Page 1

ZBL-U5600/U5700

Multichannel Ultrasonic Pile

Integrity Tester

Instruction Manual

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 2

Manual for Multichannel Ultrasonic Pile Integrity Tester

1

1

3

5

5

7

9

21

Contents

CONVENTIONS IN THIS MANUAL 0

CHAPTER 1 GENERAL 1

1.1 B

1.2 MAIN FUNCTIONS AND FEATURES

RIEF INTRODUCTION

1.2.1 Main functions............................1

1.2.2 Main Features ............................2

1.2.3 Relevant test specification .................3

1.3 M

1.4 PRECAUTIONS

1.5 DEVICE MAINTENANCE AND PRESERVATION

1.6 R

CHAPTER 2 INSTRUMENT DESCRIPTION 9

2.1 I

AIN TECHNICAL SPECIFICATIONS

ESPONSIBILITY

NSTRUMENT COMPOSITION

2.1.1 Host ....................................9

2.1.2 Transducer..............................15

2.1.3 Counting device .........................17

2.1.4 Accessories .............................21

2.2 T

EST PRINCIPLE

2.2.1 Cross-hole sonic logging for testing pipe

integrity 21

2.2.2 Ultrasonic-rebound combined method for

testing concrete strength ..........................23

2.2.3 Ultrasonic method for testing uncompacted area

and cavitation ....................................24

Novatest S.r.l.

1

info@novatest.itwww.novatest.it

Page 3

Manual for Multichannel Ultrasonic Pile Integrity Tester

26

27

28

33

41

42

43

43

43

44

44

45

45

45

47

48

49

50

51

53

55

57

CHAPTER 3 COMMON MODULE DESCRIPTION 26

3.1 S

3.2 CONTROL INTRODUCTION

TARTUP INTERFACE

3.3 SOFT KEYBOARD

3.3.1 Character input ..........................28

3.3.2 Number input............................31

3.4 W

AVEFORM DISPLAY AND OPERATION

3.4.1 Terminology .............................35

3.4.2 Dynamic waveform operation ..............37

3.4.3 Static waveform operation.................38

3.4.4 Magnify and display single-channel waveform40

3.5 F

3.5.1 O

3.5.2 OPEN FILE

3.5.3 P

ILE MANAGEMENT

PERATING MODE

ROJECT AND FILE COPY

3.5.4 PROJECT AND FILE DELETION

3.5.5 PROJECT AND FILE UPLOAD

3.5.6 E

3.6 ZERO SET

3.6.1 M

3.6.2 ACOUSTIC ZERO SET

3.7 R

3.8 BATTERY LEVEL

3.9 S

3.10 SYSTEM SETUP

3.10.1 G

XIT

ANUAL ZERO SET

ETEST

HUTDOWN

ENERAL PARAMETER

3.10.2 INSTRUMENT INFORMATION

3.10.3 I

3.11 S

NTERNET PARAMETER

OFTWARE UPDATE

Novatest S.r.l.

2

info@novatest.itwww.novatest.it

Page 4

Manual for Multichannel Ultrasonic Pile Integrity Tester

60

63

77

89

94

95

97

CHAPTER 4 CROSS-HOLE SONIC LOGGING

SOFTWARE FOR TESTING PILE INTEGRITY 60

3.1 M

3.2 P

AIN INTERFACE

ARAMETER SETUP

3.2.1 Basic parameter setup....................64

3.2.2 Advanced parameter .....................68

3.2.2.1 General parameter .......................68

3.2.2.2 Other parameters ........................72

3.3 D

ATA COLLECTION

3.3.1 Start sampling ...........................77

3.3.2 Stop sampling ...........................80

3.3.3 Retest ..................................80

3.3.4 Intensive test ............................81

3.3.5 Continued testing ........................81

3.3.6 Oblique test .............................82

3.3.7 Test next pile ............................88

3.4 V

IEW SWITCHOVER

3.4.1 Bar graph ...............................89

3.4.2 Curve graph.............................91

3.4.3 Wave train graph ........................92

3.4.4 Data list ................................93

3.5 E

CHAPTER 5 ULTRASONIC-REBOUND COMBINED

XIT

METHOD SOFTWARE FOR TESTING STRENGTH 95

5.1 M

5.2 PARAMETER SETUP

AIN INTERFACE

5.2.1 Basic parameter .........................97

Novatest S.r.l.

3

info@novatest.itwww.novatest.it

Page 5

Manual for Multichannel Ultrasonic Pile Integrity Tester

107

109

111

112

112

113

114

121

123

125

127

127

5.2.2 Advanced parameter ....................101

5.3 START TEST

5.3.1 Start sampling ..........................107

5.3.2 Stop sampling ..........................108

5.3.3 Retest .................................108

5.3.4 Test Next Object ........................108

5.4 U

5.5 SCHEMATIC GRAPH AREA

5.6 F

5.7 EXIT THE TEST

CHAPTER 6 ULTRASONIC TRANSMISSION METHOD

LTRASONIC DATA LIST AREA

ILE MANAGEMENT

FOR TESTING DEFECT AND CAVITY TEST

SOFTWARE 113

6.1 M

6.2 P

AIN INTERFACE

ARAMETER SETUP

6.2.1 Basic parameter ........................115

6.2.2 Advanced parameter ....................117

6.3 S

TAR T TEST

6.3.1 Start sampling ..........................121

6.3.2 Stop sampling ..........................122

6.3.3 Retest .................................123

6.3.4 Test next object.........................123

6.4 U

6.5 DEFECTS SCHEMATIC GRAPH AREA

6.6 F

6.7 EXIT TEST

CHAPTER 7 ULTRASONIC METHOD FOR TESTING

LTRASONIC DATA LIST AREA

ILE MANAGEMENT

CRACK DEPTH SOFTWARE 128

Novatest S.r.l.

4

info@novatest.itwww.novatest.it

Page 6

Manual for Multichannel Ultrasonic Pile Integrity Tester

128

130

136

139

141

142

142

143

144

159

7.1 MAIN INTERFACE

7.2 PARAMETER SETUP

7.2.1 Basic parameter ........................131

7.2.2 Advanced parameter ....................133

7.3 S

TAR T TEST

7.3.1 Start sampling ..........................136

7.3.2 Stop sampling ..........................137

7.3.3 Retest .................................138

7.3.4 Test the next crack ......................138

7.3.5 Test the next object .....................139

7.4 T

7.5 CRACK DATA LIST AREA

7.6 REGRESSION CURVE AREA

7.7 F

7.8 EXIT TEST

APPENDIX I RAPID OPERATION INSTRUCTION FOR

EST POINT DATA LIST AREA

ILE MANAGEMENT

SITE TEST 144

F1.1 C

INTEGRITY

F1.1.1 Preparation before Test ..................144

ROSS-HOLE SONIC LOGGING FOR TESTING PIPE

F1.1.2 Test of New Foundation Piles .............150

F1.1.3 Data Processing ........................155

F1.1.4 Report Preparation ......................157

F1.2 U

TESTING CONCRETE STRENGTH

LTRASONIC-REBOUND COMBINED METHOD FOR

F1.2.1 Preparation before test ..................159

F1.2.2 New object test .........................162

F1.2.3 Data processing ........................169

Novatest S.r.l.

5

info@novatest.itwww.novatest.it

Page 7

Manual for Multichannel Ultrasonic Pile Integrity Tester

172

F1.2.4 Report formulation ......................171

F1.3 ULTRASONIC METHOD FOR TESTING UNCOMPACTED

AREA AND CAVITATIONS

F1.3.1 Preparation before test ..................172

F1.3.2 Ultrasonic test ..........................176

F1.3.3 Data processing ........................179

F1.3.4 Report formulation ......................181

F1.4 U

LTRASONIC METHOD FOR TESTING CRACK DEPTH 181

F1.4.1 Preparation before test ..................181

F1.4.2 Ultrasonic test ..........................184

F1.4.3 Data processing ........................187

F1.4.4 Report formulation ......................189

Novatest S.r.l.

6

info@novatest.itwww.novatest.it

Page 8

Manual for Multichannel Ultrasonic Pile Integrity Tester

Conventions in this manual

A. Word with gray background and black box is a button on the

interface (e.g., OK button).

B. All buttons on the device panel are shown with【】(e.g.,【OK】

button).

C. Word with white background and black box represent software

menu command in Windows, and “→” is a separator between

different menu levels. For example, File → Open means “Open”

the command under the “File” menu.

D. Words with grey background and without box represent the name

of options or menus on the screen. Such as Object option in

selection parameter setup.

E. Sign

F. Besides descriptions in the manual, some prompt messages may

show automatically in the use of the software. Please operate

accordingly.

G. Software interfaces and pictures in this instruction manual are

only for reference. There will be changes with software upgrade

and improvement of products. No further notice is provided.

means special attention is needed here.

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 9

Manual for Multichannel Ultrasonic Pile Integrity Tester

Chapter 1 General

1.1 Brief introduction

ZBL-U5600/U5700 multichannel ultrasound pile integrity tester

is a portable special instrument which uses ultrasonic transmission

method to test the integrity of concrete foundation pile; By adopting

multichannel self-transmitting and receiving circuit, this instrument

may test multiple profiles simultaneously; putting three or four

transducers in pipe may realize full combination test for three or six

profiles, which dramatically improves test efficiency and reduces the

work intensity of on-site tester.

1.2 Main functions and features

1.2.1 Main functions

1) Ultrasonic transmission method for testing the

integrity of foundation pile (called “pile test” for

short)

2) Ultrasonic-rebound combined method for testing

compressive strength of concrete (called “strength

test” for short);

3) Ultrasonic transmission method for testing defect

and cavity in structural member (called “defect test”

for short);

4) Ultrasonic flat-measured method for testing crack

depth of concrete surface (called “crack test” for

Novatest S.r.l.

1

info@novatest.itwww.novatest.it

Page 10

Manual for Multichannel Ultrasonic Pile Integrity Tester

short);

1.2.2 Main Features

1) Multichannel self-transmitting and receiving full

combination ultrasonic test for foundation pile may

automatically and continuously collect and save

information such as depths, acoustic parameters and

waveforms of all test points on multiple profiles. With

steady and undistorted waveform, accurate interpretation of

acoustic parameter and excellent repeatability and

consistency, the on-site test speed may be dramatically

improved;

2) During the test, the test result is available and the graphic

distribution of abnormal points in each profile is shown at

any time. Meanwhile, wave train figure, curve graph and

data list of each profile may be shown;

3) During the test, sampling delay and amplification factor

may be adjusted at any time;

4) Radial transducer may be played back at any time without

any operations for repeating test;

5) With true color highlight LCD, waveform, wave speed and

amplitude of multiple tested profiles may be clearly

observed on site Data, curve, wave train figure and

schematic graph of pile integrity of all test points in all

profiles may be checked at any time, the quality of whole

pile in the test is very clear.

6) It adopts WinCE operation system with press screen and

user-friendly interface, which is simply, easy to learn and

convenient to operate;

7) With high-capacity SD card, there is no need to worry

about the storage space of test data;

Novatest S.r.l.

2

info@novatest.itwww.novatest.it

Page 11

Manual for Multichannel Ultrasonic Pile Integrity Tester

8) Built in high-performance and capacity lithium battery may

satisfy fieldwork for long time.

9) Various USB ports may be used for data transmission or

software update within the instrument or external units

such as mouse or keyboard.

10) Test data of the same project is saved under the folder

created with the title of the project for easy and reliable

management.

1.2.3 Relevant test specification

1) Technical Code for Testing of Building Foundation Piles

(JGJ106)

2) Technical Specification for Pile Testing of Highway

Engineering(JTG/T F81-01)

3) Technical Specification for Testing of Foundation Piles of

Railway Engineering(TB 10218)

4) Guangdong Province Standard – Technical Code for Testing

Building Ground Foundation(DBJ15-60)

5) Technical Specification for Testing Building Foundation

Piles in Shenzhen(SJG09)

1.3 Main Technical Specifications

Table 1.1 Main technical specifications

Item

U5600 U5700

Number of

channels

Number of profiles 3 6

Three channels,

individually

controllable

Novatest S.r.l.

Indicators

Four channels, individually

controllable

3

info@novatest.itwww.novatest.it

Page 12

Manual for Multichannel Ultrasonic Pile Integrity Tester

under test

simultaneously

Testing and reading

precision of

acoustic time

Maximum system

dynamic range

Precision of gain

control

Amplitude

measurement error

Receiving

sensitivity

Sampling interval

Number of

waveform points

Transmitting

voltage

Testing and reading

range of acoustic

time

channel crosstalk ≤1/400

0.025μs∼1638.4μs, optional multiple levels

512、1024、2048、4096, optional multiple levels

65V、250V、500V、1000V, optional multiple levels

Frequency

bandwidth

Power supply mode

Operation time ≥8 hours

Total weight 2.5kg (including built-in lithium ion battery)

Whole volume 270 mm×220 mm×75 mm

Monitor 10.4 inch, highlight, true color LCD

Operating mode Press screen

Communication

interface

AC: 220V±10%,DC: +12V

USB port, Mini port and Bluetooth, etc.

0.025μs

154dB

0.5dB

≤1dB

≤10μV

±1677ms

2∼500kHz

Novatest S.r.l.

4

info@novatest.itwww.novatest.it

Page 13

Manual for Multichannel Ultrasonic Pile Integrity Tester

1.4 Precautions

1. To make better use of the tester, please read this operation

manual carefully before use.

2. Requirements of operating environment:

Ambient temperature: 0℃~40 .℃

Relative humidity: <90%RH.

Don’t expose to direct sunlight for long term.

Corrosion protection: necessary precautions shall be

taken when used in damp, dusty or corrosive gas environment.

3. Requirements of storage environment

Ambient temperature: -20℃~+50 .℃

Relative humidity: <90%RH.

When not in use, please pack the device and store it

under ventilation, cool and dry environment. Don’t expose to

direct sunlight for long term.

If the device won’t be used for a long time, power on

and start up the device at regular intervals to have a check.

4. Avoid water ingress.

5. Anti-magnetism: avoid using the device under intense magnetic

field environment, such as near large electromagnet and

transformer.

6. Vibration-proof: prevent strenuous vibration and shock during

operation and transportation.

1.5 Device Maintenance and Preservation

1. Power supply: the instrument adopts special built-in

rechargeable lithium battery as power supply, please pay attention to

the battery indicator during the operation. Use external power supply

(AC power supply or external rechargeable battery) as soon as

Novatest S.r.l.

5

info@novatest.itwww.novatest.it

Page 14

Manual for Multichannel Ultrasonic Pile Integrity Tester

possible if the battery is low, otherwise sudden power failure may

cause loss of test data or even system damage; make sure the external

power supply is AC220±10% V when supplied by AC power,

otherwise AC-DC power supply module or even instrument may be

damaged. The device must not be supplied by other batteries and

power sources.

NOTE: After the battery of the device is exhausted,

system data and time may be lost and require resetting after

startup.

2. Charging

When the matching AC-DC power supply module is charging for

internal battery, user only needs to insert the power plug into socket of

AC220±10% V and insert the DC output to the power plug of

instrument. When charging indicator on the instrument side panel is

red, it means the built-in battery of the instrument is charging; when

indictor turns into green, it means the battery is fully charged. (The

description above is the switch of indicator colors when in shutdown

mode and non-operating status)

NOTE: To ensure full charging, please keep continuous

charging for about 8 hours and at the meantime don’t charge the

device under the environment of above 60℃.

If the device won’t be used for a long time, the rechargeable

battery would discharge naturally, resulting in decreasing of battery

level. Re-charge the device before use. During the charging, the

instrument and the AC-DC power supply may be heated which is

normal, please keep good ventilation for the instrument, AC-DC

power supply and charger in order to dissipate heat.

NOTE: Don’t charge the device with other power

adapters; otherwise, the device might be damaged.

3. Rechargeable battery: the service life of rechargeable battery is

about 500 times of charging and discharging. When nearing the end of

Novatest S.r.l.

6

info@novatest.itwww.novatest.it

Page 15

Manual for Multichannel Ultrasonic Pile Integrity Tester

service life, if the battery is found to operate abnormally (the battery

cannot be charged at all, cannot be fully charged or runs for a short

time after every full charging), the rechargeable battery might be

damaged or reach to the end of its service life. Please contact us to

replace new battery. Battery short circuit or near high temperature heat

source is prohibited.

4. Sensor: Since strong impact or vibration may result in sensor

performance reduction or damage, sensor dropping from height or

beneath weight shall be avoided.

5. After every use, the device shall be cleaned properly, to

prevent water, mud and etc. from entering into the connector, thus

resulting in performance reduction or damage of the device.

NOTE: Don’t put the device or its accessories into

water or wipe them with wet cloth!

Don’t rinse the device or its accessories with organic

solvents!

Please wipe the host and socket with soft clean and dry cloth!

Please clean socket with clean and soft brush.

6. Storage: when not in use, please pack the device and store it

under ventilation, cool, dry and room temperature environment.。 If

the device won’t be used for a long time, power on and start up the

device at regular intervals to have a check.

1.6 Responsibility

The device is sophisticated detection equipment. Our company is

not responsible when the user commits one of the following acts or

other artificial destruction.

1. Violate the aforementioned operating or storage

Novatest S.r.l.

7

info@novatest.itwww.novatest.it

Page 16

Manual for Multichannel Ultrasonic Pile Integrity Tester

environment requirements.

2. Abnormal operation.

3. Open the enclosure and dismantle any parts and components

without permission.

4. The device is seriously damaged by human or fortuitous

accidents.

Novatest S.r.l.

8

info@novatest.itwww.novatest.it

Page 17

Manual for Multichannel Ultrasonic Pile Integrity Tester

Chapter 2 Instrument Description

2.1 Instrument Composition

U5600/U5700 multiple channel ultrasonic pile integrity tester is

composed of host, radial transducer, counting device (or depth

recorder) and accessories (including power adaptor and U disk, etc.).

2.1.1 Host

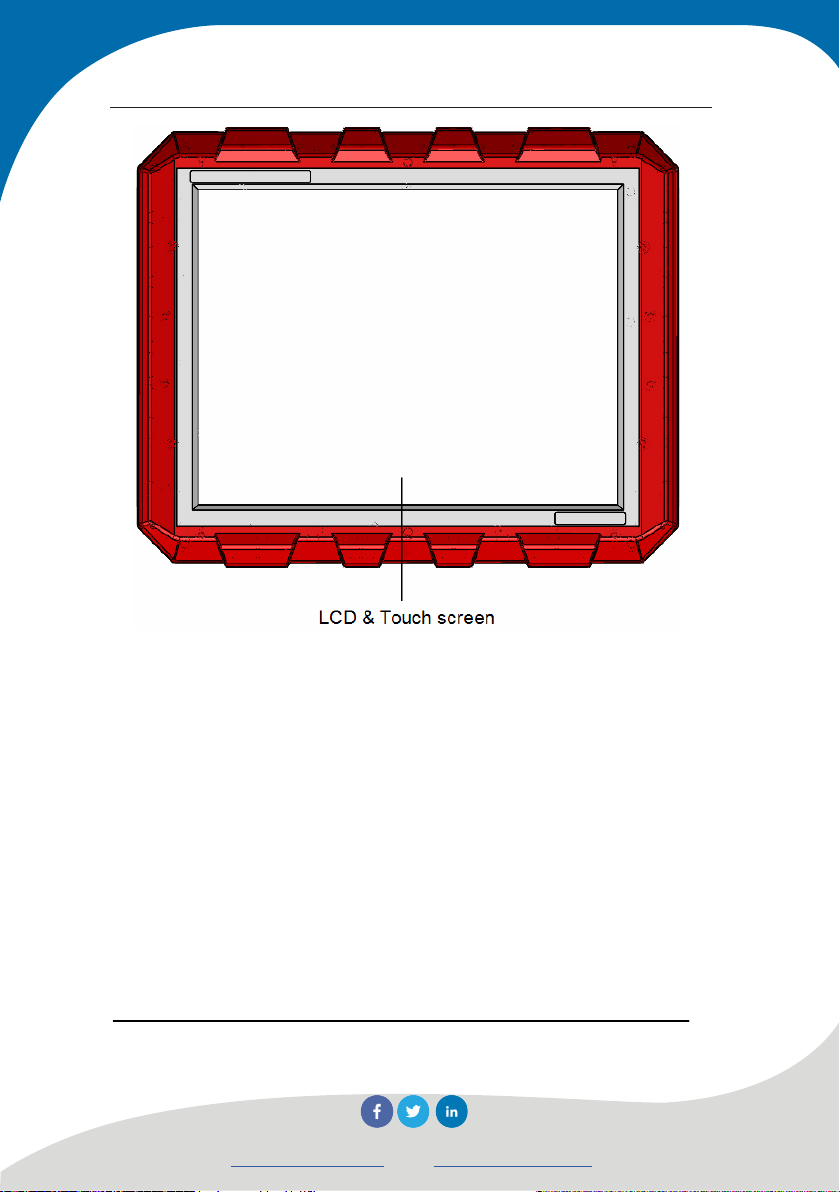

Picture of U5700 Multichannel Ultrasonic Pile Integrity Tester

appearance is shown in Figure 2.1.

9

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 18

Manual for Multichannel Ultrasonic Pile Integrity Tester

a) Tthe obverse side

10

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 19

Manual for Multichannel Ultrasonic Pile Integrity Tester

b) The reverse side

c) The left side

11

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 20

Manual for Multichannel Ultrasonic Pile Integrity Tester

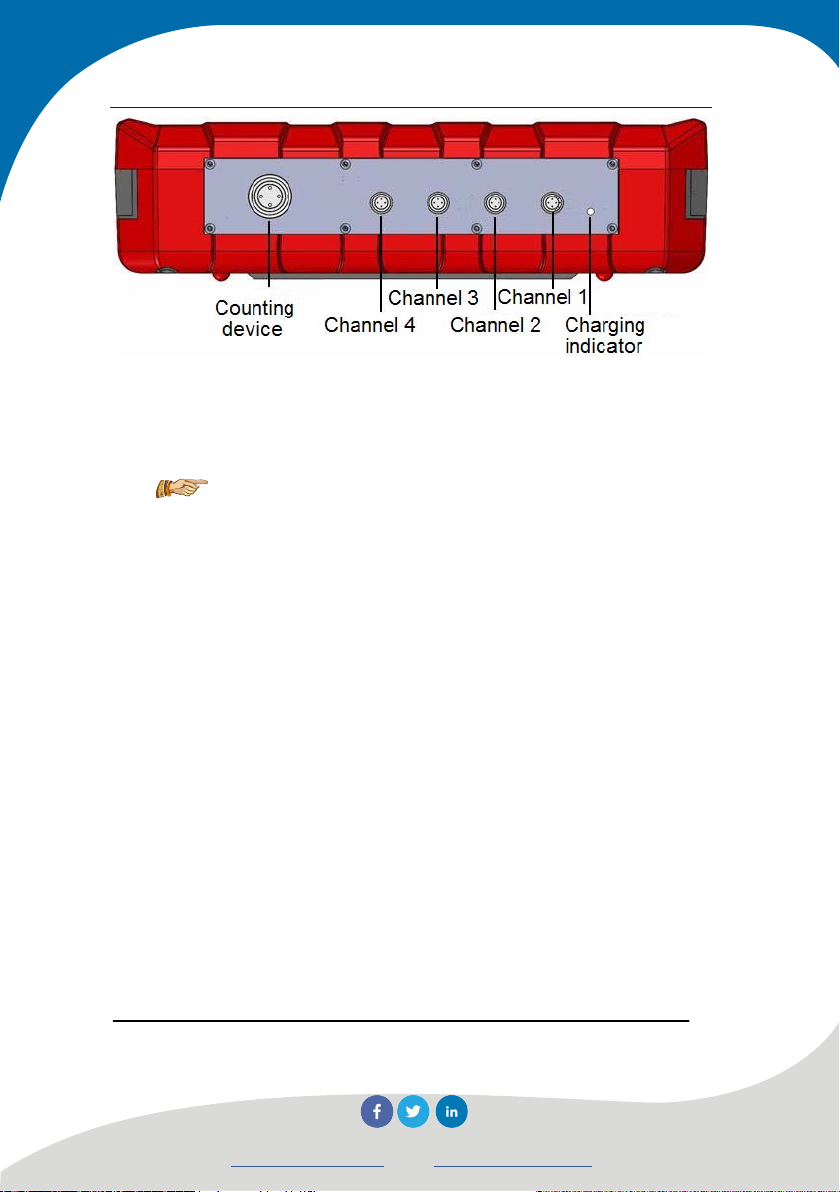

d) Front

Figure 2.1 Picture of host appearance

NOTE: The pictures above are only for reference and

may be different from the actual instruments.

2.1.1.1 LCD and press screen

LCD is mounted on instrument panel and clings to press screen.

It is used to display operation interface and test data. Protective film

on press screen surface may effectively protect press screen, and be

replaced after damage.

2.1.1.2 Power switch

It is used to power on/off instrument, long press the button of

power switch for powering on instrument and long press again for

powering off instrument. During the startup, short press power switch

12

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 21

Manual for Multichannel Ultrasonic Pile Integrity Tester

to pop up shutdown prompt, select Yes for shutdown, or else select

No.

2.1.1.3 Power socket

Insert input plug of power adaptor supplied with the instrument

into 200-240V AC power output socket to supply power for the

instrument and charge the internal battery as well.

2.1.1.4 Charging indicator

When charging indicator on the instrument side panel is red, it

means the built-in battery of the instrument is charging; when

indictor turns into green, it means the battery is fully charged .

Notes: The description above is the switch of

indicator colors when in shutdown mode and non-operating

status.

2.1.1.5 USB port

Standard USB port is provided for U disk to copy test data of

instrument and save it in computer for further analysis and file by

analysis software in Windows, or to upgrade of internal software of

the instrument.

13

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 22

Manual for Multichannel Ultrasonic Pile Integrity Tester

2.1.1.6 Mini USB Port

It is provided for connecting with PC and data transmission.

2.1.1.7 Counting device port

Connect the instrument with counting device (depth recorder)

through completely inserting the “projection” of signal wire end into

“groove” of this port and screw to tighten it.

2.1.1.8 Transducer adaptor

It is used for connection with plug of signal wire on transducer.

Adaptors of transducer on instruments in various models are

different (Model U5700 has four adaptors: Channel 1-4, Model

U5600 has only three adaptors: Channel 1-3). Completely insert the

“projection” of signal wire end into “groove” of this port for

connection.

2.1.1.9 Protective cover

USB port and power sockets etc. have protective cover

separately which is not used usually and only opened in operation for

protecting ports above mentioned.

14

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 23

Manual for Multichannel Ultrasonic Pile Integrity Tester

2.1.1.10 Support

Erect the instrument on horizontal worktop with certain dip

angle through adjusting support angle on the back for convenient

operation.

2.1.1.11 Nameplate

It indicates company name, manufacture date and factory number,

etc.

2.1.2 Transducer

2.1.2.1 Planar Transducer

Figure 2.2 Planar transducer

Composite-structure longitudinal vibration transducer (also

15

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 24

Manual for Multichannel Ultrasonic Pile Integrity Tester

known as sandwich or trumpet type transducer, commonly known as

“planar transducer” as shown in Figure 2.2) is a kind of simple

radiator utilizing thickness vibration of piezoelectric ceramics. Planar

transducer, with interchangeable radiation and receiving functions, is

used to test concrete strength and internal defect, etc.

Planar transducer is optional part. User needs two planar

transducers and signal wire for testing strength or defect of concrete

structural members.

2.1.2.2 Radial transducer

Radial transducer, also known as tubular transducer, as a kind of

columnar transducer with good symmetric properties, is particularly

suitable for penetration test of cross-hole sound wave. Radius

transducer is the sensor for transmitting and receiving ultrasonic as

shown in Figure 2.3. All special transducers with same and

interchangeable ports for multichannel pile integrity tester may be

used for transmitting and receiving. According to different number of

channels, radial transducers in different numbers may be equipped.

The length of transducer signal wire depends on the length of

foundation pile to be tested. The radial transducer for ultrasonic pile

integrity tester is special transducer which cannot be matched with or

connected to other ultrasonic instrument.

16

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 25

Manual for Multichannel Ultrasonic Pile Integrity Tester

Figure 2.3 Radial transducer

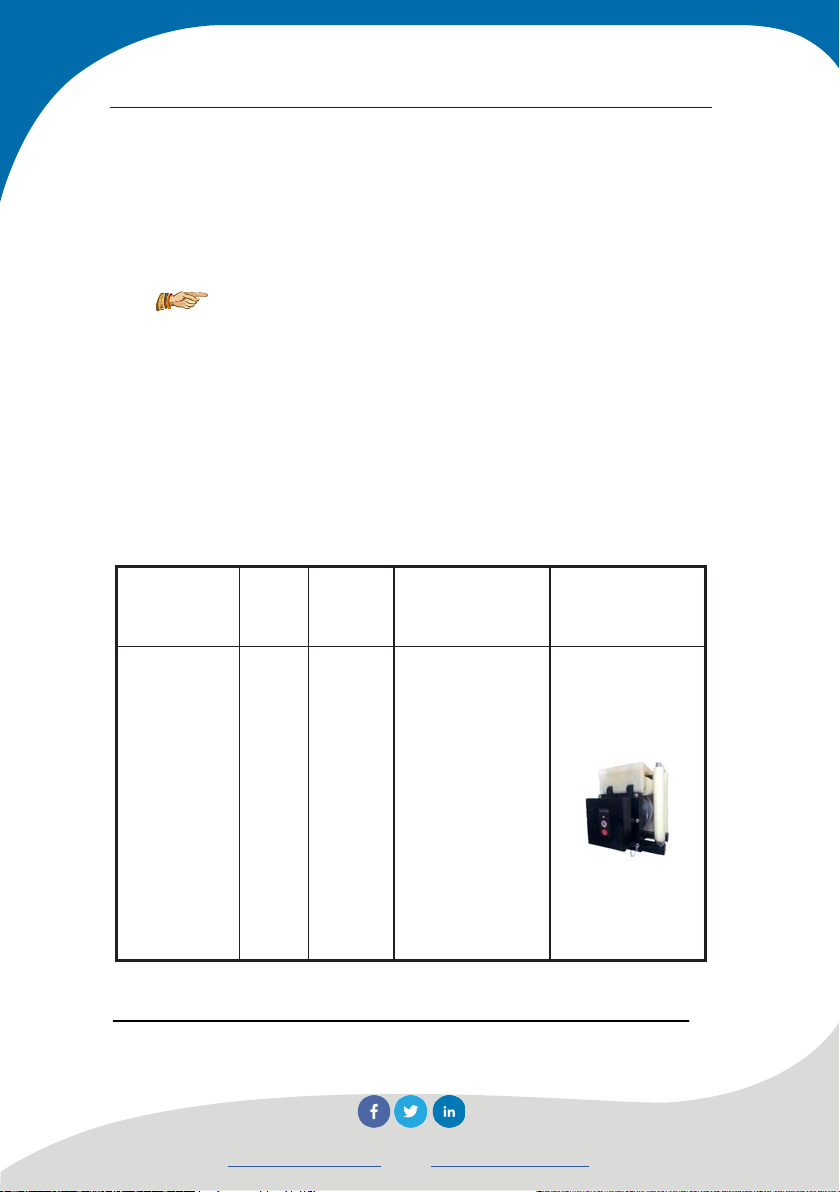

2.1.3 Counting device

Counting device (depth recorder), used for recording the depth

of transducer in pipe, may wirelessly communicate with host or

connect with hose through signal-enhancement wire. Counter wheel

must be paired with host in advance for wireless way in test; for

wired connection, just connect the countering device with host

through signal wire.

NOTE: The distance between countering device and

host adopting wireless communication shall be kept within 5m.

17

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 26

Manual for Multichannel Ultrasonic Pile Integrity Tester

Figure 2.4 Picture of counter wheel

Long press button to switch on or switch off counter wheel;

fast flashing of operation indicator after counter wheel has been

powered on refers to waiting for connection with host; after

successful connection with host, the operation indicator turns into

green and depth counting is available. When built-in lithium battery

18

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 27

Manual for Multichannel Ultrasonic Pile Integrity Tester

in counting device is low, the operation indicator start flash green,

which means charging is required. Charging indicator on panel turns

into red when built-in battery in counting device is charged; charging

indicator turning into green means the battery is full.

NOTE: Please use special charger and connection

line for charging; counting device may operate for over 20

hours after being fully charged.

Depth recorder includes counter wheel, guide wheel on pipe

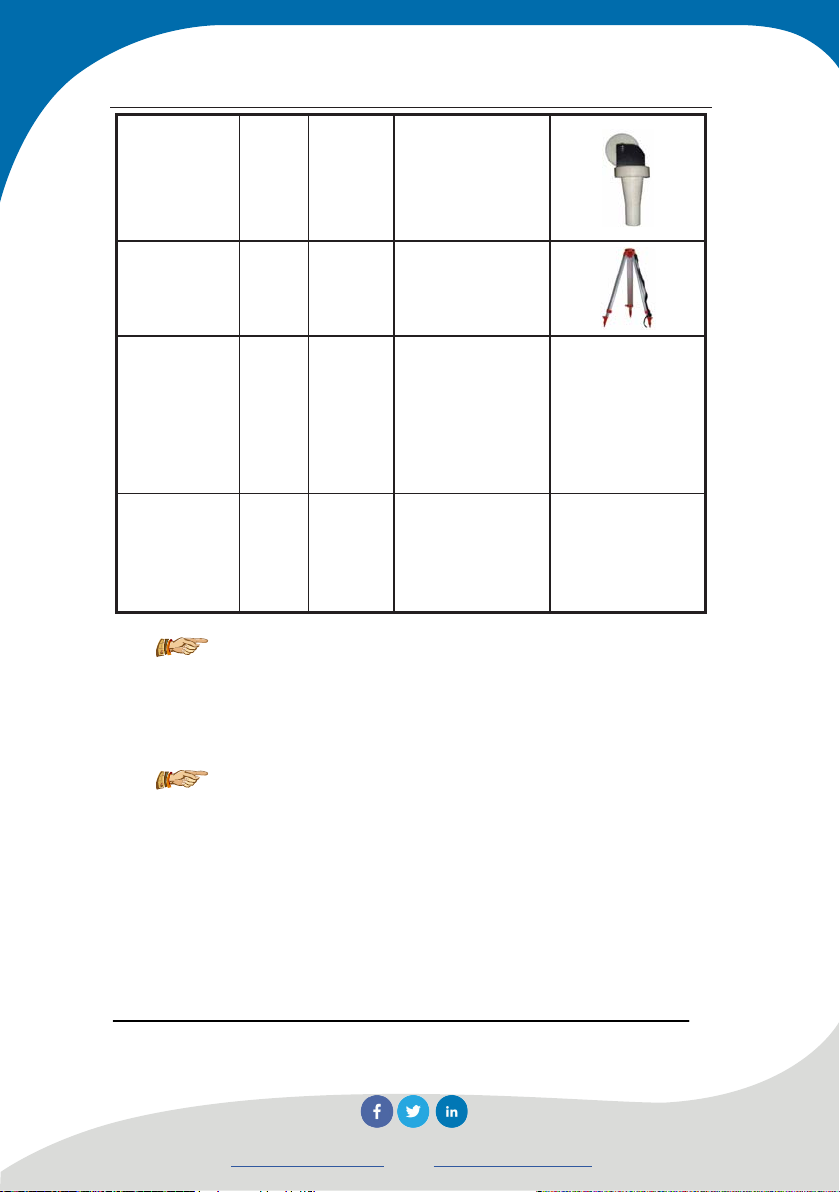

mouth and tripod, etc. as shown in Table 2.1.

Table 2.1 Table of counting device accessories

object

numb

Unit

name

Count wheel Set 1

19

er

Novatest S.r.l.

Description Picture

Connect with

instrument

through Bluetooth

or signal wire,

record position of

transducer and

guide for signal

wire of transducer

info@novatest.itwww.novatest.it

Page 28

Manual for Multichannel Ultrasonic Pile Integrity Tester

Guide wheel

on pipe

mouth

Tripod

Signal

enhancement

wire

Charger and

connection

wire

3Or 4

Piece

1

Piece

Piece 1

Set 1

Fixed on pipe

mouth to guide for

signal wire

Depth recorder

tripod

Connection wire

for depth

recording wheel

and host

Charge built-in

lithium battery in

counter wheel

(Be omitted)

(Be omitted)

NOTE: Charging connection wire is special

connection wire, one end is standard USB port and another

end is special port.

NOTE: Counting device is supplied power by the

instrument directly when it is connected with instrument by

wire and may operate normally even without power in

built-in lithium battery.

20

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 29

Manual for Multichannel Ultrasonic Pile Integrity Tester

2.1.4 Accessories

2.1.4.1 Power adaptor

Connect input plug of power adaptor with 200-240V AC power

and its output plug with power plug of host for supplying power to

the instrument and charging the internal battery as well.

2.1.4.2 Other attachments

Refer to the packing list for more retail.

2.2 Test principle

2.2.1 Cross-hole sonic logging for testing pipe integrity

The basic principle of ultrasonic transmission method for testing

pile integrity is: excite high frequency elastic pulse wave through

ultrasonic pulse emission source, use high precision receiving system

to record the fluctuant features of this pulse wave transmitting in

concrete; when concrete has discontinuous or damaged interface

inside, defect surface forms wave impedance interface, therefore,

when wave arrives to such this interface, caused transmission and

reflection of wave obviously decreases the received transmission

21

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 30

Manual for Multichannel Ultrasonic Pile Integrity Tester

energy; when concrete has serious defects such as looseness,

honeycomb or cavitations, wave scattering and diffraction will be

caused; compactness parameters of concrete in test ranges will be

obtained based on the first arrival time of wave and features of

energy attenuation, frequency change and waveform distortion degree,

etc. The property, size and spatial location of internal defect within

concrete could be obtained through treatment and analysis of tested

and recorded ultrasonic fluctuation features in different profiles and

heights.

Before construction of foundation pile, pipes in certain number

according to the pile diameter shall be pre-buried as the channel for

transducer. Every two pieces of pipe is a group in test, ultrasonic

pulse signal is transmitted from transducer in one pipe and received

by transducer in another one through water coupling (as shown in

Figure 2.5), the instrument will record the acoustic parameter such as

acoustic time and amplitude for determining whether the concrete in

this position between two pieces of pipe is normal or not. Move

transmitting and receiving transducers upward from the bottom of

pile and test the points one by one to understand the concrete

integrity of whole profile. Integrity conditions of each profile or even

the whole pile may be obtained through testing all profiles.

22

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 31

Manual for Multichannel Ultrasonic Pile Integrity Tester

Figure 2.5 Schematic diagram of cross-hole sonic logging for testing pipe

integrity

2.2.2 Ultrasonic-rebound combined method for

testing concrete strength

This combined method adopts two or more than two test

methods to test several physical quantities and establishes

relationship between them and concrete strength. “Ultrasonic pulse

speed-rebound value” combined method is the method with the most

research and widest application at home and abroad.

By adopting low frequency ultrasonic tester and rebound tester

with standard kinetic energy of 2.207J, ultrasonic-rebound combined

method tests acoustic time and rebound value separately in the same

23

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 32

Manual for Multichannel Ultrasonic Pile Integrity Tester

2.2.3 Ultrasonic method for testing

test area of structure or structure member, and calculates the concrete

strength in test area through established strength test formula.

Strong relativity exists among the wave speed, rebound value

and strength of concrete; when strength is stronger and wave speed is

faster, the rebound value is higher; after the relationship curve has

been calibrated, test the acoustic time and rebound value separately in

same test area, then calculate the concrete strength by utilizing

established strength test curve (formula 2-1):

cb

(2-1)

ecu

,

RVaf ××=

In which: a - coefficient of constant term; b, c - regression

constant; fcu,e - equivalent value of compressive strength; V –

calibrated ultrasonic speed in test area; R – calibrated average

rebound value in test area.

uncompacted area and cavitation

The speed of ultrasonic transmission is directly related to concrete

compactness, higher speed means compacter concrete and vice versa.

Ultrasonic method detects concrete defect through relative change of

acoustic parameters such as transmission time (or speed), amplitude

and frequency of received wave of pulse wave in concrete with same

technical conditions to judge the defect of concrete. Since cavitations

24

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 33

Manual for Multichannel Ultrasonic Pile Integrity Tester

or crack may destroy the integrity of concrete, sound wave has to

bypass cavitations or crack and transmit to receiving transducer; the

longer the transmission distance is, the longer the tested acoustic time

is, and acoustic speed decreases correspondingly. Reflection,

scattering and energy attenuation caused by ultrasonic on defect

interface may result in decrease of amplitude; the attenuation degrees

are different when various frequencies in sound wave encountering

defect; high frequency has large attenuation, which makes basic

frequency decreases (frequency shift). Besides, waveform conversion

and addition of sound wave at defect make waveform distortion.

25

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 34

Manual for Multichannel Ultrasonic Pile Integrity Tester

Chapter 3 Common module description

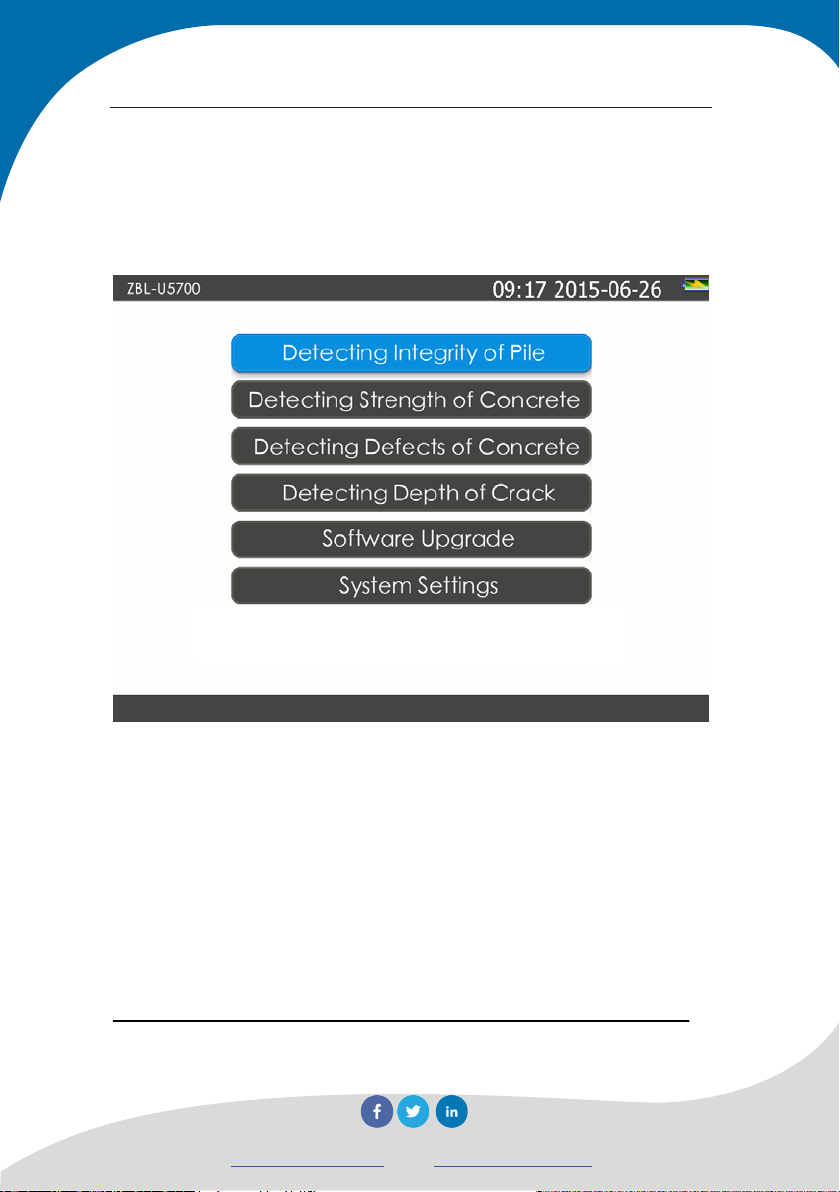

3.1 Startup interface

Figure 3.1 Startup interface

Press power switch and power on instrument, the company logo

will display for a while; after that the instrument will enter into

startup interface as shown in Figure 3.1, displaying system date, time,

remaining capacity and several function buttons (button of red letters

and grey background means not available). Pressing different buttons

to call different software; refer to following chapters for more details.

26

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 35

Manual for Multichannel Ultrasonic Pile Integrity Tester

Press button to switch to English version and

the button turns into

button to switch to Chinese version and

the button turns into .

3.2 Control introduction

Dialogue box used in the software includes various common

controls, please refer to the Table 3.1 for brief introduction.

Table 3.1 List of controls

Control

name

Button

Edit box

Example Description

Button for certain action

Used for inputting text (number or character)

; press

Pull-down

List including a series of character string,

several options may pop up when pressing

list box

downward arrow

27

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 36

Manual for Multichannel Ultrasonic Pile Integrity Tester

Single

choice box

Check box

Used when only one option out of multiple

ones may be selected

Used when one or several options out of

multiple ones may be selected: ticking “√”

means being selected, otherwise not

3.3 Soft keyboard

3.3.1 Character input

When need to input character (such as name of project or foundation

pile, etc.), press the edit box behind it, the soft keyboard as shown in

Figure 3.2 will pop up. Title bar will display the name of project and

maximum character number to be input, and edit box will display the

current character.

28

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 37

Manual for Multichannel Ultrasonic Pile Integrity Tester

a)Input mode for English

b) Input mode for Chinese

Figure 3.2 Character soft keyboards

29

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 38

Manual for Multichannel Ultrasonic Pile Integrity Tester

Operational approach of press screen is as follows:

1) When press the button of a given character or number, it

will be shown in the edit box above one by one;

2) If need to insert a character in front of a given input

character, press the place in front of the character at first, insert

the cursor in front of it and press the character which needs to be

inserted.

3) Press BS button to delete the character in front of cursor;

during the input of Chinese, delete Pinyin alphabet at first and

then character in edit box. Long press of BS button for quick

deletion. It is equivalent to the Backspace key on physical

keyboard.

4) Press ↑ button to shift into capital mode and press any

character back to lower case. It is equivalent to the Shift key on

physical keyboard; long press ↑ button to lock up capital mode,

it is equivalent to the Caps Lock key on physical keyboard.

5) Press

button to shift in Chinese input mode as shown

in Figure 3.2b, and the button turns into Eng at the same time,

which means Chinese can be input through Pinyin now. After

Pinyin characters have been input, optional Chinese characters

will be shown on the bottom of input box (if there are many

optional Chinese characters, press < and > buttons to display

other Chinese characters), press the position of character to input

30

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 39

Manual for Multichannel Ultrasonic Pile Integrity Tester

it; when press the En button, it will turn into and recover

to the mode as shown in Figure 3.2a.

6) After have pressed OK button, the input is valid and soft

keyboard is closed; if the input character is illegal or

unreasonable, relevant prompt will be shown on the bottom;

7) After have pressed Cancel button, the input is invalid and

soft keyboard is closed.

3.3.2 Number input

Figure 3.3 Numeric soft keyboards

When need to input number (such as starting elevation and pile

spacing), press the edit box behind it, soft keyboard as shown in

Figure 3.3 will pop up, the title bar displays the name of project to be

31

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 40

Manual for Multichannel Ultrasonic Pile Integrity Tester

input and its reasonable range, the edit box displays the current

number.

Operational approach of press screen is as follows:

1) When press the button of a given number, it will be shown

in the edit box above one by one;;

2) If need to insert a number in front of a given input number,

press the place in front of the number at first, insert the cursor in

front of it and press the number which needs to be inserted.

3) Press BS button to delete the number in front of cursor,

long press BS button to delete all numbers;

4) After have pressed OK button, the input is valid and soft

keyboard is closed; if the input number is illegal or unreasonable,

relevant prompt will be shown on the bottom;<0}

5) After have pressed Cancel button, the input is invalid and

soft keyboard is closed.

32

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 41

Manual for Multichannel Ultrasonic Pile Integrity Tester

3.4 Waveform display and operation

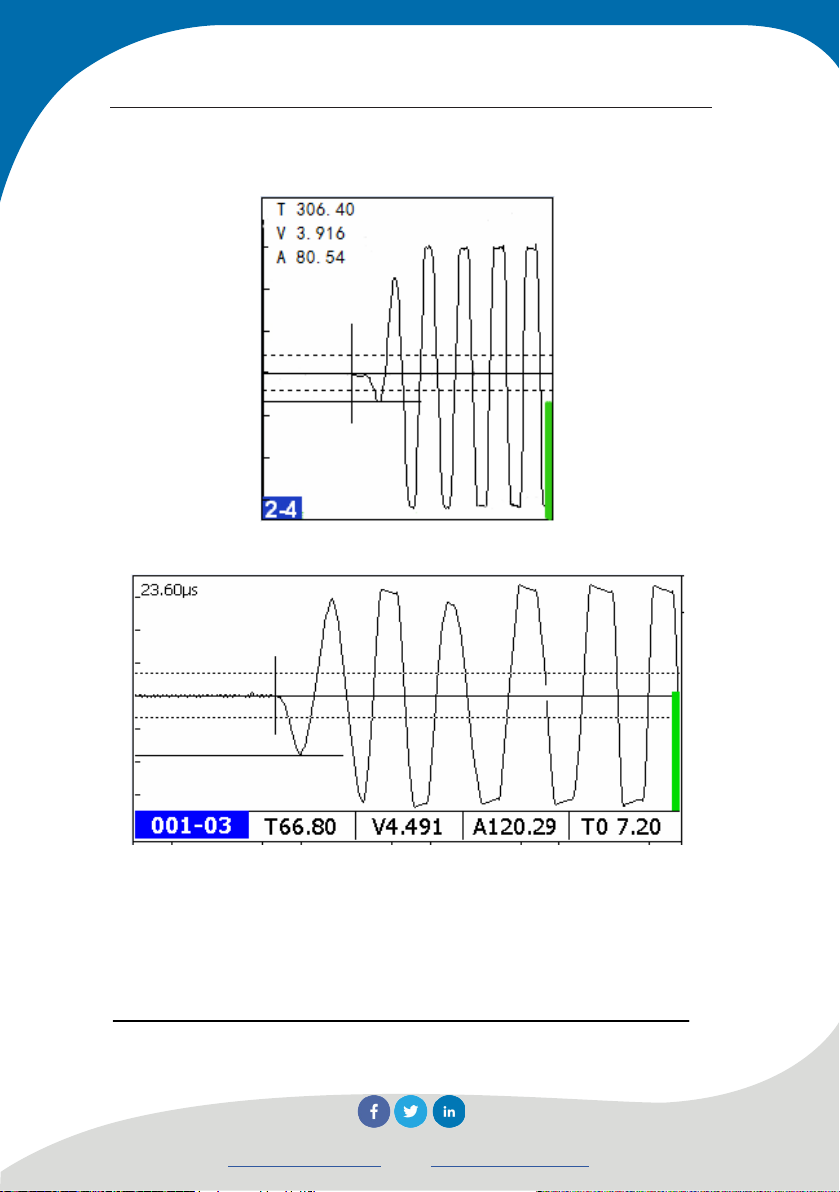

a) Single-channel waveform in pile test

b) Single-channel waveform in strength test, defect test and crack test

Figure 3.4 Schematic graph of waveform

Single-channel waveform range is used to display the waveform

and acoustic parameters, etc. of current testing point as shown in

33

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 42

Manual for Multichannel Ultrasonic Pile Integrity Tester

Figure 3.4. The top left corner of single-channel waveform range for

pile test displays acoustic parameter of head wave and the lower left

corner displays name of profile, as shown in Figure 3.4a. The bottom

horizontal row of single-channel waveform range for strength test,

defect test and crack test displays acoustic parameter and zero

acoustic time value of head wave, the lower left corner displays series

number of test point, top left corner displays delay time, as shown in

Figure 3.4b.

The vertical progress bar at the right of single-channel

waveform means the gain; when gain is increasing, the progress bar

ascends and when gain is decreasing, the bar descends.

1) Acoustic time value T: Transmission time of ultrasonic

from transmitting transducer to receiving transducer, the

unit is μs, this acoustic time value has deducted the system

zero acoustic time value;

2) Amplitude value A: The amplitude value of received head

wave of ultrasonic, it is used to measure the energy of

ultrasonic and the unit is dB;

3) Acoustic velocity value V:The transmission speed of

ultrasonic in concrete; it is a calculated value and the

calculation method is to divide spacing by T value, the unit

is km/s.

34

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 43

Manual for Multichannel Ultrasonic Pile Integrity Tester

3.4.1 Terminology

1) Dynamic sampling: It refers to the process of continuously

and repeatedly transmitting, collecting, processing,

interpreting and displaying waveform and acoustic

parameter.

2) Dynamic waveform: It refers to the continuously refreshing

waveform in single- channel waveform range on screen in

dynamic sampling.

3) Static waveform: It refers to the static waveform in

single-channel waveform range on screen when stop

sampling.

4) Head wave (preliminary wave): The first wave crest or

trough of waveform received by instrument.

5) Noise range: Manual-set noise range in dynamic sampling,

it is used to distinguish waveform from noise; any

waveforms with amplitude not exceeding such range is

considered as noise.

6) Threshold value: It is one of the automatic judging criteria

of head wave, only the waveform exceeding threshold

value line will be possibly judged as head wave; the two

dotted lines above and below base line, as shown in Figure

35

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 44

Manual for Multichannel Ultrasonic Pile Integrity Tester

3.4, are threshold value lines.

7) Base line: The approximate straight line in front of head

wave in the waveform. Longitudinally symmetrical

central line of single- channel waveform.

8) Automatic interpretation line for acoustic time: It is used to

indicate the mark line for ultrasonic system to

automatically test and read acoustic time position of head

wave.

9) Automatic interpretation line for amplitude: It is used to

indicate the mark line for ultrasonic system to

automatically test and read the amplitude position of head

wave.

10) Gain: The magnification to received signal by the system.

11) Number of delay points: The number of transmission

starting points relative to “0” point position in

single-channel waveform range.

36

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 45

Manual for Multichannel Ultrasonic Pile Integrity Tester

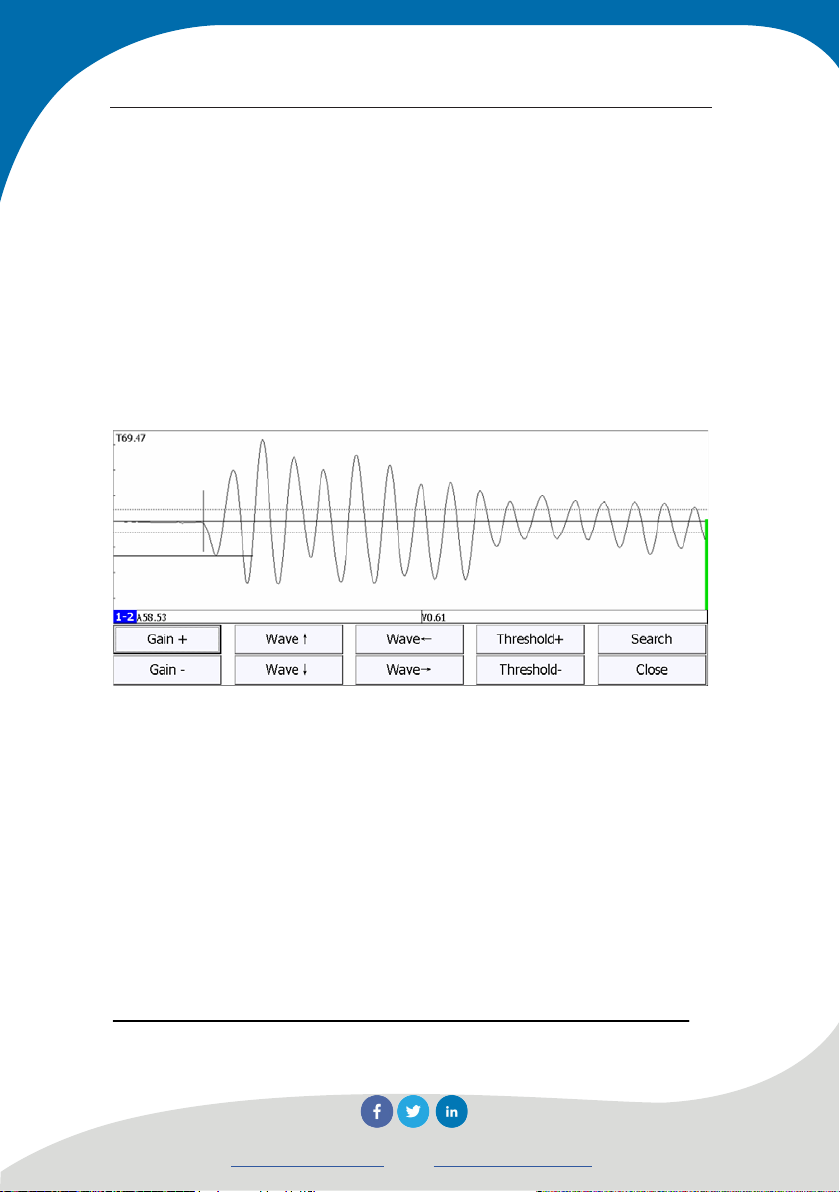

3.4.2 Dynamic waveform operation

3.5 Operation panel for dynamic waveform

In dynamic sampling, press the bottom right of the

single-channel waveform range, operation panel as shown in Figure

3.5 will pop up under the waveform.

1) Adjust gain

Press Gain+ and Gain- button or slide up and down on

waveform range to increase or decrease gain.

2) Move dynamic waveform

Slide the position of central base line of single- channel

waveform forward and backward or press Wave←and Wave→

buttons to move dynamic waveform left or right, and consequently,

decrease or increase number of delay points;

3) Automatic search

37

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 46

Manual for Multichannel Ultrasonic Pile Integrity Tester

Press Search button for automatic sampling and searching the

head wave of current waveform.

4) Adjustment of base line

Press Wave↑ and Wave↓ buttons to adjust base line position

upward or downward;

5) Adjustment of noise range width

Press Threshold+ and Threshold– buttons to increase or

decrease threshold value for determining head wave;

6)Close operation panel

Press any areas outside of single-channel waveform range to

close operation panel.

3.4.3 Static waveform operation

In the state of static waveform, press a certain waveform in

single-channel waveform range to use this channel as current channel,

one transverse cursor and one vertical cursor will appear in waveform

range, and operation panel as shown in Figure 3.6 will pop up under

current waveform.

38

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 47

Manual for Multichannel Ultrasonic Pile Integrity Tester

Figure 3.6 Operation panel for static waveform

1) Move cursor left and right

Press Left and Right buttons to move vertical (acoustic time)

cursor and display acoustic time value at cursor position in cursor

parameter area.

2) Move cursor up and down

Press Up and Down buttons to move transverse (amplitude)

cursor and display acoustic time value at cursor position in cursor

parameter area.

3) Move waveform left and right

Press Wave← and Wave→ buttons to move waveform left

and right.

4) Save the manual interpretation result

After have located the transverse (amplitude) and vertical

(acoustic time) cursors, press Save button on operation panel to

save cursor determining result, which means use the acoustic

time and amplitude values at cursor position to replace the

39

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 48

Manual for Multichannel Ultrasonic Pile Integrity Tester

acoustic time and amplitude values of current test point.

5) Close the operation panel

Press any areas outside of single-channel waveform range

to close operation panel.

3.4.4 Magnify and display single-channel

waveform

Figure 3.7 Magnify and display single- channel waveform

In the state of dynamic sampling, press the position of series

number or profile name at the lower left corner of single-channel

waveform range, the dialogue box as shown in Figure 3.7 will pop up

to magnify and display this waveform, the function of button at

bottom are as same as that described in Section 3.4.2. When press

other profile waveforms, the name of profile at lower left corner will

change to current series number and waveform correspondingly.

40

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 49

Manual for Multichannel Ultrasonic Pile Integrity Tester

Press Close button to close the dialogue box.

NOTE: Only pile testing software has this function.

3.5 File Management

File management is used to check the tested projects and files

and copy the selected projects or files to U disk; or upload it to server

or delete it.

Figure 3.8 File management interface

The interface of file management is as shown in Figure 3.8, the

left part of interface is project list, right part is list of all files of the

41

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 50

Manual for Multichannel Ultrasonic Pile Integrity Tester

current project and lower part is function button area. When data list

has a lot of information, scroll bar will appear at side of list box; drag

scroll bar to turn page and display, or slide it up and down is list area

to flip screen.

3.5.1 Operating mode

1)Press a certain project in project list, all files (without

extension) in this project will be listed in the file list. Press the

row where the file is located in the list files to select this file.

2)Press the list header for sorting, different columns has

different sorting method, name column is sorted according to

alphabetical order, time column is sorted according to

chronological order, and file size column is sorted according

to file size. Pressing for several times may switch over the

sorts by ascending order and descending order.

3)Press the first column of list header to tick off all projects or

files.

4)Press the check box in front of a certain project or file in

project or file list to tick off this project or file; press projects

or files which need to be selected to tick off several projects

or files.

42

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 51

Manual for Multichannel Ultrasonic Pile Integrity Tester

3.5.2 Open file

Select a file in file list area and press Open button to open the

selected file and return to main interface, displaying the waveform

and curve stored in this file. When no file is selected, Open button is

invalid.

3.5.3 Project and file copy

Tick off one or more projects and press Copy button to copy all

files in selected project to U disk; Tick off one or more files and press

Copy button to copy all selected files to U disk. When no project or

file is selected, Copy button is invalid.

Folder with name of “U5Pile” will be created in U disk when

copy project or file; create a subfolder with the name of the project

and then copy all files or selected files of this project to the subfolder.

Check whether U disk exists before copy file; if not, it will

prompt user to insert U disk at first.

3.5.4 Project and file deletion

Tick off one or more projects and press Delete button to delete

selected project and all files in it; Tick off one or more files and press

Delete button to delete the selected files. When no project or file is

selected, Delete button is invalid.

43

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 52

Manual for Multichannel Ultrasonic Pile Integrity Tester

It will be inquired that “whether delete selected project or file?”,

press Yes to delete it, press No for not.

NOTE: Deleted data cannot be recovered! Make sure

all data to be deleted has been kept a backup in computer

before deletion. When all data files of one project have been

deleted, the project folder will be deleted automatically.

3.5.5 Project and file upload

Tick off a project in project list and press Upload button to

upload all files in this project to test management system.

Tick off one or more files in file list and press Upload button to

upload the selected files to test management system.

When no project or file is selected, Upload button is invalid.

NOTE: Developed by Beijing ZBL Science and

Technology Co., Ltd, this test management system is used to

manage the whole process of nondestructive test; only users

who have bought this system may upload test data. Please

refer to the Operation Manual for details.

3.5.6 Exit

Press Quit button to exit from file management and return to main

interface.

44

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 53

Manual for Multichannel Ultrasonic Pile Integrity Tester

3.6 Zero set

Zero acoustic time refers to the acoustic delay between

ultrasonic instrument and transmitting and receiving transducers; zero

acoustic time must be eliminated in testing acoustic time value. Zero

set obtains zero acoustic time through test. This operation is required

when operate ultrasonic instrument and replace transducer or signal

wire in the first time.

3.6.1 Manual zero set

After have read acoustic time on waveform, find out the option

of Zero acoustic time in parameter interface, and input the acoustic

time into it manually.

3.6.2 Acoustic zero set

1) Press the Zero button in parameter interface, input

standard acoustic time in pop-up dialogue box as shown in

Figure 3.9(If use standard rod for zeroset, input the standard

acoustic time value of standard rod; if use coupling

transducer for zeroset, input 0).

2) Couple transducer according to the prompt message, press

Zero button to close this dialogue box, start sample

automatically, display waveform in waveform range and

45

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 54

Manual for Multichannel Ultrasonic Pile Integrity Tester

search head wave automatically.

Figure 3.9 Dialogue box for zeroset

3) Adjust waveform in main interface, press Stop button to

stop sampling after have found head wave, and prompt

message of new tested zero acoustic time (As shown in

Figure 3.10) will pop up automatically, press Yes button to

complete zeroset; the current acoustic value is set as zero

acoustic time, which will be written into parameter file.

Press No to cancel this zeroset result.

46

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 55

Manual for Multichannel Ultrasonic Pile Integrity Tester

Figure 3.10 Prompt of new tested acoustic time

NOTE: This function is only applicable to software

for strength test, defect test and crack test; automatic zeroset is

only available when just enter into test interface and no data

has been collected.

3.7 Retest

a) Start retesting b) Finish retest

Figure 3.11 Dialogue box of retest

If need to retest the tested point, select the point which needs

47

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 56

Manual for Multichannel Ultrasonic Pile Integrity Tester

to be retested in data list area, press Retest button to pop up prompt

box as shown in Figure 3.11a. After have coupled transducer with

the first point to be tested according to the prompt message, press

OK button to enter into retest mode, retest the points one by one

and save results until cancel retest mode or all points have been

retested. Retest button flashing in retesting samples means retest is

in progress.

If need to cancel retest, repress Retest button when stop

sampling in waveform, which means static waveform, prompt box

as shown in Figure 3.11b will pop up, press OK button to cancel

retest mode.

NOTE: This function is only applicable to software

for strength test, default test and crack test;

3.8 Battery level

Battery level is displayed by 5 boxes to divide battery level into

5 sections reasonably.

1) When battery level remains only 1 box, it will prompt as

“Low battery level, please save data and charge in time”, as

shown in Figure 3.12.

48

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 57

Manual for Multichannel Ultrasonic Pile Integrity Tester

Figure 3.12 Prompt messages for low batter level

2) When battery level remains 0 box, the instrument will shut

down after has saved data. The instrument will shut down

directly if no data needs to be saved.

3.9 Shutdown

There are three conditions in shutdown:

1) Short press power switch, if there is no data needs to be

saved, the prompt of “Shut down or not?” will appear, select

Yes to shut down, Select No for not.

2) Short press power switch, if there are some data to be saved,

the prompt of “Shut down or not?” will appear, select Yes to

save the data and shut down, Select No for not.

3) Long press power switch for hardware shutdown and

stopping software operation, which is similar to long press

power-off button on computer.

49

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 58

Manual for Multichannel Ultrasonic Pile Integrity Tester

3.10 System Setup

The system setup function is used to set instrument information

and public parameter.

Press System Setting button in startup interface to pop up

dialogue box as shown in Figure 3.9. This dialogue box includes

three property pages of General parameter, Instrument information

and Internet parameter, as shown in Figure 3.13, 3.15 and 3.16

separately. The default of each parameter is the value which has been

set last time.

After have set all parameters, press OK button to validate all

sets and return to startup interface, press Cancel button to invalidate

all sets and return to startup interface.

In the interface of system setup, press Default button, the

dialogue box of “whether restore factory setting or not?” will appear,

press Yes button to restore all parameters to factory setting or No

button for not.

In system setup interface, press Versions button to pop up

dialogue box of version information for checking software, hardware,

core or firmware, etc.

50

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 59

Manual for Multichannel Ultrasonic Pile Integrity Tester

3.10.1 General parameter

Press General label to switch to the property page as shown in

Figure 3.13 for setting System date, System time and Screen

brightness, etc.

Figure 3.13 General parameter

1. System Date

Display system date: Press the pull-down button behind it to pop

up dialogue box as shown in Figure 3.14 to display current date. After

the date has been changed, the setting will become valid immediately,

close the dialogue box, the current system date is changed.

51

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 60

Manual for Multichannel Ultrasonic Pile Integrity Tester

Figure3.14 System date setup

2. System time

Display system time: Adjust time to select hour, minute or

second and press the spin button behind it. The adjusted time will

become valid immediately and the current system time is changed.

3. Screen brightness

The brightness of LCD may be adjusted within range of 10-100,

the default is 100; press + and - buttons to increase and

decrease brightness; every press changes 10.

52

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 61

Manual for Multichannel Ultrasonic Pile Integrity Tester

3.10.2 Instrument information

(a)Instrument information

(b)Edit tester

Figure 3.15 Instrument information

53

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 62

Manual for Multichannel Ultrasonic Pile Integrity Tester

Press Instrument label to switch to the property page as shown

in Figure 3.15 for setting test information and checking instrument ID

number and certificate number, etc.

1. Information setup of test organization and tester

Test organization may be changed: press the edit box behind it

and input the name of test organization through pop-up soft keyboard

for inputting character.

Change of tester and work license number: once the tester is

selected, his/her work license number will display automatically.

Work license number may be changed only after password

verification is successful.

Press Modify Operators button to pop up dialogue box as shown

in Figure 3.15(b), user may delete an add tester and his/her work

license number. After have input tester name and work license

number into the edit box at the top of dialogue box, press Add button

to put it into list; after have selected tester and press Delete button to

delete this tester from the list; press Exit button to exit from tester

edit box.

2. Instrument information setup

Instrument information includes instrument model, ID number

and calibration certificate number, etc. Instrument model cannot be

changed by user and ID number is set in factory. Calibration date

54

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 63

Manual for Multichannel Ultrasonic Pile Integrity Tester

refers to the latest calibration date; calibration period refers to the

interval between each calibration, usually it is one year. Based on

calibration date and period, the system will remind user to calibrate

instrument at every startup within one month before every expiry date

of calibration.

3. Password verification

Since instrument information can only be changed by the person

with administration authority, all test information is not editable

(except for tester); dialogue box requiring input password will pop up

when press a certain edit box, all test information can be changed

only after password verification is successful.

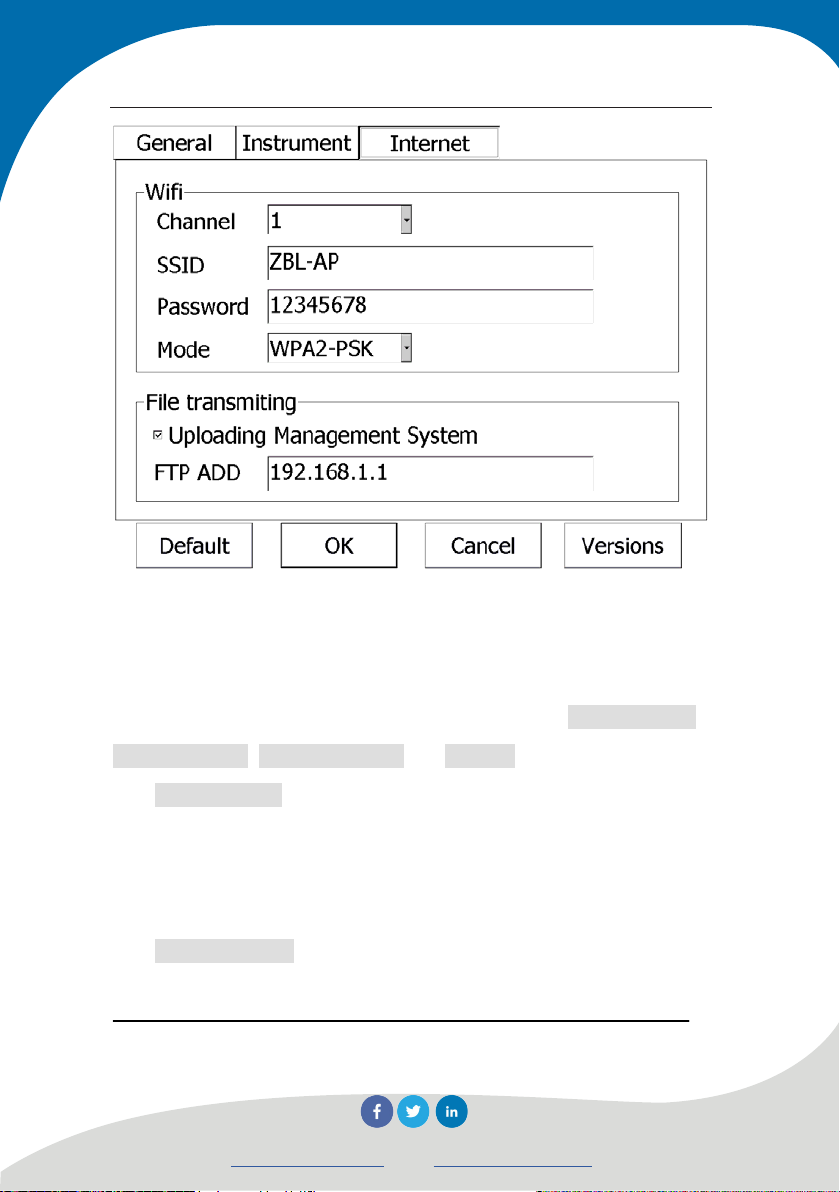

3.10.3 Internet Parameter

Press Internet label to switch to the property page as shown in

Figure 3.16 for setting WIFI parameter and file transmission.

Internet parameters can be changed only by the person with

administration authority, dialogue box requiring input password will

pop up when press a certain edit box, all parameters can be changed

only after password verification is successful.

55

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 64

Manual for Multichannel Ultrasonic Pile Integrity Tester

Figure 3.16 Internet parameter

1. WIFI Parameter setup

WIFI parameter is used to set relevant parameters when

instrument is connected through WIFI, it includes Network name,

Login password, Encryption mode and Channel.

Network name is the name of WIFI LAN generated by current

instrument, user may find out this WIFI LAN in other terminal units

with WIFI function, the default is “ZBL-(last 6 digits of the

instrument wireless MAC address)”.

Login password is the password required to input when other

terminal units need to log in the WIFI LAN of current instrument, the

56

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 65

Manual for Multichannel Ultrasonic Pile Integrity Tester

default is “zbl12345678”.

Encryption mode is the way of encryption for login password,

the options include 4 types such as Open, WEP, WPA-PSK and

WPA2-PSK, the default is WPA2-PSK. In consideration of safety, it

is suggested to use WPA2-PSK.

Channel has 12 options from 1 to 12. It is used to set frequency

range for WIFI signal transmission; user may try to change this if

WIFI signal transmission is weak, the default is 1.

2. File transmission setup

Uploading Management System is used to control instrument to

automatically upload new collected data to remote management

system. This function is valid only when used with the matching

management system from our company.

In order to make sure that test data could be transmitted to

correct server through Internet, must input correct FTP address (such

as 202.106.63.52) and port number.

NOTE: In general, FTP and WIFI setting is only

required in the first operation, if there is no change after that,

setup is not necessary anymore.

3.11 Software update

The main function of this module is to automatically update all

57

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 66

Manual for Multichannel Ultrasonic Pile Integrity Tester

software (listed in startup interface, such as startup interface and

update program) in instrument and relevant files.

After software in instrument has been updated, user may update

it by himself. Before update, user must obtain update program from

our company’s website or through other ways; the update program is

self-extracting program. The update process is simple and as follows:

1) Extract the files in update package to a certain folder in

computer;

2) Insert U disk into USB port in computer, copy the extracted

update files to root directory in U disk, take out U disk after

copy is completed;

3) Insert U disk into USB port of the instrument;

4) Power on instrument, press Software Update button in startup

interface to close current software and Start update program;

press Update button (to copy the update files in U disk to

corresponding folder in the instrument); the prompt of “Software

update is successful” will appear after update is completed;

NOTE: If there is no software needs to be updated in

U disk or U disk cannot be found, the prompt of “Update

program could not be detected, please insert U disk with

update program” will appear; if the update failed due to

storage space in the instrument is not enough, the prompt

of “”File copy failed, please check remaining storage space

58

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 67

Manual for Multichannel Ultrasonic Pile Integrity Tester

of the instrument!” will appear.

5) Press Close button to exit from update program.

59

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 68

Manual for Multichannel Ultrasonic Pile Integrity Tester

Chapter 4 Cross-hole sonic logging

software for testing pile integrity

Press Detecting Integrity of Pile button in startup interface to

enter into main interface of pile test software as shown in Figure 4.1,

it is applicable to integrity test of concrete cast-in-place pile with

built-in pipe.

3.1 Main interface

The main interface of the pile test software is composed of three

parts as follow: function button area, single-channel waveform

area and data graphic area. There are two kinds of optional

display modes for main interface to select in View: 1*6 or 2*3. 1*6

means that single-channel waveform with 6 profiles displays in the

same row (as shown in Figure 4.1a), 2*3 means that single-channel

waveform with 6 profiles displays in two rows (as shown in Figure

4.1b).

60

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 69

Manual for Multichannel Ultrasonic Pile Integrity Tester

a) 1*6 Layout

61

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 70

Manual for Multichannel Ultrasonic Pile Integrity Tester

b) 2*3 Layout

Figure 4.1 Main interface of pile integrity test

NOTE: the single-channel waveform area and bar

graph area are divided into six small areas at most according to

different number of channels in use.

1)Function button area: it is composed of several function

buttons such as File, Parameter and Sample, etc. as shown in Figure

4.1; each button may implement one common function; when button

color is grey, it means this function is invalid in such condition.

2 )Singe-channel waveform area: It is used to display

waveform and acoustic parameter of current test point in each profile;

62

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 71

Manual for Multichannel Ultrasonic Pile Integrity Tester

please refer to Section 3.4 for details.

3)Data graphic area: It is used to display bar graph, curve

graph and wave train graph, etc. And different graphs may be

switched through View button. Refer to Section 4.4 in this chapter

for details.

4)Title bar: It is used to display project name, foundation pile

name and current depth, etc. The three icons at right side separately

indicate battery level of lifting device, Bluetooth connection status

and battery level of host. When Bluetooth icon is flashing, it means

that host failed to connect with lifting device.

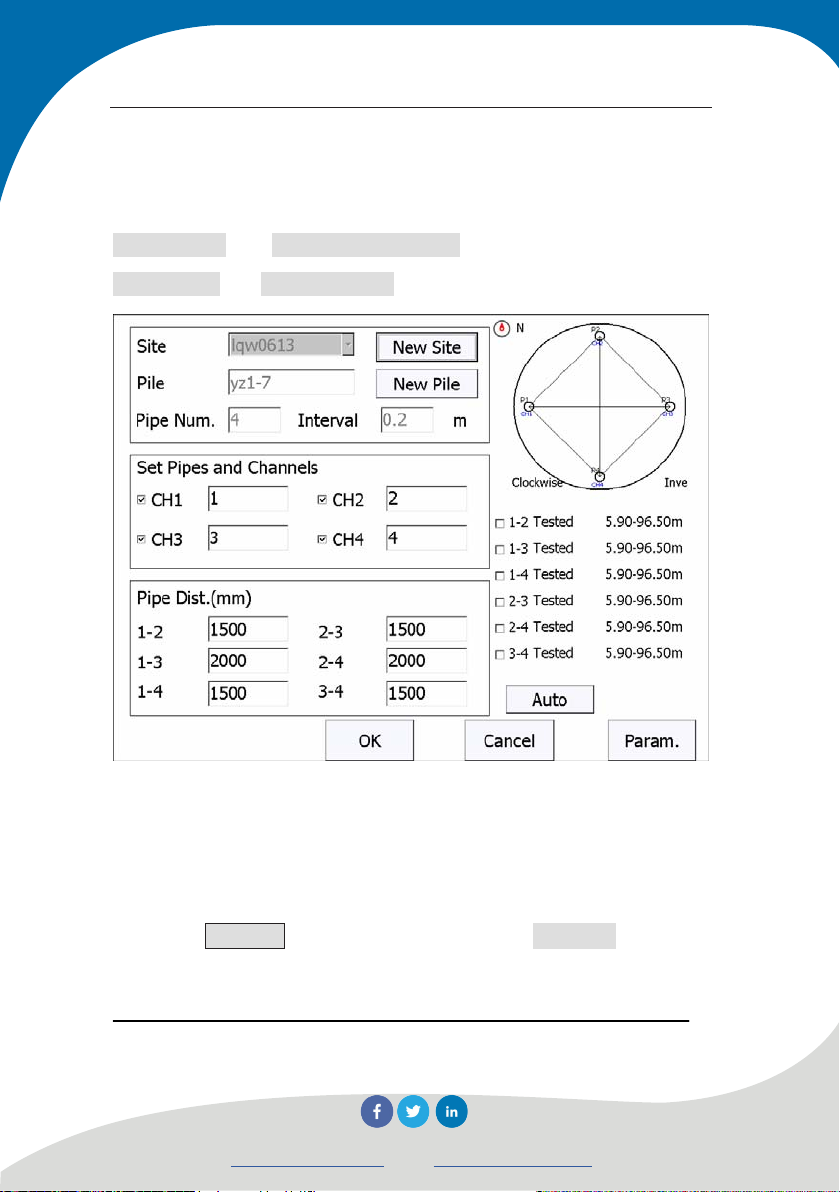

3.2 Parameter setup

Press Parameter button in main interface of pile test to pop up

dialogue box as shown in Figure 4.2. Press Advanced to pop up

property page of General parameter and Other parameters. Default of

each parameter is the value set at last time.

After have set all parameters, press OK button to validate all

settings and return to main interface; press Cancel button to

invalidate all settings and return to main interface.

63

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 72

Manual for Multichannel Ultrasonic Pile Integrity Tester

3.2.1 Basic parameter setup

Basic parameter setup interface may be used to create new

Project name and Foundation pile name and set parameters such as

Pipe spacing and Number of pipe, etc.

Figure 4.2 Parameter setup

1. Create new project or select existing project

1) Create new project

Press New Site button behind the list box of Site name to pop up

soft keyboard for inputting character, input project name to create a

subfolder with such name, all data files of tested piles will be saved

64

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 73

Manual for Multichannel Ultrasonic Pile Integrity Tester

in this folder. When create a folder, if a folder with same project

name has existed, prompt of “This project has existed already, cover

it or not?” will pop up; select Yes button to cover it, if select No,

input box for project name will pop up and require inputting new

project name.

2) Select tested project

Press T button behind pull-down list box of Site to list all tested

projects, select one to save its pile data files in this project.

2. New pile

If need to test a new pile, press New Pile behind Foundation pile

name and input the name of new pile in the pop-up soft keyboard.

When read the file of tested pile or test a certain pile, the name of this

pile will display at here and it cannot be changed.

3. Number of pipes

Press edit box behind the Number of pipes to pop up

single-choice box of number of pipes. The optional value is 2, 3 and 4.

This value is set according to the number of built-in pipes in piles to

be tested. When selected pipe, corresponding schematic graph of pipe

will display on the top right corner of dialogue box for parameter

setting based on the setting of pipe. Meanwhile, the spacing and

profile status of pipe will change accordingly based on the setting of

pipe.

65

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 74

Manual for Multichannel Ultrasonic Pile Integrity Tester

4. Test point interval

Test point interval refers to the displacement distance of sensor

between two test points. Press the edit box behind it to pop up

dialogue box (as shown in Figure 4.3) to list optional test point

spacing in m. The optional test point spacing includes 0.02, 0.05,

0.10, 0.15, 0.20 and 0.25m, press corresponding value, system will

return to the parameter interface automatically and save the setting.

Press Cancel button to return to parameter setup interface without

changing test point spacing.

Figure 4.3 Test point spacing

5. Pipe and channel setup

Pipe corresponding to the channel is set. U5600 has three

channels and U5700 has four. Every channel may be closed freely;

press check box in front of channel name to open or close channel.

Pipe corresponding to channel behind channel name may be freely

66

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 75

Manual for Multichannel Ultrasonic Pile Integrity Tester

adjusted according to the position of transducer linked with this

channel in foundation pile.

Example 1: The number of pipes set in U5600 is 3, Channel 1

corresponds to pipe 1, Channel 2 corresponds to pipe 2 and Channel

3 corresponds to pipe 3. In test, Channel 1 and 2 test Profile 1-2,

Channel 1 and 3 test Profile 1-3 and Channel 2 and 3 test Profile 2-3.

Example 2: The number of pipes set in U5700 is 4, Channel 1

corresponds to pipe 1, Channel 2 corresponds to pipe 2, Channel 3

corresponds to pipe 3 and Channel 4 corresponds to pipe 4. In test,

Channel 1 and 2 test Profile 1-2, Channel 1 and 3 test Profile 1-3,

Channel 1 and 4 test Profile 1-4, Channel 2 and 3 test Profile 2-3 and

Channel 3 and 4 test Profile 3-4.

6. Pipe distance

It refers to the clear spacing of sounding pipe outer wall in mm.

System will generate corresponding pipe spacing options

automatically according to the number of pipe. Press edit box behind

corresponding profile name to set pipe spacing in pop-up numerical

soft keyboard.

NOTE: Since pipe spacing may affect data

calculation, please set it correctly.

7. Profile list

It displays profile list of current pile and indicates that whether

each profile has been tested and tested elevation range. System

67

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 76

Manual for Multichannel Ultrasonic Pile Integrity Tester

selects untested profile as default; tick off or cancel check box in

front of profile name for manual change.

3.2.2 Advanced parameter

Press Advanced button in parameter setup interface to pop up

dialogue box as shown in Figure 4.4. This dialogue box includes two

property pages of General parameter and Other parameters. Default

of each parameter is the value set at last time.

After have set all parameters, press OK button to save

parameters have been set, press Cancel button for not.

Press Reset button in advanced parameter setup interface to pop

up dialogue box inquiring “Whether restore parameter to factory

setting?”; press Yes button to restore all parameters to factory setting

and No for not.

NOTE: If tested data exist, Reset button is invalid.

3.2.2.1 General parameter

Press General label to switch to its property page for setting

parameters such as System delay, Technical specification and

Acoustic speed limit, etc.

68

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 77

Manual for Multichannel Ultrasonic Pile Integrity Tester

Figure 4.4 General parameter

1. Instrument system delay

System delay input into the instrument. After have input a value

in “Pipe 1-2”, if the option “All profiles of the same” is selected,

values in other pipes are as same as this value. If not selected, value

of each pipe may be changed separately.

2. Selection of technical specification

After have selected corresponding test procedure, data will be

real-time analyzed and processed according to the procedure in test.

3. Acoustic speed limit

Whether limit the range of acoustic speed when search head

69

Novatest S.r.l.

info@novatest.itwww.novatest.it

Page 78