HS 3001

Integration Guide

CNN0301IG001

Version:DRAFT 0.1

10 May, 2012

General

TERMS OF USE OF NEW MATERIALS - PLEASE READ CAREFULLY

From time to time, Enfora, in its sole discretion, may make available for download on its website

(www.enfora.com), or may transmit via mail or email, updates or upgrades to, or new releases of, the

firmware, software or documentation for its products (collectively, 'New Materials'). Use of such New

Materials is subject to the terms and conditions set forth below, and may be subject to additional terms

and conditions as set forth in Enfora's Technical Support Policy (posted on its website) and/or any written

agreement between the user and Enfora.

All New Materials are provided AS IS. Enfora makes no warranty or representation with respect to the

merchantability, suitability, functionality, accuracy or completeness of any such New Materials. The user of

such New Materials assumes all risk (known or unknown) of such use. Enfora reserves all rights in such

New Materials. The user shall have only a revocable and limited license to use such New Materials in

connection with the products for which they are intended. Distribution or modification of any New

Materials without Enfora's consent is strictly prohibited.

IN NO EVENT WILL ENFORA BE RESPONSIBLE FOR ANY INCIDENTAL, INDIRECT, CONSEQUENTIAL OR

SPECIAL DAMAGES AS A RESULT OF THE USE OF ANY NEW MATERIALS. ENFORA'S MAXIMUM LIABILITY

FOR ANY CLAIM BASED ON THE NEW MATERIALS SHALL NOT EXCEED FIFTY U.S. DOLLARS ($50).

- ii -

Copyright

© 2012 Enfora, Inc. All rights reserved. Complying with all applicable copyright laws is the responsibility of

the user. Without limiting the rights under copyright, no part of this document may be reproduced, stored

in or introduced into a retrieval system, or transmitted in any form or by any means (electronic,

mechanical, photocopying, recording or otherwise), or for any purpose, without the express written

permission of Enfora, Inc.

Enfora and the Enfora logo are either registered trademarks or trademarks of Enfora, Inc. in the United

States.

251 Renner Pkwy

Richardson, TX 75080 USA

Phone: (972) 633-4400

Fax: (972) 633-4444

Email: info@enfora.com

www.enfora.com

- iii -

WARRANTY INFORMATION

[Revised: 11/11/2010]

This warranty applies to (a) products sold directly by Enfora, unless a different warranty is specified in a

written agreement between Enfora and the purchaser; and (b) products sold to end users through a

distributor authorized by Enfora, but only where the authorized distributor does not provide a separate

warranty on such products, and Enfora has agreed to provide this warranty to such end users. If you

purchased the product from an authorized distributor, please check whether this warranty from Enfora, or

a separate warranty from the distributor, applies to your purchase. This warranty does not apply to any (i)

accessories or batteries for the products; or (ii) demonstration samples or prototypes of the products.

Unless otherwise provided in a written agreement between Enfora and the purchaser, all such accessories,

batteries, samples or prototypes are provided by Enfora AS IS without any warranty of any kind.

Enfora warrants to the original purchaser of the product from Enfora or its authorized distributor (as

applicable) that, for a period of one (1) year from the date of shipment of the product from Enfora, the

product hardware will be substantially free from defects in material or workmanship under normal

operation, and the product firmware will perform substantially in accordance with the product

documentation provided by Enfora. Enfora does not warrant that (a) the product hardware or firmware

will meet the purchaser's requirements; (b) the operation of the product hardware or firmware will be

uninterrupted or error-free; or (c) the product, when integrated in, or combined with, other products or

software not supplied by Enfora, will continue to perform substantially in accordance with the product

documentation. This limited warranty is for the benefit of the original purchaser, and is not transferable.

During the warranty period, Enfora, at its expense and in its sole discretion, will repair the product, or

replace the product with a corresponding or equivalent product, if it is determined to have a covered

defect, provided that the purchaser first notifies Enfora (directly or through its authorized distributor from

which the product was purchased) of any such defect, furnishes Enfora with a proof of purchase (if

required), requests and obtains a return merchandize authorization (RMA) number from Enfora, and

returns the product under that RMA to Enfora (or, at Enfora's option, to its authorized distributor), with the

shipping charges being prepaid by purchaser. If, upon reasonable examination of the returned product,

Enfora does not substantiate the defect claimed by purchaser, or determines that the defect is not covered

under this limited warranty, Enfora will not be required to repair or replace the product, but may instead

reship the product to the purchaser (or, at Enfora's option, to its authorized distributor where the product

can be made available to purchaser), in which case the purchaser shall be responsible for paying Enfora's

cost for reshipping the product to purchaser (or to Enfora's authorized distributor), and Enfora's usual

charges for unpacking, testing, and repacking the product for reshipment to purchaser (or to Enfora's

authorized distributor).Purchaser shall bear the risk of loss or damage in transit to any product returned by

purchaser to Enfora, or any returned product not found to be defective or covered under this warranty, and

reshipped by Enfora to purchaser (or to Enfora's authorized distributor). In the event Enfora repairs or

- 4 -

replaces a defective product covered by this limited warranty, the repaired or replacement product will be

covered under this limited warranty for the remainder of the original warranty period on the defective

product, or a period of ninety (90) days, whichever is longer. If Enfora is unable to repair or replace a

defective product covered by this limited warranty, Enfora will provide to purchaser a credit or a refund

(at Enfora's option) of the original purchase price (excluding taxes and shipping charges). Any returned and

replaced product, or any product for which Enfora has furnished a credit or a refund, becomes the

property of Enfora.

Enfora shall not have any obligation to provide any firmware bug fixes, upgrades or new releases except as

may be necessary to correct any covered defect of which purchaser notifies Enfora in writing during the

warranty period. Enfora, from time to time and in its sole discretion, may make available for download on

its website (www.enfora.com), or may provide via email, certain firmware bug fixes, upgrades or new

releases for the product. Download and use of any such bug fixes, upgrades or new releases is subject to all

of the applicable terms and conditions of Enfora's technical support policy as posted and updated on its

website.

Enfora shall have no obligation under this limited warranty for (a) normal wear and tear; (b) the cost of

procurement of substitute products; or (c) any defect that is (i) discovered by purchaser during the

warranty period but for which purchaser does not request an RMA number from Enfora, as required

above, until after the end of the warranty period, (ii) caused by any accident, misuse, abuse, improper

installation, handling or testing, or unauthorized repair or modification of the product, (iii) caused by use of

any materials not supplied by Enfora, or by use of the product other than in accordance with its

documentation, or (iv) the result of electrostatic discharge, electrical surge, fire, flood or similar causes.

The purchaser (or its customers, as applicable) shall be solely responsible for the proper configuration,

testing and verification of the Enfora product prior to deployment in the field, and for ensuring that any

end user product or system into which the Enfora product is integrated or incorporated operates as

intended and meets the requirements of purchaser (or its customers). Enfora shall have no responsibility

whatsoever for the integration, configuration, testing, verification, installation, upgrade, support or

maintenance of any such end user product or system, or for any liabilities, damages, costs or expenses

associated therewith.

ENFORA'S SOLE RESPONSIBILITY AND PURCHASER'S SOLE REMEDY UNDER THIS LIMITED WARRANTY

SHALL BE FOR ENFORA TO REPAIR OR REPLACE THE PRODUCT (OR IF REPAIR OR REPLACEMENT IS NOT

POSSIBLE, PROVIDE A CREDIT OR REFUND OF THE PURCHASE PRICE) AS PROVIDED ABOVE. ENFORA

EXPRESSLY DISCLAIMS ALL OTHER WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING

WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF NON-INFRINGEMENT, MERCHANTABILITY,

SATISFACTORY PERFORMANCE AND FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL ENFORA

BE LIABLE FOR ANY INDIRECT, SPECIAL, EXEMPLARY, INCIDENTAL OR CONSEQUENTIAL DAMAGES

(INCLUDING WITHOUT LIMITATION LOSS OR INTERRUPTION OF USE, DATA, REVENUES OR PROFITS)

- 5 -

RESULTING FROM A BREACH OF THIS WARRANTY OR BASED ON ANY OTHER LEGAL THEORY, EVEN IF

ENFORA HAS BEEN ADVISED OF THE POSSIBILITY OR LIKELIHOOD OF SUCH DAMAGES.

Some jurisdictions may require a longer warranty period than specified above and, accordingly, for

products sold in those jurisdictions the applicable warranty period shall be extended as required under the

laws of those jurisdictions. Furthermore, some jurisdictions may not allow the disclaimer of implied

warranties or the exclusion or limitation of incidental or consequential damages, so the above disclaimer,

limitation or exclusion may not apply to products sold in those jurisdictions. This limited warranty gives the

purchaser specific legal rights and the purchaser may have other legal rights that vary from jurisdiction to

jurisdiction.

This limited warranty shall be governed by the laws of the State of Texas, United States of America,

without regard to conflict of laws principles. This limited warranty shall not be governed in any respect by

the United Nations Convention on Contracts for the International Sale of Goods.

Regulatory Compliance

FCC CERTIFICATION

Enfora certifies that the Enabler HS 3001 CDMA Radio Module (FCC ID: MIVCNN0301) complies with the

RF requirements applicable to broadband PCS equipment operating under the authority of 47 CFR Part 24,

Subpart E and Part 22 of the FCC Rules and Regulations. This certification is contingent upon installation,

operation and use of the Enabler HS 3001 module and its host product in accordance with all instructions

provided to both the OEM and end user. When installed and operated in a manner consistent with the

instructions provided, the Enabler HS 3001 module meets the maximum permissible exposure (MPE) limits

for general population / uncontrolled exposure at defined in Section 1.1310 of the FCC Rules and

Regulations.

The Enabler HS 3001 module is designed for use in a variety of host units, "enabling" the host platform to

perform wireless data communications. However, there are certain criteria relative to integrating the

modem into a host platform such as a PC, laptop, handheld, monitor and control unit, etc. that must be

considered to ensure continued compliance with FCC compliance requirements.

In order to use the Enabler HS 3001 module without any additional FCC certification the installation must

meet the following conditions:

l The system antenna(s) connected to the Enabler HS 3001 module must be installed to provide at

least 20cm separation from the human body during normal operation.

l The system antennas must not be co-located with any other transmitter or antenna.

- 6 -

l The system antenna(s) used with the Enabler HS 3001 module must not exceed the following levels:

l Band Class 0: the maximum gain is 2.2dBi.

l Band Class 1: the maximum gain is 8dBi.

If any of these conditions are not met then additional information should be sought from the FCC or an FCC

qualified test laboratory.

The system user manuals and other documentation must also include appropriate caution and warning

statements and information.

FCC NOTICE TOUSERS

Enfora has not approved any changes or modifications to this device by the user. Any changes or

modifications could void the users authority to operate the device. See 47 CFR Sec. 15.21. The device

complies with part 15 of the FCC rules. Operation is subject to the following two conditions: (1) This device

may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation. See 47 CFR Sec. 15.19.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on the user is encouraged to try to correct the

interference by one or more of the following measures:

l Reorient or relocate the receiving antenna.

l Increase the separation between the equipment and receiver.

l Connect the equipment into an outlet on a circuit different from that to which the receiver is con-

nected.

l Consult the dealer or an experienced radio/TV technician for help.

If the FCCID of the module is not visible when installed in the host platform, then a permanently attached

or marked label must be displayed on the host unit referring to the module.

The label should contain wording such as:

Contains FCC ID: MIVCNN0301

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) This device must accept any interference

received, including interference that may cause undesired operation.

ROHS COMPLIANCE

- 7 -

As a part of Enfora’s corporate policy of environmental protection, Enfora takes every step to ensure that

the HS 3002 modules are designed and manufactured to comply to the European Union Directive

2002/95/EC for the Restriction of Hazardous Substances (RoHS).

- 8 -

Important Safety Information

The following information applies to the devices described in this manual. Always observe all standard and

accepted safety precautions and guidelines when handling any electrical device.

l Save this manual: it contains important safety information and operating instructions.

l Do not expose the HS 3001 product to open flames.

l Ensure that liquids do not spill onto the devices.

l Do not attempt to disassemble the product: Doing so will void the warranty. This product does not

contain consumer-serviceable components.

Disclaimer

The information and instructions contained within this publication comply with all FCC, GCF, PTCRB,

R&TTE, IMEI and other applicable codes that are in effect at the time of publication. Enfora disclaims all

responsibility for any act or omissions, or for breach of law, code or regulation, including local or state

codes, performed by a third party.

Enfora strongly recommends that all installations, hookups, transmissions, etc., be performed by persons

who are experienced in the fields of radio frequency technologies. Enfora acknowledges that the

installation, setup and transmission guidelines contained within this publication are guidelines, and that

each installation may have variables outside of the guidelines contained herein. Said variables must be

taken into consideration when installing or using the product, and Enfora shall not be responsible for

installations or transmissions that fall outside of the parameters set forth in this publication.

Enfora shall not be liable for consequential or incidental damages, injury to any person or property,

anticipated or lost profits, loss of time, or other losses incurred by Customer or any third party in

connection with the installation of the Products or Customer's failure to comply with the information and

instructions contained herein.

- 9 -

Table of Contents

1 Introduction/Overview 1

1.1 Product Overview 1

1.2 HS 3001 Product Specifications 1

1.3 Reference Documents 4

1.3.1 HS 3001 Product Documentation 4

1.4 Typical Usage 5

1.5 Contacting Enfora 5

2 Module Power 6

2.1 Operating Power 6

2.1.1 Typical Input Current 6

2.1.2 CDMA Operation Input Current 6

3 Interfaces 7

3.1 Module Mounting to Host Board (Reference) 7

3.2 Connectors 10

3.3 RF Connection Options 11

3.3.1 RF Board-to-Board Connector Option 11

3.4 I/O Connector Pin Assignments 11

4 Hardware Design Guidelines 15

4.1 General Design Guidelines for Utilizing HS 3001 Modules 15

4.1.1 Advanced Tips for an RF Friendly Layout 15

4.1.2 Audio Reference Design 20

4.2 Control Connector Signal Descriptions and Functions 22

4.2.1 Module Power (PINS 87, 89, 91, 93, 95, 97, 99) 23

4.2.2 Modem Power-on and Recovery Techniques 23

4.2.3 Power Switch Logic Detect (Pin 85) 23

4.2.4 ON/OFF (PIN 37) 24

- x -

4.2.5 Phone On - PHON (PIN 35) 25

4.2.6 Internal Power Switch 26

4.2.7 Voltage Reference - VRIO_MSME1.8 (PIN 77) 26

4.2.8 USB (PINS 1, 3, 5, 7) 27

4.2.9 General Purpose Input/Output Interface 27

4.2.10 RTC Sleep 28

4.2.11 Serial Interfaces and Handshake (Pins 11, 13, 15, 21) 28

4.2.12 Digital Audio Interface (PINS 12, 14, 16, 18) 29

4.2.13 32 KHZ Output (PIN 56) 30

4.2.14 Analog-to-Digital Inputs (PIN 44 and 74) 30

4.2.15 Handset Microphone Input (PINS 65, 67) 31

4.2.16 Handset Microphone BIASOutput (PIN 63) 31

4.2.17 Handset Speaker Output (PINS 71, 73) 31

4.2.18 Headset Microphone Input (PIN 55) 32

4.2.19 Headset Speaker Output Left and Right (PINS 57, 59) 32

4.2.20 Headset Detect (PIN 47) 33

4.3 Circuit Protection 33

- xi -

1 Introduction/Overview

1.1 Product Overview

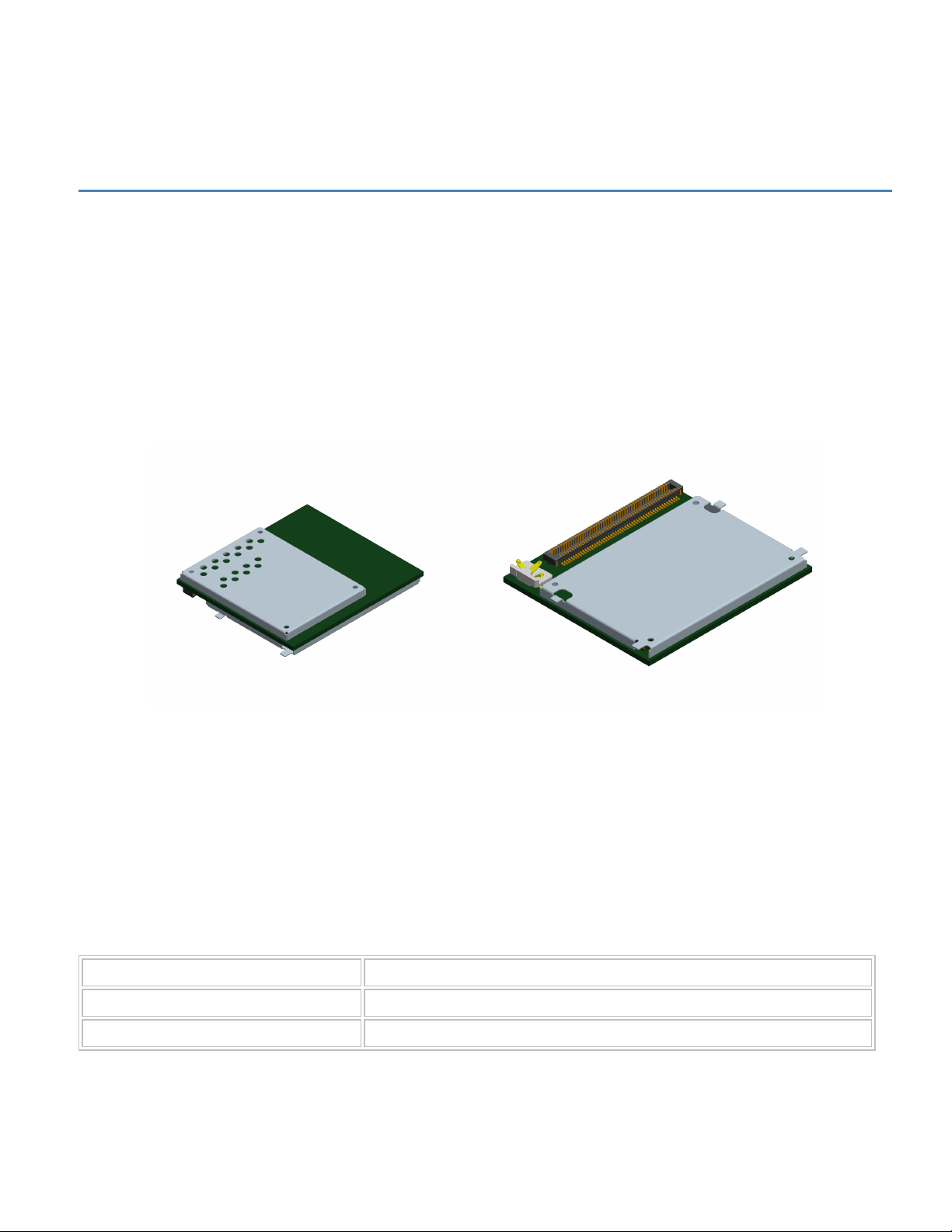

The HS 3001 modem is a compact, wireless OEM module that utilizes the Code Division Multiple Access

CDMA international communications standard to provide two-way wireless capabilities. The HS 3001

module is a fully approved CDMA device, enabling application-specific, two-way communication and

control.

The small size of the HS 3001 module allows it to be integrated easily into the application and packaging.

Figure: 1 - HS 3001 Module

1.2 HS 3001 Product Specifications

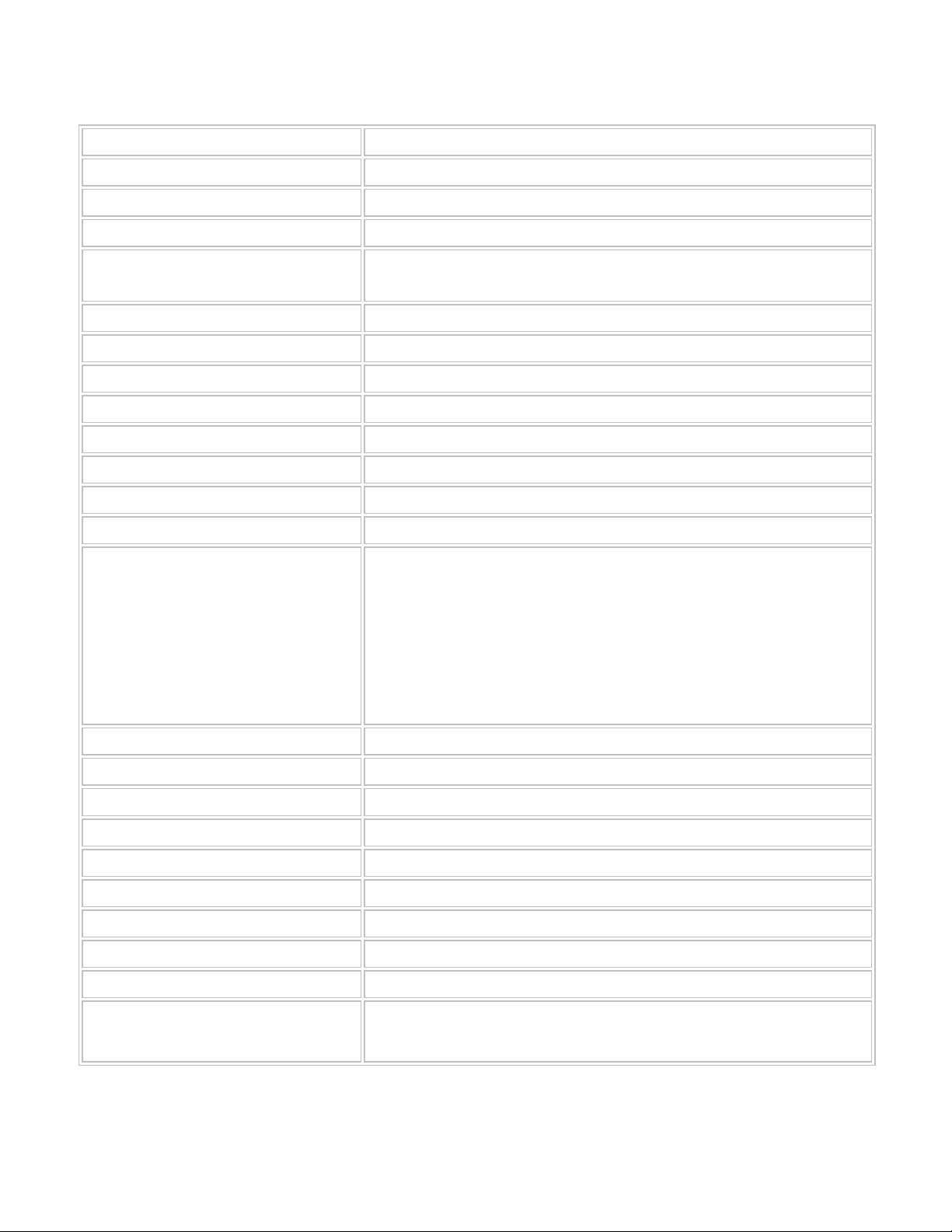

The following table lists the main features and specifications of the HS 3001 Module.

Physical Dimensions and Weight

Size (L x W x H) 28.0 mm x 25.0 mm x 4.50 mm

Weight 4 grams

- 1 -

Interfaces

Host Interface Serial Interface

Data input/output interface 100 position 0.4mm pitch connector (Molex P/N 55909-1074)

Primary serial port V.24 protocol, 1.8V levels, UART implementation, Hardware flow

control

USB port USB serial port and USB Debug (USB Debug is Enfora Use only)

GPIO Up to 8 GPIO

Audio Analog and Digital audio

Voice Supports Handset and Headset audio interfaces

Antenna Interface B2B Spring contact

Command protocol Enfora Packet API, CDMA AT command set

Reference clock 32kHz output reference clocks (accessible via 100-pin connector)

ADC 2 ADC inputs

Logic

l UART1

l PCM

l Digital Audio

l GPIO

l PWON

l Power Control

1.8 V

UART2 2.85 V

USB 3.3 V

VBUS 5.0 V

Mic Bias Out 1.8 V @ 1.5 mA max.

Audio Mic Inputs 1.0 Vp-p ±12%

Ear Audio Out TBD

Headset Out L&R TBD

Power

Electrical power Electrical power 3.3 to 4.4 Vdc (vbat)

Supply Vripple must be less than 25mV across all frequencies.

- 2 -

Peak currents and average power

dissipation

Radio Features

Frequency bands BC0-800 MHz –US Cell, BC1-1900 MHz – US PCS

Radio Mode CDMA 1xRTT, 153 kbps FL/RL

Chipset Qualcomm QSC1110

Packet Data Transfer

Protocol CDMA 1xRTT (153 kbps UL and DL)

Short Message Services Text, PDU, MO/MT, Cell Broadcast

Application Interface

Host Protocol AT commands, PPP FOTA and UDP API available in future release.

Internal Protocols PPP, UDP PAD UDP API, TCP API and TCP PAD available in future

Refer to the Operating Power table in the Technical Specifications

for peak currents and average power dissipation for various

modes of operation.

release.

Physical Interface UART, USB

Audio Interface Digital, Analog, Headset and Handset interfaces.

Audio Features Handset Microphone biasing

Headset Microphone biasing

Headset Plug/Unplug detection

Handset microphone input (MICIN, MICIP pins)

Headset microphone input (HSMIC pin)

Outputs Handset earphone outputs (EARP, EARN pins)

Headset 32 Ω stereo outputs (HSOL, HSOR pins)

Mechanical: Operational

Operational vibration, sinusoidal TBD

- 3 -

Operational vibration, random TBD

Mechanical: Storage and Transportation

Transportation vibration, packaged ASTM D999

Drop, packaged ASTM D775 method A, 10 drops

Shock, un-packaged TBD

Drop, un-packaged TBD

Environmental

CDMA Sensitivity (Typical) ≤ -108 dBm

Compliant Operating Temp. -20 °C to 60 °C (CDMA Spec Compliant)

Operating Temperature. -30 °C to 70 °C

Storage Temperature -40 °C to 85 °C

Humidity Up to 95% non condensing

Emissions FCC 47 CFR Parts 2,15,22 & 24

Regulatory

Agency approvals FCC Certification

1.3 Reference Documents

1.3.1 HS 3001 Product Documentation

1.3.1.1 Manuals

l CNN0301AT001 - HS 3001 AT Command Reference

l CNN0301TG001 - HS 3001 Transition Guide

l ENF0000SD001 - HDK Guide

- 4 -

1.4 Typical Usage

A variety of applications can use the HS 3001 module for transmitting/receiving data/voice, such as:

l Automated Meter Reading (AMR)

l Point of Sale Applications

l E-mail and Internet access

l Automated Vehicle Location (AVL)

l Machine to Machine communication (M2M)

l Telematics

l Telemetry

l Wireless Security

l Smart Phones

l Telemedicine

1.5 Contacting Enfora

For technical support and customer service dealing with the modem itself, contact the company where you

purchased the product. If you purchased the product directly from Enfora, visit the SUPPORT page on the

Enfora website. www.enfora.com

- 5 -

2 Module Power

2.1 Operating Power

2.1.1 Typical Input Current

Test Conditions:

Typical Results @ 3.6 V, 20 deg C, with 1000 μF at connector input on VBAT and RF terminated into a 50Ω

resistive load.

Traffic Data Rate: Full

BC0 Ch = 550

BC1 Ch = 550

2.1.2 CDMA Operation Input Current

Band Mode Low Nom/Avg High/Peak Units

Average Peak

MAX

BC1 550mA

BC0 490mA

MIN

BC1 130mA

BC0 115mA

- 6 -

3 Interfaces

Image TBD

Figure: 2 - Front of Module (Board-to-Board RF Conn. Version)

Image TBD

Figure: 3 - Pin 1 Reference, 100-Pin I/O Connector

3.1 Module Mounting To Host Board (Reference)

The module provides mounting tabs that must be soldered to a PCB. These tabs provide circuit grounding

for the module.

Figure: 4 - Host Board Layout

- 7 -

Figure: 5 - Module Mounting

- 8 -

Figure: 6 - Host Pads for Board-To-Board RF Connector

- 9 -

Figure: 7 - Modem Mounting Pads

3.2 Connectors

On The Modem: 100-Pin I/O Connector, Plug, SMT, Dual Row, 0.4 mm Pitch

- 10 -

l Enfora PN = CON-1040-0100

l Molex PN = 55909-1074

On The Host: 100-Pin I/O Connector, Socket, SMT, Dual Row, 0.4 mm Pitch (Mate to module)

l Enfora PN = CON-1040-0101

l Molex PN = 51338-1074

The mated height of the two connectors is 1.50 mm.

3.3 RF Connection Options

3.3.1 RF Board-to-Board Connector Option

On The Modem:

Enfora PN = CON-0009-0006

Sunridge PN = MCE-15A-G01

On The Host PCB:

No connector required.

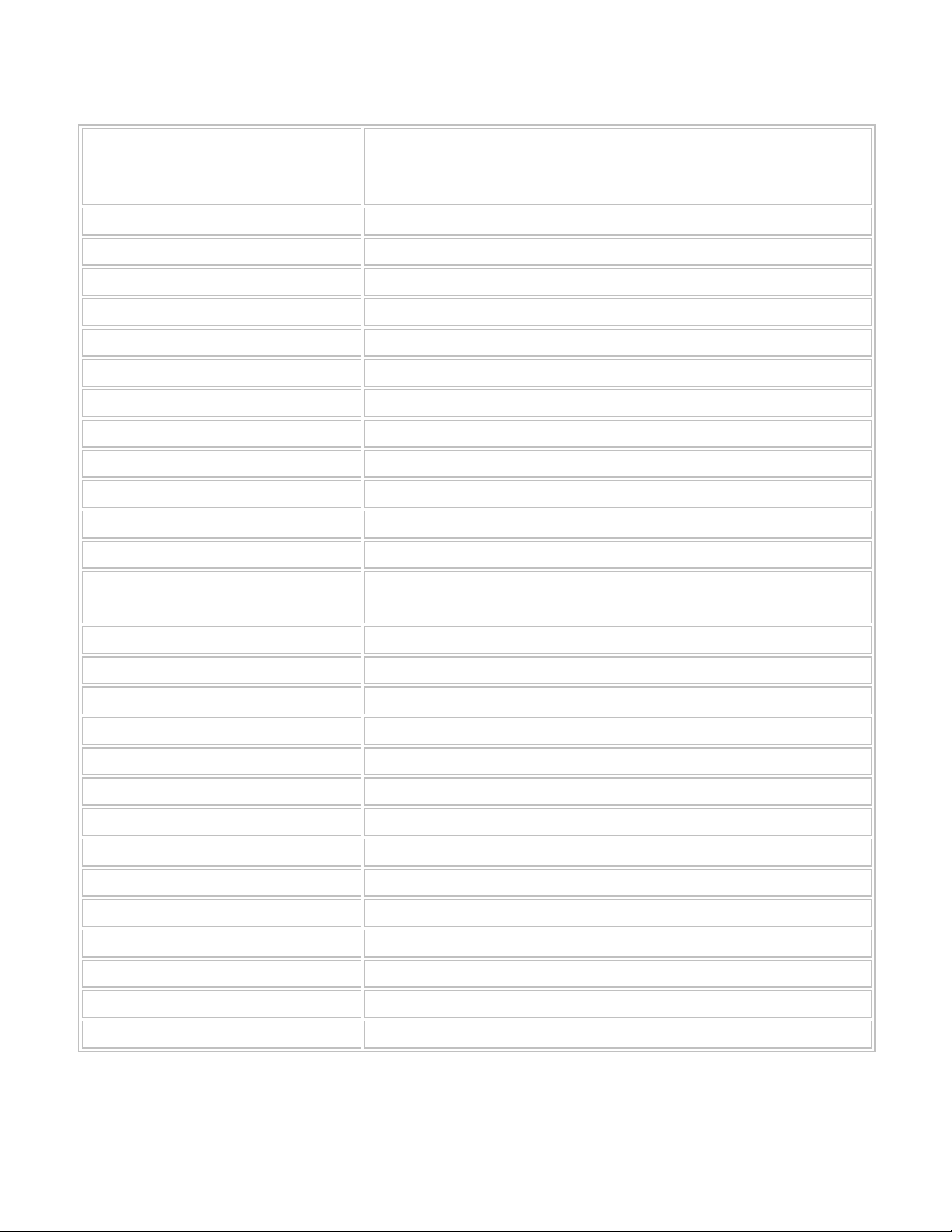

3.4 I/O Connector Pin Assignments

The following table shows the pin assignments for the input/output connector.

Pin Function Description Notes

01 VBUS USB Power

02 GND Ground

03 VBUS USB Power

04 GND Ground

05 USB_DP USB Data (+)

06 LED_SINK Current sink for LED

07 USB_DM USB Data (-)

08 Reserved N/A Do Not Connect

09 Reserved N/A Do Not Connect

10 Reserved N/A Do Not Connect

- 11 -

Pin Function Description Notes

11 UART_RTS UART1 RTS (input)

12 PCM_DIN Digital Audio I/F Data In

13 UART_CTS UART1 CTS (output)

14 PCM_CLK Digital Audio Clock

15 UART_RX UART1 RX (output)

16 PCM_SYNC Digital Audio Interface Sync

17 Reserved N/A Do Not Connect

18 PCM_DOUT Digital Audio I/F Data Out

19 Reserved N/A Do Not Connect

20 Reserved N/A Do Not Connect

21 UART_TX UART1 TX (input)

22 Reserved N/A Do Not Connect

23 Reserved N/A Do Not Connect

24 Reserved N/A Do Not Connect

25 Reserved N/A Do Not Connect

26 Reserved N/A Do Not Connect

27 UART2_RX UART 2 RX (output)

28 Reserved N/A Do Not Connect

29 UART2_TX UART 2 TX (input)

30 Reserved N/A Do Not Connect

31 Reserved N/A Do Not Connect

32 Reserved N/A Do Not Connect

33 Reserved N/A Do Not Connect

34 Reserved N/A Do Not Connect

35 PHON "Phone on" - momentary low to activate

36 Reserved N/A Do Not Connect

37 ON\OFF Power Control Switch Input

38 Reserved N/A Do Not Connect

39 Reserved N/A Do Not Connect

40 Reserved N/A Do Not Connect

- 12 -

Pin Function Description Notes

41 Reserved N/A Do Not Connect

42 Reserved N/A Do Not Connect

43 Reserved N/A Do Not Connect

44 ADC2 Analog In #2

45 Reserved N/A Do Not Connect

46 Reserved N/A Do Not Connect

47 HSDET Headset Detect

48 Reserved N/A Do Not Connect

49 Reserved N/A Do Not Connect

50 Reserved N/A Do Not Connect

51 Reserved N/A Do Not Connect

52 Reserved N/A Do Not Connect

53 MICBIAS Microphone Bias

54 GND Ground

55 HSMIC+ Headset Microphone (+)

56 CLK32K_BUF Buffered 32.768 kHz clock output

57 HSOL Headset Out Left (+)

58 GPIO_4 General Purpose IO

59 HSOR Headset Out Right (+)

60 GPIO_3 General Purpose IO

61 Reserved N/A Do Not Connect

62 GPIO_2 General Purpose IO

63 MICBIAS Microphone Bias

64 GPIO_1 General Purpose IO

65 MICIP Microphone +

66 GPIO_7 General Purpose IO

67 MICIN Microphone -

68 GPIO_5 General Purpose IO

69 GND Ground

70 GPIO_6 General Purpose IO

- 13 -

Pin Function Description Notes

71 EARP Earphone +

72 GPIO_8 General Purpose IO

73 EARN Earphone -

74 ADCIN1 ADC IN 1

75 GND Ground

76 Reserved N/A Do Not Connect

77 VRIO_MSME1.8 Reference Voltage (<5 mA) for external interfaces

78 Reserved N/A Do Not Connect

79 Reserved N/A Do Not Connect

80 Reserved N/A Do Not Connect

81 Reserved N/A Do Not Connect

82 Reserved N/A Do Not Connect

83 Reserved N/A Do Not Connect

84 Reserved N/A Do Not Connect

85 PSLOGIC On/Off logic select

86 GND Ground/Power Return/Shield

87 VBAT Power Input

88 GND Ground

89 VBAT Power Input

90 GND Ground

91 VBAT Power Input

92 GND Ground

93 VBAT Power Input

94 GND Ground

95 VBAT Power Input

96 GND Ground

97 VBAT Power Input

98 GND Ground

99 VBAT Power Input

100 GND Ground

- 14 -

4 Hardware Design Guidelines

4.1 General Design Guidelines For Utilizing HS 3001 Modules

The following guidelines are provided in an effort to allow HS 3001 module users to successfully implement

their PCB layout to obtain the best performance. This includes the lowest possible EMI emissions,

maximum thermal conduction, mechanical integrity, and voice quality. The HS 3001 module is a very

compact, high performance design, yet it is easy to interface into the final product. In order to realize its

full potential, designers should pay close attention to ground structures, the routing of RF and Digital

traces, and the size of the power supply lines.

Warning: These design tips are strictly guidelines and are not meant to be a complete

list of items that guarantee actual performance. Each application is different and

may require variation from these guidelines, however, care should be given to utilize

these sound engineering principles whenever possible

4.1.1 Advanced Tips For An RF Friendly Layout

4.1.1.1 Ground Plane

To ensure the lowest possible EMI emissions and maximum thermal conductivity, it is recommended that

all metal tabs on the cellular module shield must be soldered down onto a continuous ground plane that

runs under the entire module. Ample ground vias should be provided around the metal tabs to create a low

impedance ground. It is recommended to minimize the number of I/O and power traces and vias under the

cellular module to allow for as much ground plane as possible. An example of a good ground structure and

pad layout is shown below in Figure 1.

- 15 -

Figure: 8 - Example of good ground plane for CDMA modules

4.1.1.2 Thermal Relief

Because the ground plane acts as a large heat sink, it can affect the solderability of components. A

common method to reduce this effect is to use thermal relief around the pad in question. However, great

care must be taken when using thermal relief for high current or high frequency applications

For example, a large thermal relief like the one shown in Figure 2 can serve the purpose for general

applications such as low current, low speed data lines, DC connections and audio frequency applications.

However, such thermal relief structures should be avoided for applications where high current and/or high

frequency is involved, such as those using the cellular Module. Depending on the frequency of operation,

the long narrow thermal relief traces between the pad and the ground plane act like an RF choke. These RF

chokes become higher impedance at harmonics of the fundamental frequency making it problematic for

high frequency suppression. This can make it difficult to pass type approval testing.

- 16 -

Figure: 9 - Example of a POOR RF Thermal Relief

If thermal relief is necessary, it is recommended that you use short, fat traces similar to those shown in

Figure 3. This will still provide a solderable connection, while providing a better RF connection. Making

them shorter also allows for a more continuous ground plane due to less copper being removed from the

area. It is also recommended to have ground vias around all thermal relief of critical ground pins such as

the five cellular shield tabs.

- 17 -

Figure: 10 - Example of a GOOD RF Thermal Relief

4.1.1.3 Antenna And RF Signal Trace

The PCB trace that feeds the RF output port must be designed for a 50 ohm characteristic impedance,

coplanar, or routed into internal layers to keep the top layer continuous around and underneath the

cellular module. Ample ground vias should be provided around the RF contacts, the RF trace and launch

pad. If possible, keep I/O and power traces away from the RF port. This includes traces running parallel or

orthogonal to it. Thermal relief should not be used on the antenna output port ground pads. The designer

must pay close attention to the size of the pad and thickness of the dielectric beneath the signal pad and

trace. Most PCB manufacturers can adjust the trace width to maintain 50 ohms impedance if the traces

are identified and instructions are included on the FAB drawing. This service is typically provided at no or

minimal additional cost.

For minimum RF emissions due to the fundamental frequency of operation, the cellular module works best

with an antenna load that has a VSWR of 1.5:1 or better. The antenna should not have gain at the harmonic

frequencies, otherwise, the conducted harmonics could get amplified to a point where the product no

longer passes type approval. However, for applications where antenna quality is less than ideal, it is

recommended to have a low pass filter (Pi structure with N=3) in the RF path to the antenna. This is a

secondary plan should there be a need to lower harmonic levels at frequencies above the PCS band. The

- 18 -

pad structure may also be used to match the antenna load impedance, if required. If it is not needed, a

capacitor of low reactance may be used to bridge the Pi structure.

The RF cable going between the cellular module and the antenna is very lossy, therefore, the length of this

cable should be kept as short a possible.

4.1.1.4 VBAT Input

The HS 3001 Vbat input can have a relative high current draw that can fluctuate rapidly, especially when

transmitting at max power and burst mode. The Vbat interface must be designed to provide the required

instantaneous voltage and current with minimal voltage droop. This includes both sufficient bulk

decoupling capacitance as well as adequate layout provisions.

When laying out the connections to the cellular module interface connector, it is tempting to use traces of

the same width as the connector pins. However, this is a very compact connector and traces of that width

will not have sufficient copper. Similar to the discussion on thermal relief, the use of narrow traces to

connect the Vbat pins to the source voltage can act like a high impedance and cause a significant voltage

droop when higher currents are required as shown in Figure 4.

Figure: 11 - Example of Vbat Voltage Droop

- 19 -

If the Vbat drops too low, the cellular modules will reset. To minimize the trace loss, it is suggested to use

a larger trace that spans several pins as shown in Figure 5. Any concern about solderability can be

mitigated by using solder mask with cutouts for the individual pins as shown by the blue lines in the figure.

The layout should provide sufficient trace width over the entire trace from the Enable modules all the way

to the source of the Vbat voltage. Any transitions between layers for this trace should utilize multiple vias.

Since even the best layout will have some impedance from the source to the cellular module, sufficient

bulk decoupling capacitance is required at the Vbat input to the cellular module. It is suggested to use at

least two 1000 uF, low ESR, tantalum capacitors located very close to the cellular interface connector Vbat

pins. Any thermal relief used on these capacitors should comply with the information given above in order

to provide the lowest impedance possible. The grounding of these capacitors is critical. Therefore, it should

be a low impedance and should utilize multiple vias to the internal ground plane close to the capacitor as

well.

Figure: 12 - Example of GOOD Vbat layout

4.1.2 Audio Reference Design

The audio quality is very dependent on the circuit design and layout. As an aid to obtaining good audio

quality, a reference design has been included below.

- 20 -

4.1.2.1 Audio Schematics

- 21 -

Figure: 13 - Audio Reference Design Schematic

4.2 Control Connector Signal Descriptions And Functions

Unless otherwise noted in the following sections, all digital signals will reference the following

specifications:

Parameter Parameter/Conditions Comments MIN TYP MAX UNIT

V

IH

V

IL

V

shys

I

L

V

OH

V

OL

I

OH

I

OL

C

IN

High level Input voltage 1.17 1.83 V

Low level Input voltage -0.3 0.63 V

Schmitt hysteresis voltage 15 mV

Input leakagecurrent VDDX = Max, VIN - 0V to VDDM 200 nA

High level output voltage I out = I OH 1.35 1.8 V

Low level output voltage I Out =I OL 0 0.45 V

High level output voltage 3 mA

Low level output voltage CMOS, at p in rated drive strength 3 m A

Input Capacitance 5 pF

- 22 -

4.2.1 Module Power (PINS 87, 89, 91, 93, 95, 97, 99)

The HS 3001 module uses a single voltage source of VCC=+3.3V to 4.4V.

VBAT Parameter/Conditions Min Typ Max Units

Main Battery Supp ly Voltage In Regulation 3.3 4.4 Vdc

Peak Current 1000µF on Host at Module Co nnector 550 mA

Warning: The uplink burst will cause strong ripple on the voltage lines and should be

effectively filtered. It is recommended that 1000 µF of capacitance be placed as close

to the modem I/O connector as possible. It should be noted that the input voltage

level should not drop below the minimum voltage rating under any circumstances,

especially during the uplink burst period.

4.2.2 Modem Power-on And Recovery Techniques

The HS 3001 provides module integrators with improved modem power-on and recovery techniques, while

maintaining backwards compatibility to Enabler IIIG integrations. The addition of an internal power switch

and input power-on logic select pin, allows users the flexibility to maintain backwards compatibility or

select different power-on options. This internal power switch also allows integrators the flexibility of not

supplying an external power switch. Pin-37, previously a reset pin, has been replaced with a device power

ON/OFF pin. This pin controls the internal power switch.

Pin-85 (PSLOGIC) allows users to select the default behavior of the ON/OFF control (Pin-37). Once power is

applied via the internal power switch, Pin-35 (PHON) is used as like a phone on/off switch.

4.2.3 Power Switch Logic Detect (Pin 85)

Hardware input pin to determine the functionality of the ON/OFF pin (Pin-37). If Pin-85 is tied to VBAT,

Modem ON/OFF (Pin-37) defaults to high when open circuit, and the modem power switch will be ON. If

Pin-85 is left open, Modem ON/OFF (Pin-37) defaults to low when open circuit and the modem will be off

(requires ON/OFF to be driven high to power on).

- 23 -

Note: Externally connecting Pin-85 to ground is not recommended

4.2.4 ON/OFF (PIN 37)

Pin-37 is the ON/OFF control input for the modem's internal power switch. When it is high, the modem's

power switch will be ON. When it is low, the modem power will be OFF.

Note that Pin-35 PHON (Power On) is a signal input and is the normal method for

turning the modem ON or OFF. However, Pin 35 cannot turn the modem on if Pin 37

is low, because the modem will not have power applied to it.

Symbol Parameter Condition Min Typ Max Units

V

Enable Threshold Voltage VIN -1.75to 4.5V, ID = -250uA 0.4 1.25 V

EN_TH

I

Enable Input Current VIN = VEN =5.5V, ID = OPEN 2.5 4 uA

EN

Pulldown approximately 1M ohm.

- 24 -

NOTE: The modem may not completely shut down/reset even with a mechanical

power switch or this circuit implemented if the modem’s I/O lines have another

source of power that applies voltage to the modem.

To alleviate this situation, make sure that the interface circuitry is set to tri-state or

as an input. If this is not possible, additional hardware may be needed to shunt high

impedance lines to ground during these situations.

The un-switched power source must be capable of supporting the inrush current

required by the bulk capacitance. The enable switch can be soft started via voltage

ramp or modulation to reduce the peak current as needed.

DO NOT USE a Modem Power Switch as a routine shutdown or reset. This technique

for shutting down the modem does not properly deregister the modem from the

network. The carrier may impose penalties if a fleet of equipment does not routinely

follow a proper deregistration process. If integrators wish to use this method

routinely, than a graceful detach from the network should be accomplished first. This

can be done by sending AT$OFF.

4.2.5 Phone On - PHON (PIN 35)

This input signals the modem to start and is equivalent to a “phone power button”.

A falling-edge on this Active-Low input will switch-ON the module or switch-OFF the module. The firmware

controlled OFF function will deregister the modem from the network before shutting the modem OFF.

This input has a “weak pull-up” resistor internal to the module. If users want the modem to automatically

come on when power is applied, they can tie this line low.

If RTC Sleep is required, then the PHON line must be floated to allow the internal resistor to pull the line

high. (The RTC sleep function is not available in the initial firmware release.)

Controlling the PHON signal must only be performed by an open collector/open drain device. If controlling

this signal from a microprocessor’s I/O pin, the PHON can be pulled low when the I/O is configured to be

an output and floated high by reconfiguring the pin to be an input.

Warning: The OFF Delay is controlled by the AT$OFFDLY command. A value of 0

disables the PHON line from turning the module off. 0 is the default value.

To enable the module to switch-OFF via PHON you must set AT$OFFDLY to a value

other than 0. The valid range is 100 to 1000 milliseconds.

- 25 -

Parameter Parameter/Conditions Comments MIN TYP MAX UNIT

V

IH

V

IL

V

shys

I

L

V

OH

V

OL

I

OH

I

OL

C

IN

High level Input voltage 1.17 1.83 V

Low level Input voltage -0.3 0.63 V

Schmitt hysteresis voltage 15 mV

Input leakagecurrent VDDX = Max, VIN - 0V to VDDM 200 nA

High level output voltage I out = I OH 1.35 1.8 V

Low level output voltage I Out =I OL 0 0.45 V

High level output voltage 3 mA

Low level output voltage CMOS, at p in rated drive strength 3 m A

Input Capacitance 5 pF

4.2.6 Internal Power Switch

The modem has an internal power switch that supplies the modem operating power when ON.

Figure: 14 - Internal Power Switch

4.2.7 Voltage Reference - VRIO_MSME1.8 (PIN 77)

To be used as a voltage reference source ONLY. Do not connect current loads to this pin. This pin must be

decoupled to ground with at least a 0.1 µF capacitor at the output. Noise induced on this pin will affect the

performance of the baseband.

- 26 -

4.2.8 USB (PINS 1, 3, 5, 7)

5V Tolerant Transceiver

USB Parameter/Conditions Min Typ Max Units

Input Voltage 4.4 4.65 5.25 V

Output voltage High (Driven) 2.8 3.3 3.6 Vdc

Low 0.0 0.1 0.3 Vdc

Transceiver D+/-LeakageCurrent -2 2 μA

4.2.9 General Purpose Input/Output Interface

GPIO number Pin number

GPIO 1 64

GPIO 2 62

GPIO 3 60

GPIO 4 58

GPIO 5 68

GPIO 6 70

GPIO 7 66

GPIO 8 72

Each general-purpose signal may be selected as inputs or outputs. The GPIOs can be used independently as

a user-specified function.

Digital I/O Specifications -Baseband Functions

Parameter Comments Min Typ Max Units

V

V

V

I

IH

IL

I

I

IHPD

I

ILPU

V

V

I

OZH

I

OZL

IH

IL

SHYS

OH

OL

High level input voltage CMOS / Schmitt 1.17 1.83 V

low level input voltage CMOS / Schmitt -0.3 0.63 V

Schmitt hysteresis voltage 100 mV

Input high leakage current 1 2 No pull-down 1 uA

Input high leakage current 1 2 no pull-up -1 uA

Input high leakage current 1 with pull-down 3 30 uA

Input high leakage current 2 with pull-up -30 -3 uA

High level vot age CMOS, at pin rated drive strength 1.35 1.80 V

Low level vot age CMOS, at pin rated drive strength 0 0.45 V

3 State leakagecurrent 2 Logic h igh output 1 uA

3 State leakagecurrent 2 Logic low output -1 uA

- 27 -

I

OZHPD

I

OZLPU

I

OZHKP

I

OZLKP

C

IN

3 State leakagecurrent 2 Logic h igh output with oull down 3 30 uA

3 State leakagecurrent 2 Logic h igh output with pull-up -30 -3 uA

3 State leakagecurrent 2 Logic h igh output with keeper -20 -3 uA

3 State leakagecurrent 2 Logic h igh output with keeper 3 20 uA

Input Capacitance 7 pF

4.2.10 RTC Sleep

In this mode, the modem is off except for its Real-Time-Clock. When put into this mode, the modem can

wake itself up at a designated time/interval. See the HS 3001 AT command manual for details

4.2.11 Serial Interfaces And Handshake (Pins 11, 13, 15, 21)

The pin naming for TX/RX/RTS/CTS is referenced as a DTE .The DTE device should match their input pins to

the Enfora outputs and vice-versa. Additionally, there are AT commands that may need to be executed in

order to insure proper operation. See the chart below.

9 way D Connector Pin Number Signal Signal Direction Enfora Pin Number Enfora AT Command

2 Receive Data (RD) from DCE 15

3 Transmit Data (TD) from DTE 21

5 Signal Ground both

7 Request To Send (RTS) from DTE 11 AT+IFC

8 Clear To Send (CTS) from DCE 13 AT+IFC

Factory Set Pin Configuration

The key features of the UART in the modem mode are as follows:

l 16C750 compatibility

l Baud rates: 300,600,1200,2400,4800,9600,19200,38400,57600,115200,230400

l Supported data format:

l Data bit: 8 bits

l Parity bit: none

l Stop bit: 1 bit

l Hardware flow control RTS/CTS

The HS 3001 module is designed to be used like a DTE device.

Default settings are 8 data, 1 stop, no parity, and 115200. RTS and CTS may be used for hardware

handshaking. The serial interface is 1.8V logic. By default, hardware handshaking (AT+IFC) is enabled. The

- 28 -

module will be expecting the RTS line to be low before it will transmit data. If the integrator does not wish

to use flow control, please see below for minimal serial implementations:

For a minimal Serial implementation use one of the following two configurations:

l Connect RxData (pin 15) and TxData (pin 21) to the COM port serial data lines.

l RTS (pin 11) be pulled up through a 100K resistor if not used.

l The user must set AT+IFC=0,0 to disable flow control to communicate with the modem.

l Tie RTS (pin 11) to CTS (pin 13), on the modem to loopback the flow control signals

Notes:

l Tying RTS (pin 11) to ground to “spoof” flow control will cause the modem to draw more current.

l It is not recommended to leave RTS (pin 11) unconnected.

4.2.12 Digital Audio Interface (PINS 12, 14, 16, 18)

This port is only available in Master mode and to be used for PCM digital audio. Below are the settings for

configuring its operation and the interface specification:

4.2.12.1 Digital Audio Configuration

The default settings for the digital audio are:

l Mode = Master

l MCSI_CLK = 2.048MHz

l Word Size = 16 Bits

l Sync Pulse = 8KHz

l Frame mode = burst

l Clock edge Sync = rising edge

The following command is required to set the unit up in digital audio mode:

AT$voicepth=2

This configures the EIII module to use digital audio instead of analog audio.

4.2.12.2 Digital Audio Data Format

The 16 bit word is sent MSB first. Data received is also MSB first. No other data manipulation is done

within the module.

- 29 -

Pin Name Pin Number Signal Direction Description

PCM_RX 12 I Serial Data Input

PCM_TX 18 O Serial Data Output

PCM_CLK 14 IO Serial Clock I/O

PCM_FSYNC 16 IO Frame Synchronization I/O

4.2.13 32 KHZ Output (PIN 56)

A 32.768 kHz signal is available as an output from the module. This signal should only be used as an input

to a high impedance device. Additional loads or capacitance on the line may cause performance issues

with the module. If the line is not used, leave floating.

Parameter Comments Min Typ Max Units

Oscillation frequency 32.765 KHz

Dut y Cycle 45 50 55 %

Jitter

Cycleto cyc le 50 ns

period 10 ns

4.2.14 Analog-to-Digital Inputs (PIN 44 And 74)

The monitoring ADC (MADC) consists of a successive approximation 10–bit analog–to–digital converter

(ADC).

HKADC Specifications

Parameter Min Typ Max Units Comments

Resolution 12 Programmable to 8-bit or 10-bit

DNL -1 +3 LSB

INL -6 +6 LSB For V ref =VDD and 1.2 V (provided exter-

nally through AIN0)

Full scale error -25.6 +25.6 LSB ± *2.5% for V ref = VDD and 1.2V

Offset error -12 +12 LSB for V ref= VDD and 1.2V

Number of input

channels

Full scale input

range

Input resistance 1.5 KΩ S/H resistance

Input capacitance

GND V

5

DDA

12.4 pF S/H capacitor

V

- 30 -

Sampling time 9.6 µs

Conversion Clock 0.6 2.4 MHz 1.2 and 4.8 MHz also software pro-

grammable

Throu ghput rate 40.98 87.56 KHz

V

DDA

V

DD_MSM

VDDOperating

Current

V

DD_MSM

ating current

Pow erdown current

Oper-

2.0 2.1 2.2 V Analog power supply

1.62 1.8 1.98 V Digital power supply

0.5 mA

0.5 mA

1.0 µA

4.2.15 Handset Microphone Input (PINS 65, 67)

Parameter Test Conditions Min Typ Max Units Notes

Full scale input voltage voltage across either MIC 1P and MICiN, MIC2P and MIC2N 0.89 1.00 1.12 Vrms ± 1dB levelerror

Input impendence Difference inpu t impedance 16 20 24 KΩ

Input impendence Singleended input impedance 8 10 12 KΩ

Input offset voltage 5 5 m V

Input capacitance At each pin of all inputs 5 pF

4.2.16 Handset Microphone BIASOutput (PIN 63)

Parameter Comments Min Typ Max Units

MIC bias output voltage 1.8 V

MIC bias output current 1.5 mA

MIC bias voltage accuracy Minimum load -3 +3 %

MIC bias output voltage load regulation 30 Ω

Supply c urrent

Active State 50 100 uA

Idle State 10 100 uA

4.2.17 Handset Speaker Output (PINS 71, 73)

Parameter Test Conditions Min Typ Max Units Notes

DAC to

EAROP/EARON

fullscale outp ut

EAROP/EARON f = 498Hz, 0dBFs 38.5 48.8 61.3 mW 22 to 20kHz

f = 1.02Hz, 0dBFs 1.11 1.25 1.40 Vrms ±1 dB levelerror

- 31 -

output power,

4% or less THD +N

Output DC level,

EAR1OP and

EAR1ON with

respect to VSS

Input = .999dBFs 1.03 1.05 1.07 V

measurement

BW

4.2.18 Headset Microphone Input (PIN 55)

Parameter Test Conditions Min Typ Max Un its Notes

Full scale input voltage voltage across oin 55 and ground 0.89 1.00 1.12 Vrm s ± 1dB level error

Input impendence Singleended input impedance 8 10 12 K Ω

Input offset voltage 5 5 mV

Input capacitance At each pin of all inputs 5 pF

4.2.19 Headset Speaker Output Left And Right (PINS 57, 59)

Parameter Test Conditi ons Min Typ Max Units Notes

Both modes - HPH_LP and HPH_RN configured single ended, analog volume control =0 dB

DAC to HPH_LP and HPH_RN

fullscale outp ut

Output DC level, HPH_LP and

HRH_RN wih respect to VSS

Output impedenc e 0.5 Ω

Voice Mode - HPH_LP and / or HPH_RN configured single ended, analog volume control =0dB

HPH_LP and HPH_RN out put

power, 4% or less THD+N

DAC to HPH_LP and HPH_RN

output noise level

Both modes - HPH_LP and HPH_RN configureddifferential(HPH_LP/HP H_RN), analog volume control =0 dB

DAC to HPH_LP and HPH_RN

fullscale outp ut

DAC to HPH_LP/HPH_RN gain

error relative to gain @ -3 dBFS

Output DC level, HPH_P and

HPH_N with respect to VSS

Output impedenc e 1.0 Ω

Voice Mode - HPH_LP and / or HPH_RN configured differential (HPH_LP/HPH_RN), analog volume control =0 dB

HPH_LP/HPH_RN outp ut

power, 4% or less THD+N

DAC to HPH_LP/HPH_RN out - Input = 0.999 dBFS, Fs = 8kHz, A- 212 uVrms 22 to 20 kHz

f = 1.02kH z, 0bDFS 0.531 0.595 0.668 Vrm s

Input = 0.999 dBFs 1.03 1.05 1.07 V

f = 1.02kH z, 0bDFS 17.6 22.1 27.9 m W 22 to 20 kHz

measurement

bandwidth

Input = 0.999 dBFs, Fs = 8 kHz or 16

kHz, A-weighted

f = 1.02kH z, 0dBFS, 32Ω load 1.06 1.19 1.34 Vrms

f = 1.02kH z, -60 dBFS -1.2 1.2 dB Linearty spot

Input = .999dBFs 1.03 1.05 1.07 V

f = 498 Hz, -3 dBFS, 32Ω 17.6 22.1 27.9 mW 22to 20 kHz

106 uVrms

check

measurement

bandwidth

- 32 -

put noise level weighted measurement

bandwidth

4.2.20 Headset Detect (PIN 47)

Parameter Parameter/Conditions Comments MIN TYP MAX UNIT

V

IH

V

IL

V

shys

I

L

V

OH

V

OL

I

OH

I

OL

C

IN

High level Input voltage 1.17 1.83 V

Low level Input voltage -0.3 0.63 V

Schmitt hysteresis voltage 15 mV

Input leakagecurrent VDDX = Max, VIN - 0V to VDDM 200 nA

High level output voltage I out = I OH 1.35 1.8 V

Low level output voltage I Out =I OL 0 0.45 V

High level output voltage 3 mA

Low level output voltage CMOS, at p in rated drive strength 3 m A

Input Capacitance 5 pF

4.3 Circuit Protection

Other than very low level ESD protection within the module’s integrated circuits, the module does not have

any protection against ESD events or other excursions that exceed the specified operating parameters.

Generally, ESD protection (typically TVS/Transzorb devices) should be added to all signals that leave the

host board. This includes VBAT/VCC.

Series resistors (typically 47 ohm) can also be added in series with data lines to limit the peak current

during a voltage excursion.

Warning: It is the Integrator’s responsibility to protect the Enabler module from

electrical disturbances and excursions, which exceed the specified operating

parameters.

- 33 -

Loading...

Loading...