forged and cast

products;

hardness, if minimal surface preparation is required.

Ultrasonic contact impedance -resonance method for measuring hardness is used to measure:

hardness of objects with low mass (from 0,1 kg) and wall thickness (over 1 mm);

hardness on products with a glossy surface (if the minimum print size is required);

hardness of the surface hardened layer at the inspection site.

1.6.1 Modes

The hardness tester works in the following modes:

1. <MEASUREMENTS>:

Main scales mode (HRC, HRB, HB, HV, HS, HL, MPA);

User scales mode (U1, U2, U3);

A mode of measurement of hardness of basic materials (steel, alloy steel, stainless

steel, gray cast iron, high-strength cast iron (<CHARG>), aluminum, brass, bronze,

copper);

A mode of measurement of hardness of user materials (<USER 1>, <USER 2>);;

<CHART> mode;

<HISTOGRAM> mode;

<STATISTIC> mode;

<INTELLECT> mode;

<SIGNAL> mode.

2. <CALIBRATION>:

One point;

Three points.

3. <ARCHIVE>:

Saved measurements view.

4. <SETTINGS>:

<DATE>;

Impact Body

Inductive coil

Housing

Trigger

Plug

Charger

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 12

<TIME>;

<LANGUAGE>;

<PHOTO>;

<BRIGHTNES>;

<PALETTE>;

<SOUND>;

<RESULT>;

<VOLUME>;

<AUTO OFF>;

<RETRO>;

<FLASH>;

<TOLERANCE>;

<FILTER>;

<FILTER MODE>.

5. <MEMORY CARD>:

<SAVE>;

<LOAD>;

<CLEAR>.

6. <INFORMATION>:

About dealers;

About the device.

7. Two-way communication with PC:

Data transfer;

Transfer of calibration settings;

Interface change.

1.6.2 Leeb measurement principle (Leeb)

The dynamic principle probe (rebound method) is a separately executed device connected to the

electronic unit by means of a cable.

The principle of measuring hardness is based on the determination of the ratio of the velocities of

impact and rebound of the striker inside the probe. Carbide ball is located at the end of the impact

body, directly in contacting with the material at the time of impact. Inside of the impact body is a

permanent magnet. The striker, after pressing the trigger button, is ejected onto the surface to be

measured by a pre-charged spring. While this, the striker moves inside the inductor coil and, with its

magnetic field, induces an electromotive force (EMF) in it. The signal from the output of the induction

coil is fed to the input of the electronic unit, where it is converted into a hardness value of the selected

scale and displayed.

This method is particularly suitable for hardness measurements on solid products, coarse-grained

products, forged and cast products.

The design of the dynamic probe allows user to make more measurements per unit of time, and

working with it does not require special skills, such as with an UCI probe.

1.6.3 Ultrasonic Contact Impedance method

Ultrasonic probe (UCI ultrasonic contact impedance method) is a separately executed device

connected to an electronic unit by means of the cable.

The probe basically uses a steel rod with a diamond pyramid at the end, which is an Acoustic

Resonator (Oscillating Rod) of the built-in self-oscillator of ultrasonic frequency. When the diamond

pyramid is introduced into the tested object under the action of the fixed load of the calibrated spring,

the resonant frequency of the resonator changes, determined by the hardness of the material. The

relative change in the frequency of the resonator is converted by the electronic unit into the hardness

value basing on the selected scale and displayed.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 13

This method is suitable for hardness measurements on products of various weight and thickness,

and especially on finished products with a glossy surface, since it leaves a minimally visible imprint

after measurements.

The design of the ultrasonic probe makes it possible to carry out measurements in hard-to-reach

places (for example, the surface of gear teeth, etc.), as well as on thin-walled structures (eg. pipelines,

etc.) that can not be measured dynamically by the probe.

It should be taken into account that the result of the measurement by the UCI method depends on

the Young's modulus of the tested product.

1.7 Means of measurement, tools and accessories

The efficiency of the device is evaluated by checking the measurement of hardness on the

reference hardness test blocks, reference hardness blocks should be grounded to the grinding plate

weighing not less than 5 kg through a layer of grease. Mismatch readings must not exceed the

permissible error (Table. 1.2). If the permissible error is exceeded, calibrate the instrument in

accordance with 2.3.7.

The manufacturer should make adjustment and tuning of the device in the case of faults.

1.8 Marking and sealing

On the front panel of the device is a symbol of the device with the trademark of the manufacturer.

On the rear panel, under the battery compartment cover the serial number is printed.

1.9 Packing

The electronic unit and the probe are delivered in a package (case), excluding their damage during

transportation.

To avoid mechanical damage to the cable and connectors of the device, it is necessary to

disconnect the sensor from the device before packing it into the package.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 14

2 INTENDED USE

2.1 Operational limitations

Operation of the device should be carried out under the influence of factors and taking into

account the parameters of the monitored objects in accordance with the specified technical

characteristics, and the device must be used within its technical characteristics.

Only qualified personal, familiar with the operation manual is allowed to use with this device.

After transporting the device to the place of operation at a negative ambient temperature and

placing it into a room with a positive temperature, it is necessary to keep the product in its packaging

for at least 6 hours in order to avoid failure due to condensation of moisture.

2.2 Preparing the device for use

2.2.1 Visual inspection

Carry out visual external inspection of the device; make sure that there are no mechanical

damages to the electronic unit, the probe, the connector and the connecting cable.

2.2.2 Installing the batteries

Install the batteries into the battery compartment by unscrewing the two fixing screws and

removing the battery cover. Batteries are to be installed according to the polarity indicated on the

device (Figure 2.1). Close the battery compartment cover and screw in the screws.

Figure 2.1 - Installing the batteries

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 15

2.2.3 Connecting the Probe

Using the connecting cable connect the probe to be used to the probe socket on the electronic unit.

Connect the connecting cable making sure that the red dot on the plug and socket are in line (Figure

2.2).

Figure 2.2 - Connecting the probe

2.3 Using the device

2.3.1 Preparing the object of testing

Prepare the needed surface area of the material, removing moisture, contamination (oil, dust, etc.),

grease, scale, oxide film, and rust from it. Grind it with a grinder or sandpaper and wipe the ragged

surface.

The roughness and radius of curvature of the measured surface, as well as the weight and

dimensional characteristics of the product, should correspond to the parameters specified in the

technical characteristics of the hardness tester (Table 1.3), consider the type of probe (UCI or

dynamic) used for the measurement.

The results of measurements by the UCI method are affected not only by the properties of the

metal during plastic deformation, but also by the Young's modulus (modulus of elasticity). It entails

the need to adjust the instrument when working with products that have the Young's modulus different

from the Young's modulus of structural and carbon steels.

To determine the additional error presence, compare the results of measurements with the

measurements of the hardness of the static measurement principle. If the difference in the results does

not exceed the error of the instrument, it means that it is possible to carry out measurements on the

characteristic written in the memory of the instrument upon delivery. If the measurement error exceeds

the required accuracy, a two-point or one-point calibration of the device on the product or sample (see

2.3.7) is necessary.

If the product or measure of hardness does not meet the requirements of Table. 1.3 (mass and / or

thickness), the instrument will make measurements with additional error. It will be as big, as the

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 16

discrepancy from these requirements is. The sign of the additional error may be, either positive or

negative, depending on the specific conditions.

The reason for the additional error emergence is the parasitic oscillation at the point of contact of the

indenter with the material at the moment of measurement. This is due to the vibration of the whole

product, if its weight is low, either because of deflection product if its thickness is small.

To determine the presence of additional error compare the measurement results with the results of

measurements of hardness using a bench hardness tester.

There are three methods to eliminate the additional errors.

The first method – to make the one-point or two-point correction of the current user setting in

accordance with clause 2.3.7. It is used if an additional error of not more than 15%, and the results in a

series of measurements are stable.

The second method – by eliminating parasitic oscillations gripping articles in a vise (clutches mass

should be clearly greater weight than the indicated in Table 1.3.). To prevent damage to the product is

allowed to use on overhead jaws of a softer metal vice.

The third method (recommended) – eliminating parasitic oscillations by grounding the object to a

massive polished plate. The plate should have roughness Ra not greater than 0.4 microns, obviously

greater weight than indicated in Table 1.3, non-flatness not less than 0.005 mm, a Young's modulus of

the material from which the plate is made should be close to the Young's modulus of the product. The

lower portion of the object is to be plane-polished with a roughness Ra not greater than 0.4 microns

and flatness no more than 0,005 mm. To install the product on the plate on its support surface a thin

layer of lubricant to be used. The product is to be grinded to the plate surface so that between the

surfaces and plates were no stains of even small air gaps. Grind must be tight enough so that the

product and the plate form a single monolithic.

Also, the cause of the error may be fingerprints of different depths. The values of these depths

may differ, depending on the measured hardness (Table 2.1.). It is recommended to measure the

hardness of the layer that is 20 times greater than the indentation depth. For the reasons stated above,

the measurement result is influenced by the properties of the surface layer. The depth of penetration of

the indenter into the material is substantially smaller than with the instrument of the static type: Brinell

and Rockwell. This can lead to misalignment of the measurement results in the case of hardening,

decarbonized layer, burn marks, and martensitic spots.

Table 2.1 - The depth of the imprints on the material surface in millimeters

Probe type

100НВ

187НВ

400НВ

60,7HRC

Leeb

0,039

0,028

0,021

0,018

UCI (98 N)

0,098

0,081

0,052

0,036

UCI (50 N)

0,070

0,056

0,038

0,025

UCI (10 N)

0,031

0,025

0,017

0,011

Hardening can be formed in the surface layer after the turning and milling and rough polishing.

The softer the metal, the greater the difference between the hardness of the top layer and the inside.

Decarbonized layer with low hardness is formed by the high-temperature heat treatment. This may

be hardening, normalization, hot rolling, forging, etc. The thickness of this layer is typically less than

0.2 mm.

When heat treated steels with good hardenability by the average hardness in the surface due to

overheating may occur martensitic stains with high hardness.

2.3.2 Turning on

Turn on the device by long pressing the key < > on the control panel until the short splash

screen on the display (Fig. 2.3).

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 17

Figure 2.3 – splash screen

After this, the device switches to the main menu (Fig. 2.4), or in the <Measuring> mode (if the

probe is connected).

Figure 2.4 - Main Menu

From the Main Menu the user can access:

1. <MEASURING>;

2. <CALIBRATION>;

3. <ARCHIVE>;

4. <SETTINGS>;

5. <MEMORY CARD>;

6. <INFORMATION>.

After entering the selected sections, except the <Information>, the display is divided into two

areas: the main area and information area (upper part of the display).

In the main area Workspace section is located, and in the information provides information on the

batteries charge, connecting the device to your PC, SD card presence as well as the current time.

Before using the device, make sure that the batteries has enough power. Fully stocked LED

(green) indicates that the battery is charged to 100%. In the absence or deficiency of charge volume

(red), charge the battery charging from a charger or by connecting the device to PC.

Long press on the button < > makes the device to shut down.

2.3.3 Charging the battery

To charge the battery, the user must plug the power supply included with the hardness tester to the

power connector located on the upper end of the housing. During charging, the device can be used.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 18

Battery full time - 14 hours. Watch the device during charging. Also, the device can be charged by

connecting it to a PC.

If not using the device charge the batteries at least once per two month to avoid batteries from

failure.

2.3.4 Measurements using Ultrasonic Contact Impedance Probe U1 probe

RESTRICTION: limited use for measuring articles with a coarse-grained structure (e.g., iron)

or a mass of less than 100 grams, or less than 1 mm thick! Typically, such

products must be grounded to a massive polished plate.

1. Before measurements, it is necessary to prepare the surface according to p. 2.3.1.

2. Plug the UCI probe.

3. Turn the device on by long pressing < >.

4. Since the probe is already connected, the device immediately goes to the

<MEASUREMENTS> section (figure 2.5).

Figure 2.5 – <MEASURING> section

5. Choice the needed hardness scale, press < > to assess the choice menu (fig. 2.6), than

select the needed scale with < > and < > keys (the Rockwell C (HRC), Brinell

(HB), Vickers (HV), Rockwell B (HRB), Shore (HS), Leeb (HL), the measurement of tensile

strength (v), Tensile products of carbon steel pearlite (MPA), a user (U1, U2, U3)).

Figure 2.6 - Selecting the hardness scales

User calibration presence

Diamond indenter state

(Ready to work)

Mode

Scale

Material

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 19

6. Select the material that is going to be tested. By pressing < > open the selection menu

(fig. 2.7), with the keys < > and < > select the desired material (steel, alloy steel,

stainless steel, gray iron, ductile iron (< Nodular Iron>), aluminum, brass, bronze, copper, a

user (<USER. 1>, <USER. 2>).

Note: On supply the UCI probe only has records for steel. The rest of material may be

recorded by user.

Figure 2.7 – Material selection

7. Select a desired measurement mode (see. P. 2.3.6), using < > open mode selection menu

(fig. 2.8), using keys < > and < > select the needed mode (<GRAPH>,

<HISTOGRAM>, <STATISTICS>, <INTELLECTUAL>, <SIGNAL>).

Figure 2.8 - Selecting the metering mode

8. Place the probe thrust washer on the sample surface, keeping it in the area of support platform

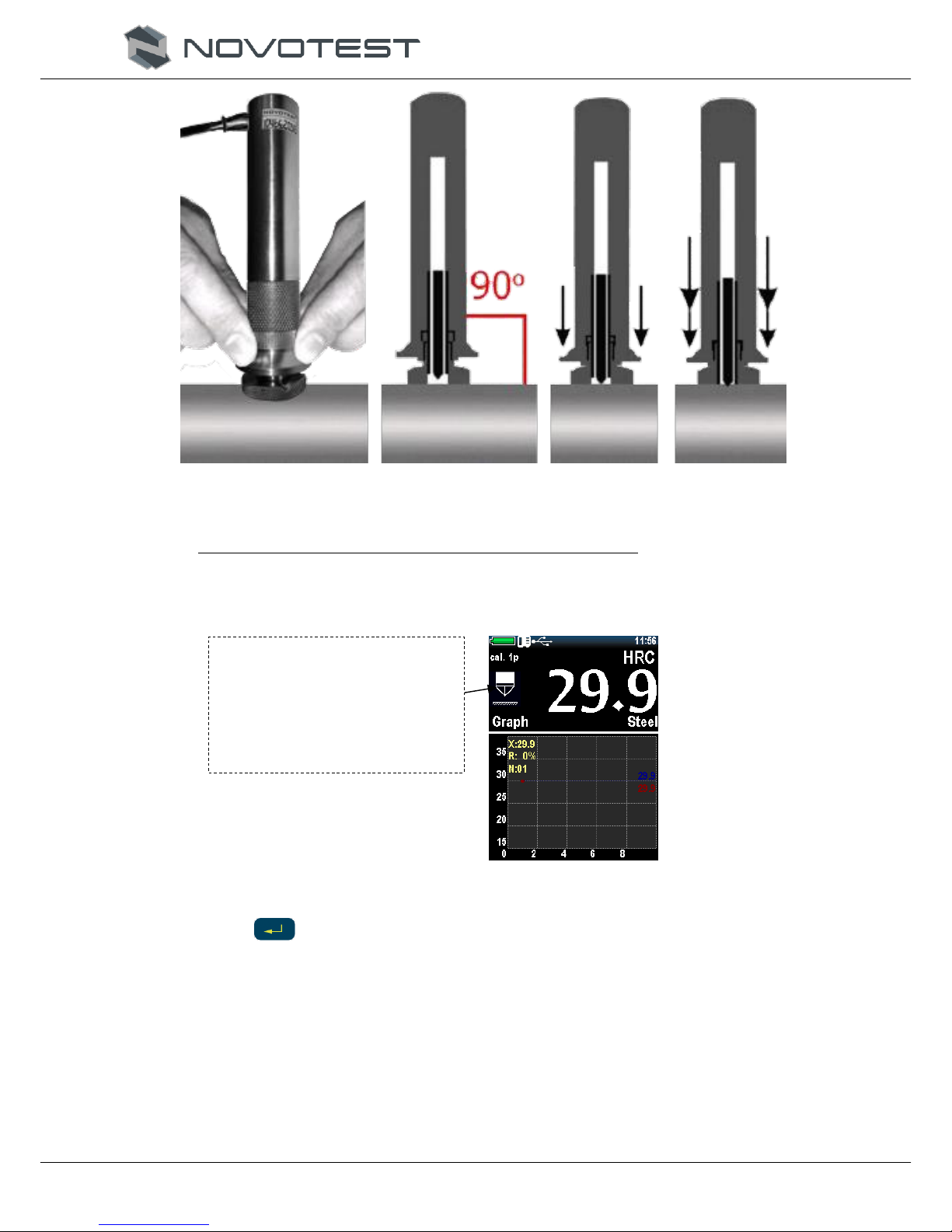

as shown in Fig. 2.9. A. Pushing on the support platform with two hands draw diamond tip of

the probe vertically to the sample until it touch the surface (Fig. 2.9, B) and non-stop, gently

(approximately while 0.5 seconds), with a pressing force (5 kg if probe UCI (50N) ) press the

diamond tip into the surface of the metal preventing rocking (Fig. 2.9 C).

Caution!

Avoid abrupt depression, because it can lead to exceeding the maximum permissible value of the error

and cleavage the diamond indenter.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 20

A B C

Figure 2.5 – Measuring with UCI U1 probe

Note: The load is set by the built in the probe controlled load spring.

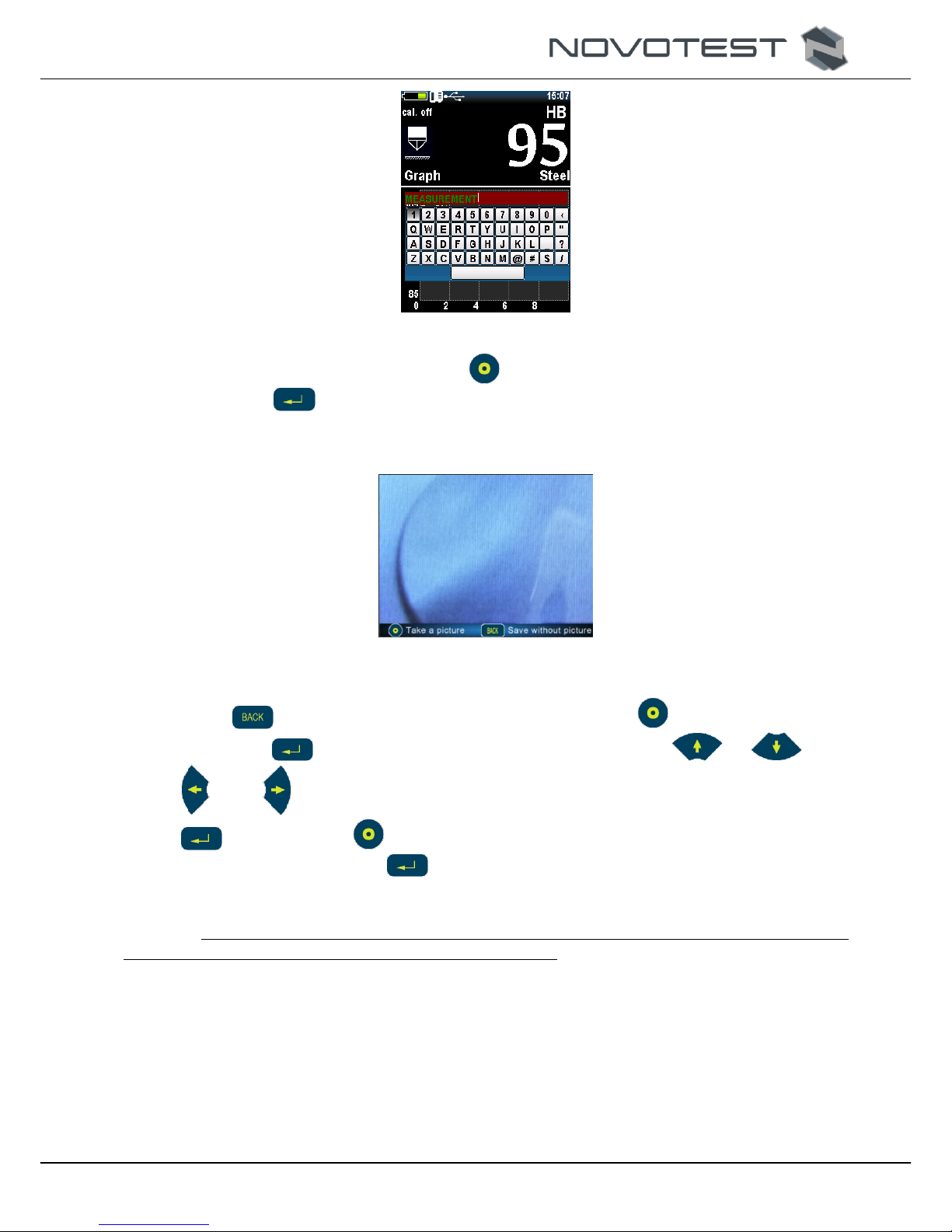

9. The display shows the value of hardness (Fig. 2.10). The measurement result is displayed on

the display until the next measurement.

Figure 2.10 - Display after measurement

10. After the measurements the user can save measurement (set of measurements) into archive by

pressing < > key (ENTER).

11. A keyboard will appear on the display to enter the measurement (set of measurements) (Fig.

2.11).

This symbol shows that the

diamond indenter is in touch

with the tested object or the

device is not ready for the next

measurement

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 21

Figure 2.11 - Entering a name for the stored dimension

12. Target on the needed symbol and press < > to select it. After entering the saving result

name press < > key to save.

13. If <PHOTO> mode is set on (See P 2.3.12 for the details about the <PHOTO> mode), than the

device will offer you to <TAKE PICTURE> or <SAVE WITHOUT PHOTO> (Fig. 2.12).

Figure 2.12 - Mode <PHOTO>

14. Press < > key to save the measurements without photo, or < > to take picture.

15. Than press < > key to save photo. Than, using navigation keys < >, < >, <

> and < > put the marker on the point, where the measurement took place, press <

> key to save, or < > to put another marker on the picture. Confirm saving of the

pointed marker by pressing < > key – saves picture without prompting to add another

marker.

Note: The distance between the fingerprint center and the edge of the specimen or adjacent

indentation should be at least 2.5 diagonal length fingerprint.

2.3.5 Measurements with the Rebound Leeb Probe

RESTRICTION: limited use for measuring objects with weight less than 5 kg or thickness less

than 10 mm without additional preparation! Typically, such products must

be grind to a massive polished plate.

1. Prepare the controlled object before taking measurements as in P. 2.3.1.

2. Plug in the Leeb probe.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 22

3. Turn the device on by long press the < > key.

4. Since the probe is connected the device goes to the <MEASUREMENT> mode at once (Fig.

2.13).

Figure 2.13 - <MEASUREMENT> SECTION

5. Select the needed hardness scale, press < > to assess the choice menu (fig. 2.13), than

select the needed scale with < > and < > keys (the Rockwell C (HRC), Brinell

(HB), Vickers (HV), Rockwell B (HRB), Shore (HS), Leeb (HL), the measurement of tensile

strength (v) Tensile products of carbon steel pearlite (MPA), user’s (U1, U2, U3)).

6. Select the desired material. By pressing < > open the selection menu (fig. 2.13), with the

keys < > and < > select the desired material (steel, alloy steel, stainless steel, gray

iron, ductile iron (<NODULAR. IRON>) aluminum, brass, bronze, copper, a user (<USER 1>,

<USER. 2>)).

7. Select a desired measurement mode, using < > open mode selection menu, using keys <

> and < > select the needed mode (<GRAP> <HISTOGRAM>,

<STATISTICS>, <INTELLECTUAL>, <SIGNAL>).

8. Press keys < > or < >, to set the measurement angle. The angle is shown at the

top of the display (Fig. 2.14). Default angle 0 degree corresponds to vertical position of the

probe, where trigger button looks up.

Figure 2.14 – Setting the angle

User calibration presence

The angle of

measurement

Mode

Scale

Material

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 23

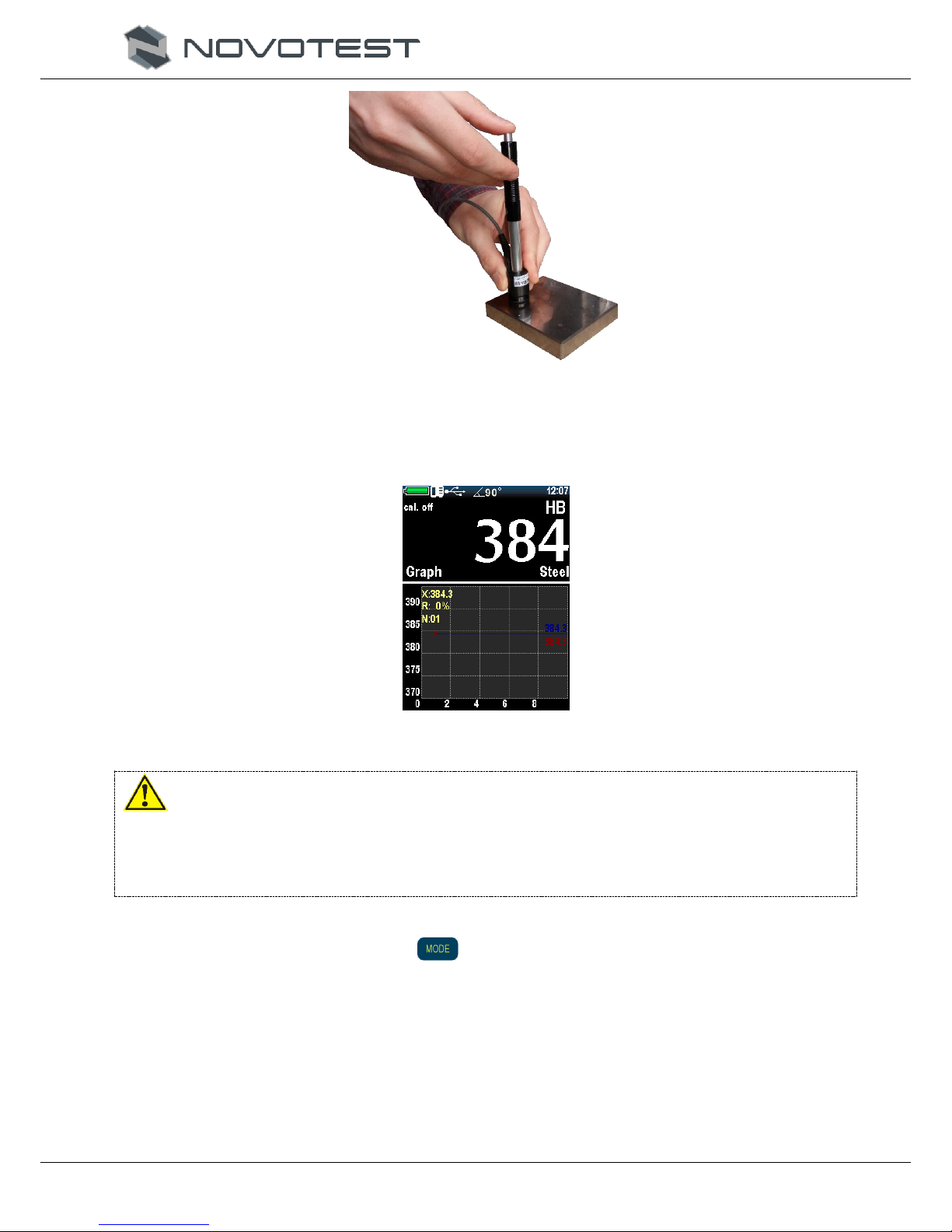

9. Set the probe onto the surface of the material at the zone of control (Fig. 2.15).

Figure 2.15 – Setting the probe

10. Hold the bottom part of the probe housing with one hand, and charge the spring of the probe

by mowing the upper part of the housing down with the other hand. (Fig. 2.16).

Figure 2.16 – Charging the spring of the probe

11. Smoothly push the trigger button on the top of the probe (Fig. 2.17). Make sure that the probe

does not move and secured to the surface of the controlled zone.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 24

Fi 2.17 – Pushing the trigger button of the probe

12. After pushing the trigger button and the Impact Body hits the surface the measured hardness

value will appear on the display. (Fig. 2.18).

Figure 2.18 – The display after the measuring with the Leeb probe

Caution!

The minimal distance between the points of measuring should be not less than 3 mm. Do not repeat

measurements on the same place, because the ??

Repeated measurements at the same point are not allowed. They give overestimated indications of the

hardness of the product due to metal cold work in the imprint zone.

2.3.6 Measurement modes

Enter measurement mode and push < > key to enter the mode selection menu (fig. 2.19). The

device will offer you the following measurement modes:

GRAPH – graph drawing mode;

HISTOGRAM – histogram building mode;

STATISTICS – statistics mode;

INTELLECTUAL – measurement failure filtration mode;

SIGNAL – signal displaying mode (for the Leeb probe only).

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 25

Figure 2.19 – Measurement mode selection

Push < > key to set up the selection.

2.3.6.1 GRAPH

In this mode, the instrument displays the value of the current measurement or the average of the

series of measurements in the form of a graph (Figure 2.20), depending on the settings in the menu

settings.

Figure 2.20 – GRAPH mode

2.3.6.2 HISTOGRAM

Histogram of a series of measurements (Fig. 2.21).

Figure 2.21 - Histogram Mode

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 26

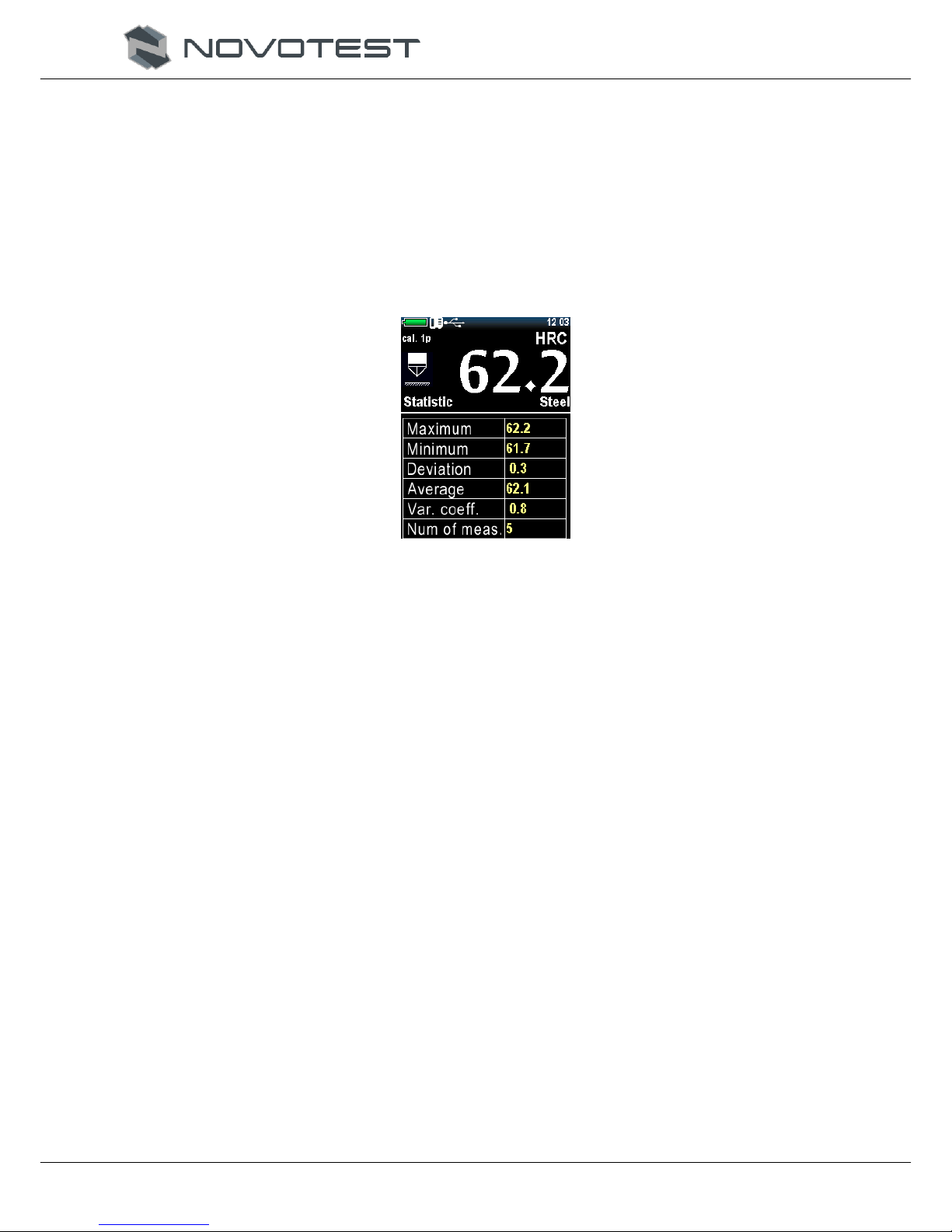

2.3.6.3 Statistics

Statistics mode allows user to view the following parameters in a series of measurements:

maximum;

minimum;

deviation;

average;

coefficient of variation of a random variable;

number of measurements.

Fig. 2.22 shows an example of work in the statistics mode, in which the table lists all the

parameters of a series of measurements.

Figure 2.22 - Statistics mode

2.3.6.4 Intelligent mode

The accuracy of the instrument is influenced by many external factors, which introduce an

additional error in the measurements. It can be:

jiggle of hand;

move of the tested object;

swaying of the probe;

surface cleanliness;

surface roughness.

For ultrasonic probe additionally:

the load is too short or too long;

probe is pressed too lightly or too hard;

low batteries.

Intelligent mode allows to determine the overall sequence of measurements. Select the first three

series of measurements that do not exceed the specified tolerance. After that, the following

measurements, which exceed the specified tolerance, will be excluded from the series, and will not be

taken into account when calculating the average value of the measured hardness from this series

(Figure 2.23).

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 27

Figure 2.23 - Intelligent mode

A hardness value filled with white means that the device has a fixed common sequence and the

intelligent mode is active (Figure 2.24).

Figure 2.24 - Active Intelligent Mode

To set the tolerance for Intelligent Mode, go to the <Settings> menu, set the tolerance values in

percentages from 1 to 10 (Figure 2.25).

Figure 2.25 - Setting the tolerance for the intelligent mode

Also, in order to reduce the influence of external factors in the device settings, you can include the

Kalman filter or the Median filter.

In order for the instrument readings to be most accurate, the user needs to select the proper filter

for the particular case.

Kalman filter

The Kalman filter is a linear filter, which is used to obtain the truest value. Also, the Kalman filter

can be defined as a filter giving the least mean square error.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 28

The main idea of the filter is to find the coefficient C that will correct the received value so that it

would differ from the real value the least.

Kalman filter is recommended to be used when measuring on a product with heterogeneous

structure, where hardness jumps can be observed, which must be taken into account when assessing

the hardness of the product. Kalman filter can reduce the influence of external factors on the

measurements, while not distorting the jumps in hardness.

Median Filter

The median filter - is a nonlinear filter that is applied to signals subjected to pulse interference.

The medial filter is recommended for measuring homogeneous products, in which should be no jumps

in the value of hardness. If, due to external factors, the probe changes the readings, the filter will

smooth it to the normal value.

2.3.6.5 SIGNAL

The mode is active only for the dynamic probe and shows the voltage. M - represents the

maximum value that corresponds to the signal (Figure 2.26).

Figure 2.26 - Signal Mode

2.3.7 Calibration

2.3.7.1. Calibration of scales

To calibrate the probe, 3 samples of material with known hardness value are needed. The hardness

range should be wider than the hardness of the material that will be measured in the future (the value

should be a maximum or more, a minimum or less, and an average).

1. Select <CALIBRATION> from the main menu. Each cell in the table corresponds to a specific

calibration scale for a particular material (Figure 2.27). All calibrations can be calibrated for

any materials and any scales, and are thus separated only for the systematization of a set of

calibrations.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 29

Figure 2.27 - Calibration Mode

2. Use the navigation keys to select the cell to be calibrated, for example, HRC for steel (Figure

2.28).

Figure 2.28 - Selecting a cell for calibration

1. Push < > to select, you will see the table as in Fig. 2.29. The device, while measurements,

receives nominal codes, the purpose of calibration is to find the correlation between the code

value and the hardness value (to create the function of dependence).

Rokwell C

Brinell

Vickers

Rokvell В

Shore

User Scales

Still

Alloy steel

Stainless steel

Cast iron

High-strength cast

iron

Aluminum

Brass

Bronze

User Material

Copper

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 30

Figure 2.29 - Calibration table

2. To start the calibration, enter the real hardness values of the samples by pressing the key

< >. Using navigation keys < > and < > to set up the real hardness values,

push < > key to enter the next value (Fig. 2.30).

Figure 2.30 - Setting real hardness values

3. Push the key < > one more time to set the first value, than the key < > to edit

harrdness value for the next samples.

4. Then move the cursor to the hardness value according to the sample, and make at least five

measurements (Figure 2.31). Make sure that the value of X (the current code value) does not

change by more than 3%.

Figure 2.31 - Measuring for calibration

Number of

measurements

Current code

value

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 31

Push < > key if there is an obvious error and the last value will be removed from the

series.

5. Move to the next nominal < >, and complete the same procedure to the other samples

(Fig. 2.32).

Figure 2.32 - Calibration performed for one sample

6. To verify that the value is correct, move the cursor to X: 000 and make several measurements

on one of the samples.

7. Push < > key to exit. Push < > (“YES”), to save, or < > key (“NO”), to exit

without saving (Fig. 2.33).

Figure 2.33 – Saving

2.3.7.2 User (additional) graduation

Each of the stored calibrations can be further adjusted.

The user grading of the hardness tester in the inter-service calibration interval is recommended in

the following cases:

if, while checking the hardness tester with the reference hardness measure, its readings are

stable, but differ from the value of the reference hardness measure;

after long-term storage (more than 3 months.);

after intensive use;

if the operating conditions (temperature, humidity, etc.) change significantly.).

To graduate the hardness tester, one (one-point graduation) or TWO (two-point calibration)

reference hardness measures with the maximum and minimum values are required at the controlled

portion of the hardness scale.

For example, we have two samples of steel with a known hardness value of HRC, and the

instrument shows a stable deviation when measuring the hardness on it.

1. To calibrate by two points, select <CALIBRATION> in the main menu (Fig. 2.34).

Reference value.

Calculating the

average value of a

series of code.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 32

Figure 2.34 - Grading

2. Use the navigation keys to select a cell for calibration, for example, HRC for steel.

3. Push < >, and the calibration window will open on the display (Figure 2.35).

Figure 2.35 - The Graduation Window

4. Push < > key to select the number of the calibration points, If there are two samples, you

must select 2 using the keys < > and < >, to confirm push < > (Fig. 2.36).

Figure 2.36 – Two points calibration

5. Moving the cursor with < > key, select the first line. Make about five measurements on

the first reference sample, the device will show the average value of the series according to the

current calibration (Fig. 2.37). If you got obvious error of measurement push < > key,

and the last measurement will be deleted from the seriers.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 33

Figure 2.37 - Calibration measurements

Push < >, and using < > and < > set the nominal hardness value of the

reference sample.

6. Use < > key to move to the next value, push < > to save the first one. After the

correction of the hardness value of the first sample the display will look like on Fig 2.38.

Figure 2.38 - After adjusting the first sample

7. Push < >, to set up the second sample value, the procedure will be the same as for the

first one. After the end of all the operations, the display will look as on Fig. 2.39.

Figure 2.39 - After adjustment for the second sample

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 34

8. Push key < > to save. Push < > (“YES”), to save, or < > key (“NO”), to exit

without saving.

9. The saved user calibration will be marked with a special state of the cell (Fig. 2.40).

Figure 2.40 - User calibration labeling

10. To delete a custom calibration, go to the custom calibration mode and set the value to “0” for

the N parameter (Figure 2.41).

Figure 2.41 - Deleting a user calibration

2.3.8 Settings

When the <SETTINGS> menu section is selected, the device enters the setting mode of the

following parameters:

<TIME>: setting the time (24h format);

<DATE>: setting the date format DAY / MONTH / YEAR;

<LANGUAGE>: selection of the menu language of the device (available in English,

Russian, etc.);

<PHOTO>: turn on / off the camera (for versions with the camera);

<BRIGHTNESS>: change the brightness of the display;

<PALETTE>: section of menu themes (creation of a color palette of the menu is made

with special software);

<SOUND>: there are 4 sound modes (off, keyboard, measurement, keyboard and

measurement);

<RESULT>: the display of measurement results can be current (an instantaneous

measurement value is displayed) and calculation of the average value;

<VOLUME>: adjust the volume of the device;

<AUTO-OFF>: setting the device to automatically turn off when not in use;

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 35

<RETRO>: allows the user to return to the measurement mode with the last measurements

saved after the device is rebooted;

<FLASH>: enable/disable camera flash (for the version with camera);

<TOLERANCE>, %: this parameter is used only for intelligent mode. The values in %

control the range of measurement deviations, which will be included in the calculation on

average for the series in the intelligent mode;

<FILTER>: Kalman or Median, and also turn off the filtering;

<FITLER MODE>: filter mode.

To make changes in the <SETTINGS> section, all the navigation keys are used: < >, < >, <

>, < >, < >. Push key < > to exit.

In Fig. 2.42 <SETTINGS> section is presented.

Figure 2.42 – <SETTINGS> section

2.3.9 Archive

When the <Archive> menu item is selected, the device enters the list of saved measurements,

which displays the name, date and time of the measurement, scale, material and average value (Figure

2.43).

Figure 2.43 - Archive

Use keys < > and < > to navigate.

After selecting the desired saved measurement, the user can view it, and print it: turn on the

printer and press < >.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 36

To delete a record from the archive, select the entry with the navigation keys and press < >,

after that the confirmation message <DELETE?> is displayed on the display, press the key < >

To delete or < >, to cancel.

2.3.10 Memory card

When the menu item <MEMORY CARD> is selected, the device goes to the memory menu

(Figure 2.44).

Figure 2.44 - Section <MEMORY CARD>

Creating backup copies of calibrations.

After calibrating the sensor, it is recommended that the user create a backup calibration (usually

the manufacturer calibrates 1-2 scales to check the probe). This is done in order to be able to back

up to the proper calibration after incorrect settings in the future.

After initial saving of the calibrations, the user can always transfer the settings to the probe. This

function is needed to resume proper calibration in case of incorrect probe settings.

Memory card cleaning.

Deleting saved records in the archive and backup copies of the calibrations: after cleaning the SD

card, the archive will be empty and the backup copies of the calibrations are saved.

At the bottom of the screen of this menu is a memory status indicator.

2.3.11 Information

In this menu item, the user can view information about the manufacturer and representative offices

around the world (Figure 2.45).

Figure 2.45 - Section <INFORMATION>

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 37

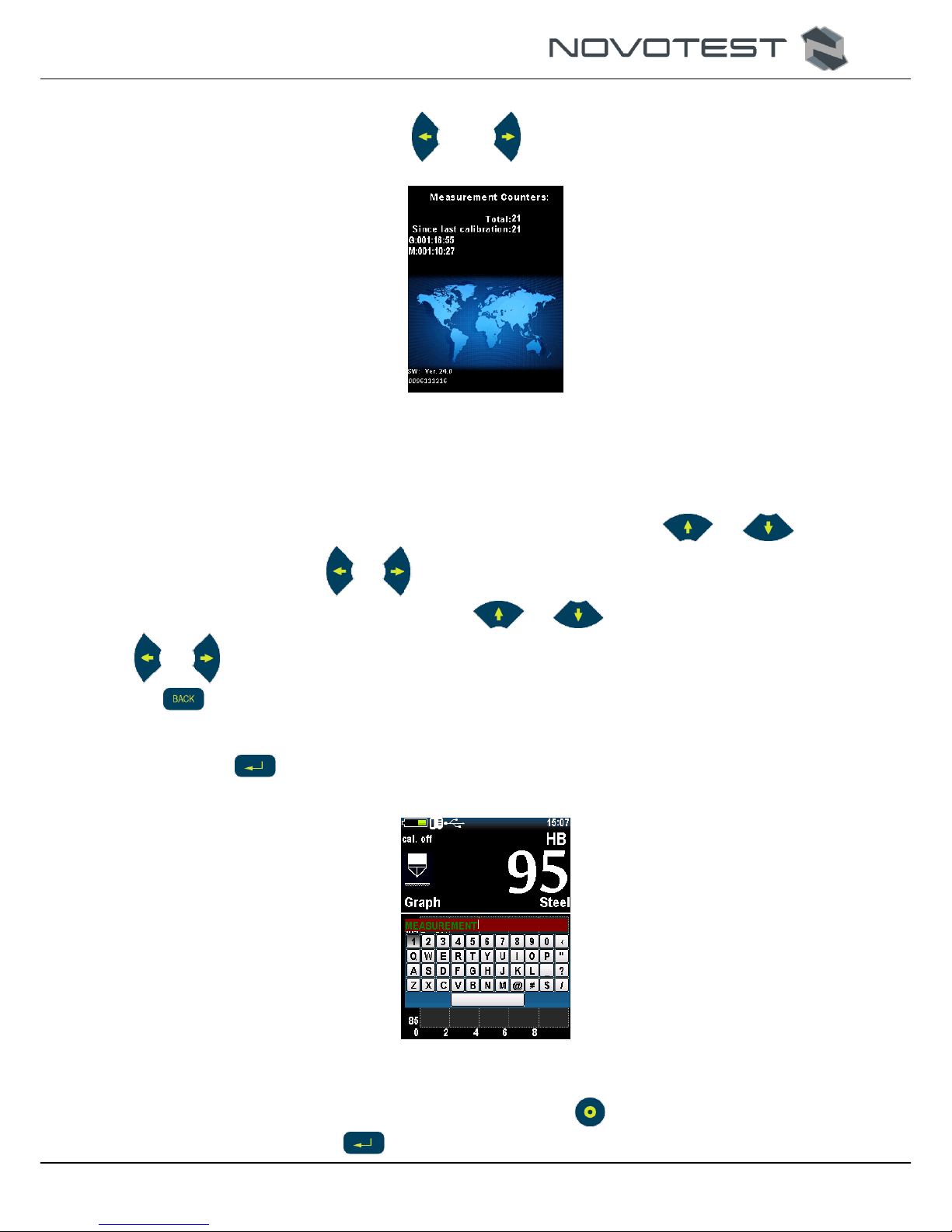

Also in this menu item the user can find information about the device and the number of

measurements, use the navigation keys < > and < > to open the needed table (Fig. 2.46).

Figure 2.46 – Information about the device and the measurements number

2.3.12 Photo fixation of the measurements

Photo fixation of the measuring point is used in models with a photo camera.

You can enable photo fixation in the device settings, For this the user needs to go to the

<SETTINGS> section from the main menu, in the settings using the keys < >, < > select

<PHOTO> and using keys < >, < > change <OFF> to <ON>. Also in the settings, the user turns

on the photo flash light, for this, using the keys < >, < > select <FLASH> and using keys

< >, < > Change <OFF> to <ON>. Then you need to exit the <SETTINGS> section with the

key < >. Now the user can start measuring.

After the measurement, to save the measurement (a series of measurements) to archive with photo

fixation of the measurement location, do next:

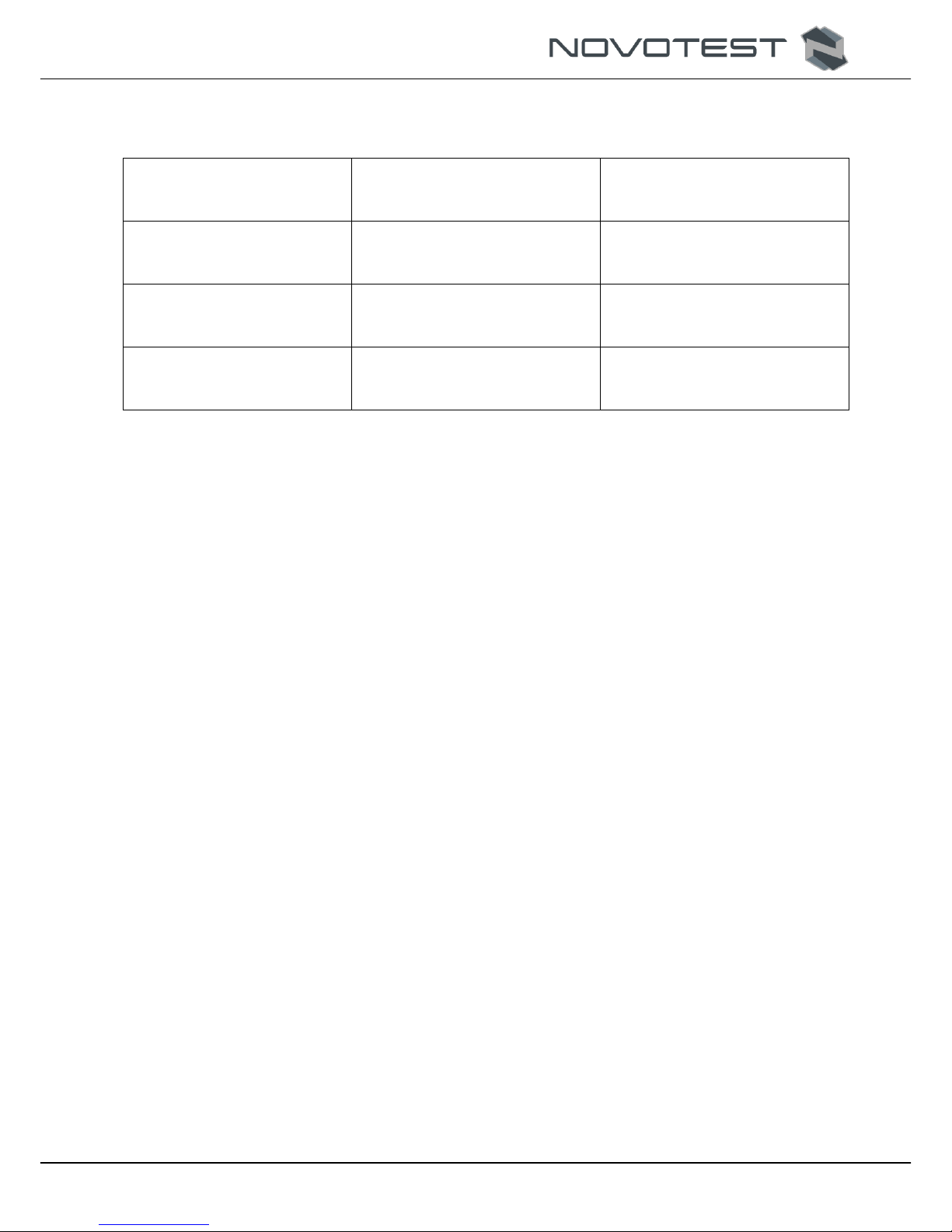

1. Push < > key (ENTER). A keypad for entering a measurement name (a series of

measurements) appears on the display (Figure 2.47).

Figure 2.47 - Entering a name for the stored measurement

2. Move the cursor to the desired character and press the < > key to select it. When you finish

typing a name, press < > to save. Further, the image from the camera will be transferred

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 38

to the display in real time and it will be offered <MAKE A PHOTO> or <SAVE WITHOUT

PHOTO> (Fig. 2.48).

Figure 2.48 - Picturing the object

3. Push key < > To save the measurement without photos, or point the camera at the

measured object so that the measuring point can be seen (if the place is poorly visible due to

lack of lighting at the time of shooting, the flash will <highlight> it if it is turned on in the

device settings) push < > to take photo.

4. After shooting, the display will look like in Fig.. 2.49.

Figure 2.49 - After shooting

5. Push < > key to save photoor key < > to take another picture.

6. After saving the photo using the navigation keys < >, < >, < >, < > specify

the measurement location in the picture (Fig. 2.50), Scale and the value of hardness, as well as

the date and time of measurement (creating a snapshot) is indicated automatically. To end the

photo fixation and save the measurement in the archive, press < >.

Note: To save a picture with one measurement point (marker), press < >, And in order to

specify the next point on the same picture, press the key < >. Confirm of storing the

indicated point with the key < > – saves a snapshot without the ability to add a new

measurement point (marker).

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 39

Figure 2.50 - Marking of the measuring point

2.3.13 Connecting to PC

2.3.13.1 Software setup

When connected the data may be send from and to the device. From the device, arched

measurement data are send. As well as real time display snapshots. To the device color palette

interface schemes could be send (may me changed in settings in the <PALETTE> section, as well as

the archived data may be controlled.

To connect the device to PC do next:

1. Copy driver “DRIVER_FT232RL” for “Windows 7” and “Windows 8” or

“CP210x_VCP_Windows” for “Windows 10” (х64 or х32 up to your OS) and the “AWP

UNIVERSAL” program (.zip type archives) to the PC hard drive or download the updated

versions from the official web site.

2. Unpack the files getting two folders (Fig. 2.51).

Figure 2.51 – Downloaded software

3. Now the user can connect the device to the PC using the USB cable supplied. After

connection, the computer detects a new connected device, but does not find a driver to work

with it, they must be installed manually.

4. For installation, go to <START> CONTROL PANEL> DEVICE MANAGER> in the <COM

and LTP PORTS> section there will be an unidentified device.

5. Open the device properties by double-clicking the left mouse button on it and clicking on the

<DRIVER> tab.

6. Click on the button <UPDATE ...> select <SEARCH DRIVERS ON THIS COMPUTER>.

7. Click on the <SEARCH> button and select the path to the downloaded (copied) folder with the

driver and press the <NEXT> button, after which the driver installation process will begin.

8. Restart the PC after successful driver installation.

9. Install the program to work with the device, for this, run the setup.exe file of the program

installation and click the <INSTALL> button (Figure 2.52).

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 40

Figure 2.52 – Installing AWP Universal

10. After the installation is completed, the shortcut for the program <AWP UNIVERSAL>

appears on the desktop.

2.3.13.2 Using the software

Connect the device to the PC using USB cable и Run the <AWP UNIVERSAL> program, after

selecting the archive location, the program will start.

In the section (Figure 2.53) <WORK WITH ARCHIVE> the user can view, print, copy and move

data from the archive.

Each record is saved with full measurement information (a series of measurements), in the record

selection window, a brief information:

Name;

Date and time;

Probe (probe);

# of the probe (probe);

# of the device.

To copy data from the instrument to the PC, the user needs to specify the measurement period, and

then press the <COPY> button.

Note: By pressing the <MOVE> button, the data is not simply copied to the PC, but also deleted

from the device memory.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 41

Figure 2.53 – Program <AWP UNIVERSAL> section <WORK WITH ARCHIVE>

After selecting a record on the right side of the program, a photo of the tested location appears (if

it is added to the record). Additional information appears in the lower part of the program in the form

of a table and a plotted chart or a histogram of a series of measurements (can be changed using the

dynamic button <GRAPH / HISTOGRAM>). Above the graph is the number of the series, the

hardness scale, and also the material of the measurement object.

The table shows such recording parameters:

Maximum;

Minimum;

Amplitude;

Average value;

Standard error;

Standard deviation;

Variation coefficient;

Uniformity of the series;

Number of measurements.

The saved data can be immediately printed, by pressing the <PRINT> button. The user can also

delete the recording from the instrument using the <DELETE> button.

The data for a certain period (set by the user) or manually selected from the archive can be moved

(deleted from the device memory) or copied (remain in the device memory) to the PC.

Also at the <WORK WITH ARCHIVE> tab the user can make settings to the program.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 42

To change the language, press the <ENG / RUS> dynamic key and the program language will

change from Russian to English or vice versa.

To change the location of the archive, click on the location of the archive and select a new archive

location.

To go to our site you need to click on one of the flags or on the planet (international in English),

after clicking the site will open in the default browser.

On the <COLOR SETTING> tab, you can create a new one or load and edit the standard color

design of the device (Figure 2.54).

Figure 2.54 – <COLOR SETTING> tab

To load the current color settings, click on the <LOAD> button, and then select the edited color

theme with the <PALETTE> button. To edit, click on the color you want to change, and select a new

one. When all colors are changed, specify the name of the palette and save it on the device with the

<SAVE> key.

On the <SCREEN COPIES> tab, the user can save the screen images on the device in real time

(Figure 2.55).

To save the image, you must press the <CAPTURE> button, after which a message that the screen

shot is saved will be displayed on the PC screen. When all the necessary actions on the device are

<CAPTURED>, the user need to click on the <LOAD> button after which the images will be saved in

the program archive.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 43

Figure 2.55 - Screen saving tab

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 44

3 TECHNICAL MAINTENANCE OF THE PRODUCT AND ITS COMPONENTS

3.1 Security measures

It is recommended that the device commissioned be periodically inspected for monitoring

purposes:

performance;

compliance with the operating conditions;

battery charge level;

absence of external damage to the component parts of the device.

When working with a charger connected to the 220V network at 50 Hz, the requirements stated in

the “Safety rules for the operation of electrical installations of consumers” are mandatory.

If the device is not used for a long time, the batteries should be turned off or removed. In doing so,

the batteries storage rules must be kept.

Those who have been instructed and certified for the II qualification group for safety in working

with electro-radio measuring devices are allowed to work with the device are.

3.2 Verification

The recommended verification interval at least once a year.

The verification procedure (calibration) - further verification, applies to hardness testers

NOVOTEST T-UD3 and establishes methods and means of their primary and periodic verification.

The verification procedure (calibration) - further verification, applies to hardness testers

NOVOTEST T-UD3 and establishes methods and means of their primary and periodic verification

Verification conditions and preparation for it

Verification of the device is carried out under climatic conditions:

temperature from 15 to 280С;

relative humidity 65 ± 15 %;

pressure 101 ± 2 kPa.

The power supply must comply with Table. 1.1. (It is possible to connect an external power

supply if polarity is maintained).

Measures of hardness during verification should be ground to a grinding plate with a mass of not

less than 5 kg, through a layer of lubricant.

3.2.1 Operations and verification means

When carrying out the verification, it is necessary to carry out the operations and to apply the

means of verification specified in Tab. 3.1.

Table 3.1 - Operations and verification means

Name of verification

operations

Number

of items

Name of

verification

means

When is a mandatory

Release from

production and

repair

Operation and

storage

1 2 3 4 5

1. Visual inspection

3.3.2 yes

yes

2. Testing

3.3.3 yes

yes

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 45

1 2 3 4 5

3. Determination of

the basic error of the

instrument according

to the HRC scale

3.3.4

Reference

hardness test

blocks

yes

yes

4. Determination of

the basic error of the

instrument according

to the НB scale

3.3.5

Reference

hardness test

blocks

yes

yes

5. Determination of

the basic error of the

instrument according

to the НV scale

3.3.6

Reference

hardness test

blocks

yes

yes

3.2.2 Visual inspection

The device should be complicated in accordance with p. 1.3.

No foreign objects detected by hearing when it tilts, should be inside the electronic unit of the

device.

No parts of the probes should have any signs of corrosion and mechanical damage.

3.2.3 Testing

The device is tested according to p 1.7, and also:

for modification of NOVOTEST T-U3, the test is performed with an Ultrasonic Contact

Impedance Probe U1;

for modification NOVOTEST T-D3 testing is carried out with a Rebound Leeb Probe.

3.2.4 Determination of the basic error of the instrument according to the HRC scale

1. Select the HRC hardness measurement.

2. Select the measurement mode statistics.

3. Carry out at least 3 measurements of HRCi on the hardness measures (excluding explicit

measurement errors).

4. 4. Determine the basic error of hardness measurement on the HRC scale using the formula:

, (1)

where n – number of measurements.

5. Select the hardness measurement on the scale of user. НRС.

6. Select the statistics measurement mode p. 2.3.5.

7. Make at least 3 measurements of HRCi on hardness reference blocks (excluding explicit

measurement errors).

8. Determine the basic error of hardness measurement on the HRC scale by the formula (1).

9. If the error exceeds the allowable value (Table 1.2), then it is necessary to calibrate the user

scale according to p. 2.3.7.

10. Repeat operations 6 through 8.

11. The basic error of hardness measurement for the HRC scale and in the scale of use. НRC

should not exceed ± 2,0 НRC.

NOVOTEST.ED.Т-UD3.000 OM

Operation Manual

Hardness Tester NOVOTEST T-UD3

Page. 46

3.2.5 Determination of the basic error of the instrument on the scale HB

1. Select the hardness measurement on the HB scale.