Novatel OEM6, OEM7 Integration Manual

OEM6 to OEM7

Integration Guide

OM-20000164 v1 February 2017

OEM6 to OEM7 Integration Guide

OEM6 to OEM7 Integration Guide

Publication Number: OM-20000164

Revision Level: v1

Revision Date: February 2017

Firmware Version: 7.200 / OM7MR0200RN0000

Proprietary Notice

Information in this document is subject to change without notice and does not represent a commitment on the part of NovAtel Inc. The information contained within this manual is believed to

be true and correct at the time of publication.

NovAtel is a registered trademarks of NovAtel Inc.

OEM7, OEM719, OEM729 and OEM7700 are trademarks of NovAtel Inc.

All other brand names are trademarks of their respective holders.

© Copyright 2017 NovAtel Inc. All rights reserved. Unpublished rights reserved under International copyright laws.

OEM6 to OEM7 Integration Guide v1 2

OEM6 to OEM7 Integration Guide

Table of Contents

OEM6 to OEM7 Integration Guide

OEM6 to OEM7 Integration Guide 2

Proprietary Notice 2

Customer Support

NovAtel Knowledge Base 6

Before Contacting Customer Support 6

Contact Information 6

Chapter 1 New for OEM7

Chapter 2 New for OEM7 – Firmware

2.1 Firmware Version Naming 9

2.2 New for OEM7 – Commands 9

2.2.1 Replaced Commands 9

2.2.2 Revised Commands 10

2.2.3 Deleted Commands 13

2.2.4 New Commands 13

2.2.5 CANCONFIG 16

2.2.6 CCOMCONFIG 18

2.2.7 COMCONTROL 21

2.2.8 CONNECTIMU 24

2.2.9 EXTERNALPVAS 26

2.2.10 FORCEGLOL2CODE 30

2.2.11 FORCEGPSL2CODE 32

2.2.12 INSCALIBRATE 34

2.2.13 INSSEED 36

2.2.14 ITBANDPASSCONFIG 38

2.2.15 ITFRONTENDMODE 40

2.2.16 ITINTERFERENCEDETECT 42

2.2.17 ITPROGFILTCONFIG 44

2.2.18 ITSPECTRALANALYSIS 46

2.2.19 J1939CONFIG 50

2.2.20 NMEAFORMAT 52

2.2.21 NVMUSERDATA 55

2.2.22 PGNCONFIG 56

2.2.23 PPPBASICCONVERGEDCRITERIA 57

2.2.24 PPPDYNAMICSEED 58

2.2.25 PPPRESET 60

2.2.26 REFERENCESTATIONTIMEOUT 61

2.2.27 RTKPORTMODE 62

2.2.28 RTKRESET 64

2.2.29 SAVEUSBCONFIG 65

2.2.30 SETINSPROFILE 66

2.2.31 SETINSROTATION 67

2.2.32 SETINSTRANSLATION 70

2.2.33 SETSEARCHTYPE 73

2.2.34 USBCONFIG 74

2.3 New for OEM7 – Logs 76

2.3.1 Replaced Logs 76

2.3.2 Revised Logs 76

2.3.3 Deleted Logs 79

OEM6 to OEM7 Integration Guide v1 3

OEM6 to OEM7 Integration Guide

2.3.4 New Logs 80

2.3.5 HWMONITOR 82

2.3.6 INSATTX 86

2.3.7 INSCALSTATUS 91

2.3.8 INSCONFIG 93

2.3.9 INSSTDEV 96

2.3.10 INSSTDEVS 98

2.3.11 INSUPDATESTATUS 100

2.3.12 ITBANDPASSBANK 102

2.3.13 ITFILTTABLE 104

2.3.14 ITPROGFILTBANK 106

2.3.15 ITPSDFINAL 109

2.3.16 J1939STATUS 112

2.3.17 LBANDRAWFRAME 114

2.3.18 MODELFEATURES 116

2.3.19 RANGECMP4 120

2.3.20 RTKASSISTSTATUS 132

2.3.21 RXSTATUS 134

2.3.22 SAFEMODESTATUS 146

2.4 New for OEM7 – SPAN 149

2.4.1 Translational Offsets 149

2.4.2 Rotational Offsets 149

2.4.3 INS Profiles 150

2.4.4 INSSeed 150

2.4.5 Multi-Line Body to Vehicle Calibration 150

2.4.6 KVH1725 and KVH1750 Baud Rate Conversion 151

2.4.7 INS Profiles 152

2.4.8 Multi-Line Body to Vehicle Frame Rotation Calibration Routine 153

2.4.9 INSSeed / Fast INS Initialization 155

Saving 155

Use at Boot-up 155

Alignment Type: Bits 26-28 156

NVM Seed Status: Bits 29-31 156

Chapter 3 New for OEM7 – Hardware

3.1 Physical changes 157

3.1.1 Shielding 157

3.1.2 Mounting 157

3.1.3 Weight 158

3.2 Electrical changes 158

3.2.1 COM Port Data Rate 158

3.2.2 Power Supply 158

3.2.3 Input and Output lines 159

3.2.4 LNA Power 159

3.3 Environmental changes 160

3.3.1 Thermal dissipation 160

3.3.2 Vibration 160

3.4 Interference 160

3.4.1 Interference from Co-Located LNA 161

3.5 Receiver Card Interface Examples 163

3.5.1 EVENT_IN, EVENT_OUT and PPS Signal Protection 163

3.5.2 Position Valid (PV) LED Driver 165

3.5.3 Communication Ports 166

3.5.4 CAN Controller Ports 167

3.5.5 USB Interface 168

OEM6 to OEM7 Integration Guide v1 4

OEM6 to OEM7 Integration Guide

3.5.6 Ethernet Port 170

Chapter 4 Receiver Technical Specifications

4.1 OEM719 Technical Specifications 174

4.1.1 OEM719 Performance Specifications 175

4.1.2 OEM719 Mechanical Specifications 177

4.1.3 OEM719 Electrical and Environmental Specifications 184

4.1.4 OEM719 Data Communication Specifications 186

4.1.5 OEM719 Strobe Specifications 188

4.1.6 OEM719 Interface Connector 190

4.2 OEM729 Technical Specifications 194

4.2.1 OEM729 Performance Specifications 195

4.2.2 OEM729 Mechanical Specifications 197

4.2.3 OEM729 Electrical and Environmental Specifications 200

4.2.4 OEM729 Data Communication Specifications 202

4.2.5 OEM729 Strobe Specifications 204

4.2.6 OEM729 Interface Connectors 206

4.3 OEM7700 Technical Specifications 214

4.3.1 OEM7700 Performance Specifications 215

4.3.2 OEM7700 Mechanical Specifications 217

4.3.3 OEM7700 Electrical and Environmental Specifications 220

4.3.4 OEM7700 Data Communication Specifications 222

4.3.5 OEM7700 Strobe Specifications 224

4.3.6 OEM7700 Interface Connector 226

OEM6 to OEM7 Integration Guide v1 5

Customer Support

Customer Support

NovAtel Knowledge Base

If you have a technical issue, visit the NovAtel Support page at www.novatel.com/support.

Through the Support page, you can contact Customer Support, find papers and tutorials or download current manuals and the latest firmware.

Before Contacting Customer Support

Before you contact NovAtel Customer Support about a software problem, perform the following

steps:

If logging data over an RS-232 serial cable, ensure that the configured baud rate can support the data bandwidth (see SERIALCONFIG command). NovAtel recommends a min-

imum suggested baud rate of 115200 bps.

1.

Log the following data to a file on your computer for 15 minutes:

RXSTATUSB once

RAWEPHEMB onchanged

GLORAWEPHEMB onchanged

BESTPOSB ontime 1

RANGEB ontime 1

RXCONFIGA once

VERSIONA once

For SPAN systems, include the following logs in the file created on your computer:

RAWIMUSXB onnew

INSUPDATESTATUSB onnew

INSPVAXB ontime 1

INSCONFIGA once

2.

Send the data file to NovAtel Customer Support: support@novatel.com

3.

You can also issue a FRESET command to the receiver to clear any unknown settings.

The FRESET command will erase all user settings. You should know your configuration

(by requesting the RXCONFIGA log) and be able to reconfigure the receiver before you

send the FRESET command.

If you are having a hardware problem, send a list of the troubleshooting steps taken and the results.

Contact Information

Log a support request with NovAtel Customer Support using one of the following methods:

Log a Case and Search Knowledge:

OEM6 to OEM7 Integration Guide v1 6

Customer Support

Website: www.novatel.com/support

Log a Case, Search Knowledge and View Your Case History: (login access required)

Web Portal: https://novatelsupport.force.com/community/login

E-mail:

support@novatel.com

Telephone:

U.S. and Canada:1-800-NOVATEL (1-800-668-2835)

International:+1-403-295-4900

OEM6 to OEM7 Integration Guide v1 7

Chapter 1 New for OEM7

When upgrading from an OEM6 receiver to an OEM7 receiver, there are several hardware and

software differences that must be accounted for in the system design.

These differences are described in the following chapters:

l

New for OEM7 – Firmware on page9

l

New for OEM7 – Hardware on page157

l

Receiver Technical Specifications on page173

OEM6 to OEM7 Integration Guide v1 8

Chapter 2 New for OEM7 – Firmware

This chapter describes the new commands, logs, features and functionality available on OEM7

receivers.

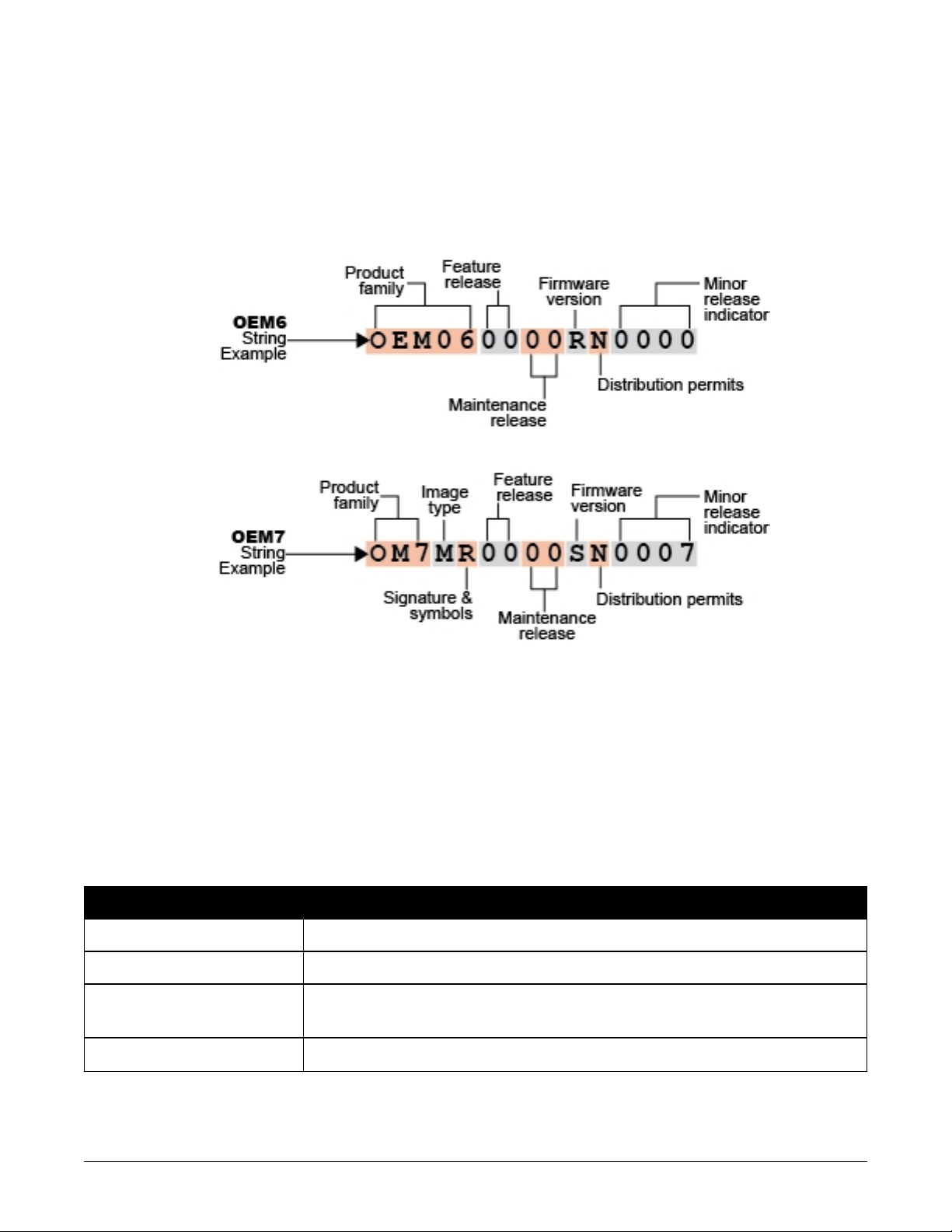

2.1 Firmware Version Naming

For information about the fields in the firmware version, refer to the VERSION log.

2.2 New for OEM7 – Commands

The following sections describe the command changes between OEM6 and OEM7.

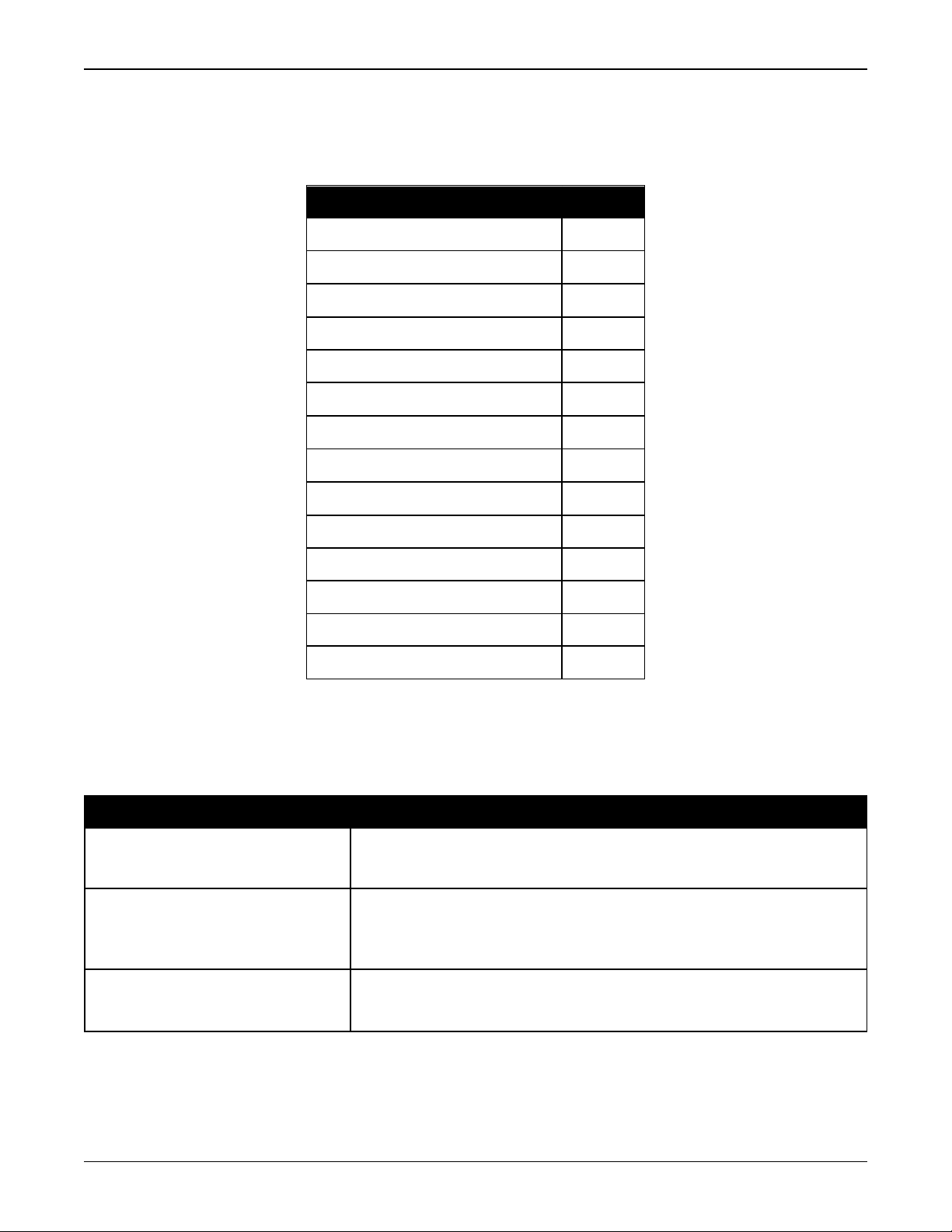

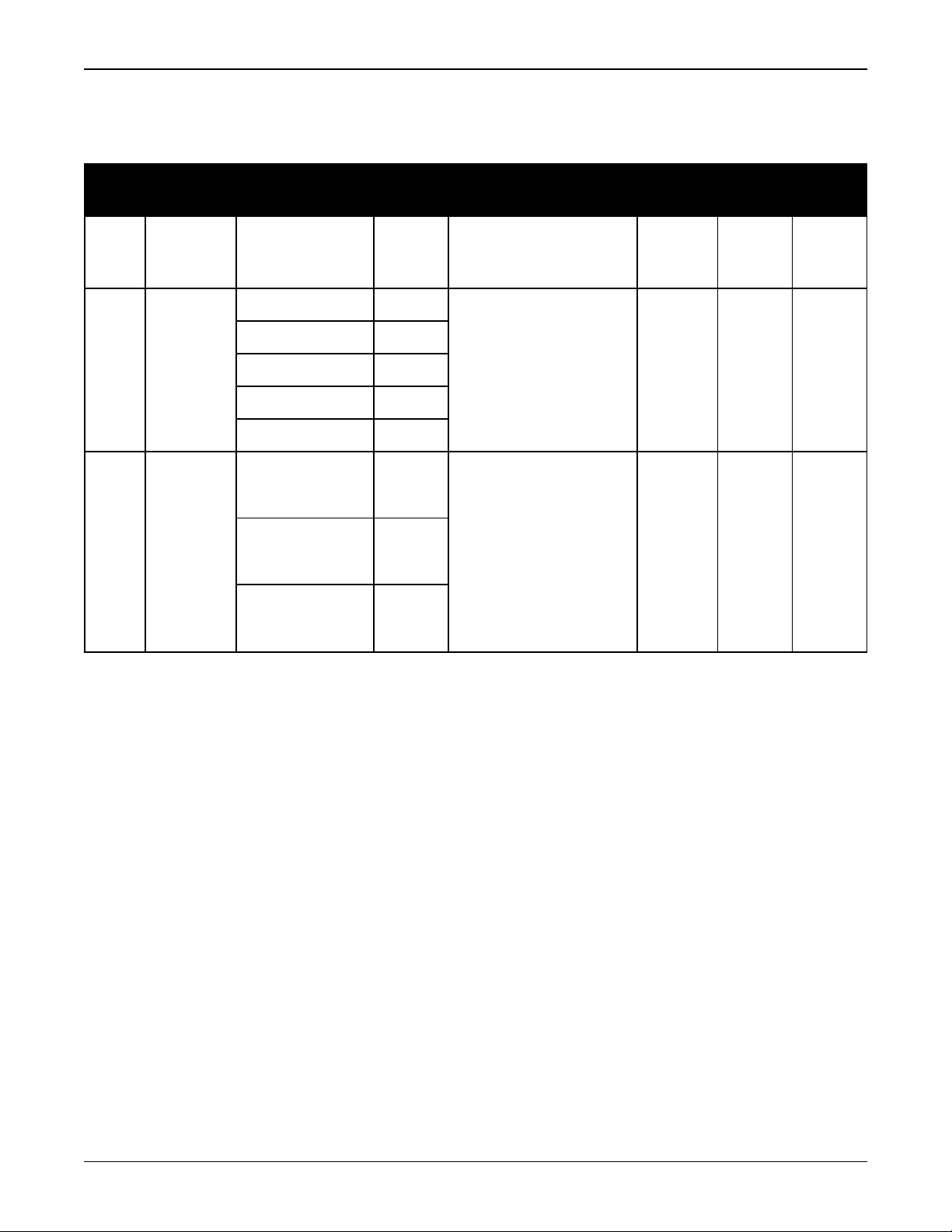

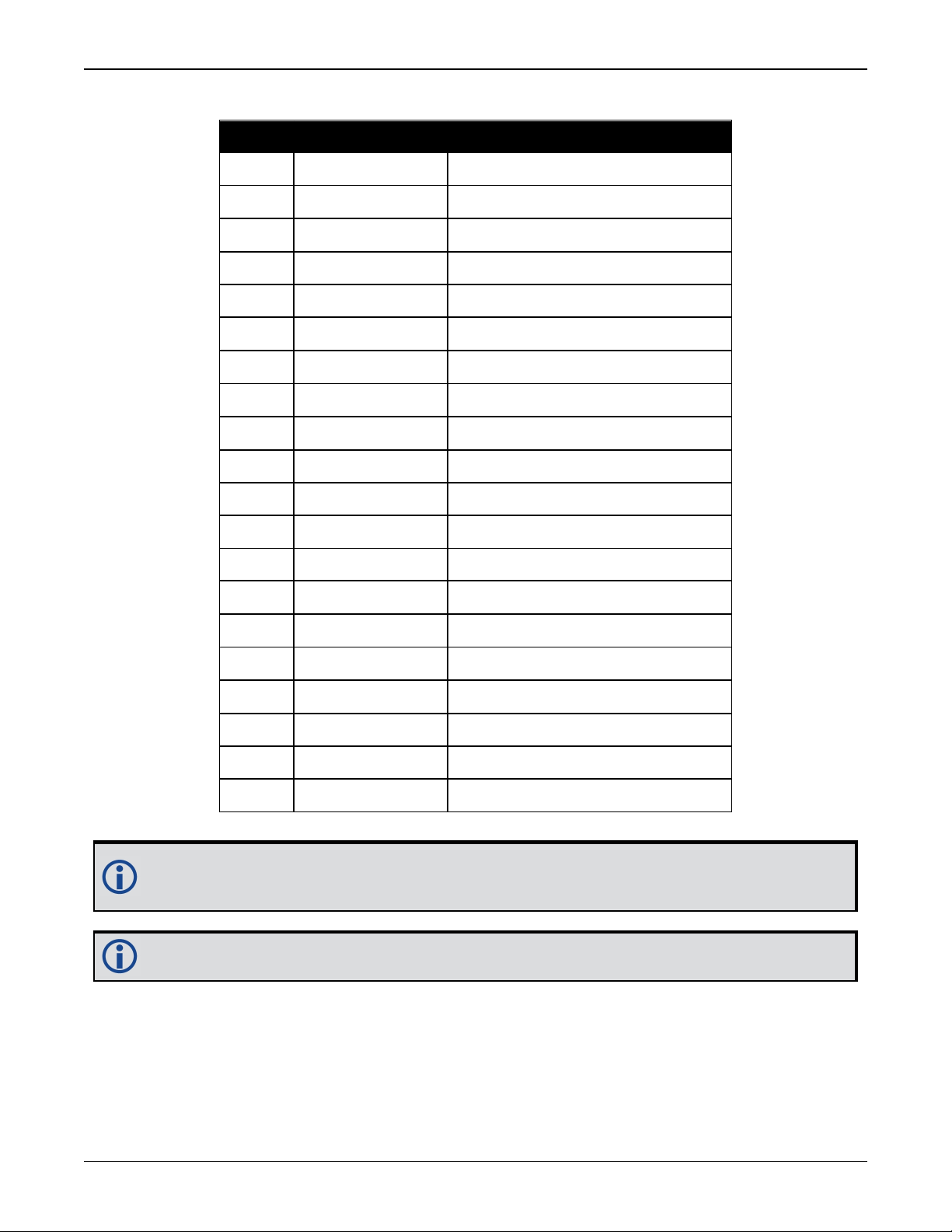

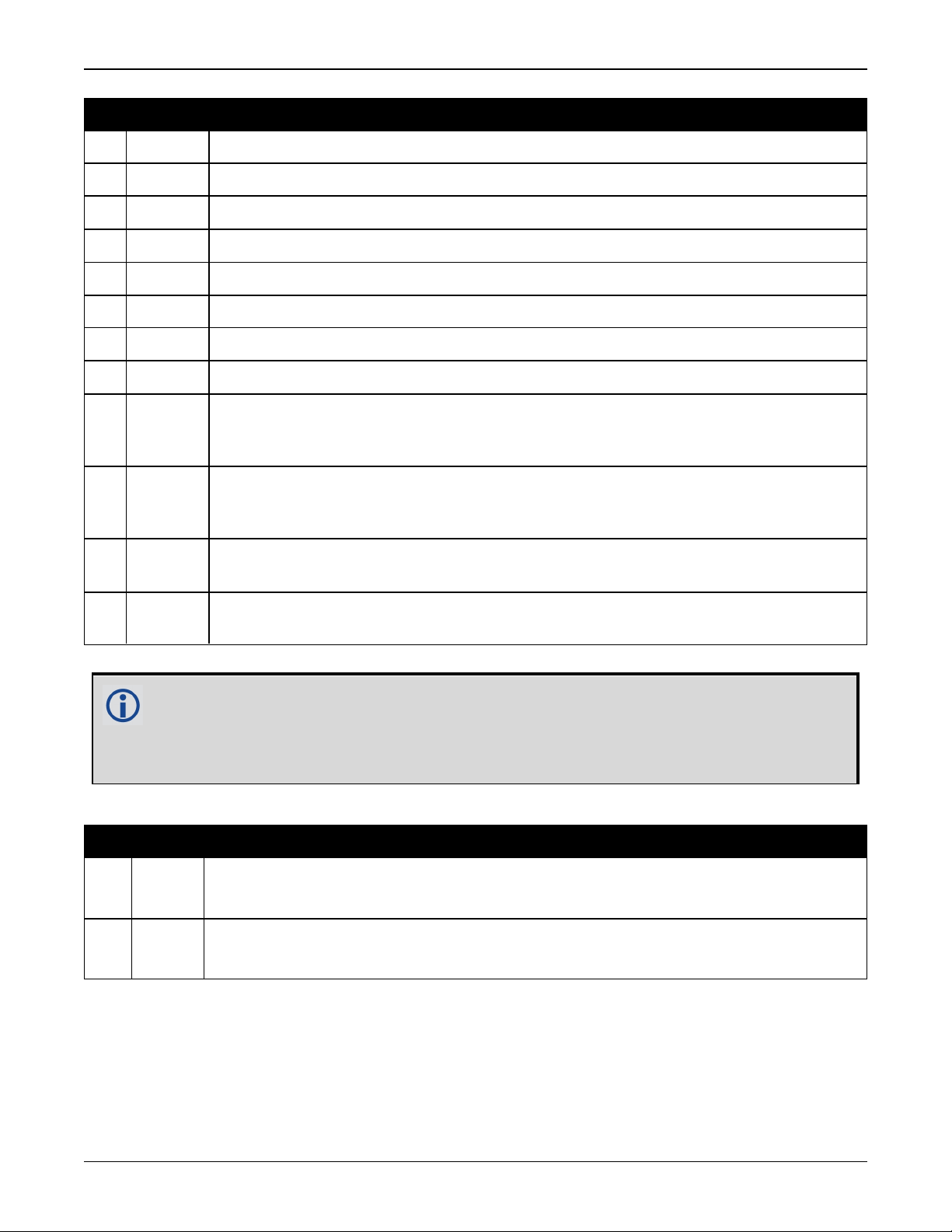

2.2.1 Replaced Commands

The following table lists the OEM6 commands that have been obsoleted and the commands that

replace them in OEM7.

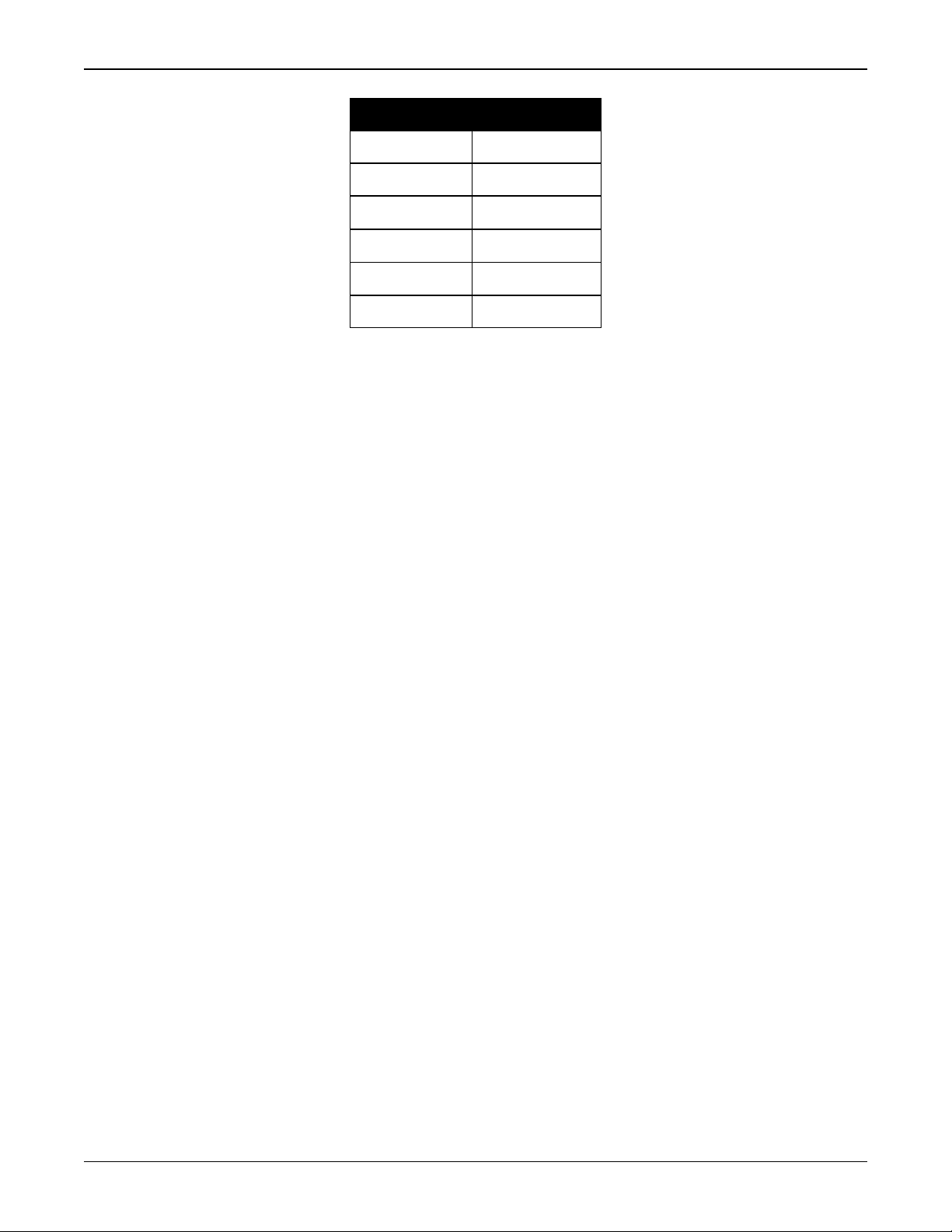

Table 1: Replaced Commands in OEM7

OEM6 OEM7

ASSIGNLBAND Use the existing ASSIGNLBANDBEAM command

ASSIGNLBAND2 Use the existing ASSIGNLBANDBEAM command

BASEANTENNAMODEL

COM Use the existing SERIALCONFIG command

Use the existing BASEANTENNAPCO command and

BASEANTENNAPCV command

OEM6 to OEM7 Integration Guide v1 9

Chapter 2 New for OEM7 – Firmware

OEM6 OEM7

COMCONFIG

EXTHDGOFFSET Use the new SETINSROTATION command (see page 67)

GIMBALSPANROTATION Use the new SETINSROTATION command (see page 67)

INSWHEELUPDATE Use the existing SETINSUPDATE command

INSZUPTCONTROL Use the existing SETINSUPDATE command

LEVERARMCALIBRATE Use the new INSCALIBRATE command (see page 34)

PDPVELOCITYOUT Use the existing BESTVELTYPE command

RVBCALIBRATE Use the new INSCALIBRATE command (see page 34)

SETGIMBALORIENTATION Use the new SETINSROTATION command (see page 67)

SETIMUORIENTATION Use the new SETINSROTATION command (see page 67)

SETIMUTOANTOFFSET Use the new SETINSTRANSLATION command (see page 70)

SETIMUTOANTOFFSET2 Use the new SETINSTRANSLATION command (see page 70)

SETIMUTOEXTOFFSET Use the new SETINSTRANSLATION command (see page 70)

SETIMUTOGIMBALOFFSET Use the new SETINSTRANSLATION command (see page 70)

Use the existing SERIALCONFIG command, INTERFACEMODE

command and ECHO command

SETINSOFFSET Use the new SETINSTRANSLATION command (see page 70)

SETINITATTITUDE Use the existing SETINITAZIMUTH command

SETINSOFFSETS

SETINSROTATION

SETMARK1OFFSET

SETMARK2OFFSET

SETMARK3OFFSET

SETMARK4OFFSET

VEHICLEBODYROTATION Use the new SETINSROTATION command (see page 67)

Use the new SETINSROTATION command on page67 and

SETINSTRANSLATION command on page70

The existing SETINSROTATION command (Message ID1796) has been

renamed SETINSROTATION_LEGACY, but retains the Message IDof

1796.

A new SETINSROTATION command (see page 67) (Message ID1921)

has been added. This new command has enhanced capability and is the

recommend command to use.

Use the new SETINSROTATION command on page67 and

SETINSTRANSLATION command on page70

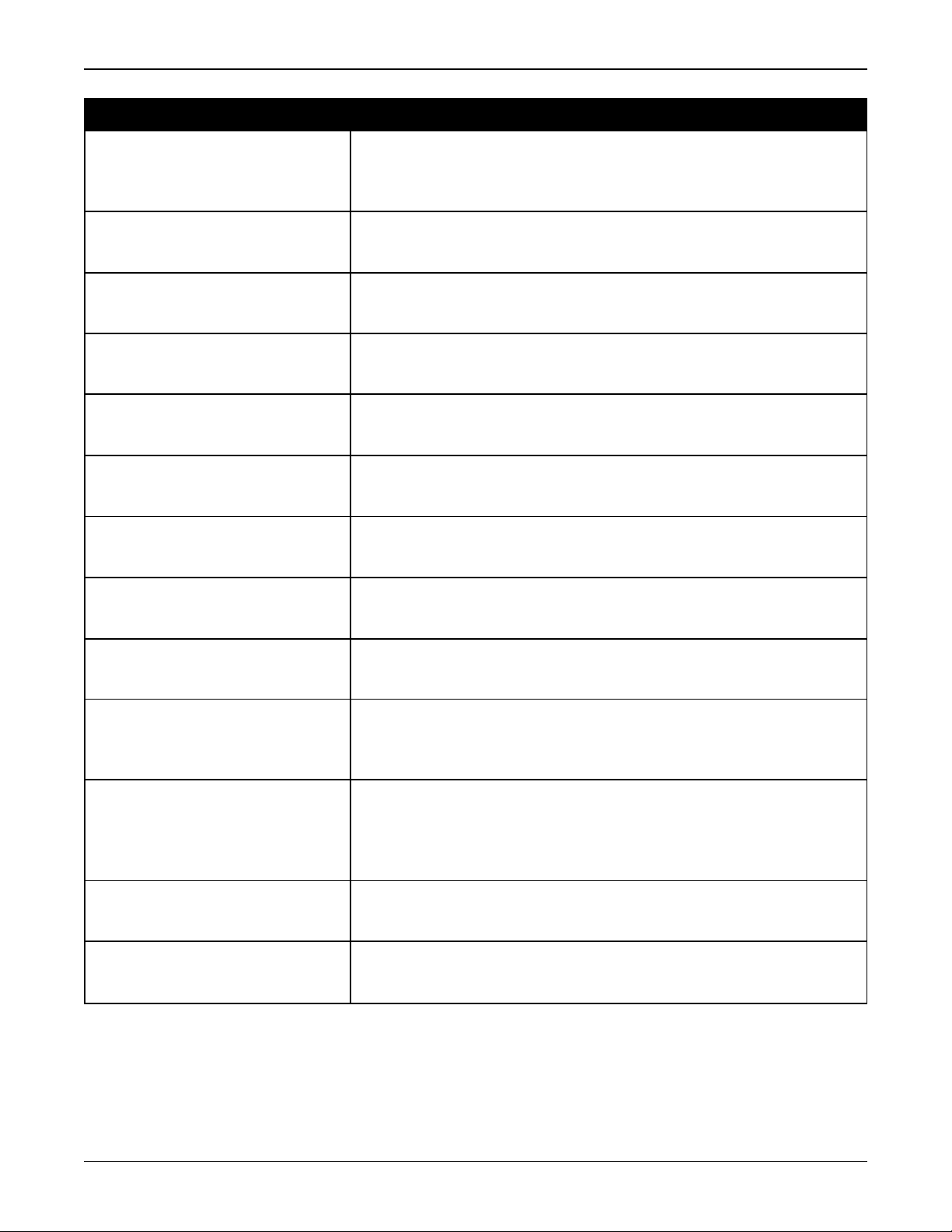

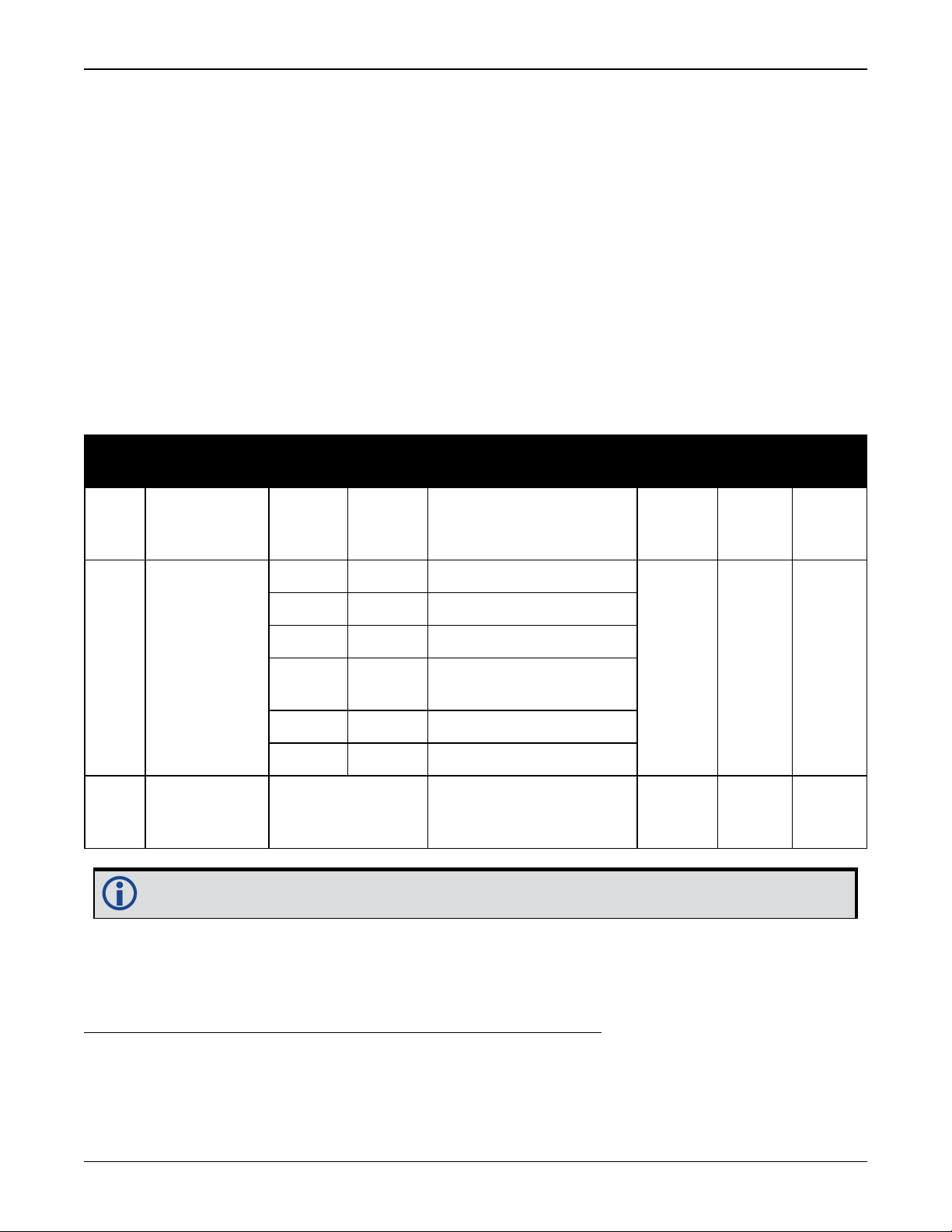

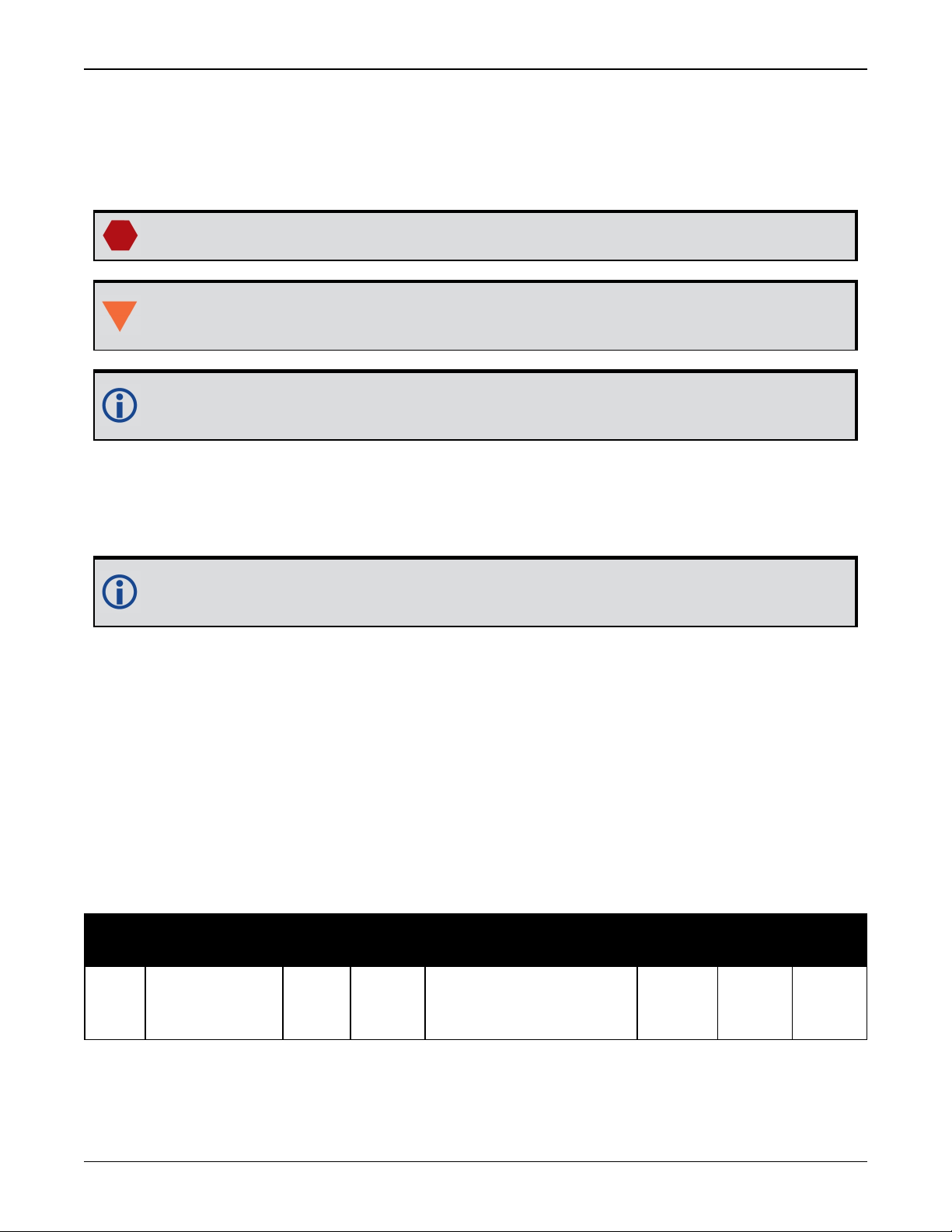

2.2.2 Revised Commands

Revised commands are listed in the following table.

OEM6 to OEM7 Integration Guide v1 10

Chapter 2 New for OEM7 – Firmware

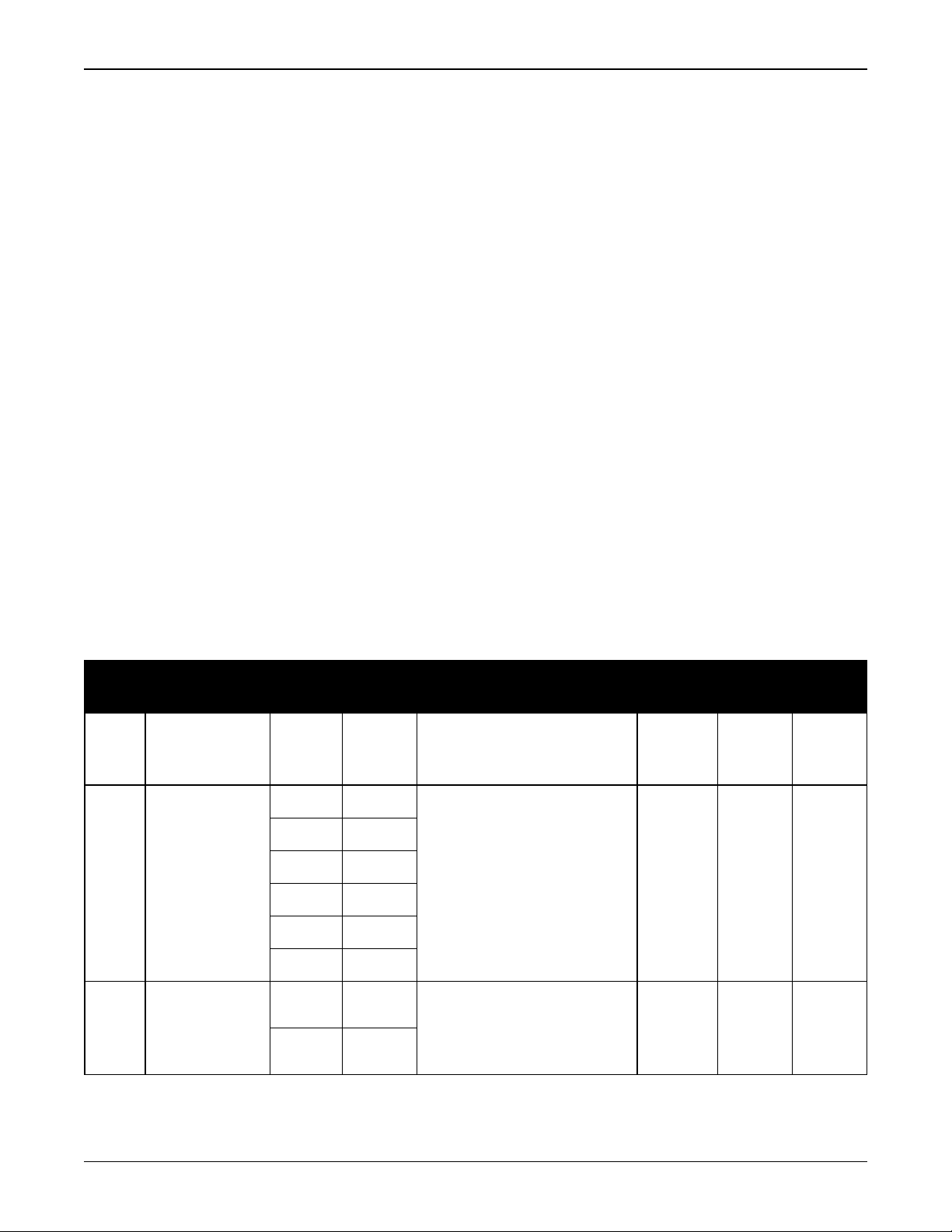

Table 2: Revised Commands in OEM7

OEM6 OEM7

3V3 option removed

ANTENNAPOWER

ASSIGN,

ASSIGNALL,

LOCKOUT,

SBASCONTROL,

The OEM7 tracks SBAS PRNs 120-158 and 183-187.

The OEM6 tracked 120-138 and 183-187

TRACKSV,

UNLOCKOUT

If a short circuit or other problem causes an overload of the current supplied to the antenna, the receiver hardware shuts down

the power supplied to the antenna. To restore power, power

cycle the receiver. The Receiver Status word, available in the

RXSTATUS log (see page 134), provides more information

about the cause of the problem.

ASSIGNLBANDBEAM

AUTH

COMCONTROL

This command now supports multiple L-Band channels.

The Frequency field is entered only in Hz.

New options were added for the State parameter

ASCII Binary Description

ERASE_

TABLE

CLEAN_

TABLE

7

8 Remove all invalid auth codes from the system

Erase all auth codes from the system. Requires a

special auth code to prevent against accidental

erasing

Special auth code for the ERASE_TABLE case:

PW5W2B,WW5TM9,WW2PCZ,WW3M4H,WW4HPG,ERASE_AUTH

Special auth code for the CLEAN_TABLE case:

4DR69H,G369W8,34MNJJ,5NHXCJ,GW7C75,CLEAN_AUTH

The COM ports available have changed to reflect the OEM7 receivers.

See the COMCONTROL command on page21

OEM6 to OEM7 Integration Guide v1 11

Chapter 2 New for OEM7 – Firmware

OEM6 OEM7

Added the EPSON G320 IMU.

Removed the Litef LCI-1 IMU.

CONNECTIMU

ETHCONFIG

EXTERNALPVAS

FRESET

INTERFACEMODE

For the IMU Type parameter, the ASCII values for IMU no longer use the

"IMU_" prefix. However, the legacy ASCIIvalues that contain the "IMU_"

prefix are still supported. The binary IMU type values have not changed.

See the CONNECTIMU command on page24

Ethernet interface hardware now automatically connects properly to the

other physical device

The format of several of the options in this command have been changed

from Double to Float.

See the EXTERNALPVAS command on page26

Added new FRESET targets.

Binary ASCII Description

10 USERDATA

Resets the user data saved using the

NVMUSERDATA command

82 USBCONFIG Resets the stored USB port settings

Added new Interface Mode options:

Binary ASCII Description

NovAtel binary message with a minimal

49 NOVATELMINBINARY

header.

Only available for CCOM ports.

The default settings for a command can not be checked by logging that

command. A command must be sent to the receiver before logging the

command will produce valid values. Refer to the command description in

this documentation for the default values.

The optional parameters Period, Offset and Hold are only used when the

LOG

Trigger is ONTIME. Previous versions of the firmware accepted (but ignored)

non-zero values for Period and Offset even if the Trigger was not ONTIME.

The firmware on OEM7 receivers will reject such commands and return an

error.

It is especially important that these values are zero when entering a LOG

command in Binary or ASCII format.

POSAVE “state” field no longer optional; default ON. A value must now be entered

SETINITAZIMUTH

OEM6 to OEM7 Integration Guide v1 12

The range for the standard deviation parameter has changed to 1 to 25

degrees.

Chapter 2 New for OEM7 – Firmware

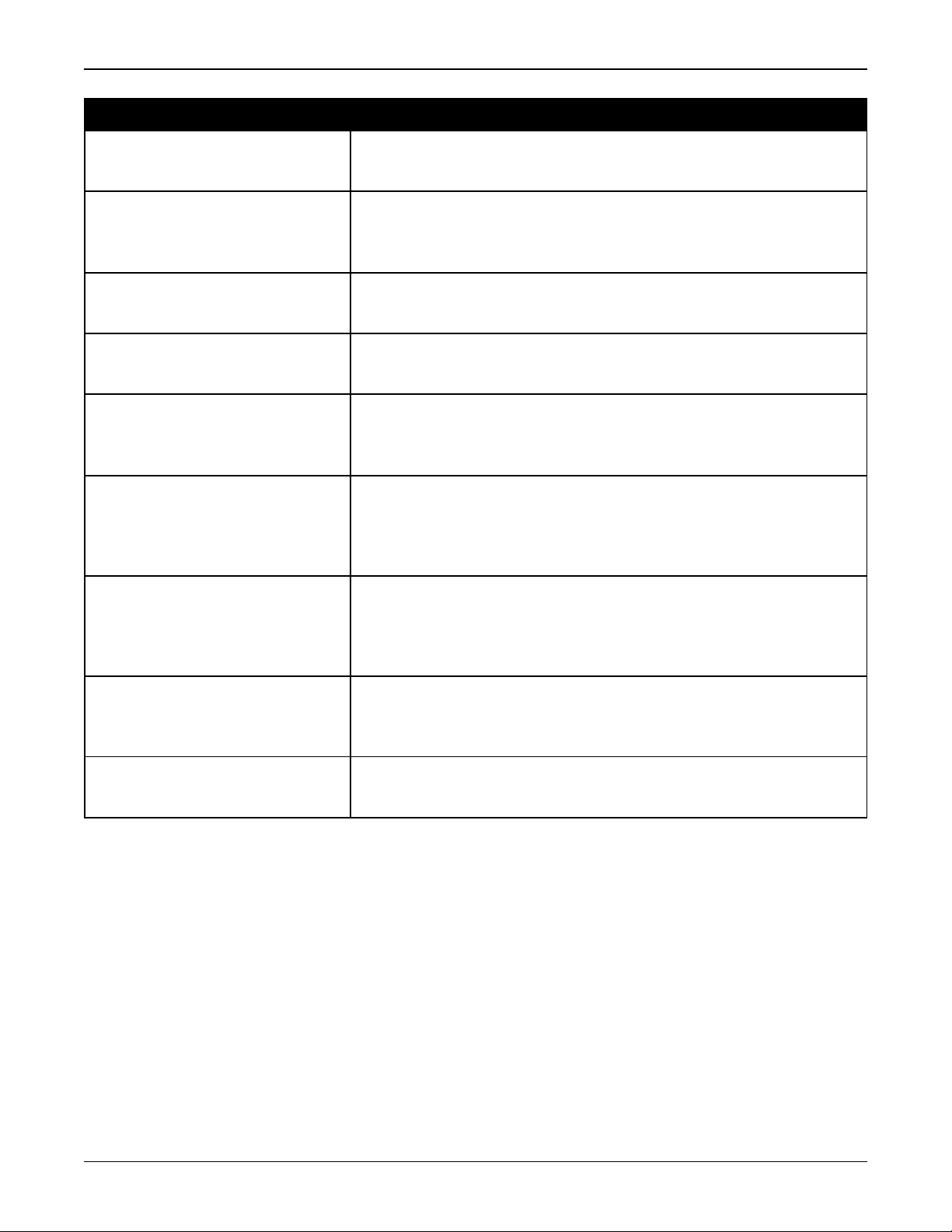

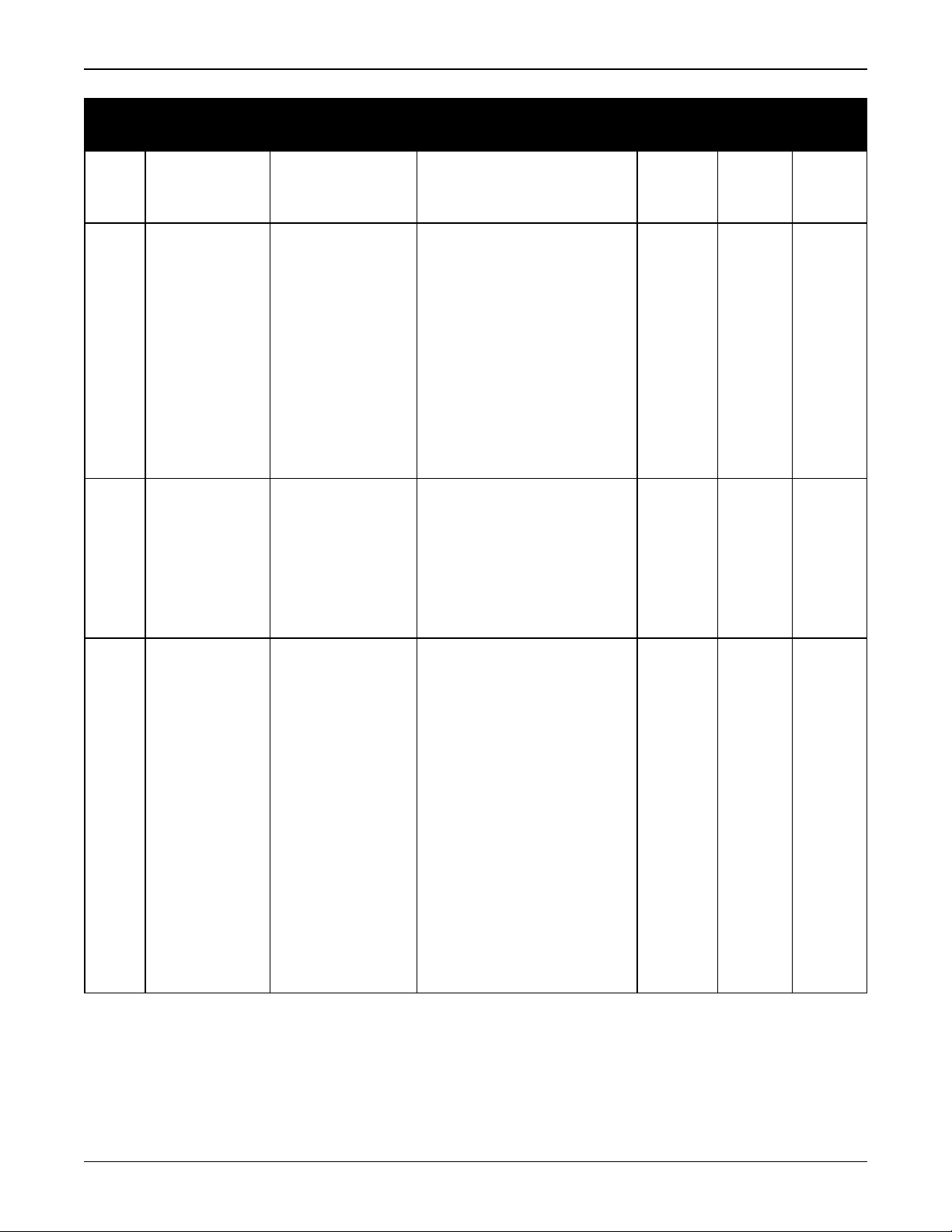

2.2.3 Deleted Commands

The OEM6 commands that are not supported in OEM7 are listed in the following table.

Table 3: Deleted Commands in OEM7

OEM6 OEM7

APPLYVEHICLEBODYROTATION obsolete

ASSIGNLBAND obsolete

ASSIGNLBAND2 obsolete

DGPSEPHEMDELAY obsolete

OMNIUSEGLONASS obsolete

PDPVELOCITYOUT obsolete

RTKCOMMAND obsolete

RTKELEVMASK obsolete

SETCANNAME obsolete

SETRTCM16 obsolete

SETRTCM36 obsolete

SETRTCMRXVERSION obsolete

SETRTCMTXVERSION obsolete

SETWHEELSOURCE obsolete

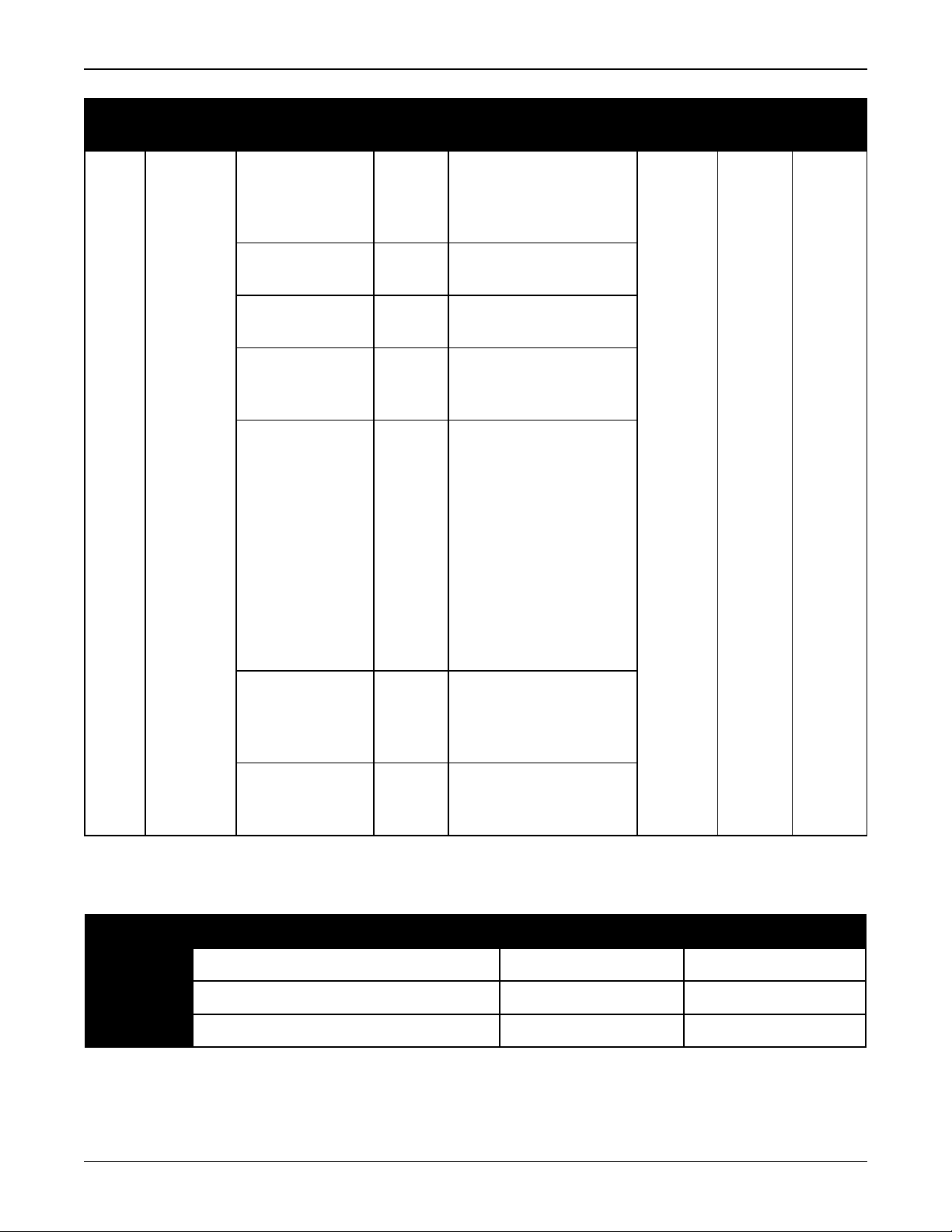

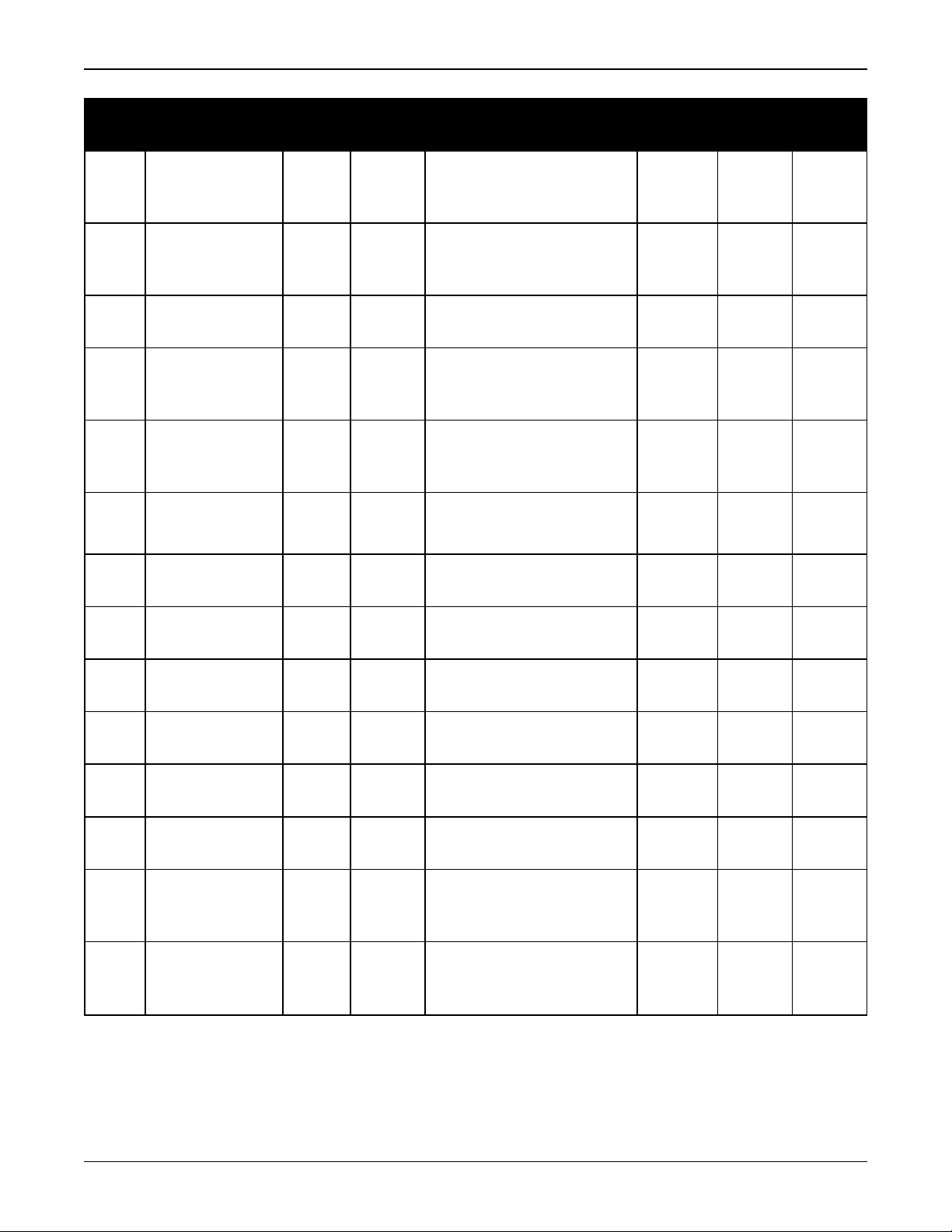

2.2.4 New Commands

The following table lists the commands added in OEM7.

Table 4: New Commands in OEM7

OEM7 Description

CANCONFIG

CCOMCONFIG

Configures the CAN port parameters

See the CANCONFIG command on page16

Binds a CAN port to a J1939 node configures the CAN protocol

used by the port.

See the CCOMCONFIG command on page18

INSCALIBRATE

OEM6 to OEM7 Integration Guide v1 13

Initiates the calibration of INS offsets

See the INSCALIBRATE command on page34

Chapter 2 New for OEM7 – Firmware

OEM7 Description

INSSEED

Enables or disables saving and restoring the last known SPAN

solution

See the INSSEED command on page36

ITBANDPASSCONFIG

ITFRONTENDMODE

ITINTERFERENCEDETECT

ITPROGFILTCONFIG

ITSPECTRALANALYSIS

J1939CONFIG

NMEAFORMAT

NVMUSERDATA

Configures a bandpass filter on the receiver

See the ITBANDPASSCONFIG command on page38

Configures the front end mode for each RF path

See the ITFRONTENDMODE command on page40

Enables and configures interference detection

See the ITINTERFERENCEDETECT command on page42

Configures filtering on the receiver

See the ITPROGFILTCONFIG command on page44

Enables and configures spectral analysis on the receiver

See the ITSPECTRALANALYSIS command on page46

Configures the CAN J1939 network-level parameters

See the J1939CONFIG command on page50

Customizes the NMEA output

See the NMEAFORMAT command on page52

Writes the data provided to NVM

See the NVMUSERDATA command on page55

PGNCONFIG

PPPBASICCONVERGEDCRITERIA

PPPDYNAMICSEED

PPPRESET

Configures the PGNs of the proprietary NMEA 2000 fast-packet

messages

See the PGNCONFIG command on page56

Sets the convergence threshold for lower accuracy PPP

solutions.

See the PPPBASICCONVERGEDCRITERIA command on

page57

Seed the PPP filter in any platform motion state

See the PPPDYNAMICSEED command on page58

Resets the PPPfilter.

See the PPPRESET command on page60

OEM6 to OEM7 Integration Guide v1 14

Chapter 2 New for OEM7 – Firmware

OEM7 Description

REFERENCESTATIONTIMEOUT

RTKPORTMODE

RTKRESET

SAVEUSBCONFIG

SETINSPROFILE

SETINSROTATION

SETINSTRANSLATION

Sets a timeout for removing previously stored base stations

See the REFERENCESTATIONTIMEOUT command on page61

Assigns a port on the rover receiver for the RTK and ALIGN

information being received

See the RTKPORTMODE command on page62

Resets the RTK filter.

See the RTKRESET command on page64

Saves the USB port configuration.

See the SAVEUSBCONFIG command on page65

Set the filter behavior to optimize the output for a specific

environment

See the SETINSPROFILE command on page66

Specifies the rotational offsets between the IMU frame and

other reference frames, such as the vehicle frame or an ALIGN

baseline

see the SETINSROTATION command on page67

Specifies the translational offsets between the IMU frame and

other reference frames, including GNSS antennas or the desired

output frame

SETSEARCHTYPE

USBCONFIG

See the SETINSTRANSLATION command on page70

Specifies the search type used by the receiver for signal

acquisition.

See the SETSEARCHTYPE command on page73

Configures the operating mode and speed of the USBport.

See the USBCONFIG command on page74

OEM6 to OEM7 Integration Guide v1 15

Chapter 2 New for OEM7 – Firmware

2.2.5 CANCONFIG

Configure CAN ports

Platform:OEM729, OEM719, OEM7700

Use the CANCONFIG command to configure the hardware parameters of the CAN ports.

Message ID: 884

Abbreviated ASCII Syntax:

CANCONFIG port switch [speed]

Factory Default:

CANCONFIG CAN1 OFF 250K

CANCONFIG CAN2 OFF 250K

ASCII Example:

CANCONFIG CAN1 OFF 500K

Field Field Type

1

2 port

3 switch

4 speed

CANCONFIG

header

The CAN port must be set to OFF (using CANCONFIG <port> OFF) before the port speed

can be changed.

ASCII

Value

- -

CAN1 1

CAN2 2

ON 1

OFF 0

See Table 5: CAN

Port Speed below

Binary

Value

Table 5: CAN Port Speed

Description Format

Command header. See

Messages for more

information.

Physical CAN port ID Enum 4 H

Sets the port to be On or

Off the CAN bus

Physical CANport speed

(bits per second)

(default = 250K

- H 0

Enum 4 H+4

Enum 4 H+8

Binary

Bytes

Binary

Offset

ASCII Value Binary Value

10K 0

20K 1

OEM6 to OEM7 Integration Guide v1 16

Chapter 2 New for OEM7 – Firmware

ASCII Value Binary Value

50K 2

100K 3

125K 4

250K 5

500K 6

1M 7

OEM6 to OEM7 Integration Guide v1 17

Chapter 2 New for OEM7 – Firmware

2.2.6 CCOMCONFIG

Configure the CAN COM port

Platform:OEM729, OEM719, OEM7700

Bind a CAN communication port to a J1939 node (see J1939CONFIG command on page50) and

specify the CAN protocol, PGN, priority and address for messages transmitted and received over

the CCOM port.

Message ID: 1902

Abbreviated ASCII Syntax:

CCOMCONFIG port node protocol [pgn [priority [address]]]

Factory Default:

CCOMCONFIG ccom1 node1 1939 61184 7 fe

CCOMCONFIG ccom2 node2 J1939 61184 7 fe

CCOMCONFIG ccom3 node1 J1939 126720 7 fe

CCOMCONFIG ccom4 none none 0 0 0

CCOMCONFIG ccom5 none none 0 0 0

CCOMCONFIG ccom6 none none 0 0 0

ASCII Example :

ccomconfig ccom1 j1939 1792 6 1b

Field Field Type

1

2 port

CCOMCONFIG

Header

ASCII

Value

- -

CCOM1 38

CCOM2 39

CCOM3 40

CCOM4 41

CCOM5 42

Binary

Value

Description Format

Command header. See

Messages for more

information.

Name of CCOM port Enum 4 H

- H 0

Binary

Bytes

Binary

Offset

CCOM6 43

NODE1 1

3 node

NODE2 2

OEM6 to OEM7 Integration Guide v1 18

The J1939 node to use.

This binds a CCOM port to

the CAN NAME/address

associated with the node.

Enum 4 H+4

Chapter 2 New for OEM7 – Firmware

Field Field Type

ASCII

Value

See Table 6:

4 protocol

CAN Protocol on

the next page

5 pgn 0 - 131071

6 priority 0-7

Binary

Value

Description Format

CAN transport protocol to

use

Any valid PGN as defined

by the J1939 protocol.

All messages transmitted

over this CCOM port will

contain this PGN value.

Only messages with this

PGN will be received on

this CCOM port

Note: This value is

ignored if the protocol is

NMEA2000.

Default CAN message

priority for transmitted

messages. (Priority 0 is

the highest priority)

Note: This value is

ignored if the protocol is

NMEA2000 or ISO15765.

Binary

Bytes

Binary

Offset

Enum 4 H+8

Ulong 4 H+12

Uchar 1 H+16

7 address 00 – FF

00 – FD:

Transmit and receive

messages to/from this

address only

FE:

Transmit and receive

message to/from the

address of the first

message received

FF:

Broadcast messages and

receive messages from

all addresses.

Note: This value is

ignored if the protocol is

NMEA2000 or ISO15765.

Hex 1 H+17

OEM6 to OEM7 Integration Guide v1 19

Chapter 2 New for OEM7 – Firmware

Binary ASCII Description

2 J1939 J1939 single packet

3 NMEA2000 NMEA2000 (single packet, multi-packet, fast packet)

4 ISO15765 ISO 15765-2 transport protocol

5 ISO11783 ISO 11783 transport protocol

Table 6: CAN Protocol

OEM6 to OEM7 Integration Guide v1 20

Chapter 2 New for OEM7 – Firmware

2.2.7 COMCONTROL

Controls the serial port hardware control lines

Platform:OEM729, OEM719, OEM7700

This command is used to control the hardware control lines of the serial communication (COM)

ports. The TOGGLEPPS mode of this command is typically used to supply a timing signal to a

host PC computer by using the RTS and DTR lines. The accuracy of controlling the COM control

signals is better than 900 ms. The other modes are typically used to control custom peripheral

devices.

1.

If handshaking is disabled, any of these modes can be used without affecting regular

serial communications through the selected COM port. However, if handshaking is

enabled, it may conflict with handshaking of the selected COM port, causing unexpected results.

2.

The PULSEPPSLOW control type cannot be issued for a TX signal.

3.

Only PULSEPPSHIGH, FORCEHIGH and FORCELOW control types can be used for a TX

signal.

Message ID: 431

Abbreviated ASCII Syntax:

COMCONTROL [port] [signal] [control]

Factory Default:

COMCONTROL COM1 RTS DEFAULT

COMCONTROL COM2 RTS DEFAULT

COMCONTROL COM3 RTS DEFAULT

COMCONTROL COM4 RTS DEFAULT

COMCONTROL COM5 RTS DEFAULT

ASCII Example 1:

SERIALCONFIG COM1 9600 N 8 1 N (to disable handshaking)

COMCONTROL COM1 RTS FORCELOW

ASCII Example 2:

COMCONTROL COM1 RTS TOGGLEPPS

COMCONTROL COM2 RTS TOGGLEPPS

COMCONTROL COM3 RTS TOGGLEPPS

ASCII Example 3:

To set a break condition on COM1:

COMCONTROL COM1 TX FORCELOW

A break condition remains in effect until it is cleared. To clear a break condition on AUX:

COMCONTROL COM1 TX DEFAULT

OEM6 to OEM7 Integration Guide v1 21

Chapter 2 New for OEM7 – Firmware

or

COMCONTROL COM1 TX FORCEHIGH

Field

Field

Type

COM

1

CONTROL

header

2 port

3 signal

ASCII Value

Binary

Value

- -

COM1 1

COM2 2

COM3 3

COM4 19

COM5 31

RTS 0

TX 2

Description Format

Binary

Bytes

Binary

Command header.

See Messages for

- H 0

more information.

Serial port to control. Enum 4 H

COM signal to control.

The controllable COM

signals are RTS, DTR

and TX. (Default =

RTS)

Enum 4 H+4DTR 1

See also Table 7: Tx,

DTR and RTS

Availability on the

next page

Offset

OEM6 to OEM7 Integration Guide v1 22

Chapter 2 New for OEM7 – Firmware

Field

Field

Type

4 control

ASCII Value

Binary

DEFAULT 0

FORCEHIGH 1

FORCELOW 2

TOGGLE 3

TOGGLEPPS 4

Value

Description Format

Disables this

command and returns

the COM signal to its

default state (Default)

Immediately forces

the signal high

Immediately forces

the signal low

Immediately toggles

the current sate of the

signal

Toggles the state of

the selected signal

within 900 μs after

each 1PPS event. The

state change of the

signal lags the 1PPS

by an average value

of 450 μs. The delay

of each pulse varies

by a uniformly

random amount less

than 900 μs

Binary

Bytes

Binary

Offset

Enum 4 H+8

Pulses the line low at

PULSEPPSLOW 5

a 1PPS event and to

high 1 ms after it. Not

for TX

Pulses the line high

PULSEPPSHIGH 6

for 1 ms at the time

of a 1PPS event

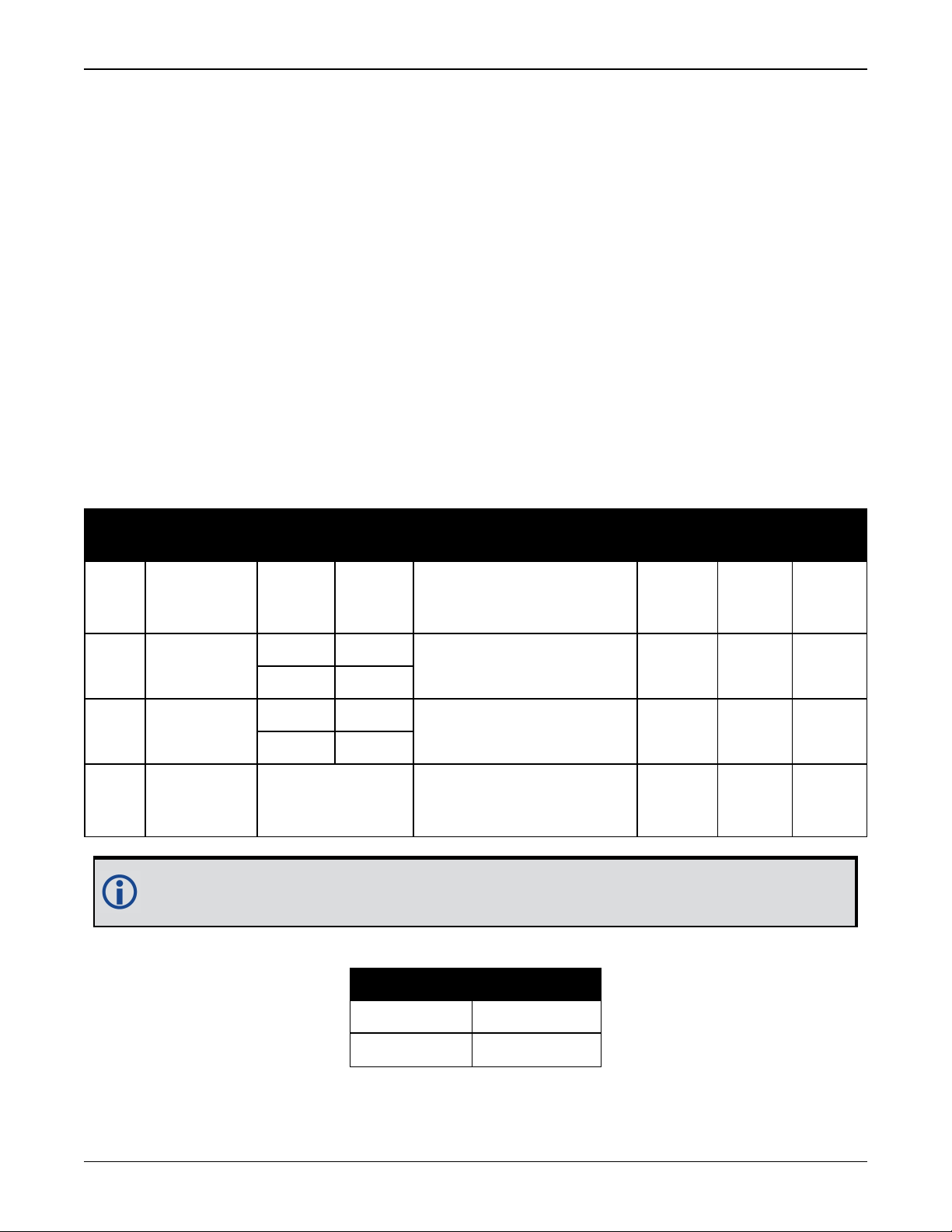

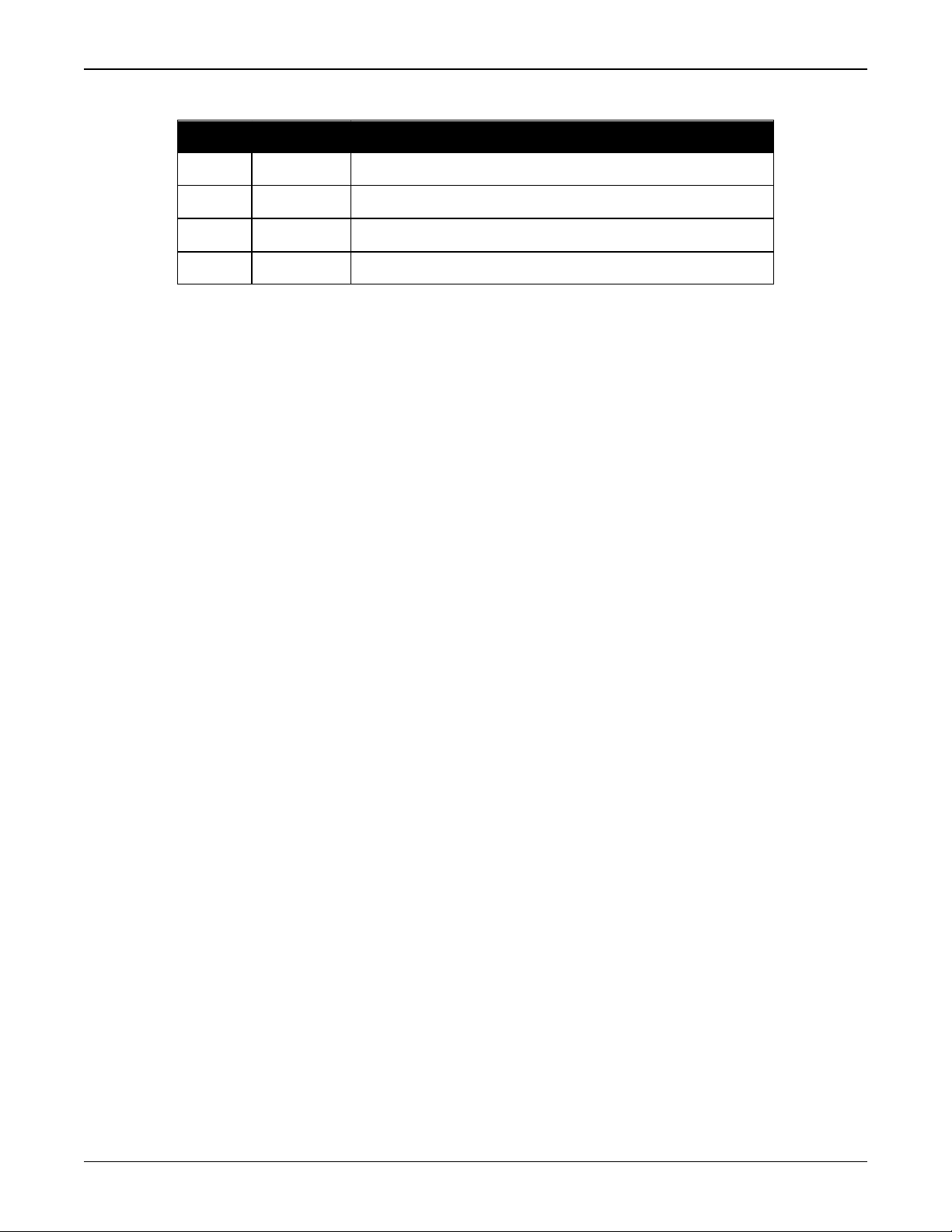

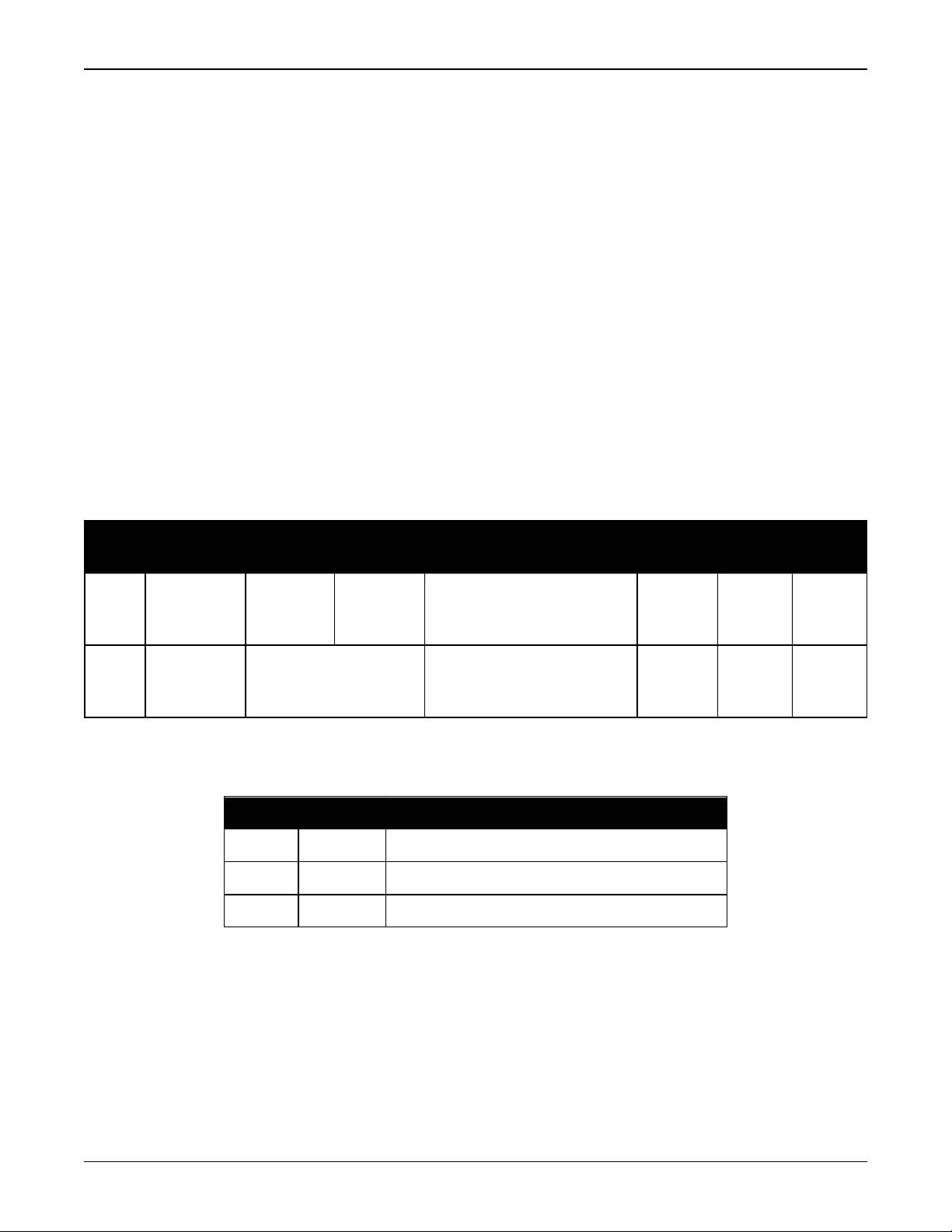

Table 7: Tx, DTR and RTS Availability

Tx Available On DTR Available On RTS Available On

OEM719 COM1, COM2 N/A N/A

OEM729 COM1, COM2, COM3 N/A COM1 and COM2

OEM7700 COM1, COM2, COM3, COM4, COM5 N/A COM1 and COM2

OEM6 to OEM7 Integration Guide v1 23

Chapter 2 New for OEM7 – Firmware

2.2.8 CONNECTIMU

Connects an IMU to a Port

Platform:OEM729, OEM719, OEM7700

Use this command to specify the type of IMU connected to the receiver and the receiver port

used by the IMU.

Message ID: 1428

Abbreviated ASCII Syntax:

CONNECTIMU IMUPort IMUType

Abbreviated ASCII Example:

CONNECTIMU COM2 LN200

Field Field Type

1

2 IMUPort

CONNECTIMU

header

1

3 IMUType

SPI, COM4 and COM5 are available only on the OEM7700.

ASCII

Value

Binary

Value

Description

Command header. See

- -

Messages for more

information.

COM1 1 IMU Port is COM port 1

COM2 2 IMU Port is COM port 2

COM3 3 IMU Port is COM port 3

SPI 7

IMUPort is the SPIport

(OEM7700 only)

COM4 19 IMUPort is COM port 4

COM5 31 IMU Port is COM port 5

See Table 8: IMU

Type on the next

IMU Type Enum 4 H+4

page

Binary

Format

Binary

Bytes

Binary

- H 0

Enum 4 H

Offset

1

The IMU-ISA-100C, IMU-FSAS, IMU-HG1900, IMU-LN200, IMU-µIMU, IMU-CPT and IMU-KVH1750 use RS-422

protocol and must be connected to a receiver port that is configured to use RS-422. Refer to the OEM7 Installation

and Operation User Manual (OM-20000168) for information about which receiver ports support RS-422 and

instructions for enabling RS-422.

OEM6 to OEM7 Integration Guide v1 24

Chapter 2 New for OEM7 – Firmware

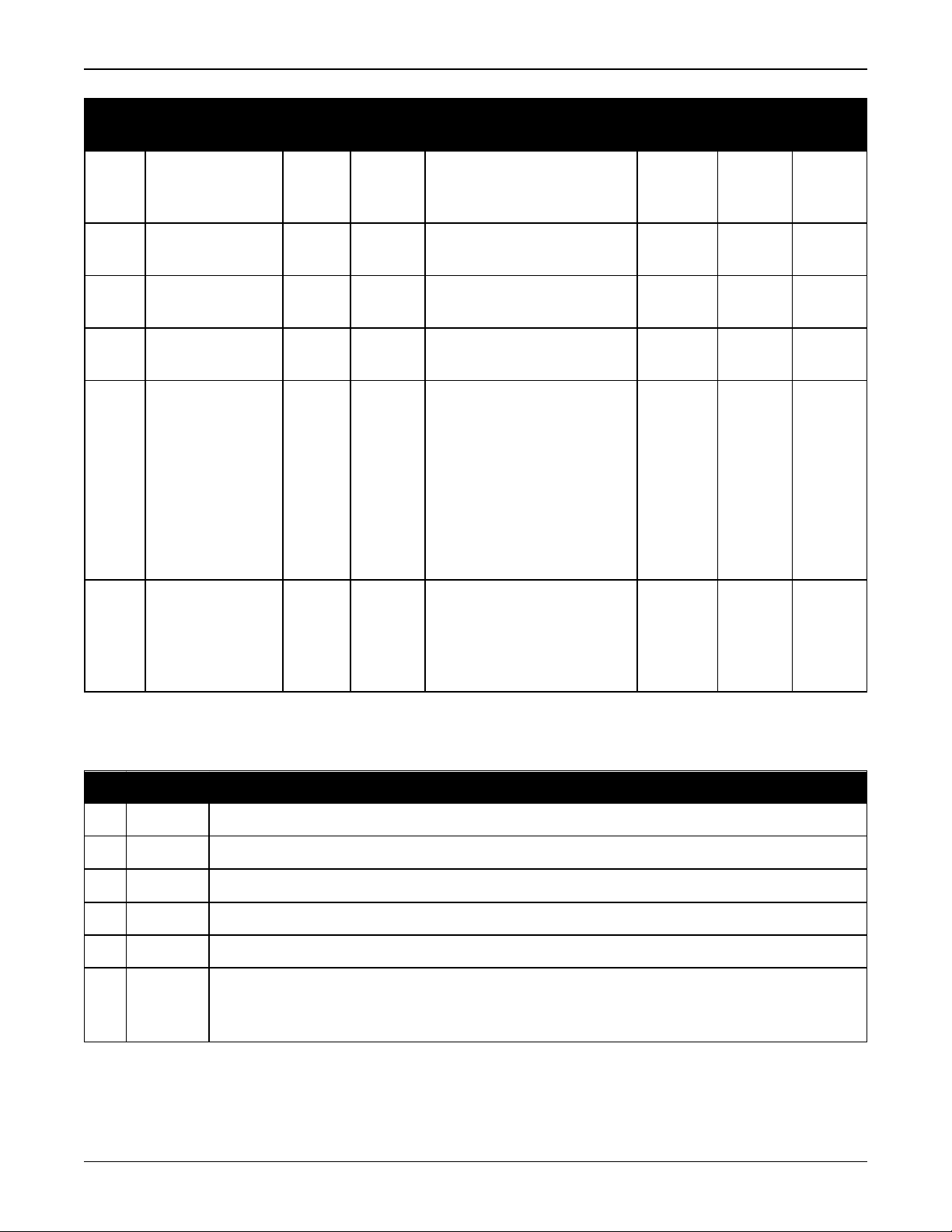

Binary ASCII Description

0 UNKNOWN Unknown IMU type (default)

1 HG1700_AG11 Honeywell HG1700 AG11

4 HG1700_AG17 Honeywell HG1700 AG17

5 HG1900_CA29 Honeywell HG1900 CA29

8 LN200 Litton LN-200

11 HG1700_AG58 Honeywell HG1700 AG58

12 HG1700_AG62 Honeywell HG1700 AG62

13 IMAR_FSAS iMAR iIMU-FSAS

16 KVH_COTS KVH IMU-CPT

20 HG1930_AA99 Honeywell HG1930 AA99

26 ISA100C Northrop Grumman Litef ISA-100C

Table 8: IMU Type

27 HG1900_CA50 Honeywell HG1900 CA50

28 HG1930_CA50 Honeywell HG1930 CA50

31 ADIS16488 Analog Devices ADIS16488

32 STIM300 Sensonor STIM300

33 KVH_1750 KVH1750 IMU

34 ISA100 Northrop Grumman Litef ISA-100

41 EPSON_G320 Epson G320

45 KVH-1725 KVH1725 IMU

52 LITEF_MICROIMU Litef µIMU

The IMU Type field also supports the legacy ASCIIvalues that contain the "IMU_" prefix.

For example, LN200 or IMU_LN200.

Values not shown in this table are reserved.

OEM6 to OEM7 Integration Guide v1 25

Chapter 2 New for OEM7 – Firmware

2.2.9 EXTERNALPVAS

Enter PVA Update

Platform:OEM729, OEM719, OEM7700

This command should only be used by advanced users of GNSS/INS.

The standard deviations entered using this command must be representative of actual

input error.

The EXTERNALPVAS command uses a short header if the command is entered in ASCII

or Binary.

This command allows a user to provide full position, velocity and attitude updates, in any combination, to the INS. The user can also provide height or attitude only updates, along with Zero

Velocity Updates (ZUPTs). These position and velocity updates are entered in local level frame

or ECEF.

The default input frame is ECEF. Updates are entered in ECEF unless Local Level is specified using the OptionsMask parameter.

Message ID: 1463

Abbreviated ASCII Syntax:

EXTERNALPVAS Position1 Position2 Position3 Velocity1 Velocity2 Velocity3

Attitude1 Attitude2 Attitude3 PosStdDev1 PosStdDev2 PosStdDev3 VelStdDev1

VelStdDev2 VelStdDev3 AttStdDev1 AttStdDev2 AttStdDev3 UpdateMask

OptionsMask

Abbreviated ASCII Example:

EXTERNALPVAS 51.13495816 -114.03232307 1064.5895 -10.4502 0.2485 -0.09598

1.3152366 -3.6474718 179.5885212 0.01 0.01 0.01 0.01 0.01 0.01 0.1 0.1 0.1

C020 1

Field Field Type

1

EXTERNALPVAS

header

ASCII

Value

- -

Binary

Value

Description

Command header. See

Messages for more

information.

Binary

Format

- H 0

Binary

Bytes

Binary

Offset

OEM6 to OEM7 Integration Guide v1 26

Chapter 2 New for OEM7 – Firmware

Field Field Type

2 Position1

3 Position2

4 Position3

5 Velocity1

6 Velocity2

7 Velocity3

ASCII

Value

Binary

Value

Description

Latitude in degrees or

ECEF X-coordinate in

metres

Longitude in degrees or

ECEF Y-coordinate in

metres

Height or ECEF Zcoordinate in metres

North velocity or velocity

along the X-axis in

metres/second

East velocity or velocity

along the Y-axis in

metres/second

Up velocity or velocity

along the Z-axis in

metres/second

Binary

Format

Binary

Bytes

Binary

Offset

Double 8 H

Double 8 H+8

Double 8 H+16

Float 4 H+24

Float 4 H+28

Float 4 H+32

8 Attitude1

9 Attitude2

10 Attitude3

11 PosStdDev1

12 PosStdDev2

13 PosStdDev3

14 VelStdDev1

15 VelStdDev2

Roll in local level in

degrees

Pitch in local level in

degrees

Azimuth in local level in

degrees

Position1 standard

deviation in metres

Position2 standard

deviation in metres

Position3 standard

deviation in metres

Velocity1 standard

deviation in

metres/second

Velocity2 standard

deviation in

metres/second

Float 4 H+36

Float 4 H+40

Float 4 H+44

Float 4 H+48

Float 4 H+52

Float 4 H+56

Float 4 H+60

Float 4 H+64

OEM6 to OEM7 Integration Guide v1 27

Chapter 2 New for OEM7 – Firmware

Field Field Type

16 VelStdDev3

17 AttStdDev1

18 AttStdDev2

19 AttStdDev3

20 UpdateMask

ASCII

Value

Binary

Value

Description

Velocity3 standard

deviation in

metres/second

Attitude1 standard

deviation in degrees

Attitude2 standard

deviation in degrees

Attitude3 standard

deviation in degrees

This mask selects which

updates are applied.

Setting a bit applies the

update and more than

one update can be

applied at one time.

See Table 9:

EXTERNALPVAS Updates

Mask below.

Binary

Format

Binary

Bytes

Binary

Offset

Float 4 H+68

Float 4 H+72

Float 4 H+76

Float 4 H+80

HEX

Ulong

4 H+84

This mask selects the

21 OptionsMask

update options. See

Table 10:

EXTERNALPVAS Options

HEX

Ulong

4 H+88

Mask on the next page.

Table 9: EXTERNALPVAS Updates Mask

Bit Mask Description

0 0x00001 Reserved

1 0x00002 Reserved

2 0x00004 ZUPT Update. No fields required in the EXTERNALPVAS command for this update.

3 0x00008 Reserved

4 0x00010 Reserved

External Position Update.

5 0x00020

This update is entered using Position1 to Position3 in the EXTERNALPVAS

command.

OEM6 to OEM7 Integration Guide v1 28

Chapter 2 New for OEM7 – Firmware

Bit Mask Description

6 0x00040 Reserved

7 0x00080 Reserved

8 0x00100 Reserved

9 0x00200 Reserved

10 0x00400 Reserved

11 0x00800 Reserved

12 0x01000 Reserved

13 0x02000 Reserved

External Velocity Update.

14 0x04000

This update is entered using Velocity1 to Velocity3 in the EXTERNALPVAS

command.

External Attitude Update.

15 0x08000

This update is entered using Attitude1 to Attitude3 in the EXTERNALPVAS

command.

16 0x10000

17 0x20000

External Heading Update.

This update is entered using Attitude3 in the EXTERNALPVAS command.

External Height Update.

This update is entered using Position3 in the EXTERNALPVAS command.

If both the External Position Update and External Height Update bits are set, only the

External Position Update will be applied.

If both the External Attitude Update and External Heading Update bits are set, only the

External Attitude Update will be applied.

Table 10: EXTERNALPVAS Options Mask

Bit Mask Description

If this bit is set, the position and velocity input frame is set to local level.

0 0x1

If cleared, the input frame is ECEF.

If this bit is set, the heading update is set relative.

1 0x2

If cleared, the heading update is absolute.

OEM6 to OEM7 Integration Guide v1 29

Chapter 2 New for OEM7 – Firmware

2.2.10 FORCEGLOL2CODE

Forces receiver to track GLONASS satellite L2 P or L2 C/A code

Platform:OEM729, OEM719, OEM7700

This command is used to force the receiver to track GLONASS satellite L2 P-code or L2 C/A code.

This command has no effect if the channel configuration contains both GLONASS L2 P and L2 C/A

channels.

Message ID: 1217

Abbreviated ASCII Syntax:

FORCEGLOL2CODE L2type

Factory Default:

FORCEGLOL2CODE default

ASCII Example:

FORCEGLOL2CODE p

Field

1

2 L2type

The following table lists which L2 signal is tracked based on the channel configuration and the

setting used for the L2type parameter.

Field

Type

FORCEGLO

L2CODE

header

ASCII

Value

- -

See Table 11:

GLONASS L2 Code

Type below

Binary ASCII Description

1 P L2 P-code or L2 Precise code

2 C L2 C/A code or L2 Coarse/Acquisition code

3 DEFAULT Set to channel default

Binary

Value

Command header. See

Messages for more

information.

GLONASS L2 code type Enum 4 H

Table 11: GLONASS L2 Code Type

Description Format

- H 0

Binary

Bytes

Binary

Offset

OEM6 to OEM7 Integration Guide v1 30

Loading...

Loading...