Novoferm Novo Speed Alu User Manual

www.novospeedsolutions.com

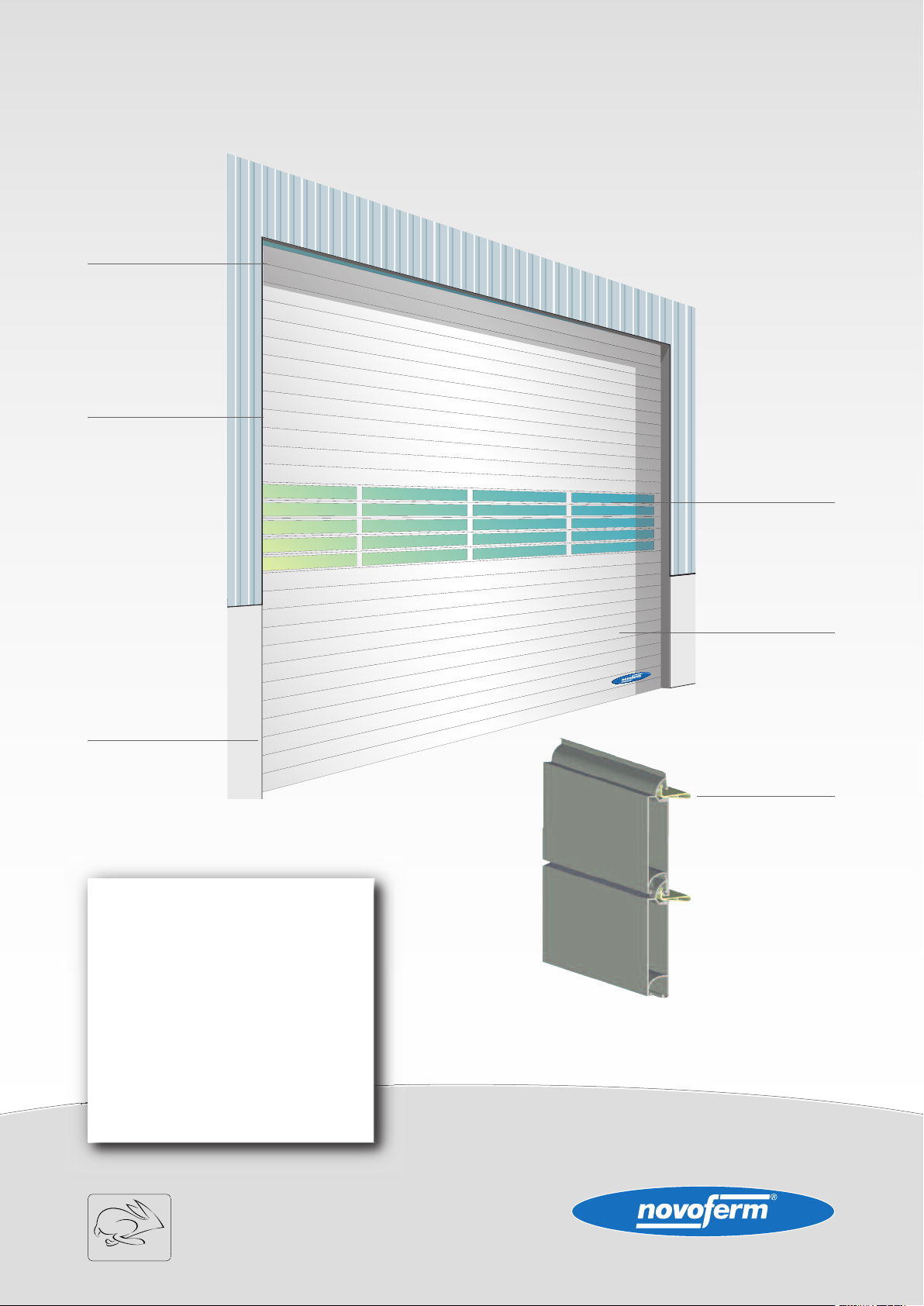

Aluminium rolling door Novo Speed Alu

Industrial outside door to 36 m2, wind resistant to 8 Beaufort

olid, self-supporting

S

onstruction

c

heavy, maintenance-free

draw springs in the guide

olumns.

c

itting of viewing and

f

entilation strips possible

v

protection with active

light curtain photocells

(optional)

Properties

• max. surface area

(WxH) = 36 m

• max. W x H = 6000 x 6000 mm

• wind resistant to 8 Beaufort

• opens at max. 2 m/sec.

• closing speed 0.5 m/s

• safe closing with edge protection and

light screen (option)

• suitable for intensive use

• strips of anodised aluminium.

2

roblem-free

replacement of individual

p

strips

spacers

for noise insulation

www.novospeedsolutions.com

Aluminium rolling door Novo Speed Alu

The Novo Speed ALU combines the advantages of an aluminium

rolling door with those of a High Speed door. As a complete exterior

door this door is weather-proof, protected against forced entry and

has an insulated door leaf. The door opens and closes at a speed

normal only achieved by rapid action roller doors. The door is then

highly suitable for intensively used exterior openings.

Advantages

• significant cost savings because now only one door is needed

• solid and self-supporting frame construction

• by using a drive with frequency control the door opens smoothly

and the time in the open position is reduced to a minimum

• the door leaf is balanced by springs in the guide columns

• slats can be simply replaced

• resistant to wind pressure to 8 Beaufort

• low maintenance costs with simple technology and an easily

accessible construction

• safe through the use of photocells and closing edge protection

• available in the RAL colour required

• application of transparent slats is possible

Composition

The door panel consists of pressed aluminium strips with PVC guide

pieces on the ends. Between the strips there is a PVC profile that

prevents the strips from rolling onto each other when the door is

opened. These profiles also ensure a major reduction of noise when

opening and closing. A tensioning system in the columns ensures

that the door panel is balanced and remains taut.

Materials

The lateral guide consists of galvanised steel columns. The slats are

pressed aluminium. These can be supplied in any RAL colour (powder coating). The profile between the strips is soft PVC.

Dimensions

• minimum width .................................................................1500 mm

• max. width .........................................................................6000 mm

• minimum height ................................................................2000 mm

• max. height ........................................................................6000 mm

• lateral space drive side.......................................................400 mm

• lateral space not driven side ..............................................250 mm

• head room ..............................................................approx. 700 mm

• fitted depth ..........................................................................900 mm

Drive

The drive consists of an industrial tube motor assembled in the

roller. As a result the necessary lateral space is minimal. The drive

is on the right-hand side of the roller as standard

Control and operation

The control system regulates a multitude of functions such as:

• adjustable open time

• continuously variable speed regulation by frequency control for

opening and closing the door

• service and run mode

• 7-segment display for controlling the various functions

• choice of permanently open or permanently shut

Other forms of operation that can be connected to the

standard control box are:

• operation by pull switch, key-operated switch, push-button,

photocell, radar, induction loop detection or by radio control

with transmitter and receiver.

Performance

The opening speed is adjustable to a max. of 2 m/s (depending on

the door size). The max. closing speed is limited to 0.5 m/s for safety reasons.

Protection

• electrical closing edge protection provided as standard

• a safety photocell 250 mm from the floor is standard.

Structural provisions

• in normal circumstances no special structural provisions are

required for the assembly and fitting of a Novo Speed Alu. The

self-supporting construction must only be fixed at the floor and

at the top.

• for the electrical connection (doors < 25 m2) there must be a

wall socket within a radius of 500 mm of where the control box

will be positioned (CEE form blue, 1 x 230V fused, slow operation 16 A and fitted with an circuit-breaker of at least 300 mA).

As standard this is fitted at a height of approx. 1500 mm from

the floor on the drive side.

• for the electrical connection (doors ≥ 25 m

wall socket within 500 mm of where the control box will be positioned(CEE form 3~NPE/400V/50Hz/16A). As standard this is fitted at a height of approx. 1500 mm from the floor on the drive

side.

• the clear opening in which the door is assembled is not available during assembly!

2

) there must be a

Technical details electric motor

mains voltage < 25 m2..............................LNPE~230V/50Hz/16AT

mains voltage ≥ 25 m2.....................................3N~400V/50Hz/16A

control voltage ...........................................................................24 V

degree of protection ..................................................................IP54

consumed power ............................................................max. 4 kW.

Auxiliary components/optional extras/accessories

• protective hood over roller and drive

• construction in IP65

• operation by push-button, pull switch. Photocell, induction loop

detection, radar or with hand transmitter

• light curtain

• half-height stop

• door interlock control

• traffic lights.

technical alterations and printing errors reserved Edition: January 2009

Loading...

Loading...