Page 1

Integration Guide:

LPP0108IG001

Enfora Enabler LPP G

Integration Guide

Version: Preliminary

Page 2

Enfora Enabler LPP G

Integration Guide

Document Title: Enfora Enabler LPP G Integration Guide

Version: Preliminary

Date: 06/20/2008

Status: Preliminary

Document Control ID: LPP0108IG001

General

All efforts have been made to ensure the accuracy of material provided in this document at the time

of release. However, the items described in this document are subject to continuous development

and improvement. All specifications are subject to change without notice and do not represent a

commitment on the part of Enfora, Inc. Enfora, Inc. will not be responsible for any loss or damages

incurred related to the use of information contained in this document.

This product is not intended for use in life support appliances, devices or systems where a

malfunction of the product can reasonably be expected to result in personal injury. Enfora, Inc.

customers using, integrating, and/or selling this product for use in such applications do so at their

own risk and agree to fully indemnify Enfora, Inc. for any damages resulting from illegal use or resale.

Copyright

Complying with all applicable copyright laws is the responsibility of the user. Without limiting the

rights under copyright, no part of this document may be reproduced, stored in or introduced into a

retrieval system, or transmitted in any form or by any means (electronic, mechanical, photocopying,

recording or otherwise), or for any purpose, without the express written permission of Enfora, Inc.

Enfora may have patents, patent applications, trademarks, copyrights or other intellectual property

rights covering subject matter in this document. Except as expressly provided in any written license

agreement from Enfora, the furnishing of this document does not give you any license to these

patents, trademarks, copyrights or other intellectual property.

©2002, 2003, 2004, 2005, 2006, 2007, 2008 Enfora, Inc. All rights reserved.

Enabler and Spider are either registered trademarks or trademarks of Enfora, Inc. in the United

States.

LPP0108IG001 Version - Preliminary – 06/20/2008

Page 3

Enfora Enabler LPP G

Integration Guide

Table of Contents

1. SAFETY PRECAUTIONS ................................................................................................................................. 1

1.1. IMPORTANT SAFETY INFORMATION ................................................................................................................ 1

2. REGULATORY COMPLIANCE FCC ............................................................................................................. 1

2.1. INTEGRATION CONSIDERATIONS AND INSTALLATION REQUIREMENTS ........................................................... 1

2.2. DISCLAIMER ................................................................................................................................................... 3

3. MANUAL OVERVIEW ...................................................................................................................................... 4

3.1. REVISION HISTORY ......................................................................................................................................... 4

H3.2. REFERENCES ................................................................................................................................................... 5

3.2.1. Enfora Enabler LPP G Product Documentation ................................................................................. 5

3.2.2. GSM Device Specifications .................................................................................................................. 5

3.2.3. US Government .................................................................................................................................... 5

3.2.4. Federal Communications Commission (FCC) ..................................................................................... 5

3.2.5. FCC Office of Engineering and Technology (OET) ............................................................................. 5

3.2.6. Industry Canada .................................................................................................................................. 6

3.2.7. Environmental Regulations .................................................................................................................. 6

3.2.8. Mechanical Specifications ................................................................................................................... 6

3.2.9. RF and EMI Specifications .................................................................................................................. 6

4. INTRODUCTION ............................................................................................................................................... 7

4.1. PRODUCT OVERVIEW...................................................................................................................................... 7

4.2. KEY FEATURES OF THE ENABLER LPP G MODULE ......................................................................................... 7

4.3. PROVIDING MULTI-BAND OPERATION ........................................................................................................... 9

4.4. SUMMARY OF FEATURES FOR THE ENABLER LPP G MODULE ........................................................................ 9

4.5. GENERAL DESIGN GUIDELINES FOR UTILIZING ENFORA GSM MODU LES ...................................................... 12

4.5.1. Advanced tips for an RF friendly layout ............................................................................................ 13

4.5.1.1. Ground Plane ................................................................................................................................................... 13

4.5.1.2. Thermal Relief ................................................................................................................................................. 14

4.5.1.3. Antenna and RF Signal Trace .......................................................................................................................... 15

4.5.1.4. Vbat Input ........................................................................................................................................................ 16

4.5.2. Audio Reference Design ..................................................................................................................... 17

4.5.2.1. Audio Schematics ............................................................................................................................................ 17

4.5.2.2. Audio Layout ................................................................................................................................................... 17

4.6. HANDLING AND SOLDERING GUIDELINES ..................................................................................................... 17

5. TECHNICAL SPECIFICATIONS .................................................................................................................. 18

5.1. ENABLER LPP G MODULE BLOCK DIAGRAM ............................................................................................... 18

5.2. DETAILED PRODUCT SPECIFICATIONS .......................................................................................................... 19

CLIMATIC: STORAGE AND TRANSPORTATION ........................................................................................................... 19

MECHANICAL: STORAGE AND TRANSPORTATION ..................................................................................................... 19

MECHANICAL: PROPOSED STANDARDS .................................................................................................................... 19

ELECTROMAGNETIC EMISSIONS ............................................................................................................................... 19

5.3. OPERATING POWER ...................................................................................................................................... 20

5.3.1. Typical Input Current ........................................................................................................................ 20

5.3.2. GSM Transmit Power ........................................................................................................................ 20

5.3.3. GSM Receiver Sensitivity ................................................................................................................... 21

6. PHYSICAL INTERFACES .............................................................................................................................. 21

6.1. MODULE MOUNTING TO HOST BOARD (REFERENCE) ................................................................................... 22

6.2. I/O PIN ASSIGNMENTS .................................................................................................................................. 25

6.3. CIRCUIT PROTECTION ................................................................................................................................... 26

6.4. ANTENNA ..................................................................................................................................................... 27

LPP0108IG001 Version - Preliminary – 06/20/2008

Page 4

Enfora Enabler LPP G

Integration Guide

6.4.1. GSM ................................................................................................................................................... 27

6.4.2. GPS .................................................................................................................................................... 27

6.5. CONTROL CONNECTOR SIGNAL DESCRIPTIONS AND FUNCTIONS ................................................................. 29

6.5.1. Module Power (Pins 30, 31) .............................................................................................................. 29

6.5.2. On/Off Signal (Pin 4) ......................................................................................................................... 30

6.5.3. On/Off Status (Pin 5) ......................................................................................................................... 30

6.5.1. General Purpose Input Signals (Pins 10, 11) .................................................................................... 30

6.5.1. General Purpose Output Signals (Pins 12, 13) .................................................................................. 30

6.5.2. Reset Signal (Pin 24) ......................................................................................................................... 30

6.5.3. USB (Pins 34, 35, 36) ........................................................................................................................ 31

6.5.4. RTC Sleep ............................................................................................ Error! Bookmark not defined.

6.5.5. Serial Interfaces ................................................................................................................................. 32

6.5.5.1. Main Serial Interface (Pins 17, 18) .................................................................................................................. 32

6.5.5.2. GPS Serial Interface (Pin 19) ................................................................................................. .......................... 33

6.5.6. Handset Microphone Input (Pins 39, 40) ........................................................................................... 34

6.5.7. Handset Speaker Output (Pins 37, 38) ............................................................................................... 34

6.6. SUBSCRIBER IDENTITY MODULE (SIM) (PINS 42, 43, 44, 45, 46) ................................................................. 35

6.6.1. Using a Remote SIM with the Enfora Enabler LPP G Module (Pins 42, 43, 44, 45, 46) .................. 36

6.6.1.1. Remote SIM Component Information .............................................................................................................. 37

7. BATTERY CHARGING CALIBRATION AND CONFIGURATION ........................................................ 38

7.1. OBJECTIVE .................................................................................................................................................... 38

7.2. SUPPORTED DEVICES .................................................................................................................................... 38

7.3. REFERENCES ................................................................................................................................................. 38

7.4. LIST OF BATTERY CHARGING COMMANDS ..................................................................................................... 38

7.4.1. Setting BCIVSF parameters ............................................................................................................... 39

7.4.2. Equipment required ........................................................................................................................... 39

7.4.3. Procedure .......................................................................................................................................... 39

7.4.4. Setting BCIISF Parameters ................................................................................................................ 40

7.4.5. Scope .................................................................................................................................................. 40

7.4.6. 6.2 Equipment required ..................................................................................................................... 40

7.4.7. 6.3 Calibration procedure ................................................................................................................. 40

7.5. SETTING BCIAVG PARAMETERS .................................................................................................................. 42

7.6. SETTING BCIMAP# PARAMETERS ................................................................................................................ 42

7.6.1. Scope .................................................................................................................................................. 42

7.6.2. Procedure .......................................................................................................................................... 42

7.6.3. Choose the BCIMAP# index .............................................................................................................. 42

7.6.4. Set the desired CI charge current for the designated charger. .......................................................... 43

7.6.5. Charge empty battery in constant current with target <ci_chgireg>. ............................................... 43

7.6.6. Note the first Vbat(mA) that occurred after the charge stopped and went to 3(SUP). ....................... 44

7.6.7. Calculate the BCIMAP# values for the parameters above the index. ................................................ 45

7.6.8. Discharge the battery, determine the remaining BCIPCT# parameters. ........................................... 45

7.7. SETTING BCIBAT# PARAMETERS ................................................................................................................ 47

7.7.1. Procedure to set the battery ID .......................................................................................................... 47

7.8. SETTING BCITMP# PARAMETERS ................................................................................................................ 47

7.8.1. Scope .................................................................................................................................................. 47

7.8.2. Equipment required ........................................................................................................................... 48

7.8.3. Procedure .......................................................................................................................................... 48

7.9. SETTING BCIDEL PARAMETERS................................................................................................................... 49

7.10. SETTING BCIOFF PARAMETERS ............................................................................................................... 49

7.11. BATTERY CHARGING CALIBRATION AND CONFIGURATION - APPENDIX 1 ................................................ 50

7.12. BCI COMMAND PARAMETERS - APPENDIX 2 ............................................................................................ 52

7.13. SET BCI PARAMETERS FOR AN ACTIVEKEY2 - APPENDIX 3 ..................................................................... 54

8. GPS PERFORMANCE ..................................................................................................................................... 56

9. GSM/GPRS MODES OF OPERATION ......................................................................................................... 57

LPP0108IG001 Version - Preliminary – 06/20/2008

Page 5

Enfora Enabler LPP G

Integration Guide

9.1. ENABLING THE TRANSMISSION MODES FOR THE GSM/GPRS SERVICES ..................................................... 57

9.2. VOICE COMMUNICATION .............................................................................................................................. 57

9.3. SMS: SHORT MESSAGE SERVICES ................................................................................................................ 58

9.4. SIM OPERATION ........................................................................................................................................... 58

9.4.1. Provisioning the SIM ......................................................................................................................... 58

9.5. GPRS SERVICES SUPPORTED BY THE ENFORA ENABLER LPP G MODULE ................................................... 58

9.6. SELECTING THE GSM MODES OF OPERATION .............................................................................................. 59

10. SOFTWARE INTERFACE .......................................................................................................................... 60

10.1. SOFTWARE INTERFACE ............................................................................................................................. 60

10.2. FORMAT FOR THE AT COMMANDS ........................................................................................................... 60

10.3. ENFORA AT COMMAND SET ..................................................................................................................... 60

11. INTEGRATION AND TESTING ................................................................................................................ 61

12. APPENDIX A - LIMITED WARRANTY ................................................................................................... 62

12.1. SCOPE ....................................................................................................................................................... 62

12.2. HARDWARE .............................................................................................................................................. 62

12.3. SOFTWARE ................................................................................................................................................ 62

12.4. OTHER CONSIDERATIONS ......................................................................................................................... 63

13. APPENDIX B - REGULATIONS AND COMPLIANCE .......................................................................... 64

13.1. GCF/PTCRB APPROVAL (FORMERLY FTA) ............................................................................................ 64

13.2. ELECTROMAGNETIC COMPATIBILITY (EMC) AND SAFETY REQUIREMENTS ............................................. 64

13.3. EMC/SAFETY REQUIREMENTS FOR THE USA .......................................................................................... 64

13.4. HUMAN EXPOSURE COMPLIANCE STATEMENT ......................................................................................... 65

13.5. COMPLIANCE WITH FCC REGULATIONS ................................................................................................... 65

13.6. UNINTENTIONAL RADIATORS, PART 15 .................................................................................................... 66

13.7. INTENTIONAL RADIATORS, PART 22 & 24 ................................................................................................ 66

13.8. INSTRUCTIONS TO THE ORIGINAL EQUIPMENT MANUFACTURER (OEM) .................................................. 67

13.8.1. OEM Responsibilities for All Products Containing the Enabler LPP G module ............................... 69

13.8.2. Specific OEM Responsibilities for Portable Products and Applications ........................................... 70

13.8.3. Specific OEM Responsibilities for Mobile Products and Applications .............................................. 70

13.8.4. Specific OEM Responsibilities for Fixed Products and Applications ................................................ 70

13.9. EMC/SAFETY REQUIREMENTS FOR THE COUNTRIES OF THE EUROPEAN UNION (EU) .............................. 71

13.10. EMC/SAFETY REQUIREMENTS FOR OTHER COUNTRIES ........................................................................... 71

14. APPENDIX C - GLOSSARY AND ACRONYMS ...................................................................................... 72

15. APPENDIX D – TABLES AND FIGURES ................................................................................................. 74

16. APPENDIX E - CONTACTING ENFORA................................................................................................. 75

LPP0108IG001 Version - Preliminary – 06/20/2008

Page 6

1. Safety Precautions

1.1. Important Safety Information

The following information applies to the devices described in this manual. Always observe all standard and

accepted safety precautions and guidelines when handling any electrical device.

Save this manual: it contains important safety information and operating instructions.

Do not expose the Enfora Enabler LPP G product to open flames.

Ensure that liquids do not spill onto the devices.

Do not attempt to disassemble the product: Doing so will void the warranty. With the

exception of the Subscriber Identification Module (SIM), this product does not contain

consumer-serviceable components.

2. Regulatory Compliance FCC

2.1. Integration Considerations and Installation Requirements

The Enabler LPP G module is designed for use in a variety of host units, "enabling" the host

platform to perform wireless data communications. However, there are certain criteria relative to

integrating the Enabler LPP G module into a host platform such as a PC, laptop, handheld or

PocketPC

compliance with FCC compliance requirements.

Operation is subject to the following two conditions: (1) this device may not cause

In order to use the Enabler LPP G module without additional FCC certification approvals, the

®

, monitor and control unit, etc. that must be considered to ensure continued

interference, and (2) this device must accept any interference, including interference that may

cause undesired operation of the device.

installation must meet the following conditions:

Maximum RF output power and antenna gain to meet Maximum Permissible Exposure

Requirements: GSM850 mode: Power at antenna port is +33 dBm. The maximum gain

is 1.4 dBi. GSM1900 mode: Power at antenna port is 30 dBm. The maximum gain is 7

dBi in order to meet the requirements of maximum 2 watts EIRP for mobile transmitters. If

RF power and/or antenna gain is desired, a separate FCC certification is required.

If used in a "portable" application such as a handheld or body worn device with the

antenna less than 20 cm (7.9 in.) from the human body when the device is operating,

then the integrator is responsible for passing additional "as installed" testing and the

device will require its own FCC ID:

SAR (Specific Absorption Rate) testing, with results submitted to the FCC for

approval prior to selling the integrated unit. If unable to meet SAR requirements,

then the host unit must be restricted to "mobile" use (see below).

Unintentional emissions, FCC Part 15; results do not have to be submitted to the

FCC unless requested, although the test provides substantiation for required labeling

(see below).

LPP0108IG001 1 Version - Preliminary – 06/20/08

Page 7

ERP and EIRP measurements for FCC Parts 22 and 24, alternatively a full retest on

FCC Parts 22 and 24 can be performed.

If used in a "mobile" application where the antenna is normally separated at least 20 cm

(7.9 in) from the human body during device operation, then an appropriate warning label

must be placed on the host unit adjacent to the antenna. The label should contain a

statement such as the following:

WARNING

RF exposure. Keep at least 20 cm

(7.9 in) separation distance from

the antenna and the human body.

Host unit user manuals and other documentation must also include appropriate caution

and warning statements and information.

If the FCCID for the Enabler LPP G module is not visible when installed in the host

platform, then a permanently attached or marked label must be displayed on the host unit

referring to the enclosed module.

For example, the label should contain wording such as:

Contains GSM/GPRS modem transmitter module

FCC ID: MIVLPP0108

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2)

This device must accept any interference received,

including interference that may cause undesired

operation.

OR

Contains FCC ID: MIVLPP0108

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2)

This device must accept any interference received,

including interference that may cause undesired

operation.

Any antenna used with the Enabler LPP G module must be approved by the FCC or as a

Class II Permissive Change (including MPEL or SAR data as applicable). The

"professional installation" provision of FCC Part 15.203 does not apply.

LPP0108IG001 2 Version - Preliminary – 06/20/08

Page 8

2.2. Disclaimer

The information and instructions contained within this publication comply with all FCC, GCF,

PTCRB, R&TTE, IMEI and other applicable codes that are in effect at the time of publication.

Enfora disclaims all responsibility for any act or omissions, or for breach of law, code or

regulation, including local or state codes, performed by a third party.

Enfora strongly recommends that all installations, hookups, transmissions, etc., be performed by

persons who are experienced in the fields of radio frequency technologies. Enfora acknowledges

that the installation, setup and transmission guidelines contained within this publication are

guidelines, and that each installation may have variables outside of the guidelines contained

herein. Said variables must be taken into consideration when installing or using the product, and

Enfora shall not be responsible for installations or transmissions that fall outside of the

parameters set forth in this publication.

Enfora shall not be liable for consequential or incidental damages, injury to any person or

property, anticipated or lost profits, loss of time, or other losses incurred by Customer or any third

party in connection with the installation of the Products or Customer's failure to comply with the

information and instructions contained herein.

The transmitter and antenna must not be co-located or operating in conjunction with any

other antenna or transmitter. Violation of this would allow a user to plug another

transmitter in to the product and potentially create an RF exposure condition.

WARNING

The transmitter and antenna must not be collocated

or operating in conjunction with any

other antenna or transmitter. Failure to observe

this warning could produce an RF exposure

condition.

The Enabler LPP G platform is designed with features

to support a robust connection. There are instances

where the module performance is beyond the control

of the intended design. Integrated designs that require

24 by 7 operation must implement power control via an

external circuit or by implementing power management

as specified within this design guide.

LPP0108IG001 3 Version - Preliminary – 06/20/08

Page 9

3. Manual Overview

This document describes the available hardware interface of the Enabler LPP G module. The

purpose of this document is to define the electrical, mechanical and software interfaces while

providing detailed technical information in order to streamline the process of hardware and

system integration.

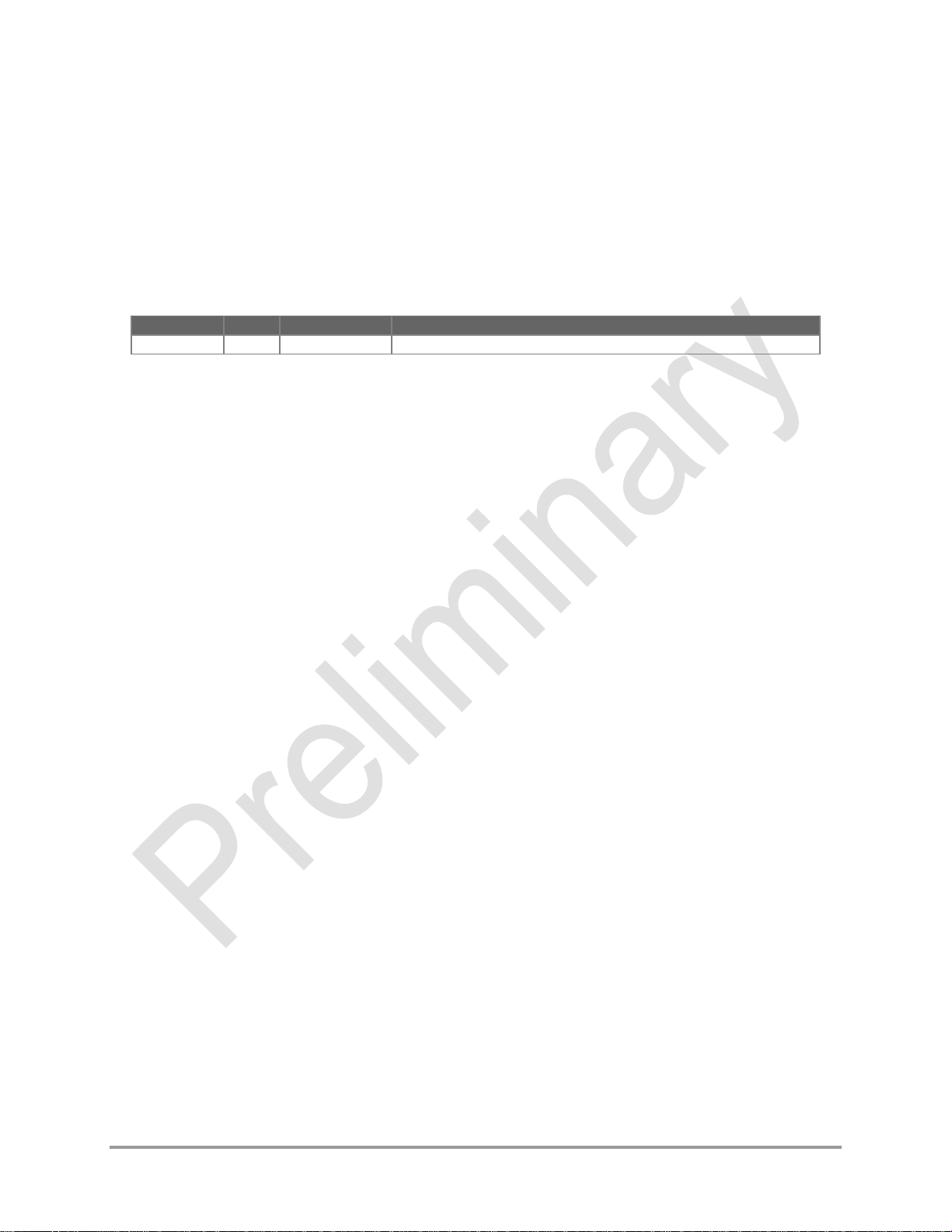

3.1. Revision History

Date Rev Author Description

06/20/08 1.00 Chuck Todd Preliminary

LPP0108IG001 4 Version - Preliminary – 06/20/08

Page 10

3.2. References

3.2.1. Enfora Enabler LPP G Product Documentation

Manuals

LPP0108AT001 - Enfora Enabler LPP G AT Command Set Reference

GSM0308UG001 - Enfora GSM-GPRS Family API Reference

LPP0108PR001 – Enfora Enabler LPP G Programming Reference

LPP0108SD001 – Enfora Enabler LPP G SDK Reference

LPP0108UG001 – Enfora Enabler LPP G Power Management Developer Tool Guide

3.2.2. GSM Device Specifications

3GPP TS 51010-1 (850, 900,1800,1900 MHz devices)

To view the latest release, go to:

http://www.3gpp.org/ftp/Specs/html-info/51010-1.htm

3.2.3. US Government

3.2.4. Federal Communications Commission (FCC)

Internet: http://www.fcc.gov/

FCC Rules, Part 24

47 CFR Subpart E--Broadband PCS

47 CFR § 24.52, sections 1.1307(b), 2.1091, and 2.1093

FCC Rules, Part 22 for GSM 850

FCC Rules, Part 15

FCC Rules, Part 2

Subpart J--Equipment Authorization Procedures

Section 2.925

3.2.5. FCC Office of Engineering and Techn ology (OET)

Internet: http://www.fcc.gov.oet/

Bulletin Number 65 "Evaluating Compliance with FCC Guidelines for Human Exposure

to Radio Frequency Electromagnetic Fields"

Supplement C "Additional Information for Evaluating Compliance of Mobile and

Portable Devices with FCC Limits for Exposure to Radio Frequency Emissions"

LPP0108IG001 5 Version - Preliminary – 06/20/08

Page 11

3.2.6. Industry Canada

RSS-132

RSS-133

ICES-003

3.2.7. Environmental Regulations

National Environmental Policy Act (NEPA) of 1969 (Part 1, Subpart 1)

RoHS Compiant

3.2.8. Mechanical Specifications

ASTM D999

ASTM D775

IEC 68-2-27

Bellcore Gr-63-CORE

ETS 300 019-1-1 Class 1.2

ETS 300 019-1-2 Class 2.1

ETS 300 019-1-3 Class 3.1

3.2.9. RF and EMI Specifications

ETSI Standards

EN 61000-4-6

EN 61000-4-3

3GPP TS 51.010-1, Section 12.2

LPP0108IG001 6 Version - Preliminary – 06/20/08

Page 12

4. Introduction

4.1. Product Overview

4.2. Key Features of the Enabler LPP G Module

The Enfora Enabler LPP G module is a compact, wireless OEM module that utilizes the Global

System for Mobile Communications (GSM) and General Packet Radio Services (GPRS)

international communications standard to provide two-way wireless capabilities via GSM services.

This GSM/GPRS module is combined with a Global Positioning System (GPS) chipset to provide

physical location, a host processor to ensure very low power standby configurations, and

vibration sensor to detect movement of the module. The Enfora Enabler LPP G module is a fully

Type-approved GSM/GPRS device, enabling application-specific, two-way communication and

control.

The small size of the Enfora Enabler LPP G module allows it to be integrated easily into the

application and packaging.

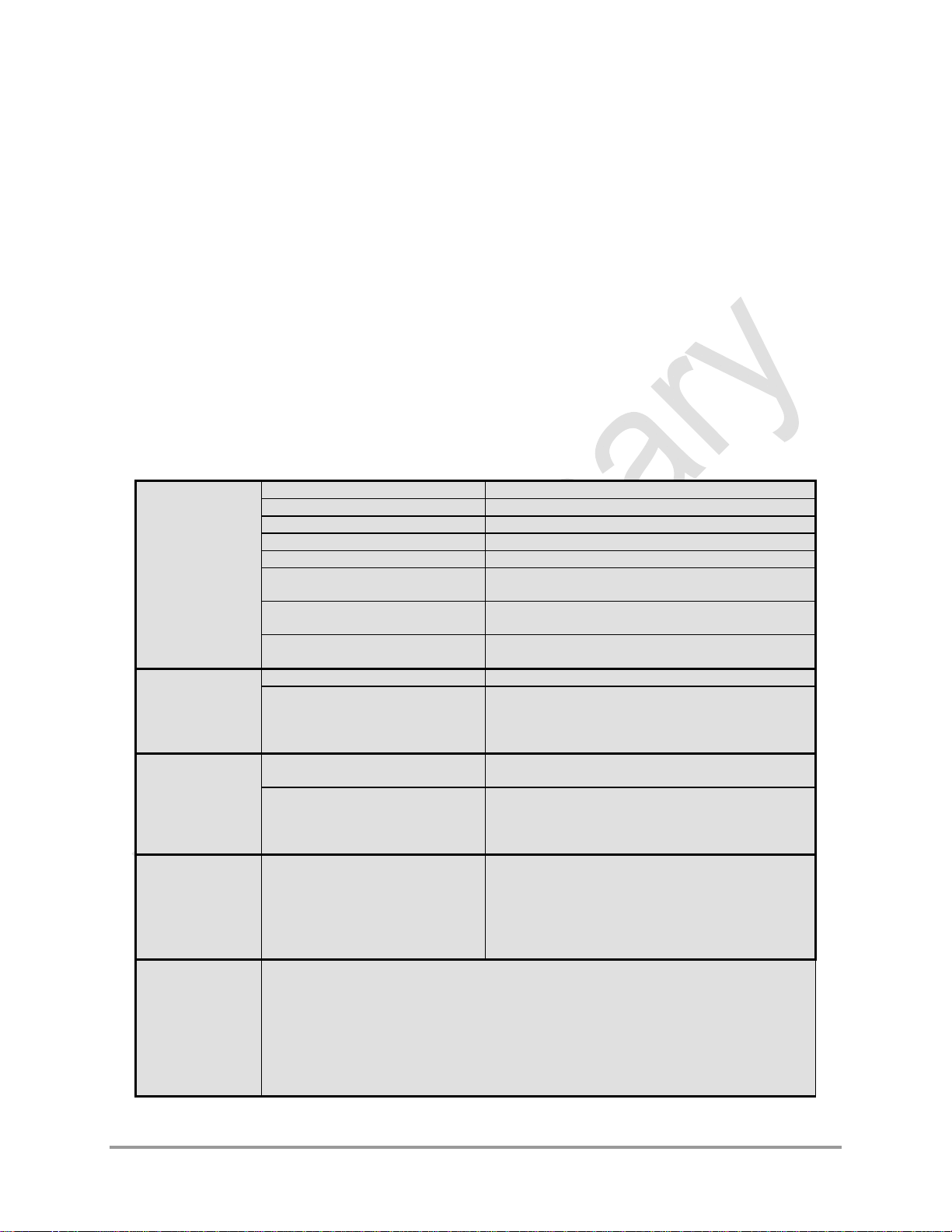

The following table summarizes the main features of the Enfora Enabler LPP G Radio Module.

Interface

Power

Radio Features

Regulatory

GSM/GPRS

Functionality

Data input/output interface 50 position 1.27mm pitch

Primary serial port 3.3V levels, ‘2-wire’ UART implementation

Secondary serial Port Single TX from GPS, NMEA data only.

USB port USB Debug and Configuration

Audio Digital audio

Command protocol Enfora Packet API, GSM AT command set, Enfora

Subscriber Identification Module

(SIM)

Battery Charger Lithium Ion battery charger, temperature and

Electrical power 3.3 to 4.5 Vdc (vbat)

Peak currents and average

power dissipation

Frequency bands EGSM 900, GSM1800, GSM 850 and GSM 1900

GSM/GPRS features supported Provides for all GSM/GPRS authentication,

Agency approvals

Mobile-originated and mobile-terminated SMS messages: up to 140 bytes or

up to 160 GSM 7-bit ASCII characters.

Reception of Cell Broadcast Message

SMS Receipt acknowledgement

Voice (EFR, FR, HR, AMR)

Supports Unstructured Supplementary Service Data (USSD)

Multi-Slot Class 10 Supported (4Rx/2TX), (5 Slot Max) PBCCH/PCCCH

Supported

MCP

USIM port with SIM detect, Optional embedded

SIM.

battery ID analog inputs

Refer to the Operating Power table in the

Technical Specifications for peak currents and

average power dissipation for various modes of

operation.

capability.

encryption, and frequency hopping algorithms.

GPRS Coding Schemes CS1-CS4 supported.

Multi-Slot Class 10 (4RX/2TX, Max 5 Slots).

GCF Type Approval

PTCRB Type Approval

FCC Certification

RTTE

CE (European Community Certification)

IC (Industry Canada) Approval

LPP0108IG001 7 Version - Preliminary – 06/20/08

Page 13

Audio Features

Outputs

SIM

Software

Handset Microphone biasing, internal

Handset microphone input (MICIN, MICIP pins)

Handset earphone outputs (EARP, EARN pins)

1.8/3 V Mini-Subscriber Identity Module (SIM) compatible

Free RTOS included

Table 1 - Enabler LPP G Key Features

LPP0108IG001 8 Version - Preliminary – 06/20/08

Page 14

4.3. Providing Multi-Band Operation

The Enfora Enabler LPP G module provides 4 frequency bands for compatibility with worldwide

frequency standards. 850/1900 frequency bands are primarily used in North and South America,

while 900/1800 bands are used throughout the world. The Enabler LPP G offers all four bands for

use worldwide.

4.4. Summary of Features for the Enabler LPP G Module

The following summarizes the main features of the Enfora Enabler LPP G Module.

Mechanical

Dimensions ................................... 38.5 mm x 33.6 mm x 4.19 mm

Weight .......................................... 8.6g

Packet Data Transfer:

Protocol……………………………………………GPRS Release 97

Coding Schemes…………………………………CS1-CS4

Multi-Slot Capability:

Packet Channel Support .............. ……………..PBCCH/PCCCH

Short Message Services:

(Demonstrated @MS10)…….MS10 (4RX/2TX) (Max 5 Slots)

GSM SMS .................................... MO, MT, CB, Text and PDU Modes

GPRS SMS .................................. MO, MT, CB, Text and PDU Modes

Voice Capability:

Speech Codec .............................. EFR, FR, HR, AMR

GSM/GPRS Radio Performance Multi-Band:

LPP0108 Radio Frequencies ....... 850 MHz, 900 MHz, 1800 MHz, and 1900 MHz

Sensitivity ..................................... <-106 dBm (Typical GPRS CS1)

850 & 900 MHz Transmit Power .. Class 4 (2 W)

1800 & 1900 MHz Transmit ......... PowerClass 1 (1 W)

System Requirements:

Host Interface ............................... Serial Interface

DC Voltage ................................... 3.3 to 4.5 Vdc

LPP0108IG001 9 Version - Preliminary – 06/20/08

Page 15

Application Interface:

Host Protocol ................................ MCP Protocol, AT Commands, OTA Enfora Packet API and

USB.

Internal Protocols ......................... UDP stack and TCP/IP stack

Physical Interface ......................... 2 serial (primary - Default rate 115,200 baud; secondary -

rate 19,200 baud), 1 USB (debug)

Audio Interface .............................. Handset microphone input (MICIN, MICIP pins), Handset

earphone outputs (EARP, EARN pins).

SIM Interface:

Remote SIM…………………………1.8/3-Volt SIM Capability

Environmental:

Compliant Operating Temp. ......... -20 °C to 60 °C (Fully GSM Spec Compliant)

Operating Temperature ………….-30 °C to 70 °C (Not fully GSM Spec Compliant)

Storage Temperature ................... -40 °C to 85 °C

Humidity ....................................... 5 to 95% non-condensing

EMC:

Emissions ..................................... FCC Parts 15,22 & 24, Class B

3GPP TS 51010-1, Section 12.2

EN 55022 Class B

LPP0108IG001 10 Version - Preliminary – 06/20/08

Page 16

A

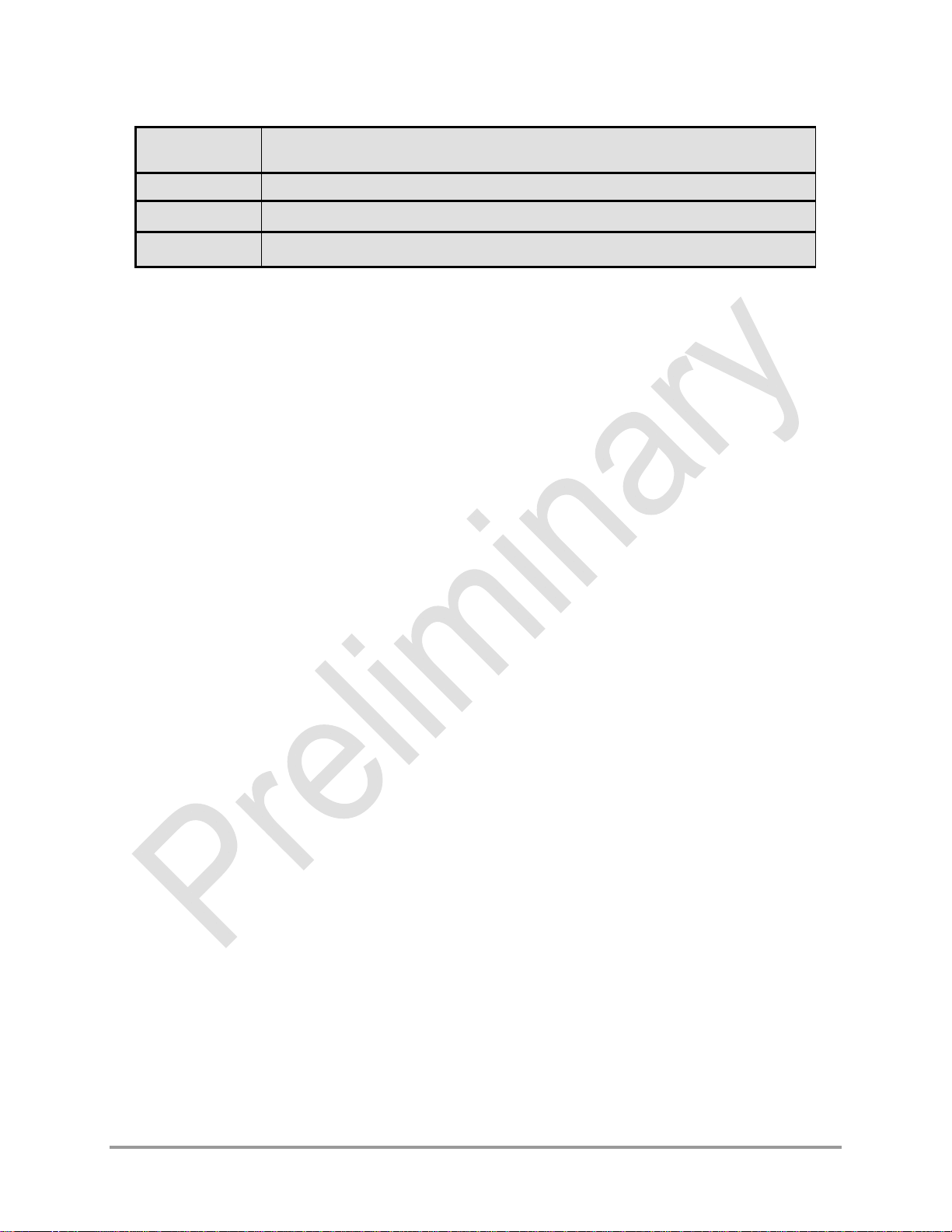

Operating Power (TYPICAL):

NOTE: UART disabled during testing; data average taken for 5 minutes; Vbat = 3.7V.

Function

Block

State

Min

Current

verage

Current

Peak

Current

MSP

Idle

3.3V TBD <2.5uA 25uA

GSM only

Idle

GPS only

Acquisition

Tracking

Motion sensor on

(no movement)

Motion sensor

with movement

Power on to

modem register

GPS enable to

first 3D fix 130dbm (~45sec)

(@ -155dbm)

2.2V TBD <2uA 22uA

2.2V TBD <7uA 40uA

3.3V TBD 3.5uA 21.5uA

2.2V TBD 14uA 2250uA

3.3V TBD 25.5uA 3750uA

TBD TBD TBD

TBD TBD TBD

TBD 56.6mA 247.5mA

TBD 76mA 80mA

TBD 72mA 78mA

GSM &

GPS

Acquisition

Tracking

Shutdown

TBD TBD TBD

TBD TBD TBD

TBD TBD TBD

Table 2: Typical Operating Power

LPP0108IG001 11 Version - Preliminary – 06/20/08

Page 17

GSM Transmit Power

1800/1900 MHz ............................ GSM Power Class 1 (30 dBm 2 dB @ antenna connection)

850/900 MHz ................................ GSM Power Class 4 (33 dBm 2 dB @ antenna connection)

GSM/GPRS Receiver Sensitivity (Typical)

1800/1900 MHz ............................ <-106 dBm, GPRS Coding Scheme 1 (CS1)

850/900 MHz ................................ <-106 dBm, GPRS Coding Scheme 1 (CS1)

4.5. General design guidelines for utilizing Enfora GSM modules

The following guidelines are provided in an effort to allow Enabler LPP G module users to

successfully implement their PCB layout to obtain the best performance. This includes the lowest

possible EMI emissions, maximum thermal conduction, mechanical integrity, and voice quality. The

Enabler LPP G module is a very compact, high performance design, yet it is easy to interface into the

final product. In order to realize its full potential, designers should pay close attention to ground

structures, the routing of RF and Digital traces, and the size of the power supply lines.

These design tips are strictly guidelines and are not

meant to be a complete list of items that guarantee

actual performance. Each application is different and

may require variation from these guidelines; however,

care should be given to utilize these sound engineering

principles whenever possible.

LPP0108IG001 12 Version - Preliminary – 06/20/08

Page 18

4.5.1. Advanced tips for an RF friendly layout

4.5.1.1. Ground Plane

To ensure the lowest possible EMI emissions and maximum thermal conductivity, it is

recommended that all metal tabs on the GSM module shield must be soldered down onto a

continuous ground plane that runs under the entire module. Ample ground vias should be

provided to create a low impedance ground. It is recommended to minimize the number of

I/O and power traces under the GSM module to allow for as much ground plane as possible.

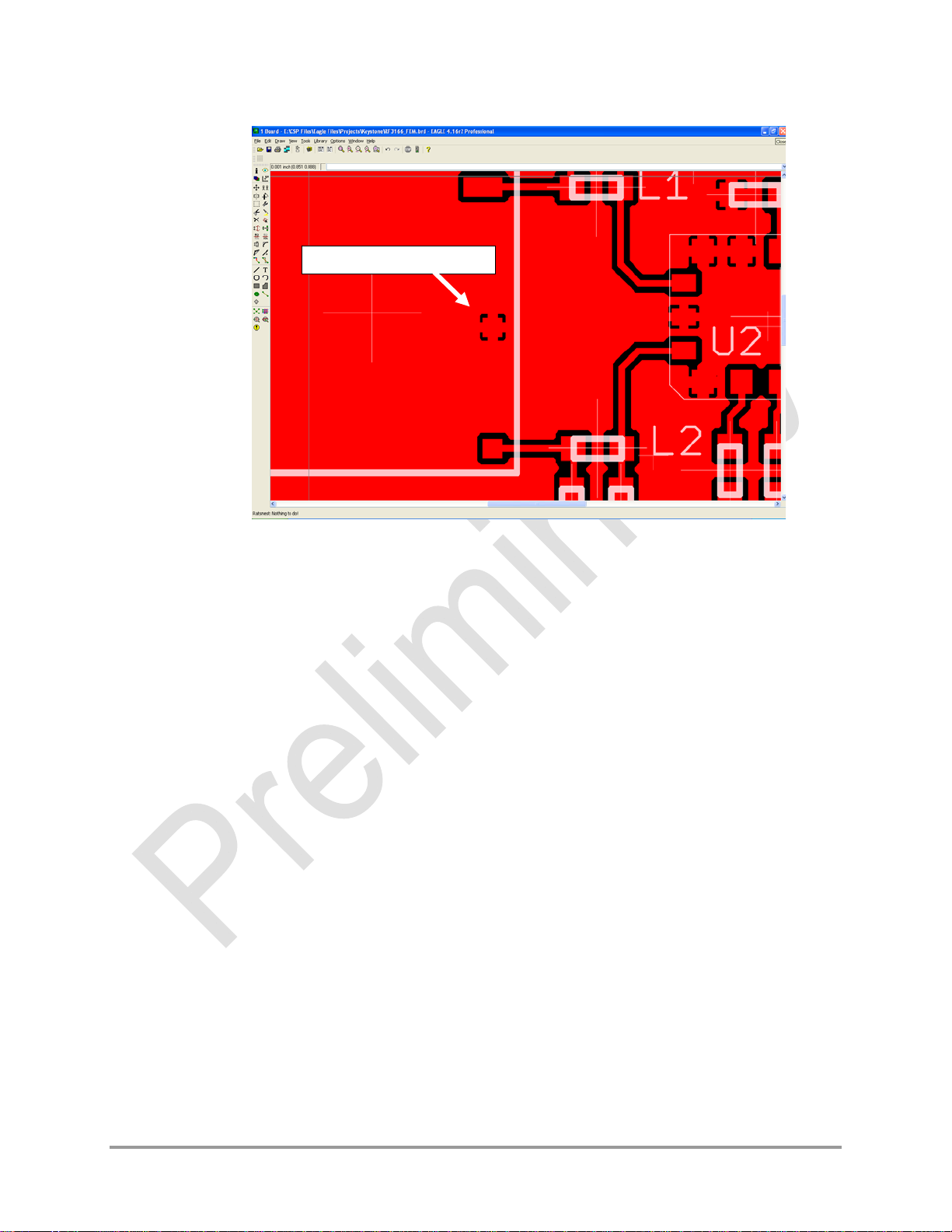

An example of a good ground structure and pad layout is shown below in Figure 1 - Example

of good ground plane for GSM modules.

Figure 1 - Example of good ground plane for GSM modules

LPP0108IG001 13 Version - Preliminary – 06/20/08

Page 19

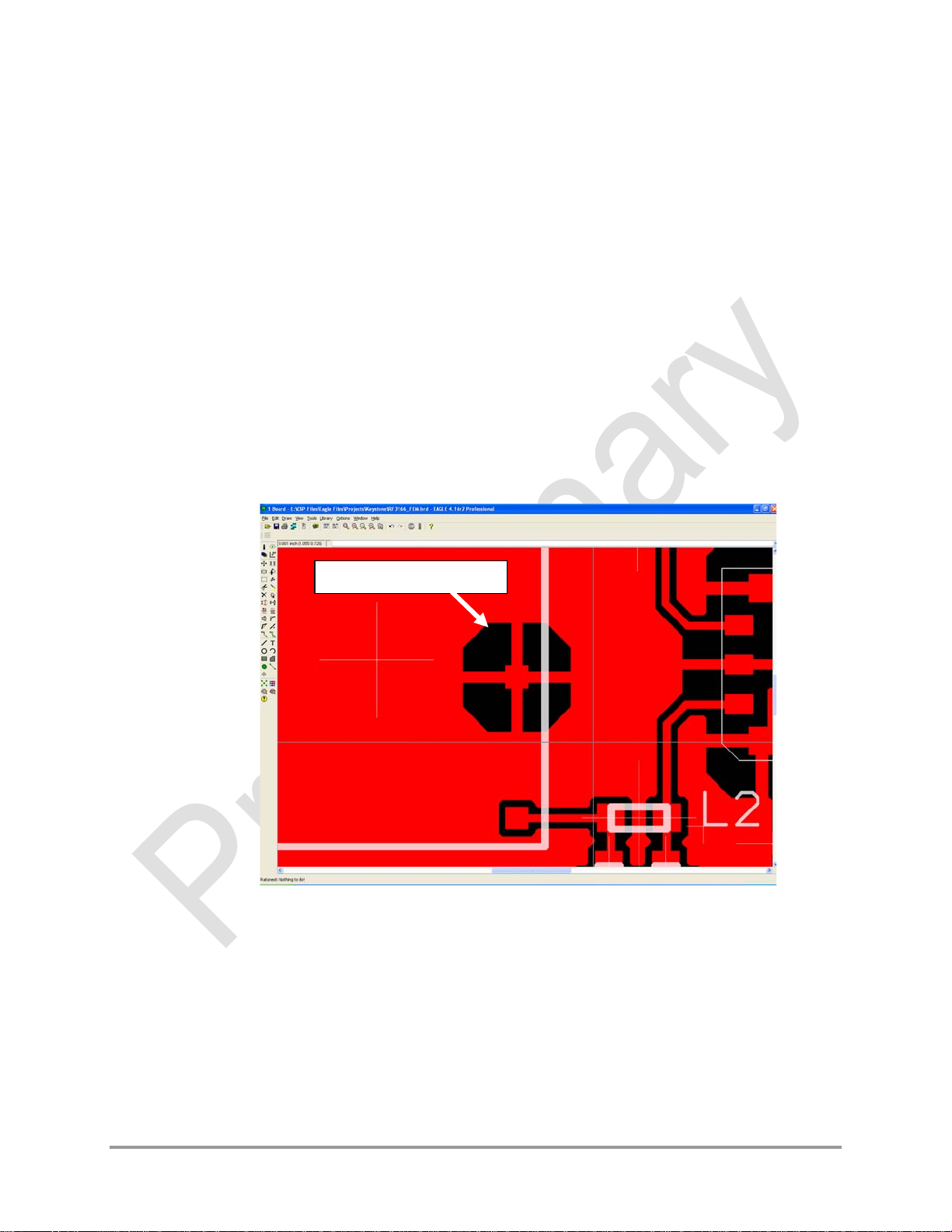

4.5.1.2. Thermal Relief

Because the ground plane acts as a large heat sink, it can affect the solderability of

components. A common method to reduce this effect is to use thermal relief around the pad

in question. However, great care must be taken when using thermal relief for high current or

high frequency applications

For example, a large thermal relief like the one shown in Figure 2 can serve the purpose for

general applications such as low current, low speed data lines, DC connections and audio

frequency applications. However, such thermal relief structures should be avoided for

applications where high current and/or high frequency is involved, such as those using the

Enabler Module. Depending on the frequency of operation, the long narrow thermal relief

traces between the pad and the ground plane act like an RF choke. These RF chokes

become higher impedance at harmonics of the fundamental frequency making it problematic

for high frequency suppression. This can make it difficult to pass type approval testing.

POOR RF thermal relief

Figure 2 - Example of a POOR RF Thermal Relief

If thermal relief is necessary, it is recommended that you use short, fat traces similar to those

shown in Figure 3. This will still provide a solderable connection, while providing a better RF

connection. Making them shorter also allows for a more continuous ground plane due to less

copper being removed from the area. It is also recommended to have ground vias around all

thermal relief of critical ground pins.

LPP0108IG001 14 Version - Preliminary – 06/20/08

Page 20

GOOD RF thermal relief

Figure 3 - Example of a GOOD RF Thermal Relief

4.5.1.3. Antenna and RF Signal Trace

The PCB trace that feeds the RF output port must be designed for a 50 ohm characteristic

impedance, coplanar, or routed into internal layers to keep the top layer continuous around

and underneath the Enabler module. Ample ground vias should be provided around the RF

contacts, the RF trace and launch pad. If possible, keep I/O and power traces away from the

RF port. This includes traces running parallel or orthogonal to it. Thermal relief should not

be used on the antenna output port ground pads. The designer must pay close attention to

the size of the pad and thickness of the dielectric beneath the signal pad and trace. Most

PCB manufacturers can adjust the trace width to maintain 50 ohms impedance if the traces

are identified and instructions are included on the FAB drawing. This service is typically

provided at no or minimal additional cost.

For minimum RF emissions due to the fundamental frequency of operation, the Enabler

module works best with an antenna load that has a VSWR of 1.5:1 or better. The antenna

should not have gain at the harmonic frequencies, otherwise, the conducted harmonics could

get amplified to a point where the product no longer passes type approval. However, for

applications where antenna quality is less than ideal, it is recommended to have a low pass

filter (Pi structure with N=3) in the RF path to the antenna. This is a secondary plan should

there be a need to lower harmonic levels at frequencies above the PCS band. The pad

structure may also be used to match the antenna load impedance, if required. If it is not

needed, a capacitor of low reactance may be used to bridge the Pi structure.

The RF cable going between the Enable module and the antenna is very lossy, therefore, the

length of this cable should be kept as short as possible.

LPP0108IG001 15 Version - Preliminary – 06/20/08

Page 21

4.5.1.4. Vbat Input

The Enabler Vbat input can have a relative high current draw that can fluctuate rapidly,

especially when transmitting at max power and burst mode. The Vbat interface must be

designed to provide the required instantaneous voltage and current with minimal voltage

droop. This includes both sufficient bulk decoupling capacitance as well as adequate layout

provisions.

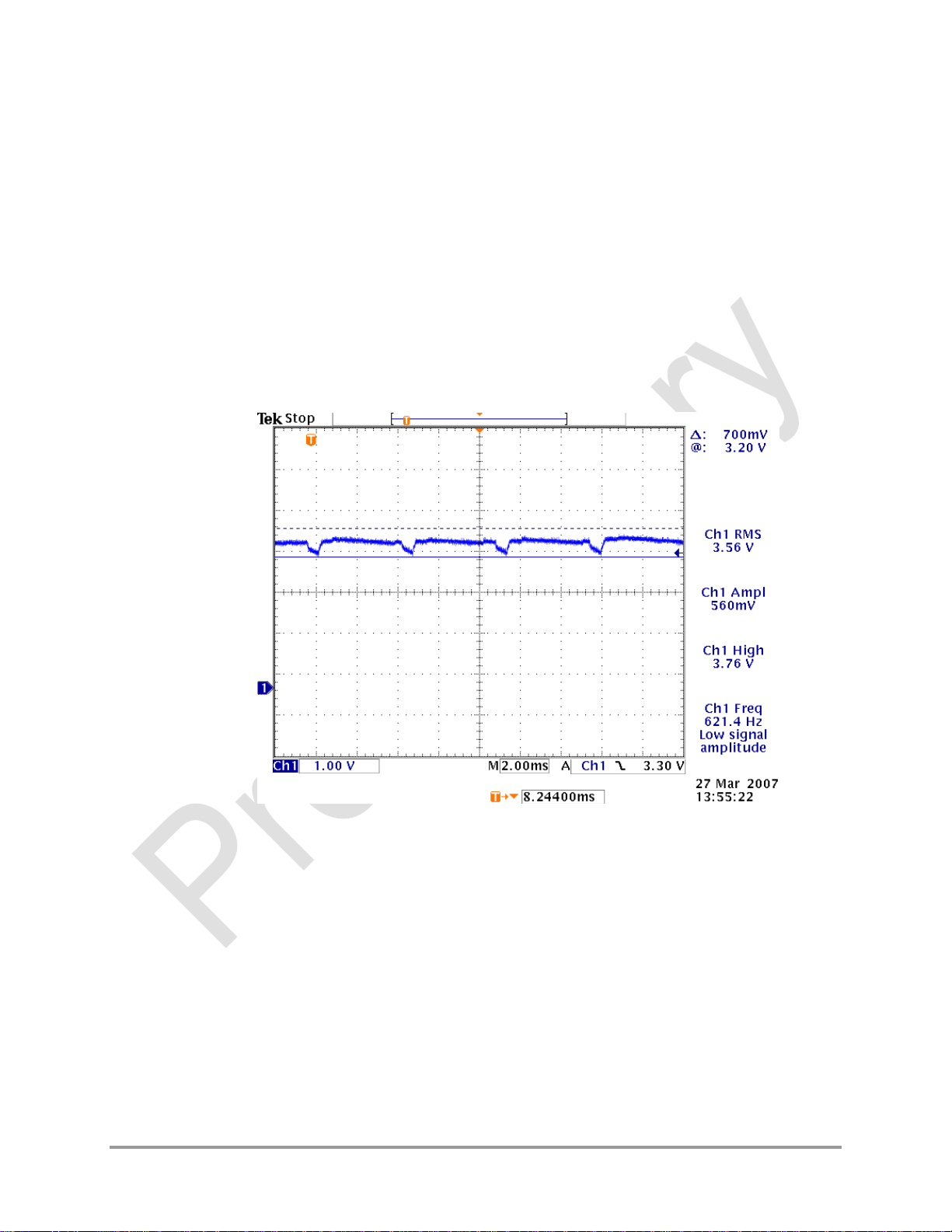

Similar to the discussion on thermal relief, the use of narrow traces to connect the Vbat pins

to the source voltage can act like a high impedance and cause a significant voltage droop

when higher currents are required as shown in Figure 4. If the Vbat drops too low, the

Enabler modules will reset. To minimize the trace loss, it is suggested to use a larger trace

that spans several pins. The layout should provide sufficient trace width over the entire trace

from the Enabler module all the way to the source of the Vbat voltage. Any transitions

between layers for this trace should utilize multiple vias.

Figure 4 - Example of Vbat Voltage Droop

Two 470 uF, low ESR, tantalum capacitors are included in the design to provide decoupling

of Vbat input voltage. Bulk decoupling capacitance is not required at the Vbat input external

to the Enabler module.

LPP0108IG001 16 Version - Preliminary – 06/20/08

Page 22

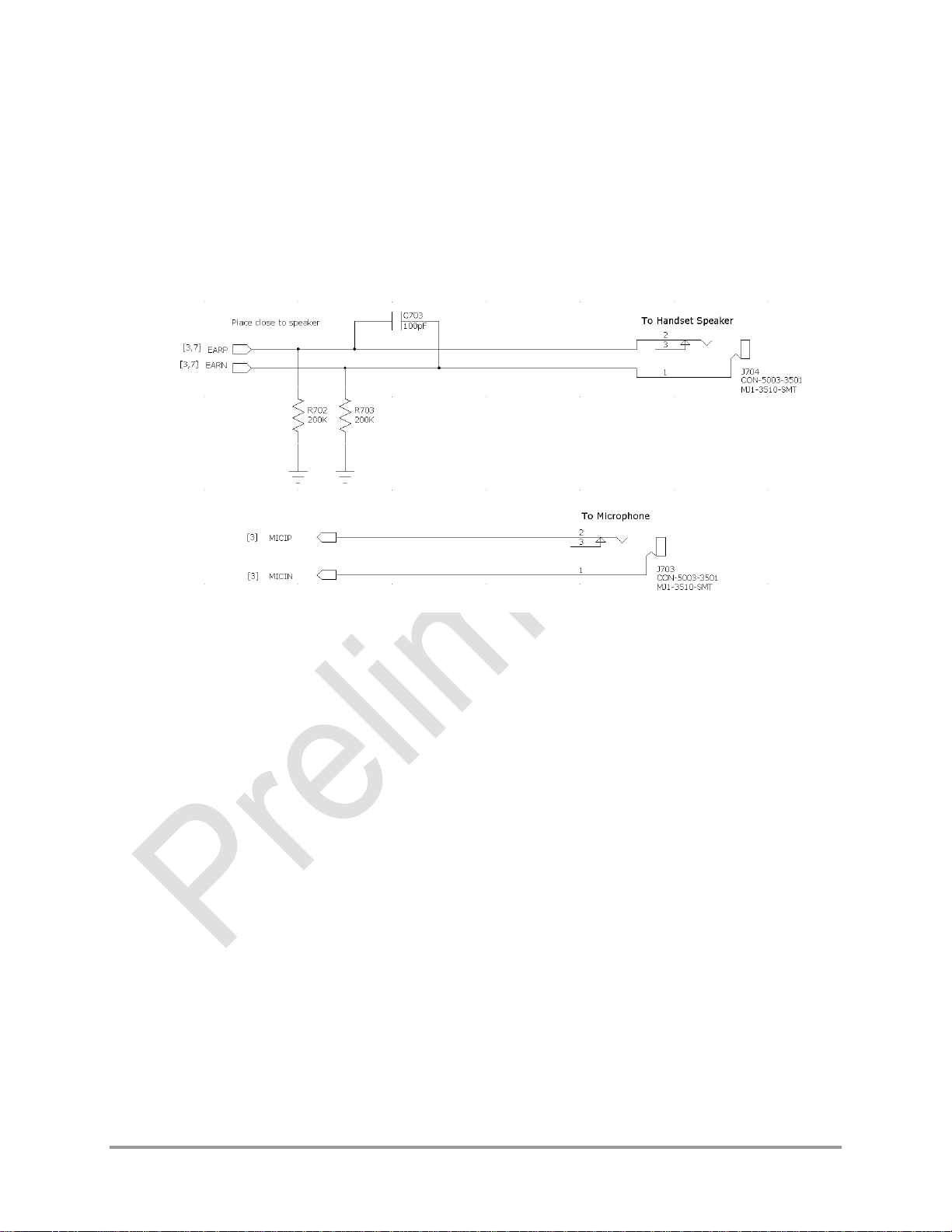

4.5.2. Audio Reference Design

The audio quality is very dependent on the circuit design and layout. As an aid to obtaining good

audio quality, a reference design has been included below. It has been proven to provide good

performance on the SDK module.

4.5.2.1. Audio Schematics

Figure 5 - Audio Reference Design Schematic

4.5.2.2. Audio Layout

Layout plots for the audio section of the SDK are available upon request.

4.6. Handling and Soldering Guidelines

The guidelines presented in IPC/JEDEC J-STD-020C for handling, preparation, and reflow of

lead-free devices should be applied to the Enabler LPP G module. Care should be taken to

minimize module moisture exposure before reflow. The module is classified as a Type 3 MSL

(moisture sensitivity level).

Additional information forthcoming

LPP0108IG001 17 Version - Preliminary – 06/20/08

Page 23

5. Technical Specifications

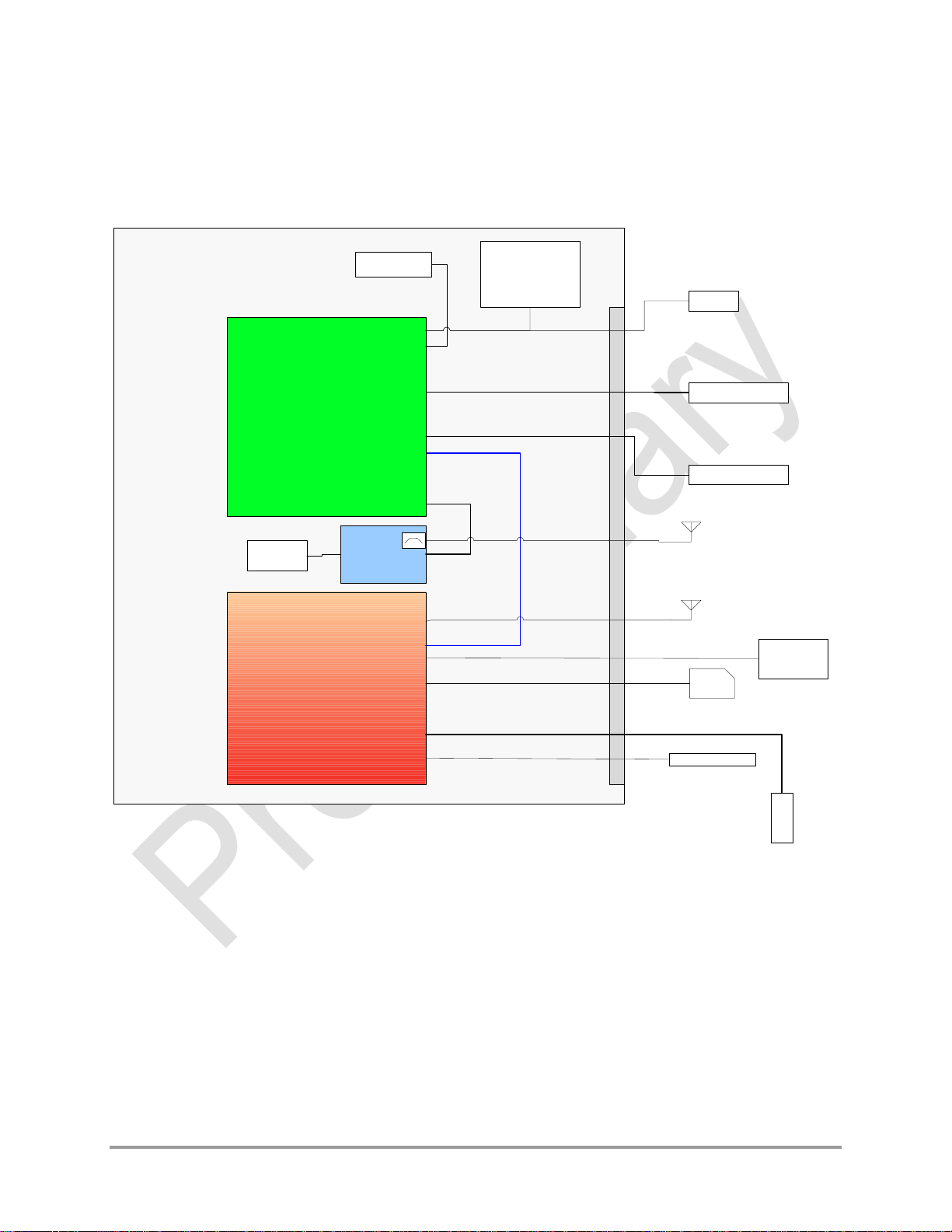

5.1. Enabler LPP G Module Block Diagram

LPP0108 Module

MSP430

16.368 MHz

TCXO

Locosto/Triton Lite

Motion Sensor

GPS

TI 5350

(I2C mode)

Power Regulation

VIO

Serial Host Interface

Reset

GPS Antenna

50 pin edge connector

GSM Antenna

Enfora

debug

SIM

interface

Handset Audio

Figure 6 - Enabler LPP G Module Block Diagram

LPP0108IG001 18 Version - Preliminary – 06/20/08

Battery

Page 24

2

5.2. Detailed Product Specifications

Physical Dimensions and Weight

Size (L x W x H) 38.5 mm x 33.6 mm x 4.19 mm

Weight < 8.6 grams

Climatic: Operational

GSM Compliant temperature

Operating temperature

-20°C to +60°C

-30°C to +70°C

Relative humidity

5 - 95%

Air pressure (altitude) 70 kPa to 106 kPa (-400 m to 3000 m)

Climatic: Storage and Transportation

Duration 24 months

Ambient temperature -40°C to +85°C

Relative humidity

5% to 95%, non condensing (at 4C)

Thermal shock -50°C to +23°C, +70°C to +23°C; < 5 min

Altitude -400 m to 15,000 m

Mechanical: Operational

Operational vibration, sinusoidal 3.0 mm disp, 2 to 9 Hz; 1 m/s

, 9 to 350 Hz

Operational vibration, random 0.1 m2 /s3 , 2 to 200 Hz

Mechanical: Storage and Transportation

Transportation vibration, packaged ASTM D999

Drop, packaged ASTM D775 method A, 10 drops

Shock, un-packaged 150 m/s2 , 11 ms, half-sine per IEC 68-2-27

Drop, un-packaged 4-inch drop per Bellcore GR-63-CORE

Mechanical: Proposed Standards

Transportation ETSI Standard ETS 300 019-1-2 Class 2.3

Transportation

Operational ETSI Standard ETS 300 019-1-3 Class 3.1

Operational

Storage ETSI Standard ETS 300 019-1-1 Class 1.2

Storage

Electromagnetic Emissions

Radiated spurious FCC Part 22 & 24 / Part 15 Class \ B

3GPP TS 51.010-1 Section 12.2

EN 55022 Class B

LPP0108IG001 19 Version - Preliminary – 06/20/08

Page 25

5.3. Operating Power

The Enfora Enabler LPP G module requires an input voltage of 3.3 Vdc to 4.5 Vdc.

5.3.1. Typical Input Current

Test Conditions:

Typical Results @ 3.8V, 20 deg C, terminated into a 50 load.

GSM Operation Input Current

Band Mode Low Nom/Avg High/Peak Units

1900

1800 21 245 1280 mA

900 21 287 1600 mA

850 21 265 1600 mA

ALL Idle 6.5

1 RX/1 TX, Full Power

GPRS Operation Input Current

Band Mode Low Nom/Avg High/Peak Units

21 240 1180 mA

4 RX/1TX, Full Power 15 269 1180 mA

1900

1800

900

850

ALL Idle

2 RX/2TX, Full Power 15 375 1180 mA

1 RX/1TX, Full Power 15 227 1180 mA

4 RX/1TX, Full Power 15 271 1280 mA

2 RX/2TX, Full Power 15 381 1280 mA

1 RX/1TX, Full Power 15 230 1280 mA

4 RX/1TX, Full Power 15 313 1600 mA

2 RX/2TX, Full Power 15 473 1600 mA

1 RX/1TX, Full Power 15 274 1600 mA

4 RX/1TX, Full Power 15 300 1600 mA

2 RX/2TX, Full Power 15 455 1600 mA

1 RX/1TX, Full Power 15 264 1600 mA

7.3

5.3.2. GSM Transmit Power

Enfora Enabler LPP G module Power Class Transmit Power

1900 MHz

1800 MHz

850 MHz

900 MHz

GSM Power Class 1 1-W conducted power maximum (30

GSM Power Class 4

dBm +/- 2 dB), measured at the

antenna port

2-W conducted power

maximum (33 dBm +/- 2 dB),

measured at the antenna port

mA

LPP0108IG001 20 Version - Preliminary – 06/20/08

Page 26

5.3.3. GSM Receiver Sensitivity

Enfora Enabler LPP G module Sensitivity Mode

1900 MHz

1800 MHz

900 MHz

850 MHz

-106 dBm (typical)

-106 dBm (typical)

6. Physical Interfaces

(Dimensions are in millimeters.)

Pin 1

GPRS Coding Scheme 1 (CS1)

GPRS Coding Scheme 1 (CS1)

Figure 7 – Side and Front of Module with Pin 1 reference

LPP0108IG001 21 Version - Preliminary – 06/20/08

Page 27

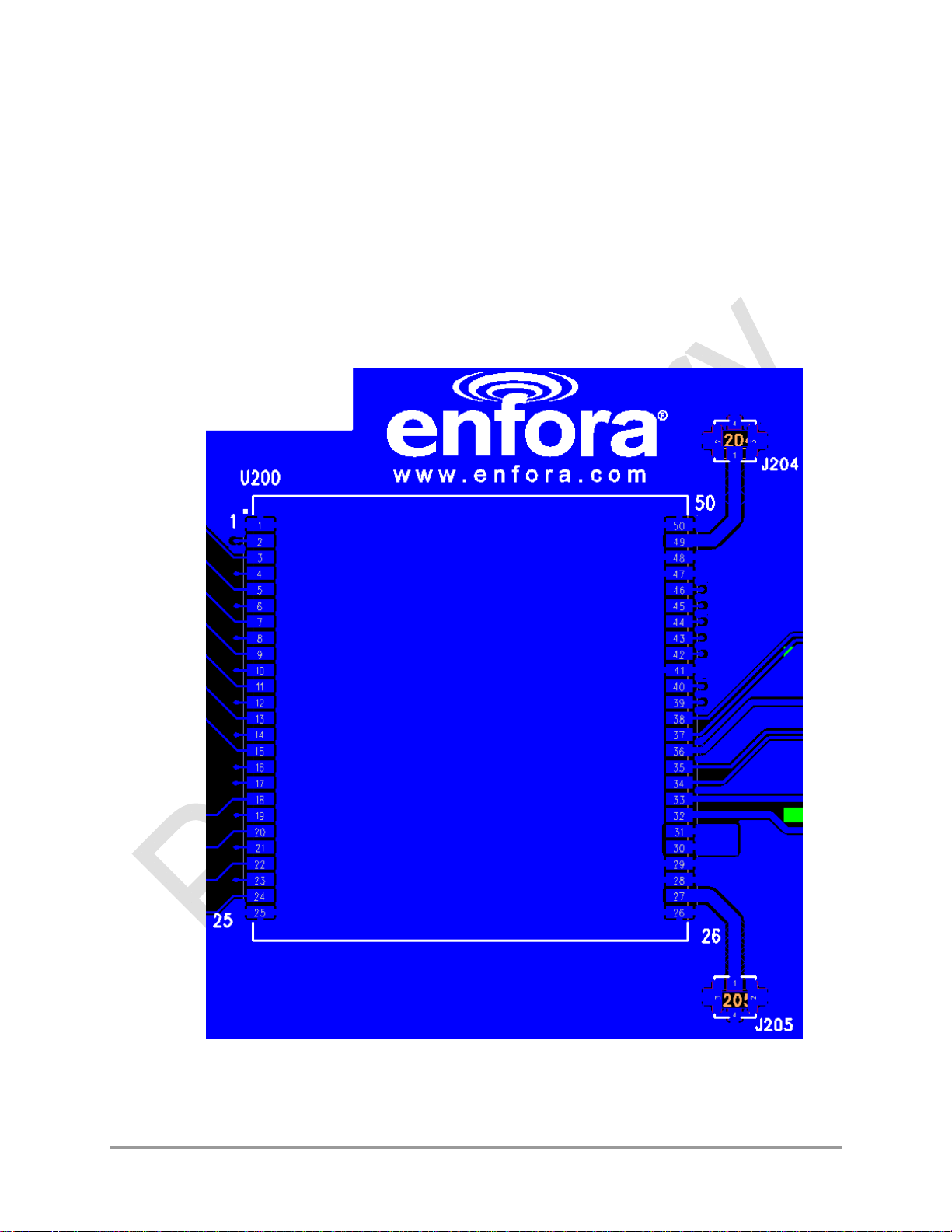

6.1. Module Mounting to Host Board (Reference)

Figure 8 - Module Footprint

LPP0108IG001 22 Version - Preliminary – 06/20/08

Page 28

Figure 9 - Copper PADs (Recommended)

Figure 10 - Solder Mask (Reccomended)

LPP0108IG001 23 Version - Preliminary – 06/20/08

Page 29

Figure 11 - Paste Mask (Reccomended) based on 0.004” stencil.

LPP0108IG001 24 Version - Preliminary – 06/20/08

Page 30

V

V

V

V

6.2. I/O Pin Assignments

The following table shows the pin assignments for the input/output connector.

Pin # I/O Enabler LPP G Description/Comments (Default Function /

Secondary Function

1 P GND System Ground

2 R BATT_TEMP Battery Temperature Input

3 P BATT_ID Battery Identification Input

4 I POWER ON/OFF Power ON/OFF control Input

5 O STATUS Power ON/OFF status Output

6 Reserved

7 Reserved

8 Reserved

9 Reserved

10 I GPI1 General Purpose INPUT 1

11 I GPI2 General Purpose INPUT 2

12 O GPO1 General Purpose OUTPUT 1

13 O GPO2 General Purpose OUTPUT 2

14 Reserved

15 Reserved

16 Reserved

17 O MSP_UART_TX UART Serial Data Output From Module

18 I MSP_UART_RX UART Serial Data Input To Module

19 O GPS_TX UART Serial Data Output (NMEA data only)

20 Reserved

21 Reserved

22 Reserved

23 Reserved

24 I MSP_RESET Reset Input

25 R GND System Ground

26 R GND System Ground

27 O GSM_RF_ANT GSM RF Output

28 R GND System Ground

29 R GND System Ground

30 P

31 P

32 PWR

33 O

34 I/O USB_D- USB Data Bus (negative Terminal)

35 I/O USB_D+ USB Data Bus (Positive Terminal)

36 I USB_VBUS USB Power Supply Line

37 O EAR+ Earphone amplifier positive output

38 O EAR- Earphone amplifier negative output

39 I MIC+ Microphone amplifier positive input (Handset)

40 I MIC- Microphone amplifier negative input (Handset)

41 R GND System Ground

42 O SIM_RESET SIM Card Reset

43 I/O SIM_CLK SIM Card Reference Clock

44 I/O SIM_IO SIM Card I/O Data

45 PW R SIM_VDD SIM Outp ut Voltage 1.8 V / 2.85 V

46 I SIM_DETECT SIM Card Detect

47 R GND System Ground

48 R GND System Ground

49 O GPS_RF_ANT GPS RF Output

50 R GND System Ground

BAT_GSM Power for GSM radio

BAT Power for non-GSM systems

IN Battery Charger input power supply

IO 2.2 / 3.3 VDC Output

Table 3 - Enabler LPP G Pin Assignments

LPP0108IG001 25 Version - Preliminary – 06/20/08

Page 31

I = Input into Module P = Power Input to Module I/O = Input/Output to/from Module

O = Output from Module R = Power Return from Module PWR = Other Power

6.3. Circuit Protection

Other than very low level ESD protection within the module’s integrated circuits, the module does

not have any protection against ESD events or other excursions that exceed the specified

operating parameters.

Generally, ESD protection (typically TVS/Transorb devices) should be added to all signals that

leave the host board. This includes V

Series resistors (typically 47) can also be added in series with data lines to limit the peak

current during a voltage excursion.

NOTE: DO NOT ADD SERIES RESISTANCE TO THE SIM ELECTRICAL LINES.

Minimum ESD Protection Levels ESD/Input Voltage

Pin #’s ESD Test Method High/

Human Body Model

Pins 4-16, 17,

18, 19, 34, 35

Pins (all

VBUS/PWR),

37, 38, 42, 43,

44, 46

RF Antenna IEC 61000-4-2 8000 V

EIA/JEDEC22-A114-A

Charge Device Model

EIA/JEDEC22-C101-A

Human Body Model

EIA/JEDEC22-A114-A

Charge Device Model

EIA/JEDEC22-C101-A

BAT/VCC

.

Peak

500 V

200 V

2000 V

500 V

Units

Table 4: ESD Protection Levels

Caution – It is the Integrator’s responsibility to protect

the Enabler LPP G module from electrical disturbances

and excursions, which exceed the specified operating

parameters.

LPP0108IG001 26 Version - Preliminary – 06/20/08

Page 32

6.4. Power Button and Status LED

The power button is polled once per second. Once the power button press is detected, the

signal is debounced using Timer A. The button must be held for three (3) seconds to deactivate

the device. Once sufficient button press and hold occurs, the status LED is enabled for three (3)

seconds. If the modem is on at the time of deactivation, the status LED on-time is extended until

the modem turns off. Next the system enters LPM4 mode and the unit is deactivated.

The MSP exits LPM4 mode when the button is pressed again. The button signal is debounced

again using Timer A. The button must be held for three (3) seconds to activate the device. If the

button is not held long enough, the system re-enters LPM4. Once sufficient button press and

hold occurs, the status LED blinks (four times per second) for three seconds. The system is now

activated.

6.5. Antenna

The LPP0108 module has two RF antenna connections. One connection is for the GSM

section of the module and the other for GPS. Please be sure to follow proper RF design

practices when designing the antennas.

6.5.1. GSM

A GSM antenna should be designed from proper RF design practices.

6.5.2. GPS

The GPS_ANT is the RF connection from the GPS antenna; no external LNA is required. The

LPP0108 can support both passive and active GPS antenna. However, external power supply

and circuitry is required for an active GPS antenna. See Figure 12 - GPS Antenna Sample

Schematic

Figure 12 - GPS Antenna Sample Schematic

Active antenna is enabled by placing a jumper on J403 in the sample schematic between pins

1 and 2.

LPP0108IG001 27 Version - Preliminary – 06/20/08

Page 33

Passive antenna is enabled by placing a jumper on J403 in the sample schematic between

pins 2 and 3.

LPP0108IG001 28 Version - Preliminary – 06/20/08

Page 34

6.6. Control Connector Signal Descriptions and Functions

Please note that the following descriptions are intended to

provide hardware-level definitions. In some cases, specific

lines will have no firmware functionality implemented.

Information for each hardware-specific feature will be noted

in the appropriate section.

6.6.1. Module Power (Pins 30, 31)

The Enfora Enabler LPP G module uses a single voltage source of VCC=+3.3V to 4.5V.

(The exact values of the uplink currents are shown in the tables in section 5.3.1.)

V

Parameter/Conditions Min Typ Max Units

BAT

Main Battery Supply

Peak Current

Voltage In Regulation 3.3 4.5 Vdc

970 F (2 x 470 uF) on Host

at Module Connector

mA

The uplink burst will cause strong ripple on the voltage

lines and should be effectively filtered.

External capacitance is not typically required by low current

or extended life applications. However, if capacitance is

added, then current leakage of the capacitor needs to be

taken into consideration for these types of applications.

It should be noted that the input voltage level should not

drop below the minimum voltage rating under any

circumstances, especially during the uplink burst period.

LPP0108IG001 29 Version - Preliminary – 06/20/08

Page 35

6.6.2. On/Off Signal (Pin 4)

The module may be set into a low power ‘off’ mode by pulling the pin low for a minimum of 3 seconds.

This will shutdown any active functions including GPS and GSM, and stop the processor. This is the

lowest power mode of the module, it can be ideally used when storing or shipping units and the controller

is not to be enabled.

Once the module is in the ‘off’ state, it can be turned ‘on’ by holding the pin low for a minimum of 3

seconds. This will start the processor, once booted the controller will be enabled and run as per the

saved settings.

The module will normally start in the ‘on’ state and enable the controller logic when power is applied.

6.6.3. On/Off Status (Pin 5)

When the On/Off pin is used to put the modem into an ‘off’ state or to turn it ‘on’, the status pin will

indicate when it has successfully entered either state.

When turning off the unit, the status signal is set high after the On/Off signal is sufficiently held low (3

seconds). The status signal is held high for normally 3 seconds but can stay enabled for up to 5-6

seconds if the system is waiting for the GSM modem to shut down.

When turning on the unit, the status line blinks for 3 seconds at a frequency of 4Hz.

6.6.1. General Purpose Input Signals (Pins 10, 11)

Two input pins are available for input and are configured in conjunction with the event engine of the GSM

modem. The voltage level of the signal must be in reference to the selected VIO voltage (Pin 33).

6.6.1. General Purpose Output Signals (Pins 12, 13)

Two input pins are available for output signals and are configured in conjunction with the event engine of

the GSM modem.

The voltage level of the signal must be in reference to the selected VIO voltage (Pin 33).

6.6.2. Reset Signal (Pin 24)

The Reset signal is used to force the micro-controller to start at a known state. When the Reset is pulled

low the micro-controller will immediately suspend any function and will not exit the reset state until the

reset signal is released to be pulled high. Once the transition from low to high is complete, the microcontroller will boot. The Reset signal is falling edge triggered, so the reset function is set immediately

when the signal is pulled low.

When using Reset, it will immediately lose the connection to the GSM network, this is not considered

ideal. Typically during a normal shutdown, the module will issue a detach request to the network to

indicate that it is being removed.

LPP0108IG001 30 Version - Preliminary – 06/20/08

Page 36

Parameter Parameter/Conditions Vcc MIN TYP MAX UNIT

VIL Input Voltage – Low or float 2.2V/3 V Vss Vss+0.6 Vdc

VIH Input Voltage – High 2.2V/3 V 0.8*Vcc Vcc Vdc

Reset

Pulse

Duration

2 µS

6.6.3. USB (Pins 34, 35, 36)

This is for Enfora Debug only

Pin Name Pin

Number

USB_VBUS 36 In 5 V tolerant power Supply VBUS line;

USB_DP 35 Analog

USB_DM 34 Analog

Signal

Direction

I/O

I/O

Description

Used only as a USB sense, not for powering the

module. (optional connection)

5 V tolerant data plus pin in USB

5 V tolerant data minus pin in USB

5V Tolerant Transceiver

USB Parameter/Conditions Min Typ Max Units

Input Voltage 4.4 4.65 5.25 V

Output voltage High (Driven) 2.8 3.3 3.6 Vdc

Low 0.0 0.1 0.3 Vdc

Transceiver D+/Leakage Current

-2 2 A

LPP0108IG001 31 Version - Preliminary – 06/20/08

Page 37

6.6.4. Serial Interfaces

6.6.4.1. Main Serial Interface (Pins 17, 18)

The pin naming for TX/RX is referenced as a DTE. The DTE device should match their input pins

to the Enfora outputs and vice-versa.

9 way D

Connector Pin

Number

1 N/A

2 Receive Data (RD) from DCE 18 Input

3 Transmit Data (TD) from DTE 17 Output

4 N/A

5 Signal Ground both

6 N/A

7 N/A

8 N/A

9 N/A

The key features of the UART in the Enabler LPP G module mode are as follows:

16C550 compatibility

Baud rate 115200 Kbits/s

Data format:

Data bit: 8 bits

Parity bit: none

Stop bit: 1bit

Flow Control: None

Signal Signal

Direction

Enfora Pin

Number

Enfora

Module

Signal

Direction

LPP0108IG001 32 Version - Preliminary – 06/20/08

Page 38

6.6.4.2. GPS Serial Interface (Pin 19)

It is optional as to whether something should be connected to the RS232 GPS DEBUG OUT.

If streaming NMEA messages are needed for external processing, above and beyond the

NMEA sent to the server, then a serial cable can be connected between this serial connector

and a PC. The baud rate is fixed at 19200.

9 way D

Connector Pin

Number

1 N/A

2 Transmit Data (TD) 19 Output

3 N/A

4 N/A

5 Signal Ground

6 N/A

7 N/A

8 N/A

9 N/A

The key features of the UART in the Enabler LPP G module mode are as follows:

Baud rate 19200 Kbits/s

Data format:

Data bit: 8 bits

Parity bit: none

Stop bit: 1bit

Signal Enfora Pin

Number

Enfora

Module

Signal

Direction

LPP0108IG001 33 Version - Preliminary – 06/20/08

Page 39

6.6.5. Handset Microphone Input (Pins 39, 40)

The handset differential inputs MICIP and MICIN can be amplified by the differential handset

microphone amplifier. This amplifier has a gain of 25.6 dB.

Handset Mic Input Parameter/Conditions Min Typ Max Units

Maximum Input Range –

Mic(+) to Mic(-)

Inputs 3 dBm0 (Max. digital

sample amplitude when PGA

32.5 mV

gain set to 0 dB)

Nominal Ref. Level –

Mic(+) to Mic(-)

Differential Input

Resistance –

Mic(+) to Mic(-)

Differential MIC

Differential MIC, MICAMP gain

= 25.6 dB

(INMODE = 0001)

-10 dBm0

36

k

Microphone PreAmplifier Gain

Differential MIC

25.6 dB

6.6.6. Handset Speaker Outpu t (Pins 37, 38)

Pin Name Pin Number Signal Direction Description

EARP 37 O Earphone positive output

EARN 38 O Earphone negative output

The earphone amplifier provides a full differential signal on the terminals EARP and EARN (Earphone).

Handset Spkr Output Parameter/Conditions Min Typ Max Units

Maximum Differential

Resistive Load

Maximum Differential

Output Swing 3.9 VPP 120

Output Swing 1.5 VPP 33

100 pF

Capacitive Load

Common Mode

At Internal Speaker (+) or (-) 200

k

Minimum Resistive Load

Common Mode

At Internal Speaker (+) or (-) 50 pF

Maximum Capacitive

Load

Amplifier Gain EARG = 1

EARG = 0

1

-11

DB

dB

RMS

LPP0108IG001 34 Version - Preliminary – 06/20/08

Page 40

Parameter Test Conditions Min Typ Max Units

Earphone output swing at

EARP-EARN

Distortion 2% and 120 , VSP input

level = +3 dBm0, amp gain = -11 dB

Distortion 2% and 33 , VSP input level

0.98 V

0.38

P-P

= -5.34 dBm0, amp gain = -11 dB

Distortion 2% and 120 , I2S input level

0.93

= +3 dBm0, amp gain = -11 dB

Distortion 2% and 120 , VSP input

3.1 3.92

level = +3 dBm0, amp gain = 1 dB

Distortion 2% and 33 , VSP input level

1.2 1.5

= -5.34 dBm0, amp gain = 1 dB

Distortion 2% and 120 , I2S input level

2.96 3.7

= +3 dBm0, amp gain = 1 dB

Earphone amplifier state in

High Z

power down

Earphone amplifier power

supply rejection

1 kHz, 100 mVp-p

50

dB

An external audio amplifier should be used for loads of less than 16 or if volume is inadequate.

6.7. Subscriber Identity Module (SIM) (Pins 42, 43, 44, 45, 46)

The SIM, an integral part of any GSM terminal device, is a “smart card” that is programmed with

subscriber information:

The user information consists of an International Mobile Subscriber Identity (IMSI)

number, which is registered with the GSM provider, and an encryption Ki (pronounced

"key"). This information consists of a microprocessor and memory installed on a plastic

card.

Note: The SIM is not provided with the Enfora Enabler LPP G module. The SIM must be

obtained from the GSM service provider and must be provisioned by the operator for data

and/or voice. Always take care to protect the SIM: the GSM terminal will not operate without

the SIM installed.

The SIM provides the IMSI for authentication. To gain access to the GSM network, the network

must recognize the IMSI number, and the terminal must be able to properly decrypt the data sent

by the network. The SIM also serves as a buffer for SMS messages, storing the message for

transmission until a radio link is available and buffering received messages until retrieved.

LPP0108IG001 35 Version - Preliminary – 06/20/08

Page 41

6.7.1. Using a Remote SIM with the Enfora Enabler LPP G Module (Pins 42, 43, 44, 45, 46)

The Enabler LPP G module does not include an on-board SIM carrier.

The module supports the use of 1.8 V and 3 V SIM cards. The module includes a hardware

interface module dedicated to Universal Subscriber Identity Module (USIM). All baud-rates

defined in ISO 7816-3 standard are supported for high-speed transmission.

The integrator must provide a suitable SIM connector.

The maximum distance from the module to the remote SIM connector must not exceed

25.4 cm (10 inches).

It is recommended to have Zero resistance between the SIM connector and the module.

External ESD Protection is Required;

15 kV Air Discharge;

8 kV Contact Discharge;

The transorb must have a low junction capacitance (typically < 10 pf) such as the following part:

Manufacturer: On Semi

Manufacturer PN: NSQA6V8AW5T2G

25.4 cm (10 in max)

Enabler LPP G

module

Remote SIM

SIM

Interface

SIM_VDD

SIM_RST

SIM_CLK

SIM_DTC

SIM_I/O

Figure 13 - Remote SIM Interface

LPP0108IG001 36 Version - Preliminary – 06/20/08

Page 42

Pin Name Pin Number Signal Direction Description

SIM_VDD 45 O SIM VDD

SIM_CLK 43 O Card Reference Clock

SIM_RST 42 O Card Reset

SIM_I/O 44 I/O Card I/O Data

SIMDTC 46 I Card detect

The module provides the regulated supply voltage for the SIM-card and the circuitry to detect the insertion

or extraction of the SIM-Card in or from the mobile.

The SIMDTC is disabled by default (see AT$SIMDTC in the EIII AT Command Manual for settings).

When enabled, the SIMDTC pin has an internal pull up to Vcc and can be configured to detect a SIM

insertion when the SIMDTC is either pulled to ground or left floating.

It can configured to detect either just a SIM removal or both removal and insertion.

When the module detects a SIM removal, it will de-register from the network. When the module is

configured to and detects a SIM insertion, it will reset the module and re-register on the network.

The SIM-card presence detection logic is active even when the system is in idle model.

USIM Parameter/Conditions Min Typ Max Units

VDD SIM VDD voltage 1.8V

3.3V

VIH High level input voltage 1.15 V

VIL Low level input voltage 0.61 V

VOH High level output voltage, IO = 4 mA Vdd-0.45 V

VOL Low level output voltage, IO = 1 mA 0.4 V

II Input leakage current ±1 A

Iout Output current 4 mA

PU PU resistance 32 k

PD PD resistance 30 k

Iz Leakage current ± 30 A

Card

Detect

Debouncing time (SIM-card insertion) 0.5 mS

Debouncing time (SIM-card extraction) 15 mS

Pull-up resistor (resistor + resistive switch) 475 k

6.7.1.1. Remote SIM Component Information

Any compatible SIM carrier can be used in conjunction with the Enabler LPP G module. For

example:

Lumberg P/N 8840_A_21.

or

Suyin P/N: 254016MA006G103ZL

1.64 1.8 1.96 V

2.7 2.85 2.95 V

LPP0108IG001 37 Version - Preliminary – 06/20/08

Page 43

7. Battery Charging Calibration and Configuration

7.1. Objective

The objective of this document is to outline how to configure the Enabler LPP G based battery charger for

specific batteries and chargers.

7.2. Supported Devices

Enabler LPP G

7.3. References

LPM0108AT001- Enabler LPP G AT Command Set

7.4. List of battery charging commands

The following is a list of Locosto/Triton-Lite battery charger AT commands, and who is responsible for

setting their parameters.

Enfora should set the default parameters so the overall charging scheme will work “out-of-the-box”.

However, it is the customer’s responsibility to configure the charging scheme to conform to their particular

battery(-ies) and charger(-s).

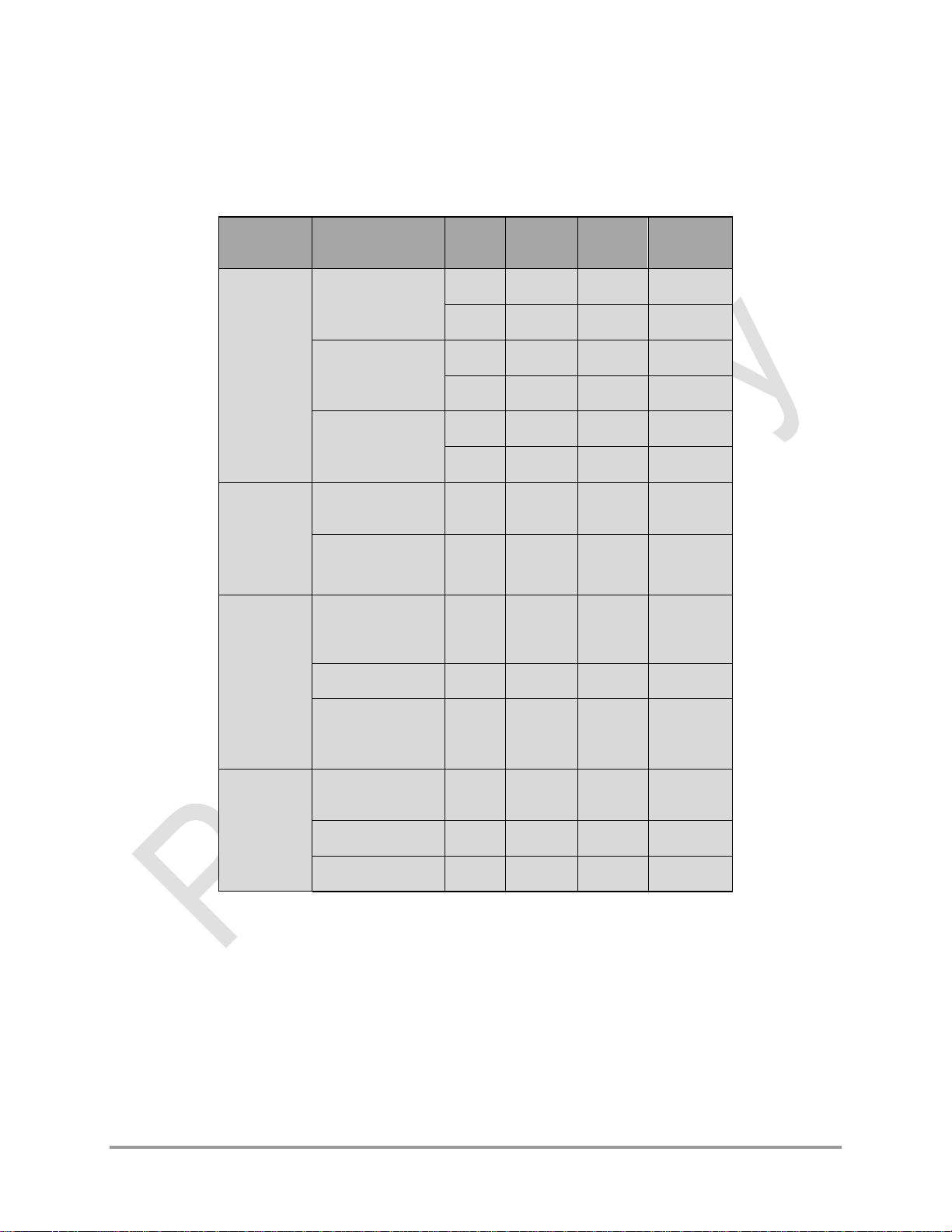

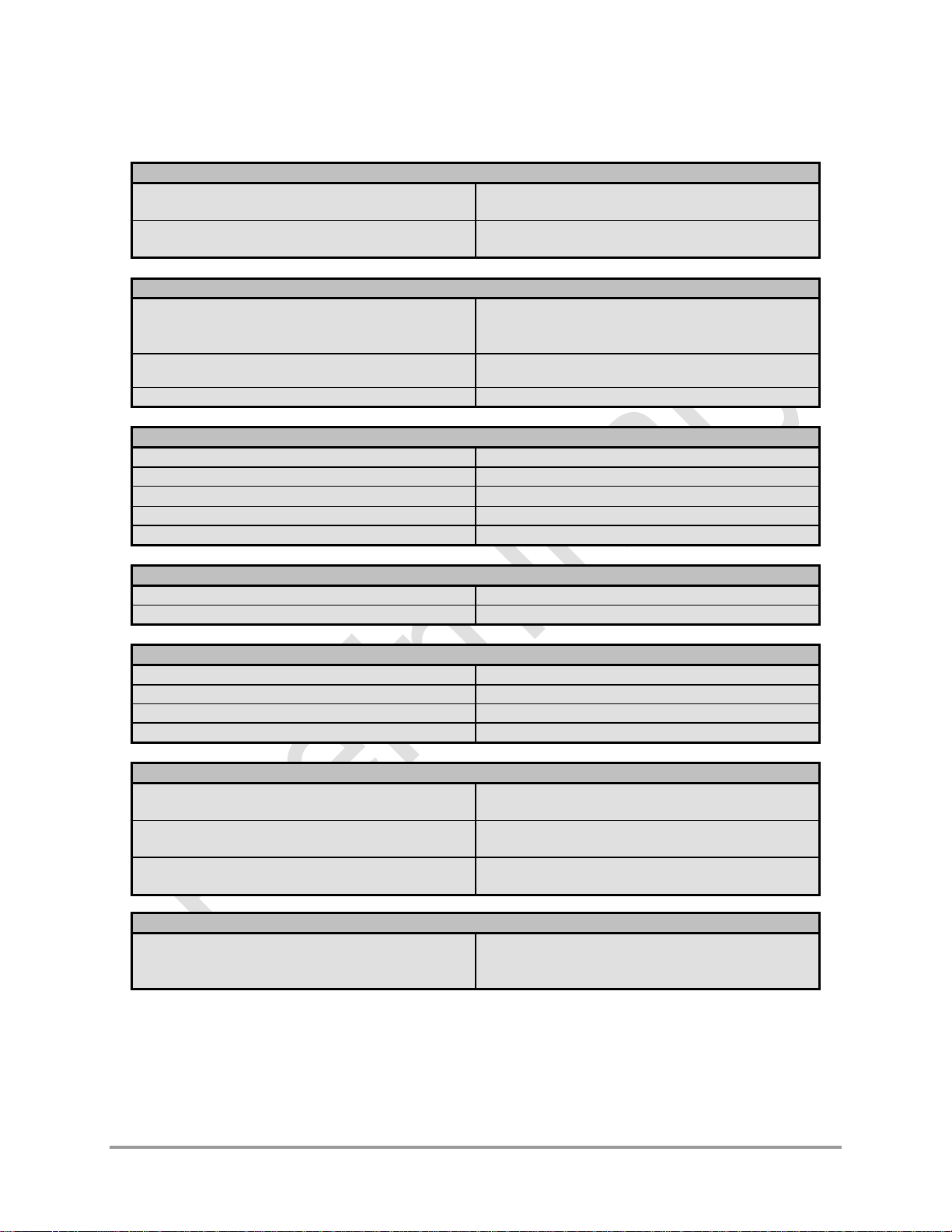

Command Information Calibrated

by Enfora

AT$BAT X

AT$BCIDBG X

AT$BCIMNI X

AT$BCIN4A X (internal

only)

AT$BCIVSF X Opt.

AT$BCIISF X

AT$BCIAVG X Opt.

AT$BCIMAP#

(1,2,3,4,5)

AT$BCIPCT#

(1,2,3,4,5)

AT$BCICHG#

(1,2,3,4,5)

AT$BCIBAT#

(1,2,3,4,5)

AT$BCITMP#

(1,2,3,4,5)

AT$BCIDEL X

AT$BCIOFF X

X X

X Opt.

X

X

X

Calibrated by

Customer

Set by

Enfora

Set by

Customer

LPP0108IG001 38 Version - Preliminary – 06/20/08

Page 44

7.4.1. Setting BCIVSF parameters

BCIVSF sets the scaling factor so the battery voltage reported by the Triton-Lite matches the real battery

voltage on the Vbat pin. This one-time calibration should be done at module production.

7.4.2. Equipment required

Programmable power supply with <10mV resolution and voltage sense lines.

A notebook or desktop computer with any version of Microsoft Windows that has the

HyperTerminal communications program. If this hardware is not available, the user could use a

DOS terminal emulation program.

7.4.3. Procedure

This procedure assumes an appropriate test fixture is used.

1. Disconnect battery (if connected), and connect power supply to Vbat test point.

2. Perform the following procedure:

Action Command Power

supply

1 Set power supply On, Voltage =

3700mV

2 Establish serial

communications with

device

3 Fill in default values.

This reads in the

parameters without

changing their values.

4 Set voltage averaging to

0. Note original value for

later.

5 Preset voltage scaling to

<num>=1700 and

<offset>=0.

6 Disable charging. AT$BCIOFF=1

7 Ensure State=3(SUP). AT$BCIDBG=2,0

8 Read Vbat (mV) after

trace update.

9 Calculate <new_num> <new_num> =

10 Set voltage scaling factor AT$BCIVSF = <new_num>,0

11 Verify results after trace

update.

12 Restore settings AT$BCIAVG=<previous>,5,10,10000

Note: The values that are red indicate the values that will need to be set.

AT$BCIAVG=,

AT$BCIVSF=,

AT$BCIISF=,

AT$BCIAVG=0,5,10,10000

AT$BCIVSF = 1700,0

Vbat(mV)=xxxx

Vbat(mV)=3700

AT$BCIOFF=0

AT$BCIDBG=0,0

Off

Calculation

1700*3700 /

Vbat(mV)

+/-10mV

LPP0108IG001 39 Version - Preliminary – 06/20/08

Page 45

7.4.4. Setting BCIISF Parameters

The charging current calibration requires measuring the current at 2 levels and determining the

adc_num and adc_offset based on the physical currents (Iphy) and reported charging currents

(Ichg_avg_mA). Two points are required to get accurate calibrations at both the high and low current

levels.

7.4.5. Scope

This calibration does not need to be done as part of a factory level production test on every device,

default values can be used to get ballpark readings. Customer level calibration is required if the

battery charge current and end-of-charge current are critical.

7.4.6. 6.2 Equipment required

1. Battery simulator, or mostly discharged battery.

2. Power supply with capability to measure current, 5-12V, 1A, to emulate wall charger. Agilent

3. A notebook or desktop computer with any version of Microsoft Windows that has the HyperTerminal

communications program. If this hardware is not available, the user could use a DOS terminal

emulation program.

7.4.7. 6.3 Calibration procedure

Step Action Command Power supply

1 Turn off

automatic

AT+CFUN=0

AT$AREG=0

VPS=3.700V

V

BATSIM

=5.000V

Calculation

registration

2 Normalize

AT$BCIISF=800,0

slope and

offset.

3 Set voltage

AT$BCIAVG=5,5,0,10000

averaging to

0. Note

original value

for later.

4 Verify

charging state

4(LCI) and

charger #.

5 Set charging

current, low

6 Cycle

charging so

AT$BAT= 40,1,#,4,3956,839

Note: # must be 2,3,4, or 5.

Assumed 2 for the remainder of this

procedure

AT$BCICHG2=

1,32,7450,4725,5725

3,4

AT$BCIOFF=1

AT$BCIOFF=0

charge

current will

take effect.

7 Measure

power supply

Read I

current.

BATSIM

Iphy1

current

8 Record

AT$BAT= 40,1,2,4,3956,<Ichg1> Ichg1

reported Ichg,

after update.

9 Set charging

current, high

AT$BCICHG2=

1,250,6050,4725,5725

3,4

10 Cycle AT$BCIOFF=1

LPP0108IG001 40 Version - Preliminary – 06/20/08

Page 46